Section 1:

Introduction

Welcome to the world of STAR TRAC. In your hands is the STAR TRAC TR 4500 Service Manual.

This manual is designed to be easy to use, providing detailed instructions on how to service and maintain

the TR 4500.

We highly recommend that you read all the applicable sections of the service manual prior to serving the

treadmill. The information on the following pages will enable you to begin easily, quickly, and safely.

Contents

1.1 How to use the Service Manual

1.2 Precautions

1.3 Product Support Assistance

1.4 Tools and Test Equipment

1.5 Treadmill Overview.

1.0

How To Use This Manual

• This Service Manual has been written to assist and instruct the repair technician on key

components for quick and efficient diagnosis of service problems.

• To assist in finding the applicable sections in the Service Manual. Each Section has a table of

contents to help locate specific symptoms and topics. Titles and major headings are located at the

top of every page.

• This manual is to be used strictly as a Maintenance manual for service and repair, not as an

owner’s manual.

• An illustrated Parts List is located at the back of this manual for identifying parts with part

numbers.

• Troubleshooting tables and Error Code Flowcharts are included for certain sections to help

diagnose the system problem and find the root cause.

1.1

Precautions

1. Always make sure that the treadmill is turned off and unplugged before starting any work, unless

otherwise noted, or when necessary for voltage testing.

2. Read each section through for NOTES before starting any work.

3. To pull apart electrical connectors, pull on the connector itself, not the wires.

4. When replacing fuses, be sure the new fuses is the correct amperage rating. Do Not exceed the

fuse amp rating. If necessary use a fuse of lower rating until the proper fuse may be attained.

5. When checking continuity at the wire connector, insert the test probe carefully to prevent the

terminals from bending.

1.2

Product Support Asistance

PRODUCT SUPPORT DEPARTMENT

STAR TRAC Product Support Department sets the industry standard in Customer Service and

Technical Assistance World Wide. Providing superior product support and customer service is at the

very heart of STAR TRAC’s business philosophy. This commitment to service has been a major

contributor to STAR TRAC’s success and growth in the worldwide fitness equipment industry.

Technical Assistance

• When purchasing a part or requesting technical assistance, please contact our Product Support

Department : CALL TOLL-FREE: 1-800-535-4634 or 800-503-1221 US and CANADA or

714-669-1660

• When placing the call, please have the following information available:

1. STAR TRAC model.

2. STAR TRAC serial number

3. Problem statement / symptom.

After Hours Voicemail Direct

• CALL TOLL-FREE: 1-800-486-4736

• When placing the call, please have the following information available:

1. STAR TRAC model.

2. STAR TRAC serial number

3. Problem statement / symptom.

4. Return phone number and contact name.

Fax Requests

• Domestic and International: Fax 714-669-0739

• When placing the fax, please supply the following information:

1. STAR TRAC model.

2. STAR TRAC serial number

3. Problem statement / symptom.

4. Return phone fax number and contact name.

5. Purchase order or reference number.

6. Part description and quantity.

7. Ship to/bill to.

Product Support Documentation Access

• Web page http://www.startrac.com/support/

• Docufacts CALL TOLL FREE 1-800-429-3228 ext. 640 US and Canada or 714-253-3878 for a list

Product Support Procedures and Bulletins.

1.3

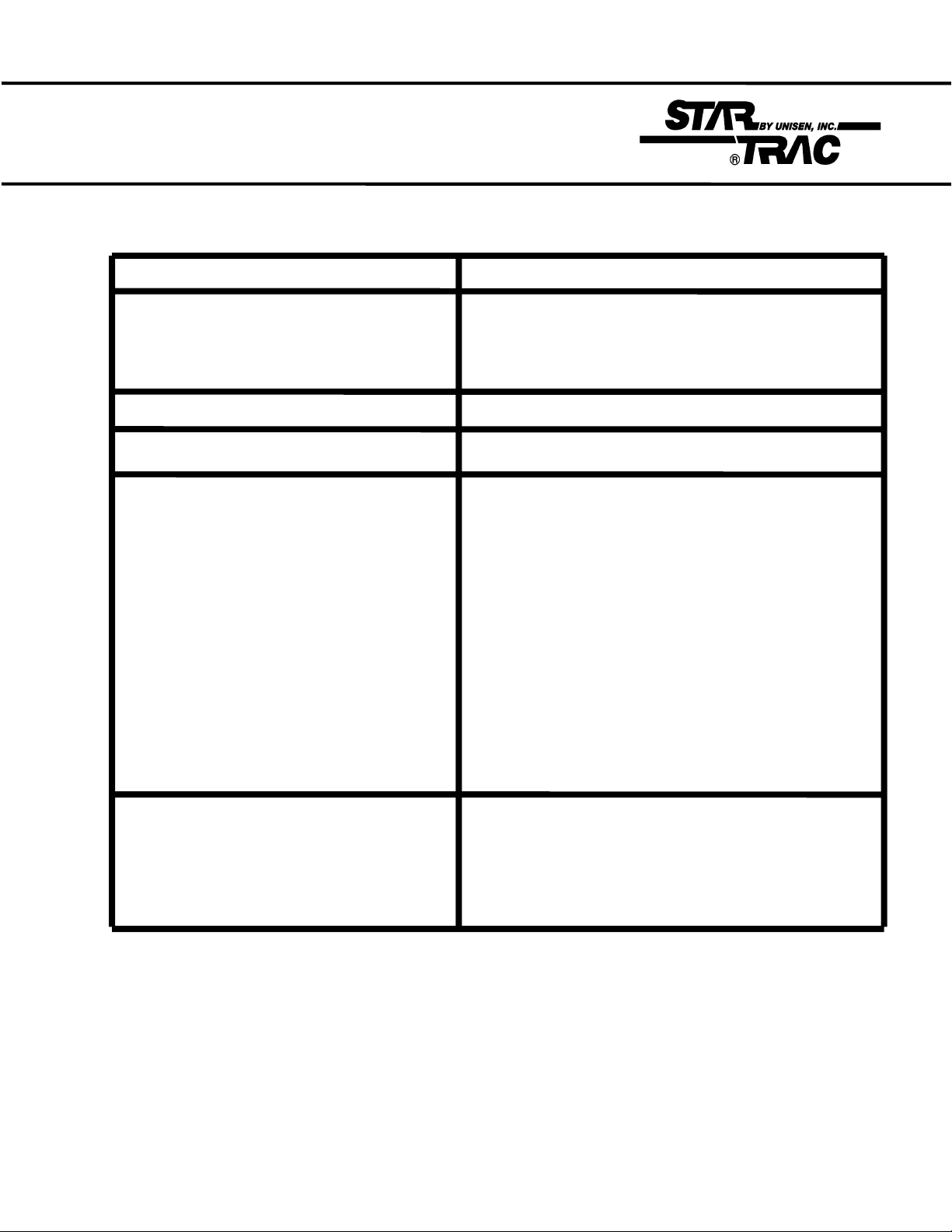

Tools and Equipment

Equipment Function

Philips Head Screwdriver #2 Shroud

Motor Control Board Assembly

Side Bed Cover and End Caps

Auto-Transformer

Small Slotted Screwdriver 3/32” Motor Control Potentiometers (MAX SPD) & (IRCOMP)

Bungee Cord 28” Suspend Motor Shroud on Display Rail

5/32” Hex Allen key Handrail assembly

5/64” Hex Allen key Display Board set screws

1/8” Hex Allen key Display Assembly

1/4” Hex Allen key Running Belt

Head Roller

Tail Roller

5/16” Wrench or Nut Driver Drive Motor Bolts

9/64” Allen Wrench Elevation Motor

17-mm Socket Wrench

Multi-meter Voltage Checks

Continuity / OHM ΩChecks

1.4

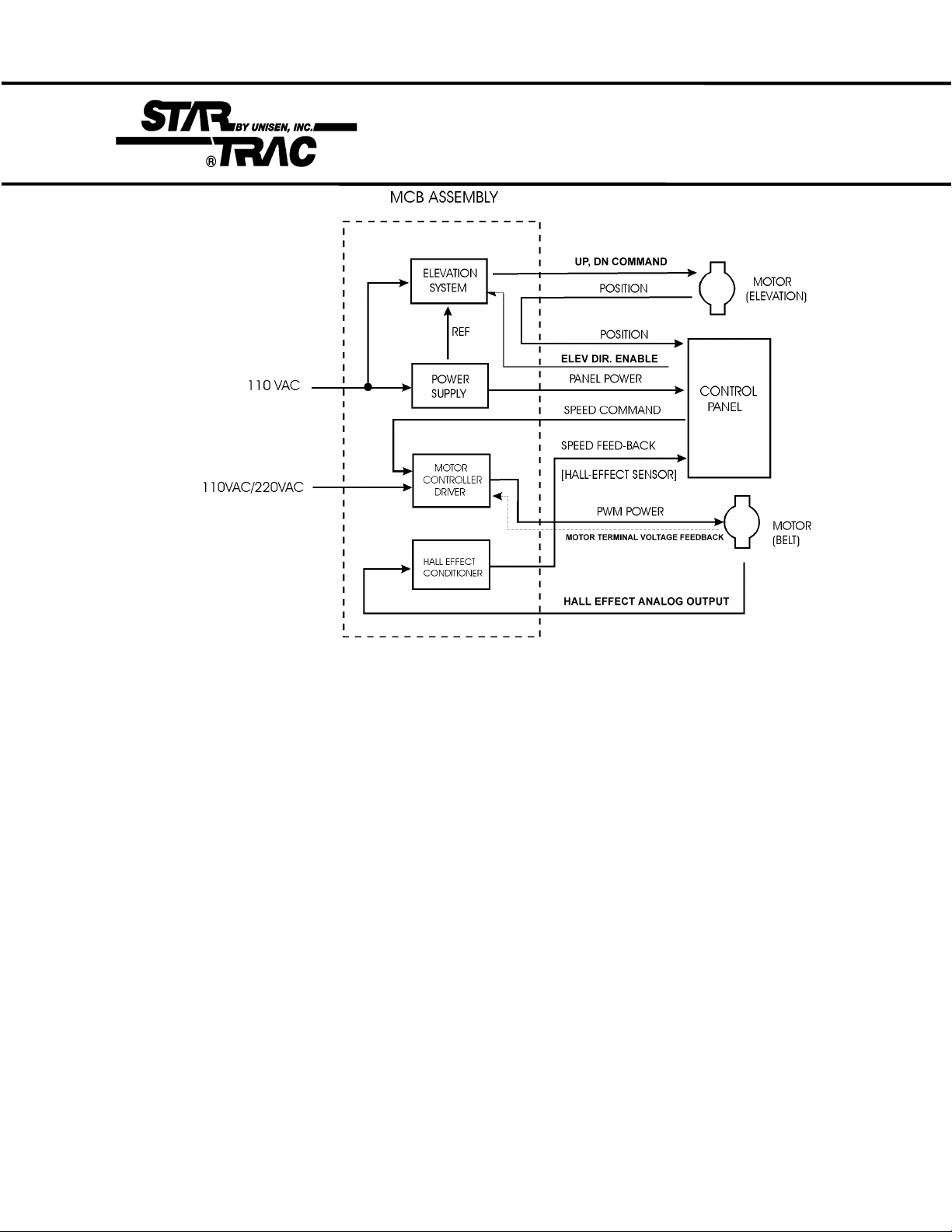

Treadmill Overview

• DC POWER SUPPLY

The MCB provides power to the display assembly. Establishes a reference voltage

and potentiameter position from the elevation motor

• RUNNING BELT MOTOR DRIVE CONTROL

Takes Alternating Current and converts it to Pulse Width Modulation

(PWM) to power the Drive Motor.

Motor voltage feedback and control-speed-commands determine the level

of PWM power delivered to the motor.

Motor Control circuits include fault sensing and safety functions.

• TACHOMETER SIGNAL CONDITIONING

The signal from the RPM sensor is fed to signal conditioning circuits on the MCB, where the signal is

converted to a digital output that is utilized by the Display Assembly to indicate belt speed.

• ELEVATION MOTOR CONTROL

The elevation circuit on the MCB receives elevation direction and enable

information from the Display Assembly, using these signals to provide

control to the Elevation Motor. Elevation position information, in turn, is

fed to the Display Assembly to indicate percent of incline.

1.5

Section 2:

Preventive Maintenance

Schedules

Performing regular preventive maintenance on all Star Trac treadmills is strongly recommended. Without

preventive maintenance, normal wear and tear may cause cumulative effects, such as misalignment and

early replacement of parts. This may result in downtime. For this reason, we highly recommend following

the manufacturer’s maintenance schedules.

Contents:

2.1 Preventative Maintenace Chart

2.2 Waxing Procedure

2.0

Preventive Maintenance Chart

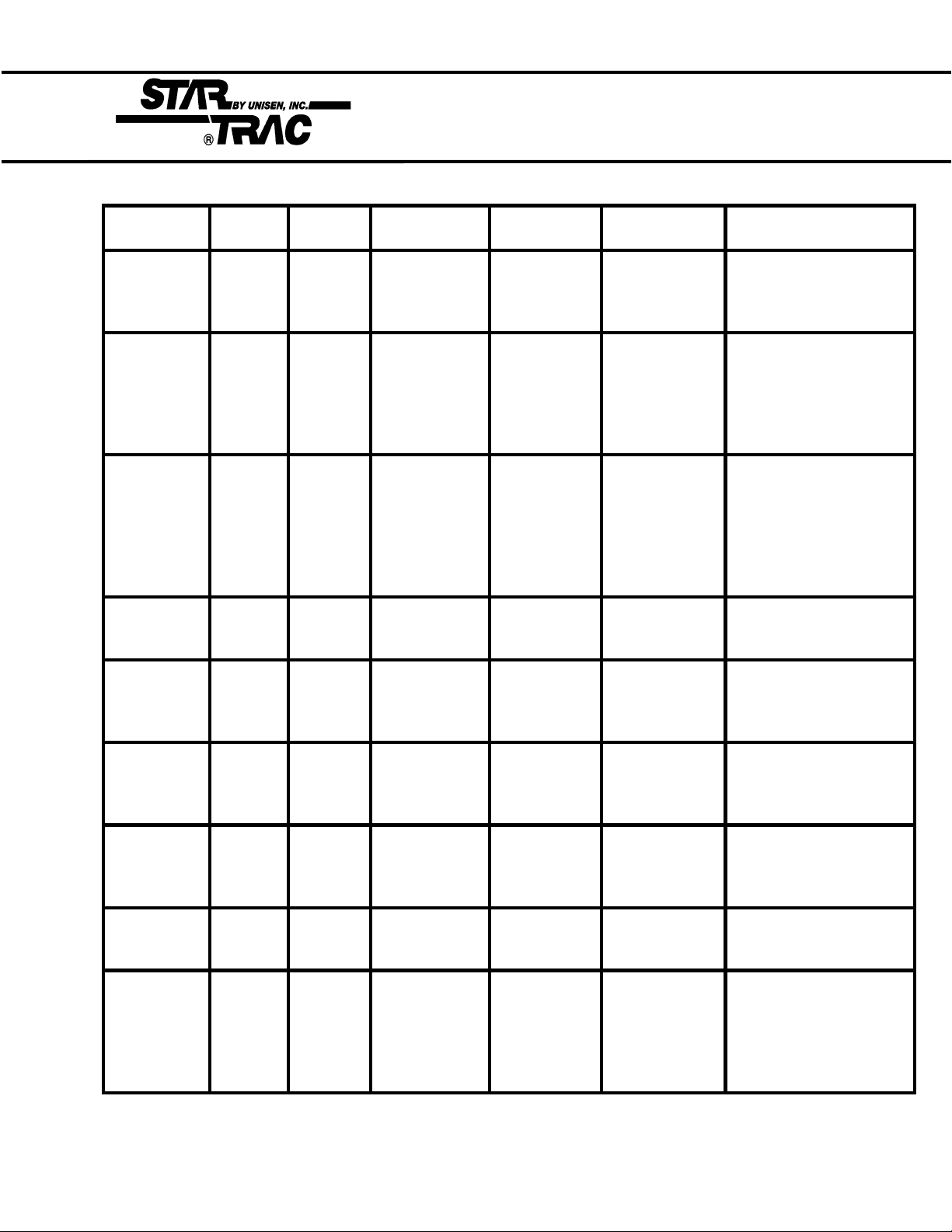

Maintenance Clean Inspect Lubricate Replace

Daily

Weekly

Monthly

Quarterly

Using a liquid

non-abrasive

cleaner, wipe

down the

following:

display board

handrails,

shroud, heart

rate grips.

Note: Do not

spray directly

onto the

display

board or heart

grips.

Elevate the

treadmill and

vacuum under

the unit.

Note: Unplug

the unit when

vacuuming.

Lift the motor

shroud and

vacuum

around the

motor and

electronics.

Clean and lubricate the elevtion screws.

Note: This

must be done

with the unit

unplugged and

turned off.

Inspect for wear

and tear on exterior parts

regularly,

especially under

the running belt.

Inspect the linecord plug and

cord for possible

damage or loose

connection.

Verify running

belt alignment

and tension.

Inspect the area

under the

treadmill for

obstructions.

Inspect the

display and

handrail screws

for loosening.

Inspect the

display panel

keys for wear.

Using a silicone

spray lubricate

the elevation

screws, while

the unit is

elevated.

Note: This must

be done with the

unit

unplugged and

turned off.

Wax the running

belt and deck

using Unisen

powder wax.

2.1

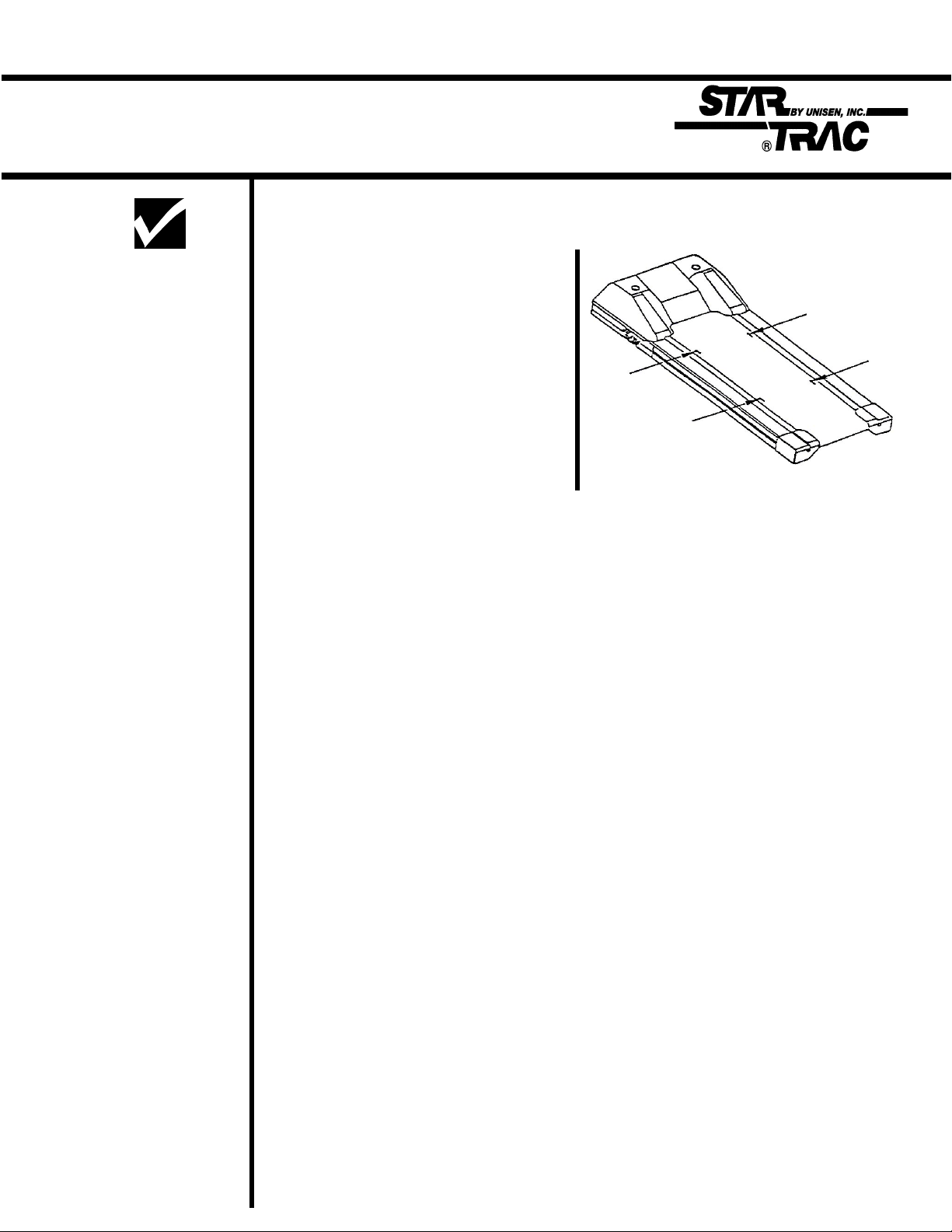

Quarterly Waxing

The treadmill is designed with an automatic prompt, which will display RE WAX

across the display screen every 2,000 miles or 3,000 kilometers. The procedure

below explains step-by- step how to apply wax and clear the RE WAX prompt.

Note: Apply wax

powder while

belt and deck are

still warm (from 5

to 15 minutes of

use) for optimum

benefit. The following steps are

done with the

treadmill off.

Time Required:

5 minutes

Tools Required:

1 Wax Powder Bag (Unisen)

Teaspoon

1 Clean Towel

Paint Stick or Yard Stick

Diluted All-purpose Cleaner (409)

Bristle Brush

PROCEDURE

STEP 1: Cleaning the deck and belt:

• Using the stick or ruler, slide a towel under the middle of the running belt from

one side of the frame to the other.

• Hold the edges of the towel, pull from head-roller down to the tailroller, then pull

the belt down to wipe the remaining of the belt. TIP: Careful when removing the

towel, it will be dirty. Fold the dirty towel and shake into trash.

STEP 2: Re-waxing the deck and belt:

• Lift the left side (facing the display) of the belt, about 12 inches down from the

motor shroud (see above figure). Hold the belt up such that the width of the belt

is elevated from the deck.

• Gently place one level teaspoon of wax powder on the deck about two inches

from the edge, and blow the wax steadily under the belt, so that the wax powder

is spread evenly across the deck (see above figure). Gently place a second

level teaspoon of wax 18 inches down the belt.

• Repeat the above step to the right side of the belt and deck.

Note: Blow away

extra wax first

from around the

siderails and

deck before wiping.

Note: The RE

WAX prompt may

be cleared either

in “Settings or

Configure Mode”.

STEP 3: Walking the wax in:

• Start the treadmill at 1 mph and walk on all sections of the belt and deck for 1

minute to ensure the wax has been evenly distributed and worked-in properly.

STEP 4: Clean-up:

• Remove any excess wax with diluted cleaner (409) and towel, or bristle brush.

STEP 5: Clear RE WAX prompt:

• Engage Settings or Configure Modes. Press and hold the “0”, “1” or(2) &

“START” keys down, release the “1” or (2) key only. Display will beep and

display SETTINGS or CONFIGURE momentarily (depending if the 1 or 2 key

was released), then UNITS will be displayed.

• Press the Incline Down Key (elevation) until LSTDCK is displayed. Press and

release the HEART Key, this will automatically transfer the accumulated

miles/kilometers into the LSTDCK, press the ENTER Key to save.

2.2

Section 3:

Diagnostics

The STAR TRAC 4500 Treadmill series contains diagnostic and customizing modes. In these modes

you are able to check accumulated data about the past usage of the treadmill, test its motor and

display controls, and investigate display code messages. For these reasons, your treadmill is equipped

with a ;

• Manager Mode (customize)

• Maintenance Mode (diagnostics)

• Motor Test Mode (diagnostics)

Contents:

3.1 Engaging Manager Mode

3.2 Engaging Maintenance Mode

3.3 Description of parameters

• Display Test Mode (diagnostics)

• Heart Rate Test Mode (diagnostics)

3.8 Engaging Motor Test Mode

3.9 Calibration

3.10 Engaging Display Test Mode

Heart rate test

3.0

Manager Mode

After having used you Star Trac 4500 treadmill for several workouts, you may wish to specially

customize your treadmill by changing some of its settings.

To engage Manager Mode:

1. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together. While holding the “ 0 ” &

“ START ” keys down, release the “ 1 ” key only.

2. The display will beep and display Manager Mode momentarily, then UNITS will be displayed.

Once the treadmill is in Manager Mode, you may use the following keys:

INCLINE KEY: Displays the next or previous parameter.

SPEED KEYS: Allows the variable to be changed within the parameter.

ENTER KEY: Saves the value if changed in the EPROM (software).

Note: ENTER KEY must be pressed, for each value changed.

STOP KEY: Exists Manager Mode and restarts the treadmill with a “warm start.”

0 – 9 KEYS: Enters new parameter values. If UNITS parameter is displayed, key 5

starts DISPLAY TEST and key 8 starts MOTOR TEST.

HEART HEART KEY: When pressed will automatically display manufactures default value.

Note: ENTER KEY must be pressed, to save the default values if changed.

3.1

Manager Mode

The following parameters may be changed using the previous keys:

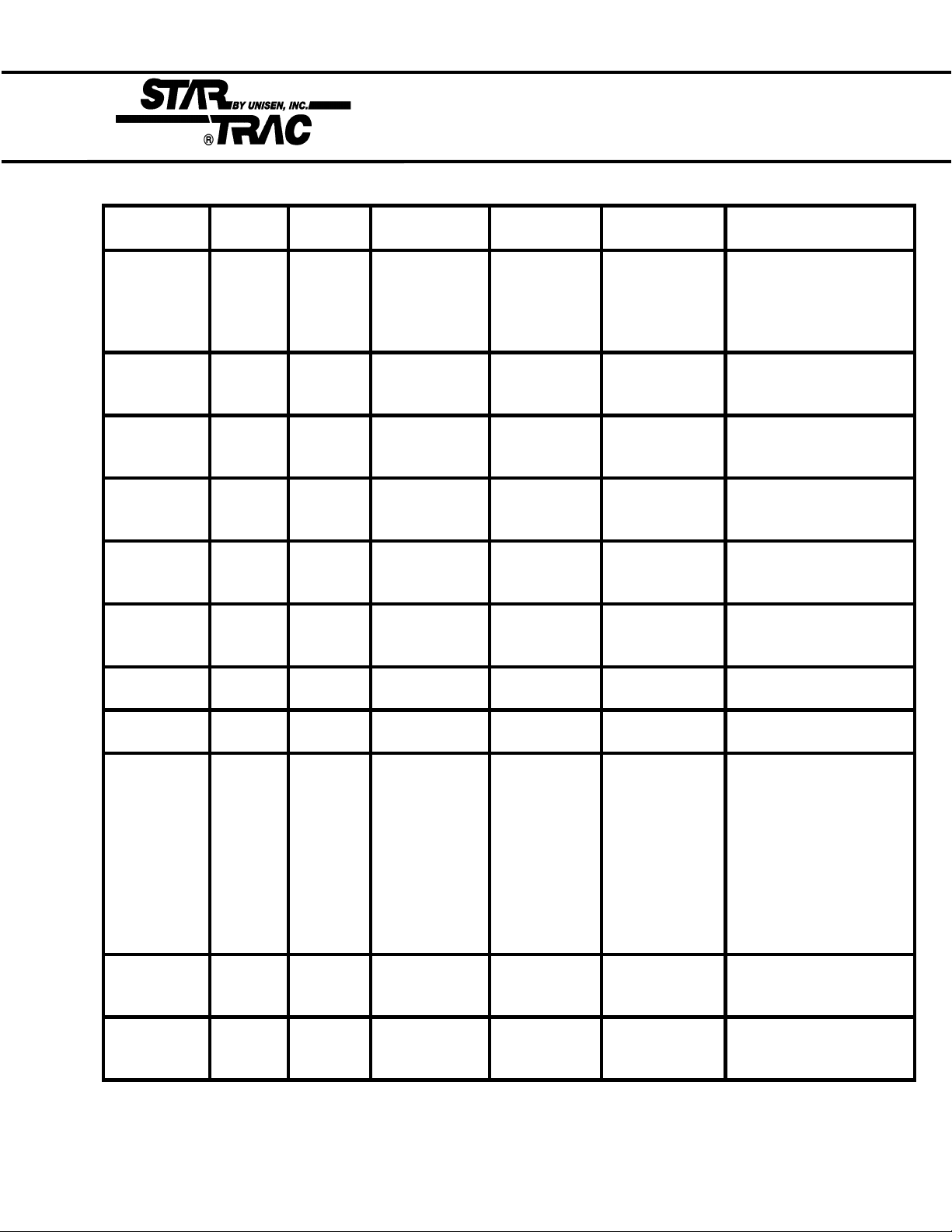

Parameters Lowest

Value

UNITS

MN SPD

MX SPD

EL OPT

TIME

OP HRS

--- --- English Metric English English= units of lbs.,

0.1 2.5 English=0.5 Metric=1.0 0.5 Minimum speed in

5.0 20.0 English=10.0 Metric=20.0 10.0 Maximum speed in

--- --- ON OFF ON Turns the elevation

5 99 99 Maximum time in

0 0 --- --- 6,553.5 Total operating hours

Highest

Value

Option 1 Option 2 Default

Value

Meaning

miles, hours, minutes

Metric= units of kg.,

km, hours, minutes.

MPH or KM/HR

MPH or KM/HR

system ON or OFF.

minutes allowed for

program, including

warm-up/cool-down.

DIST

WEIGHT

SER NO

LANG

ENTRY

0 0 --- --- 65,635 Total treadmill miles

(Units=English)

or kilometers

(Units=Metric)

0 399 --- --- 155 Defaults (to user),

typical weight in lbs/kg

depending on what

setting (UNITS=

English or Metric

0 0 --- --- 65,535 Treadmill serial

number.

--- --- --- --- English Language in English,

Dutch, German,

Portuguese, Spanish,

Swedish, or Italian.

--- --- Units Tenths Units This variable changes

the starting speed in

Units or Tenths

3.2

Maintenance Mode

Maintenance Mode includes all of the items of Manager Mode, plus additional data that is automatically

saved to properly troubleshoot in case of a problem. To engage Maintenance Mode:

1. Press and hold the “ 0 ”, “ 2 ” & “ START ” keys together. While holding the “ 0 ” &

“ START ” keys down, release the “ 2 ” key only.

2. The display will beep and display MAINTENANCE momentarily, then UNITS will be displayed.

Once the treadmill is in Maintenance Mode, you may use the following keys:

INCLINE KEY: Displays the next or previous parameter.

SPEED KEYS: Allows the variable to be changed within the parameter.

ENTER KEY: Saves the value if changed in the EPROM (software).

Note: ENTER KEY must be pressed, for each value changed.

STOP KEY: Exists Manager Mode and restarts the treadmill with a “warm start.”

0 – 9 KEYS: Enters new parameter values. If UNITS parameter is displayed, key 5

starts DISPLAY TEST and key 8 starts MOTOR TEST.

HEART HEART KEY: When pressed will automatically display manufactures default value.

Note: ENTER KEY must be pressed, to save the default values if changed.

3.3

Maintenance Mode

The following parameters may be changed using the previous keys:

Parameters Lowest

Value

UNITS

MN SPD

MX SPD

EL OPT

TIME

OP HRS

--- --- English Metric English English= units of lbs.,

0.1 2.5 English=0.5 Metric=1.0 0.5 Minimum speed in

5.0 20.0 English=10.0 Metric=20.0 10.0 Maximum speed in

--- --- ON OFF ON Turns the elevation

5 99 99 Maximum time in

0 0 --- --- 0 Total operating hours

Highest

Value

Option 1 Option 2 Default

Value

Meaning

miles, hours, minutes

Metric= units of kg.,

km, hours, minutes.

MPH or KM/HR

MPH or KM/HR

system ON or OFF.

minutes allowed for

program, including

warm-up/cool-down.

DIST

WEIGHT

SER NO

LANG

ENTRY

0 0 --- --- 0 Total treadmill miles

(Units=English)

or kilometers

(Units=Metric)

0 399 --- --- 155 Defaults (to user),

typical weight in lbs/kg

depending on what

setting (UNITS=

English or Metric

0 0 --- --- 0 Treadmill serial

number.

--- --- --- --- English Language in English,

Dutch, German,

Portuguese, Spanish,

Swedish, or Italian.

--- --- Units Tenths Units This variable changes

the starting speed in

Units or Tenths

3.4

Maintenance Mode

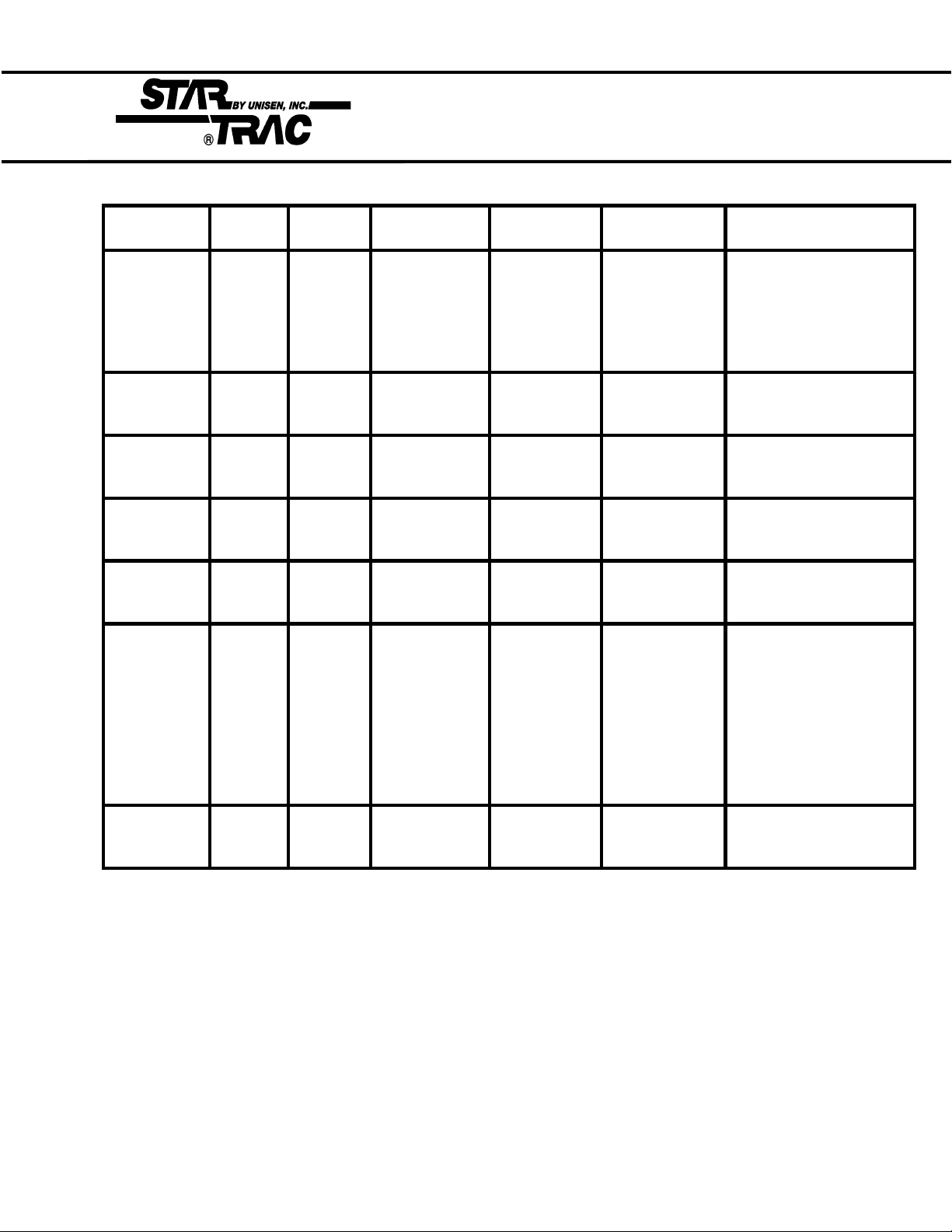

Parameters Lowest

Value

HRT CON

HRT

10 REV

CNT/REV

MN PWM

1/2 PWM

MX PWM

DATE

--- --- ON OFF OFF OFF= Heart Control

--- --- CNT DN

22.0 74.0 30.7 = For

1 255 31 =

2 50 --- --- 30 Minimum PWM to

25 170 --- --- 130 1/2 Maximum PWM to

86 255 --- --- 230 Maximum PWM to

1.00 12.99 --- --- 1.96 Treadmill

Highest

Value

Option 1 Option 2 Default

Value

POLAR

CONTACT

BOTH

110v units.

CNT DN

POLAR

CONTACT

BOTH

35.8 = For

220v units

CNT DN CNT DN= Manual

29.1 Inches of running belt

125 =

Magnetic

RPM Sensor

Optical

Sensor

Meaning

disable

ON= Heart Control

enabled

countdown heart rate

POLAR, CONTACT or

BOTH (Polar &

Contact)

travel for 10 flywheel

revolutions, measured

in inches.

1.8” pulley:30.7 (110v)

2.1”pulley:35.8(220v)

31 Number of counts per

RPM Sensor

revolution.

obtain minimum

speed, automatically

done.

obtain 1/2 maximum

speed, automatically

done.

obtain maximum

speed, automatically

done.

manufacturing date.

NO STO

0 255 --- --- 0 Number of times the

Stop Switch was down

or disconnected on

power-up since last

reset.

3.5

Maintenance Mode

Parameters Lowest

Value

KEY DN

NO RPM

SP CNG

EL STL

EL RNG

EL LOST

ELZERO

EL MAX

LSTERR

0 255 --- --- 0 Number of times the

0 255 --- --- 0 Number of times the

0 255 --- --- 0 Number of times a

0 255 --- --- 0 Number of times an

0 255 --- --- 0 Number of counts per

0 255 --- --- 0 Number of times no

0 255 --- --- 240 Represents the incline

0 255 --- --- 57 Represents the incline

0 25 --- --- 0 Indicates what display

Highest

Value

Option 1 Option 2 Default

Value

Meaning

Stop Switch was down

or disconnected on

power-up since last

reset.

display did not detect

a RMP signal.

sudden change in

speed was detected

elevation stall was

detected.

RPM Sensor

revolution.

elevation was

detected.

number for 0%.

number for 15%.

code appeared last.

18 = NO STO

19 = KEYDN

20 = NO RPM

21 = SP CNG

22 = EL STL

23 = EL RNG

24 = EL LOST

LSTELV

LSTPOT

0 255 --- --- 0 Displays the target

elevation prior to the

display code.

0 255 --- --- 0 Displays the incline

number prior to the

display code.

3.6

Maintenance Mode

Parameters Lowest

Value

LSTRES

LSTSSP

LSTPWM

LSTMSP

LST TM

LSTDCK

LSTBLT

0 2 --- --- 0 Displays

0 255 --- --- 0 Displays the speed

0 255 --- --- 0 Displays the PWM

0 255 --- --- 0 Display the actual

0 65355 --- --- 0 Displays the elapsed

0 65355 --- --- 0 Number of miles when

0 65355 --- --- --- Number of miles when

Highest

Value

Option 1 Option 2 Default

Value

Meaning

1 = Unit was resetting

to 0%.

0 = Unit finished

resetting to 0% prior

to the display code.

prior to the display

code.

number prior to the

display code.

measured speed prior

to the display code.

time, in seconds, prior

to the display code.

the deck was last

waxed. After a 2000

mile (or 3000 KM)

difference, “REWAX

BELT” will scroll in the

display until “LST

DCK” miles are

updated.

the last belt was

replaced.

3.7

Motor Test Mode

Motor Test Mode allows the treadmill to calibrate both elevation and running belt speed. Verifies RPM

Sensor feedback, Drive Motor and MCB response, and verifies Elevation Motor range (count). Also

burns in the motor, by way of the controls and displays of the treadmill.

***Caution*** : Do not stand on the running belt while performing these test.

Engage Test Mode:

1. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together (or the “0” , “2” ). While holding the “ 0 ”

& “ START ” keys down, release the “ 1 ” (or 2) key only. The display will beep and display

MANAGER (or MAINTENANCE) momentarily, then UNITS will be displayed.

2. Press and release the “8” key. Display will read: 240 3 .0 if treadmill is at 0%.

Alternative mode to enter Motor Test Mode:

1. Turn the power switch on while pressing the “ 8” key simultaneously on the display.

240 3 .0

A. Elevation Motor Range. B. PWM Duty Cycle. C. RPM Sensor Feedback

Once the treadmill is in TEST Mode, you may use the following keys:

INCLINE KEY: Adjust voltage to incline motor, inclines the treadmill in increments of 1%.

When using the Incline Keys verify the elevation system is responding correctly by the

following:

• As the treadmill elevates up and down verify the corresponding LEDs light up on the MCB.

• Verify that the Elevation Motor Range (see above A column) is changing in increments of

1% as the treadmill elevates up and down.

Caution:Do not elevate treadmill above 15% = 57 (110v units), 80 (220v units) or below

0% = 240 (110 & 220v units) mechanical damage may occur.

SPEED KEYS: Adjust the PWM duty cycle and motor speed up and down, respectively,

in increments of 0.1 mph (UNITS=English) or 0.1km/hr (UNITS = Metric).

When using the Speed Keys verify the speed control system is responding correctly by the

the following:

• As the treadmill begins to increase speed, verify that the display registers RPM feedback

(see above C column) in increments of 0.1 mph/km.

START KEY: Starts burn-in mode. (continuous operation of running belt and incline using

program 8 at maximum speed. Press STOP KEY to stop burn-in.

STOP KEY: Exists MOTOR TEST Mode and restarts the treadmill.

HEART KEY: Starts automatic calibration of minimum, 1/2 maximum, & maximum speed.

3.8

Calibration

***Caution*** : Do not stand on the running belt while performing these test.

Automatic Speed Calibration:

In this mode minimum and maximum speed is automatically calibrated. Calibration lasts less than 3

minutes; belt will be in motion during this test.

Auto-calibration should be done every time MN, MX SPD & UNITS parameters have been changed in

either SETTINGS or CONFIGURE Mode. Auto-calibration must be engaged when ever speed

controlling components have been upgraded or replaced such as; MCB, Display Board, Drive Motor &

RPM Sensor.

1. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together (or the “0” , “2” ). While holding the “ 0 ”

& “ START ” keys down, release the “ 1 ” (or 2) key. The display will beep and display MANAGER

(or MAINTENANCE) momentarily, then UNITS will be displayed.

2. Press and release the “8” key. Display will read: XXX 3 .0 if treadmill is at 0% display will read:

240 3 .0

3. Press “HEART” key, display will read: CAL treadmill will go into an automatic speed calibration for

less than 3 minutes. Press “STOP” key to exit Motor Test.

NOTE: If Auto-calibration fails to give the correct response refer to Section 4.

3.9

Display Test Mode

Display Test Mode allows you to test the light-emitting diodes (LEDs), 15-segment displays, and the

watchdog timer of the Display Control Panel by way of its own controls and displays. It also allows

EPROM version to be displayed. To enter Display Test Mode:

***Caution*** : Do not stand on the running belt while performing these test.

1. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together (or the “0” , “2” ). While holding the “ 0 ”

& “ START ” keys down, release the “ 1 ” (or 2) key.

2. The display will beep and display MANAGER (or MAINTENANCE) momentarily, then UNITS will

be

displayed.

3. Press and release the “5 key. Observe all the LEDs light up.

4. Pressing any key once will display the EPROM version.

Alternative mode to enter Motor Test Mode:

1. Turn the power switch on while pressing the “5” key simultaneously on the display. Observe all the

LEDs light up.

Once the treadmill is in Display Test Mode, you may use the following keys:

INCLINE KEYS: Lights % grade LED’s one at a time, also segments of 15-segment

screen one at a time.

PROGRAM SELECT KEY: Lights the six LEDs bordering the 15-segment display.

HEART KEY: Displays “HEART HEART” on the 15-segment display.

START KEY: Displays “START START” on the 15-segment display.

0 – 9 KEYS: Lights corresponding LEDs in the Number/Program Select Keys, (except

for key 9), alongside the Pre-Designed Program profiles.

STOP KEY: Displays “WD TEST” on the 15-segment display. Activates the watchdog

timer, resetting the processor and returning the program back to Start Mode.

3.10

Heart Rate Test

Heart Rate Test Mode tests the heart rate calculation and display capability of the treadmill if it is

equipped with contact rings or Polar wireless heart rate chest strap reception capability. To enter Heart

Rate Test Mode:

1. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together (or the “0” , “2” ). While holding the “ 0 ”

& “ START ” keys down, release the “ 1 ” (or 2) key.

2. The display will beep and display MANAGER (or MAINTENANCE) momentarily, then UNITS will

be

displayed.

3. Press and release the “5 key. Observe all the LEDs light up.

4. Press the key 3X’s, display will read SEEKING HR across the display.

5. Grasp the stainless steel contact rings or place the Polar wireless heart rate chest strap around

your chest (treadmill must be equiped with both contact and Polar).

6. In the far right display screen a blinking LED segement will flash then the average heart rate will be

displayed.

NOTE: If the above Heart Rate Test fails to give the correct reading or response, refer to Section 4.

3.11

Section 4:

Troubleshooting

Should the STAR TRAC 4500 Treadmill experience a problem or a display code appear, the following

procedures will help determine the precise reason for the problem. Included are flow charts breaking

down each individual display code with problem statements and solutions.

Contents

4.1 110v MCB Layout

4.24 Running Deck Symptoms

4.3 220v MCB Layout

4.5 Calibration Symptoms

4.7 Manual Calibration

4.8 No Display Power 110v

4.9 No Display Power 220v

4.10 Elevation Motor Symptoms

4.12 Elevation Symptoms

4.13 Heart Rate Symptoms

4.16 Polar Symptoms

4.17 Display Cable Symptoms

4.18 Drive Motor Symptoms

4.19 Head / Tail Roller Symptoms

4.26 Isolating Noise

4.27 Leveling

4.28 Static Symptoms

4.29 Vibration

4.30 Display Codes Chart

4.31 KEY DN Flowchart

4.32 NO STO Flowchart

4.33 No RPM Flowchart

4.37 SP CNG Flowchart

4.41 EL STL Flowchart

4.45 EL RNG Flowchart

4.49 EL LOST Flowchart

4.20 Drive Belt Symptoms

4.21 Running Belt Symptoms

4.0

4.53 EL NOZ Flowchart

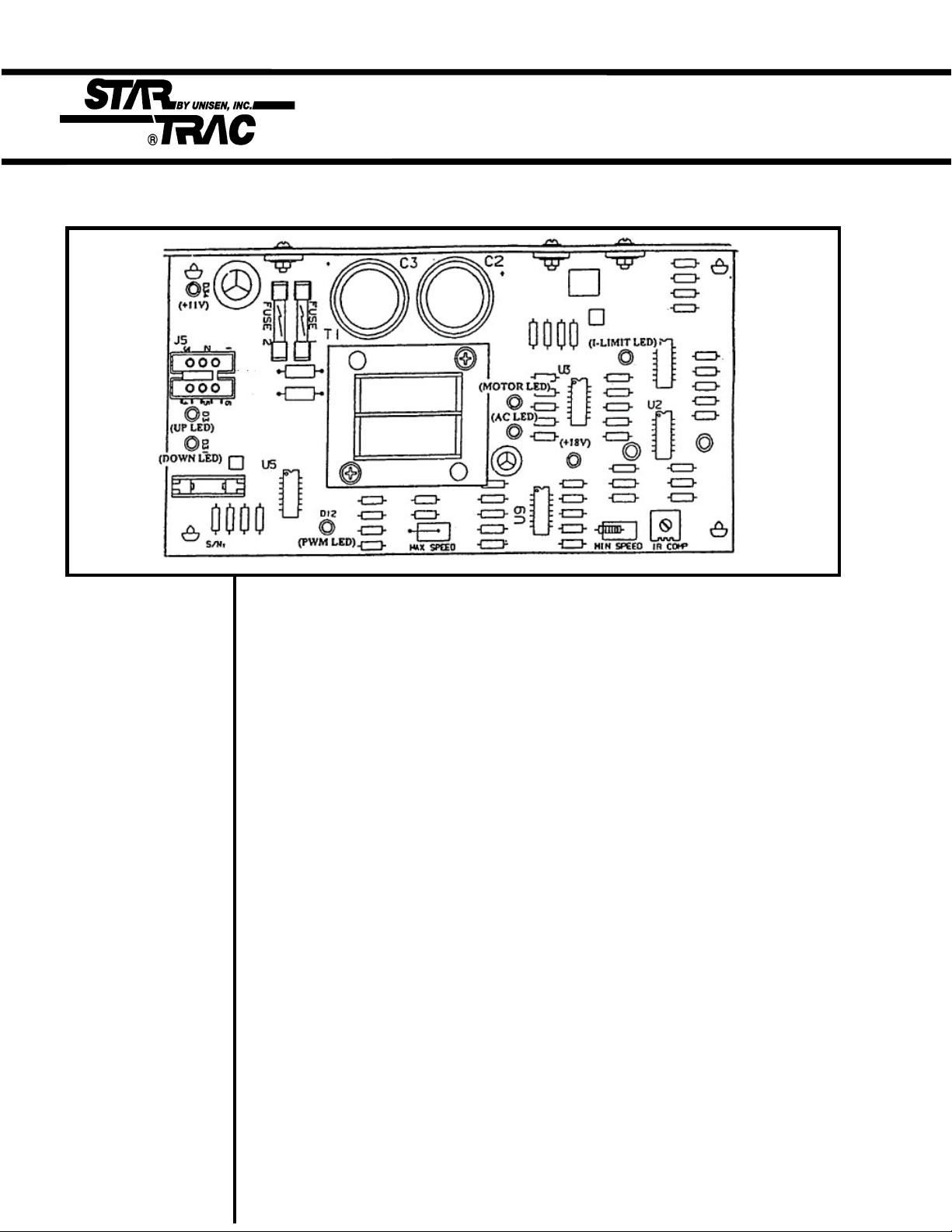

110v MCB LED Layout

The Following LEDs will help diagnose if the MCB has failed or causing intermittent problems.

** CAUTION ** AC LED - Indicates that AC power has been applied to the MCB. It does

Several of the follow- not give indication of voltage level, if this LED is not lit and the tread ing troubleshooting mill does not power up, verify the following:

require dealing with 1. The treadmill is plugged into a wall outlet.

live voltage. Have the 2. The ON/OFF switch is turned to the “ON” position.

treadmill turned off 3. Verify with a VOLT METER that 110VAC is present at the

and unplugged when outlet. Units with step-down transformers need 220VAC.

checking wire 4. Verify 110v (+/- 10%) AC voltage at AC1 & AC2 wires.

connections. After the above have been verified and the AC LED is still “OFF”, the

MCB should be replaced.

NOTE: The display +18v LED - Indicates the presence of an acceptable level of voltage to

console may still operate the MCB. If this LED is off or dim, the AC voltage level is

power up with the AC not acceptable to properly power the MCB. Verify the following:

LED off. 1. Verify with a VOLT METER that 110VAC is present on

on pins AC1 & AC2.

After the above step has been verified and the + 18V LED is still “OFF”,

and the display does not power up, replace the MCB.

+11v LED - Indicates there is +11 volts supplied to the display board. If this

LED is not lit verify the following:

1. The display cable is damaged or pinched, disconnect the

display cable and verify if the LED lights up. If LED lights up

replace the cable.

After the above has been verified and the +11 LED is still “OFF”, the

MCB should be replaced.

4.1

110v MCB LED Layout

NOTE: Engage Motor MOTOR LED - Indicates the presence of acceptable voltage to the motor.

Test Mode and If this LED is not lit one of the following conditions exists:

manually push on 1. Verify AC voltage is being applied.

the running belt to 2. Verify that MTR1/MTR2 wires are connected to the MCB.

verify RPM feedback. (This should be done with the treadmill unplugged and turned off)

After the above have been verified and the MOTOR LED is still ‘OFF”, the

MCB should be replaced.

PWM LED - Indicates that there is a valid control command from the

display to the MCB (this LED flashes only when the treadmill is

operating) If this LED is not lit verify the following:

1. Verify if the display cable is connected.

2. Verify if the display cable is damaged or pinched.

(see page 4.17 in this section for Display Cable

symptoms)

After the above have been verified and the PWM LED is still “OFF” , the

MCB should be replaced.

NOTE: If the current I-LIMIT LED - Indicates that an excessiveload is being placed on the

limit is reached, the motor. Amp readings of 26 or higher will cause the LED to

MCB will shut the light. If this LED is lit one of the following conditions exists:

treadmill down and 1. Running belt is worn.

the I-LIMIT LED will 2. Belt and deck require lubrication.

remain on until it 3. Drive motor drawing over the 26 amp peak.

resets. After the above has been verified and the I-LIMIT LED is still “ON”, the

MCB should be replaced.

UP LED - Indicates that the incline is being commanded up. If this LED is

not lit and the elevation motor will not respond, verify the

following:

1. Display cable for possible pinch or tear (see page 4.17

in this section for Display Cable symptoms)

2. Replace MCB.

DOWN LED - Indicates that the incline is being commanded up. If this LED

is not lit and the elevation motor will not respond, verify the

following:

1. Display cable for possible pinch or tear (see page 4.17

in this section for Display Cable symptoms)

2. Replace MCB.

4.2

220v MCB LED Layout

The Following LEDs will help diagnose if the MCB has failed or causing intermittent problems.

** CAUTION ** AC PWR - Indicates that AC power has been applied to the MCB. It does

Several of the follow- not give indication of voltage level, if this LED is not lit and the

ing troubleshooting treadmill does not power up, verify the following:

steps require dealing 1. The treadmill is plugged into a wall outlet.

with live voltage. 2. The ON/OFF switch is turned to the on position.

Have the treadmill 3. Verify with a VOLT METER that 110VAC is present at the

turned off and unplu- outlet. Units with step-down transformers need 220VAC.

gged when checking 4. Verify 220v (+/- 10%) AC voltage at AC1 & AC2 wires.

wire connections. After the above have been verified and the AC LED is still “OFF”, the

MCB should be replaced, if the treadmill is not operating.

NOTE: The display DISPLAY PWR- Indicates there is +11 volts supplied to the display

console may still board. If this LED is not lit verify the following:

power up with the AC 1. The display cable is damaged or pinched, disconnect the

PWR LED off. display cable and verify if the DISPLAY PWR LED lights

up. If the LED lights up replace the cable.

After the above has been verified and the DISPLAY PWR LED is still

“OFF”, the MCB should be replaced.

4.3

220v MCB LED Layout

NOTE: Engage Motor RPM SENSOR - Indicates input signal from the RPM Sensor to the MCB.

Test Mode and If this LED is not flashing during operation, verify the following

manually push on 1. RPM sensor disconnected from connector J3 at the MCB.

the running belt to 2. RPM sesnor gap misaligned.

verify RPM feedback. 3. RPM sensor faulty

After the above have been verified and the RPM LED is still “OFF”, the

MCB should be replaced.

MOTOR CONTROL - Indicates that there is a valid control command

from the display to the MCB. If this LED is not lit verify the

following:

1. Verify if the display cable is connected.

2. Verify if the display cable is damaged or pinched.

After the above have been verified and the MOTOR CONTROL LED is still

“OFF”, the MCB should be replaced.

UP LED - Indicates that the incline is being commanded up. If this LED is

not lit and the elevation motor will not respond, verify the

following:

1. Display cable for possible pinch or tear ( see page 4.17

in this section for Display Cable symptoms).

2. Replace MCB.

DOWN LED - Indicates that the incline is being commanded down. If this

LED is not lit and the elevation motor will not respond, verify the

following:

1. Display cable for possible pinch or tear ( see page 4.17

in this section for Display Cable symptoms).

2. Replace MCB.

4.4

Calibration

Troubleshooting

The following steps help troubleshoot in case Auto-Calibration procedures fail to give the correct

reading or response.

Symptom:

Auto-Calibration fluctuates.

1. Verify line voltage for sufficient voltage supply.

• If wall voltage is less than 10% than what is

required, this will cause speed fluctuation.

2. Verify unit is on a dedicated circuit breaker.

• Treadmills sharing the same circuit line will cause

intermittent problems and variation in speed.

3. Verify the following parameters are set correctly

in the Configuration Mode:

(Configuration Mode details in Section 3)

• CNT/RV : 31 = Magnetic/Cherry RPM Sensors

• 10 REV: 29.1” for 1.7” dia. motor pulley (110v)

• 10 REV: 35.8 for 2.1” dia. motor pulley (220v)

NOTE: If not sure what your 10 REV settings should

be, manually measure your drive motor pulley

diameter. Above measurements are done in inches.

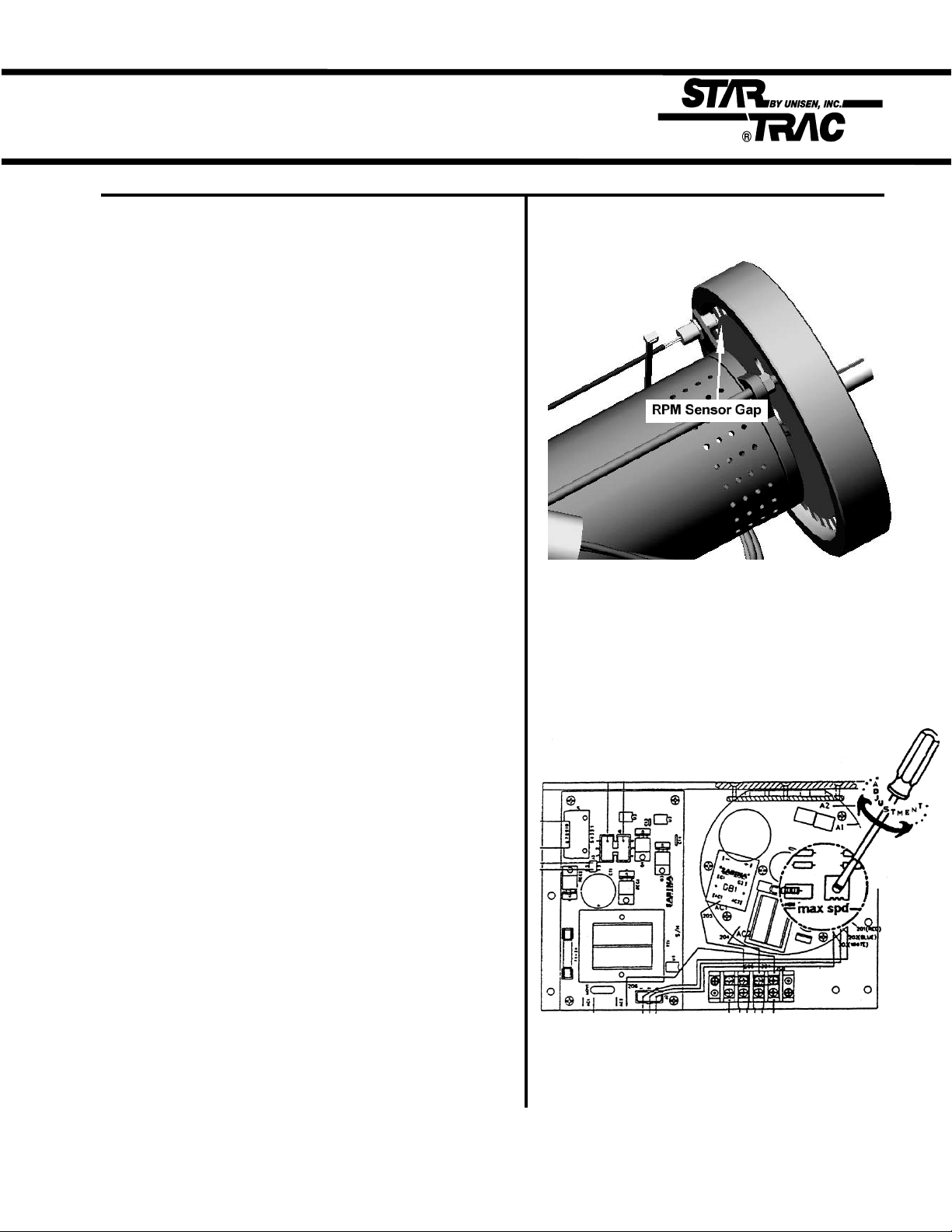

Diagram #1

4. Verify RPM Sensor alignment.

• Hall Effect/Cherry RPM Sensor is being used,

verify the gap is no more than 1/8 inch.

NOTE: See Diagram # 1.

5. Adjust IR COMP potentiometer.

NOTE: See Diagram #2, adjustment.

REPLACE: MCB if symptom continues.

4.5

Calibration Troubleshooting

Symptom:

Will not Calibrate to MAX speed.

1. Verify line voltage for sufficient voltage supply.

• If wall voltage is less than 10% than what is

required, this will cause speed fluctuation.

2. Verify unit is on a dedicated circuit breaker.

• Treadmills sharing the same circuit line will cause

intermittent problems and variation in speed.

3. Verify the following parameters are set correctly

in the Configuration Mode.

(Configuration Mode details in Section 3)

• MN SPD: 0.5 MPH or 1.0 KM/PH

• MX SPD: 10.0 MPH (110v) or 20.0 KM/PH (220v)

• CNT/RV : 31 = Magnetic/Cherry RPM Sensors

• 10 REV: 29.1” for 1.7” dia. motor pulley (110v)

• 10 REV: 35.8” for 2.1” dia. motor pulley (220v)

NOTE: To reach 20.0 KM/PH on 220v units, drive

motor pulley must be 2.1”. If not sure what your 10

REV settings should be, manually measure the drive

motor pulley diameter.

Diagram #1

Diagram #2

4. Verify RPM Sensor alignment.

• Hall Effect/Cherry RPM Sensor is being used,

verify the gap is approximately 3 business

cards or 1 credit card. If adjustment is necessary

loosen the flywheel to re-position.

NOTE: See Diagram #1.

REPLACE: RPM Sensor if RPM reading is sensitive

or feedback appears erratic.

5. Adjust the MAX SPEED potentiometer.

NOTE: See Diagram #2. (220v units only)

GO TO: Section 3.7 Manual Calibration if problem

continues.

4.6

Manual Calibration

The following procedure allows the treadmill to manually calibrate Minimum and

Maximum speeds, only in the case Auto-Calibration is not functioning correctly.

Symptom:

Will not calibrate to MN or MX speed, in the Auto-Calibration Mode.

**CAUTION** 1. Engage TEST MODE. Press and hold the “ 0 ”, “ 1 ” & “ START ” keys together

Do not stand on (or the “0” , “2” ). While holding the “ 0 ” & “ START ” keys down, release the “ 1 ”

the running belt (or 2) key. The display will beep and display SETTINGS (or CONFIGURE)

while perform- momentarily, then UNITS will be displayed.

ing these steps.

2. Press and release the “8” key. Display will read: XXX 3 .0 XXX is a variable

NOTE: Alter- number depending on the elevation position the treadmill is at. 3 indicates Speed

native mode to Command, 0 indicates RPM. If the treadmill is at 0% the display will read: 240 3 .0

enter Motor

Test Mode; turn

the power down the corresponding Speed Command number displayed for each desired

switch “ON” setting.

while pressing

the “8” key sim-

ultaneously on STEP 1.

the display.

NOTE: The MN MN SPD Speed Command number by using the “+” or “-” keys, then press the

SPD should not “START” (enter) key to save the new setting. Do this for the 1/2 MX and MX SPD.

exceed .5 MPH

or 1KPH. The

1/2 MX SPD

should be

exactly half of

the desired MX

SPD. The MX

MX SPD must

not exceed 10

MPH or 20 KPH

(220 units).

3. Press the “+” key (speed) to the desired MN SPD,1/2 MX, and MX SPD. Write

4. Press the “STOP” key. Engage Configuration/Settings Mode as described in

5. Using the “UP ELEVATION” key go to MN PWM parameter and enter the new

6. Press the “STOP” key to exit.

NOTE:Speed

Command

255 is the maximum the tread-

mill will reach.

4.7

No Display Power

The following steps help troubleshoot in case the display board fails to power up, during or before

regular operation.

110v UNIT

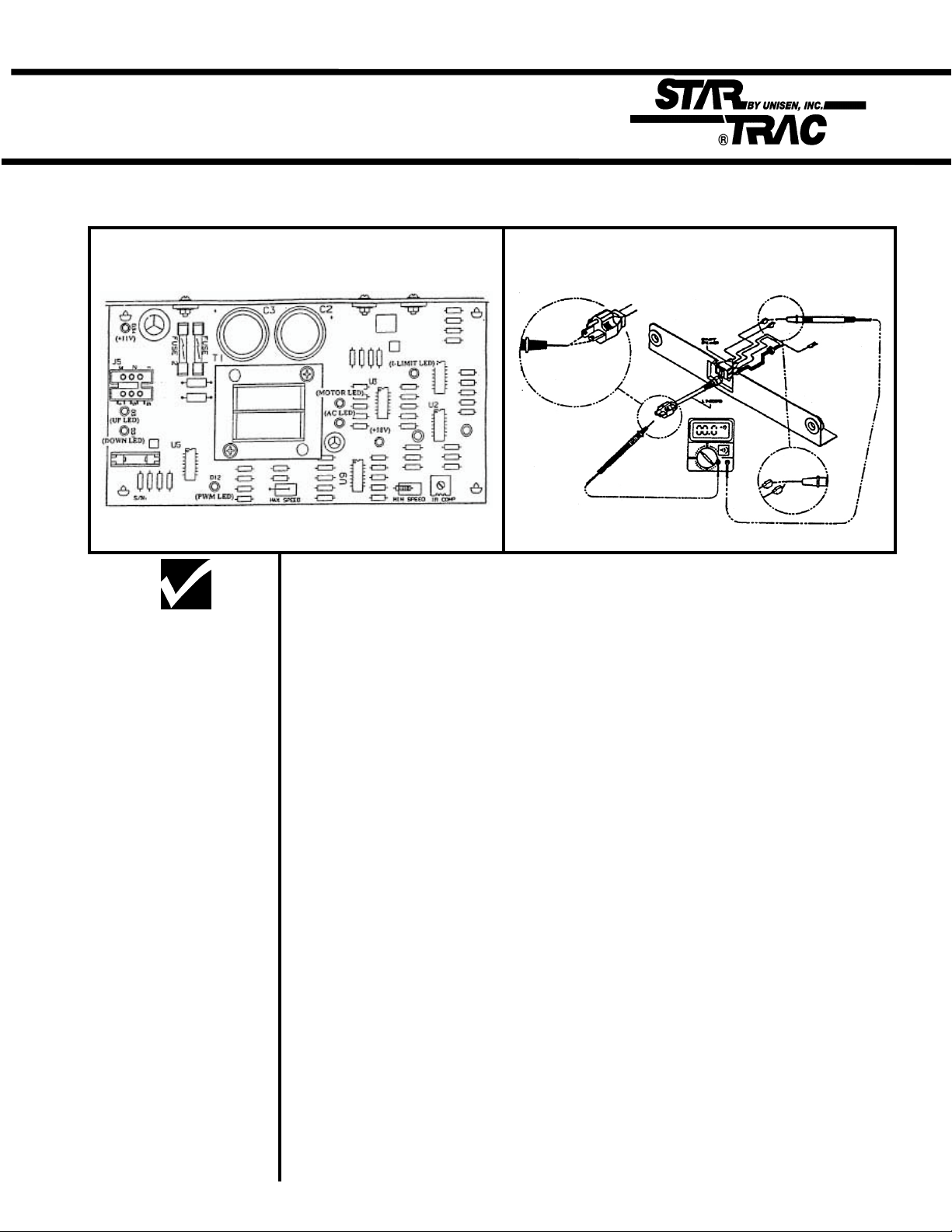

Diagram A Diagram B

1. Lift and suspend the motor shroud.

**CAUTION**

The following steps

are performed with the MCB, does not indicate voltage level. If this LED is lit go to step 3.

the treadmill “ON”. If LED is not lit verify the following: (see diagram A)

less than 90v, check wall voltage, verify unit is on a dedicated line.

REPLACE: MCB if all the above check OK.

2. Verify if LED AC is lit. AC LED indicates that AC power is being applied to

• The treadmill is plugged into the wall.

• The ON/OFF Switch is turned to the “ON” position.

• Verify wire connection AC1/AC2 on the MCB.

• Verify the ON/OFF Switch Breaker wires are connected.

• Verify 110v (+/- 10%) AC voltage at AC1/AC2. if the voltage is 0 or

• If wall voltage is correct, verify linecord continuity. (see diagram B)

3. Verify if LED +18 is lit. LED +18 indicates the presence of an acceptable

level of voltage for MCB operation.

REPLACE: MCB if +18 is not lit.

the display board. If the LED is lit go to step 5.

REPLACE: MCB if +11 is not lit.

4. Verify if LED + 11 is lit. LED +11 indicates 11v are being applied to power

5. Verify display cable connection.

• Verify display cable for possible pinch or tear mark.

REPLACE: Display board if display cable checks OK.

4.8

No Display Power

The following steps help troubleshoot in case the display board fails to power up, during or before

regular operation.

220v UNIT

Diagram A Diagram B

1. Lift and suspend the motor shroud.

**CAUTION**

The following steps

are performed with the MCB, does not indicate voltage level. If this LED is lit go to step 3.

with treadmill “ON”. If LED is not lit verify the following: (see diagram A)

less than 200v, check wall voltage, verify unit is on a dedicated line.

REPLACE: MCB if all the above check OK.

2. Verify if LED AC is lit. AC LED indicates that AC power is being applied to

• The treadmill is plugged into the wall.

• The ON/OFF Switch is turned to the “ON” position.

• Verify wire connection AC1/AC2 on the MCB.

• Verify the ON/OFF Switch Breaker wires are connected.

• Verify 220v (+/- 10%) AC voltage at AC1/AC2. if the voltage is 0 or

• If wall voltage is correct, verify linecord continuity. (see diagram B)

3. Verify if LED DISPLAY POWER is lit. This LED indicates 11v are being

applied to power the display board. If the LED is lit go to step 4.

REPLACE: MCB if DISPLAY POWER LED is not lit.

4. Verify if LED MOTOR CONTROL is lit. This LED indicates there is a valid

control command from the display to the MCB. Verify the following if LED

is off:

• Verify display cable connection.

• Verify display cable for possible pinch or tear mark.

REPLACE: Display board if display cable checks OK.

4.9

Elevation Motor

The following procedure explains the elevation system Thermal Protection and

limitations.

Symptom:

NOTE: Activation

of the thermal

protection breaker does not

cause damage to

the elevation

actuator or other

treadmill components.

Elevation system shuts-off when used consistently.

1. The Star Trac Model 4500 elevation system actuator is protected from

overheating by a thermal protection circuit. In the event that the thermal

protection breaker is activated, the treadmill’s elevation system is temporarily

disabled, and an “EL STL” display codes is displayed.

• A simple resetting of the treadmill restores full operation once the

elevation actuator has been allowed to cool for a few minutes.

2. The pre-defined workout programs 1 through 8 as well as other typical workout

regimens include elevation changes that easily fall within the operating limits of

the Model 4500’s elevation system actuator. The following information serves

as a guide for users that may wish to set a custom program that requires

frequent and/or large changes in incline.

• Incline changes greater than 5 percent should not be programmed for

intervals less than 1 minute.

• Full range incline changes (from 0 percent to 15 percent, or vice-

versa) should not be programmed for intervals less than 3

minutes.

4.10

Elevation Motor

The following procedure verifies elevation motor potentiometer response.

** CAUTION **

Do not stand on

the running belt

while performing

these steps.

NOTE: Several of

the following

steps require

dealing with “live”

voltage. Have the

treadmill turned

off and unplugged when checking wire connections.

NOTE: The potentiometer values

can be read in

Motor Test Mode,

240 = 0%, 57 =

15% for 110v

units or 80= 15%

for 220v units.

NOTE: The

values in diagram A were taken

from a properly

functioning

elevation system.

You may expect

slight variation

from machine to

machine. If the

values are 0,

check display

cable for possible

short see page

4.17 Display

Cable Symptoms.

If values are erraticly different

replace the

Elevation Motor.

Symptoms:

Elevation motor hesitates during operation.

No elevation count reading in Test Mode.

1. The elevation motor potentiometer may have failed or register incorrect values

causing the motor to hesitate while operating. The chart below (see diagram A)

is a guide for the correct elevation readings on the TR 4500.

• Using a Volt Meter verify the following values from the elevation motor at

certain elevation grades (see the chart for elevation grades).

The voltage readings may vary by +/- .05 volts. The ohms may vary by

+/- .01 k ohms. See diagram B for meter reference.

Diagram A.

% Grade Incline

number in

Motor Test

Mode

0 240 4.68 9.76k 4.8

1 228 4.44 9.33 k 4.58

2 216 4.21 8.86 k 4.37

3 204 3.98 8.41 k 4.12

4 192 3.75 7.92 k 3.88

5 180 3.51 7.48 k 3.64

6 168 3.27 6.95 k 3.42

7 156 3.04 6.48 k 3.18

8 144 2.81 6.01 k 2.95

9 132 2.57 5.50 k 2.71

10 120 2.34 4.98 k 2.48

11 108 2.11 4.48 k 2.26

12 96 1.88 3.99 k 2.03

13 84 1.64 3.52 k 1.79

14 72 1.41 2.97 k 1.55

15 60 1.17 2.48 k 1.33

DC Voltage across

Blue and Orange

wire on the Elev.

motor connector

Ohm reading between

the Blue and Orange

(elev. motor

unplugged)

DC Voltage on

Pin 4 of the

electronics

display

4.11

Elevation Troubleshooting

220v treadmill Incline Range Adjustment for Free-wheeling symptom.

** CAUTION **

Do not stand on

the running belt

while performing these steps.

Symptom:

Treadmill free-wheels at high elevation, causing the running

belt to slowly accelerates beyond the selected speed.

1. This symptom may be easily fixed by changing certain values in the Configure

Mode. Engage Manager/Maintenance Mode by holding down the “0”, “1” and

“Start” keys at the same time, and then release the “1” key only.

2. Press the elevation “↑” key until the display window reads “EL MAX 57”.

Change the “57” to “80” by pressing the “+” key.

3. Press the “START” key and the display window will show “UPDATING”. This

will save the “80” in the parameter.

4. Press the “STOP” key to exit the Manager or Maintenance Mode. Procedure

completed.

Symptom:

Elevation Motor overheats and blows the MCB fuse.

NOTE:These ranges were chosen

to optimize the

output voltage to

the elevation

motor within an

acceptable

operating range,

while still using

the present

manufacturing

tolerances of the

transformer

manufacturer.

1. The elevation motor on the 4500 series treadmill uses 115 VAC. On 230 volt

treadmills, there is an autotransformer which will lower the voltage to operate

the elevation system.

2. Line voltage may vary from location to location. Some locations have line

voltages as low as 195 VAC or as high as 250 VAC. The autotransformer has

been manufactured with two taps to accommodate these variations in voltage.

The two taps are:

• 190 to 210 VAC line voltage

• 210 to 250 VAC line voltage

4.12

Speed Troubleshooting

Symptom:

Note: This sym-

ptom may be

easily fixed by

verifying certain

values in the

Configure Mode.

Note: For each

value changed

the “ENTER” key

must be pressed

to be saved.

.

Treadmill appears/feels faster/slower than other STAR TRAC

treadmills.

1. Engage Maintenance Mode by holding down the “0”, “2” and “Start” keys at the

same time, and then release the “1” key only. Display will read MAINTENANCE

momentarily then display UNITS.

2. Using the elevation “ ↑ “ key to go through the parameteres, verify the

following parameterts have the correct values.

110V / 220V Units English 220v Units Metric

• UNITS ENGLISH METRIC

• MN SPD 0.5 1.0

• MX SPD 10.0 20.0

• ENTRY UNITS/TENTHS UNITS/TENTHS

• 10 REV 30.7 35.8

• CNT/REV 31 31

3. If any values have been changed or set back to default settings, re-engage

Auto-Calibration and re-calibrate.

4.13

Speed Troubleshooting

Symptom:

Note: This sym-

ptom may be

easily fixed by

verifying certain

values in the

Configure Mode.

Treadmill will not reach maximum speed.

1. Engage Maintenance Mode by holding down the “0”, “2” and “Start” keys at the

same time, and then release the “1” key only. Display will read MAINTENANCE

momentarily then display UNITS.

Note: For each

value changed

the “ENTER” key

must be pressed

to be saved.

Note: All 110v

units are designed to reach a

maximum speed

of 10.0 MPH.

220v units set in

metric will reach

a maximum 20.0

KM/PH.

Note: Wall voltage is very critical

when dealing

with maximum

speed. Voltages

under 100v for

110v units will

cause speed

variation, voltages under 200v

for 220v units will

cause the same

problem.

2. Using the elevation “ ↑ “ key to go through the parameters, verify the

following parameters have the correct values.

110V / 220V Units English 220v Units Metric

• UNITS ENGLISH METRIC

• MN SPD 0.5 1.0

• MX SPD 10.0 20.0

• ENTRY UNITS/TENTHS UNITS/TENTHS

• 10 REV 30.7 35.8

• CNT/REV 31 31

3. If any values have been changed or set back to default settings, re-engage

Auto-Calibration and re-calibrate.

IF the problem continues verify the following.

1. Wall voltage. (+/- 10%)

2. Dedicated Circuit Breaker.

3. Adjust MAX SPEED potentiometer (220v units). See Diagram below:

Note: Each unit

must be on its

own dedicated

circuit, very main

wall breaker.

4.14

Speed Troubleshooting

Symptom:

** CAUTION **

Running belt will

be moving at high

speed during

Step 1 & 3.

** CAUTION **

When checking

motor brushes

have the treadmill

turned off and

unplugged.

Note: Brushes

should show a

smooth pattern of

wear, cracks or

unusual wear will

cause motor to

jerk, replace if

brushes if neded.

Treadmill jerks or hesitates during operation.

1. Verify the running belt / drive belt are not loose or slipping.

• Accelerate the running belt to 3.0 (5.0 kph). Stand on the side of the

treadmill, while grasping the handrails firmly, place one foot on the

running belt with a very sharp impact. Running belt should not stop,

instead slip for a split second forcing your foot back. Drive belt should

never stop rotating over the headroller during this procedure.

• If running belt or drive belt appears loose, see page 4.26 in this section.

2. Verify motor brushes are making contact and are seated correctly.

• Remove the motor brush cover, check brushes are seated correctly by

removing the brush clip and verify contact. See diagram A for removal

instructions.

• Cleaning the motor armature with a commutator stone is highly recom-

mended to remove any possible carbon dust build up, causing the

the brushes to skip over resulting in a brief motor hesitation.

3. Adjust the IRCOMP potentiometer, located on the MCB, see diagram B.

• Bring the treadmill to its minimum speed.

• Stand on the running belt, if the belt feels jerky / hesitates adjust the

IRCOMP potentiometer until running belts feels smooth.

Symptom:

Treadmill hesitates during initial speed start-up.

1. Manually calibrate the minimum PWM as described in page 4.7 in this

section.

4.15

Heart Rate Troubleshooting

Before any troubleshooting is performed, verify that the heart rate grips are being used

** CAUTION **

Do not stand on

the running belt

while performing

these steps.

and maintained properly.

Symptom:

Intermittent or erratic heart rate reading.

1. User failing to grip all four rings completely with both left and right hands

2. An excessively tight grip on the rings can cause erratic readings. The

probability of erratic readings can be therefore lessened by:

---- reduced upper torso movement

---- a proper grasp on the grips

---- clean hands

---- clean grips

3. Excessive foreign matter (dirt) on the hands can generate electrical

interference which will cause erratic readings.

4. Clean and wipe heart rate grips after each use, for optimum results.

4.16

Heart Rate Troubleshooting

Symptom:

No Heart Rate reading.

1. Engage HEART RATE TEST. Turn the

power switch “on” while pressing key “5”

simultaneously on the display. All the

display LEDs will light up when engaged.

• Press the HEART key once, EPROM ver sion will be displayed. HEART key twice,

displays Heart/ Seeking HR.

• Grip heart rate handles, The negative (-)

symbol will begin to flash indicating heart

rate system is being registered. Do not

squeeze excessively to avoid excessive

muscle contraction (faulse readings). If

no reading is displayed go to STEP 2.

Engage MANAGER MODE, Hold the “0”,

“1”, and “START” keys together and re lease the “1” key only. Display will read

MANAGER MODE momentarily, then

UNITS will be displayed.

elevation “UP” key until display reads:

CONTCT= contact heart rate.

BOTH = both contact and polar can be

used (if software available).

“START” key to save.

2. Verify Contact Heart Rate settings.

• Scroll through the parameters using the

• Press the “+” or “-” key to change,

Diagram 1

Diagram 2

3. Verify Heart Rate receiver connection.

• Remove the display board, verify wire

connections.

NOTE: See diagram #1 Display removal.

NOTE: See diagram #2 Wire connection.

Connection is wrong or loose, reconnect

and repeat step 1.

4. Verify Heart Rate grip cables.

NOTE: See diagram #3. If connections are

wrong or loose, reconnect and repeat step 1.

4.17

Diagram 3

Heart Rate Troubleshooting

5. Connect Heart Rate Board straight to

the display input.

• By-pass the Combiner Board, insert the heart

rate wires straight to the display.

See Diagram #3 & 3a. After connection has been

repeat step 1.

REPLACE: Combiner Board if Heart Rate

registers. If no Heart Rate is registered go to

step 6.

NOTE: Step 5 can only be performed if the

software includes both Polar and Contact.

6. Check continuity/resistance between

Heart Rate grip rings and input wires.

• Disconnect both heart rate grip inputs (red &

black wires) from back of display.

• Using a Multi-meter check continuity between

the heart rate rings and its corr-

esponding output wires.

• Red wire = outside rings.

• Black wires = inside rings.

NOTE: See Diagram #4.

REPLACE: Heart Rate grip(s) if reading is

greater than 1.0Ω

Diagram 4

Diagram 5

Diagram 6

7. Check continuity/resistance of each

hand rate grip.

• Using a Multi-meter check continuity between

the two rings on the same grip.

• Black meter probe to inside ring and red

meter probe to outside ring.

NOTE: See diagram #5.

REPLACE: Heart Rate grip(s) if reading is lower

than 3 MΩ.

8. Check continuity/resistance between

the two hand rate grips.

• Measure the resistance between the two

outside rings.

NOTE: See diagram #6.

REPLACE: Heart Rate grip(s) if reading is

less than 18.0Ω

Diagram 7

4.18

Polar Heart Troubleshooting

If the display is having difficulty picking up polar heart rate readings, verify proper

usage.

** CAUTION **

Do not stand on

the running belt

while performing these step.

NOTE: Secure

the chest strap

transmitter as

high under the

pectoral muscle

(breast) as is

comfortable and

allow normal

breathing.

NOTE: Wet the

electrodes (the

two grooved

rectangular

areas) thoroughly with water.

Symptom:

Intermittent or erratic polar heart reading.

1. The maximum distance for polar heart rate to receive a signal is 3 feet.

2. Verify chest strap is correctly positioned. Chest strap electrodes must be

properly positioned and wet. See below diagrams.

NOTE: Verify

heart rate response without

operating the

running belt.

Straddling the

treadmill press

the HEART key

If heart rate is

not picked up

engage Heart

Rate Test, refer

section 2.8

3. Connect Polar Board straight to the display input.

• By-pass the Combiner Board, insert the heart rate wires straight to the

display. See Diagram 1 # 1a

REPLACE: Polar Board if Heart Rate registers. If no Heart Rate is registered go to .

4.19

Display Cable

The following symptoms indicates a faulty or pinched display cable.

Symptom:

No display power related.

**CAUTION** 1. No display power, treadmill elevation bottoms out during start-up.

Do not stand on 2. No display power, MCB LED +11 remains lit on 110v units. MCB LED Display

the running belt remains lit on 220v units.

while perform-

ing these steps.

1. In Test Mode only up direction works, MCB LED “UP” remains lit.

NOTE: Alter- 2. In Test Mode no elevation count (elevation motor pot), will elevate both directions

native mode to reads EL LOST across display in regular operation mode.

enter Motor 3. In Test Mode no elevation response, reads EL STL across display in regular

Test Mode; turn operation mode.

the power 4. In Test Mode elevation count registers slow to actual elevation response.

switch “ON” 5. Treadmill elevation without command in regular operation mode.

while pressing 6. Elevation motor hesitates in between elevation percents, MCB LEDs “UP” &

the “8” key sim- “Down” toggle back and forth.

ultaneously on 7. Elevation intermittently responds, registers different elevation display codes in

the display. regular operation mode.

Intermittent or no elevation.

Intermittent or no speed reading

1. In Test Mode belt movement, but no RPM reading. MCB LED RPM remains of

on 220v units. registers NO RPM code across display in regular operation mode.

2. In Test Mode or regular operation mode, RPM reading intermittently flashes.

3. In Test Mode or regular operation mode, RPM speed fluctuates.

4. In Test Mode MCB LED PWM (110v units) or MOTOR CONTROL (220v units)

remains off and no RPM reading is registered.

4.20

Drive Motor

The following symptoms indicates a faulty drive motor.

Symptom:

Tripping the ON/OFF switch breaker.

**CAUTION** 1. Disconnect the drive motor belt.

Do not stand on

the running belt ON/OFF switch trips, verify if the MCB LED I-LIMIT lights up (110v units), this

while perform- would indicate Drive Motor pulling higher amps than desired.

ing these steps.

NOTE: If the

ON/OFF swith 1. Disconnect the drive motor belt.

trips only with a 2. Isolate the noise. Bellow is a list of discriptions related to motor noise:

load, running ----Knocking; Noise described for bearing failure or motor magnet.

belt may be ----Grinding ; Noise describing bearings, motor brush wear.

worned. ----Squeaking; Motor brushes installed incorrectly, flywheel loose, motor

bearings.

----Howling; Usually described when motor increases to higher speeds.

2. Run the drive motor for ten minutes at a high speed (6 MPH/ 10 KPH). If the

Drive Motor making noise.

4.21

Head / Tail Roller

You may need to replace the head or tail roller if the following symptoms are

observed.

Symptom:

Thumping, knocking noise as the running belt goes over the

roller.

Verify the following:

• Delron end caps are loosening.

• Bearings are grinding or knocking.

• Lagging (coating) is loose.

• Thumping sounds (may also indicate a possible wax build up).

Note: Do not

remove all the was

as it is required to

lubricate both the

running belt and

deck.

The running deck surface is coated with a special wax. During breaking

period (first 20 – 30 hours of operation), some wax may form on the tail

roller causing a loud thumping noise. In worse cases, this may cause mistracking. If the thumping noise continues, remove the wax buildup. With the

following procedure:

1. Loosen or remove the tail roller by backing of the Allen screws. Use a ¼

“ Allen wrench.

2. Remove the largest buildup of wax deposits from the tail roller. Use a

plastic scraper, credit card or piece of wood. Never scrap with a sharp

metal object.

4.22

Drive Belt Troubleshooting

The drive belt tension may require tightening if a slipping problem occurs on the drive

pulley.

Symptom:

Running belt slips when running or walking.

1. Loosen the four motor mount kep nuts and washer using a 5/16 “ wrench.

2. Adjust the drive belt tension by turning the motor mount adjustment

(socket head cap) screw. See diagram below. Tension should be no more

than 90 lbs.

• If too tight, turn the belt tension screw counter-clockwise.

• If too loose, turn the belt tension screw clockwise.

3. Simultaneously tighten the belt tension lock nut while holding the belt

tension screw with a 5/16” wrench.

4. Simultaneously tighten the right, rear, motor mount nut, then tighten the

remaining bolts.

5. Verify if the belt is tensioned properly.

4.23

Running Belt Troubleshooting

Note: For optimal To prevent belt problems from occurring, verify the running belt is properly

performance during the adjusted and working smoothly by performing the following steps:

lifetime of the treadmill,

running belt adjust-

ments may become described as a smooth glass texture, the correct feeling should be a

necessary. All adjust- rough texture such as found on the undersides of the belt.

ments are performed

by adjusting the tail

roller Allen screws If glazed, replace the running belt. Contact your local retailer or act

with a 1/4” Allen STAR TRAC Product Support Department at 800-501-1221 or through

wrench. our web site at http://www.startrac.com.

inspect the running belt. The running belt should move smoothly, without

drifting to far to the left or right. This will cause fraying or damage to the

running belt. For proper tension and tracking, refer to Running Belt

Tension and Running Belt Tracking in this section.

If you observe the following symptoms, running belt needs to be replaced

1. On/off switch tripping to the “off” position after treadmill is used for short

period of time.

2. Running belt continues to slip after tightening . (Provided the drive belt has

been checked for proper tension)

1. Feel the underside center of the running belt, for glaze. Glaze is

2. Activate the treadmill. Stand at the back of the treadmill and visually

3. Edges of the running belt are frayed.

4. Running belt seam is coming apart.

5. Running belt beginning to fold in the middle.

4.24

Running Belt Tracking

Note: The running belt If the running belt is not centered on the tailroller and is either to far left or

may mis-track due to right, adjust tracking using the following steps::

the style of the walker

or runner.

Note: The running belt

will track to the side sides of the tail roller with a 1/4” Allen wrench in 1/4 turn increments.

less tensioned. (See below diagram)

If the running belt is tracking to the left, adjust the running belt to track

to the right. Tighten the left tailroller Allen screw by turning clockwise

or loosen the right tail roller bolt by turning counter-clockwise.

If your running belt is tracking to the right, then adjust the running belt to

track to the left. Tighten the right tail roller Allen screw by turning clock wise or loosen the left tail roller bolt by turning counter-clockwise.

mph (16 kph) and verify belt stays centered.

Tension procedure in this section.

4. Verify correct running belt tension as outlined in the Running Belt

1. Turn treadmill on. Increase speed to 3.0 mph (5.0 kph).

2. Adjust tracking by adjusting the tailroller Allen screws located at the back

3. After running belt appears to be tracking properly, increase speed to 10

Note:To ensure proper

tracking, the treadmill

leveling feet must be

adjusted to conform

to the floor surface.

For proper procedure

see Feet Leveling in

this section.

4.25

Running Belt Tension

Note: Prior to making The running belt tension may need to be adjusted over time to keep the

any adjustments to the the belt from slipping with each jogging step or at high speeds. Use the

running belt tension, following procedure for testing belt tension.

verify the drive motor

belt is properly

tensioned.

foot on the running belt with a very sharp impact. The running belt should

not come to a complete stop. The running belt should slip for a split

second, then forcing your foot back.

If the running belt does not stop with impact, the running belt may be to

tight and cause the belt and other components to premature fail.

Loosening the tail roller Allen screws a 1/4 of a turn counter-clockwise and

re-checking will be necessary.

If the running belt stops and noticeable slippage occurs, check the

location of the slippage. It can be slipping due to the drive belt slipping

over the drive motor pulley and head roller or from the running belt

slipping over the rollers.

---- If the slippage is caused from the drive belt slipping over the drive

motor pulley, loosen the motor mount bolts located at the mount

of the drive motor and tighten the adjustment bolt. For detail

more details refer to Drive Belt Tension procedure in this

section.

--- If the slippage is caused by the running belt slipping over the

rollers, tighten the running belt.

1. Accelerate the running belt to 3.0 mph (5.0 kph).

2. Stand on the side of the treadmill. Grasping the handrails firmly, place one

Note: If you do not

tighten Allen screws in increments. Repeat Step Two until running belt is tensioned properly.

equal increments, you

will mis-track the

running belt. Verify

correct belt tracking

procedure.

The running belt has been tightened too much and may require loosening, if:

Note: Do not over 1. The edges of the running belt curls down or up, causing the middle of the

tighten the running belt. belt to bubble up.

Over tightening will

cause premature 2. Running belt creaks as it goes over the rollers.

failure.

Note: If the running 3. Treadmill trips the circuit breaker (on/off switch) after tensioning.

belt creaks in spite of

being loosened, apply

dry lubricant, such as

TFE Teflon or powered

wax to the deck.

3. Tighten the left and right tail roller Allen screws clockwise in equal 1/4

4.26

Running Deck

The following procedure will help determine and properly adjust the deck bumpers.

Symptom:

Running deck squeaks when running.

1. When properly located, the side bumpers (two on each side) bear against the

delrin rods in the frame rails. The rear bumpers bear against the steel posts at

the end of the frame rails. If the bumpers are not located so they bear against

the rods as described, the running deck may shift to one side or the other

during use. This allows the rear edge of the deck to rub against the steel post.

This causes a high-pitched squeak as the user runs on the treadmill.

2. To determine if a deck has the bumpers properly located, look under the end

cap/finger guard to see if the bumpers on the end of the deck bear against the

steel posts. A problem definitely exists if the bumpers are to one sode of the

steel posts and the edge of the deck is bearing against the posts.

3. Remove the screws securing each of the four delrin rods and pull them out.

Look through the hole in the frame to see if the running deck bumper is

adjacent to the hold, such that it would bear against the delrin rod if it was

reinstalled in the hole. If all bumpers are properly located, replace the delrin

rods and examine the treadmill further for the other causes of squeaks. If one

or more bumpers is misalign, follow the procedure given below.

4.27

Running Deck

Symptom:

Running deck squeaks when running (continued).

Correcting the problem:

1. Position the deck with the rear bumpers properly aligned with the steel posts.

With a pencil, make a mark on the deck adjacent to each of the four delrin rods(

as seen from the top of the side rails).

2. Reach under the running deck, shift the deck as far as possible to tone side. On

the side that now has the edge of the deck exposed from under the frame, pull

the rear edge of the deck upward until it is just above the frame rail. Use a

screwdriver or putty knife to hold the deck above the frame. Using another

screwdriver, raise and hold the front of the deck.

3. Remove the bumper(s) that are not aligned with the pencil marks by carefully

prying them away from the deck with a screwdriver, knife or putty knife.

4. Position the bumpers (removed in the previous step) so they are adjacent to the

pencil mark(s), and drive them into the edge of the deck using a hammer.

5. Once the bumpers on the side have been installed in the proper locations,

remove the screwdrivers used to hold the deck above the frame.

6. Repeat process on opposite side of the treadmill.

7. After the bumpers have been properly installed on both sides of the running

deck, position the deck properly, and verify that all bumpers have adjacent o

the holes. Reinstall the delrin rods.

8. Test the treadmill thoroughly. The squeak should be gone.

4.28

NOTE: Verify that

the treadmill is level

before isolating any

specific component

Isolating Noise

Sounds travel throughout the treadmill making it difficult to isolate the cause of a

sound. The following procedure will help determine where a noise may be coming

from.

Isolate the noise.

1. If the noise seems to be coming from two different parts (drive motor or roller

etc.), isolate the noise by disconnecting the drive belt. Then run the drive motor

by itself. If the noise goes away, manually push the running belt to see if the

noise returns. If it does, then it is coming from the rollers.

2. Isolate the rollers. Adjust the tension on the tail roller screws until the running

belt is loose. Spin each roller by itself to determine where the noise is coming

from.

NOTE: Ensure all

assembly screws

are tight:

1. Handrails.

2. Display board.

3. Motor shroud.

NOTE: When doing

the stethoscope

method, be careful

of body placement.

Ensure all loose

items (hair, clothing

, jewelry etc) are

secure and away

from moving parts.

The Stethoscope Method

Using a long screwdriver as a stethoscope put the handle of the screwdriver to

1.

your ear. Place the opposite end of to the area where you are listening. This will

help locate where a specific noise is coming from.

Symptoms:

Rumbling

Wax buildup on the rollers.

•

• Head / tail roller bearings.

• Adjustable feet / leveling.

• Floor condition; thick carpet or wood floors.

Elevation screws dry.

•

• Elevation motor stripped.

Squeaking

Deck rubbing against the frame.

•

• Adjustable feet / leveling.

• Head roller and drive motor pulleys not aligned.

• Drive belt tensioning.

• Running belt tensioning.

• Drive motor brushes.

Knocking

Drive motor bearings.

•

• Head / tail roller bearings.

• Running belt hitting the back or front of the frame.

• Missing or worn deck cushions.

Grinding

Drive motor bearings.

•

• Head / tail roller bearings.

Motor brushes worn. 4.29

Leveling

To ensure proper tracking of the running belt, treadmill leveling should be verified.

Symptoms:

NOTE: If a leveling

foot does not make

contact with the floor

or if it lifts upwards

as weight is applied

to one corner of the

deck, this will cause

the running belt to

mis-track.

• Running belt travels to one side.

• Treadmill vibrates.

Leveling feet must be adjusted to conform to the floor surface. After the treadmill

has been leveled, tracking of the belt must be tested and adjustments made as

necessary. This two step procedure is particularly important for treadmill installed in

a residence, where floors are commonly uneven. When a treadmill is installed on

carpet, a repeat adjustment may be required after the carpet and padding have

been compressed by the treadmill feet.

1. Place the treadmill in the exact location where it is to be used.

2. Check the leveling feet at each corner of the treadmill to ensure that they make

contact with the floor surface. It may be helpful to have one person bear their

weight at one corner of the running belt, then move to another corner, etc.,

while another person notes whether one or more corners lift from the floor as

weight is applied.

---- Using a 9/16 inch open end wrench, loosen the lock number (see diagram).

---- Adjust leveler height by turning the leveler base. The wrench may be used on

the lower nut for this purpose.

---- Tighten the lock nut.

4.30

NOTE: For complete

leveling procedure, see

the following page.

Vibration

A treadmill vibrates during use if the floor or leveling feet are uneven or when

assembly bolts are loose.

Symptom:

Unit vibrates while running.

1. Verify the treadmill is on an even, uncarpeted floor.

• If no, move the treadmill to an even floor.

• If floor is carpeted, place the treadmill on a rubber mat.

2. Verify that the Leveling feet are adjusted correctly.

3. Verify the following assemblies.

• Handrails

• Slick deck

• Display board

• Motor mount

• Flywheel

NOTE: When checking

motor brushes, the

treadmill must be

turned off and

unplugged.

4. Remove the drive belt and isolate the motor.

• If the drive motor vibrates, check motor mount bolts.

• Verify that the motor brushes aren’t cracked.

4.31

**CAUTION**

When checking motor

brushes, always turn

the treadmill off and

unplug.

Static Shock

The treadmill may cause a slight shock from the display panel or handrails, due to

a faulty ground wire or a worn running belt and deck.

Symptom:

Slight shock from handrails or when using the display panel.

1. Check the line cord and plug prongs for signs of damage.

• Verify no prongs are broken, loose or missing.

2. Check the green ground wires attached to the frame for the following:

• Motor

• Line cord

3. Check running belt condition.

• Check for glazing. Replace the running belt if glazed.

• Wax slick deck.

4. Check drive motor conditions