Impact

Owner’s Manual

Star Trac StrengthTM

Star Trac FitnessTM

Impact Owner’s Manual

2008

STAR TRAC STRENGTHTM, INC.

41180 Raintree Court, Murrieta, California 92562

Phone 951.600.3800 • Fax 951.600.1706

All rights reserved

Disclaimer:

STAR TRAC STRENGTHTM makes no representations or warranties regarding the contents of this manual. We reserve the right

to revise this document at any time or to make changes to the product described within it without notice or obligation to notify any

person of such revisions or changes.

©2008 Star Trac. All rights reserved. Star Trac, the Star Trac logo are registered trademarks of Unisen, Inc. Impact Strength is a

trademark of Unisen, Inc. LockNLoad is a trademark of Innovative Strength Technology, LLC.

Table of Contents

Safety Information and General Exercise Guidelines ------------------------------------------------ 1

Exercise Guidelines---------------------------------------------------------------------------------------------5

Product Maintenance and Use--------------------------------------------------------------------------------6

Installation Instructions ------------------------------------------------------------------------------------ 8

Securing Equipment in Installation-----------------------------------------------------------------------8

Assembly and Operational Instructions----------------------------------------------------------------- 9

Abdominal-------------------------------------------------------------------------------------------------------9

Abductor-------------------------------------------------------------------------------------------------------10

Adductor-------------------------------------------------------------------------------------------------------10

Biceps Curl---------------------------------------------------------------------------------------------------- 11

Unilateral Biceps Curl--------------------------------------------------------------------------------------11

Chin/Dip Assist----------------------------------------------------------------------------------------------- 12

Deltoid Raise-------------------------------------------------------------------------------------------------- 13

Rear Deltoid /Pec Fly --------------------------------------------------------------------------------------- 13

Glute Machine------------------------------------------------------------------------------------------------14

Incline Chest--------------------------------------------------------------------------------------------------15

Kneeling Leg Curl------------------------------------------------------------------------------------------- 16

Lat Pull Down ------------------------------------------------------------------------------------------------16

Lat Pull Down (Cable)-------------------------------------------------------------------------------------- 17

Leg Curl ------------------------------------------------------------------------------------------------------- 17

Leg Extension (Center Mount)---------------------------------------------------------------------------18

Leg Extension (Side Mount) ------------------------------------------------------------------------------19

Leg Press------------------------------------------------------------------------------------------------------- 20

Low Back------------------------------------------------------------------------------------------------------20

Low Row------------------------------------------------------------------------------------------------------- 21

Overhead Triceps-------------------------------------------------------------------------------------------- 21

Pectoral Fly --------------------------------------------------------------------------------------------------- 22

Seated Leg Curl---------------------------------------------------------------------------------------------- 22

Seated Leg Press ---------------------------------------------------------------------------------------------23

Shoulder Press------------------------------------------------------------------------------------------------ 23

Standing Calf -------------------------------------------------------------------------------------------------24

Triceps Dip---------------------------------------------------------------------------------------------------- 24

Triceps Extension-------------------------------------------------------------------------------------------- 25

Unilateral Row ----------------------------------------------------------------------------------------------- 25

Chest Press ----------------------------------------------------------------------------------------------------26

Vertical Row-------------------------------------------------------------------------------------------------- 26

30° Pectoral Fly ---------------------------------------------------------------------------------------------- 27

45° Calf--------------------------------------------------------------------------------------------------------- 27

DAP – Dual Adjustable Pulley ---------------------------------------------------------------------------28

Transmission Source Replacement----------------------------------------------------------------------30

Transmission Sources--------------------------------------------------------------------------------------- 30

General Guidelines ------------------------------------------------------------------------------------------- 30

Belts - Fasteners----------------------------------------------------------------------------------------------- 31

Belts - Replacement Procedures----------------------------------------------------------------------------33

Attaching Belt to Top Plate (Synch Fastener)------------------------------------------------------ 33

Attaching Belt to Swivel Appliance (Compression Swivel Fastener) ------------------------- 33

Attaching Belt to Drive Systems (Compression Fastener)--------------------------------------- 34

Belts - Installation--------------------------------------------------------------------------------------------- 35

Cables----------------------------------------------------------------------------------------------------------- 35

Type 1. Terminal / Swedge Fitting--------------------------------------------------------------------35

Double Termination Smith Cable--------------------------------------------------------------------- 35

Triceps Pushdown Station(s)---------------------------------------------------------------------------36

Adjustable Cross Over Cable(s)-----------------------------------------------------------------------36

Cross Over Cables (Non Adjustable)-----------------------------------------------------------------38

Frame and Upholstery Management--------------------------------------------------------------------39

Framework Maintenance------------------------------------------------------------------------------------39

Upholstery Maintenance------------------------------------------------------------------------------------- 40

Warranty Information-------------------------------------------------------------------------------------41

Warranty & Disclaimer. -----------------------------------------------------------------------------------41

How to Get Parts & Service ---------------------------------------------------------------------------- 42

Preventative Maintenance---------------------------------------------------------------------------------44

Clean the Shrouds----------------------------------------------------------------------------------------- 48

Sticker Part Numbers--------------------------------------------------------------------------------------50

Appendix A: Synch Fastener Torque Specifications-------------------------------------------------56

Appendix B : Guide Rod Lubrications Procedure ---------------------------------------------------58

Appendix C: DAP handle inspection and tightening procedure-----------------------------------61

Chapter

Safety Information and

General Exercise

Guidelines

Before using this product, it is essential to read this ENTIRE operations

manual and ALL installation Instructions. It describes equipment setup

and instructs members on how to use it correctly and safely.

Health related injuries may result from incorrect or excessive use of

exercise equipment. Star Trac strongly recommends you to encourage

your members to discuss their health program or fitness regimen with a

health care professional, especially if they have not exercised for several

years, are over 35, or have known health conditions.

All STAR TRAC STRENGTHTM equipment MUST be secured to

the floor to stabilize and eliminate rocking or tipping over. This

must be performed by a licensed contractor.

Caution, pinch points. Keep hands, feet, head, limbs, fingers and hair

clear at all times from moving parts to avoid injury. Use appropriate

positioning, speed and controlled movements.

1

Important Safety Instructions

The following fitness safeguards and operating precautions are directed to

purchasers and users of the STAR TRAC STRENGTHTM equipment. Club

Managers should ensure that members and fitness staff are trained to use the

equipemtn properaly and follow these instructions. Failure to follow these

safeguards may result in injury or serious health risk.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

Read the Owner's Manual fully and carefully before assembling, servicing or using

the Weight equipment.

! WARNING: Serious injury could occur if these safety

precautions are not observed:

1. Do not use any equipment in any way other than designed or intended

by the manufacturer. It is imperative that weight stack machines as

well as any other STAR TRAC STRENGTHTM equipment is used

properly to avoid injury. Call your dealer or Star Trac at (800) 503-1221, or

USA 1-714-669-1660 for examination and repair.

2. Keep hands, feet, head, limbs, fingers and hair clear at all times from

moving parts to avoid injury. Use appropriate positioning, speed and

controlled movements.

3. Do not insert any object, hands or feet into any openings, or expose

hands, arms or feet to the drive mechanism or other potentially moving

part of the equipement.

4. DO NOT exceed maximum user weight of 350 lbs.

5. DO NOT use any equipment that is damaged and or has worn or

broken parts. Use only replacement parts supplied by STAR TRAC

STRENGTHTM.

6. DO NOT wear loose or dangling clothing while using the STAR

TRAC STRENGTH

7. Obtain a medical exam prior to beginning an exercise program.

8. If at any time during exercise you feel faint, dizzy or experience pain,

stop and consult your physician.

TM

equipment. Keep away from all moving parts.

2

9. Children must not be allowed near these machines. Teenagers must be

supervised.

10. DO NOT attempt to fix a broken or jammed machine. Notify floor

staff.

11. Use the machine only for the intended use. Obtain instruction and

DO NOT modify the machines.

12. Load plates evenly and carefully to avoid tipping equipment and

possible crushing injuries.

13. DO NOT use if guards are missing or damaged.

14. USE A SPOTTER.

15. DO NOT add incremental weights, except those provided by the

STAR TRAC STRENGTHTM.

16. MAINTAIN LABELS AND NAMEPLATES: Do not remove

labels for any reason. They contain important information. If

unreadable or missing, contact STAR TRAC STRENGTHTM for a

replacement. See Chapter ( 6 ) for part numbers.

17. SECURING EQUIPMENT: All STAR TRAC STRENGTHTM

equipment MUST be secured to the floor to stabilize and eliminate

rocking or tipping over. This must be performed by a licensed

contractor. DO NOT use the weight equipment if it is not set up and

located on a solid level surface.

18. Make sure that each machine is set up and operated on a solid level

surface. DO NOT install equipment on an uneven surface.

NOTE: Use fasteners having a minimum of 500 lbs. tensile capacity

NOTE: If legs/frame does not contact surface, DO NOT pull down

19. MAINTAIN ALL EQUIPMENT: Preventative maintenance is the

key to smooth operating equipment as well as keeping your liability to

(3/8" grade 2 bolts or better).

with anchors. Shim any leg or frame not in contact with

surface using flat washers.

3

a minimum. Inspect the STAR TRAC STRENGTHTM equipment

prior to use. DO NOT use if damaged or inoperable.

20. Ensure that any person(s) making adjustments or performing maintenance

or repair of any kind is qualified to do so.

21. Routinely inspect all accessory clips that join attachments to the cables

and replace at the first sign of wear.

22. Use only weight selector pins supplied by STAR TRAC

STRENGTHTM on weight stacks. Substitutes are forbidden.

23. Cables and belts pose an extreme liability if used when frayed. Always

replace any cable or belt at first sign of wear (consult STAR TRAC

STRENGTHTM if uncertain).

24. Fully insert weight selector pins. Partial insertion can cause weights to fall

unexpectedly. Never remove selector pin if any weights are suspended.

Never attempt to release jammed weights or parts.

25. DO NOT use Lat Pulldown Bars on Multi-jungle Crossover cable

systems or any other pulley systems. These bars are designed for lat

pulldown machines only. If improperly used, the Lat Bar because of its

weight could fall unexpectedly striking the user when weight selector

pin is pulled.

26. Lat Pulldown Machines pose a danger if used with worn or damaged

cables and connecting links. User can be struck in the head if the cable

or related parts break during use.

27. When adjusting any seat, knee hold down pad, range of motion limiter,

foothold pad or any other type of adjuster, make certain that the

adjusting pin is fully engaged in the hole to avoid injury.

28. It is the purchaser's sole responsibility to properly instruct its end users

and supervising personnel as to the proper operating procedures of all

STAR TRAC STRENGTHTM equipment. It is recommended that the

end users physical condition be evaluated prior to beginning any

exercise program.

29. Perform regular maintenance checks on the STAR TRAC

STRENGTHTM equipment. Also, pay close attention to all areas most

susceptible to wear.

30. Keep a repair log of all maintenance activities.

4

L

31. Immediately replace worn or damaged components. If unable to

immediately replace worn or damaged components then remove the

STAR TRAC STRENGTHTM piece of equipment from service until

the repair is made.

32. Make sure that all users are properly trained on how to use the STAR

TRAC STRENGTHTM equipment.

33. Make sure there is enough room for safe access and operation of the

STAR TRAC STRENGTHTM equipment.

34. Never operate the Equipment with bare feet.

35. Use only STAR TRAC STRENGTHTM supplied components to

maintain/repair the STAR TRAC STRENGTHTM equipment.

36. UNDERSTANDING EACH AND EVERY WARNING TO

THE FULLEST IS IMPORTANT. IF ANY OF THESE

WARNINGS ARE UNCLEAR, ASK FOR CLARIFICATION

FROM STAR TRAC STRENGTHTM PERSONNEL.

NOTE: It is the sole responsibility of the user/owner or facility operator to

ensure that regular maintenance is performed.

Exercise Guidelines

ike most exercise, strength training involves an element of risk. Utilize this

information to assist you and/or your members in making the experience

on STAR TRAC STRENGTHTM both productive and safe.

Prior to engaging in any strength-training program, individuals with known health

conditions and/or individuals whom are unfamiliar with the risk(s) involved with

weight training, should first consult with a physician.

All training sessions should be supervised by trained personnel.

Be certain that the warning stickers affixed on STAR TRAC STRENGTHTM,

remain on the product and unaltered. Also, be certain that all the stickers (safety,

instructional and/or other) are read and understood by each user.

5

All users should be instructed on the proper use of STAR TRAC STRENGTHTM

as well as those actions that should be avoided.

Each STAR TRAC STRENGTHTM machine has factored in adjustments to

accommodate for a wide variety of body types. Prior to use, enter a machine and

set up alignment respective to axis of rotation/anatomical joint and/or arm, leg or

torso length. This is also to include stabilizers, which can be in the form of rollers,

flat pads, or seatbelts.

In an attempt to minimize user and/or bystander injury:

§ Do not lean against framework, weight stack or any component

whether it is dynamic or static.

§ Stay clear of any components while in a dynamic state of motion.

Keep hands and feet away from cables, belts, cams and pulleys and/or

any converging action. The convergence of these transmission-based

components can cause serious injury.

§ Exercising on free weight and selectorized products should be

performed with the assistance of a spotter.

Product Maintenance and Use

Repair of any STAR TRAC STRENGTHTM equipment should be performed only

by those persons authorized by the club.

Never modify any STAR TRAC STRENGTHTM equipment nor attempt to make

adjustment(s) to or the repair of any STAR TRAC STRENGTHTM equipment

without first calling STAR TRAC STRENGTHTM. Always notify someone

authorized to make such repair.

Instruct users to report any equipment or training irregularities to supervisory

personnel immediately.

CAUTION: Do not “high pin” and/or “double pin” a weight stack. This action

is considered to be dangerous to users, by-standers and may damage your STAR

TRAC STRENGTHTM equipment. Aside from the mechanical damage that may

result, such action(s) in part, may cause weight stack to crush or pinch fingers,

6

hands and/or extremities. Do not use machine if top plate is elevated and/or

pinned in a raised position. Seek assistance from someone authorized to fix

and/or repair such condition.

7

Chapter

Installation Instructions

Securing Equipment in Installation

All STAR TRAC STRENGTHTM equipment MUST be secured to the floor to

stabilize and eliminate rocking or tipping over. This must be performed by a

licensed contractor.

Prior to installation, make sure that each machine is to be set up and operated

on a solid level surface. DO NOT install equipment on an uneven surface

or use on an uneven surface.

NOTE: Use fasteners having a minimum of 500 lbs. tensile capacity (3/8"

grade 2 bolts or better).

NOTE: If legs/frame does not contact surface, DO NOT pull down with

anchors. Shim any leg or frame not in contact with surface using flat

washers.

Figure 1. Example of shimming to stabilize frame.

8

Chapter

Assembly and Operational

Instructions

Abdominal

• No assembly required

To adjust seat height, depress

lever and slide assembly.

9

Abductor

• No assembly required

Adductor

• No assembly required

10

Biceps Curl

• No assembly required

Unilateral Biceps Curl

• No assembly required

To adjust seat height depress

lever and slide assembly.

11

Chin/Dip Assist

• No assembly required

12

Deltoid Raise

• No assembly required

To adjust seat height, depress

lever and slide assembly.

Rear Deltoid /Pec Fly

• No assembly required

13

To adjust seat pad height,

depress lever and slide

Glute Machine

• No assembly required

assembly.

To adjust waist pad height,

depress lever and slide

assembly.

14

Incline Chest

• No assembly required

To adjust seat height,

depress lever and slide

assembly.

15

Kneeling Leg Curl

• No assembly required

Lat Pull Down

• No assembly required

To adjust Thigh Pad height pull knob and

position pad

16

Lat Pull Down (Cable)

• No assembly required

For both Lat Pull Down versions:

To adjust Thigh Pad height pull knob and

position pad

Leg Curl

• No assembly required

17

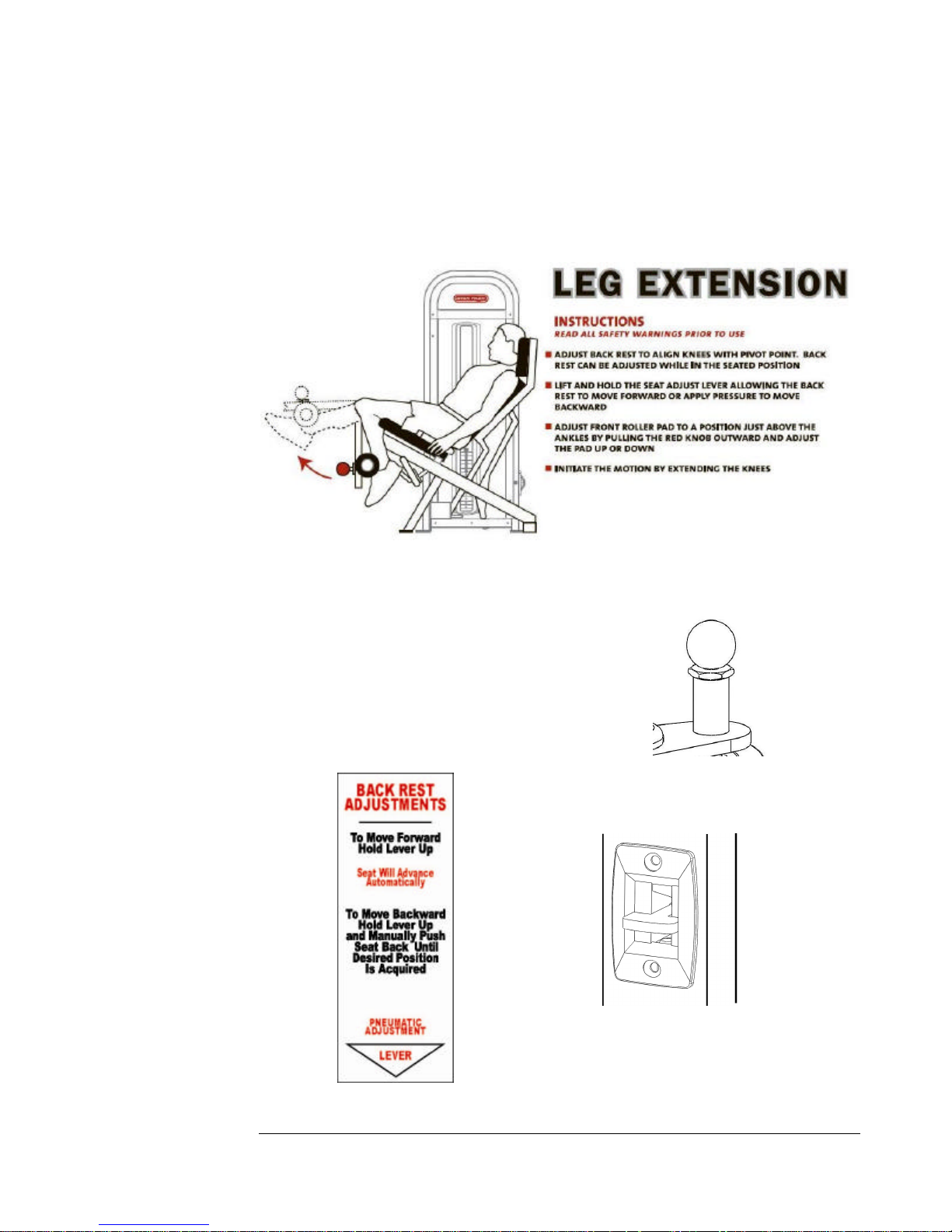

Leg Extension (Center Mount)

• No assembly required

For both the Leg Extension and Leg Curl:

To adjust Roller Pad Position pull knob and

position pad

18

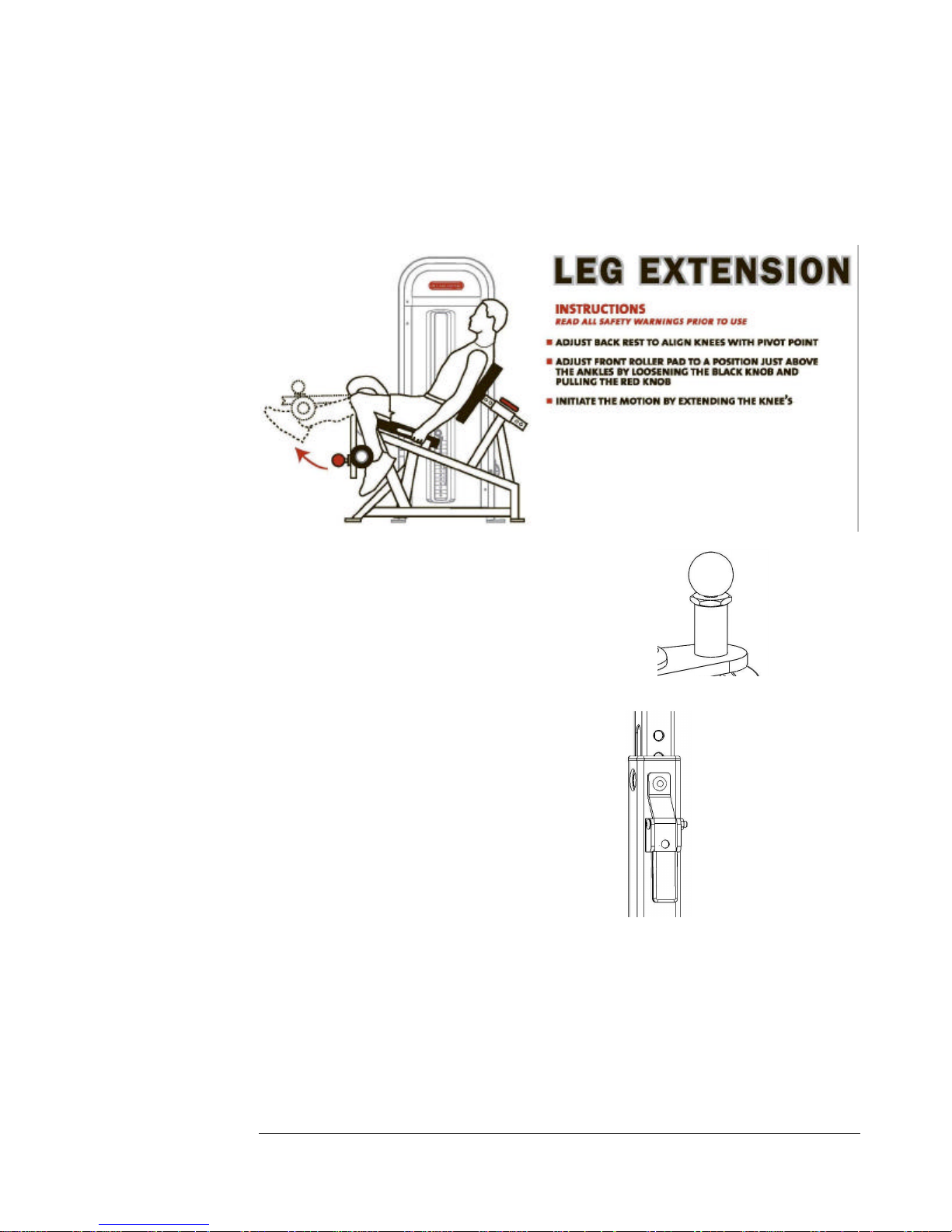

Leg Extension (Side Mount)

• No assembly required

To adjust Roller Pad Position pull knob and

position pad

To adjust Back Rest Pad

depresses lever and slide

assembly.

19

Leg Press

• No assembly required

Low Back

• No assembly required

To adjust Foot Platform pull knob and position

Foot Platform in desired location

20

Low Row

• No assembly required

Overhead Triceps

• No assembly required

To adjust seat height, depress

lever and slide assembly.

21

Pectoral Fly

• No assembly required

Seated Leg Curl

• No assembly required

22

Seated Leg Press

• No assembly required

Shoulder Press

• No assembly required

To adjust seat height, depress

lever and slide assembly.

23

Standing Calf

• No assembly required

Triceps Dip

• No assembly required

To adjust seat height, depress

lever and slide assembly.

24

Triceps Extension

• No assembly required

To adjust seat height depress

lever and slide assembly.

Unilateral Row

• No assembly required

25

Chest Press

• No assembly required

Vertical Row

• No assembly required

26

30° Pectoral Fly

• No assembly required

45° Calf

• No assembly required

27

DAP – Dual Adjustable Pulley

DAP Assembly

28

3 1

2

DAP Warning Stickers:

1. Not a Step (PN: 5220-0027)

2. Assure adjustable handle locking pin is fully engaged before exercising (PN:

5220-0031)

3. Use only authorized attachments shipped with product (PN: 5220-0026)

Adjust Handle/Roller/Pulley Assembly by pulling Red Handle away form guide rod to

disengage Locking Pin, Move assembly up or down the guide rod to desired position

and let go of handle to allow pin to engage hole in guide rod. Assure pin is fully

engaged in hole prior to starting exercise.

29

Chapter

W

Transmission Source

Replacement

Transmission Sources

STAR TRAC STRENGTHTM utilizes several types of transmissions sources; these

sources may include some or all of the following components. Cables, Belts,

Cams, Pulleys, Tie Rods, Flange Bearings, Pillow Blocks and Rod Ends. These

components should be checked and lubricated on a regular bases where applicable.

General Guidelines

orn belts and cables can be dangerous. Unexpected failure of a

transmission source can result in injury to the user and/or by-stander.

It is the responsibility of owner and/or the person managing the

goodwill of the product to frequently inspect transmission source(s) for loose

fittings and/or wear areas. Replace cables and belts at first sign(s) of wear. When

replacing and/or tightening a transmission source, be certain to check that

connection(s) are tight.

The life of any transmission source is conditional to use. Each facility is different

and as a result, STAR TRAC STRENGTHTM cannot “estimate” the life of any one

transmission source. Therefore, this responsibility must be managed at the site of

the facility.

When tightening or changing cables,

termination bolt should never exceed ¾” thread

exposure. This is the inside measurement

between lock nut and head of bolt. Check and

adjust accordingly and be certain that lock nut is

tight. The tool needed for this procedure is a

¾” box wrench.

30

Belts - Fasteners

When tightening or changing belts, there are three securing systems STAR TRAC

STRENGTHTM utilizes which you should be familiar with.

1. Synch Fastener

This is found on all top plates. When changing a belt which connects to a weight

stack, this is normally the first of the two connection sources which you will

tighten and secure. The tool required for this application is the ¼” Allen wrench.

There are two types of Synch Fastener systems on Start Trac Strength Equipment

refer to Appendix A for a description of the two types and Torque specifications

for each.

2. Compression TP Fastener

This is found on all cams and drive systems. When changing any belt, this is

normally the first of two connection sources which you will tighten and secure.

The tool require for this application is the 3/8” Allen wrench.

31

3. Compression Swivel Fastener

This is only found on the termination end for Lat Pull, Low Row and occasional

Triceps pushdown applications. The tool required for this application is the 1/8”

Allen wrench.

4. Compression Cam Fastener

This is found on all cams and drive systems. When changing any belt, this is

normally the first of two connection sources which you will tighten and secure.

The tool require for this application is the 3/16” Allen wrench.

32

Belts - Replacement Procedures

Attaching Belt to Top Plate (Synch Fastener)

1. Belt clamp must first be removed. To do so, loosen Allen head bolt on

top of Synch Fastener and back out only far enough so belt clamp may

be removed. (It is not necessary to remove this bolt).

2. Once belt clamp insert has been removed, slide belt through slot in

Synch Fastener.

3. Allow belt end to surface approximately 1” above Synch Fastener.

Hold the end of belt and push down on opposing side of belt so belt

will lay flat against bottom of belt clamp.

4. Note machined female receptacle in belt clamp insert. This receptacle

must be aligned vertically and on center of Synch Fastener so that Allen

head bolt may be properly seated.

5. Once in place, be certain to keep belt straight while tightening Allen

head bolt into belt clamp insert. (Refer to Appendix A “Synch

Fastener Torque Specs,” for detailed instructions.)

Note: Misalignment of belt may bias the top plate, which can cause center post to

abrade (clanging) weight plates below, causing center post and top plate to not

properly seat. This result poses the possibility of injury to user and/or by-stander

to exist.

Attaching Belt to Swivel Appliance (Compression Swivel Fastener)

1) With ¼” shoulder bolt removed, take end of belt and measure 2 and

½” and fold belt 180 degrees. The belt utilized for Lat Pulls and Low

Rows is a composition of multi layered nylon and will be difficult to

33

fold. Utilizing a blow dryer to temporarily soften nylon will help to

achieve end result.

2) With belt at 180 degrees, insert belt into swivel casing pushing loop

slightly beyond the ¼” hole and insert ¼” shoulder bolt.

3) With 3/16” Allen wrench, tighten shoulder bolt into casing.

Remember to tighten lock nut against shoulder bolt.

4) Locate sleeve bolt holes and insert both compression sleeves on either

side of belt making sure to align compression sleeves with bolt holes.

5) Insert ¼” tightening sleeve

bolts on either side of swivel

casing and begin to tighten.

Belt must remain on center of

swivel casing therefore,

tightening of bolts must

alternate back and forth until

each bolt has reached 200 inch

pounds. Do not tighten in a

circular manner.

Attaching Belt to Drive Systems (Compression Fastener)

1) Loosen the 3/8” Allen head bolt so that the compression clamp will

able to move freely.

2) Wrap belt around inner barrel so that the end of the belt is between the

cam and the outer belt.

3) Place clamp over belt and tighten. Tighten 3/8” Allen to

approximately 320 inch pounds.

3/8” Allen

Clamp

Belt Barrel

34

Belts - Installation

Observe the three types of belt clamps used on the STAR TRAC STRENGTHTM

in your facility as well as the cable applications and familiarize yourself with the

type(s) you will be working with.

Review all routing and belt clamps for the machine you are working on.

First, remove old belt, once removed, sandwich old belt to new example belt to

establish actual length belt needed by trimming off excess. Belt can be trimmed

by using commercial grade scissors or utility knife.

Once trimmed to desired length, route the new belt and begin securing process to

fasteners. Note: Route the belt as shown in the appropriate belt routing diagram.

Securing belt will vary depending upon application of transmission source.

Cables

There are four types of applications in which STAR TRAC STRENGTHTM

products utilize cables as a transmission source.

Type 1. Terminal / Swedge Fitting

Double Termination Smith Cable

When changing cable(s) on the STAR TRAC STRENGTHTM Smith Machine, first

and after removing old cable, take one end of (terminated) cable, place one drop

of Loctite onto threads and begin to tighten (clockwise) bolt into counter balance

(CB) until tight. This will require one ½” open-end wrench. Next, securely place

Olympic bar onto third hook (from top). Following this, with adjustable “Vice

Grips” establish setting on tool that will firmly lock grips around the 5/8” O.D.

vertical shafting which allows C.B. to travel. Once the setting for Vice Grip has

been set, lift C.B. 19” from inside of frame to bottom of C.B., place Vice Grip

underneath C.B. and clamp securely. Should Vice Grip not be tight enough, C.B.

may drop therefore; keep hands and feet from underneath C.B. Next, run cable

up and around the two overhead 4” pulleys and down to bearing assembly where

you will terminate end of cable by tightening cable into Smith Machine bearing

assembly. As with other termination end, before tightening, place one drop of

Loctite onto threads and then commence to tighten bolt head. Lastly, with both

cable ends secure, raise bar enough to clear hooks make sure cable is seated in

35

both overhead pulleys and then, slowly allow Olympic bar to descend and lock

onto next lower setting. By doing so, this process will raise C.B. at which point

you can unlock Vice Grip from shaft.

Triceps Pushdown Station(s)

Take termination end of cable and thread (push in and over) it through upper

pulley and down to weight stack. Before threading into center post, make sure

lock nut is at least, ½” above end of termination bolt. Then, place one drop of

blue “Loctite” on end of the threads of termination bolt. Clockwise, screw

termination bolt into center post. By pre measuring lock nut, you will be assured

that termination bolt has seated at least, ½” inside center post. Lastly, tighten lock

nut (turn clockwise) against center post. In addition to the “Loctite” by

tightening lock nut against center post will help to keep termination bolt from

loosening. Be certain that cable is properly seated in groove of upper pulley and

that cable hangs vertically without signs of bias or entanglement.

Adjustable Cross Over Cable(s)

Take termination end of cable and thread between pulleys (adjustable housing),

down and around low pulley to adjacent pulley residing directly under weight

stack. Next, bring cable up to high pulley thread (180 degrees) around and then

down to thread (180 degrees) around pulley residing on top plate, back up to

second high pulley where again, you will thread (180 degrees) cable around and

down into mounting plate on adjustable housing. When tightening termination

end, it will require an examination of cable tautness. Cable should deflect

approximately 1” +/- from center without raising top plate. To tighten, place

tightening nut at top of termination so that proper adjustment can be established.

Next, push termination end into hole of mounting plate until satisfactory cable

tautness has been achieved. Next, spin down tightening nut until it rests on

mounting plate. Lastly, with 3/8” open end wrench, secure termination end and

36

begin screwing ½” lock nut (will require ½” box wrench) onto termination thread

ends and begin tightening. When tight, keep box wrench on nylon locking nut

and take an open end ½” wrench and tighten down lock nut. When complete,

once again check for cable tautness. Should the cable be too tight, top plate may

rise above 2nd plate which will not allow weight stack pin to properly seat making

weight stack inoperative.

Low Swivel Station(s)

Take termination end of cable and thread under low pulley (between pulley and

guard) and follow around and continue pulling cable up to upper pulley and thread

cable through and around and down, to weight stack. Before threading into center

post, make sure lock nut is at least ½” above end of termination bolt. Then, place

one drop of blue “Loctite” on end of threads of termination bolt. Clockwise,

screw termination bolt into center post. By pre measuring lock nut, you will be

assured that termination bolt has seated at least, ½” inside center post. Lastly,

tighten lock nut (turn clockwise) against center post. In addition to the “Loctite”

by tightening lock nut against center post will help to keep termination bolt from

loosening. Be certain that cable is properly seated in groove of both pulleys and

that cable hangs vertically without signs of bias or entanglement.

37

SET SCREW

Cross Over Cables (Non Adjustable)

Like the STAR TRAC STRENGTHTM adjustable Cross Over Cables, this cable also

has a termination and swedged loop end. The termination end once threaded through

the pulleys, will also receive a loop end however, for assembly and/or replacement

reasons, it has been manufactured and designed with a termination end. First,

straighten cable to reduce bias in the cable. Take termination end and feed through

lower pulley continue up and behind weight stack shroud and up to high pulley (as

shown in diagram) then, reverse direction 180 degrees back down to pulley on weight

stack (as shown in diagram) and again, reverse direction 180 degrees to upper swivel

pulley and feed through and around. With selector (weight stack) pin unengaged, grasp

cable termination end and feed rubber ball through. Next, screw on lock nut against

rubber ball and place one drop of Loctite onto end of thread. Once this is done,

screw on cast swedge fitting (loop end) until end of fitting clears 1/8” pilot hole at end

of termination bolt. Use 9/16” open-end wrench to lock down lock nut against

swedge fitting. So that these appliances may be properly tightened, it will be necessary

to secure swedge fitting with either Vice Grips or screwdriver (as shown in diagram).

Once tight, feed cotter pin through pilot hole and wishbone ends. Upon completion,

inspect cable to insure it is properly seated inside groove of all pulleys and free of any

encumbrances.

38

Chapter

Frame and Upholstery

Management

Framework Maintenance

All STAR TRAC STRENGTHTM frameworks should be wiped down on a daily

basis. By doing so, it will not only improve the longevity of your finish(s) but aid

in identifying fatigue cracks in a frame or component, loose bolts, worn cables or

belts and other area’s which may require attention.

Frames and components can be wiped down with a damp cloth daily. Every three

to four months, utilize an easy application car wax. This (wax) protection may

preserve the powder coating from premature rusting due to corrosives found in

perspiration and allow loose particles to be more easily removed when simply

wiping your product down with a damp cloth. Do not use lacquer thinner,

acetone and/or other solvents. These chemicals will dull and possess agents

which may remove the epoxy based powder from the frame.

To repair a scratch or chip on a frame or component, first determine the severity

of the damage. Some scratches can be removed with an automotive rubbing

compound. A scratch which is too deep to rub out, like a chip, can be filled with a

“touch-up” bottle from the STAR TRAC STRENGTHTM parts department.

Typically, solid colors are the easiest to repair in contrast to textured powders. To

touch-up, you will need a color-matched paint from the STAR TRAC

STRENGTHTM parts department. Fill area in sparingly. Two coats are better than

one heavy coat. Once area is dried, aesthetic choices as to its finishing are

optional. The repair can stand-alone or, efforts to blend and color sand the repair

can be attempted. This process is a difficult one and should be practiced by

someone knowledgeable in this field.

39

Upholstery Maintenance

Due to corrosive agents in perspiration, upholstery should be cleaned daily with a

10% diluted consistency of lanolin hand cleaner in warm water. Do not use

products such as Lysol, Armoral, Windex or other abrasive detergents as they

will dry out and eventually cause Naugahyde to prematurely crack. When

cleaning upholstery, wipe down top and sides with solution and follow up with a

dry towel to remove residue(s).

Replacing upholstery pad(s) and protective wear guard(s): To replace or remove

any STAR TRAC STRENGTHTM upholstery pads will require a single 5/16” box

or socket head wrench and flat blade screw driver.

For those pads which incorporate the (black sheathed) corrosive resistant cap, take

flat blade screwdriver and wedge blade underneath cap and twist. This action will

remove cap and expose ½” bolt assembly. Next, loosen and remove all bolts

which secure pad to frame assembly. Each bolt is accompanied by one sae washer

and “retainer clip.”

Replacement of upholstery pads is just as simple. Line pad up with hole(s) in

frame and begin hand tightening one at time until all bolts are snug. Before

tightening, check that pad is properly positioned (linear to frame work), and begin

tightening bolts. Once tightened, replace corrosive cap(s).

For those upholstery applications which involve a protective wear guard, the

application of removal and assembly is the same.

40

Chapter

Warranty Information

Warranty & Disclaimer.

STAR TRAC STRENGTHTM warrants all frameworks for a period of

10 years. All moving parts are warranted for 1 year. 10 year limited

warranty on structural frame not including coatings. 90 days on

upholstery stitching only, cables and belts. Warranty is for parts only.

Warranty is good and available to the original purchaser only as noted

by STAR TRAC STRENGTHTM invoice and is not transferable nor

assumable. STAR TRAC STRENGTHTM cannot warrant products

that have been abused, neglected and or poorly maintained. All

equipment should be reviewed at the time of delivery for damage,

breakage, loosening of nuts and bolts, components and or any other

moving parts. Any and all claims for warranty must be received in

writing within 70 days of defect. Do not alter, modify or redesign any

STAR TRAC STRENGTHTM products or use any replacement parts

or materials other that those components original to STAR TRAC

STRENGTHTM as it will limit the warranty and liability of STAR TRAC

STRENGTHTM. STAR TRAC STRENGTHTM reserves the right to

change, replace or modify products, parts, accessories and or design

without notice. Deposits on cancelled orders will be subject to handling

and restocking charges.

WHAT IS COVERED

This STAR TRAC STRENGTHTM commercial exercise equipment (Product.) is

warranted to be free of all defects in material and workmanship.

WHO IS COVERED

The original purchaser or any person receiving the Product as a gift from the

original purchaser.

41

WHO PAYS TRANSPORTATION & INSURANCE FOR SERVICE

If the Product or any covered part must be returned to a service facility for repairs,

We, STAR TRAC STRENGTHTM, will pay all transportation and insurance

charges for the first year. You are responsible for transportation and insurance

charges for all subsequent years.

WHAT WE WILL DO TO CORRECT COVERED DEFECTS

We will ship to you any new or rebuilt replacement part or component, or, at our

option, replace the Product. Such replacement parts are warranted for the remaining

portion of the original warranty period.

WHAT IS NOT COVERED

Any failures or damage caused by unauthorized service, misuse, accident,

negligence, improper assembly or installation, debris resulting from any

construction activities in the Products environment, rust or corrosion as a result of

the Product(s) location, alterations or modifications without our written

authorization or by failure on your part to use, operate and maintain the Product

as set out in your Owners Manual.

OWNERS MANUAL

It is VERY IMPORTANT THAT YOU READ THIS MANUAL before

operating the Product. Remember to perform the periodic maintenance requirements

specified in the Manual to assure proper operation and your continued satisfaction.

How to Get Parts & Service

Simply call Customer Support at (800) 503-1221 or visit us on the web at:

http://support.startrac.com/Services

Before shipping:

1. Obtain a Return Authorization Number (RMA#) from Customer

Support Services

2. Securely pack your Product (use the original shipping carton, if

possible)

3. Write the RMA# on the outside of the carton

4. Insure the Product, and

42

5. Include a letter explaining the defect or problem and a copy of your

proof of purchase if you believe the service is covered by warranty

EXCLUSIVE WARRANTY

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES

OF ANY KIND EITHER EXPRESSED OR IMPLIED, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART. We

neither assume nor authorize any person to assure for us any other obligation or

liability concerning the sale of this Product. Under no circumstances shall we be

liable under this warranty, or otherwise, of any damage to any person or property,

including any lost profits or lost savings, for any special, indirect, secondary,

incidental or consequential damages of any nature arising out of the use of or

inability to use this Product. Some states do not allow the exclusion or limitation

of implied warranties or of liability for incidental or consequential damages, so the

above limitations or exclusions may not apply to you.

CHANGES IN WARRANTY NOT AUTHORIZED

No one is authorized to change, modify or extend the terms of this limited

warranty.

EFFECT OF STATE LAWS

This warranty gives you specific legal rights and you may have other rights, which vary,

from state to state.

OUR PLEDGE TO YOU

Our Products are designed and manufactured to the highest standards.

STAR TRAC STRENGTHTM wants you completely satisfied with our Products

and will do everything possible under the terms of this warranty to keep you

secure in knowing you have bought the best!

43

Chapter

Preventative Maintenance

DAILY

• Clean

o Upholstery with a mild soap and water.

o Guide rods with a cotton cloth and break-free.

o Hand grips with mild soap and water.

• Inspect

o Cables for wear or damage and proper tension (should not

exceed 3/4" deflection). Pay close attention at bends and

attachments points.

o Hardware should be checked for looseness. Tighten as

required using the proper tools.

o Frames should be inspected for wear or damage.

o Handgrips should be checked for wear or damage.

• Perform

o Wipe down upholstery with a mild soap and water or

comparable all purpose cleaner.

o Visually inspect belts and/or cables for wear at and around

connections and along entire length of belt and/or cable.

Always replace at first sign of wear.

44

! WARNING: Replace all worn cables immediately. The following

conditions indicate some types of wear.

Torn or Cracked Cable Sheath that exposes cable

Stretched cable sheath

A Kink in the cable

45

! WARNING: Replace all worn belts immediately. The following

conditions indicate some types of wear.

Belt Tear

Belt Cords Exposed

Edge Wear

46

Attachment Hole

! WARNING: Replace all worn handles immediately. Do Not use if less than

1/8” of material remains on the edge of attachment holes.

WEEKLY

• Visually inspect all hardware for loosening, tampering or wear.

o Refer to Appendix C for DAP Handle instructions

• Check jam nut on weight stack for tightness.

• Inspect all accessory and or carabineer clips or connecting links for wear.

• Check condition of handgrips.

• Check cables for stretch and adjust as necessary by loosening the large nut on top

of the weight stack and screw in the threaded plug until cable is tight and the

weight stack pin goes in all holes easily. Tighten the large nut to complete the

adjustment.

• Lubricate Guide Rods

o Refer to Appendix B for instructions

47

MONTHLY

• Clean Guide Rods with break-free on a cloth and wipe off old residue.

Clean tops of bearings at stack and inspect for heavy buildup on rods

below head plate (lift half of stack and do a visual inspection, then

clean as necessary).

Notes

• Use polishing compound (such as car wax) to clean and remove shoe

scuffs from powder coated surfaces as necessary.

Clean the Shrouds

• The shields on the Platinum Series machines are made from

POLYCARBONATE. Adherence to regular and proper cleaning

procedures is recommended to preserve the appearance.

• Impact are ABS clean with the following

Washing to Minimize Scratches

Wash POLYCARBONATE with a mild soap or detergent (e.g. Original Dawn

Dishwashing Liquid) and lukewarm water using a clean sponge or a soft cloth.

Rinse well with clean water. Dry thoroughly with a chamois or moist cellulose

sponge to prevent water spots. Do not scrub or use brushes on these products.

Fresh paint splashes, grease and smeared glazing compounds can be removed easily

before drying by rubbing lightly with isopropyl. Afterward, a warm final wash

should be made, using a mild soap or detergent solution and ending with a

thorough rinsing with clean water.

Some Important Reminders

• DO NOT use abrasive or highly alkaline cleaners on the shields.

• Never scrape shields with squeegees, razor blades or other sharp

instruments.

• Benzene, gasoline, acetone or carbon tetrachloride should never be used on

the shields.

• DO NOT clean shields in hot sun or at elevated temperatures.

48

Compatible Cleaners for Shields

The following cleaning agents have been found compatible with

POLYCARBONATE. The manufacturer's recommendations and instructions

should be followed. They are Original Dawn, Freon T.F., Palmolive Liquid,

Top Job, and Windex with Ammonia D.

Removal of Paint, Marking Pen, Labels

Butyl cellosolve works well for removal of paints, marking pen inks, lipstick,

etc. Labels, stickers, etc. may be removed using kerosene. When the solvent

will not penetrate sticker material apply heat (hair dryer) to soften the adhesive

and promote removal. GASOLINE SHOULD NOT BE USED.

49

Chapter

Sticker Part Numbers

PN: 5220-0001

8 ½ x ¾

PN: 5220-0002

4 3/8 x ¾

PN: 5220-0003

8 ½ x ¾

PN: 5220-0004

4 3/8 x ¾

50

PN: 5220-0005

3 x 1 ½

PN: 5220-0009

7 x 1 ½

PN: 5220-0010

3 x 1 ½

PN: 5240-0001

1 ½ x 4

51

PN: 5220-0011

5 x 3

PN: 5220-0013

3 x 5

PN: 5240-0002

4 x 1 1/2

52

PN: 5240-0003

2 @ 1 ½ x 6 ea.

PN: 5240-0004

16 x 1 ½

PN: 5240-0005

3/4 x 12

PN: 5240-0006

5/8 CIRCLES

53

PN: 5220-0015

5 x 3

PN: 5220-0017

7 x 1 ½

PN: 5220-0018

7 x 1 ½

PN: 5240-0008

1 ½ x 11

54

PN: 5240-0009

2 @ 1 ½ x 4

PN: 5240-0010

3/8 x 6 ¼

PN: 5240-0011

3/8 x 6 ¼

55

Appendix

Appendix A: Synch Fastener Torque

Specifications

Synch Fasteners using threaded barrels torque specification is 350-400 in-lbs.

56

Synch Fasteners using T-nut torque specification is 125-135 in-lbs.

T-Nut

**It is recommended that the T-nut be replaced after the third time of being retorqued.**

Note: If synch fasteners are not torqued within the recommended specifications

as stated above, damage may occur to the machine which could result in injury to

the user.

57

Appendix B : Guide Rod Lubrications

Procedure

There are two different types of weight stacks: One weight stack type uses the

Lock-N-Load (LNL) technology and has a shorter shroud. The second weight

stack is a typical weight stack that uses a weight pin with bungee cord. Both weight

stacks can be lubricated with ‘3-IN-ONE’ oil that can be applied in the same

manner.

Step 1: Removing Shroud Cover

Remove the shrouds by using the screwdriver (Fig. 1).

Note: Do not use a cordless drill to reinstall shroud. Cracking may occur when

tightening the screws.

Fig. 1 Fig. 2

The shroud in Fig. 2 uses on our LNL technology weight stack. This shroud does

not need to be removed to apply oil to the guide rods. The only time this shroud

needs to be removed would be to tighten or replace the guide rod collars.

Step 2: Inspecting guide rod collars

Once the shroud has been removed, check the guide rods for wear or looseness.

Check the location of the guide rod collars. Adjust them by tightening the two set

screws on each collar.

58

CORRECT INCORRECT

Fig. 3 Fig. 4

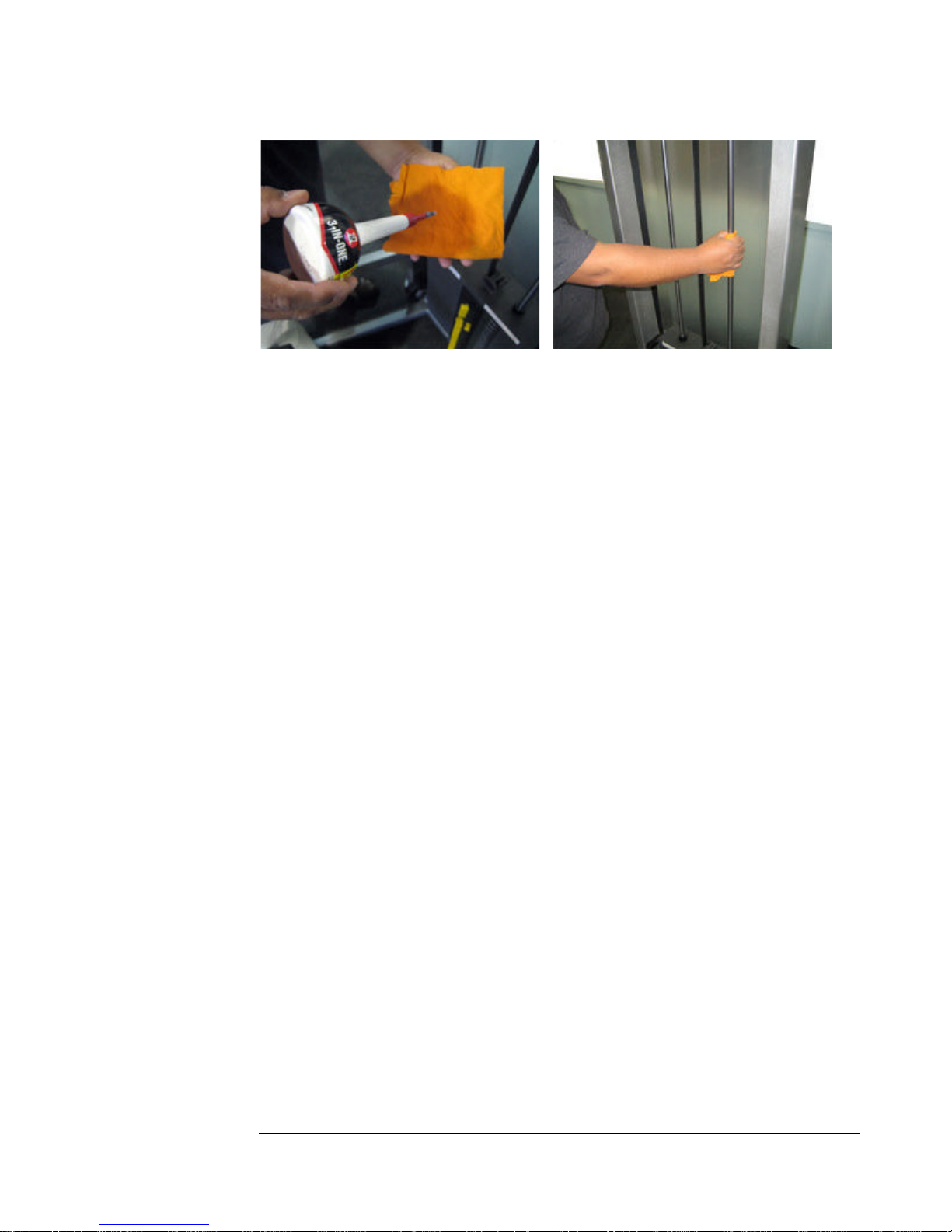

Step 3: Cleaning the guide rods

Apply alcohol directly onto a clean cloth or rag (Fig. 5). Clean each guide rod by

using an up and down motion (Fig. 6).

Fig. 5 Fig. 6

Step 4: Re-lubricating Guide Rods

Apply ‘3-IN-ONE’ oil directly onto a clean towel or rag (Fig. 7). Avoid applying

the oil directly onto the guide rods as excess or over-splashed oil may

contaminate the belts and pulleys which may cause slipping during use.

Apply oil onto guide rods from the towel or rag using an up and down motion

(Fig. 8) making sure the guide rods are oiled all the way around and evenly. Clean

all excess oil that might have spilled or accumulated on the top plate bushing.

Once excess oil has been cleaned, test unit by lifting top plate only.

59

Fig. 7 Fig. 8

Final Step:

Once the Lubricating Guide Rod procedure has been performed and all safety

checks have been performed, replace the shroud by reversing the procedure in

Step 1.

NOTE:

Star Trac does not recommend using Tri-Flow, Graphite, or oils with a graphite

base on the weight plate guide rods. If any of these products have been used in the

past, Star Trac recommends thoroughly cleaning guide rods and re-lubricating

with ‘3-IN-ONE’ oil as soon as possible.

It is recommended to perform this procedure on a weekly basis to ensure peak

performance of your Star Trac StrengthTM product.

60

Appendix C: DAP handle inspection

and tightening procedure

Tools Required

o 5/32” Hex key wrench

o 7/16” Open end wrench

Step 1 - The first step is the inspection of the adjustment handle (Fig.1), this is

performed by grasping the red handle and attempting to wiggle the adjustment

handle. If the adjustment handle feels sloppy or moves side to side excessively

then complete steps 2 - #. If the adjustment handle feels tight and operates

smoothly you are done.

Step 2 - If you find that your adjustment handle has excessive play then you

will need to adjust the rollers found inside your adjustment handles. Using

your 5/32” hex key and 7/16” wrench loosen the two ¼-20” button head

bolts and corresponding ¼-20” acorn nuts (Fig.2, Point A).

Step 3 - Use the head of the recently loosened ¼-20” button head and

corresponding ¼-20” acorn nut to push roller against adjustment tube. Keep

pressure on roller as you retighten the ¼-20” button head bolt and

corresponding acorn nut.

Step 4 - After completing the adjustment of the two rear rollers on both

adjustment handles ensure that all bolts on your adjustment handles are tight.

Now move the adjustment handles up and down the adjustment tubes to

verify smooth operation.

61

Figure 1 Figure 2

IF YOU HAVE ANY QUESTIONS OR CONCERNS

PLEASE CALL CUSTOMER SERVICE @ 1-800-503-1221

62

Loading...

Loading...