Page 1

GE Fanuc Automation

Programmable Control Products

Series 90t-70

Hot Standby CPU Redundancy

User’s Guide

GFK-0827 December 1993

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not

purport to cover all details or variations in hardware or software, nor to provide for

every possible contingency in connection with installation, operation, or maintenance.

Features may be described herein which are not present in all hardware and software

systems. GE Fanuc Automation assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m Master CIMST AR Helpmate PROMA CRO Series Six

CIMPLICITY GEnet Logicmaster Series One Series 90

CIMPLICITY 90–ADS Genius Modelmaster Series Three VuMaster

CIMPLICITY PowerTRA C Genius PowerTRA C ProLoop Series Five Workmaster

Copyright 1993 GE F anuc A utomation North America, Inc.

All Rights Reserved

Page 3

This manual is a reference to the hardware components, configuration and operation of

the Hot Standby CPU Redundancy system for the Series 90t-70 Programmable Logic

Controller. This redundancy system is one of several redundancy alternatives that may

be incorporated into a Series 90-70 Programmable Logic Controller system (see

Appendix A).

The information in this manual is intended to supplement the information contained in

the system installation, programming, and configuration information found in the

manuals listed below under ”Related Publications”.

Content of this Manual

Chapter 1. Introduction: describes the basic system features of the Hot Standby CPU

Redundancy system Control Strategy, and provides an overview of system components,

configuration, and operation.

Chapter 2. Components: describes the hardware components for the Hot Standby CPU

Redundancy system.

Chapter 3. Configuration: describes the special configuration requirements of a Hot

Standby CPU Redundancy system and provides an example of system configuration.

Preface

Chapter 4. Operation: describes the operation of a Hot Standby CPU Redundancy

system, fault detection and actions taken, and the on-line repair of a failed component.

Appendix A. Redundancy Alternatives: describes the redundancy alternatives for the

Series 90-70 Programmable Logic Controller for those readers not familiar with those

alternatives.

Related Publications

For more information, refer to these publications:

Genius I/O System User’s Manual (GEK-90486-1). Reference manual for system

designers, programmers, and others involved in integrating Genius I/O products in a

PLC or host computer environment. This book provides a system overview, and

describes the types of systems that can be created using Genius products. Datagrams,

Global Data, and data formats are defined.

Genius Discrete and Analog Blocks User’s Manual (GEK-90486-2). Reference manual for

system designers, operators, maintenance personnel, and others using Genius discrete

and analog I/O blocks. This book contains a detailed description, specifications,

installation instructions, and configuration instructions for discrete and analog blocks.

Series 90-70 PLC Installation Manual (GFK-0262). This book describes the hardware

components in a Series 90-70 PLC system, and provides the details of system installation.

Logicmaster 90-70 Programming Software User’s Manual (GFK-0263). A programming

software user’s manual for system operators and others using the Logicmaster 90-70

software to program, configure, monitor, or control a Series 90-70 PLC system.

GFK-0827

iii

Page 4

Preface

Series 90-70 PLC Reference Manual (GFK-0265). Reference manual which describes

operation, fault handling, and Logicmaster 90-70 programming instructions for the

Series 90-70 PLC.

Series 90-70 Remote I/O Scanner User’s Manual (GFK-0579). Reference manual for the

Remote I/O Scanner, which interfaces a drop containing Series 90-70 modules to a

Genius bus. Any CPU capable of controlling the bus can be used as the host. This book

describes the Remote I/O Scanner features, configuration, and operation.

Series 90-70 Bus Controller User’s Manual (GFK-0398). Reference manual for the bus

controller, which interfaces a Genius bus to a Series 90-70 PLC. This manual describes

the installation and operation of the Bus Controller. It also contains the programming

information needed to interface Genius I/O devices to a Series 90-70 PLC.

We Welcome Your Comments and Suggestions

At GE Fanuc automation, we strive to produce quality technical documentation. After

you have used this manual, please take a few moments to complete and return the

Reader’s Comment Card located on the next page.

Henry A. Konat

Senior Technical Writer

iv

Hot Standby CPU Redundancy User’s Manual - December 1993

GFK-0827

Page 5

Contents

Chapter 1 Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Standby CPU Redundancy Product 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features of the Hot Standby CPU Redundancy Product 3 . . . . . . . . . . . . .

Benefits of the Hot Standby CPU Redundancy Product 3 . . . . . . . . . . . . .

I/O Systems for Hot Standby CPU Redundancy Systems 4 . . . . . . . . . . . .

Genius I/O System 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local I/O System 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connections 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Strategy 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Hot Standby Operation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy CPU Module 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy Communications Module 7 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bumpless Switching 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronized CPUs 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Effect on Scan Time 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fail Wait Time 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch to Backup Unit Time 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configurable Backup Data Size 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Line Programming 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Line Repair 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Considerations 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Requirements 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of Terms 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commonly Used Acronyms 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

v

Page 6

Contents

Chapter 2 System Components 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy CPU 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Architecture 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Features 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Mode Switch 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Protect Keyswitch 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Status LEDs 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batter y Connectors 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial P ort Connector 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Memory Board 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy Communications Module 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RCM Features 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RCM System Status LEDS 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Selection Pushbutton 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RCM Connectors 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bus Transmitter Module 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status Indicators 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTM Connectors 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bus Receiver Module 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Bus Signal T ermination 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status Indicators 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRM Connectors 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Controller 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Controller User Features 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status Indicators 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GBC Connectors 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Racks 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

vi

Page 7

Contents

Chapter 3 Configuration 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Hot Standby CPU Redundancy System 27 . . . . . . . . . . . . . . . . .

Redundancy System Requirements 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Redundancy System Setup 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logicmaster 90 Configuration 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O System Configuration 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screens for Fault Category Configuration 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling Folders 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration with Logicmaster 90-70 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration of a Redundancy CPU Module 31 . . . . . . . . . . . . . . . . . . . . . . . . .

Redundant CPU Requirements 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redund Type 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background Window 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Sweep Mode 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constant Window Sweep Mode 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constant Sweep Mode 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ctrl Strgy 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fail Wait 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shared I/O 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a CPU Expansion Memory Board 39 . . . . . . . . . . . . . . . . . . . . .

Configuration of a Redundancy Communications Module 40 . . . . . . . . . . . . . .

Configuration of a Genius Bus Controller 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paired GBC Parameter 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Primary Redundant PLC 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select the Redundancy CPU Module 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select an Expansion Memory Board 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Redundant Communications Module 47 . . . . . . . . . . . . . . . .

Configure a Genius Bus Controller 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Genius I/O Blocks 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Bus Transmitter Module 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Secondary Redundant PLC 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Redund Type 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

vii

Page 8

Contents

Chapter 4 Operation 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1: System Operation 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up Sequence of a Redundant CPU 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incompatible Configurations 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resynchronization of the Redundant CPU 57 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot-Standby Redundancy Control Strategy 58 . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronous Scan 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Data Transfer %I, %AI and Synchronization 59 . . . . . . . . . . . . . . . . . . .

Data T ransfer from Backup Unit to Active Unit 60 . . . . . . . . . . . . . . . . . . . . .

Second Data Transfer %Q, %AQ, %R, and %M 61 . . . . . . . . . . . . . . . . . . . . .

Switching Control to Backup Unit 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Role Switch SVCREQ 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

%S References for CPU Redundancy 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy CPU Considerations 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features not A vailable with CPU 780 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Interrupts 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timed Interrupts 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VME Integrator Racks 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOP/IOSCAN Mode 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Operation 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differences in Operation for CPU 780 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RUN Disabled Mode 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration of Fault Actions 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOP to RUN Mode Transition 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background Window Time 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background User Checksum and Background Window

Timing Instructions 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Operation Information 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timer and PID Function Blocks 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timed Contacts 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVR_PRE %S Reference 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Controller Switching 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

viii

Page 9

Contents

Section 2: Fault Detection and Control Actions 72 . . . . . . . . . . . . . . .

Fault Detection 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Categories 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Fault Category Actions 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Fault Table 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faulting RCMs, Losing Links, and Terminating Communications 75 . . . . .

Fault Actions in a CPU Redundancy System 77 . . . . . . . . . . . . . . . . . . . . . . .

On-Line Repair 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining Parallel Bus Termination 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Line Repair Recommendations 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P ower Supply 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Racks 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Central Processor Unit 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy Communications Module and Cables 81 . . . . . . . . . . . . . . . . .

Redundancy Communications Link Failures 82 . . . . . . . . . . . . . . . . . . . . . . .

Bus Transmitter Module 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Controller 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Blocks 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Redundancy Alternatives 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy Alternatives 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series 90-70 Redundancy Through Application Logic 88 . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

ix

Page 10

Contents

Figure 1. Example of a Local I/O Configuration with Expansion Racks in a

Figure 2. Synchronized Hot Standby CPU Redundancy System Configuration 6 . . . . . . . . . . . . .

Figure 3. CPU 780 Locations in a Hot Standby CPU Redundancy System 14 . . . . . . . . . . . . . . . . . .

Figure 4. Redundancy CPU - IC697CPU 780 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5. Redundancy Communications Module - IC697RCM711 19 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6. Example of RCM Location in a Hot Standby CPU Redundancy System 20 . . . . . . . . . . .

Figure 7. Example of Multiple Genius Busses in a Hot Standby CPU Redundancy System 26 . . .

Figure 8. Active and Backup Sweeps 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9. Guide to Selection of Redundancy Option Key for Table 1 (Redundancy Options) 86 . .

Hot Standby CPU Redundancy System 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

x

Page 11

Contents

Table 1. Capacities for Redundancy CPU, IC697CPU780 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2. Valid Operating Mode Selection 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3. Expansion Memory Boards for CPU 780 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4. Shared I/O Data Parameters 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5. Shared I/O Reference V alues 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6. Transfer Data Size 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7. Definition for% S Reference for Redundancy Status 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8. Fault Zoom Help Text for Redundancy Error Codes 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9. Maskable Fault Group Descriptions 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10. Maskable Fault Group Actions 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11. Non-Maskable Fault Group Descriptions 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 12. Non-Maskable Fault Action Descriptions 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 13. Redundancy Options 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0827 Series 90–70 Hot Standby CPU Redundancy User ’s Guide – December 1993

xi

Page 12

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter . figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

Chapter 1 Introduction

section level 1 1

1

This chapter is an introduction to a method of CPU Redundancy for the Series 90-70

Programmable Logic Controller which is referred to as the Hot Standby CPU

Redundancy product.

figure bi level 1

table_big level 1

The contents of this chapter provide:

h

a basic description of what Hot Standby CPU Redundancy is;

h

tells what it does for you - the user;

h

provides a basic description of the components of the Hot Standby CPU

Redundancy system;

h

provides a basic description of how a system is configured using the Logicmaster

90-70 programming software configurator function;

h

lists certain restrictions that you must be aware of;

h

and defines terminology unique to this product.

For those who are not familiar with the various redundancy alternatives

which may be applied to a Series 90-70 PLC system, please refer to

A ppendix A before proceeding with this chapter. Fo r tho s e w ho a re fa m il i a r

with those redundancy alternatives please proceed with the dicussion of the ’Hot

Standby CPU Redundancy Product” below.

Note

Hot Standby CPU Redundancy Product

CPU Redundancy for the Series 90-70 Programmable Logic Controller provides a

method of allowing a critical application or process to continue operating if a failure

occurs in any single component. The CPU Redundancy system described in this guide

is the Hot Standby CPU Redundancy product. A Hot Standby CPU Redundancy system

consists of two CPUs connected to one or more Genius I/O buses. Each PLC is

configured as either Primary or Secondary. The Primary PLC is the preferred PLC and

GFK-0827

1

Page 13

1

contains all redundant Genius Bus Controllers at Serial Bus Address 31; the Secondary

PLC contains all redundant Genius Bus Controllers at Serial Bus Address 30. The CPU

that currently controls the system is called the active unit, the other CPU is the standby

unit.

If certain system failures are detected in the active unit, control is switched to the

standby unit. Control can also be switched by depressing a pushbutton on the

Redundancy Communications Module, or through the user’s logic program. When a

switch of control occurs, the units switch roles; the active unit becomes the standby unit

and the standby unit becomes the active unit.

Each PLC must have a Redundancy CPU module (catalog number IC697CPU780) and a

Redundancy Communications module (IC697RCM711) which provides the synchronization

link between the two units, (and a Bus Transmitter Module (IC697BEM713)). The

scanning process of both CPUs is synchronized to keep active and standby units in

lockstep to minimize ”bumps” or upsets to the process when switching from the active

to the standby unit. The effect of this action is a bumpless switch.

The Series 90-70 CPU Redundancy system runs synchronously with a transfer of all

control data that defines machine status and any internal data needed to keep the two

CPUs operating in sync, and is capable of executing the same program and obtaining the

same results. The transfer of data from the active unit to the standby unit occurs once

per sweep. These CPU to CPU transfers are checked for data integrity.

2 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 14

Features of the Hot Standby CPU Redundancy Product

H

Bumpless switching

h

Synchronized CPUs

h

20 millisecond scan extension (nominal). This figure is variable, depending on

amount of data transferred.

h

One scan switching (in most cases)

h

Configurable backup data size

H

No single point of failure (excluding Genius I/O)

H

Redundant backup communications

H

On–line repair of failed component

H

On–line programming

H

Same or different programs in Primary and Secondary units

H

Redundancy CPU has a 16 MHz microprocessor, configurable memory and

configurable addressing capacity

H

Redundancy Communications Module

1

h

Manual pushbutton switch for switching control between active and backup

CPUs

h

Five Status LEDs

– Board OK

– Local System Ready

– Local System Active

– Remote System Ready

– Remote System Active

H

Status Bits (%S) reflect redundancy status of Primary/Secondary units

H

Program control switching

H

Memory parity and checksums

H

Common I/O on Genius bus

H

Background Diagnostics

– Processor test

– PLC CPU EPROM CRC Validation

– User program checksumming

– Time-of-Day/Elapsed Time Clock test

H

Memory Protect Keyswitch

Benefits of the Hot Standby CPU Redundancy Product

Implementation of the Hot Standby CPU Redundancy product provides you with a

method of ensuring that a critical control system or process is uninterrupted in the event

of a failure of any single component (excluding I/O) of the PLC system.

3GFK-0827 Chapter 1 Introduction

Page 15

1

I/O Systems for Hot Standby CPU Redundancy Systems

Both Series 90-70 Local I/O and Genius I/O systems can be present in a Hot Standby

CPU Redundancy control system. The two units are not required to have matching I/O

systems. They may have different numbers of I/O racks, and different local I/O or

option modules.

Genius I/O System

A Genius I/O system is the I/O system that is included in the redundancy system as

shown below. The system can have multiple Genius I/O buses. Any Genius device can

be placed on the bus (Genius blocks, Remote I/O Scanner, etc.). The Genius devices are

under control of the active unit in the Redundancy system. The Genius Bus Controller

in the Primary Unit has a Serial bus Address of 31; the Genius Bus Controller in the

Secondary Unit has a Serial Bus Address of 30. Data from Serial Bus Address 31 is the

preferred data when data is being sent from both units to devices on the Genius bus.

Local I/O System

Local I/O can be configured in the overall PLC system; however, it is not part of the Hot

Standby CPU Redundancy system. Control of Local I/O is done normally through the

user’s logic program. The user may choose to transfer or not transfer this data. A failure

in the Local I/O system will affect the system as described in GFK-0265, the Series 90-70

Programmable Controller Reference Manual.

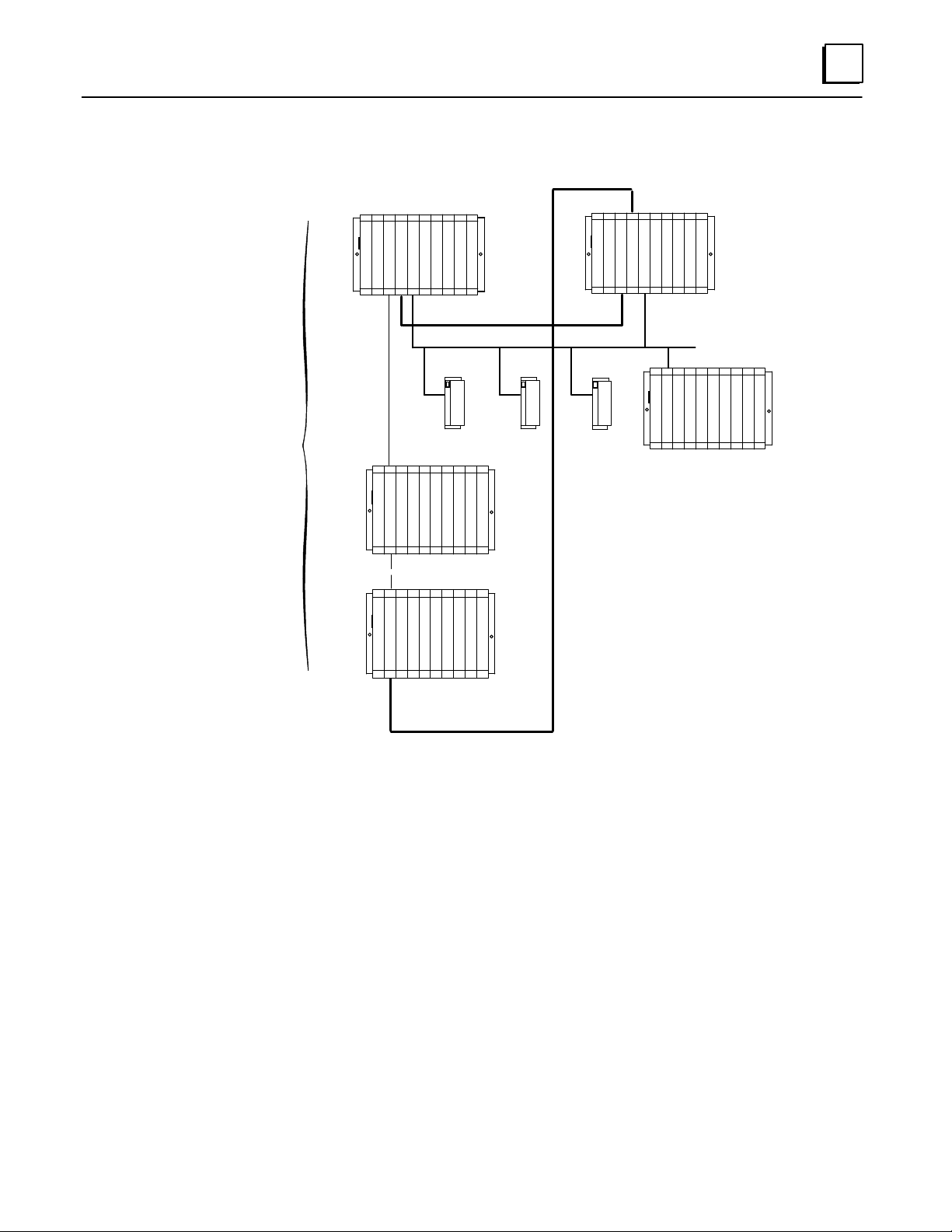

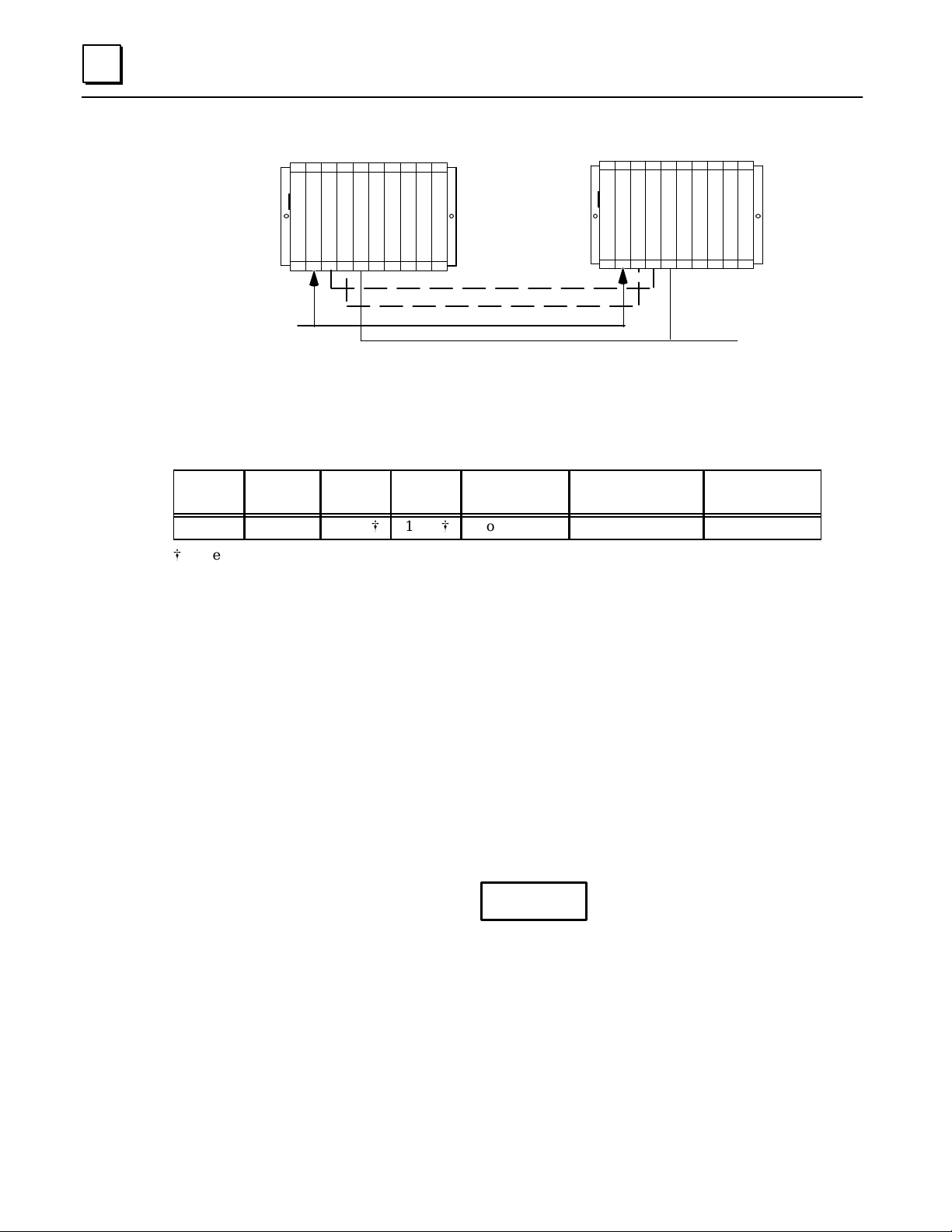

Cable Connections

The I/O system is configured ”normally” except as described below (see the following

figure). That is, a Bus Transmitter Module configured in rack 0 is connected through a

parallel I/O cable to a Bus Receiver Module in the next rack. The link is continued from

this Bus Receiver Module to the Bus Receiver Module in the next rack. This link is

continued with a maximum of six expansion racks. Then, the last Bus Receiver is

connected via an I/O cable with built-in termination (catalog IC697CBL811 (10 feet (3m))

or IC697CBL826 (25 feet (7.5m)). The last module in the parallel I/O bus link must be a

Redundancy Communications Module (RCM). This terminated I/O cable allows

replacement of the RCM without interrupting the running system. If no expansion

racks are used, the terminated I/O cable is connected directly from the Bus T ransmitter

Module to the Redundancy Communications Module.

Note

The exception to a normally configured system is that Rack 7, which

normally can contain I/O modules is not available for physical I/O

modules in a Hot Standby CPU Redundancy system.

4 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 16

PRIMARY UNIT SECONDARY UNIT

1

a47000

LOCAL I/0

CAN BE IN

RACKS

0 - 6

P

B

C

S

T

P

U

M

P

B

S

R

M

Y

Y

P

B

S

R

M

RACK 0

G

IOIOIOIOI

R

B

C

C

M

31

TERMINATED I/O CABLE

*

B

L

O

C

K

RACK 1

IOIOIOIOIOIOIOI

RACK 6

IOIOIOIOIOIOIOI

RACK 0

C

B

R

G

P

O

B

L

O

C

K

O

O

S

B

L

O

C

K

IOIOIOIOI

T

C

B

P

M

M

C

U

30

REMOTE DROP

S

IOIOIOIOIOI

P

C

S

A

N

N

E

R

O

IOI

O

O

*

Figure 1. Example of a Local I/O Configuration with Expansion Racks in a

Hot Standby CPU Redundancy System

Control Strategy

Control strategy refers to the type of redundancy alternative that may be used. For the

Hot Standby CPU Redundancy product, the control strategy is referred to as Genius Hot

Standby (GHS). The control strategy must be selected when configuring the system with

the Logicmaster 90-70 programming Software Configurator function.

Basic Hot Standby Operation

In a basic Genius Hot Standby CPU Redundancy system, Genius blocks receive outputs

from two PLCs (Primary PLC and Secondary PLC), but they are normally controlled

directly by the Genius Bus Controller at serial bus address 31 (Genius Bus Controller in

the Primary PLC). If no output data is available from bus address 31 (the preferred data)

TERMINATED I/O CABLE

I/O CABLE WITH BUILT-IN TERMINATION

*

IC697CBL811 (10 FEET (3m))

IC697CBL826 (25 FEET (7.5m)

5GFK-0827 Chapter 1 Introduction

Page 17

1

for three consecutive Genius I/O bus scans, the outputs are then controlled by the

Genius Bus Controller at serial bus address 30 (Genius Bus Controller in the Secondary

PLC).

If output data is not available from either bus address 31 or 30, the outputs go to their

configured default (OFF or hold last state). The PLC at serial bus address 31 always has

priority, therefore when the PLC with serial bus address 31 is On-line, it always has

control of the outputs.

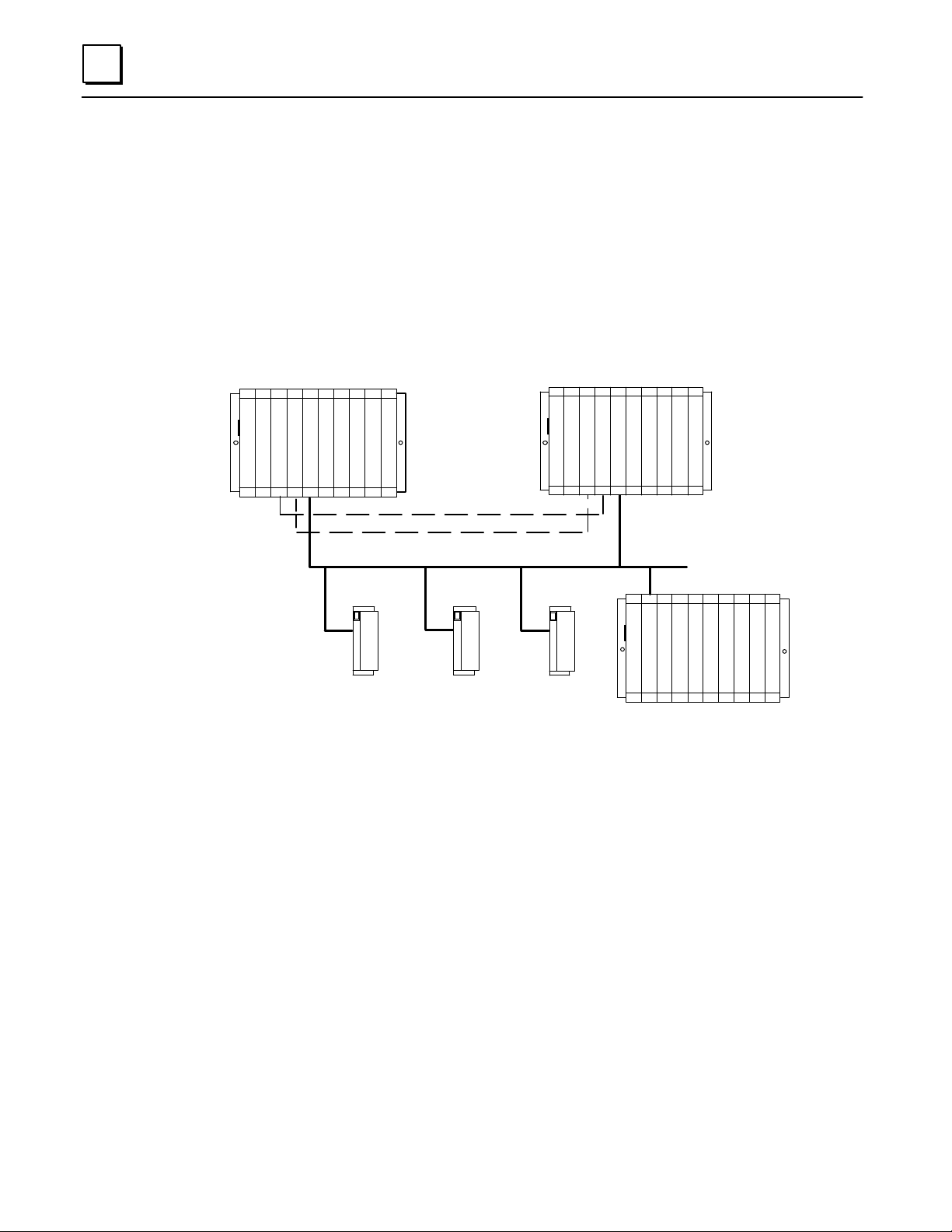

The redundancy system configuration is shown in the following figure. This example

configuration shows only the redundancy system components. As described previously,

a system can also contain Local I/O which is not a part of the redundancy scheme.

PRIMARY UNIT SECONDARY UNIT

P

P

C

G

R

B

S

P

B

C

T

U

C

M

M

31

TERMINATED I/O CABLE

*

TERMINATED I/O CABLE

*

B

L

O

C

K

B

L

O

C

K

B

C

S

T

P

M

U

B

L

O

C

K

Legend

PS.................... Power Supply.............................................. IC697PWRXXX

CPU................. Central Processor Unit.............................. IC697CPU780

BTM................. Bus Transmitter Module............................. IC697BEM713

RCM................ Redundancy Communications Module..... IC697RCM711

GBC................ Genius Bus Controller................................ IC697BEM731

BLOCK........... Genius I/O Block........................................ IC660XXXYYY

SCANNER....... Remote I/O Scanner.................................... IC697BEM733

*...................... T erminated I/O Cable................................. IC697CBL811/826

a47001

G

R

B

C

C

M

30

other Genius devices

REMOTE DROP

IOIOIOIOIOI

S

P

C

S

A

N

N

E

R

IOI

O

O

Figure 2. Synchronized Hot Standby CPU Redundancy System Configuration

6 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 18

Redundancy CPU Module

The same model of CPU must be installed in both the Primary and Secondary PLCs.

This CPU, which is the only CPU that currently supports synchronized Hot Standby

CPU redundancy, is the CPU 780 (catalog number IC697CPU780). This CPU is similar to

the existing IC697CPU782 CPU in that it has an 80386DX microprocessor which operates

at a speed of 16 MHz, supports floating point calculations, and requires an expansion

memory board which can be 128 KBytes, 256 Kbytes with 256 KBytes of non-volatile

flash memory, 256 KBytes or 512 KBytes.

It is important to note that the following features available with other

Series 90-70 CPUs are not supported by the CPU 780: I/O interrupts,

timed interrupts, the VME Integrator Racks (IC697CHS782 and

IC697CHS783), Flash memory operation, and STOP/IOSCAN mode. In

addition, the operation of several other features is changed. For more

detailed information on these features, please see Chapter 4.

As with the other Series 90-70 CPUs, the CPU 780 must be installed in slot 1 of rack 0

(CPU rack). The Primary unit and the Secondary unit must each have a Redundancy

CPU installed in slot 1 of rack 0 with one CPU configured as the Primary CPU and the

other CPU configured as the Secondary CPU. Configuration of the CPU 780 in the

Primary unit and the CPU 780 in the Secondary unit must be done separately (see

Chapter 3 for details of configuration with the Logicmaster 90-70 configurator function).

1

NOTE

Redundancy Communications Module

The Redundancy Communications Module (RCM), catalog number IC697RCM711,

provides a path (see Figure 1) for sharing data between the two CPUs in the redundant

system. The RCM has five LEDS:

H

BOARD OK

H

LOCAL SYSTEM READY

H

LOCAL SYSTEM ACTIVE

H

REMOTE SYSTEM READY

H

REMOTE SYSTEM ACTIVE.

These LEDs report the status of the health of the RCM and the control status of the Hot

Standby CPU Redundancy system. The status provided by these LEDs is also provided

in an area of %S memory (%S33 through %S39) which is accessible from the user logic

program but cannot be altered or overridden.

The module has a momentar y pushbutton switch which when depressed for 1 second

and released allows you to manually switch control from the active unit to the standby

unit. The switch between units can also be controlled through user logic

implementation of a SVC_REQ function that is activated by a discrete input point. Both

of these switch requests may only be made every 10 seconds.

In a synchronized system, I/O data is controlled by only one unit (the active unit) but is

shared between both units (active and backup units). The RCM provides the path for a

synchronizing message from the active to the backup unit which is used to synchronize

7GFK-0827 Chapter 1 Introduction

Page 19

1

the two CPUs and provides the communications path for the transfer of I/O data

between the two units. An RCM must be configured in both the Primary PLC and the

Secondary PLC. The RCM must reside in the CPU rack (rack 0) in a system and there

can be no empty slot between the RCM and the CPU (there can be other modules).

Bumpless Switching

Bumpless switching occurs when the active unit fails and system control is transferred to

the backup unit without affecting the operation of the process under control.

Synchronized CPUs

For bumpless swi tc hing to occur, the CPU in the active and backup units must operate in a

synchronous fashion, that is, the operation of both units must occur at the same time (or as

close to the same time as possible). There are two synchronization points in the swee p: on e

immediately after the input scan and the other immediately before the output scan.

Synchronization data is passed from the active to the backup unit at the first

synchronization point, which occurs after the input scan. Specifically, after the inputs are

scanned, the inputs that were just read (%I and %A I) are sent from the active to the backup

unit and the synchronization message is passed after the input data.

The second synchronization point occurs immediately after the end of the logic solution

before the output scan begins. During this time, all remaining control data, including the

%Q, %AQ, %M and %R memories is transferred from the active unit to the backup unit.

Effect on Scan Time

When a system is operating normally (no faults exist in the system) redundancy adds about

21 ms (includes 5 ms default background window setting) per PLC scan. The effect on scan

time depends on the system configuration. The followi ng number of data points and

registers is considered the base configuration on which the 21 ms was calculated.

512 %I, 512 %Q, 512 %M

256 %AI, 256 %AQ

2048 %R

Each additional 1K %I, %Q, or %M data points adds about 1.8 ms to the scan impact

(add 25% for each %I or %Q reference if point faults enabled) and each additional 1K of

%R, %AI, or %AQ registers adds about 5 ms to the scan impact (add 50% for each %AI

or %AQ reference if point faults enabled).

Fail Wait Time

When the active CPU has a failure, the backup CPU will wait for a specified time (in

milliseconds) before assuming that the link has failed. This time is referred to as the Fail

Wait time. The duration of this time must be specified during configuration of both the

Primary and Secondary units and can range from 60 ms to 400 ms (in increments of 10

ms), with the default value being 60 ms.

Switch to Backup Unit Time

The amount of time it takes to switch control from the active unit to the backup unit

depends on what caused the switch to take place.

8 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 20

If the switch occurs due to a controlled condition such as toggling the unit selection

switch on the Redundancy Communications Module or forcing a switch in the user logic

program with a SVC_REQ, or because of a fault detected by the PLC CPU, then the

switch-over will occur at the beginning of the next sweep. The delay will be up to 1

sweep with the possibility of an input and an output scan after failure detection.

If the switch occurs due to a failure of the PLC CPU (including loss of power), then the

switch will occur after the backup unit determines that the active unit has failed to

rendezvous at the synchronization point. Failure to rendezvous may take up to 2 failwait

timeouts (1 for each link) to determine that a failure has occurred. Control will not

transfer , in this case, until both links have been tried unsuccessfully.

Configurable Backup Data Size

The maximum size of the backup data (Shared I/O) is 20 KBytes of Input data and 28

KBytes of Output data. The shared I/O data configuration must be the same in both the

Primary and Secondary units. This shared I/O data is transferred from the active CPU to

the backup CPU during the CPU sweep process. A total of up to 56 KBytes of user

memory is consumed by this data transfer. A maximum of 48 KBytes of the 56 KBytes is

the total Shared I/O (20 KBytes %I, %AI; 28 KBytes %Q, %M, %AQ, and %R), while the

remainder (8 KBytes) is used by the system for internal data transfers, including

synchronizing data.

1

On-Line Programming

On-line changes to the user logic program are permitted in both the active unit and the

backup unit. The programming device must be connected to the system in which

changes are to be made in order to make any on-line changes. Note that all precautions

regarding power source and grounding for connecting the programming device must be

followed in accordance with instructions in the Series 90-70 Programmable Controller

Installation Manual, GFK-0262.

A connection and disconnection of the parallel programmer cable should only be made

with the programmer properly grounded, and Logicmaster 90 software properly booted

up and in OFF-LINE mode. For more information, refer to the Series 90-70 Installation

manual, GFK–0262.

On-Line Repair

A Hot Standby CPU Redundancy system allows you to do on-line repair of failed

components without disrupting the process under control. Control status of both the

Primary and the Secondary units can be monitored by the LEDS on the Redundancy

Communications Modules in each system. When a component of the active unit fails,

control is switched to the backup unit. The failed component can then be replaced by

removing power from the rack in which it is installed.

After replacing the failed component and returning power to the rack, the backup unit

will resynchronize with the currently active unit. The unit which had failed and was

previously the active unit will determine its role in the system as part of the

resynchronization process. If it is the Primary unit (with Serial Bus Address 31) it will

once again become the active unit, the unit with Serial Bus Address 30 (Secondary unit)

will again become the backup unit. F or mor e detailed information on replacing failed

components and resynchronization, see Chapter 4, ”System Operation”.

9GFK-0827 Chapter 1 Introduction

Page 21

1

Programming Considerations

There are several features in the operation of the Redundancy CPU which are not

supported or are different then operation of other CPUs. These features are listed below

and are described in detail in Chapter 4, ”System Operation”.

The following features are not available with the Redundancy CPU (CPU 780):

H

I/O Interrupts

H

Timed Interrupts

H

VME Integrator Rack

H

STOP/IOSCAN mode

H

Flash memory operation

The operation of the following features is different with the CPU 780 than with other

Series 90-70 CPUs:

H

RUN/DISABLED mode

H

Configuration of fault actions

H

STOP to RUN mode

H

Default Background Window Time

Configuration R equirements

The Redundancy CPU and the Redundancy Communications Module must be

configured into the redundancy system. There are several additional parameters (other

than the normal CPU parameters) that must be configured with the Logicmaster 90-70

Configurator function which are unique to the Hot Standby CPU Redundancy system.

The following items require configuration when specifying the CPU 780 (the

Redundancy CPU) as the CPU for configuration:

Configuration

Parameter Description

Fail-wait (60 ms to 400 ms) The time to wait on a failed active PLC before switching to

Control Strategy The control strategy for the cur rent configuration. Config-

Shared I/O Refer ences The references within the control of the Redundancy sys-

the backup CPU. The default value is 60 ms.

ured as a three-character identifier (GHS for Hot Standby

CPU Redundancy). The default value is GHS (currently

the only value that is valid).

tem; up to 20 KBytes of Input data and 28 KBytes of Output data is transferred. The references which may be used

as shared I/O are %I, %Q, %AI, %AQ, %R, and %M.

Redund Type Whether the CPU being configured is the Primary or Sec-

ondary CPU in the Redundancy system. Redund Type

has three possible values: PRIMARY, SECONDARY , or

SIMPLEX. SIMPLEX (not supported in this release of the

product) indicates a non–redundant system. The default

value is PRIMARY.

10 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 22

The Primary Unit and the Secondary Unit must be configured separately. That is, the

programming device should be connected directly to either the Primary or the

Secondary Unit to configure that unit. When you have completed configuring that unit,

disconnect the programmer from the configured unit and move it to the other unit and

proceed with configuration of the second unit. Refer to Chapter 3, ”System

Configuration” for details of configuring a Redundancy system

Definition of Terms

Several new or unfamiliar terms are used throughout this manual which are relevant to

the discussions of CPU Redundancy. These terms are defined in the following table.

Term Definition

A ctive Unit The unit that is actively controlling the process.

Back up Unit That unit that is synchronized with the active unit and able to take over the process.

CPU Redundancy A system with two PLC CPU units cooperating to control the same process.

Critical Component A component whose failure causes the PLC (either active or backup) in which it resides to

stop.

Hot Standby A feature of Genius blocks whereby the block prefers output data from the

Bus Controller at Serial Bus A ddress 31. When inputs from that Bus Controller are not

available, the block tak es output data from the Bus Controller at Serial Bus Address 30.

If inputs from neither Controller are available, the block places its outputs in the

designated default state.

1

Local Unit The RCM LEDs and %S status bits refer to the PLC in which they reside as

the ”Local Unit”.

Primar y Unit The unit in which the Genius Bus Controller’s Serial Bus A ddress is 31.

Redundancy A system feature that has multiple elements controlling the same process to provide alter-

nate functional channels in case of failure.

Remote Unit The RCM LEDs and status bits refer to the other PLC as the ”Remote Unit”.

For example, the P rimary Unit is the Remote Unit to the Secondary Unit and likewise

the Secondary Unit is the Remote Unit to the Primary Unit.

Secondary Unit The unit in which the Genius Bus Controller’s Serial Bus A ddress is 30.

Synchronized A unit is considered to be synchronized when it has received the latest status information

from the Active unit and is running the PLC program in parallel.

11GFK-0827 Chapter 1 Introduction

Page 23

1

Commonly Used Acronyms

A list of acronyms used in this manual are defined for your convenience in the following

table.

Acronym Definition

BRM Bus Receiver Module

BSM Bus Switching Module

BTM Bus T ransmitter Module

CPU Central Processor Unit

EPROM Erasable Programmable Read Only Memory

GBC Genius Bus Controller

GHS Genius Hot Standby Redundancy

GMR Genius Modular Redundancy

HHM Hand Held Monitor

LED Light Emitting Diode

OI Operator Interface

PLC Programmable Logic Controller

PROM Programmable Read–Only Memory

RAM Random Access Memory

RCM Redundancy Communications Module

PLD Relay Ladder Diagram

SBA Serial Bus A ddress

SNP Series 90 Protocol

VME VersaModule Europe: the backplane standard

used by the Series 90-70 PLC system

12 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 24

Chapter 2 System Components

section level 1 1

2

This chapter describes the hardware components for a Hot Standby CPU Redundancy

system. It describes the modules required for the system and provides catalog numbers

of the components. For detailed installation instructions for the Series 90-70 PLC, refer

to GFK-0262, the Series 90-70 Programmable Controller Installation Manual.

Redundancy CPU

The IC697CPU780 Central Processing Unit (CPU) has been designed specifically for

Series 90-70 Hot Standby CPU Redundancy applications. This is the only Series 90-70 CPU

that currently supports CPU redundancy .

figure bi level 1

table_big level 1

Note

It is important to note that the following features available with other

Series 90-70 CPUs are not supported by the CPU 780: I/O interrupts,

timed interrupts, the VME Integrator Racks (IC697CHS782 and

IC697CHS783), Flash Memory operation, and STOP/IOSCAN mode. In

addition, the operation of several other features is changed. For more

detailed information on these features, please see Chapter 4.

The CPU 780 supports floating point calculations, offers remote programmer keyswitch

memory protection, and has four status LEDs. Operation of this module may be

controlled by the three-position RUN/STOP switch on the module, or remotely by an

attached programmer and Logicmaster 90-70 Programming Software. Program and

configuration data can be locked through software passwords or manually by the

memory protect keyswitch. When the key is in the ”protected” position, program and

configuration data can only be changed by a programmer connected for parallel

communications (that is, to the Bus Transmitter Module).

As with the other Series 90-70 CPUs, the CPU 780 must be installed in slot 1 of rack 0

(CPU rack). In a Hot Standby CPU Redundancy system, the Primary unit and the

Secondary unit must each have a Redundancy CPU installed in slot 1 of rack 0. One

CPU is configured as the Primary CPU and the other CPU is configured as the

Secondary CPU. Configuration of the CPU 780 in the Primary unit and the CPU 780 in

the Secondary unit must be done separately (see Chapter 3 for details of configuration

with the Logicmaster 90-70 configurator function). The following figure shows the CPU

location in a Hot Standby CPU Redundancy system.

GFK-0827

13

Page 25

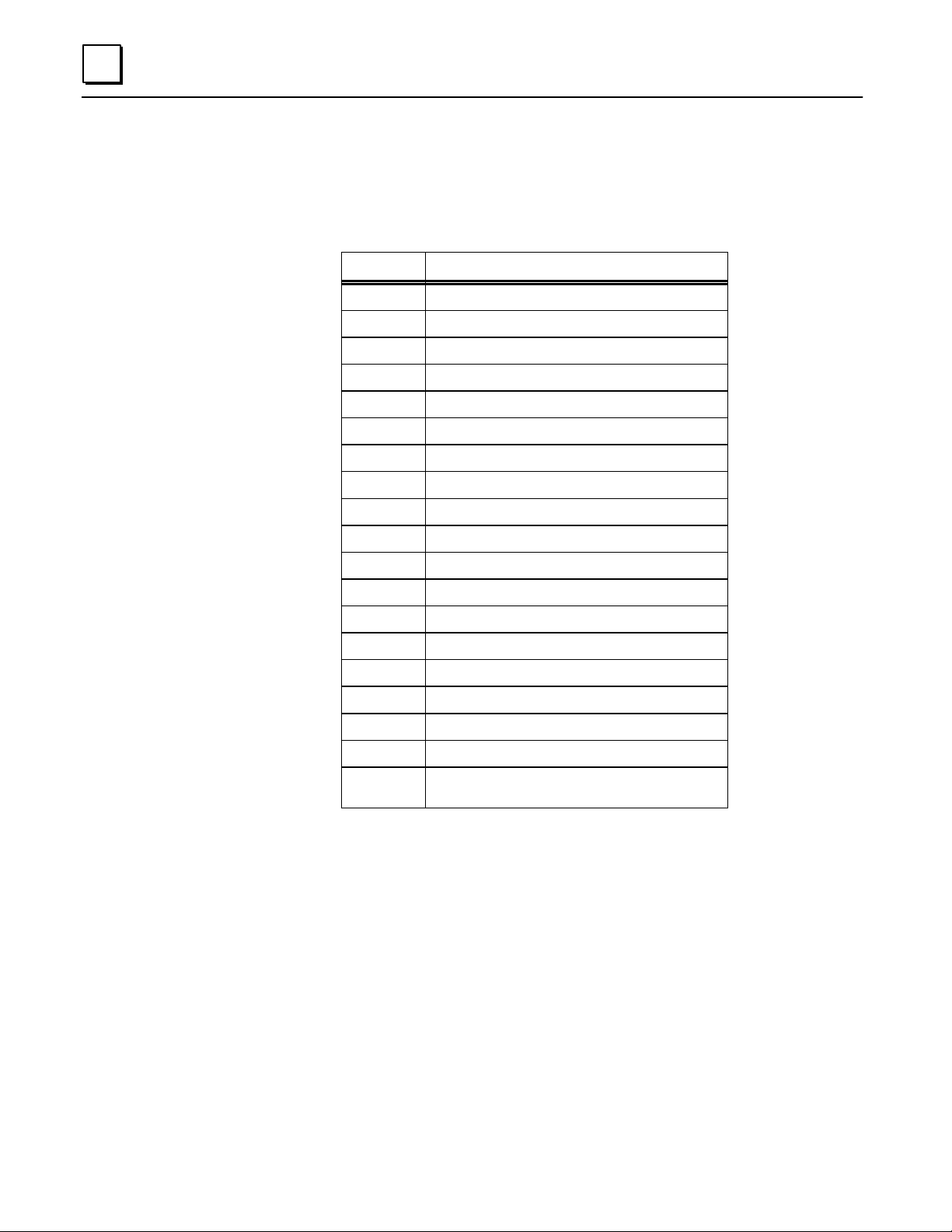

2

CPU 780

The capacities for the CPU 780 are as listed in the following table.

Speed

(MHz) Processor

16 80386DX 12288

[

The total number of Input points and Output points on the model 780 CPU cannot ex ceed 12288.

CPU Architecture

PRIMARY UNIT SECONDARY UNIT

C

P

S

G

R

B

P

B

C

T

U

C

M

M

31

Redundancy Communications Link

Redundancy Communications Link

B

C

P

T

P

S

M

U

G

R

B

C

C

M

30

Genius Bus

a47002

Figure 3. CPU 780 Locations in a Hot Standby CPU Redundancy System

Table 1. Capacities for Redundancy CPU, IC697CPU780

Input

Points

[

Output

Points

12288

On-Board

User Memory

[

not available 128/256/512 Yes

Expansion Memor y

(KBytes)

Floating Point

Math

The CPU 780 has an 80386DX microprocessor as the main processing element, on-board

memory, a dedicated VLSI processor for performing boolean operations and interfaces

to a serial port and the system bus. The microprocessor provides all fundamental sweep

and operation control, plus execution of non-boolean functions. Boolean functions are

handled by a dedicated, VLSI, Boolean Coprocessor (BCP) designed by GE Fanuc.

Program and data memory on the CPU 780 is available by the attachment of an

expansion memory board with either 128 Kbytes, 256 Kbytes or 512 Kbytes of

battery-backed CMOS RAM, or 256 Kbytes with 256 Kbytes of non-volatile flash

memory.

When the CPU board is in storage, disconnect the lithium battery if there is no

application program stored in memory. If a program is stored in memory, do not

disconnect the battery; otherwise the data will be lost.

Caution

If a Low Battery Warning occurs, replace the battery before removing

power from the rack. Otherwise there is the possibility that data will

be corrupted or the program will be cleared from memory.

Watchdog Timer

The CPU provides a watchdog timer to catch certain failure conditions. The value of this

timer is controlled by the user from the programmer. The valid range of the watchdog

14 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 26

CPU Features

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

timer is 10 milliseconds to 1000 milliseconds. The default value for the watchdog timer is

200 milliseconds. The watchdog timer resets at the beginning of each sweep. The fail

wait time is included in the watchdog check. The watchdog timer should be set to allow

for the expected scan plus two fail wait times.

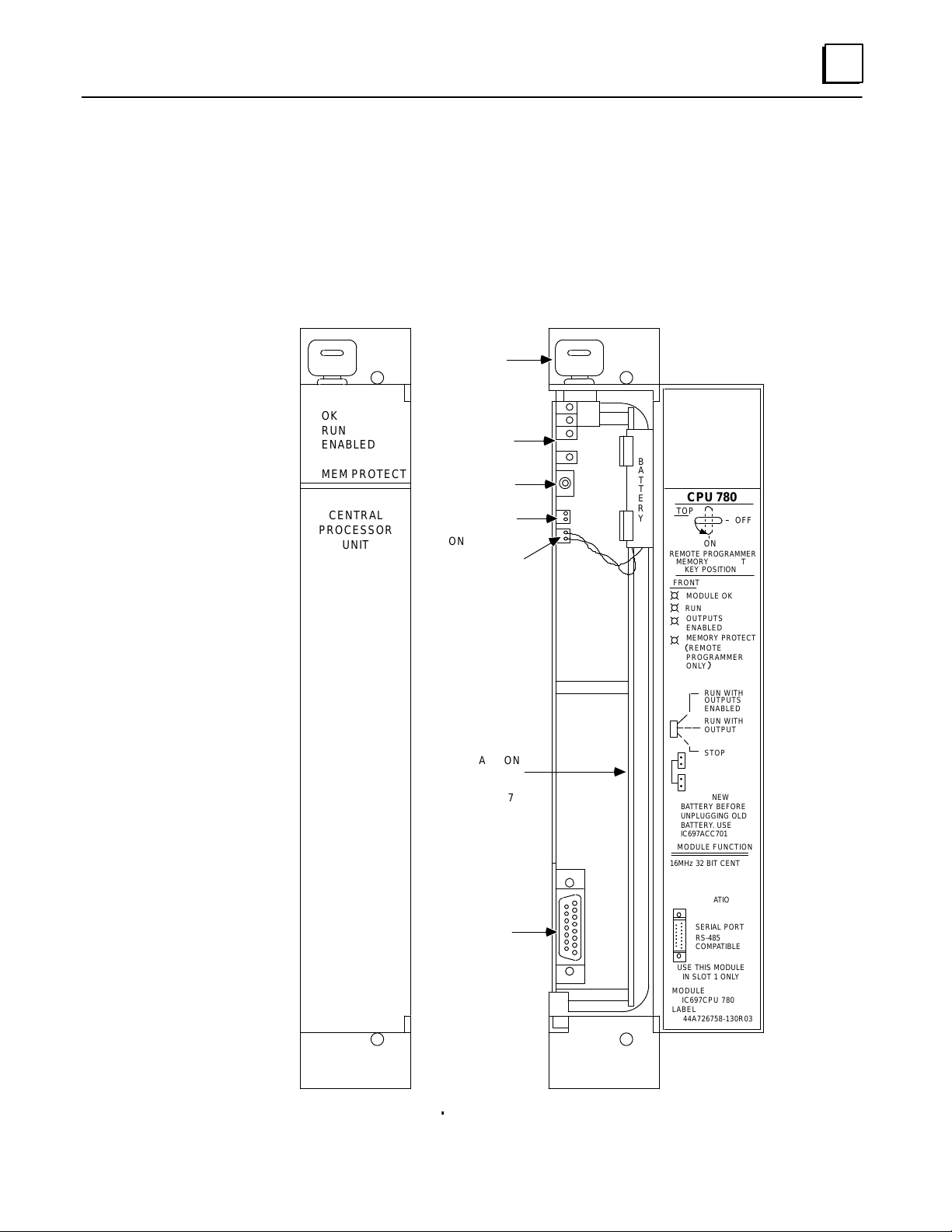

The CPU must reside in Slot 1 in rack 0, the main (CPU) rack. An illustration of the CPU

780 is shown in the following figure, followed by a description of the CPU features.

a47003

MEMORY

PROTECT

KEY

SWITCH

OK

ÎÎÎ

RUN

ENABLED

ÎÎÎ

ÎÎÎ

MEM PROTECT

ÎÎÎ

CENTRAL

ÎÎÎ

PROCESSOR

ÎÎÎ

UNIT

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

CPU

STATUS

LEDS

CPU MODE

SWITCH

OPEN

REPLACEMENT

BATTERY

CONNECTOR

CURRENTLY

INSTALLED

BATTERY

CONNECTOR

EXPANSION

MEMORY

BOARD

IC697MEM731

IC697MEM732

IC697MEM733

IC697MEM735

RS-485

COMPATIBLE

SERIAL PORT

B

A

T

T

E

R

TOP

Y

REMOTE P R O GR AMMER

MEMORY PR OTECT

FRONT

ON = OK, ENABLED

INSTALL NEW

BATTERY BEFORE

UNPLUGGING OLD

BATTERY. USE

IC697ACC701

MODULE FUNCTION

16MHz 32 BIT CENTRAL

PROCESSING UNIT

WITH FLOATING POINT

MATH COPROCESSOR

FOR HOT STANDBY

CPU APPLICATIONS

USE THIS MODULE

MODULE

IC697CPU 780

LABEL

44A726758-130R03

CPU 780

OFF

ON

KEY POSITION

MODULE OK

RUN

OUTPUTS

ENABLED

MEMORY PR OTECT

REMOTE

PROGRAMMER

ONLY

PROTECTED

RUN WITH

OUTPUTS

ENABLED

RUN WITH

OUTPUTS

DISABLED

STOP

BATTERY

CONNECTORS

SERIAL PORT

RS-485

COMPAT IBLE

IN SLOT 1 ONLY

Figure 4. Redundancy CPU - IC697CPU 780

2

15GFK-0827 Chapter 2 System Components

Page 27

2

CPU Mode Switch

Allowable Programmer

CPU Mode Switch

Position

Allowable Programmer

CPU Mode Switch

A three-position toggle switch is mounted near the top of the CPU board. This switch

selects one of three operating modes for the CPU: RUN/ENABLED, RUN/DISABLED, or

STOP. Although the mode of operation for the CPU can be controlled from both the

switch and the programmer, the switch position restricts the ability of the programmer

to put the CPU into certain modes.

The following table shows the modes that can be selected by the programmer based

upon the position of the CPU mode switch.

Table 2. Valid Operating Mode Selection

Mode Command

STOP

RUN/OUTPUTS ENABLED RUN/DISABLED

RUN/ENABLED

STOP

RUN/OUTPUTS DISABLED RUN/DISABLED

STOP STOP

Run/Outputs Enabled

The top position of the switch is Run with Outputs Enabled. With the switch in this

position, the CPU executes all portions of the sweep normally.

Run/Outputs Disabled

The middle position of the switch is Run with Outputs Disabled. When the switch is in

this position, the CPU executes all portions of the sweep normally, but physical outputs

are held in their default state, and therefore remain unchanged. Refer to Chapter 4,

page 65 for important information on the Run/Disabled mode in a Hot Standby CPU

Redundancy system.

STOP

NOTE

The STOP/IOSCAN mode is not a valid mode in a redundancy system.

Refer to Chapter 4 for detailed information.

The bottom position of the switch is labeled STOP. With the switch in this position, the

CPU communicates only with the programmer and devices connected to the serial port,

and recovers faulted modules. Any of the values in the I/O tables can be changed using

the programming computer.

16 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 28

Memory Protect Keyswitch

The Memory Protect keyswitch is located at the top of the module and has two

positions: ON and OFF. This keyswitch is used to manually lock program and

configuration data. When the key is in the ”protected” (ON) position, program and

configuration data can only be changed by a programmer connected for parallel

communications with the CPU 780 (that is, to the Bus Transmitter Module).

CPU Status LEDs

There are four LEDs mounted at the top of the CPU board which indicate the current

state of the CPU. The normal state of these LEDs when the CPU is running is ON. They

are OFF or flashing to indicate special or failure conditions.

OK

The top LED, labeled OK is an indicator of the health of the CPU. It is ON when the CPU

is functioning properly. The LED blinks when the CPU executes the power-up

diagnostics, when the system has failed, and when the remote unit is powered-up.

However, when in this state, the CPU can still communicate with the programmer (the

CPU cannot communicate with the programmer during power-up diagnostics) . The

LED is OFF when the system has failed and the CPU cannot communicate with the

programmer.

2

RUN

The middle LED, labeled RUN is an indicator of the RUN/STOP status of the CPU. It is

ON when the CPU is in the RUN/ENABLE or RUN/DISABLE mode. When the CPU is in

the STOP mode, the LED is OFF.

ENABLED

The bottom LED, labeled ENABLED indicates the state of the outputs. This LED is ON

when the outputs are enabled, and OFF when the outputs are disabled.

MEM PROTECT

This LED indicates the status of the memory protect keyswitch. When the keyswitch is

in the OFF position the LED is OFF, and the CPU can be programmed (if connected for

parallel communications, the CPU can be programmed regardless of the keyswitch

position). After the program has been verified, the toggle switch for mode selection can

be moved to the appropriate mode position. When the memory protect keyswitch is in

the ON position, the LED will be ON.

Battery Connectors

Directly below the mode switch are two identical battery connectors. The connector

wired to the lithium backup battery cable plugs into one of these connectors to connect

the battery to the CMOS memory devices. Two connectors are provided for use when

the battery requires replacement. The battery currently installed can remain connected

until the new battery is connected, thus minimizing the possibility of losing data.

17GFK-0827 Chapter 2 System Components

Page 29

2

Serial Port Connector

The 15-pin D-connector at the bottom of the module provides the connection to an

RS-422/RS-485 serial port. Its port provides a serial connection to the W ork Station

Interface (WSI) board installed in the programming computer. For applications

requiring RS-232 communications, an RS-232 to RS-422 converter (IC690ACC900) or

RS-232 to RS422 miniconverter (IC690ACC901) is available.

Note

An RS-422 Isolated Repeater/RS-232 Converter (IC655CCM590) is

available for applications requiring ground isolation where a common

ground cannot be established between components.

A standard serial COM port version of Logicmaster 90-70 programming software

provides logic programming and configuration for the Series 90-70 PLC using the COM1

or COM2 serial port of the programming device (a Work Station Interface board is not

needed). Connections for this configuration are made from the programmer’s COM1 or

COM2 serial port to the converter to the serial port on the Series 90-70 CPU.

Expansion Memory Board

The CPU 780 requires an expansion memory board (see GFK-0837 and GFK-0531C, or

later versions), for more information. The expansion memory board uses battery-backed

CMOS RAM memory devices for program and data storage. These expansion memory

boards are arranged in a 32-bit memory configuration and can only be used on the

models 780, 781 and 782 CPUs. Error checking is provided by a CPU checksum routine.

Logic program memory is continually error-checked by the CPU as a background task.

Memory parity errors are reported to the CPU when they occur.

These expansion memory boards are not compatible with the expansion memor y boards

used with the models 771 and 772 CPUs or the Programmable Coprocessor Module.

Four versions of the 32-bit memory expansion board are available as listed in the table

below. These expansion memory boards are installed on the CPU 780 module by

mounting them on a connector provided for that purpose. The CMOS RAM memory on

the expansion memory boards is backed-up by the Lithium battery mounted on the CPU

module on which the boards are installed.

Table 3. Expansion Memory Boards for CPU 780

Catalog Number Memory Size

IC697MEM731 128K Bytes

IC697MEM732 256K Bytes w/256 K Bytes Non-Volatile Flash Memory

IC697MEM733 256K Bytes

IC697MEM735 512K Bytes

Note that the current version of the expansion memory boards must be used with the

CPU 780. consult your local PLC Distributor or PLC sales office for more

information.

18 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 30

Redundancy Communications Module

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

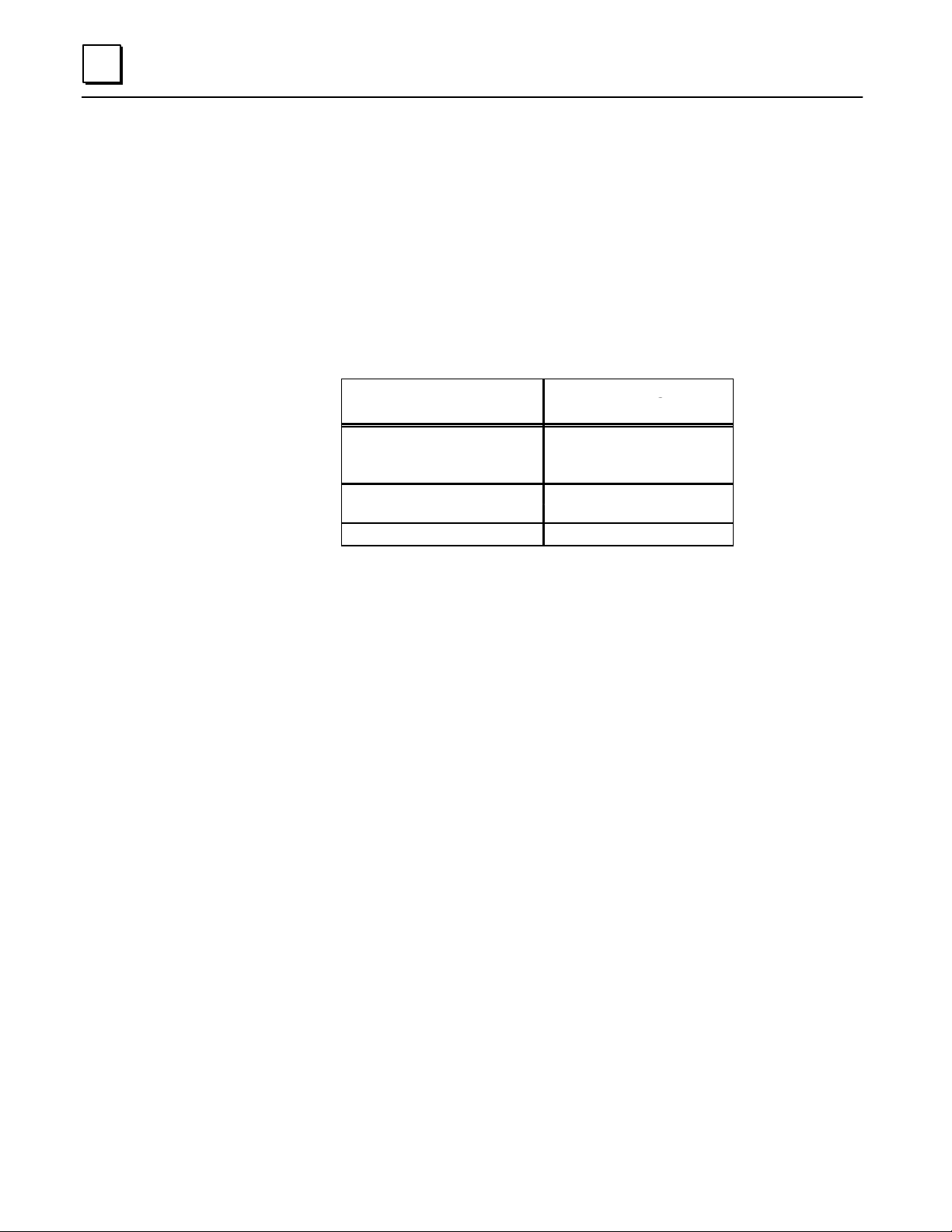

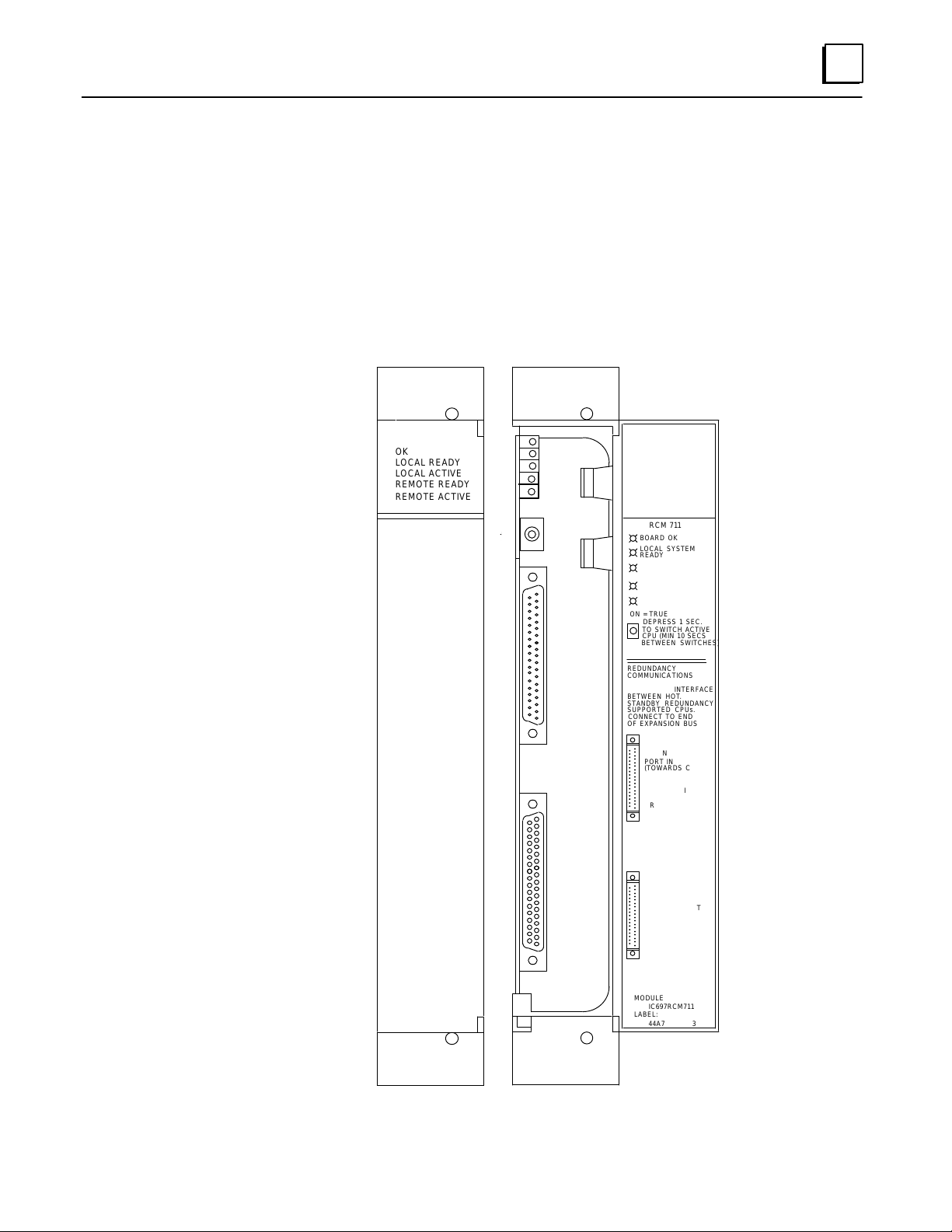

The Redundancy Communications Module (RCM), catalog number IC697RCM711, provides

a communications path for sharing data between the two CPUs in the redundant system.

In a synchronized system, I/O data is controlled by one unit (the active unit) but is shared

between both units (active and backup units). The RCM provides the communications path

between the two units. An RCM must be configured in both the Primary PLC and the

Secondary PLC. The RCM must reside in rack 0 and there can be no empty slot between

the RCM and the CPU (there can be other modules).

RCM Features

The followi ng figure shows the features of the RCM module.

ÎÎÎ

OK

LOCAL READY

LOCAL ACTIVE

ÎÎÎ

REMOTE READY

REMOTE ACTIVE

ÎÎÎ

ÎÎÎ

REDUNDANCY

ÎÎÎ

COMMUNICATIONS

MODULE

ÎÎÎ

ÎÎÎ

ÎÎÎ

Figure 5. R edundancy Communications Module - IC697RCM711

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

a47004

RCM 711

BOARD OK

LOCAL SYSTEM

READY

LOCAL SYSTEM

ACTIVE

REMOTE SYSTEM

READY

REMOTE SYSTEM

ACTIVE

ON = TRUE

DEPRESS 1 SEC.

TO SWITCH ACTIVE

CPU (MIN 10 SECS

BETWEEN SWITCHES)

MODULE FUNCTION

REDUNDANCY

COMMUNICATIONS

MODULE.

HIGH SPEED INTERFACE

BETWEEN HOT.

STANDBY REDUNDANCY

SUPPORTED CPUs.

CONNECT TO END

OF EXPANSION BUS

EXPANSION

PORT IN

(TOWARDS CPU)

TO BEM711

OR BEM713

(USE TERMINATED

CABLE CBL811

OR CBL826)

50 FT. MAXIMUM

CABLE LENGTH FROM

BEM 713 TO TO RCM711

UNUSED PORT

DO NOT INSTALL

CABLE OR

TERMINATOR

MODULE

IC697RCM711

LABEL:

44A726758–136R02

2

19GFK-0827 Chapter 2 System Components

Page 31

2

PRIMARY UNIT SECONDARY UNIT

( RACK 0 )

P

B

R

G

C

P

S

T

C

B

U

M

M

C

31

Redundancy Communications Link

Redundancy Communications Link

C

P

P

S

U

( RACK 0 )

B

R

T

C

M

M

G

B

C

30

a47005

Figure 6. Example of RCM Location in a Hot Standby CPU Redundancy System

RCM System Status LEDS

A Hot Standby CPU Redundancy system has two RCM modules, each with five LEDs

and a momentar y pushbutton switch for manually switching between the active and the

backup units. The LEDs will always be updated by the appropriate system. The RCM

has two internal timers that will automatically turn off four of the LEDs (not the board

OK LED) if the LEDs have not been updated within a specified time period. The two

remote LEDs and the two local LEDs have separate timers since they are controlled from

different systems.

The RCM has five LEDS:

H

BOARD OK

H

LOCAL SYSTEM READY

H

LOCAL SYSTEM ACTIVE

H

REMOTE SYSTEM READY

H

REMOTE SYSTEM ACTIVE.

These LEDs report the status of the health of the RCM and the control status of the Hot

Standby CPU Redundancy system. The status provided by these LEDs is also provided

in an area of %S memory (%S33 - %S39) which is accessible from the user logic program

but cannot be altered or overridden. The LEDs have the following meanings and uses.

Note that the term Local Unit when associated with a particular RCM refers to that unit

in which the RCM resides. Remote Unit refers to that unit in which the RCM is

configured by the system for addressing as being in rack 7, slot 1. Each RCM will have

an associated local and remote unit.

BOARD OK

This LED will come on when the diagnostics are complete and the RCM has been

determined to be operating normally. It will remain on unless the RCM fails.

L OCAL SYSTEM READY

Indicates whether the local unit is ready to become the active unit in a redundant PLC

configuration. If the LED is on, the local unit has been configured for redundancy, is in

RUN mode, and has performed sufficient initialization, diagnostics, and hand–shaking

to take control of the redundant system if selected as the active unit. It is the

responsibility of the local unit to set the state of this LED at least once during each

sweep; if the local unit is unable to set (or fails to set) the state of the LED, the hardware

will force the LED to off after the timer has timed out.

20 Series 90-70 Hot Standby CPU Redundancy User’s Guide – December 1993

GFK-0827

Page 32

L OCAL SYSTEM ACTIVE

Indicates whether the local unit is the controlling (or active) unit in a redundancy

system. It is the responsibility of the local unit to set the state of this LED at least once

during each sweep; if the local unit is unable to set (or fails to set) the state of the LED,

the hardware will force the LED to off after the timer has timed out.

REMOTE SYSTEM READY

Indicates whether the remote unit is ready to become the active unit in a redundant PLC

configuration. If the LED is on, the remote unit has been configured for redundancy, is

in RUN mode, and has performed sufficient initialization, diagnostics, and

hand–shaking to take control of the redundant system if selected as the active unit. It is

the responsibility of the remote unit to set the state of this LED at least once during each

sweep; if the remote unit is unable to set (or fails to set) the state of the LED, the

hardware will force the LED to off after the timer has timed out.

REMOTE SYSTEM ACTIVE

Indicates whether the remote unit is the controlling (or active) unit in a redundancy

scheme. It is the responsibility of the remote unit to set the state of this LED at least once

during each sweep; if the remote unit is unable to set (or fails to set) the state of the LED,

the hardware will force the LED to off after the timer has timed out.

2

Unit Selection Pushbutton

The module has a momentary pushbutton switch which when depressed for 1 second

and released allows you to manually switch control from the active unit to the backup unit

if the backup unit is READ Y. The status of each pushbutton is checked by the PLC CPU

software. The switch between units can also be controlled through user logic

implementation of a SVC_REQ function that is activated by user logic. After a switch

has been requested, you must wait 10 seconds before requesting another switch.

RCM Connectors

The RCM has two connectors mounted on the front of the board. The top connector is the

only one used. It is connected via an I/O cable with built-in termination to the last rack of

the other PLC system. If no expansion rack is used, it is connected to the lower connector

on the Bus T ransmitter Module of the other system. The I/O cable with built-in

termination is available in two lengths:

H

IC697CBL811, 10 feet (3 meters)

H

IC697CBL826, 25 feet (7.5 meters)

21GFK-0827 Chapter 2 System Components

Page 33

2

Bus Transmitter Module

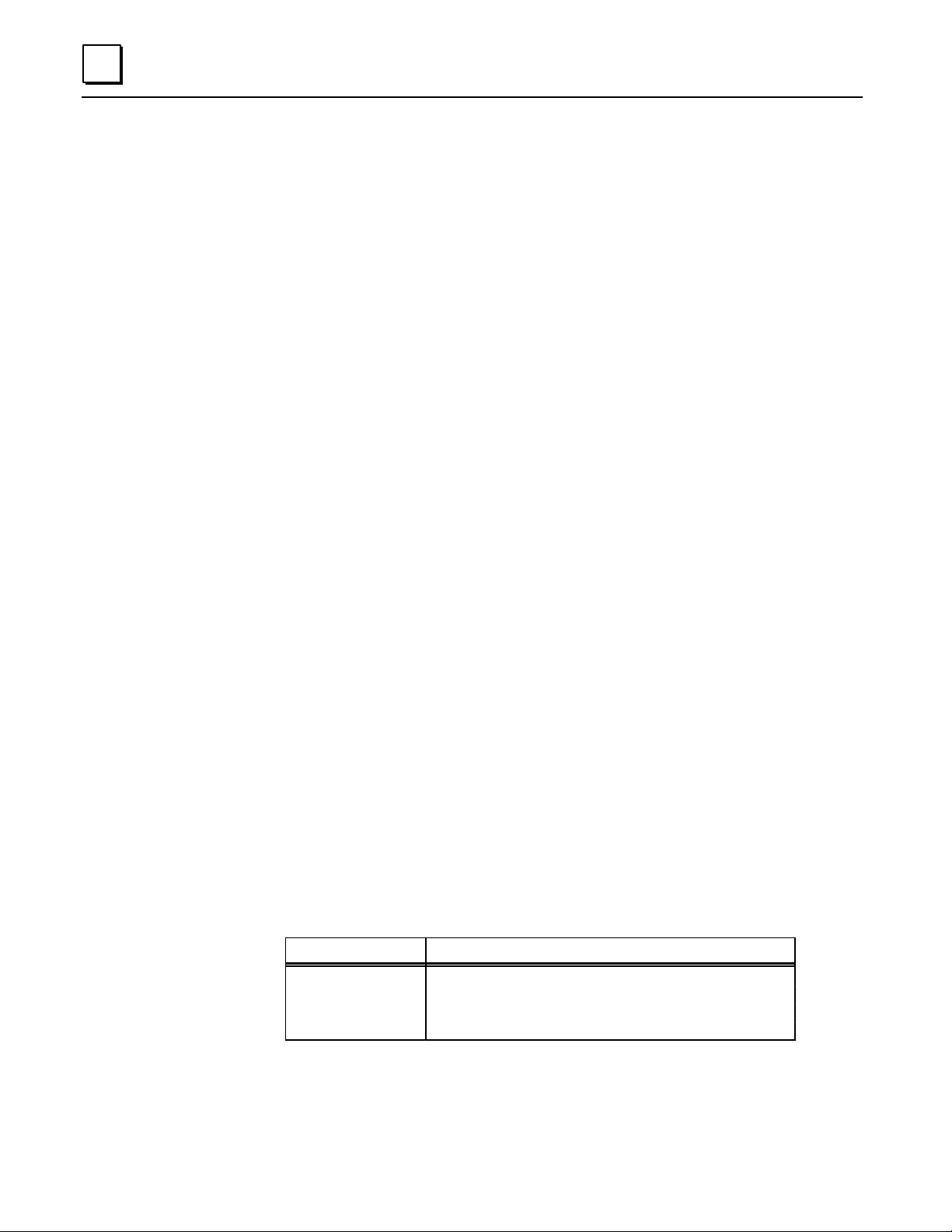

A Bus Transmitter Module (BTM), catalog number IC697BEM713, is required in both the

Primary PLC CPU rack (rack 0) and the Secondary PLC CPU rack (rack 0) in a Hot

Standby CPU Redundancy system. The BTM provides a path for Redundancy

communications when connected to the Redundancy Communications Module (RCM).

Each PLC system (Primar y and Secondary) has a BTM and an RCM in rack 0. The BTM

in one unit connects to the RCM in the other unit (or through a series or BRMs if

expansion racks are in a system).

P

S

PRIMARY UNIT SECONDARY UNIT

( RACK 0 )

B

R

G

C

P

T

C

B

U

M

M

C

( RACK 0 )

B

R

P

S

G

C

P

T

C

B

U

M

M

C

a47006

31

Redundancy Communications Link

Redundancy Communications Link

30

When included as a bus communications module in an I/O

expansion system, the BTM is a high speed parallel interface which

propagates the I/O bus signals through a cable to a Bus Receiver

Module located in the first I/O expansion rack. The BTM also

provides a high speed parallel connection to the programmer

through the W ork Station Interface board installed in the

programmer.

LED Status Indicators

There are three LEDs located at the top of the BTM. The LEDs are

labeled: OK, PGMR ACTIVE and BUS A CTIVE. As with all other

Series 90-70 PLC LEDs, they are visible through the clear plastic lens

at the top of the module’s cover . The function of each LED is

described below .

Module OK

The top LED is the MODULE OK LED and is ON when the CPU

software completes its power-up configuration of the BTM, and has

polled (or attempted to poll) each expansion rack in the system. It is