Page 1

User's Manual

FDG series Digital Force Gauge

Page 2

Contents

1. Introducti on 1

2. Operations

2.1 Choose model 4

2.2 Choose measuring heads 4

2.3 Power on/off 5

2.4 T esting 5

2.5 Hand-held or Mounting 7

2.6 St orage 7

2.7 Browse and Printing 7

3. Menus

3.1 St ructur e 8

3.2 Measurement 9

3.2. 1 U nit 9

3.2. 2 Group 9

3.2.3 Tolerance 10

3.2.4 Test Mode 10

3.2.5 Peak Time 10

3.2.6 Alarm 11

3.3 Memory

3.3.1 S torage M ode 11

3.3.2 Browse Data 12

3.3. 3 D elete Data 12

3.4 Printing 13

3.5 System Setting 15

3.5.1 Display Mode 15

3.5.2 Power Off 15

3.5. 3 Backli ght 16

3.5.4 Key Tone 16

3.5. 5 D ate/Time 16

3.5. 6 Password 16

3.5. 7 Key Setting 17

3.5.8 Default Setting 17

3.6 Language 18

3.7 Information 18

4 External Interface

4.1 US B Port 19

4.2 Multifunction Port 19

5 Maintain and Calibrat ion

5.1 Charging 22

5.2 Calibration 23

Appendix

A-1 Packing List 25

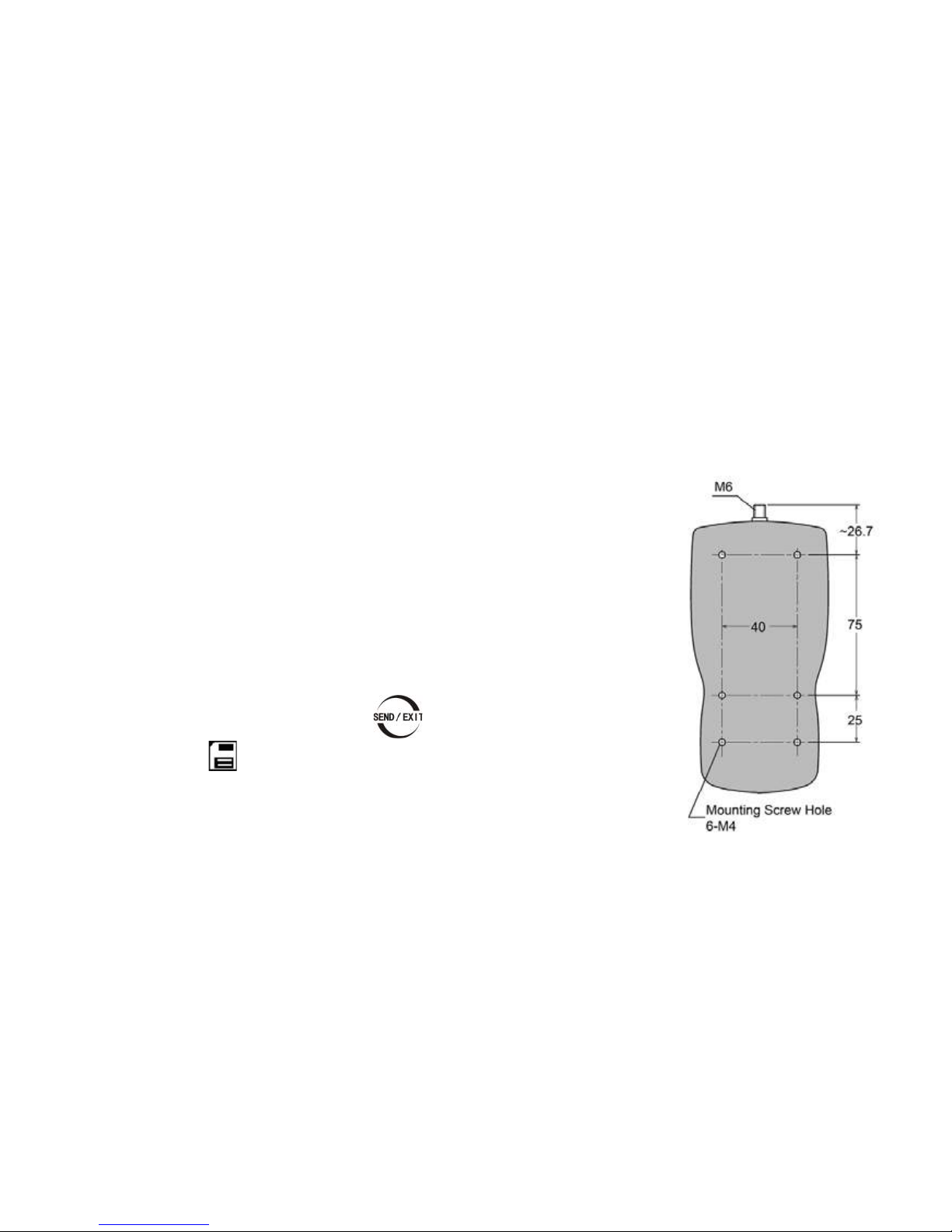

A-2 Dimensions 26

Warranty Card 27

UM411-01-0000EN-1403

Page 3

Please Carefully Read This First

●Opera t ors shou ld wear protection such as a mask and gloves i n c a s e pieces

or components break away from the unit under test.

●Whether the unit is ON or OFF, DO NOT exceed the capacity of the gauge.

NEVER exceed 150% o f th e ra ted capacity, or the load cel l will be damaged. At

110% of the rat ed capaci t y , the dis play wil l flash a warning.

●When mo unting the Digital Force Gauges, use M6 mounting screws with a

maximum insertion depth of 7 mm into the gauge.

●Hand tightens adapters, DO NOT use tools. Do not use damaged clamp.

●Measure in line tension and compression forces only. DO NOT attempt to

measure forces at an angle to the measuring shaft – damage to load cell and/or

shaf t m ay result .

●Do not attempt to repair or alter this instrument. Warranty will be voided and

damage to the unit may result.

●Use and store within the stated temperature and hu m idity ra nges, or damage

and failure may result.

●If not using for extended periods of time, recharge it for every 2 to 3 months,

or remove the batteries to prevent potential batter y leakage from causing

product damage.

Page 4

1

1. Introduction

1.1 Overview

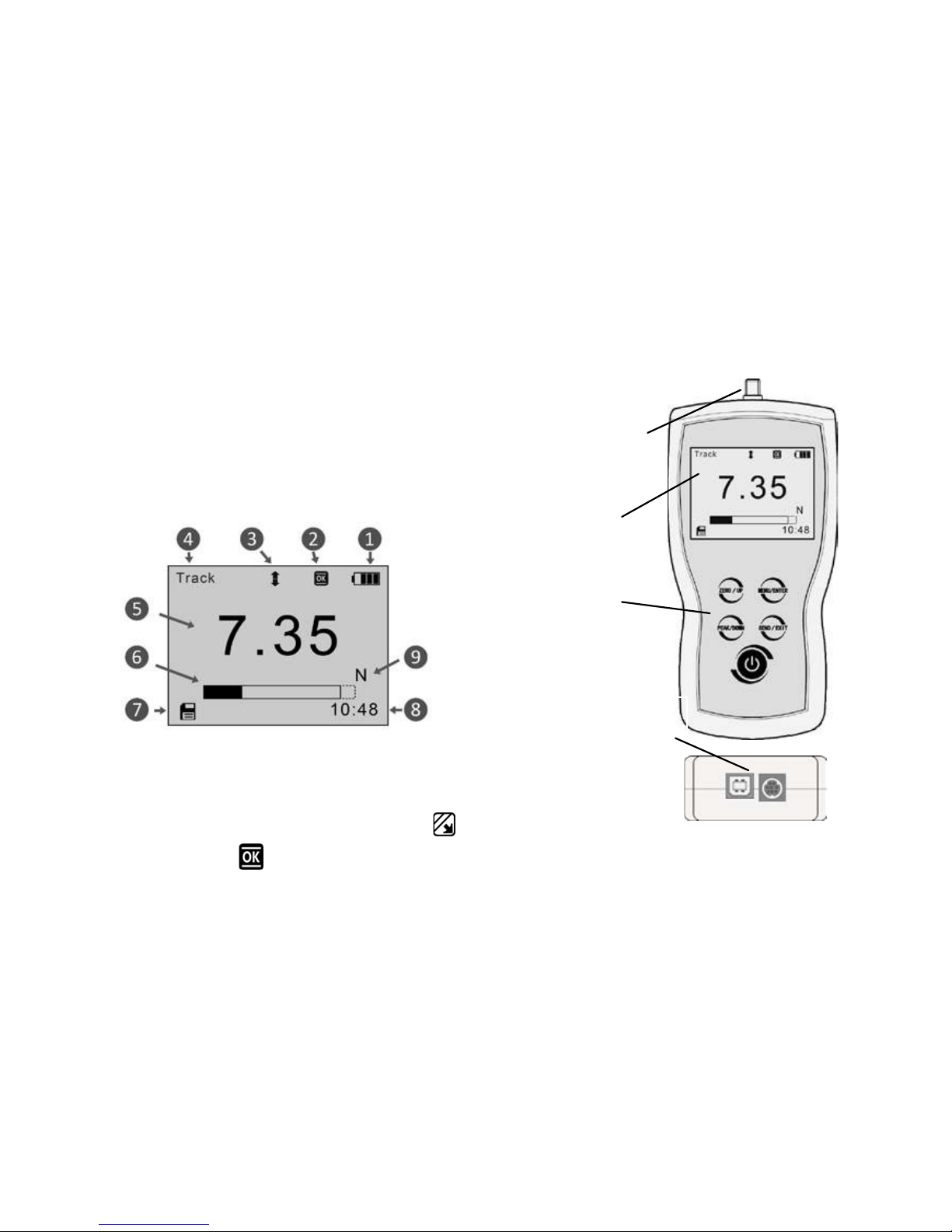

Fig.1-1.

1.2 LCD Screen

See Fig.1-2.

1. Battery icon:

Battery level or charging

status,Flashes when needs to be recharged.

2.Tolerance alarm Indicator: “ ”:

under lower limit; “ ”: between lower limit

Measuring Shaft

LCD Screen

Touch Pad

USB Port

Multifunction Port

Fig. 1-1

Fig. 1-2

Page 5

2

and upper limit; “ ”: over upper limit

3. Direction Icon: “ ” tension, “ ” compression.

4. Test Mode Icon: Three measurement modes. Track, Peak and Auto Peak.

5. Current measured value

6. Analog bar:

Indicates current position in whole capacity. When the bar enters the area

enclosed by dotted line, means overload.

7. Saving icon: Indicates data is be ing save d. 8. System time. 9. Units.

1.3 Touch Pad

Power:

Push for 2 seconds to power On or Off.

During Measurement: Print the current force value or store data, depending on the key

setting. (See3.5.7 Key S etting)

In Men us : Back or Exit.

During Measurement: Enter the menus.

In Men us : Select or En ter.

During Measurement: Track mode-Zeroing. Peak & Auto Peak modes-Resets the peak

value.

In Men us : Moves selection up or increases the v alue.

During Measurement: Changes Test Mode from Track, Peak or Auto Pea k

In Men us : Moves selection down or decreases the value.

Page 6

3

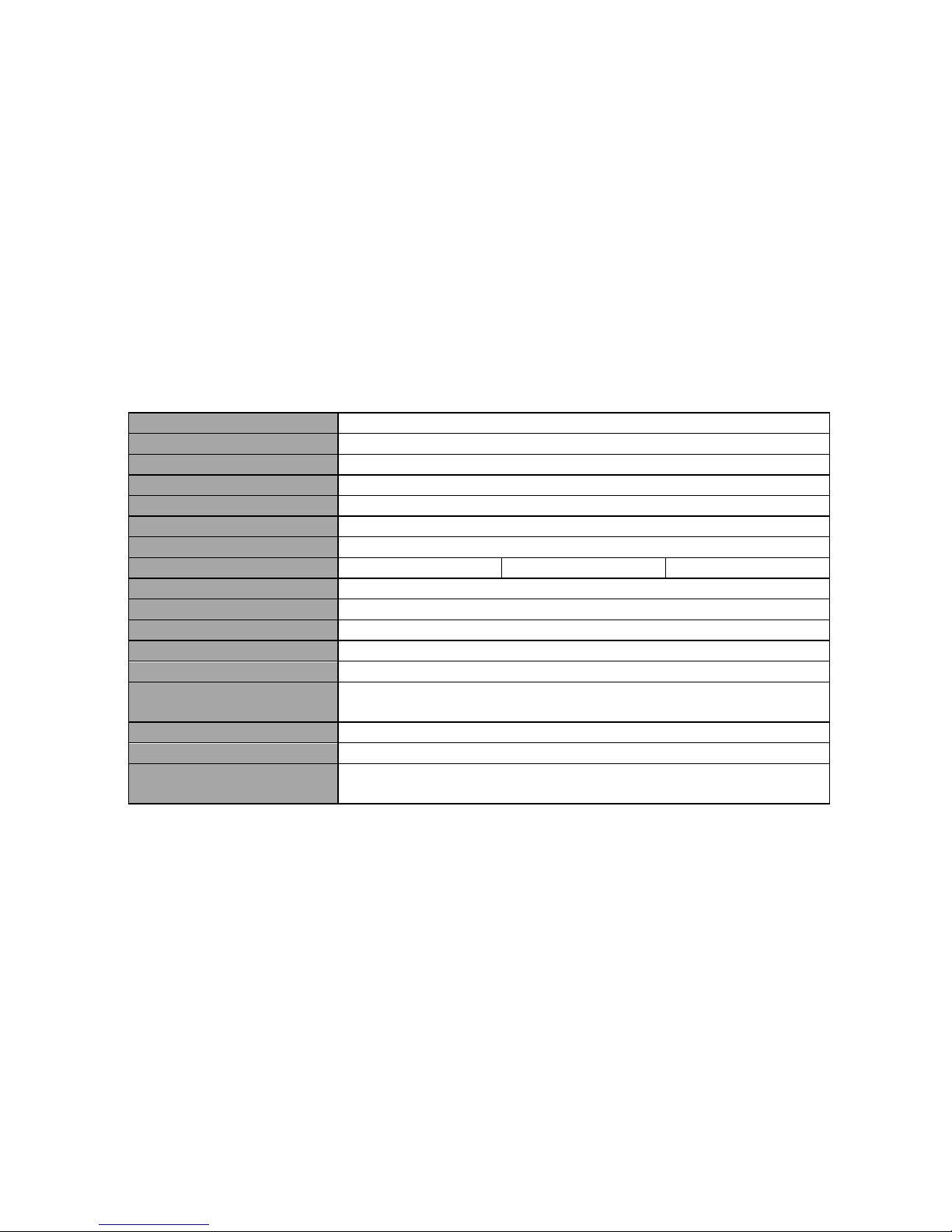

1.4 Specifications

Accuracy

± 0.2% F.S.

Selectable Units

mN, N, gf, kgf, ozf, and lbf.(Selectable)

Display

160*128 dot matrix LCD with LED Backlight

Overload

150% of F.S. (LCD flashes beyond 110% of F.S.)

Temperature Effects

<0.03% FS per °C

Measurement Mode

Peak, Autopeak or Track Mode

Set Point

Tolerance Alarm

Sampling Rate

1000 Hz

Display Update

10 time s/sec.

Memory

1000 data

Power

3.6VDC Ni-MH rechargeable batteries

Battery Life

Approximately 16 hours continuous use per full charge

Charger / Adaptor

Universal USB/BM charger, Input:110~240VAC

Outputs

USB, RS232, Set points output

Environment

Operating: -10 to 40°C, 20 to 80% RH

Storage : -20 to +50°C , 5 to 95%RH

Dimensions

145*73*35.5

Weight:

0.7 kg (1.5 lb)

Accessories

AC adapter/charger,6 attachment s: hook, flat tip, conic al tip,

chisel tip, notched tip, extension shaft

The capacity and resolution is in table on back cover.

Page 7

4

2. Operations

This series force gauge is widely used in the production practice, please do the security measures

before use, according to the following steps operate the force gauge.

2.1 Choose model

This series force gauge has a variety of models can be selected, different models corresponding to

different range and resolution, as shown in table on back cover of this manual.

Select the appropriate model based on practical need befo re us e. DO NOT exceed the c apacit y of the

gauge, or it may damage the force gauge forever.

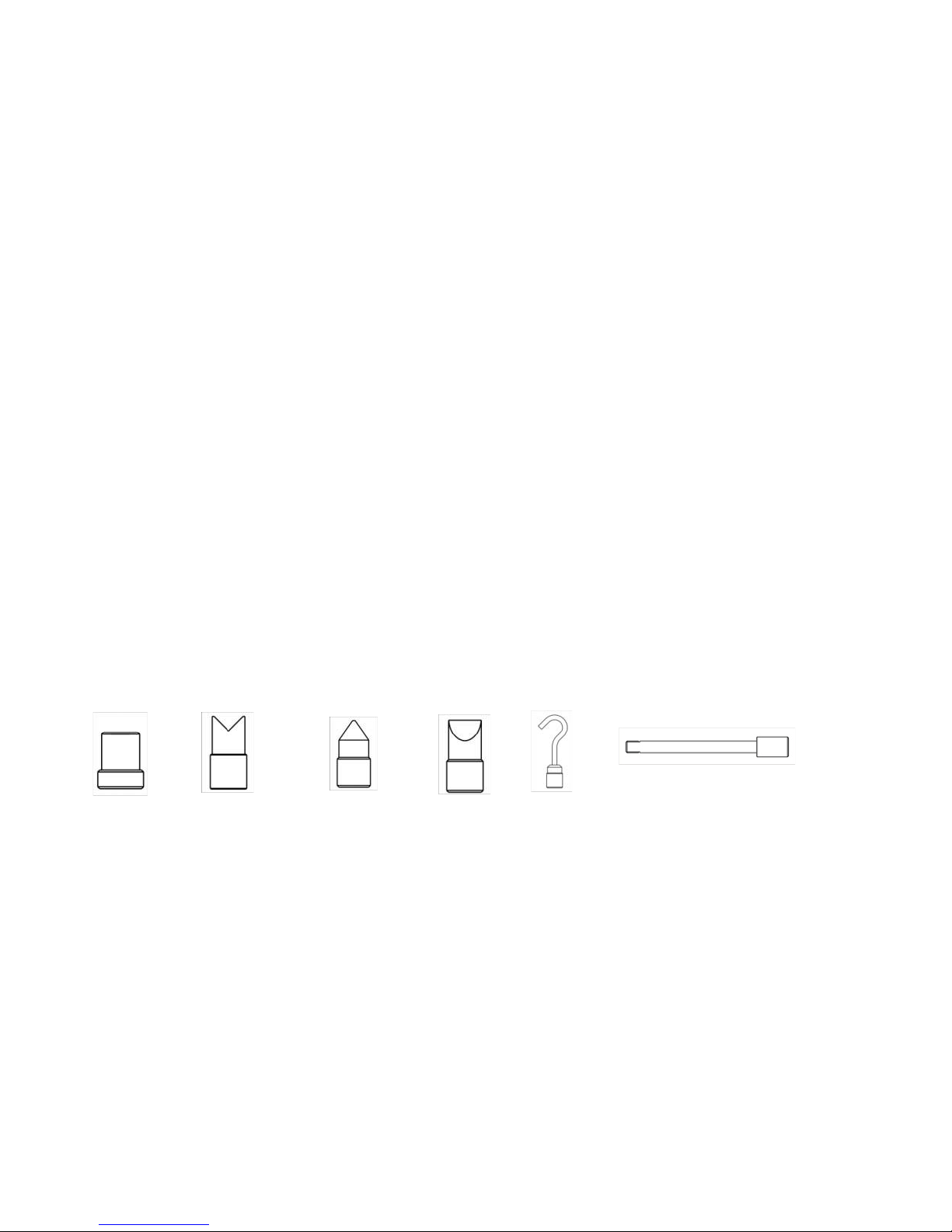

2.2 Choose measuring heads

In order to compl ete the tes t work convenient, the force gauge equipped with a variety of measuring

heads (adapters). Select the appropriate measuring heads according to the actual need.

Flat tip Not c hed tip Conical tip chisel tip Hook Extension shaft

Fig. 2-1

Page 8

5

2.3 Power on/off

Touch for 2 seconds to power On or Off.

After switching the instrument on, you should check the model wheith it is you want.

Check Battery Icon. If the power is low, should be recharged.

2.4 Testing

After completion of the test preparation, testing can be done.

2.4.1 Me asuring heads

Select the appropriate measuring head, install it in the gauge's measurement axis. Tighten it by hand,

without the use of tools. Do not u se a de formed or damaged measuring head.

NOTE: Do not use tools to vigorously tighten the measuring head, otherwi se it will dama ge the

force gauge.

2.4.2 Units

The force gauge has a variety of measurement units, select the appropriate unit of force. Under the

measure interface, press the Menu key to enter the menu interface (See 3.2.1 Unit )

Page 9

6

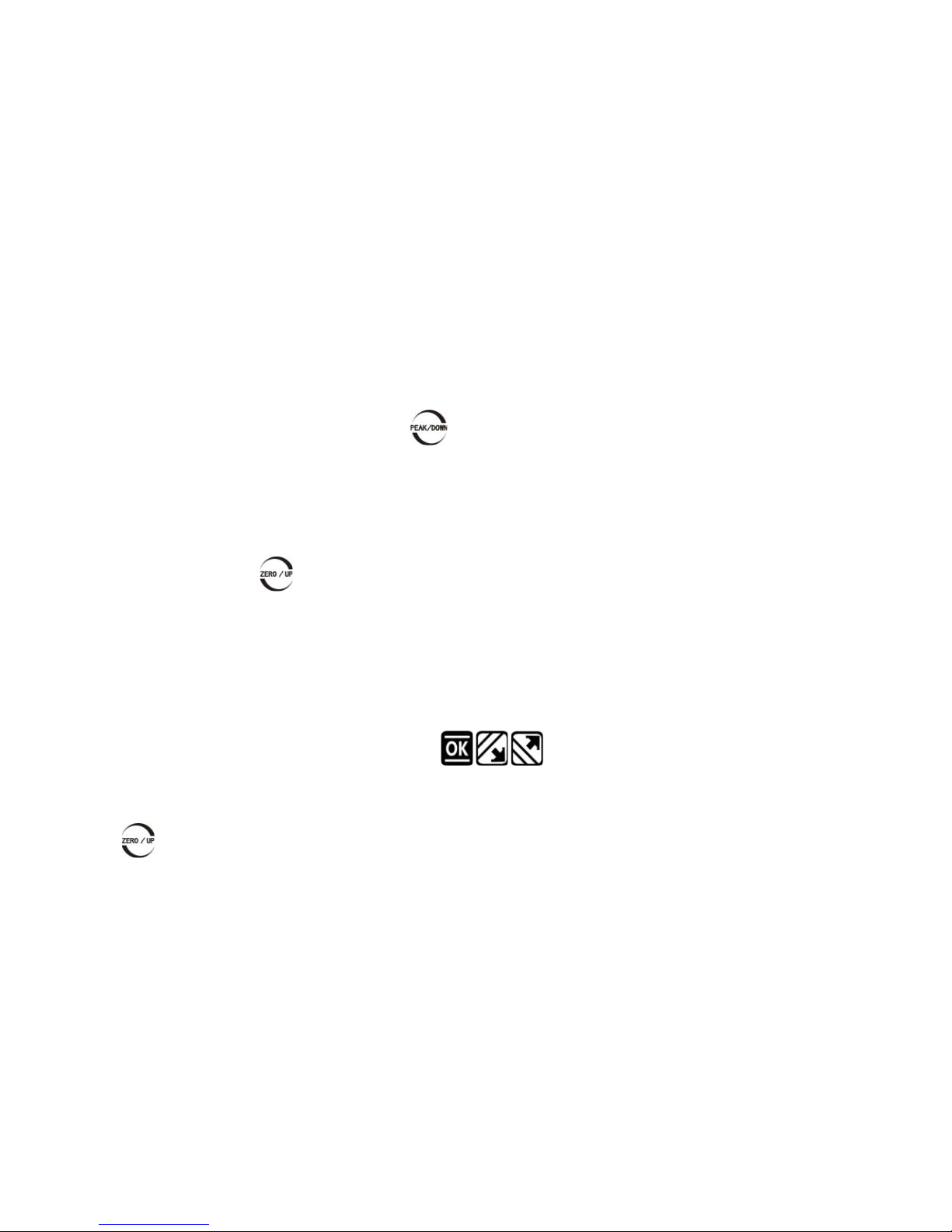

2.4.3 Test Mode

This series forc e gauge has 3 kinds of measurement test mode can cho ose.

You can select a Measure Mode by touching under the measure interface,

Or can change it in menus (See 3.2.4 Test Mode ).

Track: The real time measuring mode, under this mode, press the zero key the force

gauge will be cleared (remove tare).

Peak: Peak readings will not change until a higher value is measured. Under this mode,

touch the zero key the force gauge will update the display immediately.

Auto-Peak: In this mode, the gauge display a peak value of force in a fixed duration.

The duration time can be set in menus.

2.4.4 Tolerance Limit

The tolerance limits can be set for GO/NG measurement also. See for detail.

If you s et the al arm on and a v alid limit, The ico n will be displayed for within limit, lower

than lower limit or exceed upper limit.

2.4.5 Zeroing

Touch to clear the force gauge in tr ack mode for removing the tare.

Page 10

7

2.5 Hand-held or Mounting

The force gauge is a portable Instrument, you can do the testing hand-held, or yo u also can i nstall t he

force gauge on the test stand so as to obtain acc urate mea sureme nt result s . There are 6 M4.0

mounting screw holes on the back,can be fixed on the test stand, show as Fig. 2-2.

NOTE: The depth of the mounting hole is 8.0mm, please choose the

appro p r i ate screws, screw into the depth of the force gauge shall not be

greater than 7mm.

2.6 Storage

Measured results can be stored in the force gauge, so that y ou can

review or print them later.

Under the measure interface, touch to save value measured, and

the save icon will be displayed.

2.7 Browse and Printing

The values saved in memory can be re view ed in Browse function.

The data in memory can be printed to a report.

Fig. 2-2

Page 11

8

3. Menus

3.1 Structure

The Force Gauge has multi-level menu interface(Table 3-1).

From the home screen, touch “ ” to enter the Menu.

(Fig. 3-1、Fig. 3-2)

Touch or can move selection. Then touch

can enter the next layer of menu.

Touch can cancel t he setting or exit.

In number input, touch can increase the number, and

touch can chang e t o another digit or item.

Menu

Measurement

Unit

Group

Tolerance

Test Mode

Peak Time

Alarm

Memory

Storage Mode

Browse All

Browse Selected

Delete Selected

Delete All

Printing

Print Recent

Print Selected

Print All

System

Display Mode

Power Off

Backlight

Key Tone

Date/Time

Password

Key Setting

Default Setting

Language

Calibration

Information

Table 3-1

Fig. 3-1

Fig. 3-2

Page 12

9

3.2 Measurement

The Measurement contains six selectable items:

Unit, Group,Tolerance, Test mode, Peak Time

and Alarm. (Fig, 3-3)

3.2.1 Unit

The measuring unit can be selected under this

menu. Different range models may have

different unit selection capabilities. See Fig.3-4.

3.2.2 Group

When several test samples need to be

measured, the samples can be coded into

groups. The range is 01-99. See Fig.3-5.

Fig. 3-4

Fig. 3-5

Fig. 3-3

Page 13

10

3.2.3 Tolerance

In the Tolerance menu, program upper and lower limit

for GO/NG Measurement.

The upper limit value must be greater than the lower

limit , and both limit value can not be greater than 110%

of the rated capacity. See Fig.3-6.

3.2.4 Test Mode

Test mode can be selected. Ther e ar e three kinds of

mode: Track, Peak and Auto Peak. (Fig. 3-7) See

2.4.3 Select Test Mode also.

3.2.5 Peak Time

If AutoPeak m ode is use d, you can se t the peak value capturing time interva l- Peak Time. Default

setting of Peak Time is 5 sec.

Figure 2-6

Fig. 3-6

Fig. 3-7

Fig. 3-8

Page 14

11

The range is 1~99 seconds. (Fig. 3-8)

3.2.6 Alarm

You can turn on/off the sound of tolerance

alarm( Fig.3-9). The sound for overload alarm cannot

be turned off.

3.3 Memory

In this menu, you can set the memory mode, browse

the data in memory or delete it/them.

3.3.1 Stora ge M ode

There are two storage mode can be selected , Single

and Series.

Single: The current value displayed can be saved when touch . This mode c an be use in all 3

test mode.

Fig. 3-9

Fig. 3-10

Fig. 3-11

Page 15

12

Series: Continuous storage mode, only in Auto Peak mode is effective. When a peak capture time

interval is r eached, the peak value is saved, no

need touch any key (Fig. 3-11).

3.3.2 Browse Data

You can browse the data in memo ry with two method,

Browse All or Browse Selected. (Fig.3-12,Fig3-13)

The greatest number is the most recent data.

For Browse Selected selecting the range of data

number is needed.

Touch or can turn the page.

3.3.3 Delet e Dat a

There are 2 methods to delete the data for restoring the me mory.

Fig. 3-12

Fig. 3-13

Page 16

13

Delete selected: Delete data in number range

selected.

Delete All: Delete all data saved.

Before delete data, a warning window will pop up for

further confirmation.

3.4 Printing

The force gauge can be connected to a printer for

printing the report. In Printing menu, you can Print

Recent, Print Selected and Print All.

3.4.1 Connect Printer

Connect the printer to the force gauge with a

printing cable. Then turn on the power of printer.

3.4.2 Printing Setup

Fig. 3-14

Fig. 3-15

Fig. 3-16

Page 17

14

Print Recent: P rint some data measured recently(Fig. 3-17)

Print Selected: Prin t data in a num be r range (Fig. 3-18).

Print All: Pri nt all data in memory(Fig. 3-19).

It may take a long time to print all the data and need many printing paper, so a prompt window will pop

out to ask for confirmation.

The style of tes t report is shown as Fig.3-20.

Fig. 3-17

Fig. 3-18

Fig. 3-19

Fig. 3-20

Page 18

15

3.5 System Setting

3.5.1 Dis play Mode

LCD display direction can be transformed

acco rding to t he posit ion of for c e gauge

automatically.

You can set it to Obverse or Reve rse and not

Automatic.

3.5.2 Power Off

The force gauge can turn the power off

automatically, some time interval after no

meas uring and no any operation. 5 minutes is

default. You can change it for a longer or shorter standby.

Fig. 3-21

Fig. 3-22

Fig. 3-23

Page 19

16

3.5.3 Backlight

The force gauge can turn off backlight, some time

interval after no measuring and no any operation. You

can select this ti me or turn i t o n or off a lways.(Fig.

3-24)

3.5.4 Key Tone

(Fig. 3-25)

3.5.5 Date/Time

(Fig. 3-26)

3.5.6 Password

Some operations of force gauge may need to enter a password to pr event mis take or unexpected

change.

Fig. 3-24

Fig. 3-26

Fig. 3-25

Page 20

17

The default System password is“123”. You c an

change it to your favorite. You should enter the old

password first, then enter a new one.

3.5.7 Key Setting

The key is a multif unctio n k ey,

It can be set as "store the current display

value(Storage)" or "print the recent data (Print)".

"Storage" is default .

3.5.8 Default Setting

When t he artif icial error, and do not know how to

Fig. 3-27

Fig. 3-28

Fig. 3-29

Page 21

18

restore, the gauge can be restored to factory settings. it will lose that some imformation set by

customs.Caref ully use this function!

Restoring to Default Setting, the password must be enter and a prompt must be confirmed.

3.6 Language

Here you can select the language appropriate.

3.7 Information

Some information such as the logo, the model, the version of program and the series number are

displayed here.

Fig. 3-30

Page 22

19

4 External Interface

The fo rce gauge have 2 external ports, a

USB port and an MD8 port.

4.1 USB Port

The USB port is used to transmit data to

PC and recharge.

Connect the USB cable to a charger for recharging .

Connect to the PC for upload data. The softw are EDMS need to setup in PC , see manual of EDMS for

detail.

4.2 Multifunction Port

The MD8 port is a multifunc tion port , it include s a RS23 2 in terface for connec t to the pri nter o r co mputer ,

and two alarm outputs.

USB port MD8 port

Fig. 4-1

Page 23

20

The pins assignment of multifunction port is shown in

Table 4-1.

The specification of RS232 is shown in Table 4-2

You can change the baud rate in menus. shown in

Fig.4-2.

MD8 multifuncti on port

Pin Description

1 RS232- Transmit(TX)

2 RS232- Receive (RX)

3 RS232- Ground

4 Alarm Output A+

5 Reserved

6 Alarm Output Com 7 Alarm Output B+

8 Reserved

Table 4-1

RS232 Specifications

Data word length 8 bits

Stop bit 1bit

Parity None

Baud r ate 9600,19200,38400

Hardware Flow Control None

Table 4-2

Page 24

21

Alarm output:

There are two alarm outputs, you can connect the m to the other equipment (such as test stand, PLC

etc.), or connect to some alarm

units.

! Maximum permissible voltage

pin 7 to p in 6, pin 4 to pin 6: 35V; pin 6 to pin 7, pin 6 to pin 4: 6V.

Fig. 4-3

Fig. 4-2

Page 25

22

5 Maintain and Cali bration

5.1 Charging

When the battery are low, the icon “ ” will

be displayed. The batterie s should be charged

immediately.

Connect the gauge and the charger use the USB

cable, and then connect the charger w ith AC socket to

start charging.

It take s a b o ut 3~4 hours for fully cha rging .

You c an also us e other US B device (e .g. Laptop PC)

to recharge the gauge.

Fig. 5-2

Fig. 5-1

Page 26

23

5.2 Calibration

Because of the sensor material performa nc e or the influence of

external factors, there may be errors in a certain range aft er a

period of time use.

Should send the force gauge to a specialized testing organization

for calibration.

If you have some stansard force weights or the other standard load

and some test stand, you may calibrate it also.

① Mount the force gauge.

② Remove the tare by use of the key .

③ Enter C alibration interfac e, as Fig 5-2.

The calibration interface is shown as Fig 5-3.

④ Load a standard force.Now the value in

standard input area is just equal to the current measured value.Wait a moment for the force stability.

⑤ Touch and to input the stansard force value.

❶Calibration times

❷Current measuring value

❸Standard value input

Fig. 5-3

Fig. 5-4

Page 27

24

⑥ Touch to enter the next calibration. Touch can interrupt the calibration.

When the 5 times calibration had been finished or be interrupted, a confirm window will pop up to ask

for save or not save the calibration. (Fig. 5-3)

Touch or to sel ect, the n press .

If "YES" is selec te d , "Calibrate complete!" is displayed.

NOTE:

①Set the unit of force to the unit used in calibration previously(as shown in 3.2.1 Unit)

②Ensure that the tare weight of attachment has been remove before calibration.

③You can do any point or points calibration from 1 to 5 point., we recommend 5 points calibration.

Page 28

25

Appendix

A-1 Packing List

Page 29

26

A-2 Dimensions

Page 30

27

UM411-01-0000EN-1403

Warranty Card

Description: Digital Force Gauge

Model:

User: Tel:

Add:

Agent: Tel:

Date:

Warranty Description

Please use our product exactly according to our user's manual.

All products sold by our company or authorized dealer are covered by 12 month

warranty.

Anthropogenic causes, irresistible natural factors cause the product damage, our

company will not warranty.

Page 31

Capacity/ Resolusion

Model N kgf lbf ozf gf mN

FGD-5 5/0.0005 - 1.1/0.0001 18/0.005 500/0.05 5000/0.5

FGD-10 10/0.001 1/0.0001 2.2/0.0005 35/0.01 1000/0.1 10000/1

FGD-20 20/0.005 2/0.0005 4.4/0.001 70/0.01 2000/0.5 20000/5

FGD-50 50/0.005 5/0.0005 11/0.001 180/0.05 5000/0.5 50000/5

FGD-100 100/0.01 10/0.001 22/0.005 350/0.1 10000/1

-

FGD-200 200/0.05 20/0.005 44/0.01 700/0.1 20000/5

EFG500 500/0.05 50/0.005 110/0.01 1800/0.5

-

FGD-1000 1000/0.1 100/0.01 220/0.05 3500/1

UM411-02-3102EN-1407

Loading...

Loading...