Page 1

x

x

SERVICE MANUAL

Pro Tread AC

7600

X

Star Trac Fitness x 14410 Myford Road x Irvine, California 92606 x 800-503-1221 Tel x 714-669-1660 Tel x 714-669-0739 Fax X

http://support.startrac.com

7700

email: support@startrac.com

Page 2

Service Manual: E-TR and E-TRi

INTRODUCTION

This is the Service Manual for the Star Trac AC Pro Tread 7600 & 7700. This manual is designed to

be easy to use, providing detailed instructions on how to service and maintain the AC treadmills.

Star Trac highly recommends that you read the entire manual prior to performing any maintenance or

repair. The information on the following pages will enable you to begin easily, quickly and safely.

This is not an Owners Manual. This service manual is intended for use by a qualified technician as a

guide to diagnose and repair service issues on the referenced product.

If you have any questions or require additional assistance, contact the Star Trac Customer Service

department during regular hours of operation.

Star Trac Customer Support contact information:

USA

Hours: Monday thru Friday (excluding U.S. holidays)

Check the support website for operating hours and holiday schedule

Toll Free: 800-503-1221

Tel: 714-669-1660

Fax: 714-669-0739

Website: http://support.startrac.com

Email: support@startrac.com

Europe

Hours: Monday thru Friday

Tel: +44 (0) 1494-688264

Fax: +44 (0) 1494-688268

Website: http://support.startrac.com

Email: EuropeSupport@startrac.com

(excluding U.K. holidays)

Español

Hours: Monday thru Friday

Website: http://support.startrac.com

Email: ServiciosEnEspanol@startrac.com

Tel: 714-669-1660

Fax: 714-669-0739

(excluding U.S. holidays)

Asia/Middle East

Hours: Monday thru Friday

Tel: +65-6225-6252

Fax: +65-6225-1501

Website: http://support.startrac.com

Email: AsiaSupport@startrac.com

Email: MiddleEastSupport@startrac.com

(excluding Asia/M.E. holidays)

1

Service Manual: E-TR and E-TRi

Page 3

TABLE OF CONTENTS

INTRODUCTION.................................................................................................................................................. 1

TABLE OF CONTENTS ....................................................................................................................................... 1

PRECAUTIONS - SAFETY .................................................................................................................................. 4

ELECTRICAL SAFETY ................................................................................................................................................. 4

MECHANICAL SAFETY ...............................................................................................................................................4

EQUIPMENT PLACING ...................................................................................................................................... 5

POWER (ELECTRICITY) .................................................................................................................................... 6

Objectives .......................................................................................................................................................................... 6

Safety ................................................................................................................................... Error! Bookmark not defined.

Terminology ........................................................................................................................ Error! Bookmark not defined.

General Electricity............................................................................................................................................................ 7

Electrical Tools ................................................................................................................................................................. 7

Wiring................................................................................................................................................................................ 7

Power Cords...................................................................................................................................................................... 8

PREVENTIVE MAINTENANCE......................................................................................................................... 9

Overview............................................................................................................................................................................9

Value of Preventive Maintenance.................................................................................................................................... 9

Determining When to Perform Maintenance................................................................................................................. 9

Preventive Maintenance Cautions................................................................................................................................... 9

Preventive Maintenance Schedule................................................................................................................................. 10

*Running Belt & Deck Rewaxing..................................................................................................................................................10

DAILY ............................................................................................................................................................................. 11

Clean ..............................................................................................................................................................................................11

Inspect ............................................................................................................................................................................................ 11

WEEKLY ........................................................................................................................................................................ 12

Clean ..............................................................................................................................................................................................12

Inspect ............................................................................................................................................................................................ 12

MONTHLY ..................................................................................................................................................................... 13

Clean ..............................................................................................................................................................................................13

Inspect ............................................................................................................................................................................................ 13

Lubricate.........................................................................................................................................................................................13

BI-MONTHLY.................................................................................................................... Error! Bookmark not defined.

Calibration and System Check ........................................................................................................Error! Bookmark not defined.

AS NEEDED ...................................................................................................................................................................13

Belt Service .................................................................................................................................................................................... 13

RUNNING BELT................................................................................................................................................. 14

Importance of Running Belt Maintenance ................................................................................................................... 15

1

Service Manual: E-TR and E-TRi

Page 4

Running Belt “Do Not’s” ...............................................................................................................................................................15

Cleaning a Running Belt ................................................................................................................................................ 16

Running Belt Tension..................................................................................................................................................... 17

Running Belt Alignment ................................................................................................................................................ 20

Roller Care & Maintenance........................................................................................................................................... 21

Applying Wax to a Waxless Running Belt ................................................................................................................... 22

MAINTENANCE MODE .................................................................................................................................... 24

Engaging Maintenance Mode ........................................................................................................................................ 24

Maintenance Mode Keys................................................................................................................................................ 25

DISPLAY PARAMETERS .................................................................................................................................. 26

Parameter Defaults.........................................................................................................................................................26

Parameter Setting Definitions ....................................................................................................................................... 28

MAINTENANCE MODE – TEST MODES ....................................................................................................... 31

DISPLAY TEST ............................................................................................................................................................................31

MOTOR TEST...............................................................................................................................................................................31

BELT/DECK TEST .......................................................................................................................................................................31

CALIBRATE SCALE....................................................................................................................................................................32

CSAFE TEST.................................................................................................................................................................................33

HEART RATE TEST.....................................................................................................................................................................33

INFRARED TEST .........................................................................................................................................................................33

LAST ERROR LIST ...................................................................................................................................................................... 33

MAINTENANCE MODE – AUTO CALIBRATION ......................................................................................... 34

LAST ERROR LIST DEFINITIONS ................................................................................................................. 35

DEFINITIONS...............................................................................................................................................................................35

LAST ERROR LIST BANKS........................................................................................................................................................ 35

DFR INFORMATION......................................................................................................................................... 36

DFR’s ............................................................................................................................................................................................. 36

Same Codes, Different Meanings................................................................................................................................................... 36

How Do You Know What or If a DFR Code Has Been Captured?................................................................................................ 36

SOFTWARE - DISPLAY..................................................................................................................................... 37

Uploaders......................................................................................................................................................................... 37

Uploading Software into the Uploaders........................................................................................................................ 38

SOFTWARE - MCB ............................................................................................................................................ 45

Uploading Software into the AC MCB with MCB Uploader .....................................................................................46

PART REPLACEMENT PROCEDURES.......................................................................................................... 50

Table Of Part Replacement Procedures ....................................................................................................................... 50

Running Belt Tensioning Procedure............................................................................................................................. 51

TROUBLESHOOTING ....................................................................................................................................... 55

Table Of Troubleshooting Documents..........................................................................................................................55

“Check Speed System” and “Check Motor System”...................................................................................................................... 56

DFR Code 1000000, 100000 and 10000 ........................................................................................................................................57

DFR Code 4000.............................................................................................................................................................................. 58

2

Service Manual: E-TR and E-TRi

Page 5

DFR Code 1000.............................................................................................................................................................................. 59

DFR Code 800 & 400.....................................................................................................................................................................60

DFR Code 200................................................................................................................................................................................61

DFR Code 40, 20 & 10...................................................................................................................................................................62

DFR Remaining Codes...................................................................................................................................................................63

Slipping Running Belt.....................................................................................................................................................................64

3

Service Manual: E-TR and E-TRi

Page 6

PRECAUTIONS - SAFETY

The 7600 and 7700 treadmills are wired for either 120 VAC nominal or 230 VAC nominal power input.

They are equipped with a specific electric cord and plug to permit connection to the proper electric

circuit. Make sure that the product is connected to a dedicated power line having an outlet with the

same configuration as that of the plug. NO adapter should be used with this product. If the product

must be reconnected for use on a different type of electric circuit, the reconnection should be made

by qualified service personnel.

Your safety and the safety of those around you must come first

when working on any piece of Star Trac equipment!

ELECTRICAL SAFETY

x Always make sure that the equipment you are working on is turned off and unplugged BEFORE

performing any work, unless otherwise noted, or when necessary for voltage testing.

x When replacing fuses, be sure the fuses are of the correct amperage rating. DO NOT exceed the fuse

amp rating. If necessary use a fuse of lower rating until the proper fuse may be obtained.

x When checking continuity at the wire connector, insert the test probe carefully to prevent the terminals

from bending.

x To pull apart electrical connectors, pull on the connector itself, not the wires.

MECHANICAL SAFETY

x When working on any mechanical equipment, be sure they are not moving when placing your body

parts anywhere near them.

x Avoid wearing loose clothing and jewelry while performing work on any unit with moving parts, whether

they are moving or not.

The 7600 and 7700 treadmills weight approximately 323 lbs (146.5 kg). Use caution when lifting,

moving or servicing.

4

Service Manual: E-TR and E-TRi

Page 7

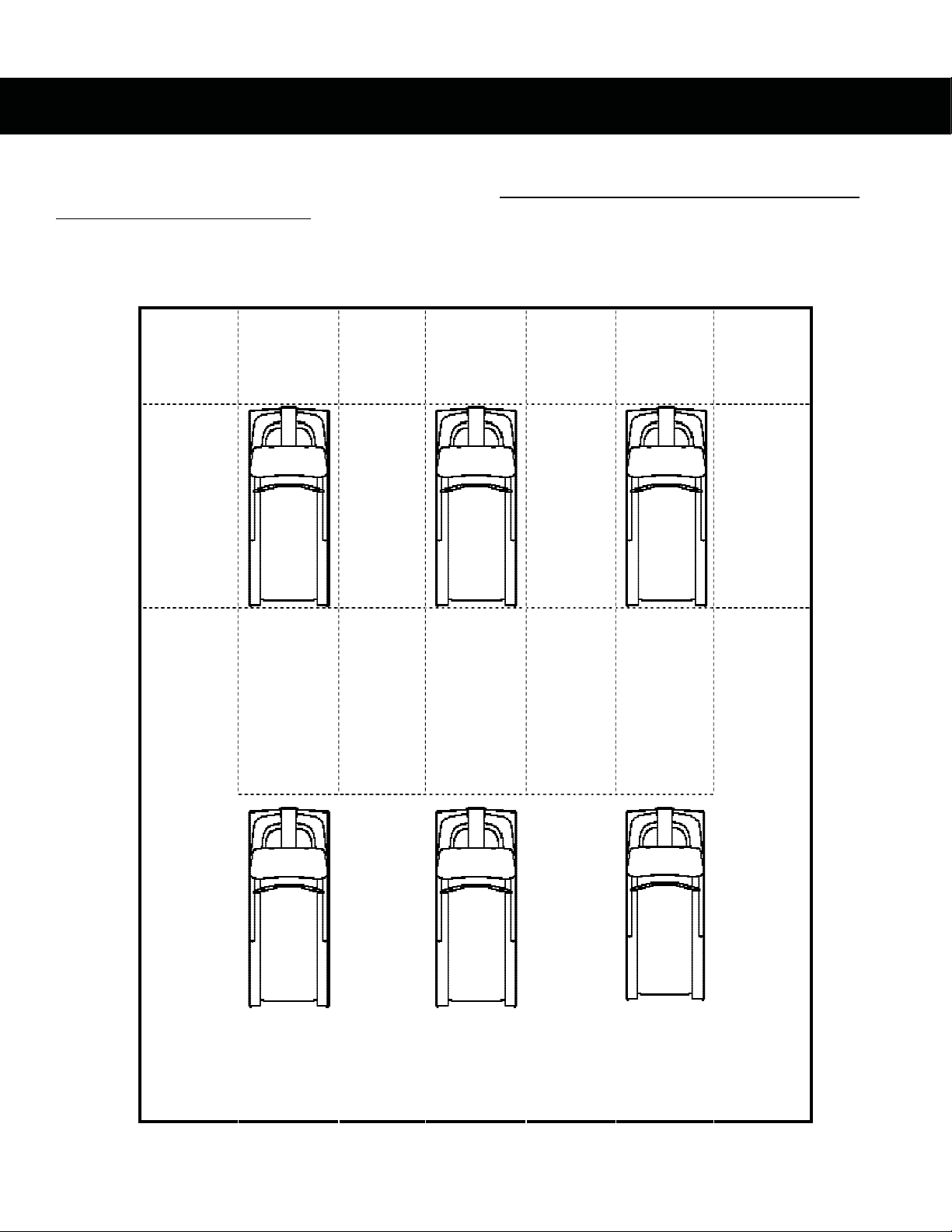

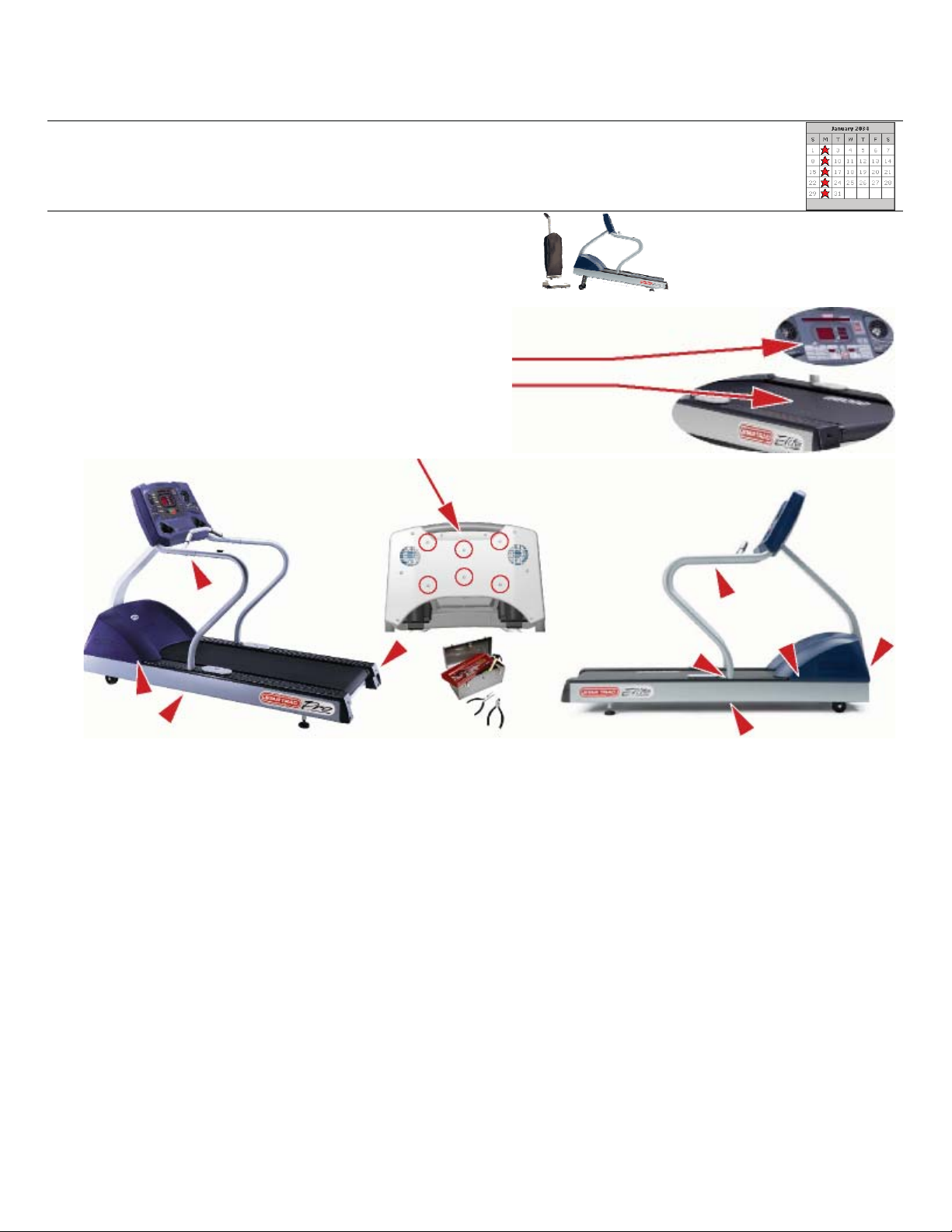

EQUIPMENT PLACING

Star Trac recommends that treadmills be spaced a minimum of 20.0 inches (0.5 m) apart to allow

safe and easy ingress and egress. More importantly, there must be at least 48 inches (1.25 m) of

free space behind the treadmill.

The Pro Series treadmill measures: 85.5” l by 34.0” w (217 x 86.5cm). See the following graph for

proper equipment spacing requirements:

inches

(0.5 m)

m 20.0 o

m 20.0 o

inches

(0.5 m)

inches

(1.25 m)

m 48.0 o

m 20.0 o

inches

(0.5 m)

m 20.0 o

m 48.0 o

inches

(0.5 m)

inches

(1.25 m)

m 20.0 o

inches

(0.5 m)

m 20.0 o

m 48.0 o

inches

(0.5 m)

inches

(1.25 m)

m 20.0 o

inches

(0.5 m)

5

Service Manual: E-TR and E-TRi

Page 8

POWER (ELECTRICITY)

Objectives

If you are not qualified/comfortable working with electricity you should consult a certified electrician.

This section should provide you with the information necessary to properly service your Star Trac unit

by giving you:

x A basic understanding of electrical safety

x A basic understanding of electrical terminology

x A basic understanding of electricity in general

x A basic understanding of electrical tools

x An overview of your Star Trac unit

Safety

See the “PRECAUTIONS – SAFETY” section of this manual.

Terminology

CURRENT – The number of electrically charged particles that flow past a given point on a

circuit in a given time

AMPERE (AMP) – A measure of current

VOLT – Measures the current pressure of a circuit

x Star Trac refers to the 2 most common global voltages as:

o 110V (or 110VAC)

o 220V (or 220VAC)

WATT – The rate at which an electrical device consumes energy

OHM – A measurement of resistance

o Ohm’s Law:

Current:

I = current, V = voltage, R = resistance

I = V / R

V

I =

R

Depending on what you are trying to solve, other variations can be made:

Voltage:

Resistance:

V = I x R

R = V / I

All variations of Ohm’s Law are mathematically equal to one another.

RESISTANCE – Used to dissipate passing current into heat to lower a voltage. Resistance

is measured in Ohm’s.

POTENTIOMETER (POT) – An electronic component which has an adjustable resistance

HOT wire – Delivers power to the unit. Typically has black, brown, or red insulation

NEUTRAL wire – Once electricity has done its work, it goes back through the neutral wire

to complete the circuit. Typically has white or blue insulation

GROUND wire – In addition to the neutral wire, the ground wire offers current another path

should an electrical short happen. Also help to dissipate static build-up from the running

belt and other components. Typically has green insulation (may be bare copper in some

cases)

6

Service Manual: E-TR and E-TRi

Page 9

General Electricity

Star Trac refers to the two most common global voltages as:

x 110V (or 110VAC)

x 220V (or 220VAC)

Voltages worldwide can vary. Star Trac products are designed to be stable within most voltages:

x For 110V systems the voltage range is: 110 VAC – 125 VAC 50/60hz

x For 220V systems the voltage range is: 190 VAC – 250 VAC 50/60hz

Electrical Tools

MULTIMETER – Used to test voltages, amperages and ohm readings. They

can vary on type from digital (as shown to the right) or analog. For this service

manual we will refer to the digital style for diagnostics.

Wiring

The 7600 or 7700 series treadmill is intended for commercial usage. Depending on the location type

and country a unit is manufactured for, it will come equipped with a special power cord and plug.

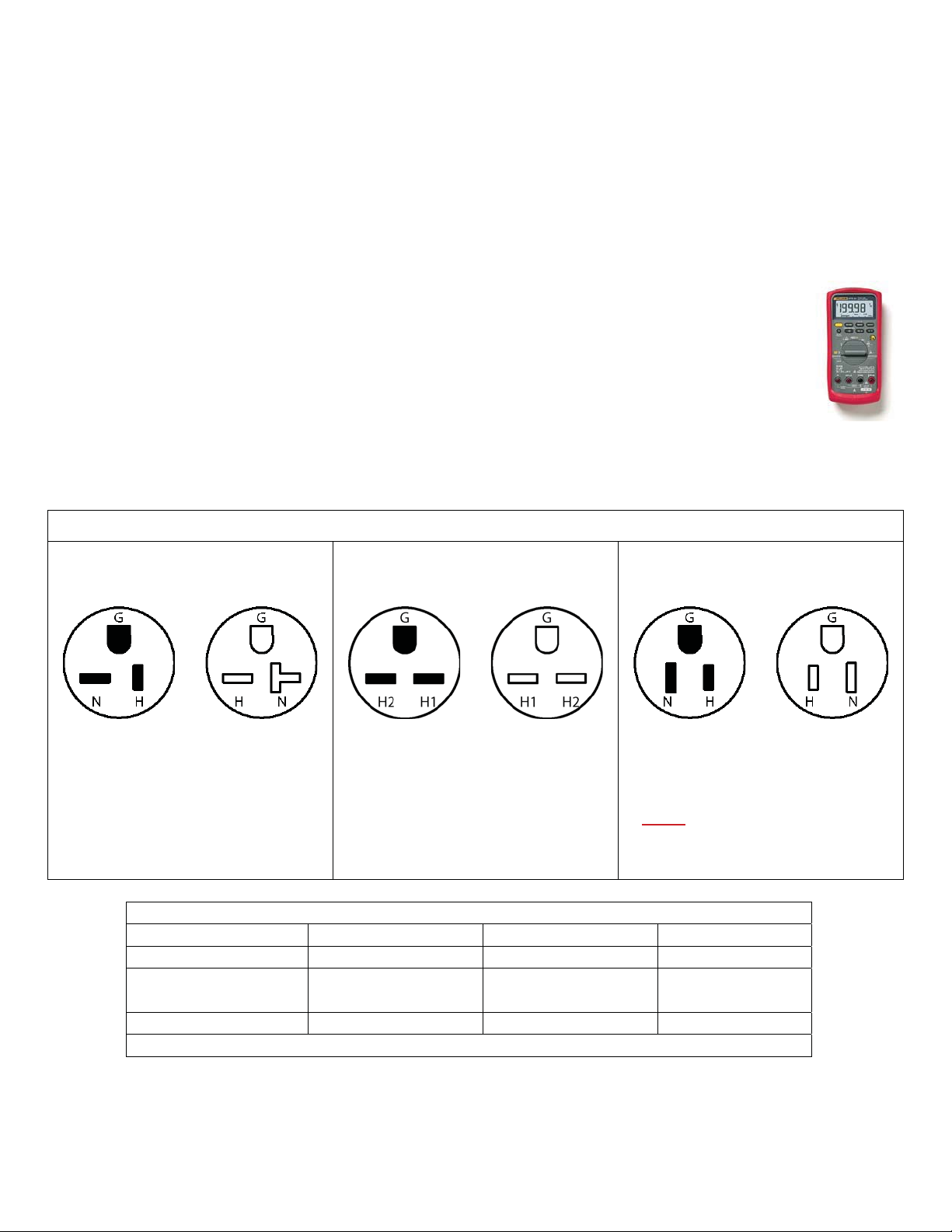

NEMA Configurations (U.S.A.)

110V Commercial 220V Commercial 110V Home

NEMA 5-20 NEMA 6-15 NEMA 5-15

Plug Receptacle Plug Receptacle Plug Receptacle

In this configuration, the HOT line is in

the normal 110V position, while the

NEUTRAL line has been turned 90q.

In this configuration, both the HOT and

NEUTRAL 220V lines are horizontal

(both opposite from the 110V config.)

This is the US standard 15 amp

configuration. Both HOT and

NEUTRAL lines are vertical.

THIS CONFIGURATION SHOULD

ONLY

BE USED ON TREADMILL

MODELS INTENDED FOR HOME

USE WITH A 15 AMP CIRCUIT

BREAKER!

Wire Configurations

HOT NEUTRAL GROUND

USA Wire

European Wire

Black White Green

Brown Blue Green/White

Green/Yellow

US Plugs

Small Flat prong Large Flat prong Round prong

Note: Some US units may have European wiring colors.

Star Trac treadmills require a “Dedicated” power line for proper operation and safety. Units should

never share a neutral or ground line. One 20 amp (or 15 amp) breaker per panel per treadmill only.

7

Service Manual: E-TR and E-TRi

Page 10

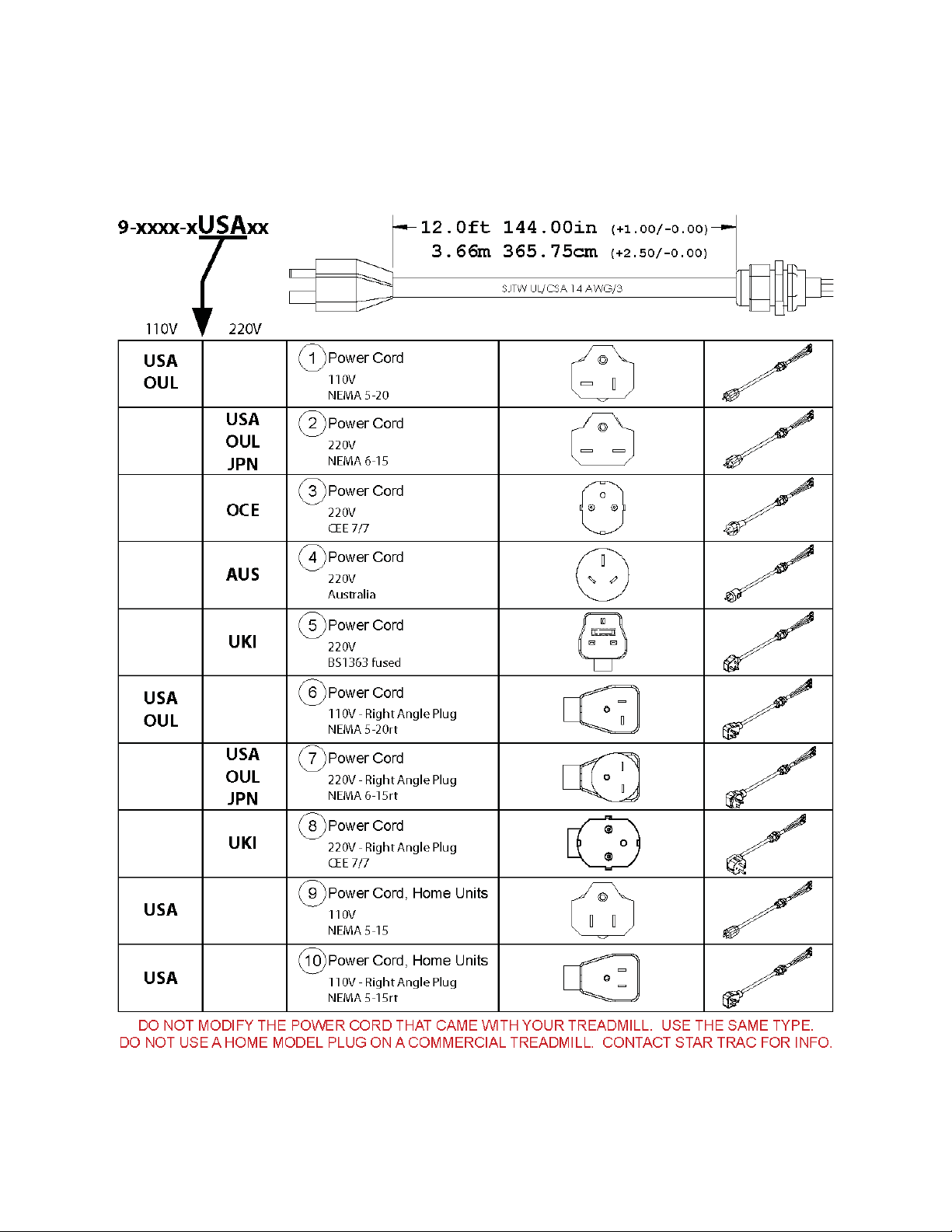

Power Cords

Below are the power cords you will find installed onto a Star Trac treadmill. Note the configuration of

the prongs for power and polarization:

8

Service Manual: E-TR and E-TRi

Page 11

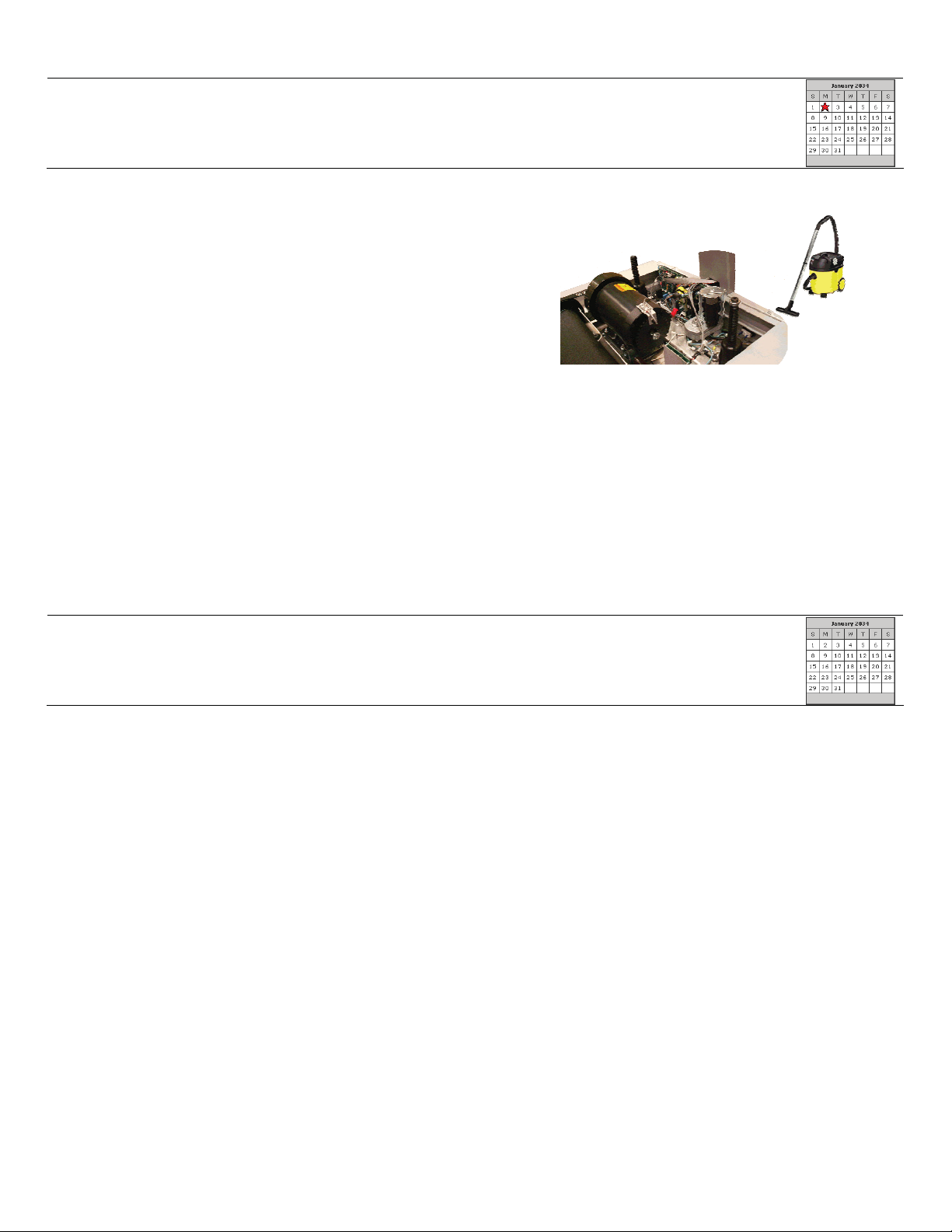

PREVENTIVE MAINTENANCE

Overview

Preventive maintenance (PM) is a schedule of planned maintenance actions

aimed at the prevention of failures. PM is the best way to preserve and enhance

equipment reliability by keeping key components clean and free of debris. PM

activities may include cleaning, vacuuming, visual inspections of key

components, lubrication, etc. The better your PM program is, the more

dramatically you can increase the life of your product and significantly reduce

equipment failures.

Value of Preventive Maintenance

Long-term benefits of proper regular preventive maintenance include:

x Decreased product downtime

x Decreased cost of repair

x Improved product reliability

x Continuous user satisfaction

Long-term effects and cost comparisons usually favor preventive maintenance

over performing maintenance actions only when the system fails.

Determining When to Perform Maintenance

Some types of PM need to be performed more often than others. The frequency of PM depends a

great deal on the use and environment of the unit.

Star Trac has a baseline of procedures that should be performed at pre-determined intervals (as

outlined in the “Preventive Maintenance Schedule” section). It is imperative to understand that this is

a baseline and PM schedules should be adapted to the environment and usage that the unit receives.

Preventive Maintenance Cautions

x While maintaining equipment you will want to avoid spraying any liquids directly onto any

surface of the unit. Always spray cleaning solutions onto a clean towel first then wipe the unit.

x While vacuuming the floor area using an upright vacuum, avoid getting the power cord caught

in the beater-brush of the vacuum.

x Disconnect the power cord from the wall before vacuuming under the shroud.

x Use extreme caution while vacuuming around wires and/or electrical components under the

shroud.

x Do not attempt to clean the running belt with a mop

x Do not apply any cleaners, protectants or solutions onto the running belt (i.e. Armor All,

SlickStuff, belt dressing, etc.)

9

Service Manual: E-TR and E-TRi

Page 12

9

9

9

9

9

9

9

9

9

9

9

9

9

Preventive Maintenance Schedule

This section provides a comprehensive list of factory recommended PM requirements, along with

detailed procedures for performing each task.

DAI LY

WEEKLY

MONTHLY

AS NEEDED

Wipe down all surfaces including:

Display, handrails shroud and heart rate grips.

Clean under the running belt (soft cloth only)

Visually inspect running belt for alignment and tension

Ensure the power cord is not under the treadmill

Vacuum floor under and around treadmill

Inspect inside surface of running belt and top of deck

Correct any display or handrail squeaks and rattles

Visually inspect display panel (keypad) for wear

Vacuum inside shroud

Visually inspect the drive belt

Visually inspect the power cord for pinches or breaks

Wipe clean and lubricate elevation screws

Change belt and flip/new deck

Running belt & deck rewaxing*

* *

*Running Belt & Deck Rewaxing

The Pro Tread models 7600 and 7700 are equipped from the factory with a “Waxless” running belt

and deck system. It is not necessary to regularly wax, rewax or lubricate the running belt and deck.

Wax may be applied to alleviate running belt noise (see waxing instructions).

10

Service Manual: E-TR and E-TRi

Page 13

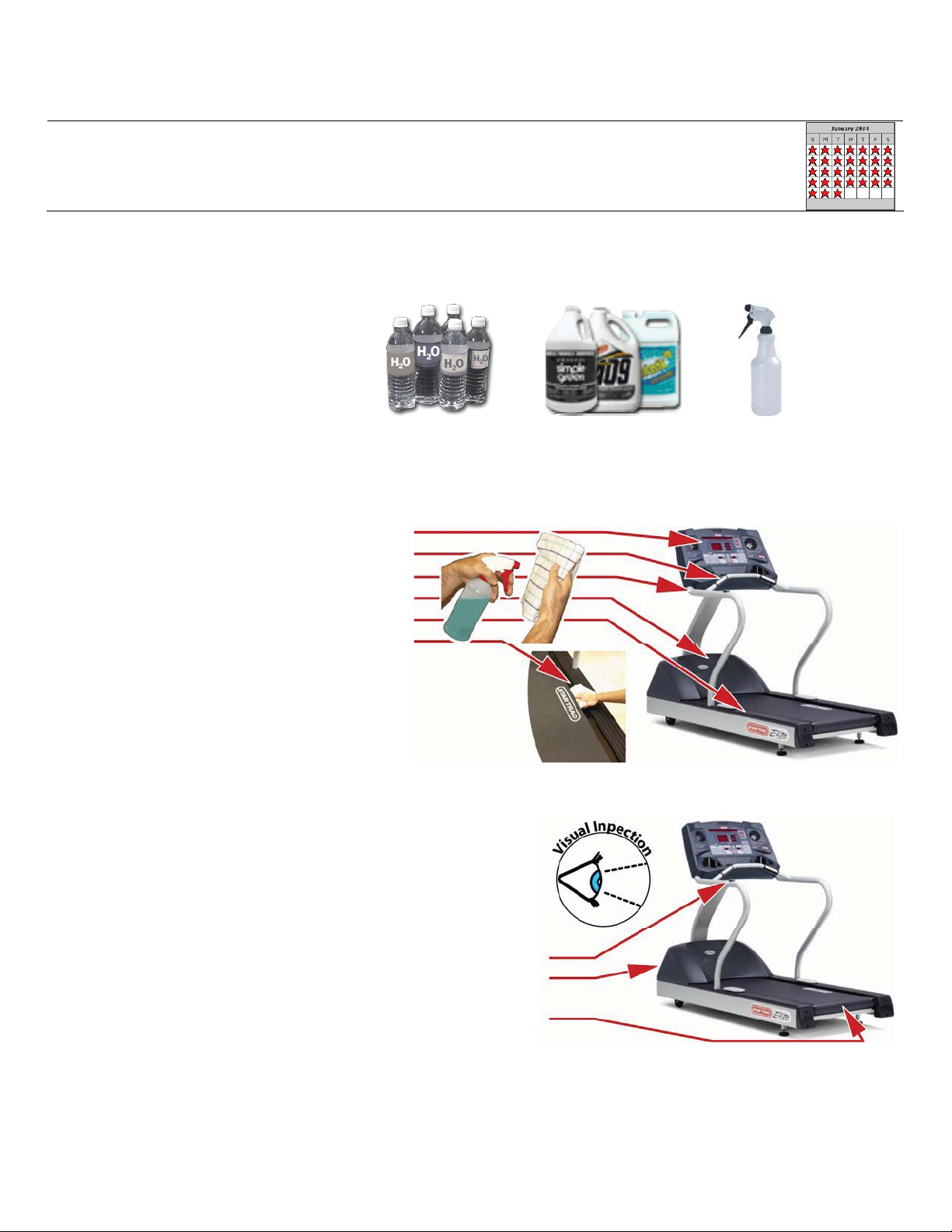

DAILY

Clean

x Use a 5:1 dilution ratio (5 parts water to1 part Simple Green, Formula 409,

Fantastic,or the like).

+ =

(5 parts water) (1 part cleaner)

Apply cleaning solution to a clean cloth then wipe the following areas (Do not spray

directly onto surfaces):

o Display (Keypad)

o Heart Rate Grips

o Handrails

o Shroud

o Side Bed Covers

o Under Belt Edge

Inspect

x Inspect running belt for proper alignment

(see Running Belt section for adjustment)

x Inspect for wear and tear on exterior parts

to include:

o Side stop switch for function

o Shroud, housing and other

plastics for damage

o Running belt seam for tears or

splits

11

Service Manual: E-TR and E-TRi

Page 14

WEEKLY

Clean

Inspect

x Inspect display panel (keypad) for wear

x Inspect inside of running belt and top of

x Inspect all mounting hardware and

Elevate the treadmill and vacuum the floor

around and underneath.

deck

correct any squeaks or rattles

12

Service Manual: E-TR and E-TRi

Page 15

MONTHLY

Clean

x Unplug the treadmill and remove the

Inspect

x Inspect the drive belt for tension and wear.

x Inspect the power cord for pinches and/or

broken prongs

Lubricate

shroud. Use a portable vacuum with

dust attachment to clean any dust, dirt

or debris from inside the shroud area.

Use extreme caution to not damage

any components or knock and

connections loose

x Wipe and debris from the elevation screws then lubricate. Use a spray lithium grease or a

thin coating of grease. Avoid thin lubricants (i.e. TriFlow, WD-40, or the like).

AS NEEDED

Belt Service

x In high use locations, it may be advisable to replace the running belt with a new one to

prevent undetected wear. It is advisable to replace a running belt in a high use location in a

preventive manner, to prevent potential wear related issues. A worn or wearing belt can

cause undetectable issues.

13

Service Manual: E-TR and E-TRi

Page 16

RUNNING BELT

Once a deck surface has been used, it should not be used again.

You must install a new belt and new deck surface together. Most Star Trac decks are double-sided

so they can be flipped to utilize both sides. Failure to install a new belt over a fresh deck surface will

cause the belt to burn along the center walking area, the edges will curl, electrical components will

create so much heat as to begin to fail, and will not be covered under warranty.

The Pro Tread models 7600 and 7700 are equipped from the factory with a “Waxless” running belt

and deck system. It is not necessary to regularly wax, rewax or lubricate the running belt and deck

on these models. Wax may be applied to alleviate running belt noise (see waxing instructions).

During a non-belt and/or deck related service, if a running belt and/or deck are removed, it may be

acceptable to re-install the belt and deck as long as no visible signs of wear are present or the

situation does not require replacement.

If replacing a deck due to wear, it is advisable to replace the running belt as well, because wear is

commonly caused in conjunction with the running belt.

If you have questions on whether or not to replace a running belt and/or deck, contact Star Trac

Customer Support.

14

Service Manual: E-TR and E-TRi

Page 17

Importance of Running Belt Maintenance

The running belt is the most important part of a treadmill. It is what a treadmill is all about. It is the

core component that must be maintained to insure many years of continued function.

By performing a few maintenance steps at regular intervals, you can help to:

x Increase the life of a running belt

x Reduce unnecessary down-time

x Prevent electrical component failures

Dirt is an abrasive. When it builds up under a running belt, it can act like sandpaper, wearing off the

slick coating of the deck and reducing the life of both the running belt and deck surface.

Additionally, lack of proper PM can cause a running belt to over heat and can delaminate (separate

the layers of the belt) resulting in curled edges, folded edges and ripples in the center of the walking

area.

Checking for proper running belt tension can help ensure that the running belt is not too loose. If a

running belt is too loose, it has the potential of tracking to the side and becoming damaged.

A worn running belt will cause other components (i.e. MCB, Drive Motor, etc.) to develop enough heat

that over time will cause failure to those components.

Taking care of a running belt at regular intervals can greatly reduce maintenance costs and

unnecessary downtime.

Running Belt “Do Not’s”

x Do not use Armor All, Slick Stuff, WD-40 or the like, on the running surface of a belt

x Do not use cleaners with ammonia or alcohol on the belt

x Do not use any lubricants under the running belt

x Do not over-tension a running belt

x Do not wash a running belt then reinstall it

x Do not reuse a deck surface when installing a new running belt

15

Service Manual: E-TR and E-TRi

Page 18

Cleaning a Running Belt

The running belt should be cleaned to help prevent dirt build up and maintain a nice appearance for

users.

To properly clean a running belt you will need:

TOOLS & MATERIALS

x Clean towel (1)

x Paint stick or ruler (1)

x Diluted all-purpose cleaner (409, Simple Green, etc.)

x Bristle brush

CLEANING PROCEDURE:

1. CLEAN BETWEEN DECK & BELT:

A. Using the paint stick or ruler, slide a dry towel under the middle of the belt from one side of the

frame to the other.

B. Hold the edges of the towel and pull towards the tail roller then pull back towards the head

roller.

C. Rotate the running belt around and repeat to completely wipe the entire underside of the belt.

TIP: Fold the dirty towel and shake into trash.

2. CLEAN BELT SURFACE

Spray the diluted cleaning solution onto a towel then wipe the running belt surface. For

heavier soiled areas, spray a tiny bit of solution onto the spot and use the bristle brush to

gently agitate the spot then wipe with the towel.

3. CLEAN SIDEBED COVERS

Spray the towel with cleaning solution to give a final wipe of the sidebed covers to help ensure

cleanliness.

16

Service Manual: E-TR and E-TRi

Page 19

Running Belt Tension

Proper running belt tension and tracking are important to maintain the performance and life of the

belt. It is recommended to follow this tensioning and tracking procedure whenever the running belt or

deck is replaced or as needed.

PARTS REQUIRED

x Masking tape and pen or pencil

x Ruler or tape measurer

TOOLS REQUIRED

x 1/4” Allen wrench

FREQUENCY

After: 1,000 Miles (1,600 Km) OR 1 Month. Whichever comes first.

x Clean deck with dry cloth and retighten belt using procedure below.

After: 6,000 Miles (10,000 Km) OR 6 Months

12,000 Miles (20,000 Km) OR 12 Months

18,000 Miles (30,000 Km) OR 18 Months

24,000 Miles (40,000 Km) OR 24 Months

30,000 Miles (50,000 Km) OR 30 Months

OR whichever comes first.

x Clean deck with dry cloth. Clean between the belt and deck using the “Cleaning A

Running Belt” section. Clean the head and tail rollers using the “Roller Care &

Maintenance” section. Retighten belt using the following procedure “Running Belt

Retensioning Procedure”.

17

Service Manual: E-TR and E-TRi

Page 20

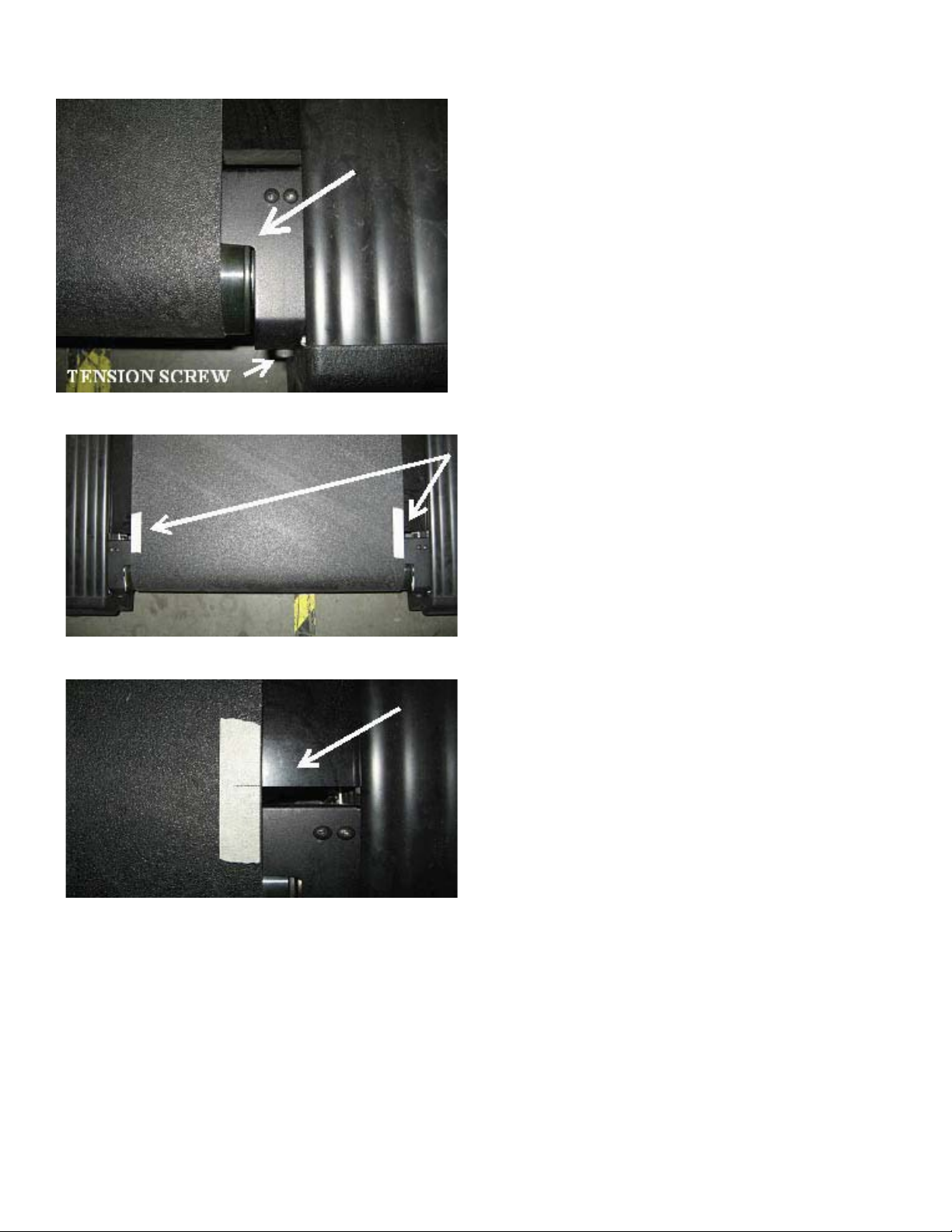

RUNNING BELT RETENSION PROCEDURE

Fig 1

Step 1: Release tension of running belt by

unscrewing the tension screws until the roller

touches the finger-guard. The belt should be

completely relaxed.

(Note: This applies to both left & right fingerguards.)

Step 2: Apply a piece of masking tape on the

edge of the running belt on both sides.

Fig 2

Fig 3

Step 3: Draw a line on each piece of masking

tape aligned with the edge of the deck.

(Note: Be careful not to move the belt or roller

while drawing the lines.)

18

Service Manual: E-TR and E-TRi

Page 21

Step 4: Check to make sure that both lines are

aligned with the edge of the deck at the same

point. (See Fig 4)

Fig 4

Step 5: Using a ruler or tape measure, draw a

line on each piece of tape parallel to each first

line at a distance of 3/8” (9.5mm) from each first

line. (See Fig 5)

Step 6: You are now ready to begin tensioning

the belt. Before beginning, make sure the line on

each piece of tape closest to the tail roller is

aligned with the edge of the deck on each side.

(See Fig 5)

Fig 5

Step 6: Using the 1/4" Allen wrench begin

tightening the tensioning screws (see Fig 1). You

will tighten (or stretch) the run belt until the

forward lines on the tape are aligned with the

edge of the deck.

Be careful to ensure the Tail Roller does not

turn while you are stretching the belt. If the

Tail Roller turns while you are stretching the

belt, start the procedure over. If the Tail

Fig 6

Roller turns while stretching the belt you will

not obtain proper tension.

When finished, remove the tape from the running

belt.

19

Service Manual: E-TR and E-TRi

Page 22

Running Belt Alignment

Step 1: Start the treadmill and set the speed to

3.0 mph (5.0 kmh). Make sure the running belt

tracks to the center (see Fig 7).

If the running belt shifts or tracks to either side

(left or right), follow the appropriate procedure

below.

Fig 7

To move belt back towards the center

if it has tracked to the LEFT side:

Turn the LEFT

bolt ¼ turn

clockwise

To move belt back towards the center

if it has tracked to the RIGHT side:

Turn the RIGHT

bolt ¼ turn

counter-clockwise

Repeat above steps until the running belt tracks in the center.

Turn the LEFT

bolt ¼ turn

counter-clockwise

bolt ¼ turn

Turn the RIGHT

clockwise

20

Service Manual: E-TR and E-TRi

Page 23

Roller Care & Maintenance

The care and maintenance of the head and tail rollers are as important as the care and maintenance

of the running belt. Dirt buildup on the rollers can cause noise, rough feelings and unwanted belt

tracking.

CLEANING

Scrape any dirt and debris build up from the roller using a plastic scraper or an old credit card. Do

not use anything metal or sandpaper, as you will damage the coating on the roller. Vacuum up any

debris from the rollers.

ROLLER “DO NOT’s”

x

Do not lubricate the roller bearings. They are a sealed type bearing and any lubricant you

attempt to apply, will not penetrate the seal.

x Do not scrape a roller with metal. Use a plastic scraper or a credit card only.

x Do not use sandpaper to clean the rollers

21

Service Manual: E-TR and E-TRi

Page 24

S

S

A

AFFEETT

Y

Y FFII

R

R

S

STT!!

Applying Wax to a Waxless Running Belt

While it is generally not necessary to add wax to a waxless style running belt, if the running belt is

making unacceptable noises or is experiencing tracking difficulties, adding wax the underside of the

belt will improve the grip between the belt and the rollers which will reduce the noise and improve the

tracking response. This procedure should ONLY be performed by a person that is familiar with

waxing of running belts and is physically able to do so.

Parts Required

x Bottle of Micronized Powdered Paraffin Wax (Part No. 140-3180)

x #2 Phillips screwdriver

x Towel - 36” x 12” (90cm x 30cm) is suggested

x Plastic drinking straw – large diameter

Caution should be exercised at all times when performing the following procedure. If

you do not feel comfortable with this, stop immediately and obtain the services of a

qualified Service Provider.

Step 1:

x Place the towel between the deck and the running belt (Fig 1).

x Step on the sides of the towel and run the treadmill at 2 mph (3 kmh) (Fig 2).

¾ Make sure the towel does not come loose while the running belt is moving.

x Run the treadmill for about 1 minute then stop the treadmill.

x When the treadmill stops, remove the towel (Fig 3).

x Wipe around the deck edges with the clean part of the towel.

Fig 1

Fig 2

Fig 3

22

Service Manual: E-TR and E-TRi

Page 25

Step 2:

x Using the screwdriver, remove the three screws from the left and the three screws from

the right finger guards (Fig 4).

x Remove both finger guards (Fig 5).

Fig 4

Fig 5

CAUTION

Be mindful of loose clothing, long hair, loose and/or hanging jewelry, etc.

Step 3:

: The next step involves working near moving parts. BE CAREFUL!

x Insert the straw onto the bottle of wax (Fig 6).

x Start the treadmill at 3.0 mph (5.0 kmh).

x While the treadmill is running, squirt about 5-8 times on the left

side onto the underside of the running belt (Fig 7) and 5-8 times

on the right side onto the underside of the running belt (Fig 8).

x Check the bottle and make sure you have used at least half

bottle of wax (Fig 9). It may be necessary to use a full bottle

x Run on the treadmill for about 2 minutes.

the

Fig 6

Fig 7

Step 4:

x Stop the treadmill and reinstall both finger guards with screws (Fig 11).

x Wipe off any excess wax (Fig 12).

Fig 11

Fig 8

Fig 12

Fig 9

23

Fig 10

Service Manual: E-TR and E-TRi

Page 26

MAINTENANCE MODE

The Maintenance Mode allows you to query and modify the settings of the Star Trac product.

Engaging Maintenance Mode

Press and hold the

While holding all three keys release the

+ + keys.

key only.

A beep will sound and the display will

read “MAINTENANCE MODE”

momentarily in the information window.

Once in the Maintenance Mode release all of the keys.

The display will read “UNITS:

ENGLISH” (or “UNITS: METRIC”)

depending on your settings.

You will now be in the Maintenance Settings mode for you unit. As a safety precaution, the unit will

only stay in the Maintenance Mode for approximately 45 seconds after the last key stroke entry. As

long as you are adjusting settings or scrolling through parameters, the unit will stay in mode.

24

Service Manual: E-TR and E-TRi

Page 27

WARNING

Maintenance Mode Keys

The following keys are used to search through and modify the Maintenance Settings:

INCLINE keys: Display the next and previous parameters.

SPEED keys: Adjust the value of the displayed parameter up and down

respectively. Some parameters can utilize the number pad.

ALPINE PASS: Sets parameter back to its default factory setting. Note:

For parameter “LAST DECK” this key will set the parameter to the current

“MILEAGE” value to clear the “REWAX BELT” message.

OK key: Updates (saves) the value of the display setting in the memory.

START key: Used to initially enter the Maintenance Mode and updates

changed parameter values.

NUMBER PAD: Used to directly enter numeric values.

STOP key: Used to exit the Maintenance Mode.

Do not operate the unit for a workout while in the Maintenance Mode or Motor Test Modes.

25

Service Manual: E-TR and E-TRi

Page 28

DISPLAY PARAMETERS

Parameter Defaults

The following parameters can be accessed by entering the Maintenance Mode. When installing a

new display electronic board, it will come with factory default settings. Depending on the model and

voltage of unit you are installing the board into, you may need to adjust your settings by referencing

the following chart.

Parameter 110V Setting 220V Setting Default Parameter Ranges

UNITS

MINIMUM SPEED

MAXIMUM SPEED

ELEVATION

TIME

OPER HOURS

DISTANCE

WEIGHT

SERIAL NO

LANGUAGE

ENTRY

HEART RATE

METS

WATTS

PAUSE

SCALE

INFRARED COM

CSAFE

FAN

AUTO STOP

ENTERTAINMENT

ACCELERATION TIME

DECELERATION TIME

LOCK OUT

LOCK OUT ID

RAIL STOP

STOP SWITCH

10_REV

CNT/REV

MINUMUM PWM

1/2 MAXIMUM

MAXIMUM PWM

PERSON DETECT 1

PERSON DETECT 2

PERSON DETECT 3

DATE

ENGLISH ENGLISH, METRIC

0.5

(0.8kph)

10.0

(16.0kph)

ON OFF, ON

99 20 - 99

0 0 – 65535

155 0 – 350

0 0 – 65535

ENGLISH ENGLISH, DUTCH, FRENCH,

UNITS UNITS, TENTHS

BOTH CONTACT, POLAR, BOTH

OFF OFF, ON

OFF OFF, ON

45 20 – 120

ON OFF, ON

ON OFF, ON

ON OFF, ON

ON OFF, ON

OFF OFF, ON

OFF OFF, ON

35 25 – 60

30 20 - 60

OFF OFF, ON

12345 0 - 65535

ON OFF, ON

E-STOP E-STOP, LANYARD

376 376 376 0 – 740

31 31 31 0 – 125

(VARIES) (VARIES) 34 0 – 110

(VARIES) (VARIES) 200 0 – 340

(VARIES) (VARIES) 400 0 – 495

17 17 17 0 – 150

30 30 30 0 – 150

40 40 40 0 – 150

1.98 0.00 – 9.99

0.5

(0.8kph)

12.0

(20.0kph)

0.5

(0.8kph)

12.5

(kph)

0 0 – 65535

0.5 – 5.0

(0.8 – 8.0kph)

5.0 – 12.5

(8.0 – 20.0kph)

GERMAN, PORTUGUESE,

SPANISH, SWEDISH, ITALIAN,

KATAKANA

26

Service Manual: E-TR and E-TRi

Page 29

Parameter 110V Setting 220V Setting Default Parameter Ranges

NO RAIL STOP

KEY DOWN

SPEED CHG

ELEV STALL

ELEV RANGE

ELEV LOST

CHECK MOTOR SYS

ERROR CAPTURES

PROGRAM CAPTURES

CHECK SPEED SYS

FUSE BITS ERROR

ELEVATION ZERO

ELEVATION MAX

LAST DECK

LAST BELT

LAST MOTOR

CS AUTO STATUS

MODEL

HR CALC. TIME

MANUAL

FOREST WALK

TRAIL

ALPINE PASS

RANDOM

5K LOOP

10K LOOP

CUSTOM PALM

DYNAMIC HR

CONSTANT HR

QUICKSTART

FITNESS TEST

FIRE FIGHTER

US ARMY TEST

USMC TEST

USAF TEST

NAVY TEST

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

240 240 240 0 – 242

70 70 70 0 – 170

0 0 – 65535

0 0 – 65535

0 0 – 65535

ON OFF, ON

PRO AC PRO S, PRO, PRO ELITE,

PRO AC, PRO ELITE AC

30 0 – 99

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

0 0 – 65535

Note: Some parameters shown above may or may not display in your unit.

27

Service Manual: E-TR and E-TRi

Page 30

Parameter Setting Definitions

The following are the definitions of each parameter from the Maintenance Mode.

UNITS:

MINIMUM SPEED:

MAXIMUM SPEED:

ELEVATION:

TIME:

OPER HOURS:

DISTANCE:

WEIGHT:

SERIAL NO:

LANGUAGE:

ENTRY:

HEART RATE:

METS:

WATTS:

PAUSE:

SCALE:

INFRARED COM:

CSAFE:

FAN:

AUTO STOP:

ENTERTAINMENT:

ACCELERATION

TIME:

DECELERATION

TIME:

LOCK OUT:

LOCK OUT ID:

Footnotes:

1 When replacing a display electronic board, it is a good idea to write down this number and set it into the

new electronic board to help keep accurate records of parameters with the unit.

2 When resetting the Rewax Belt message (LAST DECK parameter), this is the number that will automatically

be copied into the LAST DECK parameter to set the current mileage.

Sets the conversion for speed, distance and weight between US and Metric

measurements. (Conversions: Km = Miles x 1.6 x Lb = Kg x 2.2)

Sets the minimum start up speed for the unit.

Sets the maximum speed available for the unit.

Turns the elevation (incline) system on or off.

Sets the maximum workout time for the unit. Can be used in a high-use facility

or location that wishes to limit usage times of a unit.

The accumulation of hours the unit has been used

The accumulation of miles the unit has been used

1

1,2

Sets the default weight, usually 155 lbs (70 kg) that the unit will use to

calculate calories to be used if a user does not enter their weight during

workout setups.

The last few numbers of the unit serial number. *May or may not be used

Sets the language that the display will show.

Sets how the numbers will be entered during key strokes:

(UNITS = 1.0 increments, TENTHS = 0.1 increments)

Sets the type of Heart Rate to use: (POLAR only, CONTACT only or BOTH).

Used for workout feedback. *Consult an Owners Manual or a certified trainer

for definition.

Used for workout feedback. *Consult an Owners Manual or a certified trainer

for definition.

Sets the amount of time in seconds that a unit will pause when the side stop

switch or the stop key is pressed during a workout.

Turns the scale feature on or off.

Turns the infrared communication system on or off.

Turns the CSafe power outlets on or off.

Turns the fan system on or off.

*Not used at this time. Be sure this parameter is set to OFF.

Turns the entertainment system on or off.

Sets the amount of time the unit will take (in seconds) to go from 0.0 mph to

achieve the maximum speed as set in the MAXIMUM SPEED parameter.

Sets the amount of time the unit will take (in seconds) to go from the maximum

speed as set in the MAXIMUM SPEED parameter down to 0.0 mph.

Used to disable use of the unit unless the LOCK OUT ID has been entered.

A number combination used to lock out the display from use.

1

28

Service Manual: E-TR and E-TRi

Page 31

RAIL STOP:

Used to turn the side stop switch port on or off on International units.

*Note: This parameter should always be ON unless the mechanical stop

switch is installed.

STOP SWITCH:

10_REV:

Sets the type of International stop switch is in use: U.S.A. or International

Sets the speed and distance calculation value. This is the distance (in

inches) that the running belt travels for every 10 revolutions of the drive

1

CNT/REV:

motor

Sets the number of timing notches (or target ticks) that the RPM sensor

passes in each revolution of the RPM target1

MINIMUM PWM:

1/2 MAXIMUM:

MAXIMUM PWM:

PERSON DETECT 1:

PERSON DETECT 2:

PERSON DETECT 3:

DATE:

Sets the PWM value the unit needs to calculate the MINIMUM SPEED3

Sets the PWM value the unit needs to calculate half of the MAXIMUM

SPEED

3

Sets the PWM value the unit needs to calculate the MAXIMUM SPEED3

An internal calculation setting. Leave at default setting.

An internal calculation setting. Leave at default setting.

An internal calculation setting. Leave at default setting.

The date of manufacture of the unit. *May or may not be used

1

The following parameters are used to keep track of Error Codes that may have been displayed during

use. These should be reset (defaulted) back to 0 (zero) during each maintenance session.

To Reset: While on the parameter, press the “ALPINE PASS” key to reset value to 0, then press the “OK”

key or the “START” key to save the change.

NO RAIL STOP:

Side stop switch (in left handrail) disconnected or broken. Rare occasions

may be caused by faulty display electronic board.

KEY DOWN:

One or more keys on the display panel may be sticky or stuck. Rare

occasions may be caused by faulty display electronic board.

SPEED CHG:

Defined as a change in the speed feedback of 2.0 mph or more in more than

2 seconds.

ELEV STALL:

The elevation system did not detect any elevation movement, or the system

moved too slow.

ELEV RANGE:

The elevation system detected it went too high or too low than what the

parameters are set to.

ELEV LOST:

The elevation system has lost communication with the elevation sensor

inside the elevation motor.

CHECK MOTOR

SYS:

CHECK SPEED SYS:

See the TROUBLESHOOTING - CHECK MOTOR SYSTEM section of this

manual.

See the TROUBLESHOOTING - CHECK SPEED SYSTEM section of this

manual.

FUSE BITS ERROR:

Footnotes:

1 When replacing a display electronic board, it is a good idea to write down this number and set it into the

new electronic board to help keep accurate records of parameters with the unit.

3 When replacing a display electronic board, it is not necessary to change this value. It will automatically

Change during the Auto-Calibration procedure.

Fault during software upload.

29

Service Manual: E-TR and E-TRi

Page 32

ELEVATION ZERO:

ELEVATION MAX:

LAST DECK:

Sets the value for 0% (zero percent) for the elevation motor sensor.

Sets the value for 15% (maximum incline) for the elevation motor sensor.

This parameter is used for models with a waxable

have a waxless

style treadmill and REWAX BELT appears on your display,

style running belt. If you

go to the MODEL parameter and make sure your unit is set for the correct

model.

LAST BELT:

A parameter available for you to enter the mileage (DISTANCE) at which the

running belt was replaced. This aids in your record keeping.

LAST MOTOR:

A parameter available for you to enter the mileage (DISTANCE) at which the

drive motor was replaced. This aids in your record keeping.

CS AUTO STATUS:

MODEL:

An internal calculation setting. Leave at default setting.

Sets the model that the display electronic board will be used on. Note that

some features may not work (fans, scales, entertainment, etc.) if this setting

is incorrect.

HR CALC. TIME:

Sets the amount of time the Heart Rate system will seek to acquire a heart

rate reading before it resets and begins seeking again if not detected.

The following parameters are used to keep track of which programs users are selecting. These

parameters do not affect the functionality of the unit, but can be used to log the types of programs

users prefer to use.

MANUAL

FOREST WALK

TRAIL

ALPINE PASS

RANDOM

5K LOOP

10K LOOP

CUSTOM PALM

DYNAMIC HR

Check with a Star Trac sales representative for definitions

CONSTANT HR

QUICKSTART

FITNESS TEST

FIRE FIGHTER

US ARMY TEST

USMC TEST

USAF TEST

NAVY TEST

30

Service Manual: E-TR and E-TRi

Page 33

MAINTENANCE MODE – TEST MODES

Within the Maintenance Mode parameters are a few Test Modes that can be used to test various

functions of the unit. While in the Maintenance Mode, set the following parameter and use the

functions as listed to utilize each parameter.

DISPLAY TEST

The Display Test can be used to test each individual key for function and response, and can

also be used to verify led function and display.

Press ‘Start’ key

Press ‘Start’ key

Press ‘Start’ key

Press ‘Start’ key

Press ‘Stop’ key twice to return to the MAINTENANCE MODE

Press ‘1’ key

Press ‘Speed Plus’ key

Press ‘Speed Minus’ key

Press ‘Stop’ key twice to return to the MAINTENANCE MODE

Press ‘2’ key

Press ‘Stop’ key to verify function then press again to return to the MAINTENANCE MODE

Note: You can also access the Display Test right away when entering the Maintenance Mode:

When the display reads UNITS: ENGLISH (or UNITS: METRIC),

press the ‘5’ key then follow the procedures above.

Display will enter DISPLAY TEST and await your next command

Display will cycle thru a self test and display all led’s in a sequenced pattern

Display will enter DISPLAY TEST and await your next command

MC1 Vx.x CKSM xxxx will display

MC2 Vx.x CKSM xxxx will display

MC1 Vx.x CKSM xxxx will display

Display will enter DISPLAY TEST and await your next command

Display will read KEYBOARD TEST

Press any key except ‘Stop’ to verify function.

Loop

MOTOR TEST

This parameter is used by Star Trac at the factory.

*For MOTOR TEST MODE, see the MOTOR TEST MODE section of this manual.

BELT/DECK TEST

This parameter is used by Star Trac at the factory.

31

Service Manual: E-TR and E-TRi

Page 34

CALIBRATE SCALE

Press ‘Start’ key

Enter your exact weight *It is advisable to weigh yourself for accuracy just before performing this step.

After entering your weight press either the ‘Start’ or ‘OK’ keys.

Display will read :

If no weight entered, unit will read:

If no weight entered, unit will read:

If no load cells detected, unit will read:

Press ‘1’ key

Press ‘2’ key

Press ‘3’ key

Press ‘4’ key

Press ‘Stop’ key once to return to the CALIBRATE SCALE mode

Press ‘Stop’ key a second time to return to the MAINTENANCE MODE

Display will enter CALIBRATE SCALE mode and scroll the following:

1 = INPUT SPAN WEIGHT

2 = CAL SPAN WEIGHT

3 = CAL ZERO WEIGHT

Loop

4 = VERIFY WEIGHT

PRESS STOP TO EXIT

Pressing ‘Stop’ will return to MAINTENANCE MODE

Unit will read REF WEIGHT = 155

STEP ON WEIGHT PADS

PRESS OK TO BEGIN

Loop

Pressing ‘OK’ will read CALIBRATING X (X = your entered weight)

CAN NOT CALIBRATE

NO WEIGHT ACQUIRED

PRESS OK TO RETRY

PRESS STOP TO EXIT

Loop

Pressing ‘OK’ will return to previous step

Pressing ‘Stop’ will return to MAINTENANCE MODE

Display will read:

PLACE CAL WEIGHT

ON WEIGHT PADS

PRESS OK TO BEGIN

Loop

After pressing ‘OK’ unit will read CALIBRATING X (X = calibrated weight)

CAN NOT CALIBRATE

NO WEIGHT ACQUIRED

PRESS OK TO RETRY

PRESS STOP TO EXIT

Loop

Pressing ‘OK’ will return to previous step

Pressing ‘Stop’ will return to MAINTENANCE MODE

Display will read:

REMOVE WEIGHTS

PRESS OK TO BEGIN

After pressing ‘OK’ unit will read CALIBRATING X (X = weight zero)

CAN NOT CALIBRATE

NO WEIGHT ACQUIRED

PRESS OK TO RETRY

PRESS STOP TO EXIT

Loop

Pressing ‘OK’ will return to previous step

Pressing ‘Stop’ will return to MAINTENANCE MODE

Display will read: WEIGHT= 0 and display the weight as detected

32

Service Manual: E-TR and E-TRi

Page 35

º

¼

CSAFE TEST

This parameter is used by Star Trac at the factory.

HEART RATE TEST

The Heart Rate Test mode can be used to simultaneously test the function and response for

both the contact and Polar heart rate systems.

Press ‘Start’ key

, , Grab the HR grips

(If applicable) Polar strap *If you have a Polar transmitter or a polar signal simulator then signal will be detected

Press ‘Stop’ key twice to return to the MAINTENANCE MODE

INFRARED TEST

This parameter is used by Star Trac at the factory.

Display will read POLAR 0 CONTACT 0

CONTACT X should detect your heart rate then display the reading

and processed by the Polar system and display the value as POLAR X

LAST ERROR LIST

The Last Error List is a list bank of the last five issues the unit has captured into its memory for

diagnosis of an issue. To access the Last Error list banks, follow the procedure below. For

more information including DFR, see the DFR section in this manual.

Press ‘Start’ key

Press ‘Start’ key

Press ‘Start’ key

When opening the banks, #1 is the first code that was captured, #2 the second, #3 the third

and so on. If more than 5 codes have been captured, bank #5 will always be the latest code

captured and the previous number will be replaced accordingly.

For a list of definitions for the Last Error List, see the LAST ERROR LIST DEFINITIONS

section in this manual.

Press ‘Start’ key

Press ‘Stop’ key twice to return to the MAINTENANCE MODE

Press ‘1’ key

Press ‘Speed Plus’ key

Press ‘Speed Minus’ key

Press ‘Stop’ key twice to return to the MAINTENANCE MODE

Press ‘2’ key

Press ‘Stop’ key to verify function then press again to return to the MAINTENANCE MODE

Display will enter DISPLAY TEST and await your next command

Display will cycle thru a self test and display all led’s in a sequenced pattern

Display will enter DISPLAY TEST and await your next command

MC1 Vx.x CKSM xxxx will display

MC2 Vx.x CKSM xxxx will display

MC1 Vx.x CKSM xxxx will display

Display will enter DISPLAY TEST and await your next command

Display will read KEYBOARD TEST

Press any key except ‘Stop’ to verify function.

Loop

33

Service Manual: E-TR and E-TRi

Page 36

MAINTENANCE MODE – AUTO CALIBRATION

Electrical voltages vary between locations. The treadmill can run through an auto-calibration process

to allow the electronics to balance out with the speed control.

To run an auto-calibration procedure, do the following:

Auto-Calibration

DO NOT LEAVE THE TREADMILL UNATTENDED WHILE RUNNING

THE AUTO-CALIBRATION PROCEDURE AS IT WILL RUN THE

BELT TO THE MAXIMUM SPEED SETTING.

1. Enter the Maintenance Mode (see “Engaging Maintenance Mode”).

The display will read:

2. Enter the Motor test mode by pressing the ‘8’ key once. The display

will read:

3. Start the auto-calibration process by pressing the ‘Forest’ key once

and immediately stepping off of the treadmill.

The center number (3) as shown above, will begin to increase, running

belt will move and the center number will on the right hand side of the

display (0.0) will move .

The treadmill running belt will begin to move in the following manner:

x Running belt will move, center number will increase and the

numbers on the right hand side of the display ‘0.0’ will move

34

Service Manual: E-TR and E-TRi

Page 37

DEFINITIONS

LAST CODE

LST CHK

LAST MTR CURR

LAST STAT

LAST OPHR

LAST ODOM

LAST PRGM

LAST DFR

LAST TIME

LAST MSPD

LAST PWM

LAST SSPD

LAST EPOT

LAST ELEV

LAST ERROR LIST DEFINITIONS

The last code (Check Speed Sys, Key Down, Elev Stall, etc.)

Check Sum at time of incident. Check Sum is part of the software language.

Motor Current sensed at time of incident.

Total unit OPER HOURS (Operating Hours) at time of incident.

Total unit DISTANCE (mileage) at time of incident.

Program that was running at time of incident.

See DFR INFO below.

Time in seconds during the program incident occurred.

The Measured Speed at time of incident.

The PWM at time of incident.

The Set Speed at time of incident.

The Elevation System Potentiometer reading at time of incident.

The set Elevation at time of incident.

LAST ERROR LIST BANKS

Bank 1 Bank 2 Bank 3 Bank 4 Bank 5

LAST

CODE

LST

CHK

LAST

MTR

CURR

LAST

STAT

LAST

OPHR

LAST

ODOM

LAST

PRGM

LAST

DFR

LAST

TIME

LAST

MSPD

LAST

PWM

LAST

SSPD

LAST

EPOT

LAST

ELEV

0000000

0000

0

0000000

0

0.0

0

0.0

0

0.0

Note: Some newer software version display electronic boards may read FUSE B in the LAST CODE

field as a default. It can be ignored since it displays when the software was installed at the factory.

0

0

0

0

LAST

CODE

LST

CHK

LAST

MTR

CURR

LAST

STAT

LAST

OPHR

LAST

ODOM

LAST

PRGM

LAST

DFR

LAST

TIME

LAST

MSPD

LAST

PWM

LAST

SSPD

LAST

EPOT

LAST

ELEV

0000000

0000

0

0000000

0

0.0

0

0.0

0

0.0

0

0

0

0

LAST

CODE

LST

CHK

LAST

MTR

CURR

LAST

STAT

LAST

OPHR

LAST

ODOM

LAST

PRGM

LAST

DFR

LAST

TIME

LAST

MSPD

LAST

PWM

LAST

SSPD

LAST

EPOT

LAST

ELEV

0000000

0

0000000

0.0

0.0

0.0

0

0

0

0

0

0000

0

0

LAST

CODE

LST

CHK

LAST

MTR

CURR

LAST

STAT

LAST

OPHR

LAST

ODOM

LAST

PRGM

LAST

DFR

LAST

TIME

LAST

MSPD

LAST

PWM

LAST

SSPD

LAST

EPOT

LAST

ELEV

0000000

0000

0

0000000

0

0.0

0

0.0

0

0.0

0

0

0

0

LAST

CODE

LST

CHK

LAST

MTR

CURR

LAST

STAT

LAST

OPHR

LAST

ODOM

LAST

PRGM

LAST

DFR

LAST

TIME

LAST

MSPD

LAST

PWM

LAST

SSPD

LAST

EPOT

LAST

ELEV

0

0000000

0

0000

0

0

0

0000000

0

0.0

0

0.0

0

0.0

35

Service Manual: E-TR and E-TRi

Page 38

DFR INFORMATION

DFR’s (Drive Fault Records)

The AC MCB (Motor Control Board) monitors the drive system and reports any anomalies by

triggering what is called a DFR (Drive Fault Record) code.

Same Codes, Different Meanings

The AC System has the same codes as the DC system but the meanings may not necessarily be the

same, specifically “CHECK SPEED SYSTEM” and “CHECK MOTOR SYSTEM”. You must now take

in to account that the MCB may have issued a DFR code which has shut the treadmill down and

display one of the “CHECK” codes. In most cases you will find that a DFR code has been flagged and

caused the unit to shut down.

How Do You Know What or If a DFR Code Has Been Captured?

There are two ways to check to see if a DFR code has been captured:

1. Check the LAST ERROR LIST in the Maintenance Mode

x Engage the Maintenance Mode and access the LAST ERROR LIST

(see “LAST ERROR LIST” in the “MAINTENANCE MODES – TEST MODES” section)

x Scroll the parameters until you come to the LAST DFR

x There will be an 8 digit number that is the DFR code

Example: LAST DFR(X) 00004000 (over temp on motor or drive).

o Ignore the first set of zero’s before the number. This example will be

considered a 4000 code

o If the Last DFR list reads LAST DFR(X)00000000, a DFR has not been

recorded by the MCB and reported to the display. Follow the appropriate

troubleshooting steps for the code displayed (i.e. ELEVATION STALL, etc.)

2. Count the blinks from the Status led’s on the MCB

x When the MCB records a DFR, the three Status

led’s (Led 1, Led 2 and Led 3) will blink together

simultaneously

x The Status led’s will blink the number of times

that indicate the particular DFR code

x There will be a short pause in the blinking to

show counting separation (Count the blinks

between the pauses)

Example: Count 15 blinks, pause, 15 blinks

again would indicate a 4000 DFR code, which is

an “over temp on motor or drive”

*See DFR Code Chart in the “Troubleshooting” section, for blink reference chart.

36

Service Manual: E-TR and E-TRi

Page 39

SOFTWARE - DISPLAY

The display on the AC Pro Tread contains the software to operate the treadmill. This software may be

updated via the “uploaders” or by replacing the display electronics which contains an updated version

of the software.

Uploaders

Uploaders are two small grey boxes that contain the primary (MC1)

and secondary (MC2) software for the display. In order to use these

uploaders you must install software onto a computer which allows

you to upload the treadmill software into each box. Those boxes can

be used to update the software in the E-TR and E-TRi treadmill

displays.

Software updates occur to add new features or enhancements to the

system. When these updates are available, the treadmill software

files will be posted on the Star Trac Support web site

(http://support.startrac.com/Software) and can be downloaded onto

the PC and uploaded into the uploader boxes.

Uploader kit contains all

parts shown above.

Part number: 800-3899

37

Service Manual: E-TR and E-TRi

Page 40

Uploading Software into the Uploaders

The following procedure explains how to upload software into the grey uploader boxes. The software

may be downloaded from the Star Trac Support Website (http://support.startrac.com/Software).

Click on the Service Provider tab at the top then click on the Latest Product Software link.

The Pro Tread Series display uses a flash memory system to store the software that runs the

treadmill. To update the software requires the use of two “uploader” boxes and a PC. (Note: The PC

is to upload the software into the uploaders only.)

This section will explain:

x Assembling the uploader boxes and connecting the RS232 cable to the PC.

x Installing the FISP software onto your PC (FISP software is used to put the Pro Tread software

into the uploader boxes).

x Installing Pro Tread software into the uploaders for two micro controller types (Mega 103 and

Mega 128)

o Primary and Secondary box

Time Required

x 10-15 minutes

Parts Required

x (2) Uploader kits

Note: There are two styles of uploaders. The newest style (USB) is:

Star Trac part number: 610-0281 which contains one each of

the following parts:

**You will need 2 each of 610-0281 kits in

Tools Required

x Phillips head screw driver

x PC computer with Windows 95 or higher

Software Required (on your PC)

x Winzip (or equivalent)

9 (1) Grey uploader box

9 (1) Data cable

9 (1) USB cable

8 The USB style uploaders do not require a

battery pack.

order to have Primary and Secondary

software available during uploads.

38

Service Manual: E-TR and E-TRi

Page 41

You will need Winzip (or equivalent) installed on your PC. If you do not have a zip file extractor

program, you can get a free version from www.winzip.com

.

Obtaining the FISP and Latest Software

1. Open your web browser and go to the

Support Website (*1). Click on the ‘Service

Providers’ tab (*2). Click on ‘Latest Product

Software’ (*3). Click on the ‘FISP Loader

4. Move your mouse pointer into the white

space but do not hover over a folder. Right

click in the white space (*1). Hover your mouse

over ‘New’ (*2) to open the window to the right.

Click ‘Folder’ (*3) to create a New Folder.

Program’ link (*4).

2. When you choose FISP Loader Program,

the following window will appear. Click ‘Save’.

5. Rename the ‘New Folder’ to ‘AVRISP’.

Make sure the ‘File Name’ and ‘Save as type’

are as shown below:

3. The following window will appear. Do not

click ‘Open’ yet.

6. You should now have the following window

open. Click ‘Save’.

39

Service Manual: E-TR and E-TRi

Page 42

7. Open your web browser in the Latest

Product Software section. Click on the latest

Display Version of software for the 7000 (7k)

treadmills.

8. When you choose Display Ver X.X / X.X, the

following window will appear. Click ‘Save’.

Extracting (Unzipping) the Zip Files

1. Open the ‘AVRISP’ folder. Right click on

‘fisp_setup.zip’ then left click on ‘Open with

Winzip’.

2. If using the free trial of Winzip and you have

the screen as below, click on ‘Use Evaluation

Version’.

9. The following window will appear. Make

sure you are in the ‘AVRISP’ folder. Click

‘Save’.

<End of procedure>

3. Once extracted, a new window will appear

as shown below. Click and hold on the

‘fisp_setup.zip’ icon then drag it to the white

space in the ‘AVRISP’ folder.

4. Close the ‘Winzip’ window only. Leave the

‘AVRISP’ window open.

40

Service Manual: E-TR and E-TRi

Page 43

5. In the ‘AVRISP’ folder, right click on

‘Pro_tread-disp_verXX_XX.zip’ then left click on

‘Open with Winzip’.

6. Once extracted, a new window will appear as

shown below with 2 files in it. Click and hold in

the white space next to the lower file (*1) and

drag the selection box across both files to select

them both (*2). Once both files are selected,

click and hold one of them and drag them to the

white space in the ‘AVRISP’ folder (*3).

Connecting the USB Cable to the PC

1. On the back of your PC (or on the front on

newer PC’s), locate the USB port. Plug the

USB cable in to the USB port on the PC.

2. Plug the smaller end of the USB cable in to

the uploader. The led should glow Orange

when connected to a PC.

7. The ‘AVRISP’ folder should look like this:

41

Service Manual: E-TR and E-TRi

Page 44

Installing the FISP Program on the PC

1. In the ‘AVRISP’ folder, open the executable

file for the FISP program called ‘fisp_setup.exe’.

If a ‘Security Warning’ window appears,

click ‘Run’).

4. Create the Start Menu folder as ‘Fisp’.

5. This is your choice for a desktop icon.

6. Click ‘Install’ to install Fisp on your PC.

2. Click ‘Next’ to run the setup wizard.

3. Make sure you are going to install into the

‘AVRISP’ folder then click ‘Next’.

7. Click ‘Install’ to install USB driver.

8. Once installed, you should get the following

window. Click ‘OK’.

9. Click ‘Finish’ to complete the wizard.

42

Service Manual: E-TR and E-TRi

Page 45

Uploading the Software into the Uploader

1. Be sure the upload is plugged in to the USB

cable and the USB cable is plugged in to the

PC and the Orange led is lit on the uploader.

2. Open the ‘AVRISP’ folder. Open the ‘Fisp’

folder.

3. Open the ‘fisp.exe’ program.

5. Under the ‘Device’ drop down menu, choose

the ‘Mega128’.

. PROJECT CHANGE POINT .

You will need to upload one program at a time.

‘Primary’ or ‘Secondary’. Follow the next steps

to upload the Primary program into the Primary

uploader. When prompted at Step 12, return to

this point to upload the Secondary program into

the Secondary uploader.

6. Click once in the white space under ‘Flash

Filename’ (*1). When the ‘Open Intel Hex File’

window opens, click on ‘Primary_VXX.a90’ (*2)

then click ‘Open’ (*3).

4. The Fisp program will automatically detect

your uploader and will display the FISP USB

Ver X.X as shown below.

7. Click on the ‘Device’ – ‘Options’ button.

43

Service Manual: E-TR and E-TRi

Page 46

8. The ‘Device’ – ‘Options’ window will appear

with several tabs.

LOCK BITS - Uncheck all:

FUSE BITS – Check “SUT0 Fuse” only

10. Click on ‘Load Fisp’ to send software to the

uploader.

11. You will see a Transferring Date” status

window. Click ‘Close’ when prompted.

FUSE BITS HIGH – Check “CKOPT

Fuse” and “JTAG Fuse” only.

FUSE BITS EXTENDED – Uncheck all.

9. Once all check boxes are set as above, click

‘OK’ to finish and close window.

12. This will complete the programming of the

Primary uploader. Return to the Project

Change Point to complete the Secondary

uploader.

. RETURN TO PROJECT CHANGE POINT .

13. Use a sticker or tape and mark each

uploader as “Primary” or “Secondary”. It is also

a good idea to put the version of software and