START International ZCM1000, M1000 Series, ZSM2000 Series Manual

ZCM1000/M1000 Series

CONTENTS

Read this user’s manual before use to ensure proper operation. Keep the manual on hand

for reference in case there is a problem.

Warranty Information

Notes

Features

Description of Parts and Functions

Operation

Specications

Troubleshooting

Preventive Maintenance

Exploded Views/Parts Breakdown

Parts List

Page 2

Page 3

Page 3

Page 4

Page 5-6

Page 7

Page 7

Page 8

Page 9-13

Page 14-22

WARRANTY POLICY FOR LD SERIES LABEL DISPENSERS

START International warrants all parts on ZCM series tape dispensers against defects in design,

materials and work manship for a period of 360 days. Parts excluded from this are: cutting blades,

silicone rollers and cutter liners; these parts are considered “wear parts”. Labor to replace defective

parts will be performed at no charge for the rst 180 days after date of purchase. Warranty does not

cover transportation costs.

START International’s sole obligation under this warranty is limited to repair, replacement or credit

of the purchase price, at our option, which do not properly perform the function for which they were

designed.

Warranty repair is contingent upon START’s examination and determination that alleged defects have

not been caused by misuse, abuse, improper installation or application, repair, alteration, accident or

neglect in use, storage, transportation or handling.

The above warranty and remedy constitutes START International’s sole liability hereunder and are in

lieu and exclusive of all other warranties and remedies expressed, implied, or statutory , including, but

not limited to, those of merchantability and tness for a particular purpose.

REPAIR POLICY

Contact START INTERNATIONAL to determine nature of problem.

Furnish START with the following information:

1. Who the unit was purchased from.

2. Model number and serial number.

3. Date purchased (copy of invoice or packing slip required).

START will issue an RMA (Return Material Authorization) for the repair. Return machine to START

by freight, insured and prepaid. START will notify the customer if there is a repair charge.A $25.00

evaluation charge will apply to all non-warranty repairs, which will be applied to repair change.

For the full Warranty & Repair policy please visit www.STARTinternational.com

2

FEATURES

• Will dispense butt-cut and die-cut material.

• Adjustable photosensor for pinpoint accuracy.

• Handled lock rod makes scrap removal easy.

• No tools required for adjustment.

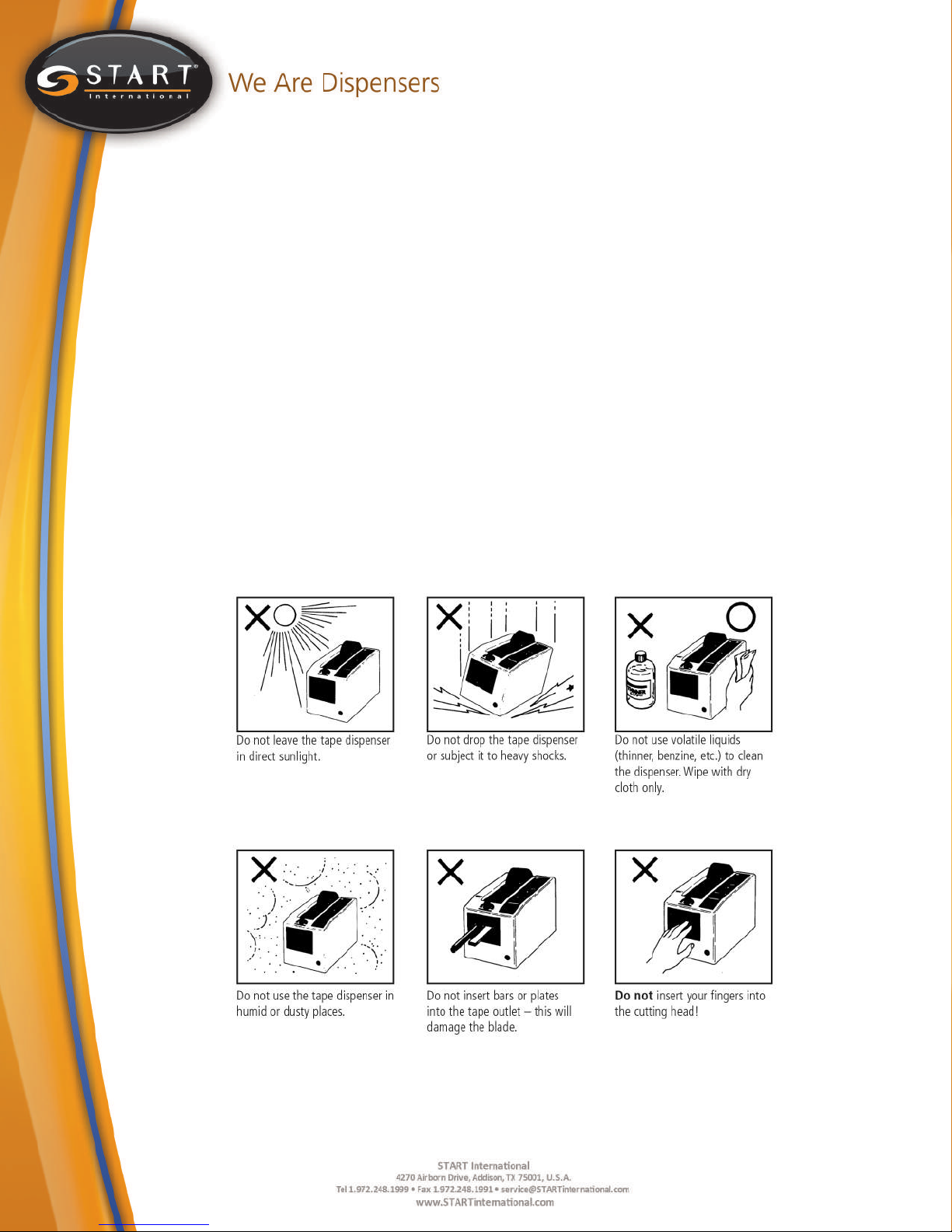

NOTES

• Keep strip plate free of adhesive build-up.

• Clean photosensor with compressed air or dry cloth.

• Do not drop the dispenser or subject it to heavy shock.

• Turn off machine when not in use.

3

DESCRIPTION OF PARTS AND FUNCTIONS

4

OPERATION

Using Automatic Feed:

1. Plug in power cord and turn unit on.

2. Set tape on the center of reel and stick the end of the tape onto the metal feed roller.

Press ADVANCE key until tape feeds through cutting unit. If the tape will not feed through

the cutter, fold corners of the tape to form a triangle shape and re-feed (Fig. A).

3. Press CUT key to cut tape.

4. Set the tape length.

Press MM key to set length of 0-9mm.

Press CM key to set length of 20-990 mm.

5. Set PRESSURE knob

• If tape curls or slips, increase pressure.

• If tape creases, decrease pressure.

6. Turn sensor switch ON. Tape will be fed to set length and cut. When the piece of tape is

removed from machine, another piece will be fed and cut. (Turn sensor switch OFF when

not in use.)

Using ADVANCE / CUT key

With AUTO SENSOR switch OFF, press ADVANCE / CUT key. Tape will be fed to set length

and cut.

Using ADV ANCE key

Press ADVANCE key until desired tape length has been fed. (This key overrides the preset

length.) Press cut to cut tape.

Changing tape

Press the REVERSE key. The feed roller will rewind the tape away from cutter area. Remove

the tape manually.

In case of tape jam

Press REVERSE key to remove tape from cutter area. Rewind and replace tape on roller.

Also, remove cutter unit to verify no tape is stuck on roller or cutter.

5

OPERATION (CONT’D)

To Replace Cutter Unit

Turn off auto sensor and power before removing cutter

unit. Pull sensor plug out, then pull cutter unit forward while

pressing the knob on the top of the unit

(Fig. 1).

T o replace blades, remove the two screws inside head. Blade

can then be lifted out and replaced. Before remounting the

cutter unit to the frame, the lower blade must be bottomed

out. If it is not completely down, use a screwdriver to lower it

(Fig. 2).

Remount the cutter unit by aligning the bottom of the unit

then pushing in the top.

Replacing the Separating Roller

Turn off the sensor and power before removing the separating roller. Remove the cutter unit, then remove the two

screws (Fig. 3).

To remove roller holder, grip rubber ring in the center of separating roller and pull. Then remove the screws on the left

and right of the roller holder and pull off shaft and gear

(Fig. 4).

• Set the tape properly as described in these instructions. (If the end of the tape is folded when

the tape is set, the tape may jam at the tape outlet.)

• This machine will cut virtually any type of pressure sensitive tape (aluminum, lament, etc.). If

tape is thicker than .05” or thinner than .03”, test for compatibility.

• Because of tape differences (elasticity, stickiness, etc.), some tapes may not cut at the set

length. If this occurs, adjust the set length accordingly.

• If tape sticks to the blade, remove the cutter unit, clean with alcohol and apply silicone oil to

the blade.

• To reduce jamming, remove tape from machine when not in use.

6

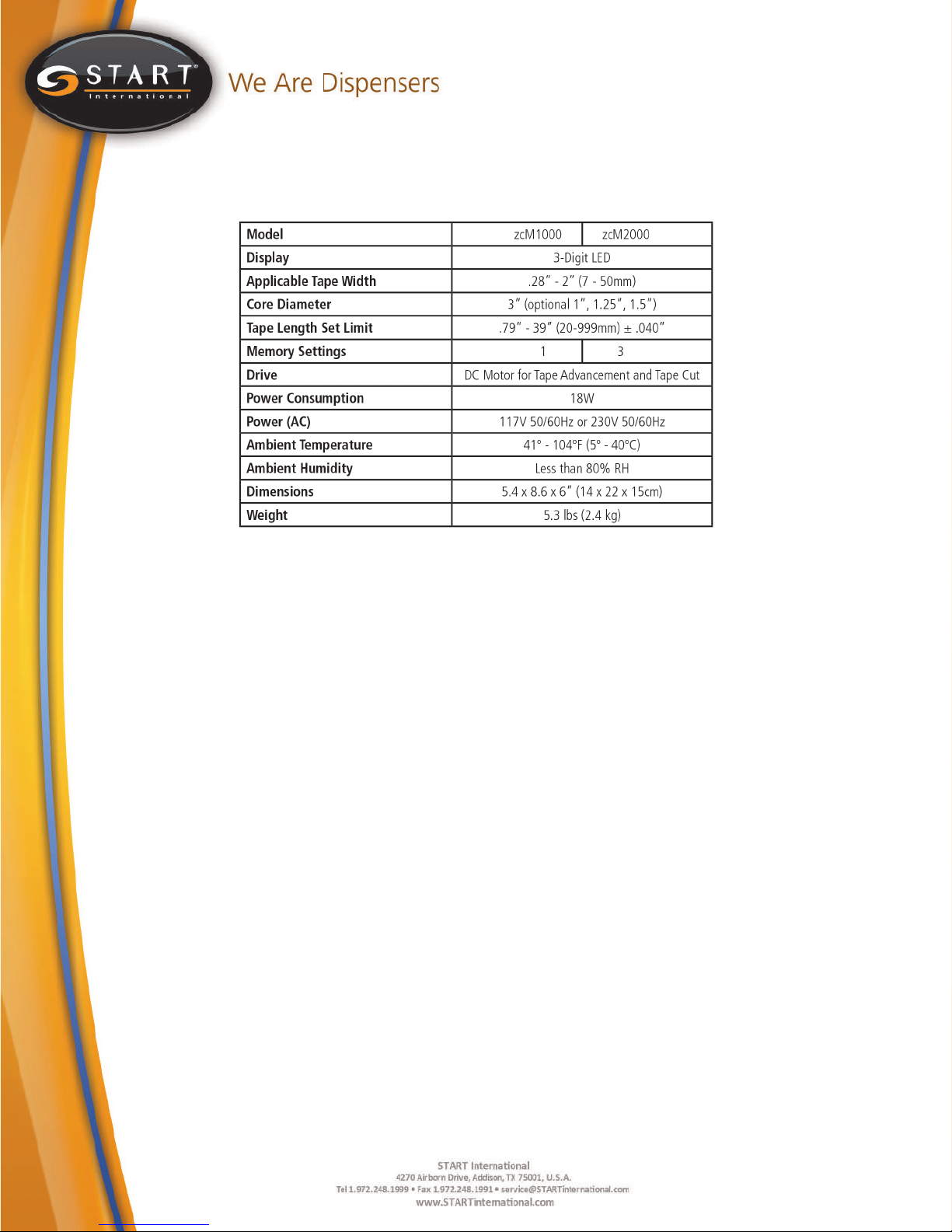

SPECIFICATIONS

TROUBLE SHOOTING

When problems occur, carry out the following procedures. If the tape dispenser does not operate

normally after following the troubleshooting procedures, contact your supplier.

1. If the motor does not drive:

• Check that the power cord is plugged in.

• Check that the power switch is turned on.

2. If the tape does not cut:

• Make sure the cutter unit is set properly and clean.

3. If the LED does not light:

• Check that the power cord is plugged in.

• Check that the power switch is turned on.

4. If the tape does not advance:

• Check if the tape is jammed at the roller or in the cutter unit.

• Check that the tape is set properly.

5. If the auto sensor does not work:

• Check that the sensor plug is plugged in.

• Check that the sensor switch of cutter unit is on.

• Check that the sensor part of the cutter unit is not stained.

6. If the tape advancing does not stop:

• Check that the tape is centered. If not, set the tape at the center of the feed roller so that

the sensor will see the tape.

7

Loading...

Loading...