Page 1

THERMAL REWRITE CARD

READER / WRITER

TCP100/2000 series

Installation Guide & Specifications

Thank you for choosing the TCP100/2000 Thermal rewrite card system.

This “Installation Guide & Specifications” includes very important

instructions for safety.

Please read this manual before you start the system,

and follow the instructions.

Star Micronics Co., Ltd.

Special Products Operating Division

Page 2

C•O•N•T

1. HANDLING NOTES--------------------------------------------------------- 1

2. OUTLINE ---------------------------------------------------------------------- 4

3. UNPACKING------------------------------------------------------------------ 5

4. APPEARANCE AND NOMENCLATURE ------------------------------ 6

5. CONNECTION TO EXTERNAL UNITS AND SETTING ----------- 7

6. CLEANING -------------------------------------------------------------------- 8

7. TROUBLE SHOOTING ---------------------------------------------------- 9

8. GENERAL SPECIFICATIONS ----------------------------------------- 10

•

E•N•T

•

S

Page 3

1

HANDLING NOTES

At the installation:

1) Install the TCP100/2000 reader/writer on a flat surface. Minimize any

shock or vibration to the reader/writer, as shock or vibration may cause

injury and/or failure.

2) Keep the TCP100/2000 reader/writer away from hands of the children.

3) Do not use or leave the TCP100/2000 reader/writer in direct sunshine or

near a source of heat such as fire or stove. It may cause generation of

heat which can bring failure, malfunction, skin burn, etc.

4) Keep the TCP100/2000 reader/writer away from liquids such as water,

oil, etc. Do not use or leave TCP100/2000 reader/writer in high humidity.

5) Keep the TCP100/2000 reader/writer away from dust, metal powder,

etc.

6) Keep the TCP100/2000 reader/writer away from corrosive gases, flammable gas, chemicals or steams. Exposure may cause generation of heat,

electric shock, malfunction, etc.

7) Keep the TCP100/2000 reader/writer away from magnetic sources to

avoid erasing or damaging data stored on card.

8) Do not use the power supply in the unspecified range. This may cause

generation of heat, electric shock, malfunction, etc.

9) Make sure that the power cable is plugged close enough to disconnect

immediately when the unusual is found.

10) Do not connect the AC power plug to the same outlet used for other

electrical noise generation devises, such as an electrical motor, etc. This

may cause malfunction, failure, etc.

11) Make sure that the power cable is plugged into the outlet certainly. The

earth terminal should be grounded to avoid electric shock, failure, etc.

12) Provide enough room around the TCP100/2000 reader/writer. If not, it

may cause generation of heat, malfunction, failure, etc.

13) Do not leave the cleaning liquid in direct sunshine or near a source of

heat such as fire or stove. It may cause generation of heat which can

bring skin burn, etc.

14) Do not drink or drop in your eyes the cleaning liquid. It may cause

damage to your body.

15) Keep the cleaning liquid away from hands of the children.

1

Page 4

During the operation:

1) Do not use any other card but specified by Star Micronics Co., Ltd. It

may cause malfunction, failure, etc.

2) Do not use wet or oily stained card. Do not touch card with wet or

stained hand. It may cause malfunction, failure, etc. If the card gets

stained, please perform cleaning of the card and the unit. (For the cleaning of the unit, refer to Chapter 6. CLEANING.)

3) Keep the card away from magnetic source, such as magnet, speaker, TV,

etc. The data on the card may be damaged or erased.

4) Do not leave the card in high temperatures, such as inside of the car. It

may cause the bend of card, or erase the printed data on the card.

5) Do not insert bent card into the TCP100/2000 reader/writer. It may cause

the card jamming.

6) Do not insert the card in the unspecified direction. It may cause malfunction.

<Specified Direction>

[TCP110] [TCP192] [TCP2000]

7) Do not insert any other object into the TCP100/2000 reader/writer but

the specified card. It may cause failure, electric shock, etc.

8) Do not interrupt the card feeding procedure (inserting, discharging). It

may cause malfunction, or injury.

9) Do not turn off the power during the card processing. It may cause the

damage, or erase the data on the card.

2

Page 5

10) When the unusual (such as noise, stench, smoke, fire, etc.) is found, turn

off the power immediately. Then disconnect the plug. If the TCP100/

2000 reader/writer being kept using, it may cause failure, skin burn, etc.

Contact our sales/tech support team for repair.

11) Connect and disconnect the power cable only with power turned off and

while holding the plug. Do not put any heavy objects on the power

cable. Stop using the cable immediately if any damage or deformation

is found on it. Contact our sales/tech support team for repair.

12) Disconnect the power cable from socket, if the TCP100/2000 reader/

writer is not used for long time.

13) Do not use the TCP100/2000 reader/writer when the environment (such

as temperature, humidity) changes drastically. It may cause dew condensation which can bring malfunction, etc. Leave the TCP100/2000

reader/writer in the new environment at least for one hour, before restart.

14) Do not use the TCP100/2000 reader/writer under dew condensation. It

may cause malfunction, failure, electric shock, etc.

15) Clean the TCP100/2000 reader/writer everyday in order to maintain the

reliability . No cleaning may cause error operation. (Refer to Chapter 6

CLEANING.)

16) Do not disassemble, modify and repair the TCP100/2000 reader/writer

by yourself. It may cause malfunction, failure, injury, etc. Contact our

sales/tech support team for repair.

17) Do not leave the card in direct sunshine or a fluorescent light for long

time, as the card surface may get discolored.

18) In case the printed context is erased: It can be reprinted, if the data in the

magnetic stripe remains.

19) If the card gets stained: Unclean or oily card lowers the read/write and

print quality . In such a case, please clean the card and the unit. (For the

cleaning of the unit, refer to Chapter 6 CLEANING.)

20) If you use continuously the same card, please leave at least 3-minute

intervals. It is not necessary in the general operation; using different

cards one after another.

3

Page 6

2

The TCP100/2000 series is a reading/writing device for specified IC card or

reading device for ISO magnetic stripe type card.

It also has print/erase capability to human readable area on the surface of the

card. This series is compatible with most host computers and various P.O.S.

systems.

(TCP2000 series does not support for IC card.)

The main features of the TCP100/2000 series are as follows:

Model Name

OUTLINE

1. Reads/writes data from/to a magnetic stripe on the card (depends

on the model type).

2. Reads/writes data from/to IC chip on the card (TCP100 series only:

depends on the model type).

3. Prints/erases characters/graphics to/from a human readable area.

4. Serial interface of RS-232C(housed unit), or CMOS(mechanism

unit).

5. The human readable area of the card may be re-used up to approx.

500 times under the proper condition.

TCP110ZD Magnetic stripe read/write

3 lines human readable printing (upper part of a card)

Housed unit

TCP192TD Specified IC card read/write

3 lines human readable printing (lower part of a card)

Housed unit

TCP2000ZD Magnetic stripe read/write

Human readable wide printing on PET card

Housed unit

4

Page 7

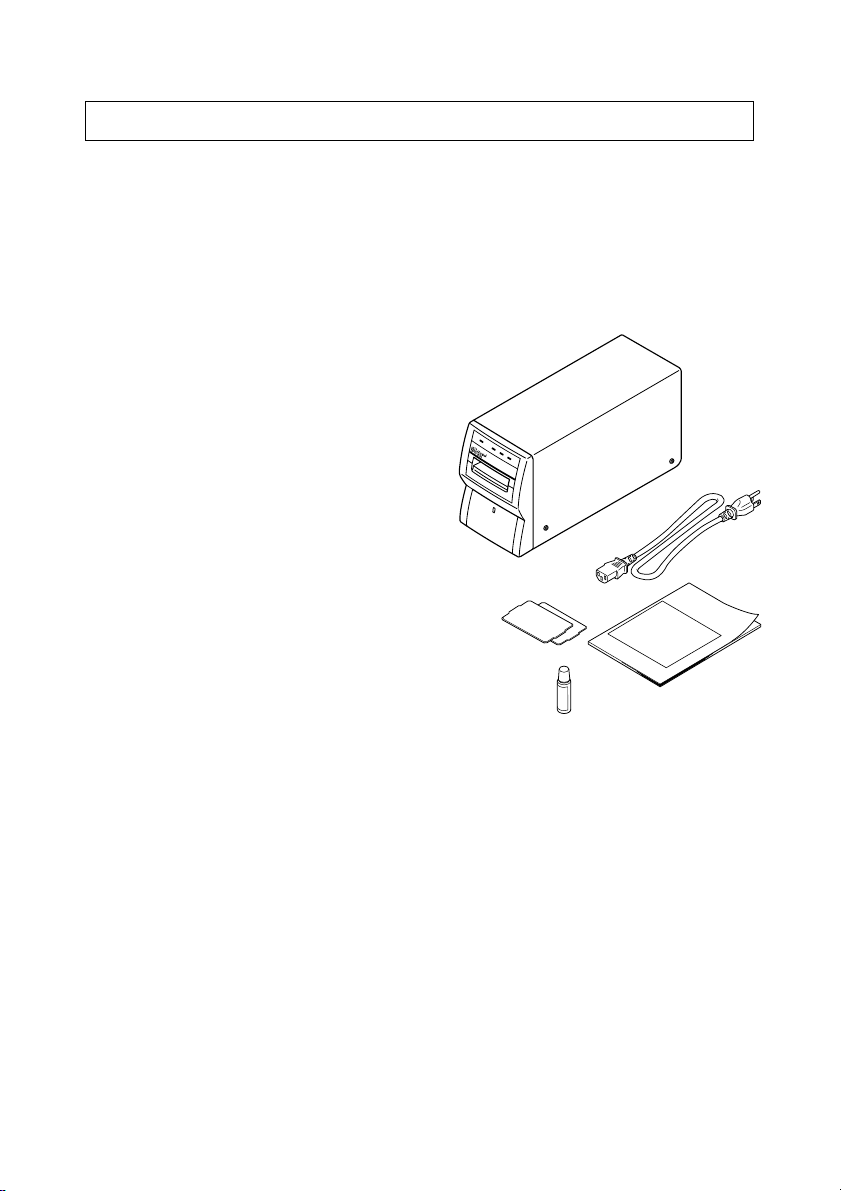

3

After unpacking the unit, check that all the accessories are included in the

individual box.

UNPACKING

Housed unit (TCP100/2000 series)

1 TCP100/2000 unit

2 Power cable

3 Cleaning cards (2 pcs)

4 Cleaning liquid

5 Installation Guide

(this manual)

&

Specifications

3

1

2

5

4

5

Page 8

4

APPEARANCE AND NOMENCLATURE

Housed unit TCP100/2000 series

4

3

5

6

9

1

2

[TCP100] [TCP2000 back]

0

0

8

7

8

A

7

1 Switch Cover This cover protects the power switch of the system.

Push to open and close.

2 Power Switch This switch turns the power of the system ON/OFF.

3 POWER LED This LED indicates that the power of the system is on.

4 READY LED This LED indicates that the card processing is ready.

5 OK LED This LED indicates that the card has been processed

without error.

6 ERROR LED This LED indicates that the card has not been read due

to an error e.g. jamming of the card in the reader/writer.

7

RS232C Serial Connector

This connector interfaces the connection between host

computers and the reader/writer.

8 AC Power Inlet Connect this inlet to the power source with the attached

AC power cable.

9 Cleaning Button Push this button under the power ON condition, then

insert the cleaning card which is soaked with the cleaning liquid.

0

Modular Connector

This interfaces the connection between MCD2000 (Star

original numerical key pad).

A

Interface convert switch

This switch changes the available interface : RS232C

(right side) or modular connector (left side).

IMPORTANT!

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

A three terminal earth grounded power supply cable is attached to TCP100/

2000 housed unit. For safety, do not remove the ground pin.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

6

Page 9

5

<Connecting the interface cable>

1 Turn OFF the power of the host computer and the reader/writer.

2 Plug in an end of the interface cable to the reader/writer connector and

3 Fasten two screws located at both the shoulders of the interface cable

4 Modular connector: Connects to Star original stand-alone terminal

CONNECTION TO EXTERNAL UNITS AND SETTING

(Housed unit TCP100/2000 series)

the other end to the serial port of the host computer.

connectors.

MCD2000 by specified cable.

Please set the interface convert switch to the left side.

Note) Do not connect to any external devices other than MCD2000.

[TCP100] [TCP2000]

<Serial Interface (RS-232C)>

1 Applicable connector : D-sub 9 pin (female)

2 Mating connector : D-sub 9 pin (male)

3 Connector terminals : See the table below

4 I/O circuit : See the table below

5 Level : RS232C

6 Cable : Cross (reverse) cable

Pin No. Signal name Direction Function

2 RXD IN Received data

3 TXD OUT Transmitted data

4 DTR OUT Data-terminal-ready (always ON after reset)

5 S-GND - Signal ground

6

7 RTS OUT Request-to-send (always ON after reset)

CTS/DSR IN Clear-to-send / Data-set-ready (no detection)

*

CTS is assigned to pin #8 at TCP2000.(no detection)

*

7

Page 10

6

CLEANING

6-1 Using the cleaning card

Two cleaning cards and one bottle of cleaning liquid for cleaning the magnetic head, rollers, etc. are supplied in the enclosed plastic bag.

(1) Dimensions of cleaning card

Felt surface

22.0

54.0

85.6

89.6

(2) Frequency of cleaning

1. Daily or every 300 times of printing.

2. When read/write errors occur continuously, or print quality gets low.

(3) How to use

1. Open the Front Cover and push the Cleaning Switch.

2. Apply penetration of the cleaning liquid to the felt surfaces (both sides)

of the cleaning card.

3. Insert the cleaning card from the card slot.

4. Allow the system approximately 1 minute for drying.

5. Ethel alcohol solvent may also be applied for cleaning.

Unit : mm

Felt surface

IMPORTANT!

Do not use the bent cleaning card.

Bent card will cause a card jam.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

8

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Cleaning switch

Front cover

Page 11

7

TROUBLE SHOOTING

Difficulties when the power is turned ON.

Symptom Possible cause Remedy

Power

LED lamp

does

notlight up.

Power

LED lamp

light up.

Card is not

accepted

Card is

accepted

Card is not

accepted

Card is

accepted,

but main

unit does

not

properly

run.

Power cable is not properly

plugged in.

Power cable is broken.

Power fuse is blown.

LED indicators are broken.

Trouble with the main unit.

Card failure

Flaw or bend of card,

loss of card data,

using other user’s card.

Head is stained.

System does not properly run.

Trouble with the main unit.

Properly plug in power

cable.

Consult technical

support.

Use applicable card.

Clean the head with

cleaning card.

Consult technical

support.

Difficulties during the operation

Symptom Possible cause Remedy

Card is not ejected. Card jamming Reset the power.

Card is not applicable.

Using other user’s card

Read/write error Card data is erased by

a magnetized source.

Card is bent.

Card has flaws.

Head is stained.

Use applicable card.

Issue new card.

Clean the head with

cleaning card.

9

Page 12

8

Card type PVC (thick card) PET (thin card)

Card feeding part Driving method Feed roller

Magnetic recording part ISO Track 1,2 : read ISO Track1, Track2,

IC recording part Physical ISO7816/1 compatible

Printing part Printed characters 24 characters×3 lines 20 characters×13 lines

Environment Installation place Indoor

condition

Reliability Unit service life 300,000 times under proper condition

Applicable card Specified thermal rewrite card

Power supply AC100V, 120V, 230V

Interface RS232C D-sub 9 pin

Weight Approx. 3.3Kg Approx. 3.5Kg

Dimension

GENERAL SPECIFICATIONS

TCP100 TCP2000

Card inserting Face up in one direction

direction

Card feed speed 350mm/s (high speed) 350mm/s (high speed)

40mm/s (low speed) 30mm/s (low speed)

Track 3 : read/write Track 3 : read/write

Characteristics

Size ISO7816/2 compatible

Signal/protocol Consult your supplier to

check the applicable IC

chip manufacturer and

model name

(480×320 dots)

Character font Alpha-numeric (standard),

Chinese characters (option), Graphics

Font configuration 12×24, 24×24, 48×24, 12×24, 24×24, 48×24

(dots) 24×48, 48×24 24×48, 48×48, 8×16

16×16, 32×16, 16×32

32×32

Dot pitch 0.1mm Vertically 0.125mm Vertically

0.1mm Horizontally 0.121mm Horizontally

Operating

temperature 5 to 35°C, 20 to 80%RH (no condensation)

and humidity

Storage

temperature -30 to 65°C, 20 to 90%RH (no condensation)

and humidity

Vibration 1.5G, 7 to 100Hz, XYZ direction each 1hr

resistance (when packed)

50/60Hz

(depends on the destination)

1 10(W)×143(H)×308(D) mm 110(W)×143(H)×326(D) mm

10

Page 13

Special Products Operating Div.

Card System Sales Section

536 Nanatsushinya, Shimizu, 424-0066, Japan

Tel: 81-543-47-0122 , Fax: 81-543-48-5013

http://www.star-micronics.co.jp

2000.07

59082055

Loading...

Loading...