State SW 37-670 User Manual

COMMERCIAL ELECTRIC BOILERS

A DIVISION OF A. O. SMITH CORPORATION

RENTON, WASHINGTON

www.statewaterheaters.com

Instruction Manual

MODELS SW 37-670

INSTALLATION - OPERATION - SERVICE -

MAINTENANCE - LIMITED WARRANTY

ASME

Thank you for buying this energy efficient boiler

from us. We appreciate your confidence in our

products.

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED 0110 316393-000

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use, and servicing of this boiler.

Many safety-related messages and instructions have been provided in this manual and on your own boiler to warn you and others of

a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important that the

meaning of each safety message is understood by you and others who install, use, or service this boiler.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous

DANGER

WARNING

CAUTION

situation which, if not avoided, will result in

death or injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert symbol

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety

message, and how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive

harm. This appliance can cause low level exposure to some of the substances listed.

• QualiedInstallerorServiceAgency:

Installation and service of this boiler requires ability equivalent to that of a Qualied Agency (as dened by ANSI below) in the eld

involved. Installation skills such as plumbing and electrical supply are required in addition to electrical testing skills when performing

service.

indicates a potentially hazardous situation

which, if not avoided, could result in property

damage.

IMPORTANT DEFINITIONS

• ANSIZ223.12006Sec.3.3.83:

“Qualied Agency” - “Any individual, rm, corporation or company that either in person or through a representative is engaged in and is

responsible for (a) the installation, testing or replacement of gas piping or (b) the connection, installation, testing, repair or servicing of

appliances and equipment; that is experienced in such work; that is familiar with all precautions required; and that has complied with all

the requirements of the authority having jurisdiction.”

2

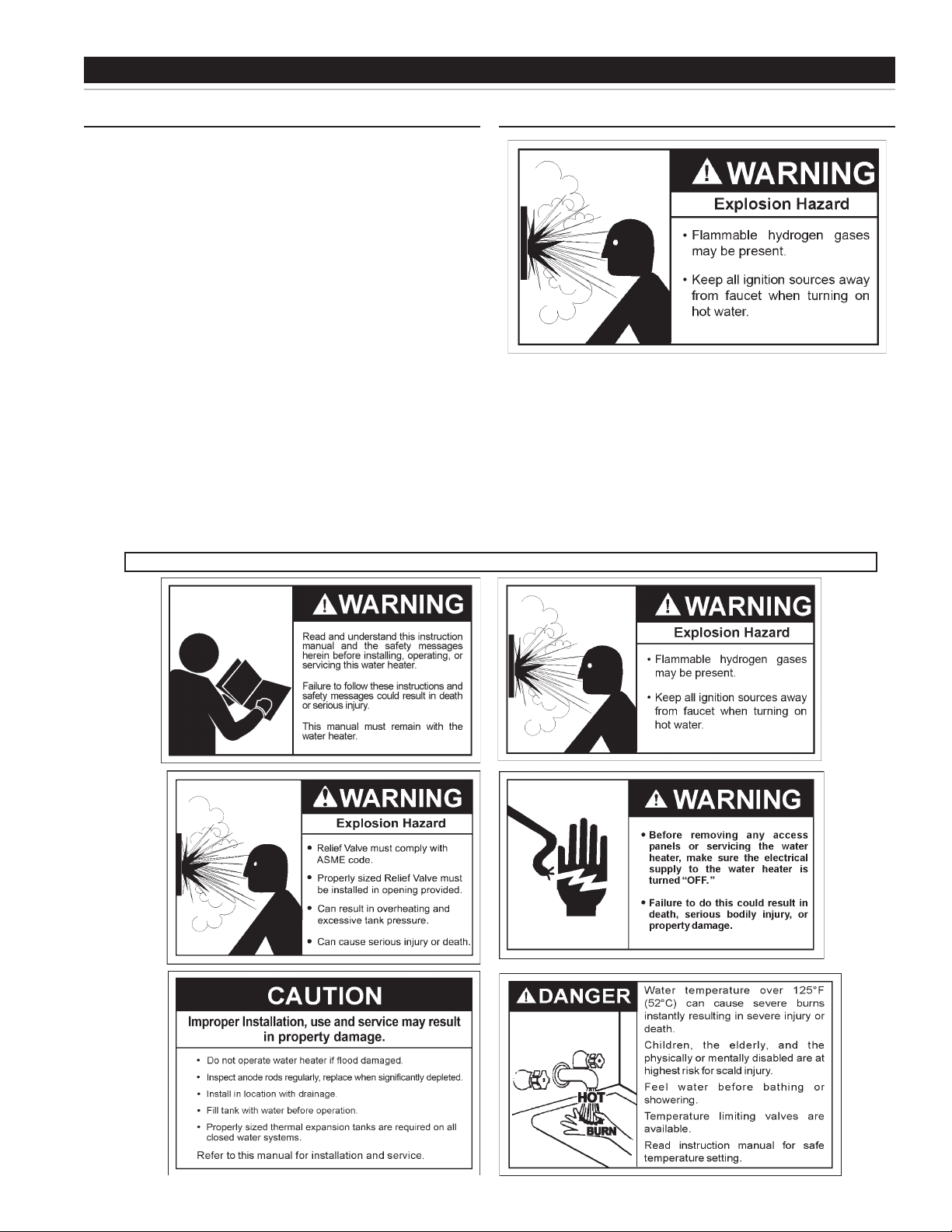

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER

WATER. Immediately call a qualied service technician to inspect

the appliance and to replace any part of the control system which

has been under water.

If the unit is exposed to the following, do not operate boiler until all

corrective steps have been made by a qualied service agency.

1. External re.

2. Damage.

3. Firing without water.

GROUNDING INSTRUCTIONS

This boiler must be grounded in accordance with the National Electrical

Code and/or local codes. These must be followed in all cases. Failure

to ground this boiler properly may also cause erratic control system

operation on ELECTRONIC CONTROL models.

This boiler must be connected to a grounded metal, permanent wiring

system, or an equipment grounding conductor must be run with

the circuit conductors and connected to the equipment grounding

terminal or lead on the boiler.

When servicing this unit, verify the power to the unit is turned off prior to opening the control cabinet door.

HYDROGEN GAS (FLAMMABLE)

Hydrogen gas can be produced in a hot water system served by this boiler

that has not been used for a long period of time (generally two weeks or

more). Hydrogen gas is extremely ammable. To reduce the risk of injury

under these conditions, it is recommended that the hot water faucet be

opened for several minutes at the kitchen sink before using any electrical

appliance connected to the hot water system. If hydrogen is present there

will probably be an unusual sound such as air escaping through the pipe

as the water begins to ow. THERE SHOULD BE NO SMOKING OR

OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

3

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE...........................................................2

GENERAL SAFETY INFORMATION .......................................................................3

Precautions ....................................................................................................3

Hydrogen Gas (Flammable) ...........................................................................3

TABLE OF CONTENTS ...........................................................................................4

INTRODUCTION .....................................................................................................4

Preparing for the Installation ..........................................................................4

DIMENSIONS AND CAPACITIES DATA .................................................................5

FEATURES AND COMPONENTS ..........................................................................8

APPROVALS ...........................................................................................................9

MODEL AND RATING .............................................................................................9

LOCATING THE NEW BOILER ...............................................................................9

Facts to Consider About the Location ............................................................9

INSTALLATION .....................................................................................................10

Required Ability ............................................................................................10

General ........................................................................................................10

Pressure Relief Valve ...................................................................................10

Water Line Connections ...............................................................................10

Closed Water Systems ................................................................................. 11

Thermal Expansion ......................................................................................11

ELECTRICAL DATA ...............................................................................................12

General ........................................................................................................12

Branch Circuit ...............................................................................................12

Calculating Amperage/Overcurrent Protection .............................................12

Boiler Circuits ...............................................................................................12

Control Circuits .............................................................................................12

WIRING DIAGRAMS .............................................................................................13

OPERATION ..........................................................................................................15

Important ......................................................................................................15

General ........................................................................................................15

High Temperature Limit ................................................................................15

Filling the Boiler ............................................................................................15

Initial Start Up ...............................................................................................15

Temperature Regulation ...............................................................................15

Temperature Controls ...................................................................................16

Draining ........................................................................................................16

MAINTENANCE ....................................................................................................17

Schedule ......................................................................................................17

System Cleaning ..........................................................................................17

Flushing ........................................................................................................17

Sediment Removal .......................................................................................17

Lime Scale Removal ....................................................................................17

TROUBLESHOOTING CHECKLIST .....................................................................18

Not Enough or No Hot Water .......................................................................18

Water is Too Hot ...........................................................................................18

Boiler Makes Strange Sounds ......................................................................18

Leakage Checkpoints ...................................................................................18

WARRANTY ..........................................................................................................19

INTRODUCTION

Thank You for purchasing this boiler. Properly installed and

maintained, it should give you years of trouble free service.

Abbreviations Found In This Instruction Manual:

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• GAMA - Gas Appliance Manufacturer’s Association

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section of this manual rst and

then the entire manual carefully. If you don’t follow the safety

rules, the boiler may not operate safely. It could cause DEATH,

SERIOUS BODILY INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, operation,

and maintenance of the electric boiler. It also contains warnings

throughout the manual that you must read and be aware of.

All warnings and all instructions are essential to the proper

operation of the boiler and your safety. READ THE ENTIRE

MANUAL BEFORE ATTEMPTING TO INSTALL OR OPERATE

THE BOILER.

Detailed installation diagrams are in this manual. These

diagrams will serve to provide the installer with a reference

for the materials and method of piping suggested. IT

IS NECESSARY THAT ALL WATER PIPING AND THE

ELECTRICAL WIRING BE INSTALLED AND CONNECTED

AS SHOWN IN THE DIAGRAMS.

Particular attention should be given to the installation of

thermometers at the locations indicated in the diagrams as

these are necessary for checking the operation of the heater.

fuses always use the correct size for the circuit. See page 12

through 14.

The principal components of the heater are identied on page 8.

The model and rating plate on page 9 interprets certain markings

into useful information. Both of these references should be used

to identify the heater, its components and optional equipment.

2. The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements

of the power company. In the absence of code requirements,

follow NFPA-70 (current edition). The National Electrical Code

may be ordered from: National Fire Protection Association, 1

Batterymarch Park, Quincy, MA 02269.

3. If after reading this manual you have any questions or do not

understand any portion of the instructions, call the toll free

number on the back cover for further assistance.

A sample rating plate and barcode tag are shown on page 9 of

this manual. In order to expedite your request, please have the

serial number and item ID from the barcode tag available for the

technician.

4. Carefully plan your intended placement of the boiler. Examine

the location to ensure the boiler complies with the “Locating the

New Boiler” section in this manual.

Installation and service of this boiler requires ability equivalent

to that of a licensed tradesman or qualied agency (page 2) in

the eld involved. Plumbing and electrical work are required.

5. For installation in California this boiler must be braced or

anchored to avoid falling or moving during an earthquake. See

instructions for correct installation procedures. Instructions may

be obtained from California Ofce of the State Architect, 1102 Q

Street, Suite 5100, Sacramento, CA 95811.

Be sure to turn off power when working on or near the electrical

system of the heater. Never touch electrical components

with wet hands or when standing in water. When replacing

6. Massachusetts Code requires this boiler to be installed in

accordance with Massachusetts 248-CMR 2.00: State Plumbing

Code and 248-CMR 5.00.

4

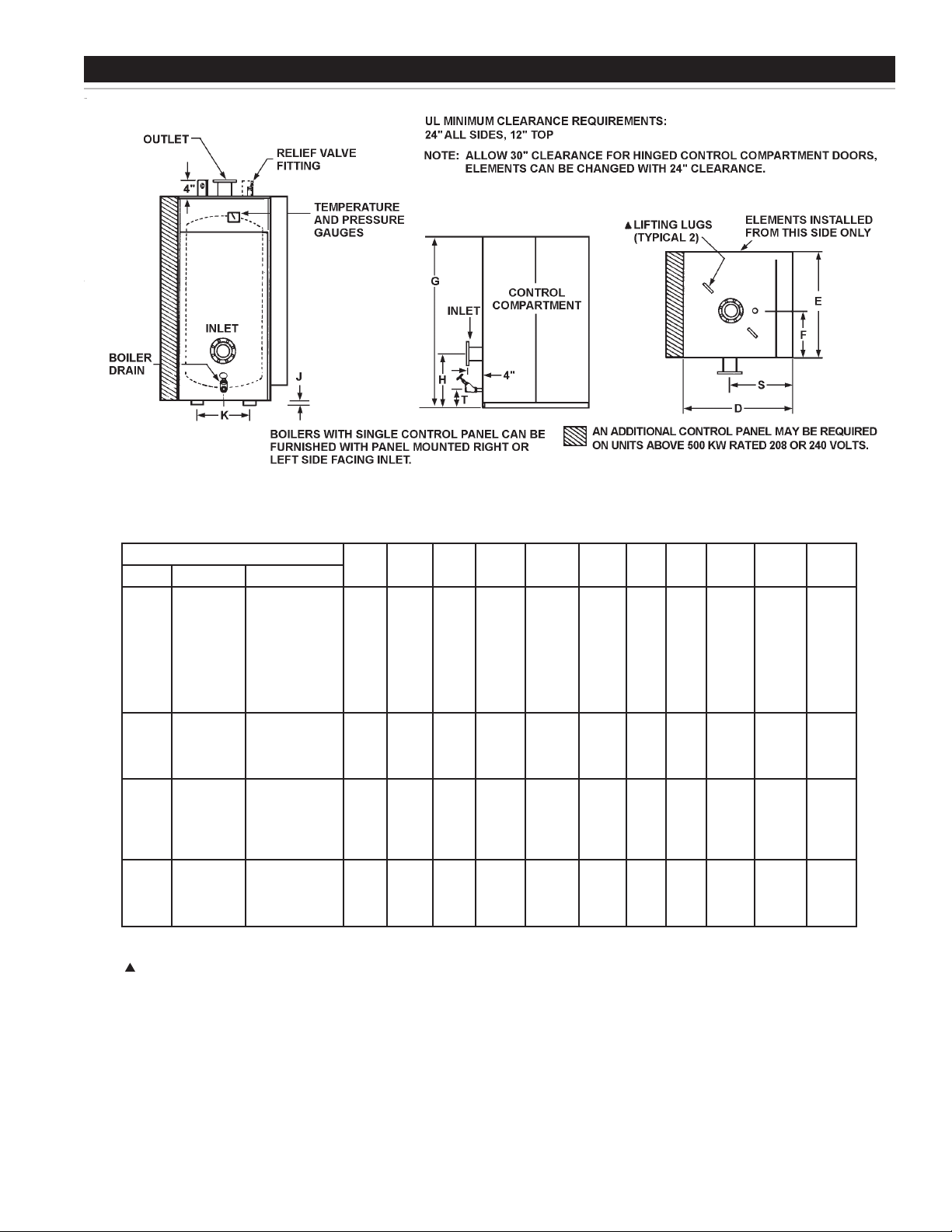

DIMENSION DATA

SIZES AND DATA NW37 THRU NW150

Model Number

Prex Gal. Cap. Std. KW Input

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

* All ttings under 4” will be threaded type. All ttings 4” and larger will be anged. 3” ttings extend 4” beyond jacket.

** Where overall height is a problem a larger diameter vessel with a reduced height may be furnished.

Lifting lugs and channel skid base on 96 gallon and larger units.

37

37

37

37

37

37

37

37

60

60

60

60

96

96

96

96

96

150

150

150

150

45K

60K

75K

90K

105K

120K

150K

180K

210K

240K

270K

300K

330K

390K

420K

450K

480K

540K

600K

660K

720K

D E F G** H J K S T

32

30

12

42

32

32

32

32

32

32

32

32

32

32

32

36

36

36

36

36

46

46

46

46

30

30

30

30

30

30

30

30

30

30

30

38

38

38

38

38

44

44

44

44

12

12

12

12

12

12

12

12

12

12

12

16

16

16

16

16

19

19

19

19

42

42

42

42

42

42

42

57

57

57

57

69 1/2

69 1/2

69 1/2

69 1/2

69 1/2

69 1/2

69 1/2

69 1/2

69 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

12 1/2

17

17

17

17

17

20

20

20

20

-

-

-

-

-

-

-

-

-

-

-

-

1 1/2

1 1/2

1 1/2

1 1/2

1 1/2

2

2

2

2

17

17

17

17

17

20

20

20

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

-

20

22

22

22

22

22

27

27

27

27

Inlet* &

Outlet*

4

4

4

4

4

4

4

4

4

4

4

4

5

5

5

5

5

5 1/2

5 1/2

5 1/2

5 1/2

Boiler

Drain

3

3

2

3

3

3

3

3

3

3

3

3

4

4

4

4

4

5

5

5

5

1

1

1

1

1

1

1

1

1

1

1

1

1 1/4

1 1/4

1 1/4

1 1/4

1 1/4

1 1/2

1 1/2

1 1/2

1 1/2

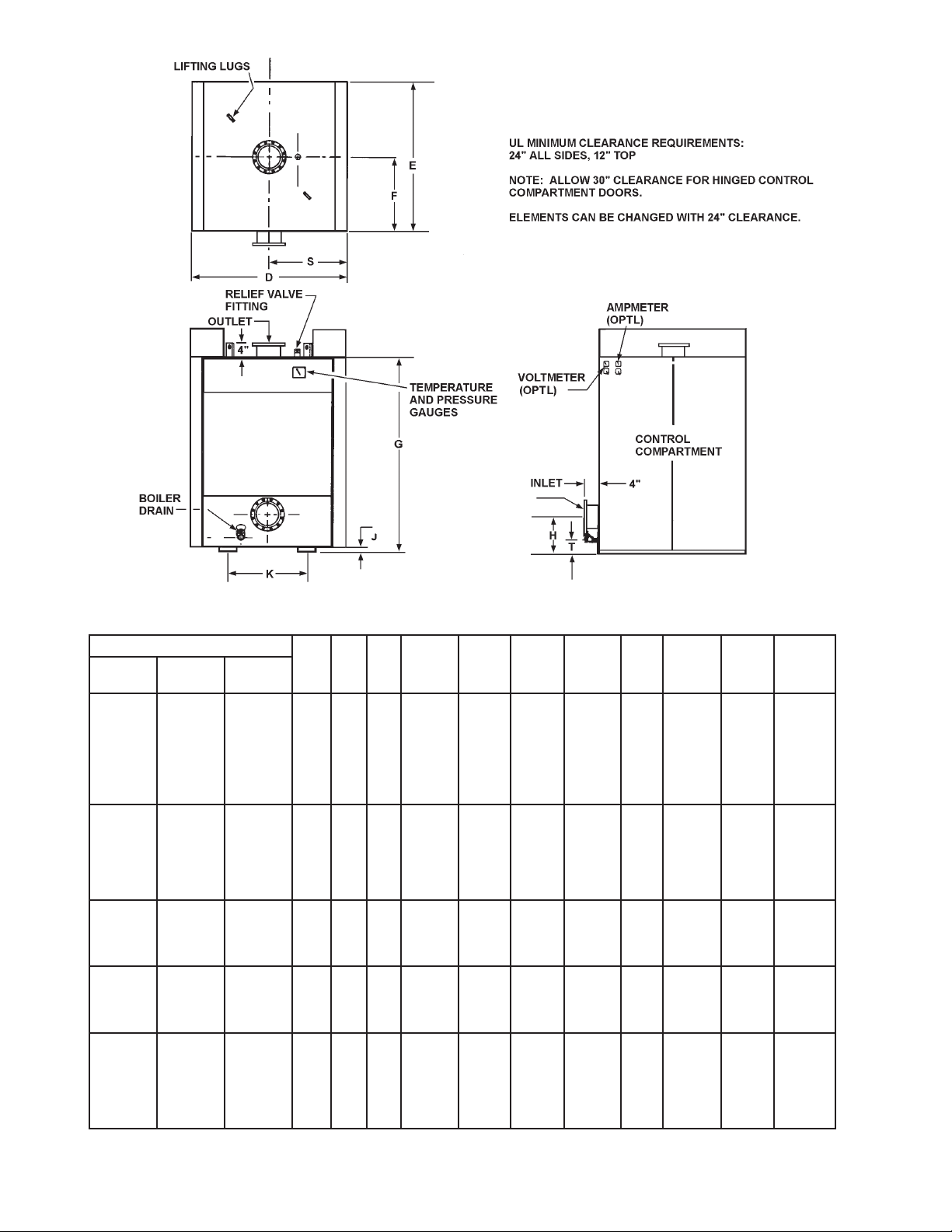

5

SIZES AND DATA NW220 THRU 670

Model Number

Prex Gal. Cap.

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

NOTE: For boilers 3400KW to 6000KW, consult factory.

* All ttings under 4” will be threaded type. All ttings 4” and larger will be anged.

** Where overall height is a problem a larger diameter vessel with a reduced height may be furnished.

220

220

220

220

220

220

220

334

334

334

334

334

334

400

400

400

400

500

500

500

500

670

670

670

670

670

670

Std. KW

Input

780K

840K

900K

960K

1020K

1080K

1140K

1200K

1260K

1380K

1500K

1620K

1740K

1800K

1860K

1980K

2100K

2200K

2340K

2460K

2580K

2700K

2820K

2940K

3060K

3180K

3300K

D E F G** H J K S T

60

50

25

60

60

60

60

60

60

60

60

60

60

60

60

66

66

66

66

72

72

72

72

78

78

78

78

78

78

50

50

50

50

50

50

50

50

50

50

50

50

56

56

56

56

62

62

62

62

68

68

68

68

68

68

25

25

25

25

25

25

25

25

25

25

25

25

28

28

28

28

31

31

31

31

34

34

34

34

34

34

71

71

71

71

71

71

71

99

99

99

99

99

99

90 1/2

90 1/2

90 1/2

90 1/2

90 1/2

90 1/2

90 1/2

90 1/2

96 1/2

96 1/2

96 1/2

96 1/2

96 1/2

96 1/2

21

21

21

21

21

21

21

25

25

25

25

25

25

25 1/2

25 1/2

25 1/2

25 1/2

26 1/2

26 1/2

26 1/2

26 1/2

30 1/2

30 1/2

30 1/2

30 1/2

30 1/2

30 1/2

2

2

2

2

2

2

2

2

2

2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

25 1/2

30

30

30

30

34

34

34

34

38

38

38

38

38

38

30

30

30

30

30

30

30

30

30

30

30

30

30

33

33

33

33

36

36

36

36

39

39

39

39

39

39

5 1/2

5 1/2

5 1/2

5 1/2

5 1/2

5 1/2

5 1/2

7 1/4

7 1/4

7 1/4

7 1/4

7 1/4

7 1/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

7 3/4

Inlet* &

Outlet*

5

5

5

5

5

5

5

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

Boiler

Drain

1 1/2

1 1/2

1 1/2

1 1/2

1 1/2

1 1/2

1 1/2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

6

Loading...

Loading...