Page 1

HEATING PUMP FOR SWIMMING POOLS

(THP05 - THP30s)

INSTALLATION

AND USER MANUAL

EN

Page 2

2

Contents

I. Applications ...................................................................4

II. Characteristics ................................................................4

III. Technical parameters .....................................................4

IV. Dimensions . ..................................................................5

V. Directions for installation . ............................................6

VI. Operating instructions . ..................................................8

VII. Testing . .........................................................................10

VIII. Safety precautions . .......................................................10

IX. Maintenance ................................................................. 11

X. Solving common malfunctions .................................... 11

Thank you for choosing our product and trusting our company. To ensure that using this product brings

you joy, please read the instructions carefully and follow the user manual exactly before use, to prevent

equipment damage or unnecessary injuries.

EN

Page 3

3

I. Applications

1. To s et u p an effect ive and economic pool temperature that it is comfortable and pleasant for you.

2. The user can select the model’s technical parameters according to the professional manual. Pool heating was optimised in the factory (see table with technical parameters).

II. Characteristics

1. Highly effective titanium heat exchanger

2. Sensitive and accurate temperature regulation. Water temperature display

3. Ecological coolant R407c

4. Protection against high and low pressures

5. Automatically switches off when it goes below the minimum temperature

6. Forced anti-freezing with regulation temperatures

7. Air pump of international trademark

8. Easy installation and operation

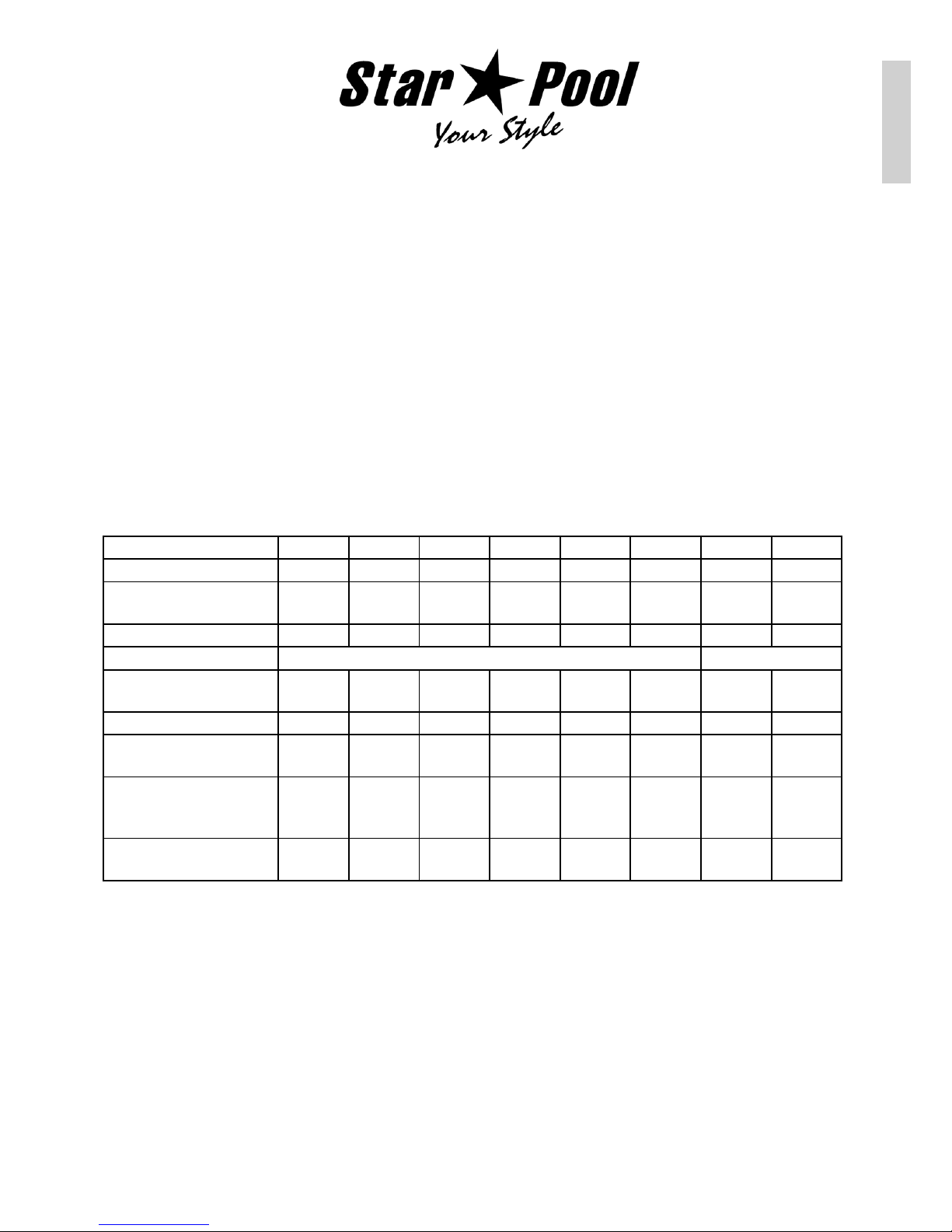

III. Technical parameters

Model

THP05 THP06 THP09 THP12 THP16 THP23 THP23s THP30s

Input in kW

0,7 0,93 1,4 1,8 2,4 3,7 3,7 4,5

Heating performance

in kW

5 6 9 12 16 23 23 30

Effi c i e n c y

≥ 6,2 ≥ 6,2 ≥ 6,2 ≥ 6,2 ≥ 6,2 ≥ 6,2 ≥ 6,2 ≥ 6,2

Infeed

for one phase 220 - 240V~50Hz 3N-380V~50Hz

Rated current/ Max.current in A

4,6/6,4 4,6/6,4 6,4/8,2 8,2/11 10,9/14,1 17,5/26,5 5,6/8,5 6,8/9,5

Sound dB(A)

≤ 48 ≤ 48 ≤ 48 ≤ 48 ≤ 50 ≤ 56 ≤ 56 ≤ 58

Net weight/ Gross weight

in kg

45/50 45/50 52/57 65/70 85/93 102/110 102/110 123/133

Specifi c a t i o n s f o r w a t e r

supply and discharge

piping in mm

50 50 50 50 50 50 50 50

Recommended water fl o w

m3/h

≥ 3 ≥ 3 ≥ 3 ≥ 5 ≥ 6,5 ≥ 10 ≥ 10 ≥ 10

Warning:

1. This product can work satisfactorily in a water temperature range of +5°C to +40°C and at an air

temperature of +7° to +40°C; outside these ranges, it will not be effi c i e n t . P l e a s e n o t e t h a t p o o l h e a t i n g

performance and its parameters vary according to conditions.

2. On the grounds of technical improvement, related parameters may be periodically adapted without

further notice. For details, see the factory label.

EN

Page 4

4

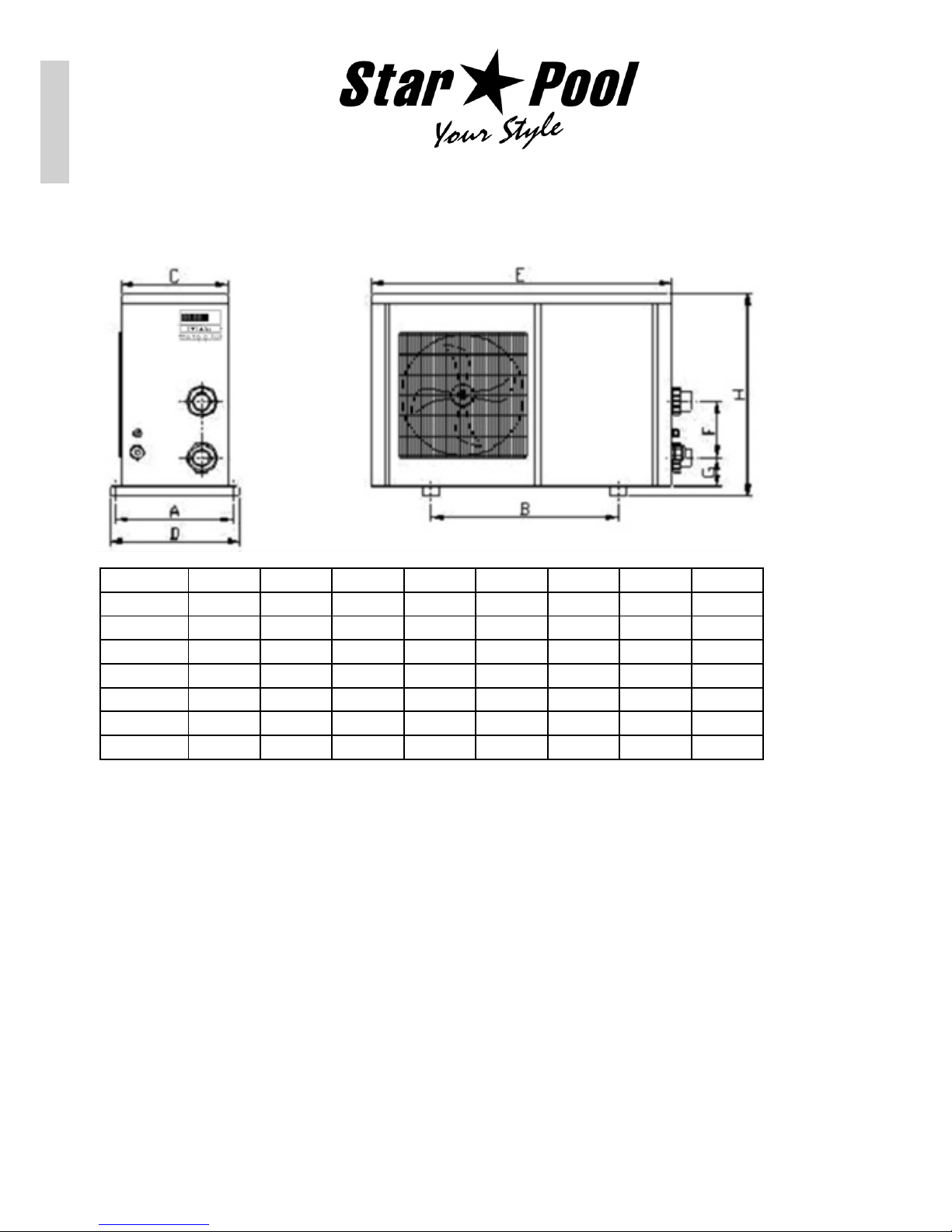

IV. Dimensions

Dimensions shown above are in mm.

Note:

The picture shown above is a diagram of technical conditions for pool heating. It serves only as a reference

for the technician during the installation and adjustment of the equipment. On the grounds of continuous

improvement, product parameters may change without previous notice.

Model A B C D E F G H

THP05 330 580 285 350 930 200 83 550

THP06 330 580 285 350 930 200 83 550

THP09 330 580 285 350 930 200 83 550

THP12 330 650 300 350 1000 280 83 630

THP16 330 650 300 350 1000 280 83 630

THP23 438 770 425 470 1120 350 83 950

THP30S 438 810 425 470 1180 600 83 950

EN

Page 5

5

V. D i r e c t i o n s f o r i n s t a l l a t i o n

1. Diagram of water piping connections

(Warning: diagram serves only as an illustration, pipeline confi g u r a t i o n i s o n l y r e f e r e n t i a l )

Signal cable

Diagram of pool heating piping

Drai-

nage

Outfl o w o f c o n d e n s a t e

Water i nt o the p oo l

Water t re atment ap paratus

Infl o w

Pump

Infl o w o f w a t e r i n t o t h e p o o l

Filter tank

Mains supply

EN

Page 6

6

2. Electrical connections diagram

Note: Pool heater must be correctly earthed.

Equipment protection alternatives and cable specifi c a t i o n s

MODEL

THP05 THP06 THP09 THP12 THP16 THP23 THP23s THP30s

Circuit

breaker

Rated current A

15 15 15 20 25 40 15 20

Rated residual current mA

30 30 30 30 30 30 30 30

Circuit breaker A

15 15 15 20 25 40 15 30

Mains supply (mm2)

3x2.5 3x2.5 3x2.5 3x2.5 3x4 3x6 5x2.5 5x4

Signal cable (mm2)

3x0.5 3x0.5 3x0.5 3x0.5 3x0.5 3x0.5 3x0.5 3x0.5

Note: The information above is for a mains cable of ≤ 10 m. If the mains cable is ≥ 10 m,

the conductor diameter must be increased. The signal cable can be a maximum of 50m

long.

Power supply

Circuit breaker/fuse

(secured by the customer)

Mains supply

Pool terminal block

Earthing

Power supply

Circuit breaker/fuse

(secured by the customer)

Mains supply

Pool terminal block

Earthing

EN

Page 7

7

3. Installation instructions and requirements

Pool heating must be installed by a skilled team. Users must not install it independently because it could

cause injury, or damage to the equipment.

A. Installation

1) Pool heating must be installed in a place with good ventilation;

2) The frame must be prepared with screws (M10) into the concrete base or brackets. The concrete base

must be strong and anchored. The bracket must be strong with an anticorrosive treatment.

3) Do not block the infl o w o r o u t fl o w a r e a w i t h a r t i c l e s w h i c h w o u l d o b s t r u c t t h e fl o w o f a i r . T h e r e m u s t

not be any obstruction within 50cm behind the main equipment; otherwise, heating performance will be

decreased or absent.

4) The equipment requires a pump attachment (supplied by the customer). Recommended pump specifi c a tion: fl o w : s e e t e c h n i c a l p a r a m e t e r s , m a x . t r a n s p o r t h e i g h t ≥10 m;

5) Once the equipment is operating, condensate will leak from the lower part. Give attention to this occurrence. Insert nozzle (accessory) into the opening and secure well. Then attach the condensate drainage

tube.

B Electrical connection

1) Connect equipment to corresponding mains. The voltage must correspond with the product’s specifi e d

voltage.

2) Earth the equipment correctly

3) Electrical connection must be carried out by a professional technician and according to the connection

diagram.

4) Install protection against leakage current according to local regulations (leakage current ≤ 30 mA).

5) The mains supply and signal cable must be arranged systematically and logically, so that cables do not

interfere with each other.

C. After completing all connections and repeated inspection, switch the equipment on.

VI. Operating instructions

Picture of the button arrangement

Setting up water

temperature and time

Timer inspection

Timer switched on On

On / Off

Clock

Timer

switched-off

Timer

pilot light

Heating/cooling

indicator

EN

Page 8

8

CLOCK TIME SWITCHED ON TIME SWITCHED OFF

AUTO/EH COOLING HEATING

1. Operating display

A. The display shows the time when the equipment is off

B. The display shows water temperature in the pool when the equipment is off

2. Adjusting water temperature

A. This function is accessible regardless of whether the equipment is off or on.

B. To adjust the water temperature, press the button or . The temperature will fl a s h o n t h e r e g u l a -

tor. Press the button to adjust to the required water temperature or .

C. After 5 seconds, the regulator display returns to its normal mode.

3. Adjusting time

A. This function is accessible regardless of whether the equipment is off or on.

B. To adju st th e tim e, pr es s the butt on . When the t ime o n scr ee n be gi ns to fl a s h , p r e s s t h e b u t t o n

again to adjust hours. Adjust the value with the button and . Before the time stops fl a s h i n g , p r e s s

the button for adjusting minutes. Adjust the value with the button and . After adjustment,

press the button and water temperature will be displayed. After 30 seconds, the regulator display

returns to its normal mode.

4. Adjusting time of switching on and off of the timer

A. To ad just the time that the timer is switched on, press the button . Wh en t he p ilot lig ht t urns on

and begins to fl a s h , p r e s s t h e b u t t o n a g a i n t o a d j u s t h o u r s . A d j u s t t h e v a l u e w i t h t h e b u t t o n

and . Before the time stops fl a s h i n g , p r e s s t h e b u t t o n f o r a d j u s t i n g m i n u t e s . A d j u s t

the value with the button and . After adjustment, press the button “TIMER ON” and water

temperature will be displayed. After 30 seconds, the regulator display returns to its normal mode.

B. To a djus t th e ti me t hat the time r is swi tche d off, pres s the button . Whe n th e pi lot ligh t tu rns on

and begins to fl a s h , p r e s s t h e b u t t o n a g a i n t o a d j u s t h o u r s . A d j u s t t h e v a l u e w i t h t h e b u t t o n

and Before the time stops fl a s h i n g , p r e s s t h e b u t t o n f o r a d j u s t i n g m i n u t e s . A d j u s t t h e

value with the button and . After adjustment, press the button and water temperature will

be displayed. After 30 seconds, the regulator display returns to its normal mode.

C. Cancelling the adjusted time of switching on and off of the timer. To cancel the adjusted time of

switching on and off of the timer, press the button or . When the displayed information

starts to fl a s h , p r e s s t h e b u t t o n . W h e n t h e t i m e r p i l o t l i g h t s w i t c h e s o f f a n d w a t e r t e m p e r a t u r e i s

shown on the display, the adjusted time of switching on and off of the timer has been cancelled. After

30 seconds, the regulator display returns to its normal mode.

1

1

1

0

0

1

0

0

1

0

0

EN

Page 9

9

VII. Testing

1. Examination before use

A. Check installation of the whole apparatus and pipeline connections according to the relevant plan.

B. Check the electrical connection according to the relevant diagram, check earth connection.

C. Check that the equipment’s main switch is switched-off.

D. Check the adjusted temperature.

E. Check the supply and outfl o w o f a i r .

2. Tria l

A. The user must “start the pump before the equipment and switch off the equipment before the pump”,

otherwise the equipment will be damaged.

B. The user must start the pump and check that there are no leakages in the water system; then adjust the

temperature on the thermostat and switch the equipment on.

C. The pool heater is equipped with a guard in the form of a delayed start function; when starting the equip-

ment, the ventilator starts 1 minute before the compressor.

D. After starting the heater, check that the equipment does not make excessive noise during operation.

VIII. Safety precautions

1. Warning

A. Adjust to a suitable temperature to give a pleasant water temperature; avoid over- or under-heated water.

B. Do not block air supply or outfl o w a r e a w i t h o b j e c t s w h i c h c o u l d o b s t r u c t t h e a i r fl o w , o t h e r w i s e t h e

heater’s performance will decrease or it could even switch off.

C. Do not insert hands into the heat pump’s outfl o w a n d d o n o t r e m o v e t h e v e n t i l a t o r m e s h . I t c o u l d c a u s e

injury.

D. If anything unusual occurs during operation, such as noise, smell, smoke or electrical leak, please switch

the equipment off immediately and contact the local seller. Do not try to eliminate the fault yourself.

E. To avoid fi r e , d o n o t u s e o r s t o r e t h e e q u i p m e n t n e a r t o fl a m m a b l e l i q u i d s o r g a s e s s u c h a s t h i n n e r , p a i n t

or fuel.

F. For optimal heating effects, install a heat insulating material on the pipes between the pool and the

heater. During operation of the heater, cover the pool with a heat insulating cover.

G. Connecting piping between the heater and the pool must be ≤10 m, otherwise the heating performance

cannot be guaranteed.

H. Equipment in this range is most effective at temperatures +15°C to +25°C.

2. Safety

A. Please keep the main on-switch out of reach of children

B. If there is a power failure during operation, the heater will switch on automatically once the power is res-

tored. Therefore, please switch the heat off during a power failure and after power is restored, re-adjust

the temperature.

C. During a thunderstorm, please switch off the power supply, to protect the equipment from damage by

lightning.

D. During long-term non-use, disconnect power and drain water from the equipment by turning on the tap

in the supply pipeline.

EN

Page 10

10

IX. Maintenance

A. Before examination and repair disconnect the heater’s power supply.

B. In winter, drain the water from the equipment and disconnect the power supply to prevent damage to the

equipment. Cover the casing with plastic sheeting which will protect it from dust.

C. Clean the equipment with neutral household cleaning materials or with clean water, never use petrol,

thinner or other similar materials.

D. Check screws, cable and connection regularly.

X. Solving common malfunctions

Malfunction

Equipment does not start

functioning

Reason Solution

Power supply switched-off Wait f or i t to be s witch ed -o n again

Equipment switched-off Switch on equipment

Blown fuse Change it

Fallen circuit breaker Switch on fuse again

Reaches air release but

heating is not suffi c i e n t .

Blocked air supply Remove obstruction

Blocked air outfl o w Remove obstruction

Protection in the form of 3 minute time delay Wait

Adjusted temperature is too low

Increase the adjusted temperature

correspondingly

If the above shown malfunctions cannot be solved, please contact a specialist and state the equipment model and

give a detailed description of the malfunction.

Warning! To prevent potential injuries, do not take apart or repair the pool heater

yourself.

Malfunction codes

No. Malfunction code Description of malfunction

1 EE 1 Protection against high pressure

2 EE 2 Protection against low pressure

3 EE 3 Protection against low water pressure

4 EE 4 Protection of three-phase sequence (only for three-phase equipment)

5 PP 1 Pool and bath heater sensor malfunction

6 PP 2 Suction sensor malfunction

7 PP 3 Spiral heating pipes sensor malfunction

8 PP 4 Intake pipe sensor malfunction

9 PP 5 Air temperature sensor malfunction

10 PP 6 Protection against compressor displacement overloading

11 PP 7

If the temperature is <5°C, protection in the form of automatic switching off

(it is not a malfunction)

EN

Page 11

11

Guarantee conditions

Guarantee conditions are in accordance with business and guarantee conditions of your supplier.

Product safe liquidation after service life expiring

Ensure ecological liquidation by specialized fi r m a t p r o d u c t s s e r v i c e l i f e e x p i r i n g

Claims and service

Complains and claims are proceeded according to proper law about consumer protection. In the event of

inquest irremovable mistakes will turn on his supplier.

Date.....................................................................

Printing mistakes reserved.

Yo ur se l le r

EN

Loading...

Loading...