StartingLine SB-2-610-G Instruction Manual

Service Bulletin

SB-2-610-G

Replaces SB-2-610-F

ATTENTION!

READ BEFORE ATTACHING THE AIR HOSE

HVLP AIR SUPPLY REQUIREMENTS

FULL SIZE GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 13 CFM.

TOUCHUP GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 8 CFM.

NOTE: USE 5/16" OR LARGER I.D. AIR HOSES

¡ATENCIÓN!

LEA ANTES DE FIJAR LA MANGUERA DE AIRE

REQUISITOS DE SUMINISTRO DE AIRE DE ALTO VOLUMEN BAJA PRESIÓN (HVLP)

PISTOLA HVLP: Una presión de entrada de 30 PSI (libras

por pulgada cuadrada) proporciona 10 PSI en la boquilla.

Consume 13 CFM (pies cúbicos por minuto).

NOTA: UTILICE MANGUERAS CON DIÁMETRO INTERNO DE 7.94 MM (5/16 DE PULG.) O MÁS GRANDE

PISTOLA RE-TOQUE: Una presión de entrada de 30 PSI (libras

por pulgada cuadrada) proporciona 10 PSI en la boquilla.

Consume 8 CFM (pies cúbicos por minuto).

ATTENTION !

LIRE AVANT DE FIXER LE TUYAU D’ARRIVÉE D’AIR

HVLP AIR SUPPLY REQUIREMENTS

EXIGENCES HVLP CONCERNANT L’ALIMENTATION EN AIR

PISTOLET Á PEINTURE:

2,07 BAR (30 PSI) donne une pression de 0,69 BAR (10 PSI)

à l’anneau déflecteur. Utilise 0,37 m

Une pression à l'admission de

3

(13 pi3) à la minute.

PISTOLET DE RETOUCHE:

2,07 BAR (30 PSI) donne une pression de 0,69 BAR (10 PSI)

à l’anneau déflecteur. Utilise 0,23 m

Une pression à l'admission de

3

(8 pi3) à la minute.

REMARQUE : UTILISER UN TUYAU D’UN DIAMÈTRE INTÉRIEUR DE 7,94 MM (5/16 PO) AU MINIMUM.

Page 2 SB-2-610-G

READ BEFORE ATTACHING THE AIR HOSE

FULL SIZE GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 13 CFM.

TOUCHUP GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 8 CFM.

ATTENTION!

HVLP AIR SUPPLY REQUIREMENTS

NOTE: USE 5/16" OR LARGER I.D. AIR HOSES

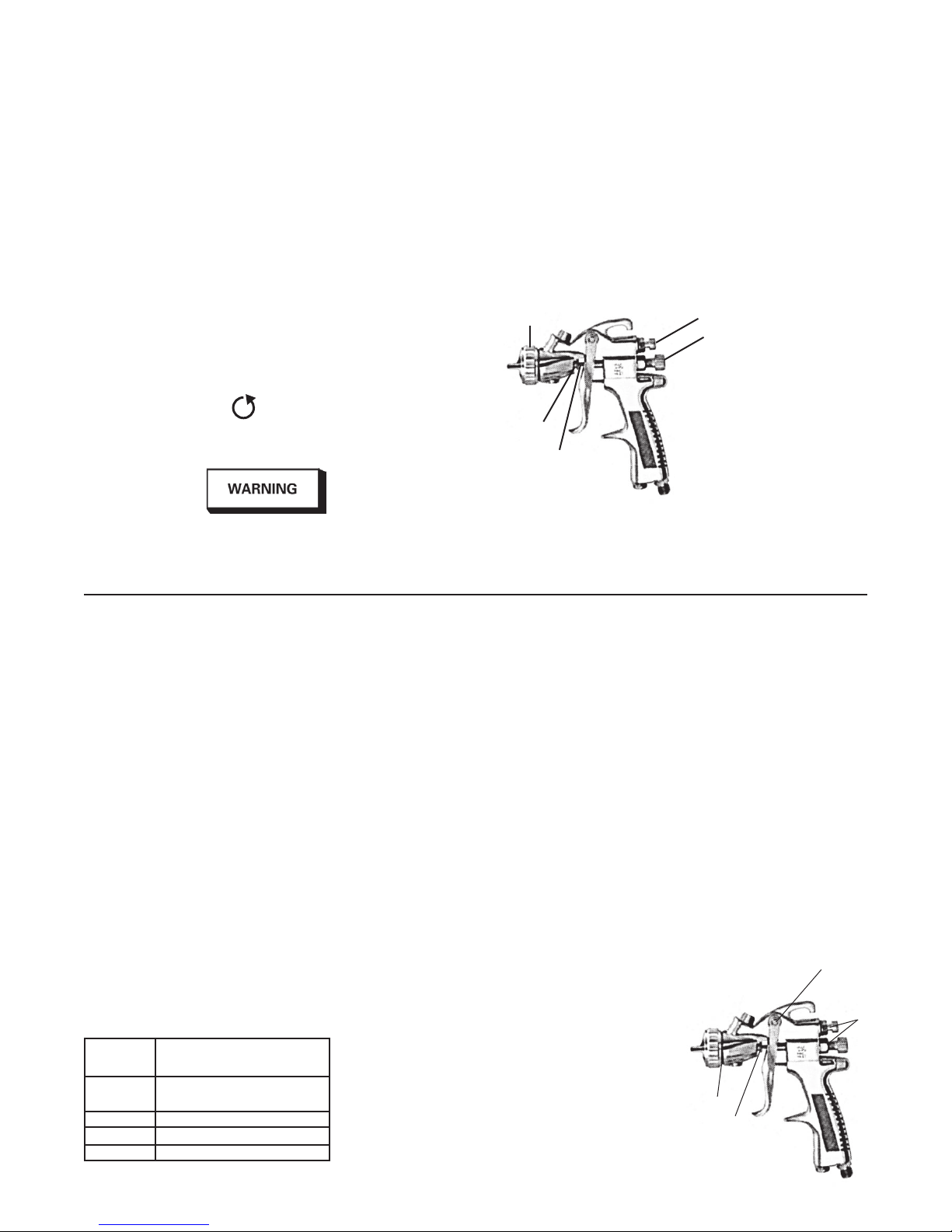

SET-UP AND ADJUSTMENT INSTRUCTIONS

1. Attach cup to gun and

flush solvent through gun

to remove oils.

2. Tighten packing nut—see

instructions.

3. Fully open fan and fluid

needle controls (turn

counter-clockwise).

A failure resulting in injury or damage may be caused by pressure

beyond top of scale, excessive vibration or pressure pulsation, excessive instrument temperature, corrosion of the pressure containing

parts or other misuse of the air adjusting valve with gauge.

Spray a test area. Turn the fluid needle

adjusting knob counterclockwise until a

full coat is obtained.

If the finish is too sandy and dry, the

material flow may be too low for the

atomization air pressure being used.

Turn the fluid needle adjusting knob

counterclockwise to increase fluid flow.

If the finish sags, there is too much material flowing for the atomization air pressure

being used. Turn the fluid needle adjusting

knob clockwise to decrease fluid flow.

Pattern width can be altered by turning spreader adjustment valve, either

clockwise to decrease the width or counterclockwise to increase the width.

Adjust inlet air pressure to provide a uniform dispersion of atomized paint throughout the pattern. Keep air pressure as low

as possible to minimize bounce-back and

overspray. Excessive pressure will result in

split spray patterns. Inadequate pressures

will cause heavy centered patterns and

poor atomization.

Fluid Tip

Size (mm) Applications

1.0 General purpose, light to medium

viscosity material.

1.3 Top coats.

1.5 Top coats and primer sealers.

1.8 Primers.

4. If desired, attach air adjusting valve with gauge and/

or quick disconnect to air

inlet, then attach hose.

5. Spray test and adjust air

pressure, fan size, and

fluid flow as required.

Recommended spray

distance is 6-8 inches.

CLEANING

For routine cleaning, it is not necessary

to remove cup from gun. Remove lid and

properly dispose of any excess paint. Pour

in a small amount of clean solvent. The

amount will vary with different coatings and

solvents. Reinstall lid. Shake cup to wash

down the inside surfaces. Pull trigger to

allow some solvent to be flushed through

gun. Remove lid and pour out dirty solvent.

Add a small amount of clean solvent and

repeat procedure. Wipe exterior of lid with

a clean cloth and clean solvent.

If a paint filter was used in the bottom of

the cup outlet, it should be removed and

cleaned at this time.

To clean air cap and fluid tip, brush exterior with a stiff bristle brush. If necessary

to clean cap holes, use a broom straw

or toothpick if possible. If a wire or hard

instrument is used, extreme care must

be used to prevent scratching or burring

of the holes which will cause a distorted

spray pattern.

To clean fluid passages, remove excess

material at source, then flush with a suitable solvent. Wipe gun exterior with a

solvent dampened cloth. Never completely

immerse in solvent as this is detrimental

to the lubricants and packings.

PREVENTIVE MAINTENANCE

PACKING ADJUSTMENT INSTRUCTIONS

AIR CAP

PACKING

NUT

FLUID NEEDLE

The packing nut is intentionally left loose so the PTFE packing

does not take a "set" before the spray gun is used. This allows

full utilization of the packing.

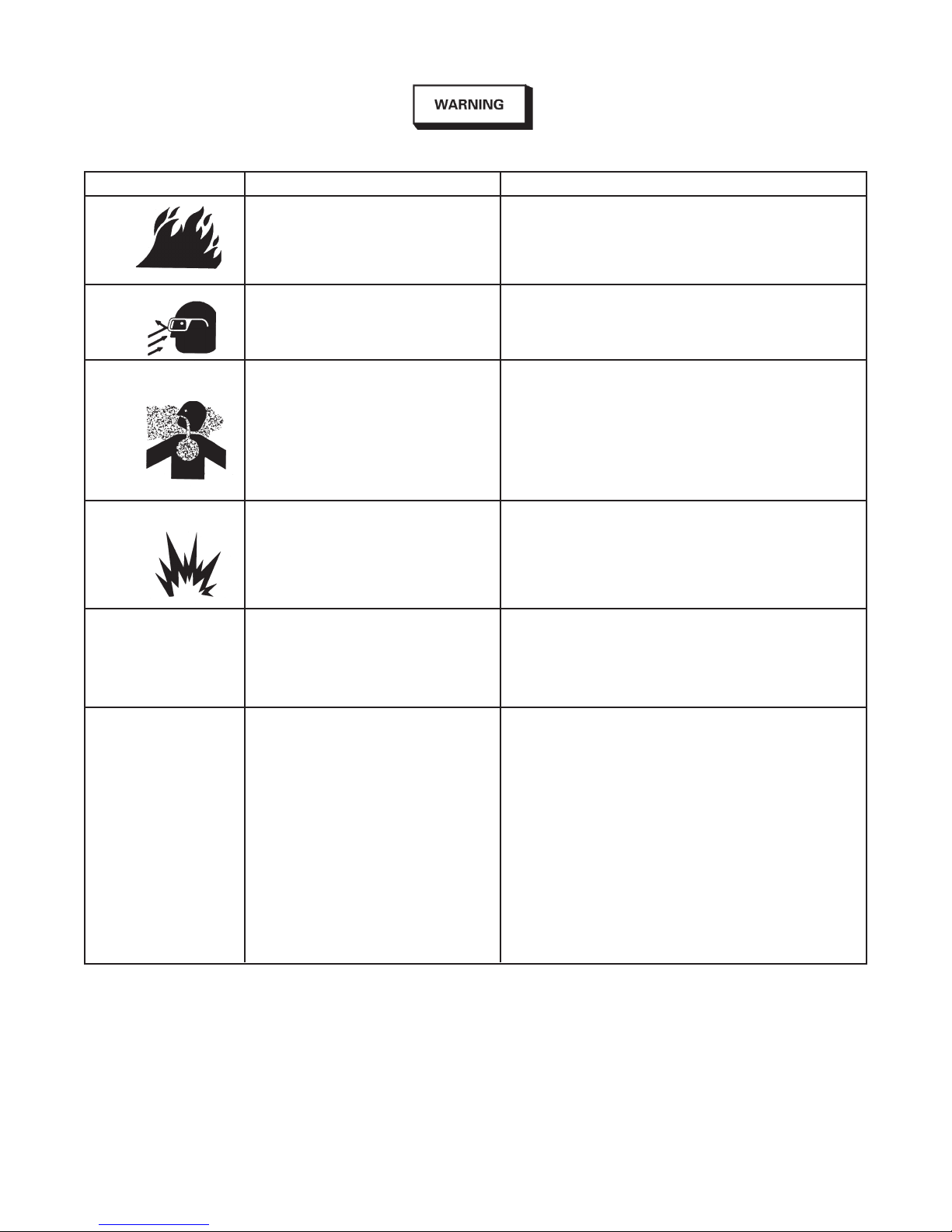

Spray Gun Lubrication

Apply a drop of SSL-10 spray gun lube at

trigger bearing stud and the stem of the air

valve. The shank of the fluid needle where

it enters the packing nut should also be

oiled. The fluid needle packing should be

kept soft and pliable by periodic lubrication.

Make sure the baffle and retaining ring

threads are clean and free of foreign matter.

Before assembling retaining ring to baffle,

clean the threads thoroughly, then add two

drops of SSL-10 spray gun lube to threads.

The fluid needle spring and air valve spring

should be coated with a very light grease,

making sure that any excess grease will

not clog the air passages. For best results,

lubricate the points indicated, daily.

A. Trigger Points

B. Packing

C. Adjusting Valve

D. Baffle/Air Cap Threads

FAN CONTROL

FLUID NEEDLE CONTROL

Before using this spray gun,

the packing nut should be

adjusted as follows:

1. Tighten packing nut until

fluid needle starts to bind

in the packing.

2. Loosen packing nut just

enough so the fluid needle

moves freely.

A

D

B

C

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire

Solvent Spray

Solvent and coatings can be highly

flammable or combustible especially when

sprayed.

During use and while cleaning and flushing,

solvents can be forcefully expelled from

fluid and air passages. Some solvents can

cause eye injury.

Adequate exhaust must be provided to keep air free of

accumulations of flammable vapors.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray area.

Wear eye protection.

SB-2-610-G Page 3

Inhaling Toxic Substances

Explosion Hazard Incompatible Materials

General Safety

Cumulative Trauma

Disorders ("CTD's")

CTD's, or musculoskeletal

disorders, involve damage

to the hands, wrists,

elbows, shoulders, neck,

and back. Carpal tunnel

syndrome and tendonitis

(such as tennis elbow or

rotator cuff syndrome) are

examples of CTD's.

Certain materials may be harmful if inhaled,

or if there is contact with the skin.

Halogenated hydrocarbon solvents - for

example; methylene chloride and 1,1,1,

- Trichloroethane are not chemically

compatible with the aluminum that might

be used in many system components. The

chemical reaction caused by these solvents

reacting with aluminum can become violent

and lead to an equipment explosion.

Improper operation or maintenance of

equipment.

Use of hand tools may cause cumulative

trauma disorders ("CTD's").

CTD's, when using hand tools, tend to affect

the upper extremities. Factors which may

increase the risk of developing a CTD include:

1. High frequency of the activity.

2. Excessive force, such as gripping,

pinching, or pressing with the hands and

fingers.

3. Extreme or awkward finger, wrist, or arm

positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD's can also be caused by such activities

as sewing, golf, tennis, and bowling, to

name a few.

Follow the requirements of the Material Safety Data Sheet

supplied by your coating material manufacturer.

Adequate exhaust must be provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of inhaling

sprayed materials. The mask must be compatible with the material

being sprayed and its concentration. Equipment must be as prescribed by an industrial hygienist or safety expert, and be NIOSH

approved.

Guns with stainless steel internal passageways may be used

with these solvents. However, aluminum is widely used in other

spray application equipment - such as material pumps, regulators, valves, and this gun and cup. Check all equipment items

before use and make sure they can also be used safely with these

solvents. Read the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Operators should be given adequate training in the safe use

and maintenance of the equipment (in accordance with the

requirements of NFPA-33, Chapter 15). Users must comply with

all local and national codes of practice and insurance company

requirements governing ventilation, fire precautions, operation,

maintenance, and housekeeping. These are OSHA Sections

1910.94 and 1910.107 and NFPA-33.

Pain, tingling, or numbness in the shoulder, forearm, wrist,

hands, or fingers, especially during the night, may be early

symptoms of a CTD. Do not ignore them. Should you experience

any such symptoms, see a physician immediately. Other early

symptoms may include vague discomfort in the hand, loss of

manual dexterity, and nonspecific pain in the arm. Ignoring early

symptoms and continued repetitive use of the arm, wrist, and

hand can lead to serious disability. Risk is reduced by avoiding or

lessening factors 1-7.

Loading...

Loading...