Page 1

C O M M E R C I A L

™

ULTRA FORCE

UP TO 96% EFFICIENT COMMERCIAL GAS WATER HEATERS

The UItra Force™SUF product line is the

most efficient State commercial water

heater line ever built. With a storage tank of

up to 130 gallons, high BTU input and up

to 96% thermal efficiency, these models deliver more hot water for every energy dollar.

A single Ultra Force unit is an ideal energysaving choice for restaurants and other

mid-sized commercial applications.

Multiple Ultra Force water heaters can be

manifolded together to meet the demands

of large commercial and industrial

applications.

Down-Fired Low-NOx

Powered-Burner Design

• Top-mounted radial burner design

ensures optimum combustion efficiency.

Fully Submerged, Spiral-Shaped

Condensing Heat Exchanger

• Spiral shaped heat exchanger coils keeps

hot flue gases swirling through the heat

exchanger maximizing heat transfer and

efficiency.

•

Spiral shaped heat exchanger reduces

the accumulation of lime scale; maintains higher efficiency performance

over time.

Standard Power-Vent or

Power-Direct Vent Flexibility

• Vertical or sidewall power-venting

• Vertical or sidewall powered-direct vent

draws all combustion air from outside

the building.

• Vents using inexpensive PVC, ABS or

CPVC pipe. Canadian installations

require ULC S636 listed PVC or CPVC

pipe for intake and exhaust.

• Air intake and vent runs can be up

to 120 equivalent feet.

Space-Saving Design, with Zero

Clearance to Combustibles

• Approved for installation on

combustible flooring.

All Controls Including Gas Valve

nd Combustion Air Blower

a

Located on Top

• Provides easy access during installation

and service.

• Protects against high water damage.

• Protected from dirt and incidental

damage.

Advanced Electronic

Control System

• Microprocessor controls all water heater

functions including ignition and temperature regulation.

• Precise temperature control adjustable

from 90° F to 180° F.

• Large LCD display provides detailed

operational and diagnostic information

in plain English for ease of operation

and service.

• Ultra Force water heaters

are iCOMM

ble and can be monitored

from remote locations.

Call 1.888.WATER02

for more information.

Powered Anodes

(Standard on All Models)

• Provide long-lasting tank protection

• Non sacrificial anodes never need

replacing unless damaged.

ASME Construction

• Optional on 120, 150, 199 and

250 models.

• Standard on 300, 400 and 500 models.

Maximum Hydrostatic

Working Pressure: 160 psi

CSA Certified and ASME Rated

T&P Relief Valve

™

compati-

For more information on Ultra Force™contact:

State Water Heaters,

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com December 2009R

Page 2

C O M M E R C I A L

™

ULTRA FORCE

UP TO 96% EFFICIENT COMMERCIAL GAS WATER HEATERS

Other Ultra Force™Features:

Commercial Grade Glass-Lined Tank and Heat Exchanger

or Long-Term Protection Against Corrosion

f

Heat exchanger glass-lined on both water and vent sides to protect against corrosive flue

•

gases and condensate inside the coil

Handhole Cleanout

• For easy inspection and cleaning

Compliance

• Meets or Exceeds theThermal Efficiency and Standby Loss Requirements of the U. S.

Department of Energy and Current Edition of ASHRAE/IESNA 90.1

• Complies with SCAQMD Rule 1146.2 and other air quality management districts with

similar requirements for NOx emissions

• The 120-250K BTU models are design-certified by CSA International, according to

ANSI Z21.10.3 - CSA 4.3 Standards governing storage-type water heaters

• The 300-500K BTU models are design-certified by Underwriter's Laboratories (UL),

Inc., according to ANSI Z21.10.3-4.3 CSA Standards governing storage-type

water heaters

• Design-certified by Underwriter's Laboratories (UL), Inc., to NSF Standard 5

Three-Year Limited Tank Warranty

• For complete warranty information, consult written warranty shipped with water heater

or contact State Water Heaters

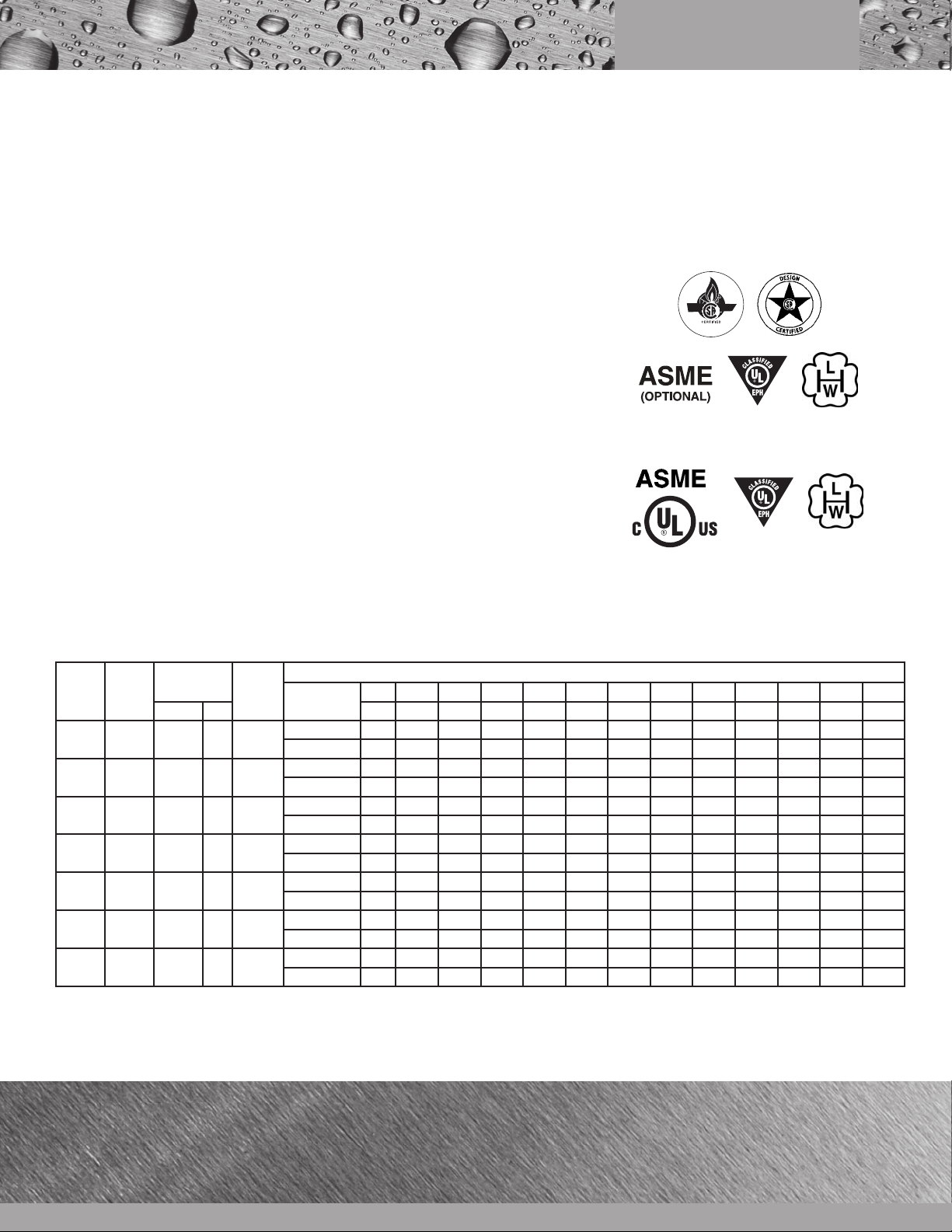

SUF 60 120NE - SUF 100 250NE Models

SUF 130 300NEA - SUF 130 500NEA Models

RECOVERY CAPACITY

TYPEOF

MODEL

SUF60

120NE

SUF100

150NE

SUF100

199NE

SUF100

250NE

SUF130

300NEA

SUF130

400NEA

SUF130

500NEA

Recovery capacities arebased on heater performance at 95% and 96% thermal efficiency.

Add “A” to model number when ordering ASME. Optional on SUF 60 120NE - SUF 100 250NE Models. Standardon SUF 130-300-500 NEA Models.

Maximum gassupply pressurefor 120 - 250: 10.5˝ w.c. natural gas 14˝ w.cpropane. Maximum gas supply pressure for 300 - 500 10˝ w.c. natural gas 13˝ w.c. propane.

Manifold pressure: 4˝ w.c. natural gas 10˝ w.c. propane. Electrical requirements: 120/60Hz VAC, Blower 2.2 Amps FL, Igniter 4.0 Amps.

GAS

NATURAL/

PROPANE

NATURAL/

PROPANE

NATURAL/

PROPANE

NATURAL/

PROPANE

NATURAL/

PROPANE

NATURAL/

PROPANE

NATURAL/

PROPANE

INPUT

BTUH KW Cº 17 Cº 22 Cº 28 Cº 33Cº 39 Cº 44 Cº 50 Cº 56 Cº 61Cº 67 Cº 72 Cº 78 Cº

120,000 35

150,000 44

199,900 58

250,000 73

300,000 88

399,900 117

499,900 146

Thermal

Efficiency

95%

95%

95%

95%

96%

96%

95%

Approx.

Capacity

60 U.S. Gals. GPH 461 345 276 230 197 173 154 138 126 115 106 99

227 Litres LPH 1744 1308 1046 872 747 654 581 523 476 436 402 374

100 U.S. Gals. GPH 576 432 345 288 247 216 192 173 157 144 133 123

379 Litres LPH 2179 1635 1308 1090 934 817 726 654 594 545 503 467

100 U.S. Gals. GPH 767 575 460 384 329 288 256 230 209 192 177 164

379 Litres LPH 2904 2178 1743 1452 1245 1089 968 871 792 726 670 622

100 U.S. Gals. GPH 960 720 576 480 411 360 320 288 262 240 221 206

379 Litres LPH 3632 2724 2179 1816 1557 1362 1211 1090 991 908 838 778

130 U.S. Gals. GPH 1164 873 699 582 499 436 388 349 318 291 269 250

492 Litres LPH 4406 3304 2644 2203 1888 1652 1469 1322 1201 1102 1017 945

130 U.S. Gals. GPH 1552 1164 931 776 665 582 517 465 423 388 359 332

492 Litres LPH 5875 4406 3525 2938 2518 2203 1958 1750 1602 1469 1356 1259

130 U.S. Gals. GPH 1919 1439 1151 959 822 720 640 576 523 480 443 411

492 Litres LPH 7263 5447 4358 3631 3113 2724 2421 2179 1981 1816 1676 1556

Fº 30 Fº 40 Fº 50Fº 60 Fº 70Fº 80 Fº 90 Fº 100Fº 110 Fº 120Fº 130Fº 140 Fº

U.S. Gallons/HrandLitres/Hr at TEMPERATURERISEINDICATED

December 2009R

Page 3

C O M M E R C I A L

™

ULTRA FORCE

UP TO 96% EFFICIENT COMMERCIAL GAS WATER HEATERS

DIMENSIONS AND SHIPPING WEIGHTS

MODEL

NUMBER

UF 120

S

UF 150

S

UF 199, SUF 250

S

SUF 300, 400 &500

Water Connections: 1-1/2˝

DIMENSIONS

A B C D E F G H I STD. ASME

3/7.62 27.75/70.5 6.3/16 35/88.9 55.5/141 48/121.9 11/27.9 42/106.7 47.5/120.6 460/208 490/222

3/7.62 27.75/70.5 6.3/16 55.5/141 75.5/191.8 68.5/174 11/27.9 63/160 69/175.3 555/252 595/270

3/7.62 27.75/70.5 6.3/16 55.5/141 75.5/191.8 75.5/191.8 11/27.9 63/160 69/175.3 555/252 595/270

N/A 33.12/84.1 4.86/12.34 50.77/129 75.5/191.8 69/175.3 12/30.5 63/160 69/175.3 N/A 855/408

APPROX. SHIPPING

WEIGHT

SUF 120 & 150

*Minimum clearance to remove top cover

MAXIMUM EQUIVALENT VENT LENGTHS SUF 120-250

*NUMBEROF

90° ELBOWS

INSTALLED

One(1) 45feet(13.7 meters) 115 feet (35.0 meters)

Two(2) 40feet(12.2meters) 110 feet (33.5 meters)

Three (3) 35feet(10.7 meters) 105 feet (32.0 meters)

Four(4) 30feet (9.1 meters) 100 feet (30.5 meters)

Five (5) –––––– 95 feet (29.0 meters)

Six(6) –––––– 90 feet (27.4 meters)

* Maximum number of 90° elbows allowed for the vent (exhaust) pipe

is four (4) when installing3 inch pipe and six (6) when installing 4

inch pipe. Maximum number of 90° elbows allowed for intake air

pipe is four (4) when installing 3 inch pipe and six (6) when

installing 4 inch pipe. Two(2) 45° elbows equal one (1) 90°elbow.

3 INCH PIPE 4 INCH PIPE

MAXIMUMFEET (METERS) MAXIMUM FEET (METERS)

MINIMUMSUPPLY GAS LINE SIZE

MODEL NATURAL GAS PROPANEGAS

SUF 60 120 NE 1/2”N.P.T. 1/2” N.P.T.

SUF 100 150 NE 3/4” N.P.T. 3/4”N.P.T.

SUF 100 199 NE 3/4” N.P.T. 3/4”N.P.T.

SUF 100 250 NE 3/4”N.P.T. 3/4” N.P.T.

SUF 130 300 NE 1-1/4”N.P.T. 1-1/4” N.P.T.

SUF 130 400 NE 1-1/4” N.P.T. 1-1/4”N.P.T.

SUF 130 500 NE 1-1/2” N.P.T. 1-1/4”N.P.T.

MAXIMUM EQUIVALENT VENT LENGTHS SUF 300 - 500

*NUMBEROF

90° ELBOWS

INSTALLED

One(1) 65 feet (19.8meters) 115 feet (35.0 meters)

Two(2) 60 feet(18.2 meters) 110 feet (33.5 meters)

Three (3) 55 feet (16.8meters) 105 feet (32.0meters)

Four(4) 50 feet (15.2 meters) 100 feet (30.5 meters)

Five (5) 45 feet (13.7meters) 95 feet (29.0meters)

Six(6) 40 feet (12.2meters) 90feet(27.4 meters)

* Maximum number of 90° elbows allowed for the vent (exhaust) pipe

is six (6). Maximum number of 90° elbows allowed on the intake air

pipe is six (6). Two (2) 45° elbows equal one (1) 90° elbow.

4 INCH PIPE 6 INCH PIPE

MAXIMUMFEET (METERS) MAXIMUM FEET (METERS)

SUF 199 & 250

SUF 300, 400 & 500

*Center line of water outlet on

top of the water heaters is

approximately 7 inches from the

front edge of the water heater

Page 4

C O M M E R C I A L

™

ULTRA FORCE

UP TO 96% EFFICIENT COMMERCIAL GAS WATER HEATERS

INSTALLATION CONSIDERATIONS

1. Condensate Drain – This is a fully condensing water heater and should be located near a drain to permit proper disposal of condensate.

2. Vent Termination – Exhaust gases of this water heater are less than 140° F. In cold climates, water vapor in flue gases will condense into a

cloud of vapor where the vent exits the building. This vapor can gradually discolor exterior building surfaces. Vent termination should be

located where this vapor cloud and potential discoloration are not a concern. Extending the vent termination up to 6" from the wall helps

vapor from being trapped along a building's face. To avoid this problem, the vent can be terminated on the roof. Always locate vent termination above the maximum snowline, and do not locate vent termination above a walkway.

3. Air Intake – In cold climates, air intake should be located at least four feet from the vent termination of the water heater and any other appliance vents that discharge moisture-laden air (such as clothes dryers). This will help prevent freeze-over of the intake screen required to

prevent foreign objects from entering the intake pipe. Air intake should be located above the maximum snowline.

4. Blockage Sensors – The water heater is equipped with sensors to shut it down if blockage of vent or air intake occurs. The water heater

control system will display detailed diagnostic information on the LCD screen to help service technicians quickly locate and correct the

problem.

5. Noise – Vent terminal should be located away from bedroom windows or other areas where blower noise will be objectionable. Avoid

venting into corners or confined areas, which will amplify sound. Anchoring intake or vent pipe walls or ceilings can cause noise to be

transmitted to living areas, and isolation mounts should be used where anchoring is required.

6. Optional Concentric Vent Kit - Helps to minimize unsightly wall/roof penetrations.

SUF 60 120NE - SUF 130 300NEA vent kit p/n 9006328005

SUF 130-400-500 NEA vent kit p/n 9006144005

SUGGESTED SPECIFICATION

™

Gas water heater(s) shall be State Ultra Force

of ___________________BTU/hr., a recovery rating of ____ GPH at 100º F temperature rise, and thermal efficiency of____%. Heaters shall meet or

exceed the thermal efficiency and standbyloss requirements ofthe U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1 and comply

with SCAQMD Rule 1146.2 and air quality management districts with similar requirements for low NOx. In addition, heater(s) shall: 1) Have a power

burner that requires no special calibrations on start-up. 2) Have seamless glass-lined tank construction in which the glass coating is applied to the water

side surfacesof thetank after the tank has been assembledand welded. 3) Have a condensing flue coil thatis coated onthe flue gas side withacid-resistant

glass lining designed for usein condensing heaters. 4) Have a control system that includesan integrated solid-state temperature andignition control device

with integral diagnostics, LCD fault display capability and a digitaldisplay of temperaturesettings. 5) Equipped with a CSACertified and ASME Rated

T&P Relief Valve. 6) Be approved for0˝ clearance to combustibles. 7)Heatershall be supplied with maintenance free (unless damaged)powered anodes.

120K-250K BTU Input:

ForStandard Power Venting: Water heater(s) shall besuitable forstandard power venting using a (3” or 4”) ____ diameter PVC pipefor a total distance

of (50ft. or 120 ft.) ____ equivalent feet of vent piping.

For Power Direct Venting: Water heater(s) shall be suitable for power direct venting using a (3” or 4”) ____ diameter PVC pipe for a total distance of

(50 ft. or 120 ft.) ____ equivalent feet of vent piping and (50 ft. or 120 ft.) ____ equivalent feet of intake air piping.

300K - 500K BTU Input:

ForStandard Power Venting: Water heater(s) shall be suitable for standard power venting using a (4” or 6”) ____ diameter PVC pipe for a total distance

of (70 ft. or 120 ft.) ____ equivalent feet of vent piping.

For Power Direct Venting: Water heater(s) shall be suitable for power direct venting using a (4” or 6”) ____ diameter PVC pipe for a total distance of

(70 ft. or 120 ft.) ____ equivalent feet of vent piping and (70 ft. or 120 ft.) ____ equivalent feet of intake air piping.

Water heater should incorporate the iCOMM™ system for remote monitoring, leak detection and fault alert.

For complete information on limited warranties, consult written warranty or contact the State Customer Care Center at 1-800-365-0024.

State Industries, Inc., reserves the right to make product changes or improvements without prior notice.

Model ________________, with a storage capacity of ____ gallons, an input rating

For more information on Ultra Force™, contact:

State Water Heaters

500 Tennessee Waltz Parkway,

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com December 2009

SCGSS00207 © 2009 State Industries, Inc. Printed in U.S.A

Loading...

Loading...