Page 1

•

•

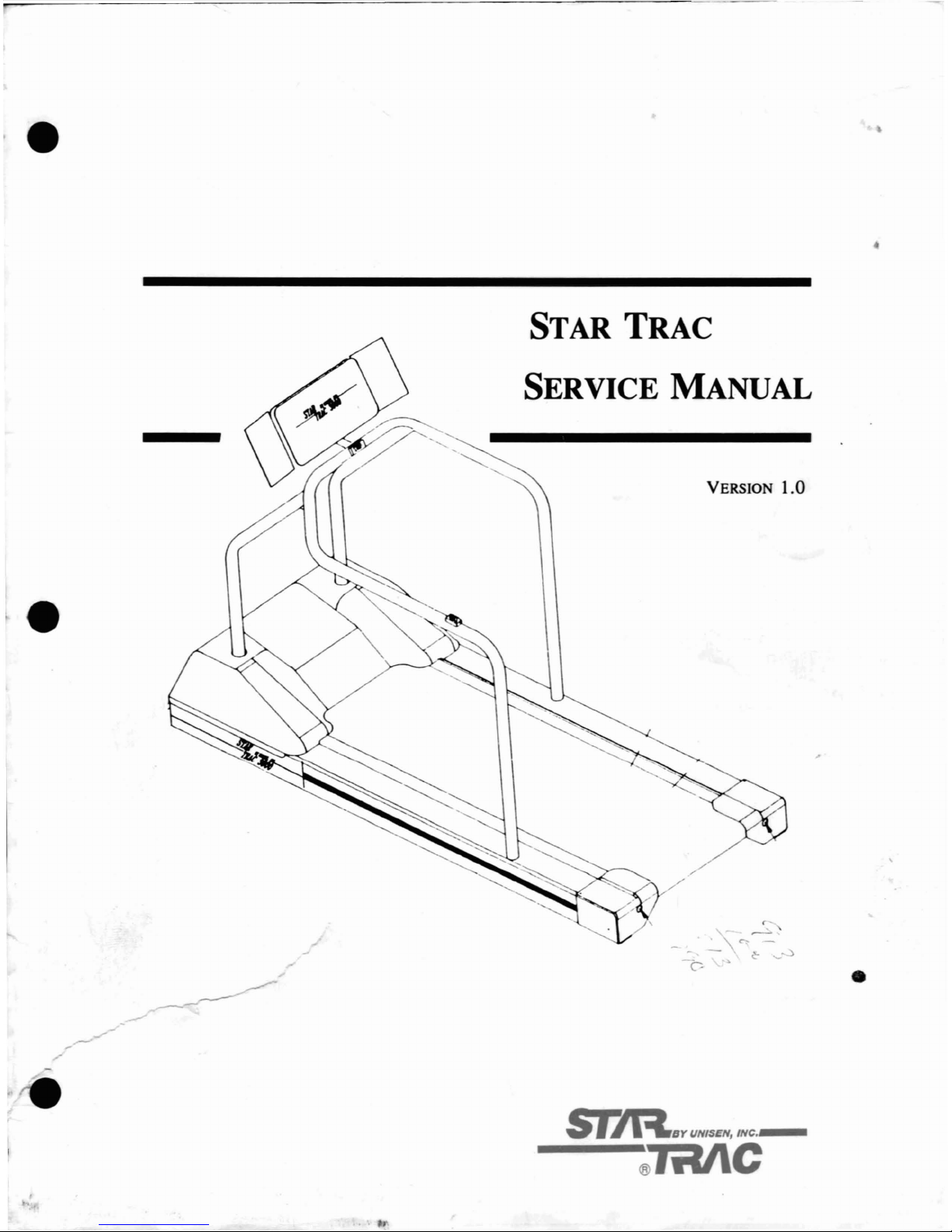

STAR TRAC

SERVICE MANUAL

VERSION 1.0

r

~

~

-

- -

.)

- G

~

c

......

•

"

~Jr=I,BYUNISEN,

INC._

®liIIlC

Page 2

Copyright 1993, Unisen, Inc. All rights reserved, including those to reproduce this bookorpart

thereof

in

any form without first obtaining written permission from Unisen, Inc.

Every effort has been made to keep the information current; however, periodically changes are made to

the information herein,

and these changes willbeincorporated into new editionsofthis publication. All

product names

and logos are trademarksoftheir respective owners. Printedinthe USA, 01093.

•

•

•

Page 3

••

FOR

ADDITIONAL SUPPORT

Customer Service

Unisen, Inc.

14352 Chambers Road

Tustin, California 92680

Telephone: 714

I 669 - 1660

Fax: 714

I 838 - 6286

~.

Hotline Telephone:

Technical Assistance:

Sales Assistance:

800

I 535 - 4634

800

I 503 -

1221

800

I 228 - 6635

NOTE:

For

faster service, please have your

STAR

TRAC

Model and Serial

Numbers available.

Page 4

••

•

Page 5

---

•

ACKNOWLEDGEME

TS

We

wish to extend thanks to the entire STAR TRAC Customer

Service team for their support. And, a special thanks to Dennis Vega

and Sandy Sather for their valuable technical assistance.

l~

........

;;;;.;...-

_

Page 6

•

••

•

Page 7

r

•

CONTElVl'S

TABLE OF CONTENTS

PAGE

NUMBER

r

•

'.

How

TO

USE

TIllS

MA

AL

7

CHAPTER 0 E:

PREvE

TlVE

MAl

TE

A

CE

9

DAILY

10

WEEKLY

11

BnNEEKLY

12

MONTI-U.Y

13

CHAPTER

Two:

DIAG

OSTIC

TEST 15

ACTIV

AT

G MOTOR

TEsT

MODE

16

ACTIVATIG DlSPLAY

TEsT

MODE

25

CHAPTER THREE: TROUBLESHOOTI G ERROR CODES 27

SPEED

ERRORS 28

ELEVATlO ERRORS 38

FS

ERRORS 52

CPU

ERRORS 55

No DISPLAY POWER 57

CHAPTER

Fo

R:ICREASING

MECHA

leAL

UPTIME 59

Ru

G BELT TROUBLESHOOTING

60

DRIVE MOTOR TROUBLESHOOTING 65

HEAD-

AND TAll..ROLLER TROUBLESHOOTING 68

TREADMILL

VmRA

TIO TROUBLESHOOTING 69

TREADMll...L STATIC AND SHOCKING TROUBLESHOOTING

71

Page 8

-------------------

-

CO!'ffENTS

PAG£

NUMBeR

•

CHAPTER FIVE: REPLACEMENT PROCEDURES

72

DISPLA Y CABLE

74

EMERGENCY STOP SWITCH

78

ELEVATION MOTOR

81

MOTOR BELT

85

ELEVATION SENSOR

87

LIMIT

SWITCH

89

RPM

SENSOR

92

MOTOR CONTROL BoARD

95

FLYWHEEL

98

MOTOR PULLEY

101

HANDRAILS

104

SUK

DECK

106

RUNNING BELT

110

•

ELEVATION CANS

115

INDEX

117

•

Page 9

~.

•

How

TO

USE

TIns

MANuAL

This service manualisintended to assistinpreventive maintenance, troubleshooting,

and replacing worn parts for the STAR TRAC 2000 and 3000 Series Treadmills.

STAR

TRAC

MODELS

2000P Series

~1~0

STAR TRAC Programmable

2000S Series

STAR TRAC Simple

2000J Series

~

\

STAR TRAC Jogger

2000W Series

STAR TRAC Walker

3000P Series STAR TRAC Programmable

3000S Series

STAR TRAC Simple

3000J Series

STARTRAC Jogger

3000W Series ST

AR

TRAC Walker

In

Chapter

One: Preventive Maintenance, you will find the recommended

maintenance guide for your treadmill.

Keep~ng

a regular preventive maintenance

schedule increases the treadmill uptime and runners' enjoyment.

In

Chapter

Two: Diagnostic Test you will learn how to acti ate the Motor Test

Mode and Display Test Mode to prevent problems and service your treadmill.

Correcting problems and troubleshooting error codes are covered

in

Chapter

Three:

Troubleshooting

Error

Codes.

Chapter

Four: Increasing Mechanical ptime provides hints and tips for preventing

and troubleshooting common mechanical problems.

Chapter

Five: Replacement

Procedures

details with text and illustrations how to replace the worn parts.

Page 10

Chapter Four: Increasing echanical Uptime provides hints and tips for preventing

and troubleshooting common mechanical problems.

Chapter Five: Replacement

Procedures

details with text and illustrations how to replace the worn parts.

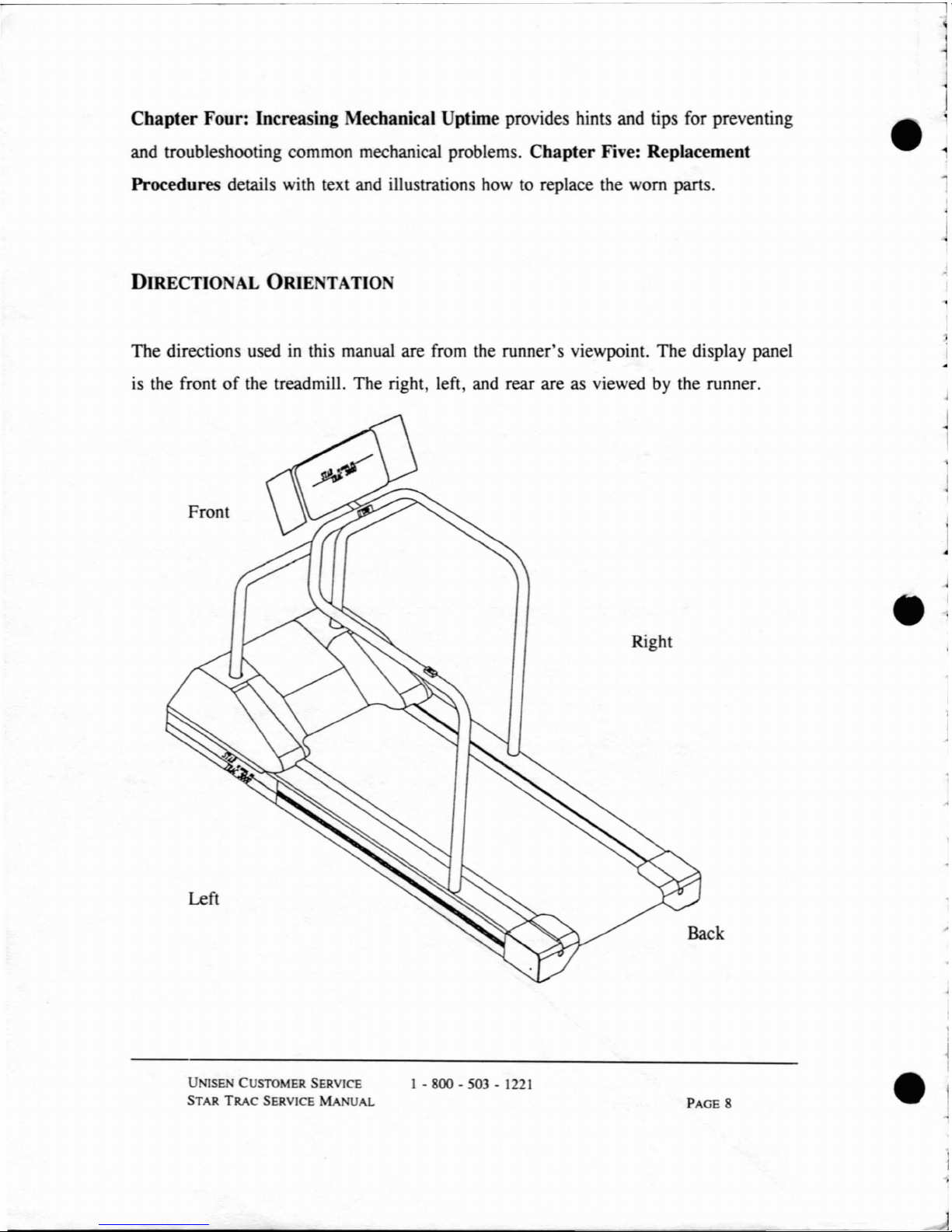

DIRECTIO AL

ORlE

TATIO

The

directions usedinthis manual are from the runner's viewpoint.

The

display panel

is the front

of

the treadmill. The right, left and rear are as viewed by the runner.

•

Front

Left

UNISE

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MA

UAL

I - 800 - 503 -

1221

Right

Back

PAGE 8

•

Page 11

•

CHAPTER

ONE:

PREVENTIVE

MAINTENANCE

•

Performing regular preventive maintenance on all STAR TRAC treadmills is strongly

recommended. Without preventive maintenance, normal wear and tear may cause

cumulative effects, such as misalignment and early replacement

of

parts.Inaddition,

the more the treadmill is

in

use, the stricter you should adheretothe preventive

maintenance schedule.

NOTE:Ifany unusual problems, such as error codes and blown circuit breakers,

occur, please refer to Chapter Three: Troubleshooting Error Codes.

•

UNlSEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANuAL

1 -

800-503-1221

PAGE 9

l~

_

Page 12

DAILY PREVENTIVE MAINTENANCE

You should perform the following maintenance on a daily basis.

• Use a cloth and diluted all-purpose cleaner to remove any dust, dirt,

and other substances from the main

part

of

the treadmill. Wipe the

display panel, console, handrails, and motor cover. Avoid using cleaner

under the running belt.

• To ensure the longevity

of

the running belt, clean under the running

belt with a soft,

dry cloth.

To clean, slide the cloth between the running belt and the deck from

one side

of

the frametothe other side. You may need a rulerorrod to

slide towel under the running belt.

Then, holding the edges

of

the cloth, pull the cloth from the headroller

to the tailroller.

NOTE:

Do

NOT clean the running belt by activating the treadmill. Do

NOT place feet or any weight on the running belt when cleaning the

treadmill.

•

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

I - 800 - 503 -

1221

PAGE

10

•

Page 13

You should perform the following maintenanceona weekly basis.

•

•

•

•

•

Check the running belt for alignment and tension.

NOTE: Do NOT automatically tighten the belt daily. For additional

infonnation on how to verify belt alignment

or

correct a belt that has

slipped or mistracked, please refer

to Chapter Four: Increasing

Mechanical Uptime.

Verify power cord is not under the treadmill.Ifthe power cord is

placed under the treadmill, it may become pinched

or

bind up the

elevation screws. This results

in

error codes or treadmill damage.

WEEKL

Y PREVENTIVE MAINTENANCE

Elevate the treadmill and vacuum the floor under the treadmill. Be

careful nottobump the elevation switches as you sweep.

• Inspect the deck and running belt surfaces for unusual wear.

Check the deck for worn areas where the underlying fiber board

or

soft

spots are visible. Inspect the underside center

of

the running belt for a

worn, glazed appearance.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

11

Page 14

•

Walk on the deck surface.Ifany portion feels soft, replace the deck.

NOTE: For information on replacing a worn deck or belt, please refer

to Chapter Five: Replacement Procedures.

•

•

If

you have a 3000 Series, check the subdeck and weardeck screws.

If

loose, tighten them.

BIWEEKLY

PREVENTIVE MAINTENANCE

You should perform the following maintenance biweeklyortwice a month basis.

•

Vacuum around the motor and electronics by removing the shroud

cover and lifting the motor shroud.

Raise the motor shroud and suspend it from the display neck with the

bungie cord, from your STAR TRAC Treadmill Toolkit.

Be sure to

avoid bumping or damaging the RPM disc and sensor, elevation sensor,

limit switches, and wire connections.

NOTE:

To

raise the motor shroud, use the Phillips screwdriver to

remove the screw in the motor shroud. Gently lift the motor shroud

up

the display handrail.

Using

the bungie cord from the STAR TRAC

Toolkit, hold the motor shroud

at the top

of

the display handrail.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

12

•

Page 15

•

To

replace the motor shroud, remove the bungie cord and

Lower

the

motor shroud until it touches the frame. Press the sides

of

the motor

shroud to the frame and attach the

veLcro

fasteners. Using the Phillips

screwdriver, tighten the screw in the center

of

the motor shroud.

MONTHLY

PREVENTIVE

MAINTENANCE

You should perform the following maintenance once a month.

• Lubricate the elevation screws with a silicon lubricant to prevent rust

accumulation.

• Activate Motor Test Mode and Display Test ModeofDiagnostic Test.

This will diagnose any unforeseen maintenance and error codes.

NOTE: For additionaL information on activating Diagnostic Test,

please refer to Chapter

Two:

Diagnostic test.

••

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1-

800-503-1221

PAGE

13

Page 16

e.

e·

e

Page 17

r

I

[

I

•

•

--

--

-----------------

CHAPTER Two:

DIAGNOSTIC TEST

The STAR TRAC software program contains a self-diagnostic test mode that precisely

determines the reason for

an

error. This chapter outlines howtoactivate Diagnostic

Test and diagnose the problem.

Diagnostic Test consists

of

the Motor Test Mode and Display Test Mode. You will

use the test mode to check the motor, sensors (if they are working and calibrated),

and switches (if they are active and responding). The Display Test Mode checks the

keyboard response and

Qualityofthe LEDs. The Diagnostic Tests are the best

methods for determining specific failure areas

on

the STAR TRAC treadmill.

Remember,

in

Diagnostic test, you areincommand. Pay attention to the display

panel. The LED lights and readouts show you the exact position and limits

of

the

treadmill.

In

this chapter,

you

will learn:

CONTENTS

ACTIVATING MOTOR TEST MODE

ACTIVATING DISPLAY TEST MODE

PAGE

NUMBER

16

25

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

1 - 800 -

503

- 1221

PAGE 15

Page 18

ACTIV

ATING

MOTOR TEST MODE

OF

DIAGNOSTIC TEST

Use the Motor Test Modetocheck the motor, sensors (if they are working and

calibrated), and switches (if they are active and responding).

In

addition, you may be

instructed to activate the Motor Test Mode during preventive maintenance

or

troubleshooting.

To activate Motor Test Mode, please follow these instructions.

If

your treadmill does

not respond, please refer

to

Chapter Four: Increasing Mechanical Uptime or

contact STAR TRAC customer service.

•

..

Step One

Tum the power switchtothe OFF position.

Place the treadmill into the Motor Test Mode.

Step Two

•

If

you have a Jogger, Programmable,orSimple with number

keys, simultaneously press key number 8, while turning the

power switch

to

ON.

•

•

If

you have a Walker or Simple with no number keys,

simultaneously press the

- (minus) key, while turning the power

switch

to

ON.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE 16

•

Page 19

•

Step Three Verify the display panel reads:

Verify the running belt

is

not moving.

•

If

you have a 2000 Series treadmill from 1990orearlier, verify

the display panel reads:

If

the running beltisnot moving, proceed to the next step.

If

the running belt begins moving, then:

•

To

raise the motor shroud, use the Phillips screwdriver

to remove the screw holding the motor shroud to the

frame. Gently raise the motor shroud up the display

handrail.

Using

the bungie cordfrom the STAR TRAC

Toolkit, hold the motor shroud at the top

of

the display

handrail.

I

J

r

•

Step Four

o

o

3

2

0.0

0.0

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 - 1221

PAGE 17

Page 20

•

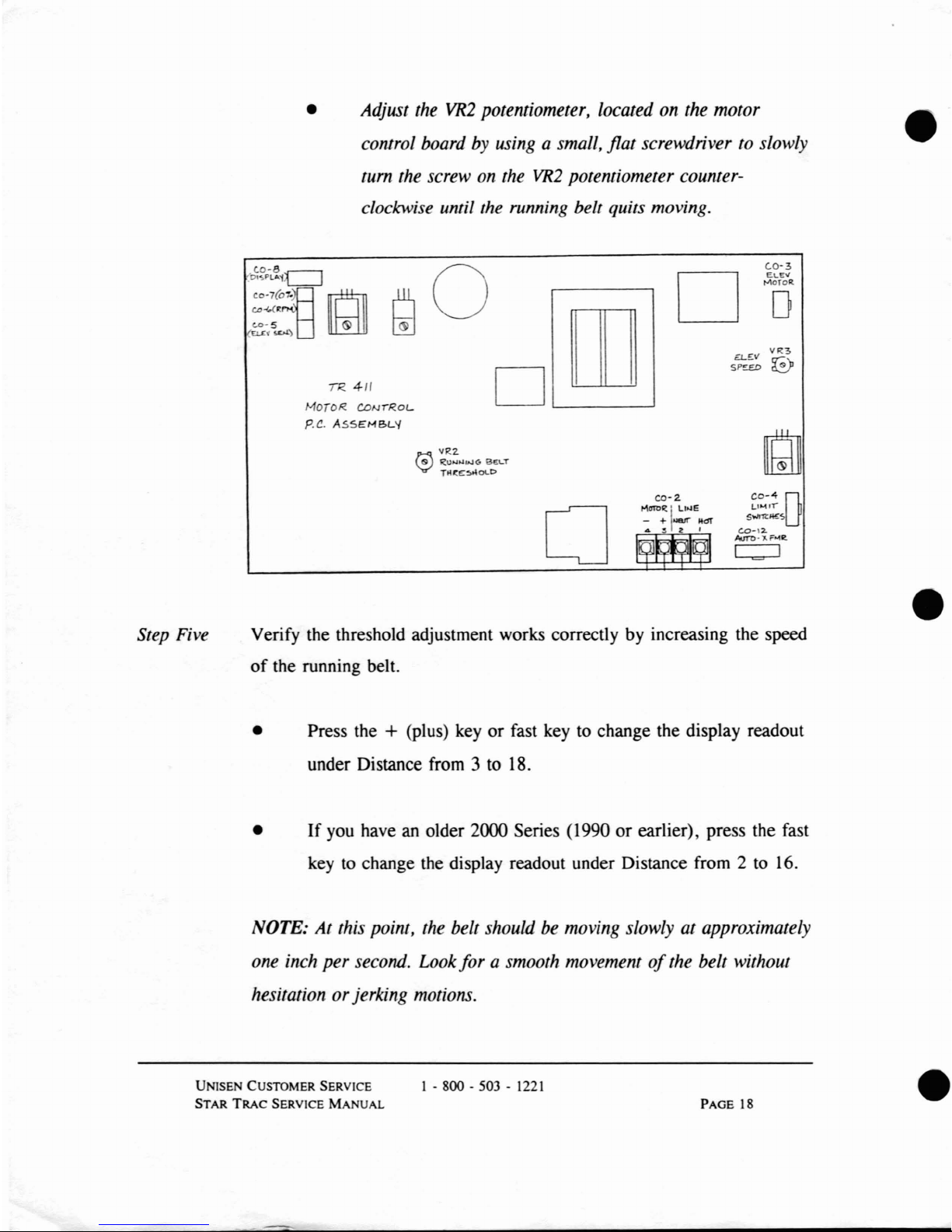

Adjust the

VR2

potentiometer, located on the motor

control board by using a small, flat screwdriver to slowly

tum

the screw on the

VR2

potentiometer counter-

clockwise until the running belt quits moving.

•

TR

4/1

JV1oroR.

CONTRoL

p.C.

ASSEMBL'{

rn

D

L-.-..----J

D

(,0-3

ELE"

"""OTOR.

o

o

co-2.

>1aTl>'t

I

L,,,e

- +.....,...

"dT

..

2 I

CO-4D

L'

.....

'l

S"'''!l:1l!£

c.o-\2.

AurD·'J,.F

.....

1it

C::::J

•

Step Five Verify the threshold adjustment works correctly by increasing the speed

of

the running belt.

• Press the

+ (Plus) key

or

fast key to change the display readout

under Distance from 3 to 18.

•

If

you haveanolder 2000 Series (1990orearlier), press the fast

key to change the display readout under Distance from 2 to 16.

NOTE:

At

this point, the belt should be moving slowly at approximately

one inch per second. Look

forasmooth.

movementofthe belt without

hesitation orjerking motions.

UN1SEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

18

•

Page 21

•

•

If

The

belt doesn't move or moves too fast, then adjust the

belt speed.

• Adjust the

VR2

potentiometer, located on the

motor control board by using a small, flat

screwdriver.

To

increase the running belt speed, carefully

tum

the screw clockwise.

To

decrease

The

running belt speed, carefully

tum

the

VR2

screw counter-clockwise.

• Verify the running beltismoving at approximately

one inch per second.

• Replace the motor shroud by removing

The

bungie

cord and lowering the motor shroud until

it

TOuches

the frame. Press the sidesofthe motor

shroud to the frame and attach the velcro

fasteners.

Using

the Phillips screwdriver, tighten

the screw

in the centerofthe motor shroud.

•

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

19

Page 22

Step Six

CAUTION

Do not stand on the running belt while the treadmill is

in

test mode.

Verify the RPM sensor works correctly as the running belt continues

moving at approximately one inch per second.

•

If

you have a Programmable, check the LED numbers located

under Pre-Designed Programs on the Display Panel Board.

Numbers one/two and five/six should toggle slowly.

•

•

If

you have a Jogger, Walker,orSimple, verify the elapsed

time and distance lights toggle.

If

not, then:

• Check the alignment

or

adjustmentofthe RPM

disc and the RPM sensor

cabLe

connection.

• Adjust the potentiometer, Located on the RPM

sensor.

•

If

aligned but the LEDs do not toggLe,

repLace

the

RPM sensor.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE

20

•

Page 23

•

Step Seven Verify the RPM sensor is calibrated by pressing the + (Plus) key

or

fast key to raise the display readout from

0.0

to 3.5 (5.6

km

per hour).

•

If

you have a ProgrammableorSimple, verify the numbers 0 to

7, located under Percent Grade, are lit and number 8 is

blinking.

•

If

you have a Jogger, verify the numbers

0.0to3.5,

located

under Percent Grade, are lit and number

4.0

is blinking.

•

If

you have a Walker, verify the numbers 7 and 8, located under

Elapsed Time, are toggling.

If

yes, the RPM sensoriscalibrated.

If

no, then:

• Check for excessive dust on the RPM sensor and

disc.

• Remove the dust from the RPM sensor and disc,

blow air into the RPM disc area.

Or,

with a toothbrush, gently brush one side

of

the RPM disc and then gently brush the other side

of

the disc.

Be

careful youdonot hit the RPM

sensor with the toothbrushorany foreign objects.

• Adjust the potentiometer on the RPM sensor,

as

describedinStep Six.

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

21

Page 24

NOTE:Ifyou have a Walker, please skiptoStep

Ten.

Steps Eight and Nine discuss

elevation.

•

Step Eight

Verify the 0% (zero percent) switch at 0% grade and above 0% grade.

NOTE:

The

treadmill does not display the actual elevation during the

Motor Test Mode.

•

If

you have a Programmable, check under Pre-designed

Programs and verify LED number 4 is on and LED number 8 is

off, when the elevation is at 0% grade. Raise the elevation to

above 0% percent grade and verify that the LED number 4 is

off and LED number 8

is

on.

•

If

you have a Jogger, check under Percent grade and verify

LED number 7.S is on, when the elevation is at 0% grade.

Raise the elevation to above

0%

grade and verify the LED

number 7.5 is off.

•

•

If

you have the Simple, check under Percent Grade and verify

the number

15ison at

0%

grade. Raise the elevation to above

0% grade and verify the number

15isoff.

If

not, check the elevation switches cable connection.

NOTE:

If

thereisan

elevation-related problem, you may disable

the elevation system.

This

allows the treadmill to operate

nonnaLLy,

without the elevation operation.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE 22

•

Page 25

p

r

l

•

l

•

To

disabLe

the eLevation

mOlor,

turn the power switch off. Then

simuLtaneousLy press the key number 0, while turning the power

switch

to ON.

The

dispLay

readoUl

says ELV OFF. The eLevation

will be disabLed until the power switch is turned off.

Jfyou

have a Simple with no numbers, simultaneously press the

DOWN Arrow key, while turning the power switch

to ON. The

dispLay

readout says ELV

OFF.

The

eLevation is disabLed until

the power switch is turned off.

NOTE:

In

the Diagnostic test, it is possibLe, aLthough unlikeLy, you could override the

system. For exampLe,

if

you press the elevation up arrow key, the treadmill elevates

until you release the up arrow key. On the early 2000 Series treadmill, it is possible

to overdrive the elevation

Limit

switches and eLevation grades.

Be sure

to pay attention to the display panel as you work with the treadmill in

Diagnostic test. The

LED

Lights

and readouts show you the exact position and

Limits

of

the treadmill.

Step Nine

Check the elevation motor speed.

• Press the UP Arrow key while verifying the elevation speed

located under Total Calories

in

this Test Mode. The elevation

motor speed should read approximately 60 revolutions per

second, as the treadmill elevates.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

23

Page 26

•

Press the DOWN Arrow

key

while verifying the elevation speed

located under Total Calories

in

this Test Mode. The elevation

motor speed should read approximately 60 revolutions per

second or higher, as the treadmill descends.

If

not, then:

• Adjust

VR3

on the Motor Control Board.

To

increase the speed,

tum

VR3

clockwise.

To

decrease the speed,

tum

VR3

counter-clockwise.

If

yes, proceed to the next step.

If

the display numbers aren't reading, check the elevation

sensor connection.

•

Step

Ten

If

an error code appears,

tum

the power switch to

OFF.

Wait

four seconds, then

tum

the power switch to

ON.

Replace the motor shroud by removing the bungie cord and lowering

the motor shroud until it touches the frame. Press the sides

of

the

motor shroud

to

the frame and attach the velcro fasteners. Using the

Phillips screwdriver, tighten the screw

in

the centerofthe motor

shroud.

•

Step Eleven Exit the Motor Test Mode by pressing the STOP key.

• Tum the power switch

to

OFF. Wait four seconds, then tum the

power switch

to

ON.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

24

•

Page 27

•

ACTIVATING DISPLAY

TEST

MODE

OF DIAGNOSTIC

TEST

Use the Display Test Modetocheck the display panel, key response, and quality

of

the LEDs. In addition, you may be instructed to activate the Display Test Mode

during preventive maintenance

or

troubleshooting.

To activate Display Test Mode, please follow these instructions:

Step One

Step

Two

Tum

the power switch to the OFF position.

Place the treadmill into Display Test Mode.

•

If

you have a Programmable, Walker,orSimple with number

keys, simultaneously press the key number 5, while turning the

power switch to ON.

•

•

If

you have a JoggerorSimple with no number keys,

simultaneously press the

+ (Plus) key, while turning the power

switch to ON.

NOTE:Ifyou cannot access Display Test Mode, you may need to

replace the display panel. For addifional injonnafion on

troubleshooting the display panel, please refer

to Chapter Three:

Troubleshooting

Error

Codes.

•

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE 25

Page 28

Step Three All the LEOs on the Display Panel should be lit. Press any key, except

the STOP key, to display the EPROM number.

• Please make note

of

this EPROM number.Ifthere are problems

with the display panel, STAR TRAC requires this EPROM

number to ship the correct replacement part.

•

Step Four

Step Five

Check the key response by individually pressing each key on the

display panel. Each key should beep and display a pattern

of

LED

lights on the display panel readout. The 0 key will beep, but no LED

lights will

be displayed.

If

not all the LEDs to form the pattern are lit, you may need to

replace the display panel. For additional information, please

refer

to Chapter Three: Troubleshooting Error Codes.

Exit the Display Test Mode.

• Press the STOP key.

• Tum the power switch to OFF. Wait four seconds, then tum the

power switchtoON.

•

UNlSEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

5

I - 800 - 503 -

1221

PAGE

26

•

Page 29

•

•

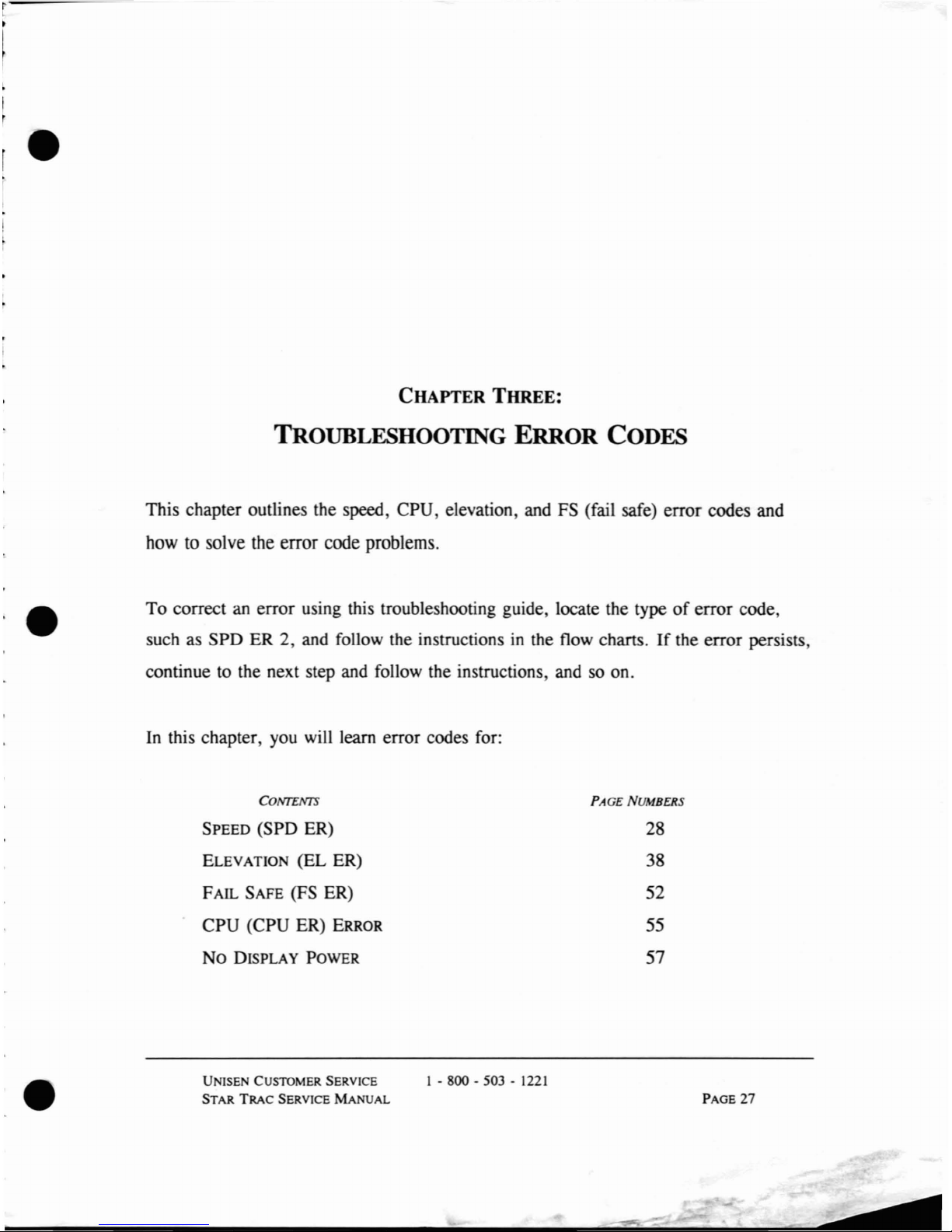

CHAPTER

THREE:

TROUBLESHOOTING ERROR CODES

This chapter outlines the speed, CPU elevation, and FS (fail safe) error codes and

howtosolve

the

error

code

problems.

To correct an error using this troubleshooting guide, locate the typeoferror code,

such as

SPD

ER 2, and follow the instructionsinthe flow charts.Ifthe error persists

continue to the next step and follow the instructions and so on.

In

this chapter, you will learn error codes for:

•

CONTEIVTS

SPEED

(SPD

ER)

ELEVATION

(EL

ER)

FAIL

SAFE

(FS ER)

CPU (CPU ER) ERROR

No

DISPLAY POWER

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MA

UAL

1 - 800 - 503 -

1221

PAGE NUMBERS

28

38

52

55

57

PAGE

27

Page 30

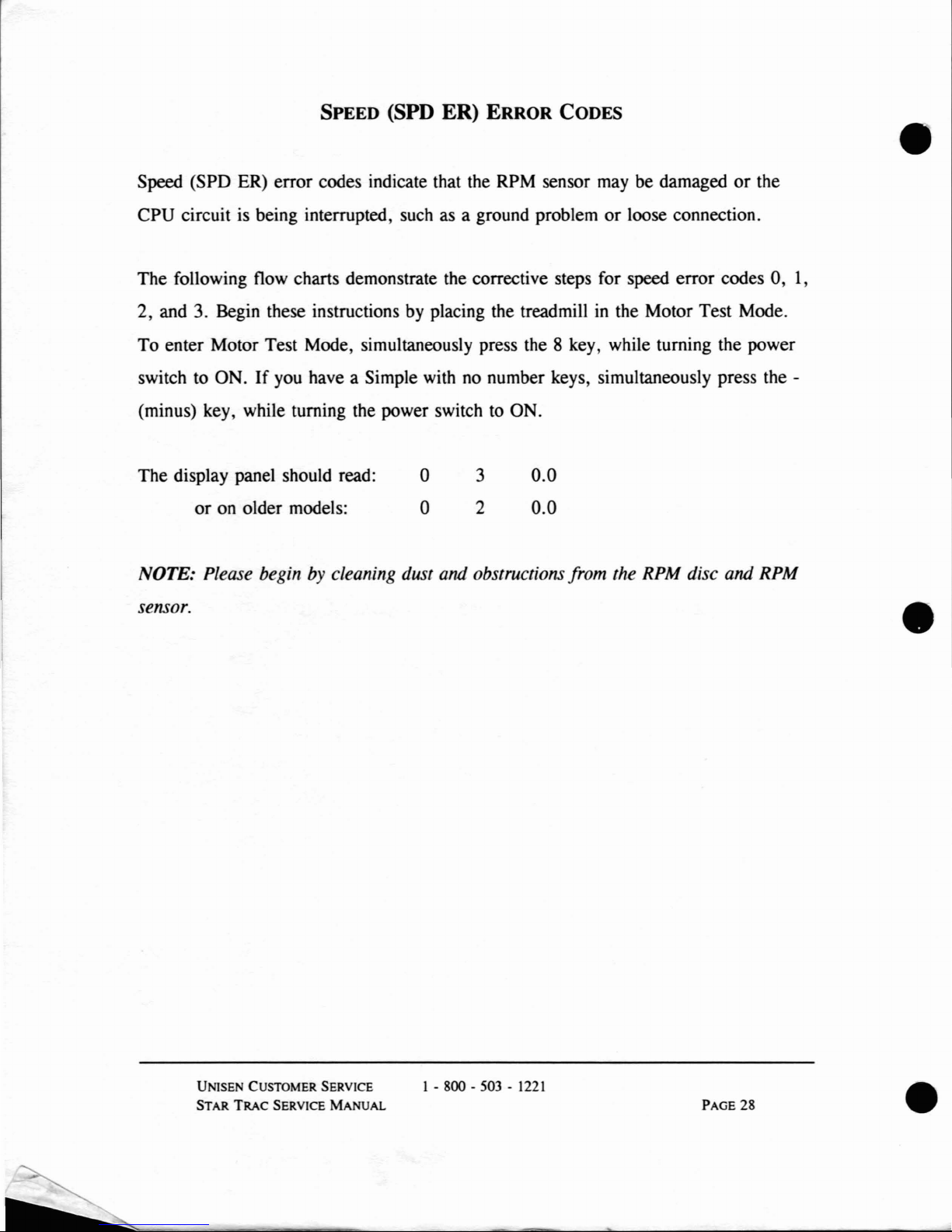

SPEED

(SPD

ER)

ERROR CODES

Speed (SPD ER) error codes indicate that the RPM sensor may be damaged or the

CPU circuit is being interrupted, such

as

a ground problem or loose connection.

The following flow charts demonstrate the corrective steps for speed error codes 0,

1,

2, and 3. Begin these instructions by placing the treadmillinthe Motor Test Mode.

To enter Motor Test Mode, simultaneously press the 8 key, while turning the power

switch to ON.

If

you have a Simple with no number keys, simultaneously press the -

(minus) key, while turning the power switch to ON.

•

The display panel should read:

or

on older models:

o

o

3

2

0.0

0.0

NOTE: Please begin by cleaning dust and obstructions from the RPM disc and RPM

sensor.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

28

•

Page 31

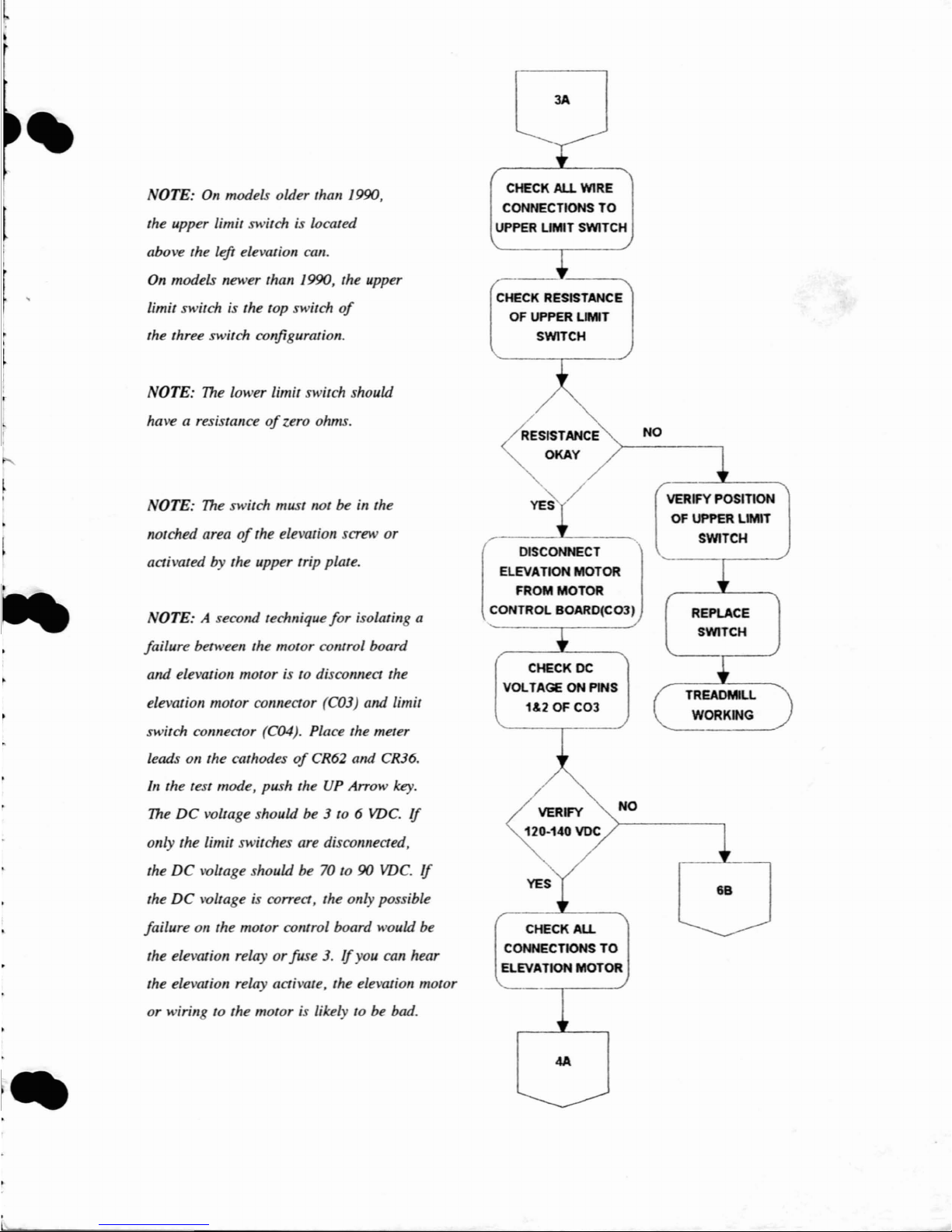

OTE:

On

models older than 1990,

the upper limit switch is located

above the left elevation can.

On

models newer than 1990, the upper

limit switch is the top switch

of

the three switch configuration.

NOTE: The lower limit switch should

have a resistance

of

zero ohms.

OTE: The switch must not be

in

the

notched area

of

the elevation screw or

activated by the upper trip plate.

OTE: A second technique

for

isolating a

failure between the motor colltrol board

and elevation motor is to disconnect the

elevation motor connector (C03)

and limit

switch connector (C04). Place the meter

leads on the cathodes

of

CR62 and CR36.

In

the test mode, push theUPArrow key.

The

DC

voltage should be 3 to 6 VDe.

If

only the limit switches are disconnected,

the

DC

voltage should be 70 to90VDe.

If

the

DC

voltage is correct, the only possible

failure on the motor colltrol board would be

the elevation relay

or

fuse 3.Ifyou can hear

the elevation relay activate, the elevation motor

or wirin to the motor is likely to be bad.

]A

CHECK ALL WIRE

CONNECTIONS

TO

UPPER

UMIT

SWITCH

CHECK RESISTANCE

OF UPPER LIMIT

SWITCH

~SISTANCE

~

OKAY

YES /

[

DISCONNECT

ELEVATION

MOTOR

FROM MOTOR

CONTROL

BOARD(COJ)

CHECK DC

VOLTAGEONPINS

1&2 OF

C03

NO

CHECK

ALL

CONNECTIONS

TO

ELEVATION

MOTOR

4A

NO

VERIFY POSITION

OF

UPPER LIM1T

SWITCH

REPLACE

SWITCH

TREADMILL

WORKING

6B

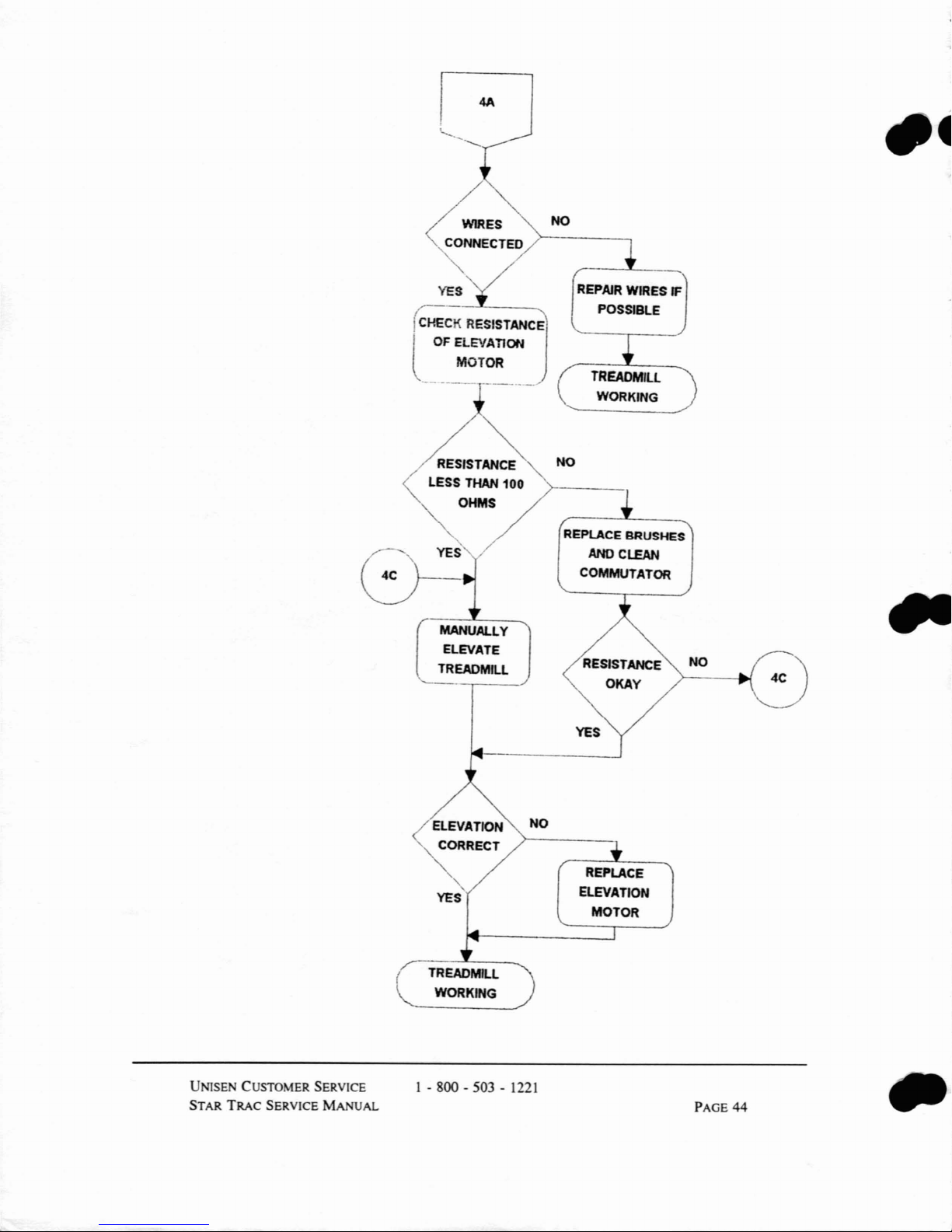

Page 32

o

~

•

~ES

<CO:ECTED

YES

C-

!

CHECK

l

cr

RESISTANCJE'

OF

ELEVATION

MOTOR

-----

RESISTANCE

LESS THAN

OHMS

UALLY

ELEVATE

TREADMIU

_._--

100

NO

REPAIR

POSSIBLE

TREADMIll

WORKING

NO

REPlACE

ANoC~

COMMUTATOR

WIRES

IF

BRUSHES

UNISE CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

TREADMILL

WORKING

1 - 800 - 503 -

1221

NO

REPLACE

ELEVATION

MOTOR

PAGE

44

Page 33

NOTE:

On

models older than 1990,

the

0% switch is located next to the

lower limit switch under the treadmill.

On

models newer than 1990, the 0%

switch is the bortom switchofthe

three switch configuration.

NOTE:

The

0% switch should have a

resistance

of

infinite ohms at 0%

and 0 ohms above 0%.

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

5A

CHECK

All

WIRE

CONNECTIONS

TO

ZERO PERCENT

SWITCH

CHECK RESISTANCE

OF

ZERO PERCENT

SWITCH

RESISTANCE

OKAY

REPLACE

SWITCH

TREADMill

WORKING

1 - 800 - 503 -

1221

YES

RECHECK ALl

WIRES

PAGE

45

Page 34

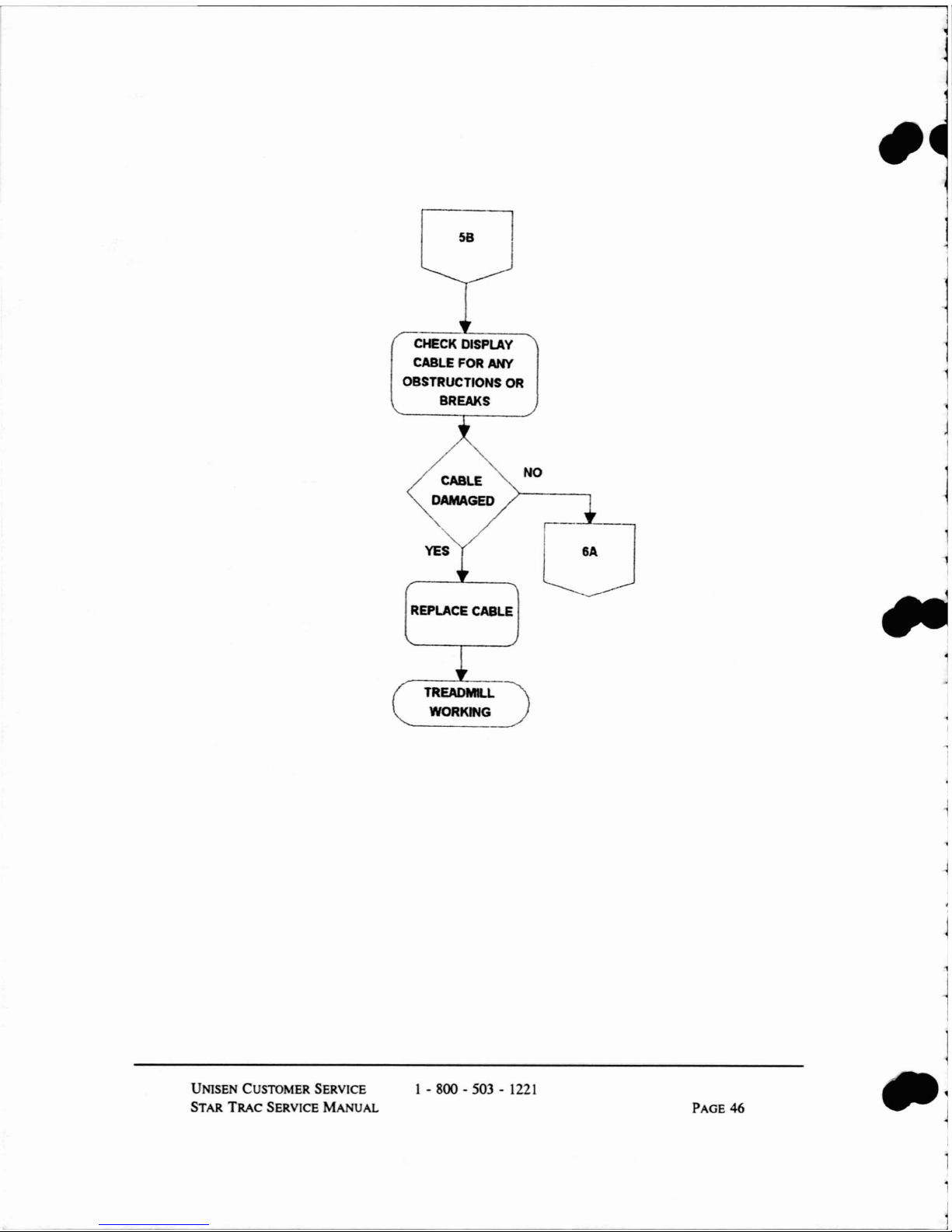

58

CHECK

DISPLAY

CABLE

FOR

ANY

OBSTRUCTIONS

OR

BREAKS

J

j

CABLE

DAMAGED

NO

6A

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

REPLACE

CABLE

TREADMILL

WORKING

1 - 800 - 503 -

1221

PAGE

46

Page 35

•

OTE: Simultaneously press the key

number 5 (on Simples without number

keys, press the + (plus) key), while

turning the power switch to

ON.

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

6A

ENTER DISPLAY

TEST

MOOE

/

//

/ KEYS

RESPOND

~-~

("

REPLACE

t,

FACEPLATE

--,-

TREADMILL

WORKING

I -

gOO-503-1221

YES

OOONNECT

DISPlAY

CABLE

ON MOTOR

CONTROL AND

DISPLAY BOARD

IF

ERROR CONTINUES,

REPLACE DISPLAY

CABLE

AND/OR DISPlAY

BOARD

PAGE

47

Page 36

For older models:

NOTE: For transfonner with resistor:

red/white

black/white

red/black

red/white

black/white

red/black

= approx. J6 ohms

= approx. 4 ohms

= approx. J3 ohms

= approx. 4. 7 ohms

= approx.

2.

7 ohms

= approx.

2.3

ohms

68

~

-"

CHECK RESISTANCE

AUTOT':SFOR_

J

NO

REPLACE AUTO

TRANSFORMER

TREADMILL

WORKING

YES

REPlACE

MOTOR

CONTROL

80ARD

..

NOTE:Ifthe elevation error cominues, disable the elevation circuit by turning the power switch to

OFF.

Wait

four

seconds, then simultaneously press the key number 0

(on

Simples without number keys,

press the

DOWN

Arrow key), while turning the power switchtoON.Toenable the elevation circuit,

turn the

power

switch to

OFF.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

48

.,

Page 37

NOTE:

To

ellter Motor Test Mode,

please

refer to the instructions

on page 38.

ELEVATION

ERROR 2

( ENTER TEST

MODE

ELEVATE TREADMILL.,

THEN DOWN

TO

ZERO

LEVEL

SPEED

NO

CORRECT

>------------,

PAGE

49

ADJUST

VR3

ON

MCB

TO

THE

CORRECT SPEED

GOTOELEV.

ERROR 1 OR 3

FLOWCHART

1A

NO

~EVATES

TREADMILL

WORKING

RESET

TREADMIlL

BY

TURNING POWER

SWITCH OFF THEN

ON

CHECK ELEVATION

MOTOR

SPEED WHILE

MOTORISOPERATING

I - 800 - 503 -

1221

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

NOTE:Inthe test mode, the

correct Speed is displayed

uruler Elapsed

Time.

NOTE:

VR3islocated on the

right cellter

of

the motor

control board.

NOTE: When ascending, the

elevation speed should be

between

55

and 60.

When

desceruling, the speed should

befaster than

60.

Page 38

FAIL SAFE (FS

ER)

ERROR CODE

Fail safe (FS ER) error codes are caused by shorted or faulty keys on either the

display panel

or

the emergency stop switch.

The following flow charts demonstrate the corrective steps for fail safe error codes 1

and 2. Begin these instructions by placing the treadmill

in

Display Test Mode.

NOTE:Ifthe

FS

Error Code occurs when you are entering Motor Test Mode, you

may

have pressed the wrong key number. Confinn the typeofSTAR TRAC treadmill

(programmable, simple, jogger,

or

walker) and verify the key number. Re-enter test

mode.

Begin these instructions by placing the treadmillinthe Display Test Mode.

To

enter

Display Test Mode, simultaneously press the key number 5, while turning the power

switch to the ON.

If

you have a Simple without number keys, simultaneously press

the

+ (Plus) key while turning the power switch

to

the ON.

--

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 - 1221

PAGE

50

Page 39

TREADMILL

WORKING

•

FS ERROR 1

TURN POWER SWITCH

TO

-OFF-

WAIT 2 I

SECONDS THEN

TUR

TO-OW

INPUT

ANY

I

INSTRUCTiON I

ERROR

CODE

~O

_

CONTIN7

YES

ENTER DISPLAY

TEST

MODE

YES

•

OTE:

To

ellter Display

Test

Mode,

please refer to the instructions

on

page 50.

(

PRESS

EACH

KEY,

THE

DISPLAY

BEEPS

AND CHANGES

CHANGE

FACEPLATE

NO

REPLACE FACE

PLATE

OR

DISPLAY

ASSEMBLY

TREADMILL

WORKING

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

TREADMIlL

WORKING

1 - 800 - 503 -

1221

PAGE 51

Page 40

NOTE:

To

enter Display

Test

Mode,

please refer to the instrucriollS

on page 50.

UNISE CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

FS ERROR 2

DISCONNECT

EMERGENCY

STOP

SWITCH FROM BACK

OF DISPLAY BOARD

CONNECT

2 PINS ON

DISPLAY

BOARD

TOGETHER USING A WIRE

OR PAPER CLIP

ENTER DISPLAY

TEST

MODE

REPLACE

DISPLAY BOARD

TREADMIlL

WORKING

1 - 800 - 503 -

1221

REPLACE

REMOTE

STOP SWITCH

AND/OR

CABLE

PAGE

52

•

•

•

Page 41

•

•

CPU

(CPU

ER)

ERROR

CODES

The CPU (CPU ER) error codes indicate the CPU (central processing unit) circuit is

being interrupted by a ground problem, loose connection, or static noise.

The following flow chart demonstrates the corrective steps for all CPU error codes.

CAl.mON

Always unplug the STAR TRAC treadmill from the power outlet,

prior

to

troubleshooting.

(

OFF/ON POWER

SWITCH CYCLED TOO

FAST

[

URN

POWER

SW'9CH'

TO

-OFF-

WAIT 2

SECONDS THEN TURN

TO

-ON-

/

/CPU

ERROR

" CONTINUES

"

NO

YES

1A

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

TREADMIll

"")

WORKING

./

1 - 800 - 503 - 1221

PAGE

53

Page 42

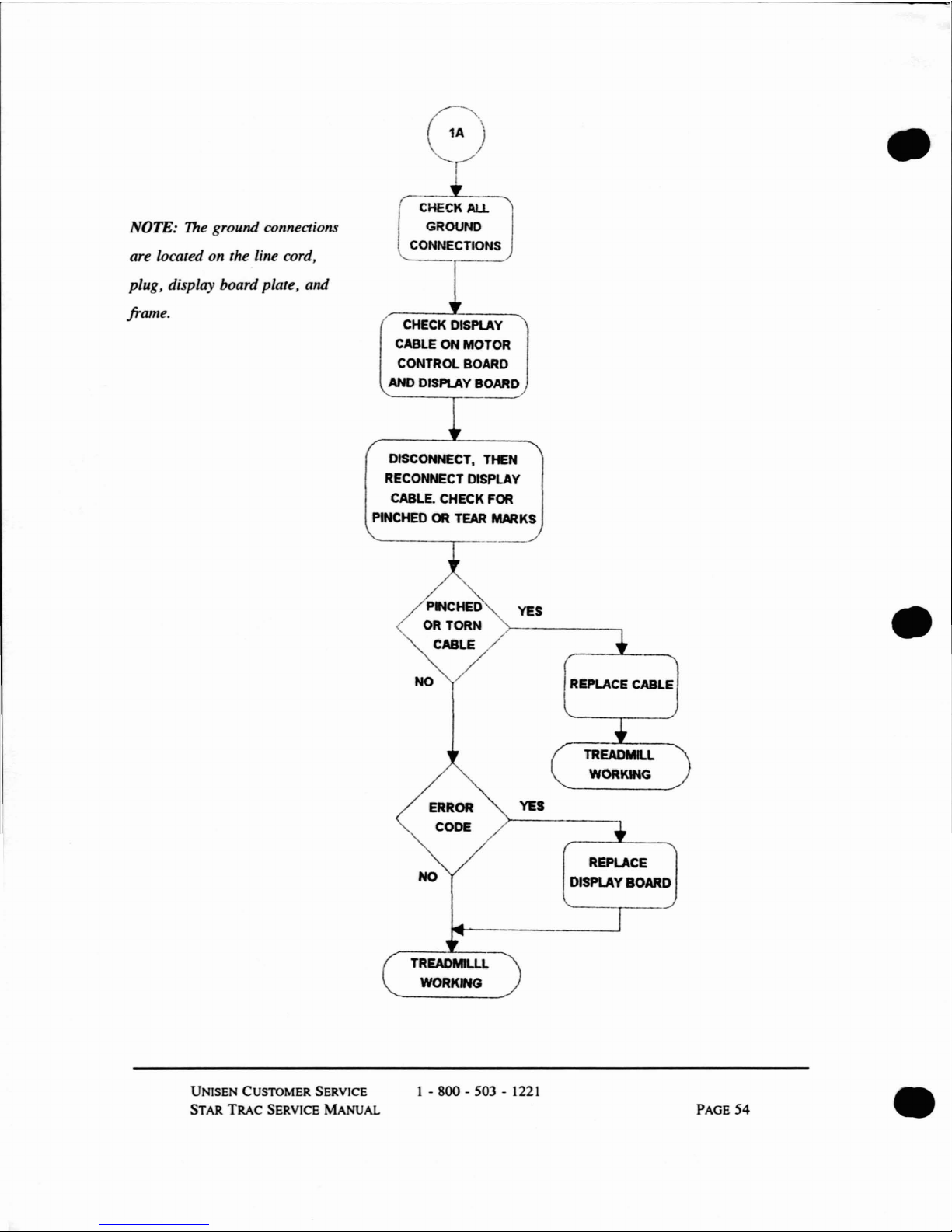

NOTE:

The

ground connections

are located on the line cord,

plug, display board plate,

and

frame.

G

r

I

CHECK

AU.

GROUND

\.. CONNECTIONS

CHECK

DISPlAY

CABLE ON MOTOR

CONTROl. BOARD

AND

DISPlAY

BOARD

DISCONNECT. THEN

RECONNECT DISPLAY

CABLE. CHECK

FOR

PINCHED

OR

TEAR

MARKS

•

NO

YES

YES

REPLACE CABLE

TREADMILL

WORKING

•

NO

REPLACE

DISPlAYBOARD

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANuAL

TREADMlU.L

WORKING

1 - 800 - 503 - 1221

PAGE

54

•

Page 43

•

•

No

DISPLAY

POWER

When the power switch is turned to ON, you should be able to read the display.

If

not, begin by visually inspecting the treadmill, wall circuit breaker and power

switch.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE

55

Page 44

NOTE:

The

flat ribbon cableisconnected

to

the venical connection.

The

round cable

is connected to the horizolltal connection.

OTE:

The

REG 2 is located 011 the upper left

of

the motor colltrol board. Place the red lead

of

the meter on the left sideofREG 2 and black

lead on the center groulld

serl!}

.

NO DISPLAY

POWER

VERIFY WALL CIRCUIT

BREAKER IS ON,

TREADMIUISPLUGGED IN

AND

POWER SWITCH IS ON

VERIFY

AC

INPUT

VOLTAGE AT PINS

1 & 2

OF CO-2 ON MOTOR

CONTROL BOARD

----~

VERIFY DISPLAY

CABLE IS PLUGGED

IN

TO

CORRECT

CONNECTOR

(CO-8)

VERFY

8VDC ON

REG 2

VERIFY 8VOC ON

REG1

•

•

UNlSE

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

2A

1 - 800 - 503 -

1221

NO

REPLACE MOTOR

CONTROL BOARD

TREADMI.l.

WORKING

PAGE 56

•

Page 45

REPACE

DISPLAY CABLE

VERIFY 8VDC ON

REG

1

ON

DISPLAY BOARD

..

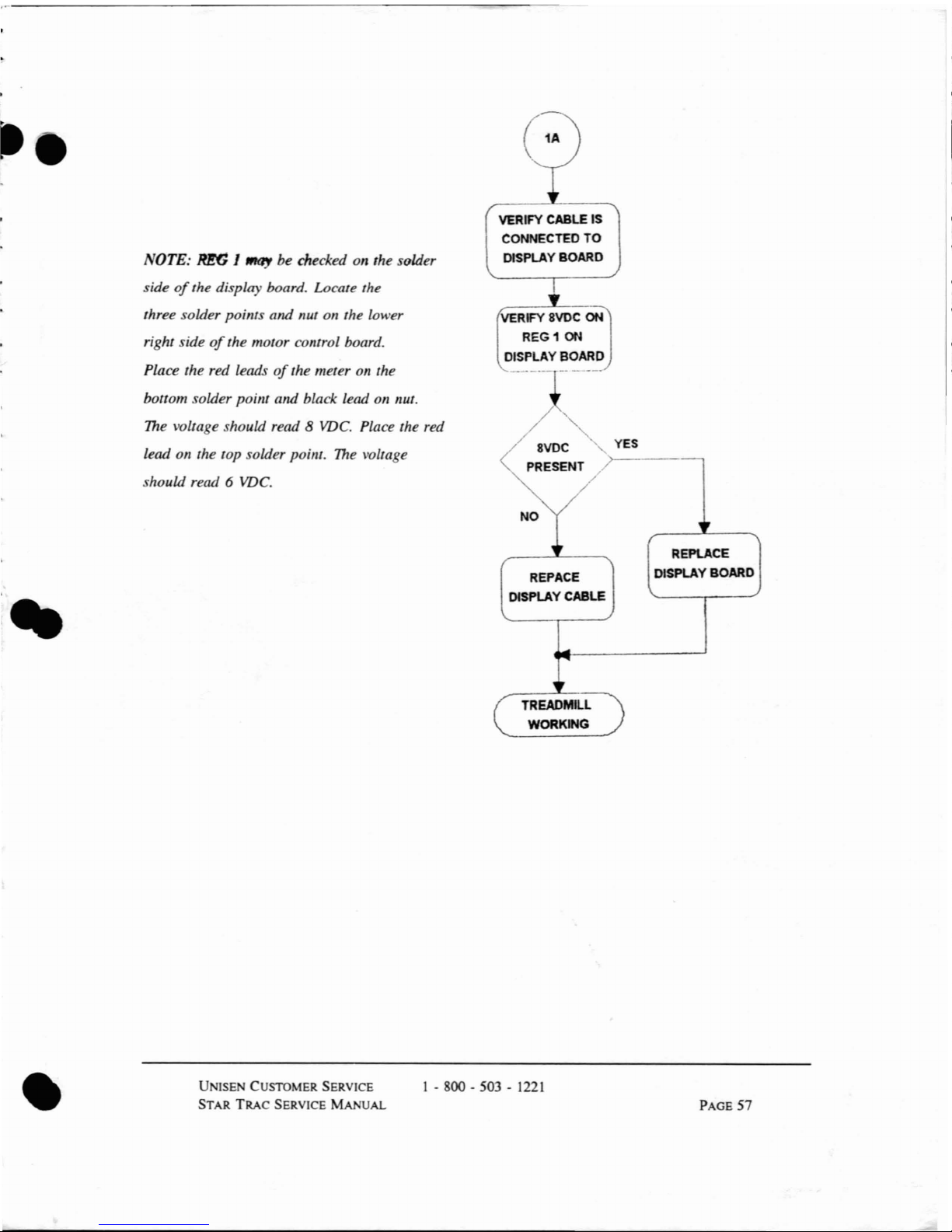

OTE:

RE6

J

"'l1Y

be checked on the solder

side

of

the display board. Locate the

three solder poillts and nut on the lower

right side

of

the motor control board.

Place the red leads

of

the meter on the

bottom solder point and black lead on nut.

The

voltage should read 8

VDC.

Place the red

lead on the top solder poillt.

The

voltage

should read

6

VDC.

VERIFY CABLE IS

CONNECTED

TO

DISPLAY BOARD

/ 8VDC

PRESENT

TREADMILL

WORKING

YES

)>---_.--,

REPlACE

DISPLAY BOARD

•

U ISE CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

57

Page 46

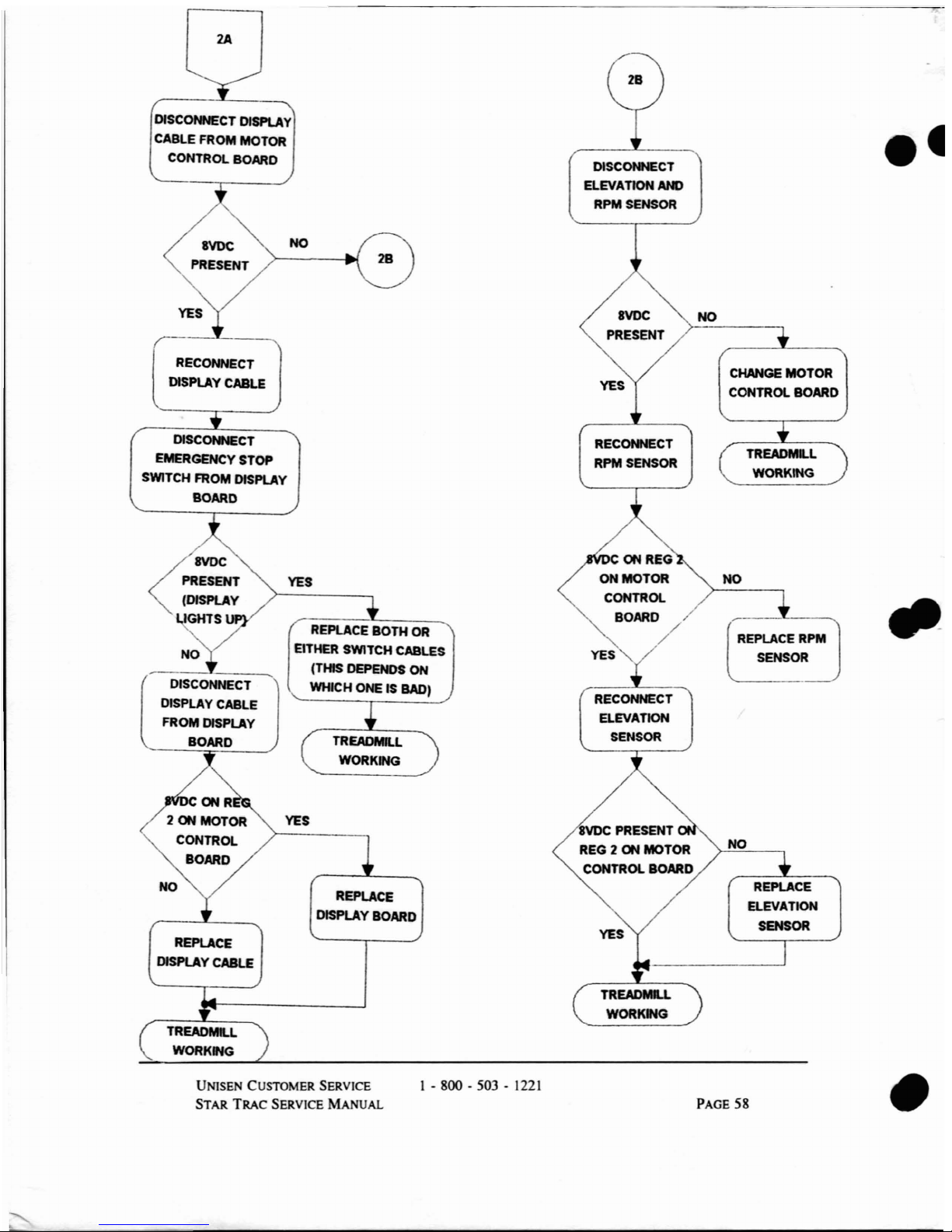

2A

DISCONNECT DISPLAY

CABLE FROM MOTOR

CONTROL BOARD

DISCONNECT

ELEVATION AND

RPM SENSOR

REPLACE

ELEVATION

SENSOR

TREADMl..L

WORKING

CHANGE

MOTOR

CONTROL BOARD

NO

YES

RECONNECT

RPM SENSOR

8VDC PRESENT

REG 2 ON MOTOR

CONTROL BOARD

REPlACE

DISPLAY BOARD

NO

YES

RECONNECT

DISPLAY CABLE

REPlACE

DISPLAY

CABLE

DISCONNECT

EMERGENCY STOP

SWITCH FROM

DISPlAY

BOARD

ON

REG

ON

MOTOR

NO

YES

CONTROl.

-

BOARD/

REPlACE

BOTH

OR

REPLACE RPM

NO

EITHER SWITCH CABLES

YES

SENSOR

(THIS DEPENDS

ON

(

DISCONNECT

WHICH ONE IS BAD)

RECONNECT

DISPLAY CABLE

ELEVATION

FROM

DISPLAY

SENSOR

BOARD

TREADMILL

WORKING

TREADMILL

WORKW<;

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

TREADMLL

WORKWG

PAGE

58

•

Page 47

..

CHAPTER FOUR:

INCREASING MECHANICAL UPTIME

This chapter describes simple preventive maintenance guidelines that increase

treadmill uptime and reduce mechanical downtime.

In

this chapter, you will troubleshooting of:

CONTENTS

RUNNING

BELT

DRIVE

MOTOR

HEAD-

AND TAILROLLER

TREADMilL

VmRA

TIO

TREADMILL

STATIC

AND SHOCKING

PAGE

NUMBERS

62

65

68

69

71

•

UNISE CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANuAL

1 - 800 - 503 -

1221

PAGE

59

Page 48

RUNNING BELT TROUBLESHOOTING

For

optimal performance during the lifetimeofthe treadmill, running belt adjustments

may become necessary. All adjustments are performed by turning the tailroller

adjustment with a one-quarter inch Allen wrench.

To

troubleshoot your running belt before any problems occur, you may verify the

running belt is properly adjusted and working smoothly by performing the following

four steps:

Step One

Step

Two

Place your hand under the middleofthe running belt. You

should not feel any glaze.

If

the undersideisglazed, replace the running belt.

Elevate the treadmill to the maximum grade. Then, without

electronically activating the running belt, stand at the top

of

the

running belt and gently push

off

from the front handrail. You

should be able to coast

to

the bottomofthe treadmill.

If

you are not able to coast to the boltom, check the wax

glaze, belt tension, and wax build

up

on the tailroller.

If

okay, replace the running belt.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

60

•

Page 49

Step Three

Activate the running belt electronically. Stand at the backofthe

treadmill and visually inspect the running belt. The running belt

should move smoothly, without drifting from side to side.

If

the running beltisnot moving smoothly or is drifting

from side to side, check the belt tracking as outlined in

Running Belt

Tracking

in this section.Ifokay, replace

the

running belt.

To

replace the running belt, please

refer

to Chapter Five: Replacement Procedures.

..

If

you observe the following symptoms, then the running belt must be replaced:

• Blown breaker after short use.

• Slipping continues after tighten tailroller tension.

• Edges

of

running belt fraying.

• Seam

of

running belt pulling apart.

• Middle

of

running belt folding.

NOTE:Ifyour running belt requires replacement, contact Unisen.

Be

sure to have

your model number and serial number handy.

For

instructions on replacing a running

belt, please refer to Chapter Five: Replacement Procedures.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE 61

Page 50

If

the running belt is moving from side to side, the tracked may require adjusting.

Please use the following steps.

NOTE: Turning the bolts as little as one-quanerofa bolt may have substantial effect.

The

best tracking position is

114"to112"

(6mm

to 12mm) from the headroller pulley.

If

your running belt is tracking to the right, then adjust

the running belt to track to the left. Loosen the left

tailroller bolt by turning counter-clockwise

or

tighten the

right tailroller bolt by turning clockwise.

Verify the running belt tracking. Continue adjusting, as

necessary, by turning the tailroller bolt one quarter at a time.

•

RUNNING

BELT

TRACKING

Adjust the tracking by turning the tailroller bolt one quarter tum

at a time.

•

If

your running belt is tracking to the left, then adjust the

running belt to track

to

the right. Tighten the left

tailroller bolt by turning clockwise

or

loosen the right

tailroller bolt by turning counter-clockwise.

Step

Two

Step One

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

62

•

Page 51

•

RUNNING BELT SLIPPAGE

AND

TENSION

The running belt tension

may

needtobe adjusted over time to keep the running belt

from slipping each jogging step or at high speed.

An easy method for testing belt

slippage, before it becomes a problem

is

as follows:

•

Step One

Step

Two

Step Three

Accelerate the running beltto2 mph.

Stand at the side

of

the treadmill. Grasping the handrails firmly,

place one foot on the treadmill with a very sharp impact. The

running belt should not stop.

If

the running belt does not stop, the running belt tension

is good.

If

the running belt stops and slippage occurs, check that

the location

of

the slippage.Isit caused by the running

belt slipping over the rollers or the drive belt slipping

over the pulleys? Loosen the motor mount bolts and

tighten motor adjustment bolt.

This causes the drive belt

to tighten.

If

the slippage is caused by the running belt slipping over

the rollers, tighten the running belt.

Tighten the left and right tailroller bolts by turning clockwise.

Always tighten or loosen the two tailroller bolts the same

number

of

quarter turns.

•

PAGE

63

Page 52

Step Four

Repeat Step Two and Three. Continue adjusting, as necessary.

However, do not overtighten the running belt.

•

NOTE:

The

overtighteningofthe running belt causes premature failureofrunning

belts

or

rollers.

The running belt has been tightened too much and may require loosening, if:

• You

can't

slide your hand under the belt and raise your hand

one quarter

of

an inch.

• The edge

of

the running belt curls down, causing a bubble in the

middle.

• Running belt creaks as it runs over the rollers.

NOTE:

If

the running belt creaks in spiteofbeing tightened, apply dry lubricant,

such as TFE Teflon, to the slik deck. While this will stop the creaking

for

a short

time, the running belt may still need replacement.

•

Page 53

•

•

DRIVE

MOTOR

TROUBLESHOOTING

The following adjustments relating to the drive motor

may

be required when the drive

motor is replaced

or

misadjustment is indicated. However,ifthe following symptoms

are observed, the drive motor may require

repl.:icing:

• Motor control board stops working.

• Motor grinds and knocks.

• Motor hesitates and jerks.

• Flywheel begins sparking.

NOTE:Ifthe display panel indicates an error code,

fix

the error code prior to

replacing the drive motor.

If

the flywheel begins sparking, check the motor brushes.

For additional infonnation, please refer to Chapter Three: Troubleshooting Error

Codes.

•

UNlSEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

65

Page 54

DRIVE BELT TENSION TROUBLESHOOTING

The drive belt tension may require tightening,ifa slipping problem occurs on the

drive pulley. You will need a medium Phillips screwdriver and two 1/2" wrenches.

•

Step One

Step

Two

Step Three

Step Four

Step Five

Remove the power cord from the power outlet.

Raise the motor shroud by using the Phillips screwdriver to

remove the screw

in

the motor shroud. Gently lift the motor

shroud up the display handrail. Using the bungie cord from the

ST

AR

TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

Loosen the four motor mounting nuts, using a 1/2" wrench.

Place the mounting nuts to the side.

Loosen the belt tension locknut, using a 1/2" wrench.

Adjust the belt tension by turning the belt tension screw.

If

too tight,

tum

the belt tension screw counter-

clockwise.

If

too loose,

tum

the belt tension screw clockwise.

•

NOTE:

The

easiest methodfor achieving optimum tension is

loosening the drive belt. Tum the belt tension screw clockwise

until the belt

is

taut, then

tum

the tension screw one additional

full rotation.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 -

800-503-1221

PAGE

66

•

L

---=----

_

Page 55

I~

(

•

•

Step Six

Step Seven

Step Eight

Step Nine

Simultaneously, tighten the belt tension locknut, while holding

the belt tension screw with a 1/2" wrench.

Simultaneously, tighten the right rear motor mounting nut while

moving the flywheel backwards. Then tighten the other three

motor mounting nuts.

Replace the motor shroud by removing the bungie cord and

lowering the motor shroud until it touches the frame. Press the

sides

of

the motor shroudtothe frame and attach the velcro

fasteners. Using the Phillips screwdriver, tighten the screw

in

the centerofthe motor shroud.

Plug the treadmill into the power outlet.

•

UNlSEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

67

Page 56

HEAD-

A D TAlLROLLER TROUBLESHOOTING

You may needtoreplace the head- or tailroller, if you observe the following

symptoms:

• Delron end caps are loosening.

• Bearings are grinding and knocking.

• Lagging (coating) is loose.

• Thumping sounds (indicates a possible wax buildup)

NOTE: For information on replacing the head- or tai/roller, please refer to Chapter

Five: Replacement Procedures.

•

•

UNISE CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

68

•

Page 57

•

TREADMILL VIBRATIONS TROUBLESHOOTING

A treadmill vibrates during useifthe floor is unevenorbolt is loose. You may

diagnose treadmill vibration problems by following these steps:

•

Step One

Step

Two

Step Three

Verify the treadmill is on

an

even, uncarpeted floor.

If

no, move the treadmill to an even floor.

If

flooriscarpeted, place treadmill on a rubber mat.

If

yes, proceed to next step.

Verify all the handrail bolts and the bottom weld under the

handrail bolt are secure.

If

no, tighten the bolts.

If

yes, proceed to next step.

Verify all the slik deck bolts are secure.

If

no, tighten the bolts.

Ijyes,

proceed to next step.

•

UN1SEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 -

gOO-503-1221

PAGE

69

Page 58

Step Four

Step Five

Step Six

Step Seven

Verify the flywheel is secure.

If

no, tighten the bolts.

If

yes, proceed to next step.

Verify the elevation screws are even.

If

no, make elevation screws even.

If

yes, proceed to next step.

Remove the drive belt and isolate the drive motor.

If

the drive motor vibrates, check the motor mount bolts.

If

loose, tighten the motor mount bolts.Ifnot, check the

motor brushes

for

wear or the motor mount

for

cracking.

If

the drive motor does not

Vibrate,

proceed to next step.

Check the drive motor shaft for damage.

If

yes, replace the drive motor shaft.

If

no, replace the drive motor.

•

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 -

800-503-1221

PAGE

70

•

Page 59

•

TREADMILL STATIC AND SHOCKING TROUBLESHOOTING

The treadmill may cause a slight shock from the display panel or handrails, due to a

faulty ground wire or worn running belt and slik deck. To diagnose the source

of

the

treadmill static and shocking follow these steps:

•

Step One

Step

Two

Check the line cord and plug prongs for signsofdamage. Verify no

prongs are broken, loose or missing.

NOTE: A damaged line cord may cause a shock between treadmills.

If

damaged, contact Unisen

for

a replacement.

Check the green groundwireonthe frame.

If

damaged, contact Unisen

for

a replacement.

Step Three

Check the display panel for metal ground plate.

If

damaged, contact Unisen

for

a replacement.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE

71

Page 60

~~----

-------

•

•

•

Page 61

•

•

CHAPTER FIVE:

REPLACEMENT PROCEDURES

This chapter outlines the procedures for replacing mechanical and electrical

components

of

the STAR TRAC treadmills. Before replacing any parts, verify the

problem by using the Diagnostic Test, detailed

in

Chapter Two: Diagnostic Test.

NOTE:Ifyou have additional assistance, please contact STAR TRAC Hotline at 800 /

503 - 1221.

In

this chapter, you will learn replacement procedures for:

CONTENT'S PAGE NUMBERS

CONTENT'S

PAGE NUMBERS

DISPLAYCABLE

74

MOTOR CONTROL

BoARD

95

EMERGENCY

STOP

SWITCH

78

FLYWHEEL

98

ELEVA

nON

MOTOR

81

MOTOR PULLEY

101

MOTOR

BELT

85

HANDRAILS

104

ELEVATION SENSOR

87

SUK

DECK

106

LIMIT

SWITCH

89

RUNNING

BELT

110

RPM

SENSOR

92

ELEV

ATION CANS

115

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 -

800-503-1221

PAGE

73

Page 62

DISPLAY CABLE REPLACEMENT

You will need the following tools for replacing the display cable:

• 9/16" Wrench

• 5/32" Hex Key

• Eight feet rollofstring and a small weight, such as keysora fishing

sinker

• 5/64" Allen Wrench

CAUTION

Always tum the power switchtothe OFF position. Unplug the treadmill power

cord from the power outlet.

•

•

Step One

Step

Two

Verify the STAR TRAC treadmill is unplugged from the power

outlet.

Raise the

m·otor

shroud by using the Phillips screwdriver to

remove the screw

in

the motor shroud. Gently lift the motor

shroud

up

the display handrail. Using the bungie cord from the

STAR TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE

74

•

Page 63

NOTE:

!fyour

treadmill does not have handrails, please skip to Step Five-A.

F

I

I

~

"

I

•

•

Step Three

Step Four

Remove the display panel faceplate.

• Using a 5/64" Allen wrench, remove the five small hex

screws from the back

of

the display console. Place the

five screws to the side.

• Gently dislodge the display panel from the console.

• Disconnect the Display Cable and Stop Switch cable,

if

applicable, from the display panel.

• Place the display panel

in

a safe place.

If

your

treadmill has handrails, remove the display handrail

assembly.

• Using a 9/16" wrench, loosen the U-bolt nuts and

washers from both sides

of

the treadmill. Set the nuts

and washers

in

a safe place.

• Using a 5/32"

hex

key, remove the two buttonhead

screws below the Display handrail. Set the buttonhead

_

screwsina safe place.

• Disconnect the Display cable from the Motor Control

Board and carefully lift the display handrail away from

the elevation screws. Set the Display handrail in a safe

place.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1 - 800 - 503 -

1221

PAGE

75

Page 64

Step Five

Remove the current display cable by removing the mylar insert

•

that holds the display cable against the handrail.

•

Tie a string to the current display cable at the display

panel faceplate assembly.

•

Remove the display cable from the bottomofthe

handrail, by pulling the string. The string should be

threaded through both ends

of

the handrail.

•

Tie a string to the new display cable at the display panel

faceplate assembly.

•

Carefully pull the string with the new display cable

attached, through the handrail.

•

Replace the mylar insert that holds the display cable

against the handrail.

Step Five-A

If

your treadmiU does not have handrails, disconnect your

•

display cable from the motor control board.

• Tie a string to the current display cable at the display

panel faceplate assembly.

• Remove the display cable from the bottom

of

the

handrail, by pulling the string. The string should be

threaded through both ends

of

the handrail.

• Tie a string to the new display cable at the display panel

faceplate assembly.

• Carefully pull the string with the new display cable

attached, through the handrail.

• Connect the display cable to the motor control board.

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

76

•

Page 65

...

•

NOTE:Ifyour treadmill does not have side handrails, please skip to Step Seven.

Step Six

Step Seven

Replace the display handrail assembly.

• Using a 5/32"

hex

key, replace and tighten the two

buttonhead screws below the display handrail.

• Using a 9/16" wrench, tighten the U-bolt nuts and

washers on both sides

of

the treadmill.

• Reconnect the display cable to the motor control board

and carefully replace the display handrails over the

elevation screws.

Replace the display control board.

•

•

•

•

Connect the display cable and the emergency stop switch

to the back

of

the display panel.

Using a 5/64" Allen wrench, replace the five hex screws

from the backofthe display console. Verify the bottom

right hand screw is the ground (largest screw) and that it

isincontact with the metal plate attached to the display

panel.

Gently replace the display panel from the console.

Step Eight

Replace the motor shroud

by

removing the bungie cord and

lowering the motor shroud until it touches the frame. Press the

sides

of

the motor shroudtothe frame and attach the velcro

fasteners. Using the Phillips screwdriver, tighten the screw

in

the centerofthe motor shroud.

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

77

Page 66

Step Nine Plug the STAR TRAC treadmill into the power outlet.

Tum

the

power switch to ON.

•

•

UNISE CUSTOMER SERVICE

STAR

TRAC

SERVICE MANUAL

1-

gOO-503-1221

PAGE 78

•

Page 67

a

l

I

•

••

EMERGENCY STOP SWITCH REPLACEMENT

NOTE: Treadmills without side handrailsdonot have emergency stop switches.

You will need the following tools for replacing the emergency stop switch:

• 9/64" Wrench

• 5/32" Hex Key

• Roll

of

String

CAUTIO

Always tum the power switch to the OFF position. Unplug the treadmill power

cord from the power outlet.

Step One

Step

Two

Verify the STAR TRAC treadmillisunplugged from the power

outlet.

Remove the left side handrail.

• Using a 5/32" hex key, remove the two buttonhead

socket screws below the display handrail.

• Slowly remove the side handrail from the display

handrail.

•

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

79

Page 68

Step Three

Step Four

Step Five

Step Six

Step Seven

Step Eight

Remove the two screws holding the emergency stop switch and

place the two screws to the side.

Disconnect the emergency stop switch from the side handrail.

Insert the new emergency stop switch.

• Replace the two screws that hold the emergency stop

switch

in

place.

Reconnect the emergency stop switch by replacing the two

buttonhead screws.

Connect the remote display cable to the extension cable

in

the

handrail.

Replace the side handrail.

• Slowly reinsert the side handrail to the display handrail.

• Using a 5/32" hex key, replace the two buttonhead

socket screws below the display handrail.

• Verify the display cable is not pinched.

NOTE:

The

treadmill displays an

FS

2 error code when the

power

is

tumed on,ifthe display cable is pinched.

•

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANUAL

I - 800 - 503 -

1221

PAGE 80

•

Page 69

•

ELEVATION MOTOR REPLACEMENT

NOTE:

Treadmills with no elevation do not have an elevation motor.

You will need the following tools to replace the elevation motor:

•

•

Two 17mm Wrench

1/8" and 5/65" Allen Wrenchs

•

•

Phillips Screwdriver

1/4" Nutdriver

•

• PairofPliers

CAUTION

Always tum the power switchtothe OFF position. Unplug the treadmill power

cord from the power outlet.

Step One

Step Two

Verify the STAR TRAC treadmill is unplugged from the power

outlet.

Raise the motor shroud by using the Phillips screwdriver to

remove the screw

in

the motor shroud. Gently lift the motor

shroud

up

the display handrail. Using the bungie cord from the

ST

AR

TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

•

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANuAL

1 - 800 - 503 -

1221

PAGE

81

Page 70

Step Three

Step Four

Step Five

Step Six

Step Seven

Step Eight

Disconnect the elevation sensor (CO-5) from the motor control

board.

Disconnect the elevation motor connection

(CO-3) from the

motor control board.

Lay the treadmill

on

its side.

Remove the four screws located on the switch panel at the base

of

the treadmill. Place the screwsina safe place.

• Gently remove the switch panel as far as possible without

stressing the wires.

Remove the tension from the elevation belt by loosening the

idler pulley.

• Simultaneously loosen the top nut

of

the idler pulley with

a

17

mm

wrench, while holding the bottom nutinplace

with a second

17

mm

wrench.

Remove the elevation motor pulley, by using a 5/65" Allen

wrench

to

loosen the two setscrews. Set the setscrews in a safe

place.

•

•

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

82

•

Page 71

•

•

Step Nine

Step

Ten

Step Eleven

Step Twelve

Remove the four mounting screws and washers from the bottom

of

the elevation platform, using a 1/8" Allen wrench. Set the

mounting screws and washers in a safe place.

• Remove the elevation motor.

Install the new elevation motor with the square end down.

• Align the elevation motor so the sensor mounting studs

are close to the drive pulley shaft

of

the drive motor.

• Replace the four mounting screws and washers on the

bottom

of

the elevation platform. You will need to use a

1/8" Allen wrench.

Replace the elevation motor pulley. Tighten the two setscrews,

using a 5/65" Allen wrench.

• Check that both

of

the elevation motor pulleys are

straight.

Replace the tension on the elevation belt by tightening the idler

pulley.

• At the same time, tighten the top nut

of

the idler pulley

using a

17

mm

wrench and hold the bottom nut in place,

using a second

17

mm

wrench.

Replace the switch panel at the base

of

the treadmill. Tighten

the four screws.

•

Step Thineen

UNISEN

CUSTOMER

SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

83

Page 72

Step Founeen

Step Fifteen

Step Sixteen

Step Seventeen

Step Eighteen

Step Nineteen

Stand the treadmillina upright position.

Connect the elevation motor sensor (CO-3) on the Motor

Control Board.

Connect the elevation sensor (CO-5) on the Motor Control

Board.

Replace the motor shroud by removing the bungie cord and

lowering the motor shroud until it touches the frame. Press the

sides

of

the motor shroud to the frame and attach the velcro

fasteners. Using the Phillips screwdriver, tighten the screw

in

the centerofthe motor shroud.

Plug the treadmill into the power outlet.

Tum the power switch to the ON position.

•

•

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1-

800-503-1221

PAGE

84

•

Page 73

•

MOTOR

BELT

REPLACEMENT

CA

TION

Always tum the power switchtothe OFF position. Unplug the treadmill power

cord from the power outlet.

Step One

Verify the STAR TRAC treadmillisunplugged from the power

outlet.

•

Step

Two

Raise the motor shroud by using the Phillips screwdriver to

remove the screw

in

the motor shroud. Gently lift the motor

shroud up the display handrail. Using the bungie cord from the

ST

AR

TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

Step Three

Remove the motor belt from the motor pulley.

3

UNlSEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

PAGE 85

while firmly pushing down

and to the left on the motor

belt (where it approaches the

motor pulley). Continue

until the drive belt slides.

• Simultaneously, rotate the

flywheel forward, then

backward one revolution,

I "

I,

, ,

, ,

I -

800-503-1221

6

t.IO

P

eE._

S

SETSCAE

....

S

1 '.'OiCA F

CV

4

'.~OTC

S F'i

•

Page 74

Step Four

Step Five

Step Six

Step Seven

Step Eight

Step Nine

•

Position the new motor beltonthe headroller pulley. Try to

position the motor belt so that it touches the fust two

or

three

grooves.

Place the forward end

of

the motor belt to the immediate left

of

the motor pulley.

Replace the motor belt

on

the motor pulley.

Simultaneously, rotate the flywheel forward, then backward one

revolution, while firmly pushing

down andtothe right on the

motor belt. Continue until the drive belt slides on.

Replace the motor shroud by removing the bungie cord and

lowering the motor shroud until it touches the frame. Press the

sides

of

the motor shroudtothe frame and attach the velcro

fasteners. Using the Phillips screwdriver, tighten the screw

in

the centerofthe motor shroud.

Plug the treadmill into the power outlet.

Tum the power switch

to

the ON position.

•

•

.,

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANuAL

1 - 800 - 503 -

1221

PAGE

86

•

Page 75

#'

•

ELEVATION

SENSOR

REPLACEMENT

NOTE: Treadmills without elevationdonot have elevation sensors.

You will need the following tools to replace the elevation sensor:

• Phillips screwdriver

• 1/4" nut driver

CAUTION

•

Always tum the power switch to the OFF position. Unplug the treadmill power

cord from the power outlet.

Step One

Step

Two

Step Three

Verify the STAR TRAC treadmillisunplugged from the power

outlet.

Raise the motor shroud by using the Phillips screwdriver to

remove the screwinthe motor shroud. Gently lift the motor

shroud

up

the display handrail. Using the bungie cord from the

ST

AR

TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

Remove elevation sensor cable, located at CO-5, from the motor

control board.

•

UNISEN CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

87

Page 76

Step Four

Step Five

Step Six

Step Seven

Step Eight

Step Nine

Step

Ten

Verify half-moon elevation disc is positioned away from the

optical sensor.

• Using a 1/4" nut driver, remove the two nuts and

washers from the elevation sensor disc.

• Remove the elevation sensor board. Place to one side.

Place new elevation sensor between the elevation disc.

• Replace the two nuts and washers.

Position the elevation sensor between the walls

of

the optical

sensor

on

the elevation sensor board. The elevation disc should

not make contact with the optical sensor walls.

Reconnect the elevation sensor cable to position CO-5 on the

motor control board.

Replace the motor shroud by removing the bungie cord and

lowering the motor shroud until it touches the frame. Press the

sides

of

the motor shroudtothe frame and attach the velcro

fasteners. Using the Phillips screwdriver, tighten the screw

in

the centerofthe motor shroud.

Plug the treadmill into the power outlet.

Tum the power switch

to

the ON position.

•

•

UNISEN CUSTOMER SERVICE

STAR TRAC SERVICE

MANuAL

1 - 800 - 503 -

1221

PAGE

88

•

Page 77

•

LIMIT SWITCH REPLACEMENT

You will need the following toolstoreplace the limit switch:

• one Phillips screwdriver

• one slot head screwdriver

CAUTION

Always tum the power switch to the

OFF

position. Unplug the treadmill power

cord from the power outlet.

•

Step One

Step

Two

Verify the STAR TRAC treadmill is unplugged from the power

outlet.

Raise the motor shroud by using the Phillips screwdriver to

remove the screw

in

the motor shroud. Gently lift the motor

shroud up the display handrail. Using the bungie cord from the

ST

AR

TRAC Toolkit, hold the motor shroud at the topofthe

display handrail.

•

UNISEN

CUSTOMER SERVICE

STAR

TRAC

SERVICE

MANUAL

1 - 800 - 503 -

1221

PAGE

89

....

.....

...............

c4

Page 78

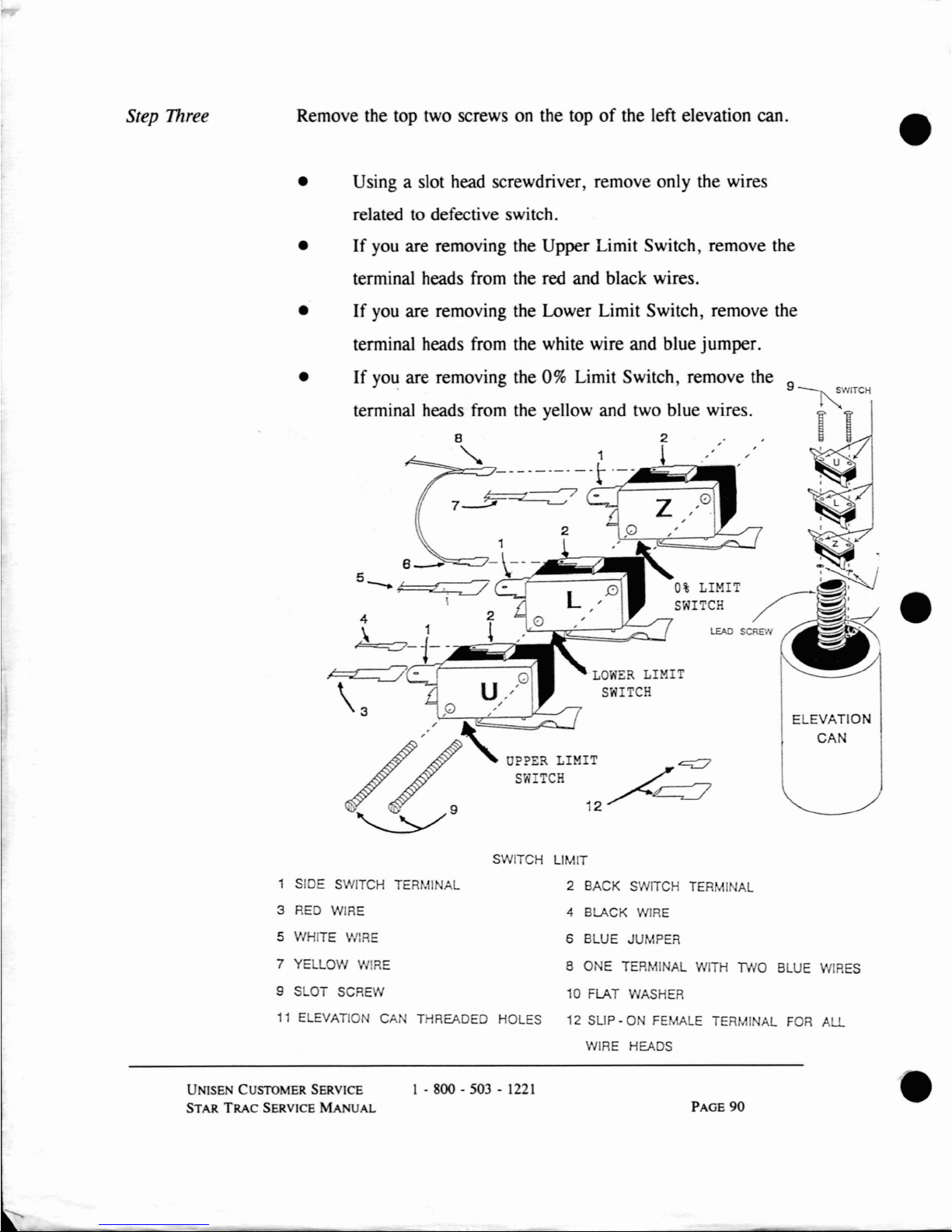

Step Three

Remove the top two screws on the topofthe left elevation can.

•

•

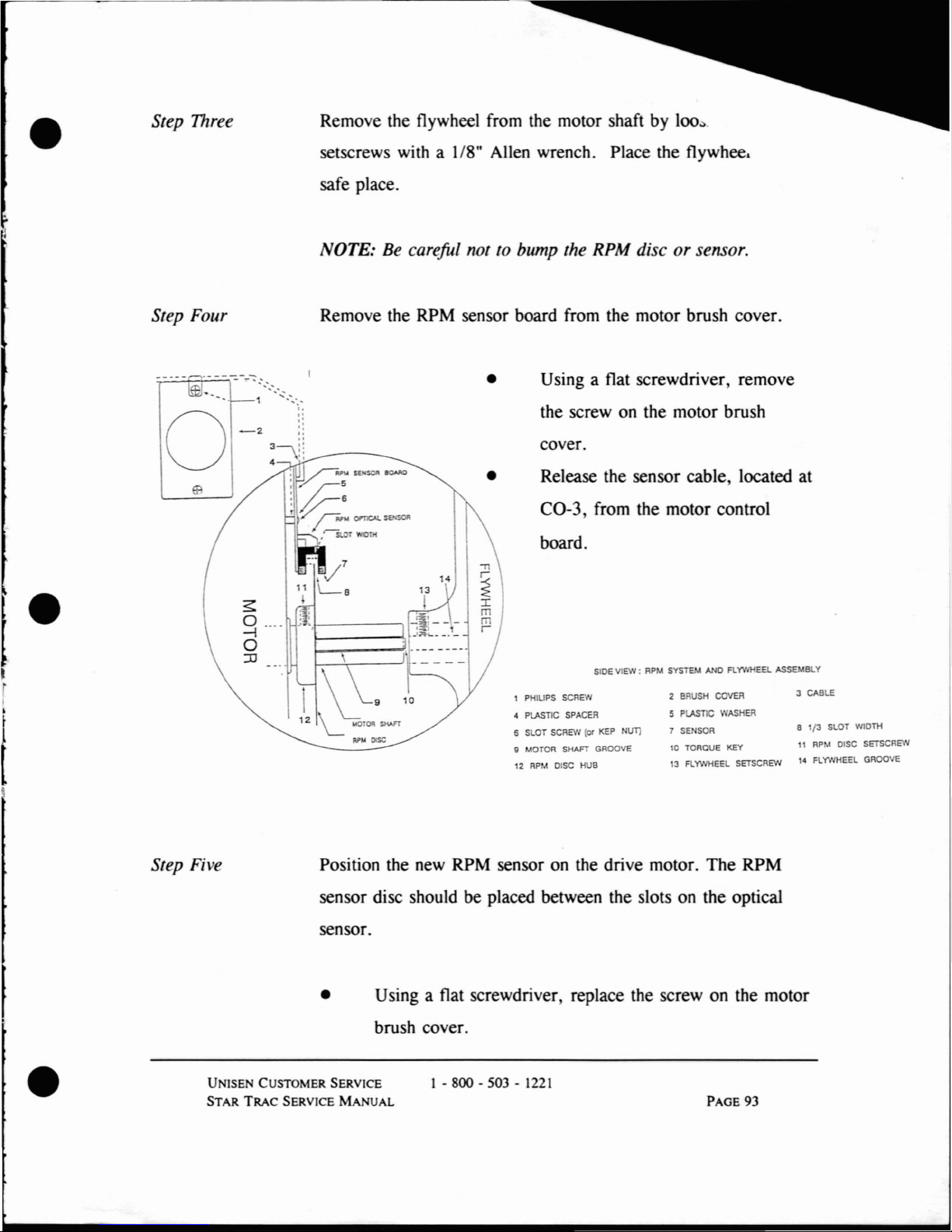

• Using a slot head screwdriver, remove only the wires