State AGT-705-NE Installation Manual

On-Demand Water Heater

System Design Manual

Design information for single and multiple unit

installations for residential, commercial, recirculation and storage tank systems.

PRINTED 0209 186965-001

Table of Contents

Certifications..................................................................................3

Installing Gas Water Heater

Water Quality and Scale ................................................................8

Pump Sizing for Circulation..........................................................9

Tank Water Heaters in a Circulation Loop

Additional Guidelines

Pump Sizing for Storage Tank Applications

Pressure Loss Curves

Domestic Hot Water - Standard Installation

1 Water Heater

2 Water Heaters (H3 Water Heaters (H4 Water Heaters (H5 Water Heaters (H6 Water Heaters (H-

Domestic Hot Water with Optional Freeze Protection

on Outdoor Models

1 Water Heater

2 Water Heater

3 Water Heaters (H-36 Water Heaters (H-6-

Domestic Hot Water with Circulation Systems

1 Water Heater - Preferred (H1 Water Heater - Optional (H-1-RO)

2 Water Heaters - Preferred (H-2-RP)

2 Water Heaters - Optional (H3 Water Heaters - Preferred (H-3-RP)

6 Water Heaters - Preferred (H-6-RP)

Domestic Hot Water with Backup Storage Tanks

1 Water Heater

1 Water Heater with Circulation (H2 Water Heaters (H-22 Water Heaters with Circulation (H3 Water Heaters (H-33 Water Heaters with Circulation (H6 Water Heaters (H-66 Water Heaters with Circulation (H-

Maintenance Procedure

Scale Flush Procedure (MP-01)

(H-1).......................................................................14

2).....................................................................15

3).....................................................................16

4).....................................................................17

5).....................................................................18

6).....................................................................19

(H-1-E)...................................................................20

s (H-2-

(H-1-T)...................................................................30

E).................................................................21

E).................................................................22

E).................................................................23

T) ..................................................................32

T) .................................................................34

T) .................................................................36

...........................................................4-7

....................................................................10

..................................................................12-13

1-RP)...............................................24

................................................25

............................................26

2-RO)..............................................27

............................................28

.............................................29

1-TC)........................................31

2-TC)......................................33

3-TC)..................................... 35

6-TC)..................................... 37

.......................................................38

...................................10

...............................11

2

Approvals

ATI-305-N GTS-305-NI GT-305-NI

ATI-305-P GTS-305-PI GT-305-PI

ATO-305-N GTS-305-NE GT-305-NE

ATO-305-P GTS-305-PE GT-305-PE

ATI-505-N GTS-505-NI GT-505-NI

ATI-505-P GTS-505-PI GT-505-PI

ATO-505-N GTS-505-NE GT-505-NE

ATO-505-P GTS-505-PE GT-505-PE

ATI-705-N GTS-705-NI GT-705-NI

ATI-705-P GTS-705-PI GT-705-PI

ATO-705-N GTS-705-NE GT-705-NE

ATO-705-P GTS-705-PE GT-705-PE

*ATI-705A-N *GTS-705-NIA *AGT-705-NI

*ATI-705A-P *GTS-705-PIA *AGT-705-PI

*ATO-705A-N *GTS-705-NEA *AGT-705-NE

*ATO-705A-P *GTS-705-PEA *AGT-705-PE

The models listed in this manual have received the following certifications except where noted:

Certified to applicable U.S.

standards for appliances using

gas or other petroleum fuel.

Certified to applicable Canadian

standards for appliances using

gas or other petroleum fuel.

U

P

C

R

Certified by the Uniform

Plumbing Code (UPC)

Certified by National Sanitation

Foundation (NSF), www.nsf.org

(indoor models must use the

NSF approved top guard)

*

Water heaters are built in accordance with the requirements of the ASME Boiler

and Pressure Vessel Code and received the Certificate of Authorization from the

National Board. The heat exchanger has the NB and the HLW stamps.

Air-Conditioning, Heating and

Refrigeration Institute

Met the California Energy

Commission (CEC) standards

Approved by the Commonwealth

of Massachusetts (G1-0208-249)

Received New York City’s Material

and Equipment Acceptance (MEA)

(MEA 327-02-E Vol. 09)

(MEA 327-02-E Vol. 10)

(MEA 327-02-E Vol. 11)

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to

publish a list of substances known to the State of California to cause cancer, birth defects, or other

repoductive harm, and requires businesses to warn of potential exposure to such substances.

WARNING: This product contains a chemical known to the State of California to cause cancer, birth

defects, or other reproductive harm.

This appliance can cause low-level exposure to some of the substances included in the Act.

3

Installation

Consumer Information

The on-demand water heaters must be installed according to all local and state codes or, in the absence

of local and state codes, the “National Fuel Gas Code”, ANSI Z223.1 (NFPA 54) - current edition.

CSA American, Inc. National Fire Protection Association

8501 East Pleasat Valley Road 1 Batterymarch Park

Cleveland, OH 44131 Quincy, MA 02269

Check your phone listings for the local authorities having jurisdiction over your installation.

Consumer Responsibilities

This manual has been prepared to acquaint you (trained service technician) with the installation, operation, and maintenance of the on-demand water heater and provide important safety information in these

areas.

Read all of the instructions thoroughly before attempting the installation or operation of the water heater.

Service to the on-demand system should only be performed by a trained service technician.

Massachusetts code requires this water heater to be installed in accordance with Massachusetts Plumbing

and Fuel Gas Code 248 CMR Section 2.00 and 5.00.

Water Temperature Regulation

For systems with storage tanks, the water

temperature in certain situation may vary up

to 30°F (16.7°C) higher or lower at the point

of use such as, bathtubs,showers, sink, etc.

HOTTER WATER CAN SCALD: Water heaters, are intended to produce hot water. Water

heated to a temperature which will satisfy

space heating, clothes washing, dish washing, and other sanitizing needs can scald and

permanently injure you upon contact. Some

people are more likely to be permanently injured by hot water than others. These include

the elderly, children, the infirm, or physically/

mentally handicapped. If anyone using hot

water in the home fits into one of these

groups or if there is a local code or state law

requiring a certain temperature water at the

hot water tap, then you must take special

precautions.

WARNING

Water temperature over 125°F can cause

severe burns instantly or death from scalds.

Children, disabled and elderly are at highest

risk of being scalded.

Feel water before bathing or showering.

Temperature limiting valves are available.

4

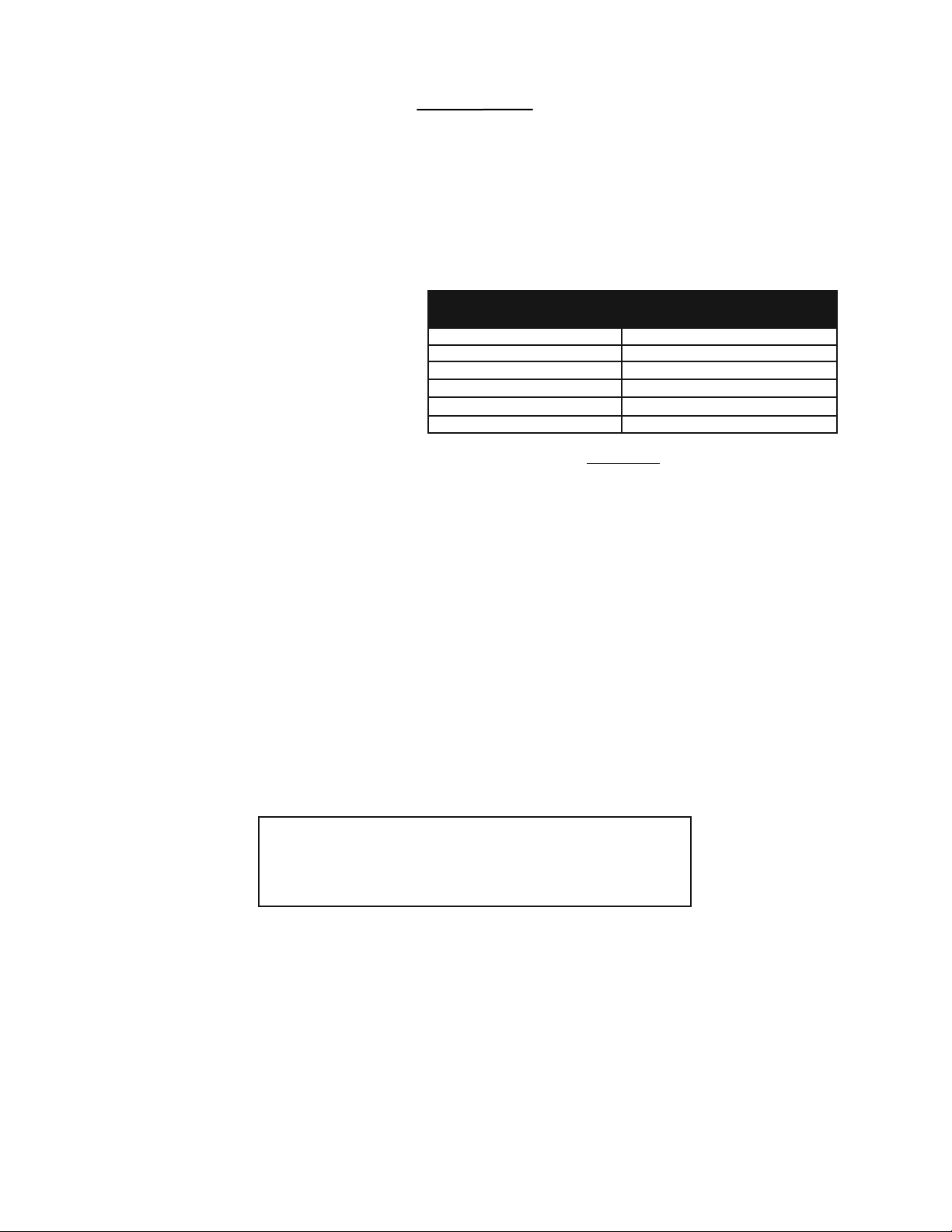

Installation

In addition to using the lowest possible temperature setting that satisfies your hot water needs, a means

such as a mixing valve, should be used at hot water taps used by these people or at the water heater.

Mixing valves are available at plumbing supply or hardware stores. Follow manufacturer’s instructions for

installation of the valves. Before changing the factory setting on the thermostat see table below. Using

the lowest hot water temperature that meets your needs will also provide the most energy efficient operation of the water heater.

Never allow small children to use a hot water

tap, or to draw their own bath water. Never

leave a child or handicapped person unattended in a bathtub or shower.

NOTE: A water temperature range of 120

°F -

140°F (49°C-60°C) is recommended by most

dishwasher manufacturers.

Temperature

Settings

160°F (71°C)

150°F (66°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (54°C) About 30 seconds

120°F (49°C) More than 5 minutes

80°F (27°C) - - - - - - - - - - - - - - - -

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

About 1/2 second

Table “A”

The thermostat of the water heater has been factory set at 120° F, to reduce the risk of scald injury. It is

adjustable and can be reset to the desired temperature setting. Some states have a requirement for a

lower setting. If you need hotter water, follow directions for temperature adjustment, but beware of the

warnings in this section.

Site Location

• Select a location near the center of the water piping system.

• Consider the exhaust vent system piping and combustion air supply requirements when selecting the

water heater location. The venting system must be able to run from the water heater to the termina tion with a minimal length and number of elbows.

• Locate the water heater near the existing gas piping. If installing a new gas line, locate the water

heater to minimize the pipe length and elbows.

NOTE: This water heater must be installed according to all

local and state codes or, in the absence of local and state

codes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA

54)-current edition.

• The water heater should be located in an area not subject to freezing temperatures. Water heaters

located in unconditioned spaces (i.e., attics, basements, etc.) may require insulation of the water piping

and drain piping to protect against freezing. The drain and controls must be easily accessible for oper ation and service. Maintain proper clearances as specified on the data plate.

5

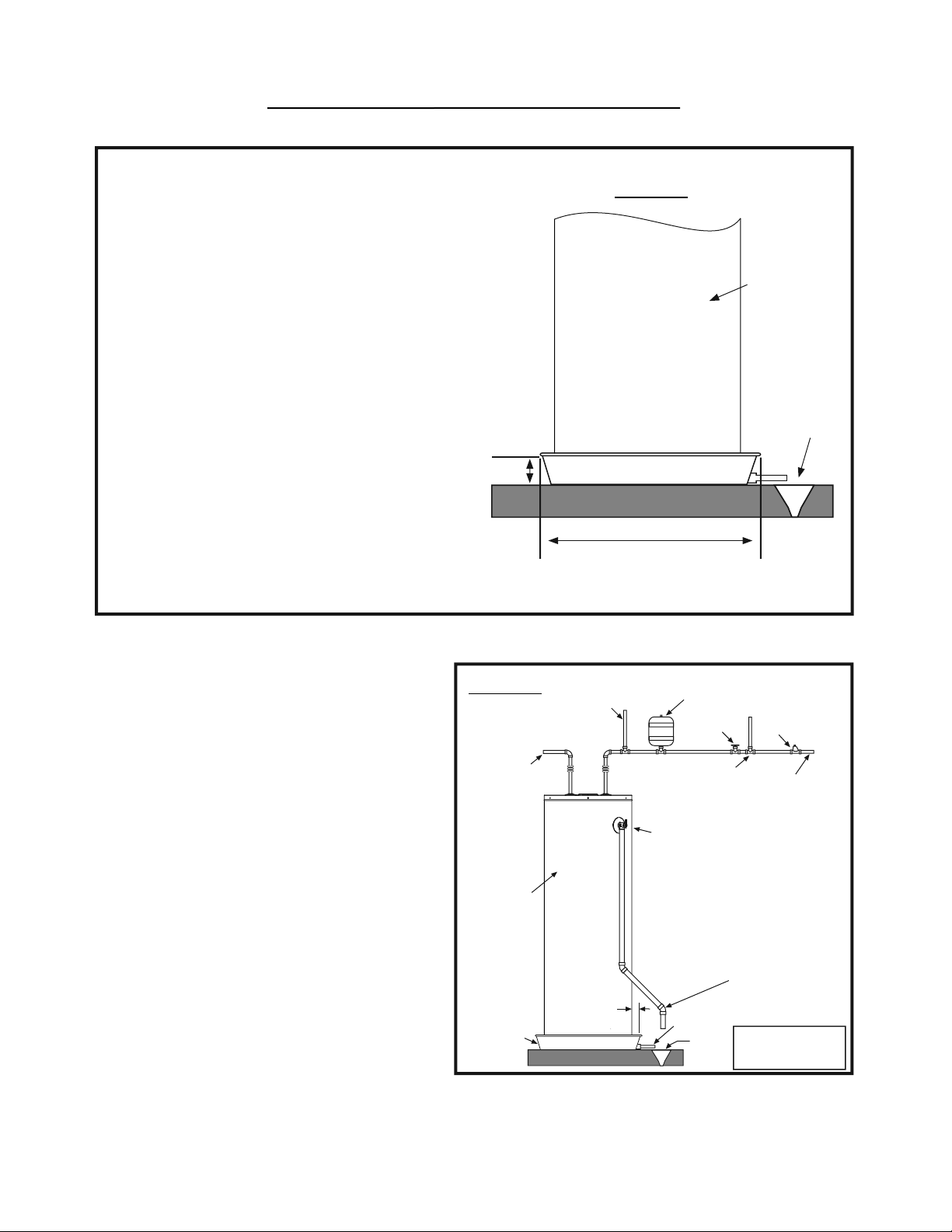

For Storage Tank System Installation

CAUTION - PROPERTY DAMAGE HAZARD

The storage tank should be located in an area

where leakage of the tank or connections will not

result in damage to the area adjacent to the storage

tank or to lower floors of the structure. Due to the

normal corrosive action of the water, the tank will

eventually leak after an extended period of time. Also

any external plumbing leak, including those from

improper installation, may cause early failure of the

tank due to corrosion if not repaired. If the owner/

operator is uncomfortable with making the repair a

qualified technician should be contacted. A suitable

metal drain pan should be installed under the storage

tank as shown below, to help protect the property

from damage which may occur from condensate formation or leaks in the piping connections or tank. The

pan must limit the water level to a maximum depth of

1-3/4” and be two inches wider than the tank and

piped to an adequate drain. NOTE: The pan must

not restrict combustion air flow. Locate the storage

tank near a suitable indoor drain. Outside drains are

subject to freezing temperatures which can obstruct

the drain line. The piping should be at least 3/4” ID

and pitched for proper drainage.

1-3/4”

max.

Figure “1”

A suitable metal drain pan

should be installed under

the storage tank.

At least 2” greater than

the storage tank.

Storage Tank

Pipe to an

adequate drain

Closed System/Thermal Expansion

CAUTION - PROPERTY DAMAGE HAZARD

As water is heated, it expands (thermal expansion). In a closed system, the volume of water

will grow. As the volume of water grows, there

will be a corresponding increase in water pressure due to thermal expansion. Thermal expansion can cause premature tank failure (leakage).

This type of failure is not covered under the

limited warranty. Thermal expansion can also

cause intermittent temperature-pressure relief

valve operation: water discharged from the valve

due to excessive pressure build up. The temperature / pressure relief valve is not intended for

the constant relief of thermal expansion. This

condition is not covered under the limited warranty.

A properly-sized thermal expansion tank should

be installed on all closed systems to control the

harmful effects of thermal expansion. Contact a

local plumbing service agency to have a thermal

expansion tank installed.

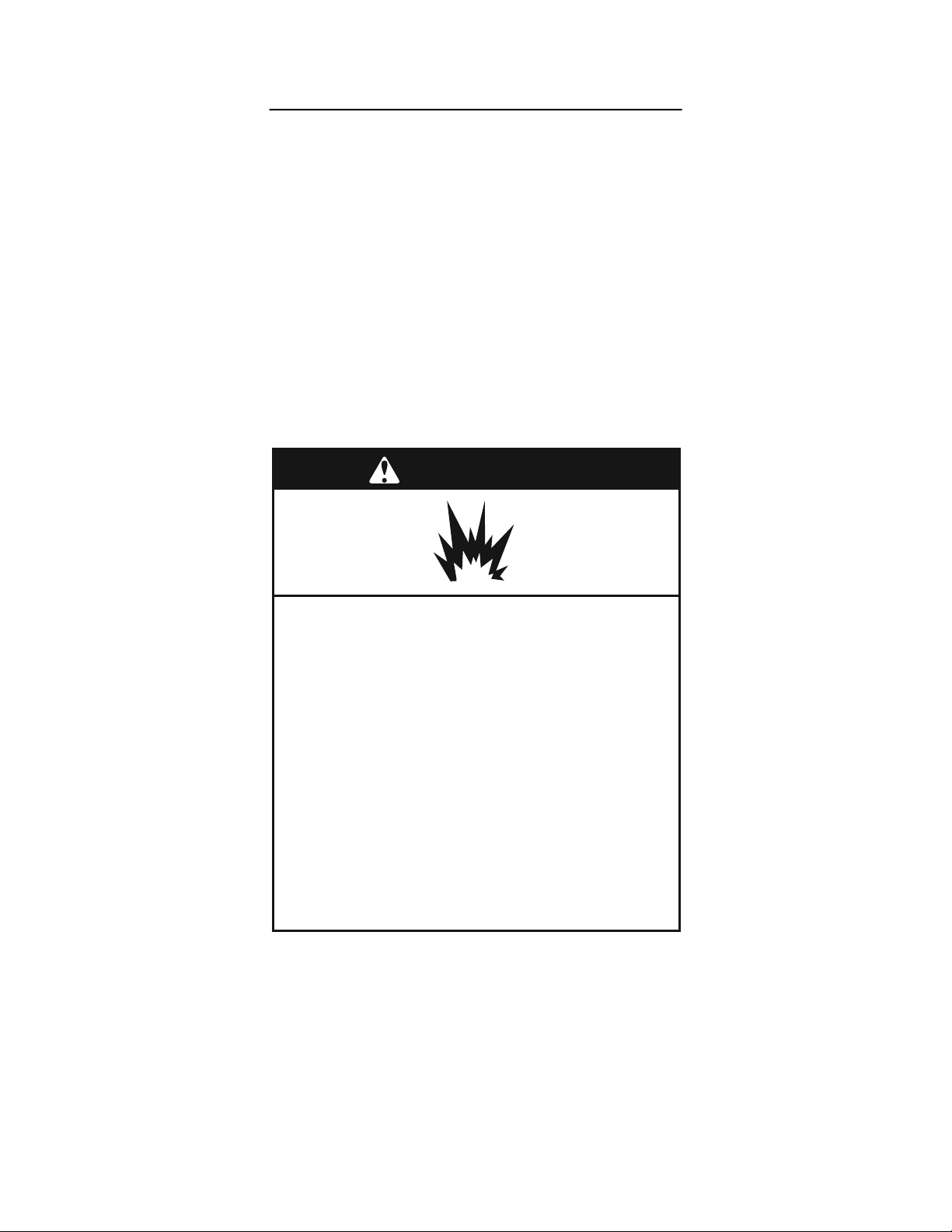

Figure “2”

Typical water

piping installation

Hot Water

Outlet

Storage

Tank

Metal Drain

Pan 1-3/4”

Depth Max.

Hot Water

Return Line

1“ Min.

In a closed system use a

thermal expansion tank

Cold Water

Inlet Valve

Cold Water Supply

to Fixture

Temperature and

Pressure Relief Valve

Drain line 3/4”

ID Min.

Drain

Pressure Reducing

Valve with Bypass

Main Water

Supply

Discharge line

6” Max. above drain

Massachusetts:

Install a vacuum relief

in cold water line per

section 19 MGL 142

6

For Storage Tank System Installation

Temperature and Pressure Relief Valve

For protection against excessive pressures and temperatures, a temperature and pressure relief valve

must be installed in the opening on the on-demand storage tank. This valve must be design certified by

a nationally recognized testing laboratory that maintains periodic inspection of the production of listed

equipment or materials as meeting the requirements for Releif Valves for Hot Water Supply Systems,

ANSI Z21.22. The function of the temperature and pressure relief valve is to discharge water in large

quantities in the event of excessive temperature or pressure developing in the water heater. The valve’s

relief pressure must not exceed the working pressure of the water heater as stated on the data plate.

IMPORTANT: Only a new temperature and pressure relief valve should be used with your water heater.

Do not use an old or existing valve as it may be damaged or not adequate for the working pressure of

the new water heater. Do not place any valve between the relief valve and the tank.

WARNING

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

service technician replace it.

Examples of a qualified service technician

include: Licensed plumbers, authorized gas

company personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death, or explosion.

7

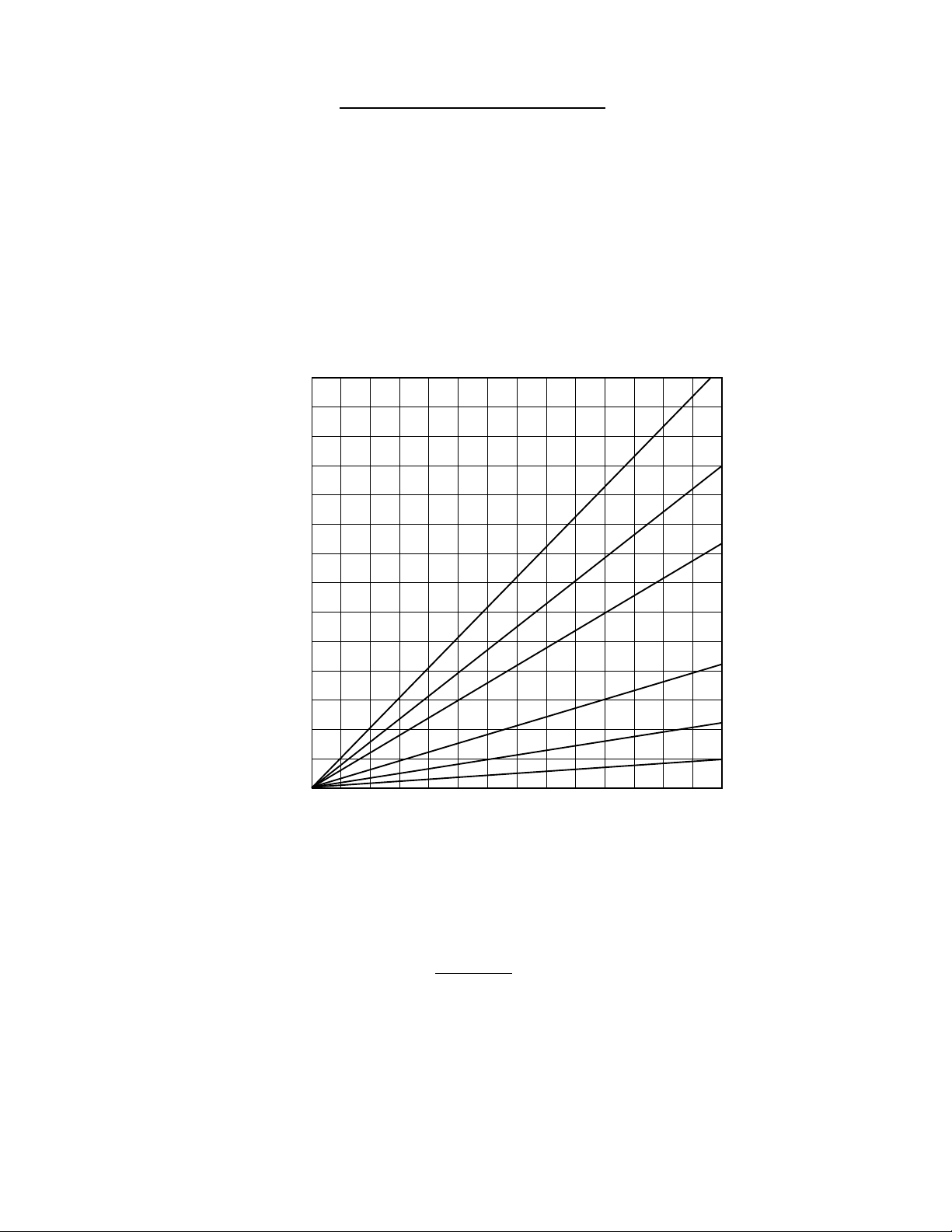

Water Quality and Scale

A complete water analysis and an understanding of system requirements are needed to protect the

on-demand water heaters and water heating systems from scale. Water analysis shows whether

water is hard or soft. Hard water, unless treated, will cause scaling or liming of the heat exchanger.

The rate of scaling increases with temperature and usage because calcium carbonate and other

scaling compounds lose solubility (fallout of solution) at higher temperatures. For example, for every

20°F over 140°F, the rate of scale increases by a factor of 2 (See figure below). Reference target

water quality levels found in the operation / installation manual and consider water treatment if these

levels are exceeded. *

LIME DEPO SITED, lb/yr

210

180

150

120

90

60

30

BASED ON 10 grains/gal HARDNESS

*

180°F

170°F

160°F

150°F

140°F

0

300

0

900

1500

2100

2700

3300

120°F

3900

WATER USAGE, gal/day

Figure “3”

*Source 2003 ASHRAE Handbook HVAC Applications

8

Pump Sizing for Circulation

1. Use the chart below or one appropriate for your conditions to determine the heat loss in the length of

the hot water supply and return piping. For example, 100 ft of 1-1/2 in bare copper tubing results in a

heat loss of 5300 Btu/h.

Approximate Heat Loss from Piping at 140 ºF Inlet, 70 ºF Ambient *

Nominal Size, in. Bare Copper Tubing,

Btu/h-ft

2/1-2

* Source: 2003 ASHRAE Handbook HVAC Applications

1/2 in. Glass Fiber Insulated

Copper Tubing, Btu/h-ft

7.71 03 4/3

3.02 83 1

4.32 54 4/1-1

4.52 35 2/1-1

6.92 66 2

8.33 08

5.93 49 3

4.84 021 4

Table “B”

2. Determine the acceptable temperature drop at the last fixture in the loop. For example, if the supply

temperature from the water heater is 120 ºF (49 ºC) and an acceptable temperature at the last fixture

is 100 ºF (38 ºC) then the acceptable temperature drop is 20 ºF (7 ºC).

3. Calculate the required pump flow rate using the following formula:

FLOW RATE (gpm) = HEAT LOSS (BTU / h)

500 X ACCEPTABLE TEMPERATURE DROP (ºF )

4. Based on the above calculations select a pump for the type of circulation system you will be utilizing:

A). Preferred Method (reference drawing H-1-RP) - Reference pump manufacturers flow vs.

pressure specifications to select a pump that can provide the flow rate calculated above

while overcoming the pressure loss through:

• Tank water heater (reference manufacturer’s information)

• All building supply and return plumbing in the circulation loop (reference

local plumbling codes, standards, or practices)

B). Optional Method (H-1-RO) - Reference pump manufacturers flow vs. pressure specifications

to select a pump that can provide 3 gpm of flow or the flow rate calculated above, whichever

is greater, while overcoming the pressure loss through:

• On demand water heater (reference flow vs. pressure

being used)

• Optional storage tank (reference manufacturer’s information)

• All building supply and return plumbing in the circulation loop (reference

local plumbling codes, standards, or practices)

NOTE: Only use pumps of brass or stainless steel construction. Do not use pumps of iron

construction as they will oxidize and clog the inlet filter on the appliance.

curve of the model

9

Tank Water Heaters in a Circulation Loop

The following applies when using a tank water heater (gas or electric) to provide heat for a circulation

loop. Drawing H-1-RP is an example.

The heat output of the tank must be equal to or greater than the calculated circulation loop heat loss.

(Reference page 5, Step 1 on calculating heat loss).

Electric Tank Water Heater

Since the input and output are the same for an electric tank water heater, this can be expressed as:

Electric Tank Input (Kw) >

3413

(1 Kilowatt = 3,413 BTU)

Gas Tank Water Heater

When using a gas style water heater, the efficiency of the tank must be taken into account.

Available Btu output = (Btu input of tank) x (efficiency) >

Example:

30,000 Btu input gas tank

0.62 Efficiency

30,000 x .62 = 18,600 available Btu output

Circulation loop heat loss (Btu/h)

Circulation loop heat loss (Btu/h)

Additional Guidelines

On-demand water heaters not recovering a storage tank: In applications involving a commercial

dishwasher, a hot water circulation loop feeding the dishwasher is required.

On-demand water heater recovering a storage tank: In applications involving a commercial dishwasher,

a hot water circulation loop feeding the dishwasher may be required depending on the distance between

the dishwasher and the storage tank. Refer to local codes when determining the need for circulation

loops to dishwashers.

10

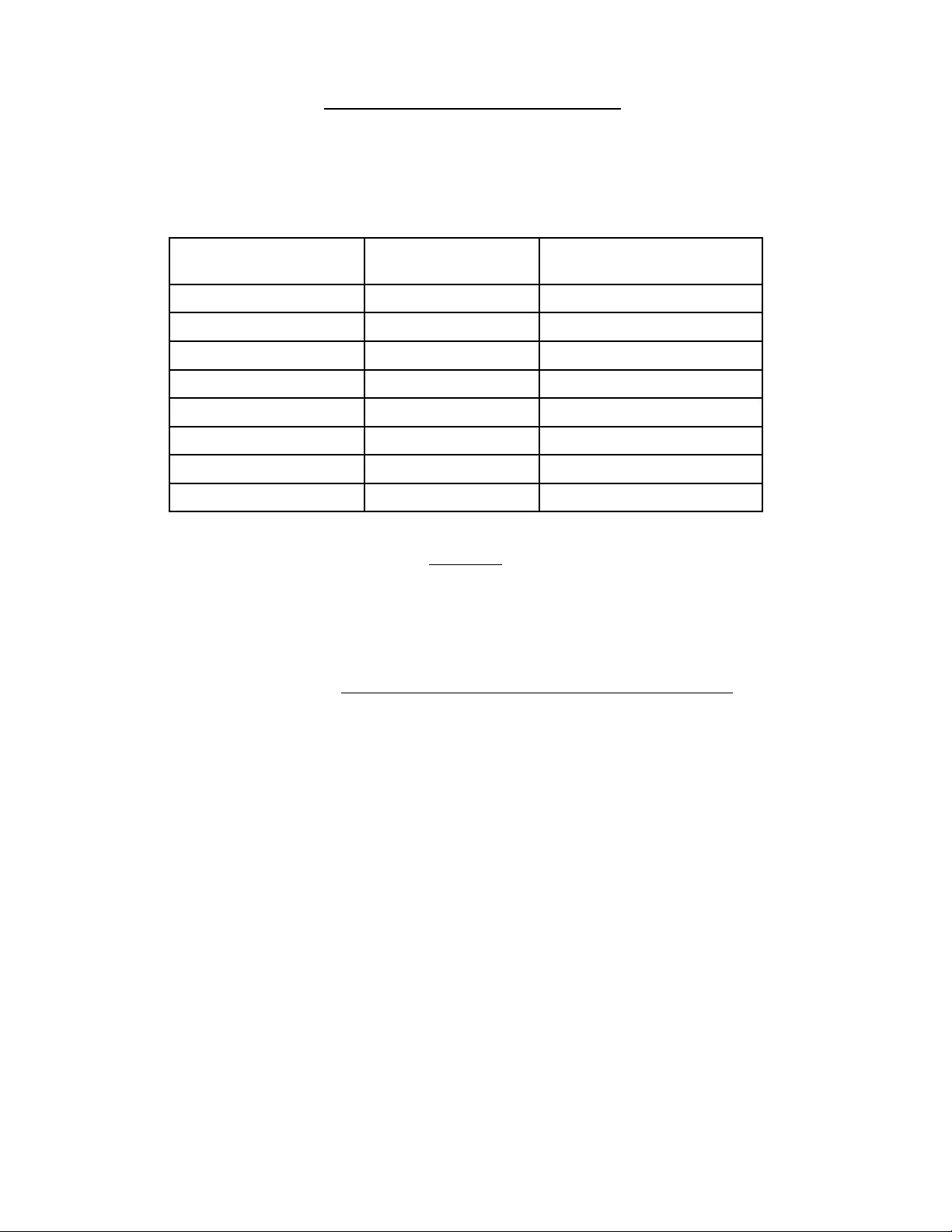

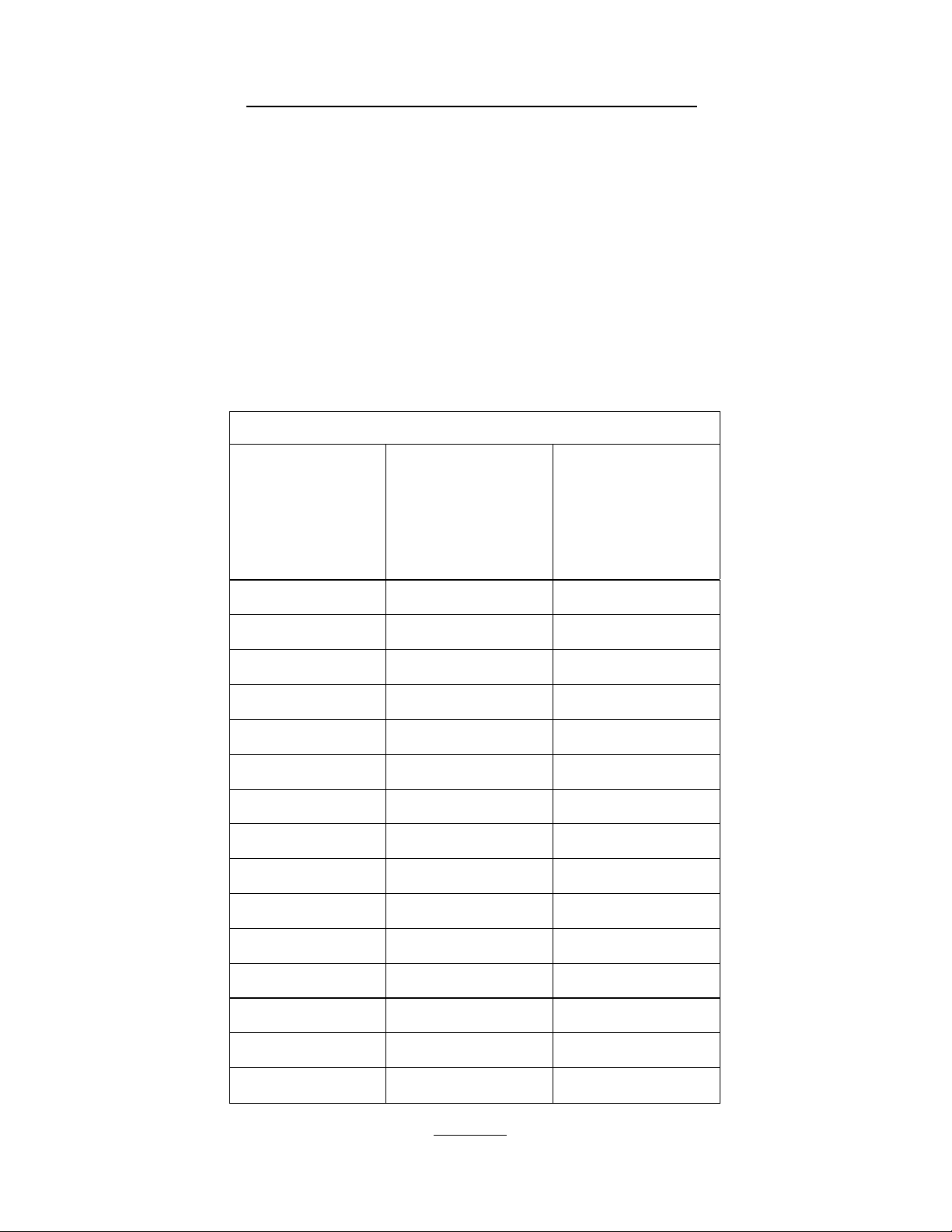

Pump Sizing for Storage Tank Application

The following applies when using on-demand water heaters to recover a storage tank.

Drawing H-1-TC is an example.

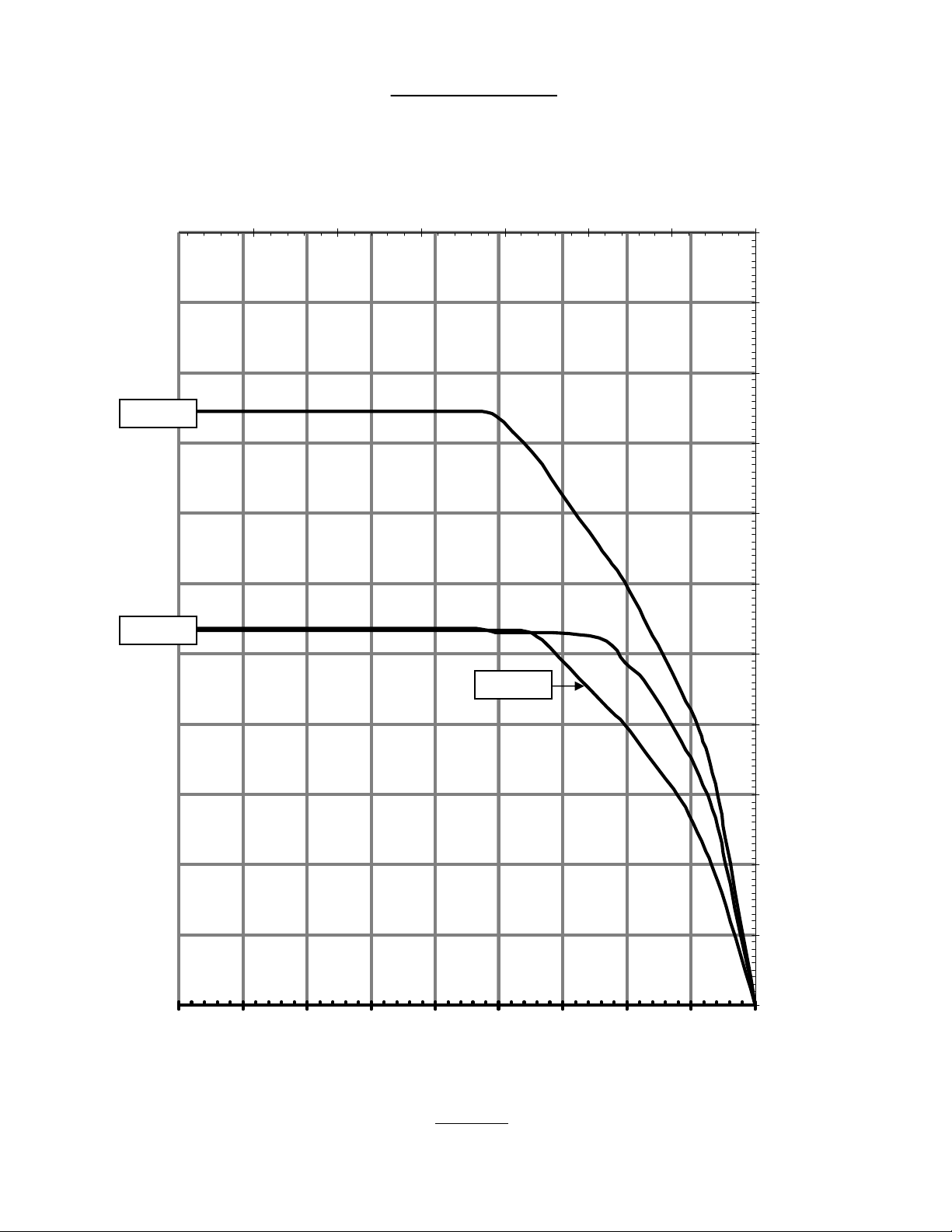

On-Demand water heaters have a pressure loss which must be considered in the system design.

Reference the pressure loss curve for the heater model being used to determine the pump size for the

desired recovery rate.

For recommended pump sizes use the table below. Additional pressure losses in plumbing between the

Heater(s) and the storage tank must also be taken into consideration.

The specified pump size is to provide maximum recovery of the storage tank. A smaller pump size may

be used, but could result in longer recovery time of the tank. Please contact the Tech Services department

with any questions on pump sizing.

NOTE: Only use pumps of brass or stainless steel construction. Do not use pumps of iron

construction as they will oxidize and clog the inlet filter on the app

Pump Flow Requirements

Number of

On-Demand

705/505

Water Heaters

liance.

305

1 6 gpm @ 30' head 5 gpm @ 25' head

2 12 gpm @ 30' head 10 gpm @ 25' head

3 18 gpm @ 30' head 15 gpm @ 25' head

4 24 gpm @ 30' head 20 gpm @ 25' head

5 30 gpm @ 30' head 25 gpm @ 25' head

6 36 gpm @ 30' head 30 gpm @ 25' head

7 42 gpm @ 30' head 35 gpm @ 25' head

8 48 gpm @ 30' head 40 gpm @ 25' head

9 54 gpm @ 30' head 45 gpm @ 25' head

10 60 gpm @ 30' head 50 gpm @ 25' head

11 66 gpm @ 30' head 55 gpm @ 25' head

12 72 gpm @ 30' head 60 gpm @ 25' head

13 78 gpm @ 30' head 65 gpm @ 25' head

14 84 gpm @ 30' head 70 gpm @ 25' head

15 90 gpm @ 30' head 75 gpm @ 25' head

Table “C”

11

100/101 Series

Pressure Loss Curves

Pressure Loss (ft head)

505

305i

60.0

50.0

40.0

30.0

20.0

10.0

0.0

305e

45.0

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

Water Flow (gpm)

01234567891011

Pressure Loss (psi)

Figure “4”

12

Loading...

Loading...