Page 1

STORAGE TANKS

State Custom Storage Tanks

State Custom Storage Tanks are designed for storing potable water. Fitting

locations of these custom-line tanks match the needs of normal installations.

Sizes from 80 to 12,500 Gallons – ASME Code

steel tanks are constructed of Code material.

ASME Code Construction – All tanks are

constructed to the requirements of the ASME Code. These

ASME Code tanks are available at 125, 150 & 160 PSI working

pressure. Consult factory for ASME code tanks are with greater or

lesser working pressures with special configurations, materials and

pressures.

Lining and Coatings – Each lining and coating has

particular capabilities and limitations. Please consult the factory or

your local State Water Heater representative for recommendations

on the uses of linings for specific applications. Lined tanks receive one

prime coat of paint on external surface. Thorough investigation on

the service life of steel tanks with protective coatings or linings

has led to the recommendation of the following linings:

– Glass-lined – All internal surfaces exposed to water are glass-

lined per ASME HLW code procedures.

– Cement Lined

a specially formulated cement over the interior of the vessel. This

lining adds a great deal of weight to the tank; however, with proper

application very little tank corrosion occurs over a long life.

– Epoxy Lined – The application of specially formulated epoxy

makes this lining suitable for cold or hot water storage.

COMMERCIAL

– Cement lining consists of a careful hand application of

For Copper Tube Tank Heaters

consult the factory.

Limited Warranty Outline

– Glass-Lined, Cement, Epoxy: If the tank should leak

any time during the first five years, under the terms of

the warranty, State Water Heaters will repair or replace

the tank; installation, handling and local delivery extra.

The Coil has a one year limited warranty.

– NOTE: This Outline Is NOT A Warranty. For complete

information, consult the written warranty or State Water

Heaters.

For more information on Storage Tanks contact:

State Water Heaters

500 Tennessee Waltz Parkway, Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

Cathodic Protection – Glass-lined, cement and epoxy tanks

are furnished with anodes designed for maximum protection.

All tanks will be supplied with the fittings located as indicated on the

drawings unless specified otherwise.

Inspection Openings

– Glass-lined – Manhole and handhole openings are available as

optional feature.

– Cement Lined – One 11˝ x 15˝ manhole standard equipment on

30˝ diameter and larger.

– Epoxy Lined – One 11˝ x 15˝ manhole standard equipment on

30˝ diameter and larger.

Optional

– Military specification tanks

– Manholes, handholes, additional openings, lifting lugs, angle legs,

ring base and saddles are available at extra cost.

STMSS00207

May 2011R

Page 1 of 4

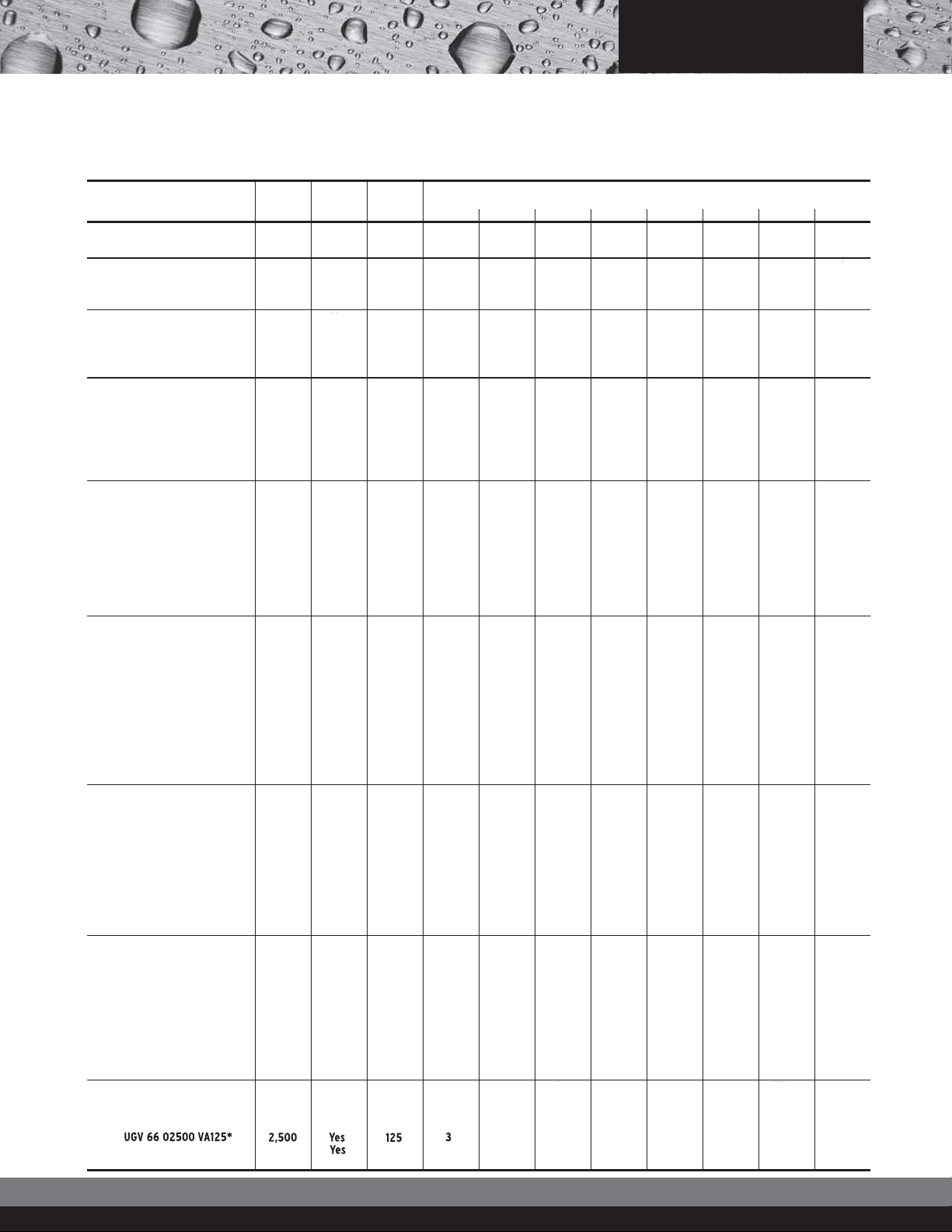

Page 2

STORAGE TANKS

State Custom Storage Tanks

SPECIFICATIONS

Model Gallon ASME Working

UGV 20 00080 VA125 8 Yes 125 2

UGV 20 00100 VA125 100 Yes 125

UGV 24 00125 VA125 120 Yes 12 21⁄2

UGV 24 00140 VA125 140 Yes 12 21⁄2

UGV 24 00175 VA125* 175 Yes 12 21⁄2

UGV 30 00175 VA125 Yes 12 2

UGV 30 00200 VA125 200 Yes 12 2

UGV 30 00250 VA125 250 Yes 12 2

UGV 30 00300 VA125* 300 Yes 12 2

UGV 36 00250 VA125 250 Yes 125 21⁄2

UGV 36 00300 VA125 300 Yes 125 21⁄2

UGV 36 00350 VA125 350 Yes 125 2

UGV 36 00400 VA125 400 Yes 125 2

UGV 36 00500 VA125* 500 Yes 125 21⁄2

UGV 36 00550 VA125

UGV 42 00375 VA125 375 Yes 125 3

UGV 42 00450 VA125 450 Yes 125 3

UGV 42 00500 VA125 500 Yes 125 3

UGV 42 00600 VA125 600 Yes 125 3

UGV 42 00700 VA125 700 Yes 125 3

UGV 42 00800 VA125* 800 Yes 125 3

UGV 42 00900 VA125

UGV 42 01000 VA125

UGV 48 00500 VA125 500 Yes 125 3

UGV 48 00600 VA125 600 Yes 125 3

UGV 48 00700 VA125 700 Yes 125 3

UGV 48 00750 VA125 750 Yes 125 3

UGV 48 00900 VA125 900 Yes 125 3

UGV 48 01000 VA125 1,000 Yes 125 3

UGV 48 01250 VA125* 1,250 Yes 125 3

UGV 48 01500 VA125* 1,500 Yes 125 3

UGV 48 01750 VA125

UGV 48 02000 VA125

UGV 54 00650 VA125 650 Yes 125 3

UGV 54 00750 VA125 750 Yes 125 3

UGV 54 00900 VA125 900 Yes 125 3

UGV 54 01000 VA125 1,000 Yes 125 3

UGV 54 01250 VA125* 1,250 Yes 125 3

UGV 54 01500 VA125* 1,500 Yes 125 3

UGV 54 01800 VA125* 1,800 Yes 125 3

UGV 54 02000 VA125

UGV 54 02500 VA125

UGV 60 00800 VA125* 800 Ye 125 3

UGV 60 01000 VA125* 1,000 Yes 125 3

UGV 60 01250 VA125* 1,250 Yes 125 3

UGV 60 01500 VA125* 1,500 Yes 125 3

UGV 60 01750 VA125* 1,750 Yes 125 3

UGV 60 02000 VA125* 2,000 Yes 125 3

UGV 60 02250 VA125

UGV 60 02500 VA125

UGV 60 03000 VA125

UGV 66 01000 VA125 1,000 Yes 125 3

UGV 66 01500 VA125* 1,500 Yes 125 3

UGV 66 02000 VA125* 2,000 Yes 125 3

UGV 66 03000 VA125

UGV 66 03500 VA125

Nominal Standard

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Pressure

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

Capacity

8

100

125

140

175

175

175

200

250

300

250

300

350

400

500

550

375

450

500

600

700

800

900

1,000

500

600

700

750

900

1,000

1,250

1,500

1,750

2,000

650

750

900

1,000

1,250

1,500

1,800

2,000

2,500

800

1,000

1,250

1,500

1,750

2,000

2,000

2,200

2,500

3,000

1,000

1,500

2,000

2,000

3,000

3,500

ABCDE F GH

2

2

1

⁄2

2

1

⁄2

2

1

⁄2

2

1

1

⁄2

⁄2

2

1

1

⁄2

⁄2

2

1

1

⁄2

2

⁄2

1

1

⁄2

2

⁄2

1

⁄2

2

1

⁄2

2

1

1

⁄2

2

⁄2

1

1

⁄2

2

⁄2

1

⁄2

2

1

⁄2

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

⁄4 11⁄2 6

3

⁄4 11⁄2 6

3

⁄4 21⁄2 8 1 24 66 8

3

⁄4 21⁄2 8 1 24 75 8

3

⁄4 —8 124908

3

⁄4 21⁄2 8 1 30 60 8

3

⁄4 21⁄2 8 1 30 71 8

3

⁄4 21⁄2 8 1 30 84 8

3

⁄4 —8 130998

3

⁄4 21⁄2 8 1 36 60 8

3

⁄4 21⁄2 8 1 36 71 8

3

⁄4 21⁄2 8 1 36 86 8

3

⁄4 21⁄2 8 1 36 93 8

3

⁄4 — 8 1 36 122 8

3

⁄4 —

3

⁄4 21⁄2 10 1 42 67 10

3

⁄4 21⁄2 10 1 42 79 10

3

⁄4 21⁄2 10 1 42 88 10

3

⁄4 21⁄2 10 1 42 103 10

3

⁄4 21⁄2 10 1 42 119 10

3

⁄4 — 10 1 42 134 10

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

⁄4

3

4

⁄

3

⁄4

3

⁄4

3

⁄4 3 10 1 54 71 10

3

⁄4 3 10 1 54 81 10

3

⁄4 3 10 1 54 95 10

3

⁄4 3 10 1 54 105 10

3

⁄4 — 10 1 54 129 10

3

⁄4 — 10 1 54 153 10

3

⁄4 — 10 1 54 181 10

3

⁄4

3

⁄4

3

⁄

4

3

⁄4 — 10 1 60 88 10

3

⁄4 — 10 1 60 107 10

3

⁄4 — 10 1 60 126 10

3

⁄4 — 10 1 60 146 10

3

⁄4 — 10 1 60 165 10

3

⁄4

3

⁄4

3

⁄4

3

⁄4 3 10 1 66 75 10

3

⁄4 — 10 1 66 107 10

3

⁄4 — 10 1 66 139 10

3

⁄4

3

⁄4

3

⁄4

COMMERCIAL

Dimensions In Inches

3

⁄4 20 60 6

3

⁄4 20 72 6

8

8

8

1

1

1

24

8

8

8

8

8

8

10

3

3

3

3 10 1 48 73 10

3

3 10 1 48 81 10

3

3 10 1 48 93 10

3

3 10 1 48 105 10

3

3 10 1 48 117 10

3 10 1 48 137 10

3

— 10 1 48 159 10

— 10 1 48 190 10

3

3

10

10

10

10

10

10

1

1

1

1

1

1

1

1

1

1

30

36

36

42

42

42

48

48

48

48

3

3

3

3

10

10

10

—

—

— 10 1 60 72 10

10

10

10

10

10

10

10

10

—

—

—

3

10

10

10

10

10

10

—

—

—

10

10

10

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

54

54

54

54

54

60

60

60

60

60

60

60

60

60

66

66

66

66

66

66

60

72

66

75

90

60

71

84

99

60

71

86

93

122

125

67

79

88

103

119

119

134

134

150

166

73

81

93

105

117

137

159

190

220

250

95

105

129

153

181

200

224

72

72

88

88

107

107

126

126

146

146

165

165

185

204

243

75

107

139

171

203

235

71

71

81

81

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

STMSS00207

Page 2 of 4

Page 3

STORAGE TANKS

State Custom Storage Tanks

SPECIFICATIONS CONTINUED

Model Gallon ASME Working

UGV 72 02500 VA125* 2,500 Yes 125 3

UGV 72 03000 VA125* 3,000 Yes 125 3

UGV 72 03500 VA125* 3,500 Yes 125 3

UGV 72 04000 VA125* 4,000 Yes 125 3

UGV 72 04500 VA125*

UGV 84 04000 VA125* 4,000 Yes 125 3

UGV 84 05000 VA125* 5,000 Yes 125 3

UGV 84 06000 VA125* 6,000 Yes 125 3

UGV 84 08000 VA125* 8,000 Yes 125 3

UGV 96 07500 VA125* 7,500 Yes 125 3

UGV 96 10000 VA125* 10,000 Yes 125 3

UGV 96 12500 VA125* 12,500 Yes 125 3

Note: Listed tanks are standard sizes only, other size and capacity tanks available and will be built

to specification.

*Vertical installation requires addition of angle iron legs or ring base.

It is recommended that 54˝ diameter and larger tanks be ordered with angle legs rather than threaded

leg sockets for vertical installations.

Specify for horizontal or vertical installation.

No leg sockets provided on horizontal tanks.

For single-wall and double-wall copper tube tank heaters, consult factory representative.

These ASME Code tanks are available at 125,150 &160 PSI working pressure.

When factory jacketed and insulated tanks are ordered, the size and locations of the standard tank

openings may differ slightly from what is shown here. Consult the factory.

Nominal Standard

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Pressure

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

Capacity

2,500

2,500

3,000

3,000

3,500

3,500

4,000

4,000

4,500

4,000

4,000

5,000

5,000

6,000

6,000

8,000

8,000

7,500

7,500

10,000

10,000

12,500

12,500

ABCDE F GH

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

COMMERCIAL

Dimensions In Inches

3

⁄4 — 10 1 72 147 10

3

⁄4 — 10 1 72 174 10

3

⁄4 — 10 1 72 201 10

3

⁄4 — 10 1 72 228 10

3

⁄4

3

⁄4 — 10 1 84 173 10

3

⁄4 — 10 1 84 212 10

3

⁄4 — 10 1 84 252 10

3

⁄4 — 10 1 84 330 10

3

⁄4 — 10 1 96 244 10

3

⁄4 — 10 1 96 319 10

3

⁄4 — 10 1 96 395 10

—

10

10

10

10

10

10

10

10

10

10

10

10

1

1

1

1

72

72

72

72

172

1

1

1

1

1

1

1

84

84

84

84

96

96

96

AA

147

147

174

174

201

201

228

228

254 10

173

173

212

212

252

252

330

330

244

244

319

319

395

395

A

10

10

10

10

10

10

10

10

10

10

10

A

A

A

OVERALL

ASME

PLATE

BE

A

B

A

THREADED LEG SOCKETS

State Custom Storage Tanks

(20˝ thru 96˝ Diameter Tanks)

OVERALL

OUTLET

A

A

B

ASME

PLATE

AA

E

A

B

AA

INLET

1-1/4” CONTROL

State Custom Storage Tanks With Heating Coils

(Horizontal Configuration)

AA

OPENING

A

C

A

A

BB

B

B

AAA

A

A

T&P VALVE

OPENING

OVERALL

A

B

A

B

B

A

A

1-1/4” CONTROL

OPENING

ASME

PLATE

A

A

THREADED LEG SOCKETS

( 20” THRU 48”) TANKS

A

B

C

A

C

State Custom Storage Tanks With Heating Coils

(Vertical Configuration)

For more information on State® contact:

State Water Heaters

500 Tennessee Waltz Parkway, Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

STMSS00207 May 2011R

Page 3 of 4

Page 4

STORAGE TANKS

State Custom Storage Tanks

TANK SADDLES

PART NO.

P2-2600-20 20 22

P2-2600-24 24 26

P2-2600-30 30 32

P2-2600-36 36 38

P2-2600-42 42 44

P2-2600-48 48 50

P2-2600-54 54 56

P2-2600-60 60 62

P2-2600-66 66 58

P2-2600-72 72 74

P2-2600-84 84 86

P2-2600-96 96 98

ANK DIA. A

T

B

6

6

6

6

6

6

8

8

8

10

10

10

COMMERCIAL

Tank Saddles

Custom Commercial Storage Tank Model Number Break Down

UGV66 01500VA125

U = Unjacketed

J = Jacketed

SPECIAL NO TE:

G = Glass-Lined

E = Epoxy

B = Black Steel

C = Cement

All model numbers appearing on rating plate and carton labels will be compressed.

V = 5 Year

Warranty

Diameter

V = Vertical

H = Horizontal

SUGGESTED SPECIFICATIONS

SAMPLE SPECIFICATION FOR STATE CUSTOM STORAGE TANKS

ASME storage tank shall be State Custom Storage Tank model __________________________. Capacity shall be _____ gallons with a diameter of _____ inches. Tank(s) shall

be constructed and stamped according to ASME specifications for _____ psi working pressure. Manhole (11˝ x 15˝), handhole (4˝ x 6˝) or inspection openings (2-2˝)

shall be installed in accordance with ASME Code requirements and manufacturer’s standard practice. Tank to be constructed of (carbon steel) _________. Lining

shall be (glass, epoxy, cement) ______________. Tank(s) lined with (glass, cement, epoxy) _____________lining shall be equipped with the number and size of magnesium

anode rod(s) sufficient to provide adequate protection for the tank lining. Tank shall be (vertical, horizontal) _________________ design and provided with (four) ___________

(angle iron legs, threaded leg socket(s) _______________ ring base, ____________ saddles.

Tank heaters shall be Model No. ____________ ˝ OD 20 gauge copper “U” tubes. Heater to have ________ square feet of heating surface to heat ____________ gallons

per hour from _____________ degrees F to ____________ degrees F with heating media of ____________psi steam (or _________ degrees F boiler water). The element shall

be constructed so that the entire section can be removed from the tank for cleaning and inspection.

3

⁄4

SAMPLE SPECIFICATION FOR TANK HEATERS

In keeping with our policy of continuous product improvement

specifications are subject to change without prior notice

A = ASMEGallon Capacity

ASME Pressure Rating =

100# or 125# or150# or 160#

EXAMPLE: UGV6601500VA125

For more information on State® contact:

State Water Heaters

500 Tennessee Waltz Parkway, Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

STMSS00207

May 2011R

Page 4 of 4

© 2011 State Water Heaters

Loading...

Loading...