Page 1

SOLAR COLLECTOR TILE ROOF MOUNTING INSTRUCTIONS

CAUTION

ALL PERSONS WORKING ON ROOFS SHOULD

HAVE SUCCESSFULLY COMPLETED A FALL SAFETY

COURSE AND SHOULD BE PROPERLY EQUIPPED

WITH THE APPROPRIATE SAFETY EQUIPMENT

WARNING

AFTER COMPLETION OF THE COLLECTOR

MOUNTING AND PRIOR TO SYSTEM CHARGING THE

COLLECTORS MUST BE COVERED BY A BLANKET OR

OTHER MEANS TO AVOID SOLAR RADIATION FROM

HEATING THE COLLECTORS. THE SURFACES OF THE

COLLECTOR CAN BECOME EXTREMELY HOT AND

COULD POSE A BURN HAZARD.

The most important structural consideration is to securely

BASIC TOOLS AND MATERIALS

Drill & Drill Bits

Saw (Hand or Circular w/Extension Cord)

Tape Measure

Chalk Line

Utility Knife

Level

Pliers

7/16” & 9/16” Wrenches & 8” & 10” Adjustable Wrenches

125 Southeast Parkway, Franklin, TN 37068

PHONE: 1-800-433-2545 • FAX: 1-800-433-2515

anchor the solar collector and the mounting hardware to the

structural members of the roof with the stainless steel hardware

provided. The solar collector must be attached to the mounting

hardware as detailed in Figure 17.

Preserving the integrity of the roof membrane is the

mostimportantroongconsideration.Ensurethatallroof

penetrations required to plumb and mount the solar collector

areproperlyashedandsealedinaccordancewithstandard

roongpractices.

If the region is subject to hurricane conditions, additional

steps may be required to secure the collector and mounting

hardware to the structural members. In certain areas of the

country, local building codes may require collector wind load

testingorprescribespecicmountingprocedures.Consult

your local building department.

Install the collectors as described in the Tile Roof Mounting

instructions.

Ratchet w/ 7/16” & 9/16” Sockets

Roof Sealant

10 linear feet of 2” x 4” or 2” x 6” lumber for spanner

mounting per number of collectors in the system

6’ x 8’ or 6’ x 10’ Tarp (1 per collector)

Installation Hardware (Supplied) Includes:

• Hardware & Mounting Brackets

TILE ROOF MOUNTING / SPANNER MOUNTING

Although there are other installation methods for mounting

solar collectors, it has been determined that the spanner

mounting method is the most suitable for this application.

Consult with you installer if other mounting means are

required for your installation.

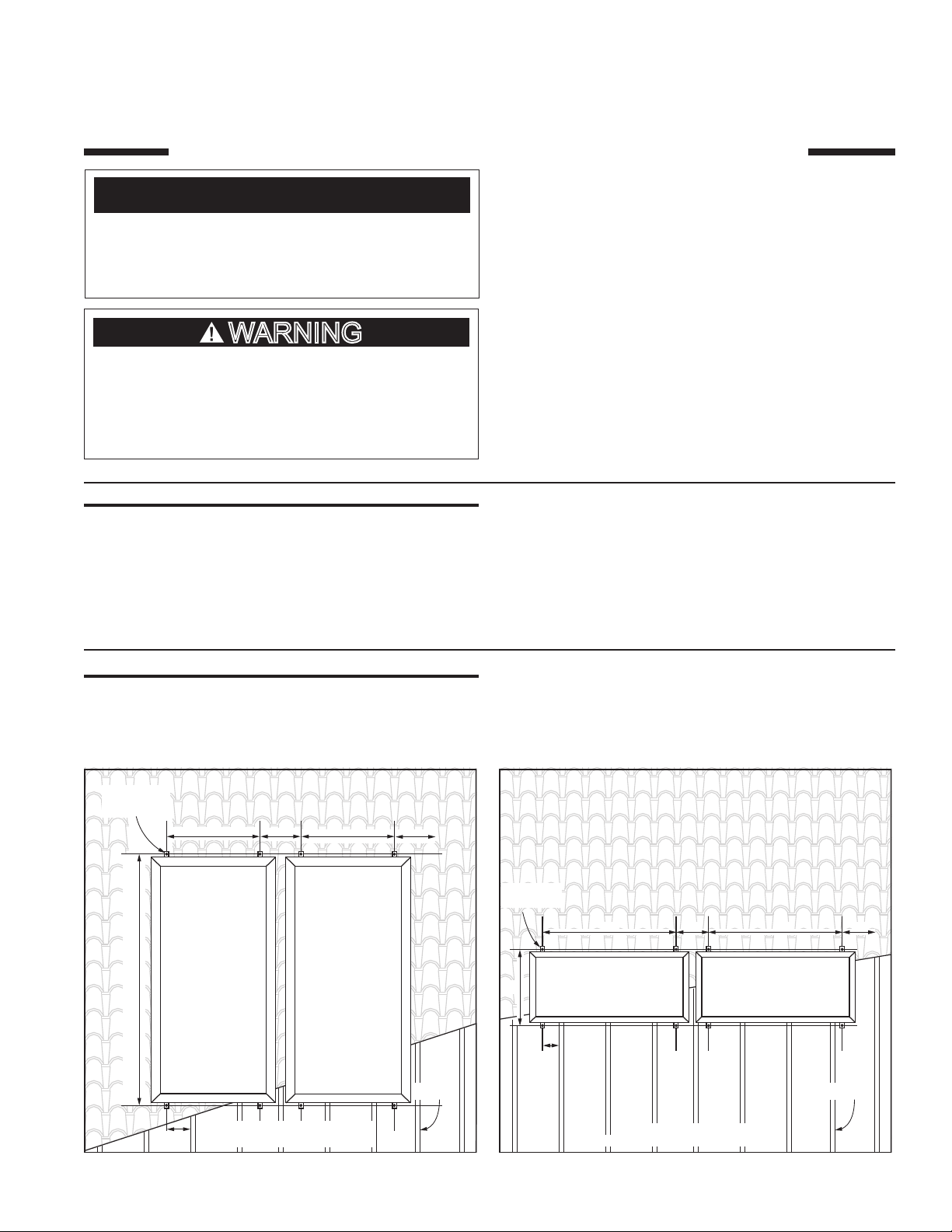

MOUNTING

POINTS

B” B”C”

A”

C”

RAFTER

MOUNTING

POINTS

A”

D”

B” B”C”

C”

RAFTER

D”

VERTICAL MOUNT

BASED ON 16” CENTER RAFTERS

Figure 1.

PRINTED 0311 319355-001

1

HORIZONTAL MOUNT

BASED ON 16” CENTER RAFTERS

Figure 2.

Page 2

NOTICE

* IF MOUNTING WITH AN OPTIONAL TILT MOUNT

KIT, FOR OPTIMAL COLLECTOR ANGLE REFER TO

ITS INSTRUCTION SHEET FOR THE APPLICABLE “A”

DIMENSION.

COLLECTOR A B C D

Vert. 3.5’ X 7’ 86* 32 14 7-1/4

Vert. 4’ X 8’ 97* 35 16 11-3/4

Vert. 4’ X 10’ 121* 35 16 11-3/4

Horiz. 3.5’ X 7’ 42.25* 62 28 13-1/2

Horiz. 4’ X 8’ 47* 72 28 12

Horiz. 4’ X 10’ 47* 94 30 9

Table 1.

1. Locate the mounting points for the mounting brackets

per Figure 1 for vertical mounting or Figure 2 for

horizontal mounting and Table 1. Layout the roof as

specified.

Figure 4.

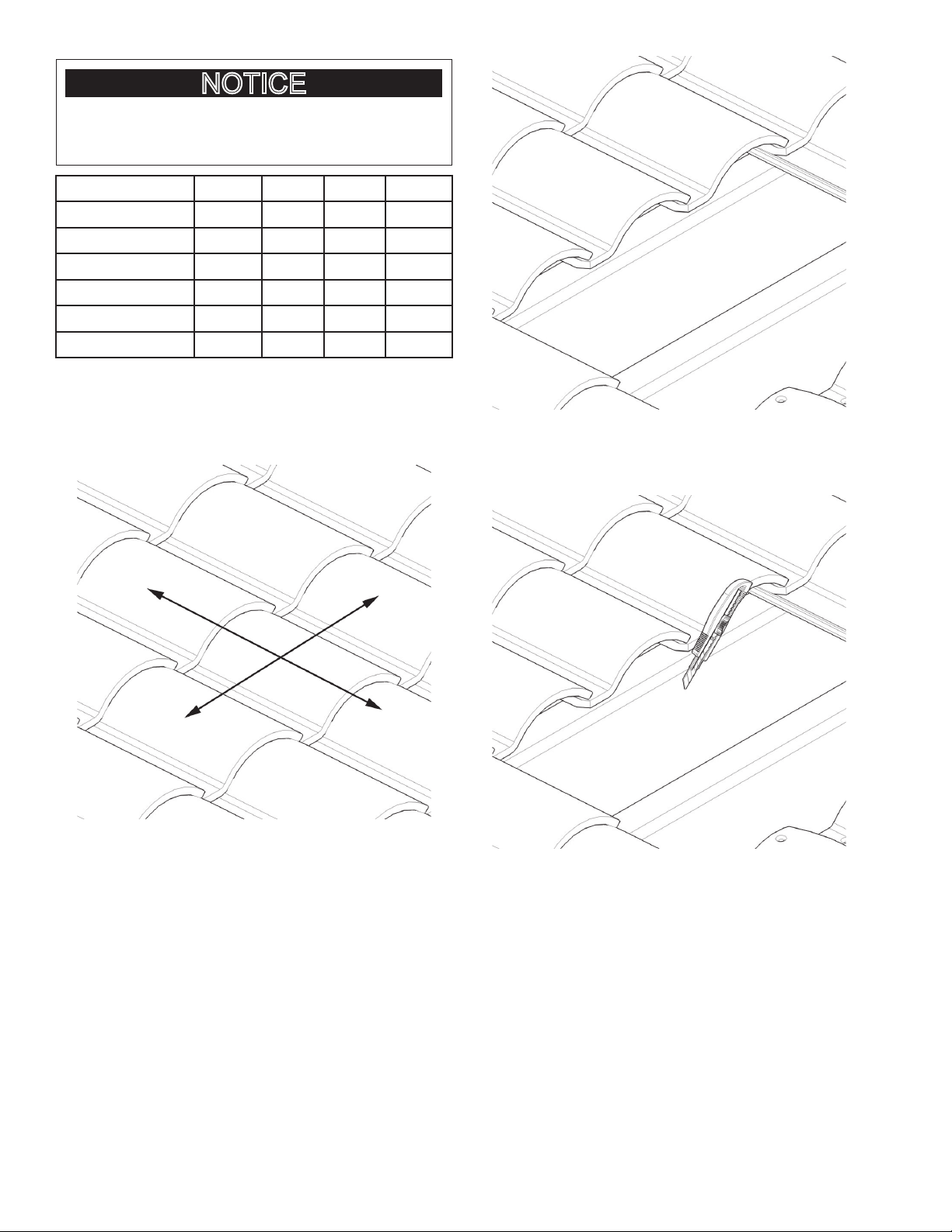

2. Determine which course of the roof you wish to

penetrate. It may be necessary to remove a few tiles to

locate the rafter locations. See Figures 3 & 4.

Figure 3.

Figure 5.

2

Page 3

Figure 6.

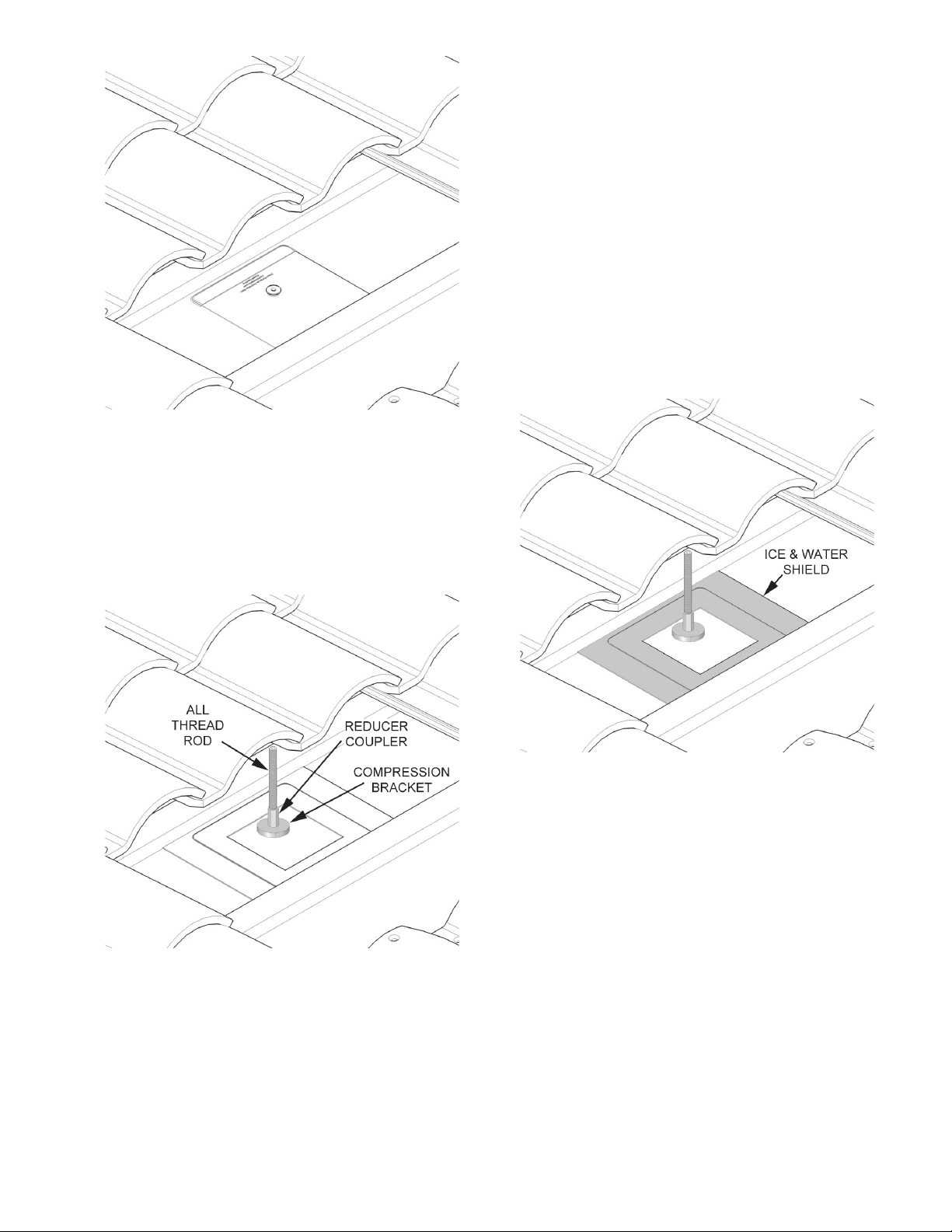

3. Determine the location of the flashing and cut a slit in the

roofing paper so the upslope edge of the flashing can

slide under the paper when installed. See Figures 5 & 6.

4. Once the flashing location has been determined, mark

the position of the center of the flashing bushing on the

roof paper. Remove the flashing.

5. Drill a 5/16” hole between the rafters at the center mark

of the flashing bushing.

using a 2” x 4” or similar lumber. Spanners must be

long enough to span at least two rafters. In the attic or

crawl space drill a 5/16” hole through each spanner and

insert the all-thread through it. Secure each spanner to

the rafters with decking or wood screws. See Figure 16.

9. Fabricate spacer blocks, one for each mounting bracket,

using a 2” x 4” or similar lumber the same width of the

rafter next to each all-thread. Place spacer blocks next

to the all-thread between the spanner and roof. Secure

each spacer block to the spanners with decking or

wood screws. Spacer blocks are necessary to avoid

deformation of the roof. See Figure 16.

10. With a stainless steel nut, lock washer and fender

washer secure the all-thread to each spanner. Tighten

down until the compression bracket washer is tightly

secured to the roof and flashing (approx. 97 inch

pounds). Be careful not to over tighten and dish out

the roof underneath the mounting bracket washer and

flashing. See Figure 16.

Figure 7.

6. Slide the flashing back under the roof paper and position

it so that the center of the flashing bushing is aligned

with the center of the drilled hole.

7. A piece of 12” length of stainless steel 5/16” all-thread

is then inserted through the hole in the roof and the

flashing bushing. Attach the compression bracket

washer and 5/16” x 3/8” SS reducer coupler to the 5/16”

SS –all thread as shown. The all-thread should extend

about 4” below the roof rafters. See Figures 7 & 16.

8. Fabricate spanners, one for each mounting bracket,

Figure 8.

11. Install an Ice & Water Shield (not included) around the

flashing to provide a water tight seal. See Figure 8.

3

Page 4

Figure 9.

12. Measure from the surrounding tiles to determine where

the 3/8” x 6” SS all-thread will penetrate the tile and

mark the tile accordingly.

13. Drill a 3/8” hole through the tile at the marked location.

See Figure 9.

Figure 10.

14. Replace the tile being certain that the drilled hole aligns

with the SS coupler. See Figure 10.

Figure 11.

15. Position the 3/8” SS all-thread through the hole in

the tile, thread it into the SS coupler and tighten. See

Figure 11.

Figure 12.

16. Thread a 3/8”-16 SS hex nut down the 3/8” SS all-thread

to just above the top surface of the tile. Do not tighten

the nut against the tile. See Figure 12.

17. Push one of the EPDM bonded washers down the 3/8”

all-thread until it rests against the top of the nut. Be

sure that the EPDM side is facing up. See Figure 12.

4

Page 5

Figure 13.

18. Clean the tile and cover the penetration with the

included 12” x 12” 3 Lb. lead flashing. Form the lead

flashing to match the contour of the tile. Measure and

drill a 3/8” hole in the lead flashing for the location of

the 3/8” all-thread. Be sure that there is a minimum of

3” of flashing all the way around the 3/8” all-thread and

tuck the up slope end of the flashing a minimum of 3”

up under the above tile. See Figure 13.

Figure 15.

21. Thread the support nut down the 3/8” all-thread to the

desired height. See Figure 15.

22. When installing the remainder of the support nuts be

sure all are at the same height as the others.

Figure 14.

19. Push another EPDM bonded washer down the threaded

rod until it rests against the top of the flashing being sure

that the EPDM side is facing down. Refer to Figure 14.

20. Thread another 3/8”-16 SS hex nut down the 3/8”

all-thread and tighten it against the washer. Refer to

Figure 14.

5

Page 6

ROOF

MEMBRANE

ROOF

TILES

MOUNTING

BRACKET

EPDM

WASHERS

LEAD

FLASHING

FLASHING

STAINLESS STEEL

ALL THREAD ROD, NUT,

LOCK WASHER &

FLAT WASHER

SUPPORT NUT

SS NUTS

REDUCING

COUPLING

CP COMPRESSION

WASHER

ROOF

RAFTER

SPACER

BLOCK

DECKING/WOOD

SCREWS

WOOD SPANNER

(2” x 4” or 2” x 6” LUMBER)

Figure 16.

23. Install the mounting brackets on top of the support nut

with the stainless steel flat washer, lock washer, & nut.

See Figure 16.

24. Install the mounting brackets on top of the support nut

with the stainless steel flat washer, lock washer, & nut.

See Figure 16.

25. Repeat steps 1 - 24 as needed for the remainder of the

mounting bracket locations.

PLYWOOD

SHEETING

ROOF

RAFTER

FENDER WASHER

LOCK WASHER & NUT

6

Page 7

ATTACHING COLLECTOR TO MOUNTING BRACKETS

Once all of the mounting brackets have been secured to

the roof the solar collector(s) can be installed. See Figure

17 for these instructions.

1. Insert the stainless steel channel nut w/spring inside

of the mounting bracket.

2. Fasten the solar collector mounting clip to the channel

nutwiththestainless steelbolt,lock-washer,andat

washer as shown. Do not tighten. Repeat step for the

other mounting bracket locations.

3. The solar collector can now be set on the mount-

ing brackets. To aid in handling the collectors on the

roof the mounting clips may be tightened to the lower

mounting brackets prior to raising the collectors. The

SOLAR COLLECTOR

FRAME

STAINLESS STEEL BOLT,

LOCK WASHER,

& FLAT WASHER

collector can then be set on the lower mounting brackets while the top clips are fastened over the lip on the

collector frame.

4. After the solar collector is in position, locate the upper

mounting clip so that its lip over-hangs the lip of the

solar collector frame as shown. Tighten the mounting

clip to the solar collector frame securely. Repeat for

the other upper mounting clips.

5. Once the upper mounting clips are secured, the bottom mounting clips can be loosened and retightened

over the collector lip as directed in step 4.

6. Repeat steps as needed for other solar collectors.

MOUNTING

CLIP

CHANNEL NUT

with SPRING

(One Piece Part)

MOUNTING

BRACKET

SUPPORT

NUT

Figure 17.

7

Loading...

Loading...