Page 1

Dot Matrix Printer

SP300 Series

Programmer’s Manual

Page 2

Page 3

TABLE OF CONTENTS

1. CONTROL PANEL ..............................................................................1

1-1. Basic Operation ............................................................................1

1-2. Switch Operation (Combined Switch Operation) ........................2

2. SERIAL INTERFACE ..........................................................................7

2-1. Interface Specifications ................................................................7

2-2. Interface Circuit ...........................................................................8

2-2-1. RS-232C Serial Interface ..................................................8

2-2-2. Current Loop (option) .......................................................8

2-2-3. RS-422A Serial Interface (option) ....................................9

2-3. Connectors and Signals ..............................................................10

2-4. Interface Connections................................................................. 12

2-5. Installing the Optional Interface Board ......................................13

2-6. Data Structure.............................................................................14

2-6-1. DTR mode .......................................................................14

2-6-2. X-ON/X-OFF mode ........................................................16

2-6-3. STX-ETX mode ............................................................. 19

3. PARALLEL INTERFACE..................................................................22

3-1. Interface Specifications ..............................................................22

3-2. Interface Timing .........................................................................22

3-3. Connectors and Signals .............................................................. 24

4. Emergency Suspension........................................................................25

5. VALIDATION PRINTING (Models with validation function only) . 26

5-1. Operating Method ......................................................................26

5-2. Printing Format ..........................................................................27

5-3. Data format.................................................................................27

5-4. Other ........................................................................................... 27

6. AUTO CUTTER (Auto-cutting models only).....................................28

6-1. Cutting Method ..........................................................................28

6-2. Cutting position ..........................................................................28

6-3. Auto cutting control codes .........................................................28

6-4. Other position to be observed ....................................................28

Page 4

7. CONTROL CODES ............................................................................29

7-1. Control Codes Used for Character Setting .................................32

7-2. Control Codes Used for Line Spacing .......................................36

7-3. Control Codes Used for Page Layout......................................... 37

7-4. Control Codes Used for Graphics Printing ................................41

7-5. Control Codes Used for Download Characters ..........................46

7-6. Control Codes Used for Peripheral Units................................... 49

7-7. Other Control Codes .................................................................. 50

8. CHARACTOR CODE TABLES ...................................................... 55

8.1 U.S.A. & Europe (DIP SW2-1: ON, SW2-2: ON).....................55

8.2 IBM Character Set #1 (DIP SW2-1: OFF, SW2-2: ON) .......... 57

8.3 IBM Character Set #2 (DIP SW2-1: ON, SW2-2: OFF) ........... 59

8.4 JAPAN (DIP SW2-1:, OFF, SW2-2: OFF)................................61

8.5 International Character Sets .......................................................63

• For DIP switch settings, refer to Installation Manual.

• Models with validation function: SP312F, SP317F

Page 5

1. CONTROL PANEL

1-1. Basic Operation

1 “ON LINE” switch

POWER

3

ALARM

4

5

ON LINE

1

FEED

2

Fig. 1-1 Control panel

3 “POWER” lamp (green LED)

• Lights when the power for the printer is on.

4 “ALARM” lamp (red LED)

• Lights when the paper is out.

If the paper is out, load a new roll then press the “ON LINE” switch.

• Flashes when the front cover is open or a mechanical error (motor lock etc.)

occurs. The buzzer will give one short beep followed by a long beep.

Mount the front cover properly and press the “ON LINE” switch. If the

buzzer still sounds and the “ALARM” lamp flashes, this signifies that a

mechanical error has occurred. Locate the cause of the error and turn the

power for the printer off and back on again to reset the printer.

(In case of a mechanical error, the data will not be cleared even if the power

is turned off.)

5 “ON LINE” lamp (green LED)

LED lit: Printer is ON LINE

LED off: Printer is OFF LINE

LED flashes: Validation printing mode is set.

When all lamps 3 to 5 light simultaneously and the buzzer sounds continuously, a CPU error has occurred. In case of a CPU error, turn off the power then

turn it on again. When turning off the power, the data will be cleared.

Switches the printer between “ON

LINE” and “OFF LINE”. Whenever the printer switches between

“ON LINE” and “OFF LINE”, the

buzzer gives one short beep (“ON

LINE” and “OFF LINE”, switching

is possible only when the paper is

loaded in the printer.)

2 “FEED” switch

• When this switch is pressed and

then released within 0.5 sec.,the

paper feeds one line.

• When this switch is depressed for

more than 0.5 sec.,the paper feeds

continuously.

(The above paper feed operation

is possible for both “ON LINE”

and “OFF LINE” modes.)

– 1 –

Page 6

1-2. Switch Operation (Combined Switch Operation)

1 <SELF PRINT TEST>

FEED + POWER ON (Turn the power on while holding the FEED switch

depressed.)

Self-printing will be performed according to the VER. NO., DIP switch

settings and character order. When the FEED switch is held continuously

during self printing, only the characters will print out repeatedly.

In models with cutter, cutting will be done after self-printing is performed

according to the VER. NO., DIP switch setting and character order. When the

FEED switch is pressed after completed self-printing, character printing and

cutting will be repeatedly performed.

Fig. 1-2 Self printing sample (when using serial interface printer)

– 2 –

Page 7

2 <Hexadecimal dump mode>

ON LINE + POWER ON (Turn the power on while holding the ON LINE

switch depressed.)

Each of the signals sent from the computer to the printer will be printed out

in hexadecimal code.

This function allows you to check if a control code sent to the printer by the

program being used is correct or not. The buzzer will sound once to indicate

the printer is in hexadecimal dump mode.

After the program has been run, the last line buffer should be flushed by

pressing the ON LINE switch. To turn off the mode, it is necessary to turn off

the printer completely.

Fig. 1-3 Hexadecimal printing sample

3 <CLEAR PRINT BUFFER> (Single Head Only)

FEED + ON LINE + POWER ON (Turn the power on while holding both

the FEED and ON LINE switches depressed.)

This operation clears the printer buffer. (The buzzer gives two short beeps.)

When DIP switch 1-7 of this printer is set to ON (which is the factory presetting),

the RAM back-up function operates to maintain the data in the data buffer, even

if the power for the printer is shut off due to power failure, etc.

However, when the printer power is shut off for more than 10 hours, the data

content will become unstable and its content could degenerate and become unusable in the worst instances. For this reason, when the printer power is turned

off for more than 10 hours, perform the above operation to clear the data in the

data buffer.

Note that the data in the buffer can also be cleared by control code <CAN>.

4 <MICRO FEED>

ON LINE + FEED Press the FEED switch while holding the ON LINE

switch depressed when the printer is OFF LINE and the paper will feed in very

small increments.

– 3 –

Page 8

5 <PAGE TOP> (Sprocket-type Only)

ON LINE + FEED (Press the FEED button while holding the ON LINE

button depressed when the printer is ON LINE) The buzzer gives three short

beeps and the printer sets the page top.

6 <Dot alignment adjust mode> (Twin Head Only)

FEED + ON LINE + POWER ON

This mode enables adjustment of the forward and backward printed line alignment by 1/2-dot increments. The adjustment procedure is explained on the

following pages.

– 4 –

Page 9

1. Enter the Dot Alignment Adjust Mode by turning on the power while

pressing the ONLINE and FEED switches.

2. When Dot Alignment Adjust Mode starts, the buzzer will sound twice and

“Dot Alignment Adjust Mode” is printed.

3. Seven dot alignment patterns are printed as shown below. The patterns are

arranged with the backward printed lines more toward the left as the patterns

are printed down the page; the fourth pattern is the standard. The asterisk (*)

indicates the pattern printed with the current setting.

– 5 –

Page 10

4. To choose a pattern with a closer alignment of the forward and backward

printed lines, count from the top down to the desired pattern and press the

FEED switch the counted number of times. (The buzzer sounds each time the

FEED switch is pressed, up to a maximum of seven times. However, if the

FEED switch is pressed more than seven times, a warning sounds.)

5. Press the ONLINE switch after the setting is made. (If the power is turned off

before the ONLINE switch is pressed, the new setting becomes invalid.)

When the setting is entered, the buzzer sounds once and the chosen starting

position of the backward printed line is stored in the memory.

This setting does not change if the machine’s power is turned off.

A pattern using the selected setting and followed by “Adjust Completed!” is

printed.

If the ONLINE switch is pressed to end step 5 without changing the setting,

“Adjust Completed!” is printed and the mode is exited.

* To set the starting position of the backward printed line to 0, simultaneously

press the ONLINE and FEED switches in step 4. The mode automatically

continues on to step 5, then a pattern using the selected setting and followed

by “Adjust Completed!” is printed.

– 6 –

Page 11

2. SERIAL INTERFACE

2-1. Interface Specifications

1 Data transmission method: Asynchronous serial interface

2 Baud rate: Selectable from 150, 300, 600, 1200,

2400, 4800, 9600, 19200 (Twin Head

only) bps (Refer to Installation

Manual.)

3 Word length Start bit: 1 bit

Data bit: 7 or 8 bits (selectable. Refer

to Installation Manual.)

Parity bit: Odd, even or none

(selectable. Refer to Installation

Manual.)

Stop bit: 1 or 2 bit length

4 Signal polarity RS-232C (Standard feature)

MARK : Logic “1”(–3V to –25V)

SPACE : Logic “0” (+3V to +25V)

Current loop (optional)

MARK : Logic “1”(current ON)

SPACE : Logic “0” (current OFF)

RS-422A (Optional)

MARK : Logic “1”

A is –0.2V or less than B

SPACE : Logic “0”

A is 0.2V or more than B

Mark [1]

Space [0]

b0 b1 b2 b3 b4 b5 b6 (b7)

ABCD

A: Start bit

B: Data bits

C: Vertical parity bit

D: Stop bit

– 7 –

Page 12

2-2. Interface Circuit

2-2-1.RS-232C Serial Interface

Input (RXD, CTS)

Printer Host computer

75189 or equivalent

Output (DTR, FAULT, TXD, RCH, RTS)

Printer Host computer

75188 or equivalent

Fig . 2-1 RS-232C interface circuit

2-2-2.Current Loop (option)

Input (TTY-RXD, TTY-RXDR)

Printer

Output (TTY-TXD, TTY-TXDR)

Printer

R

R

+V

+V

Host computer

Host computer

Note: Adjust “R” so that the loop current is set within 10 to 20 mA.

Fig. 2-2 Current loop interface circuit

– 8 –

Page 13

2-2-3.RS-422A Serial Interface (option)

Input (RD, RS)

Printer Host computer

A

B

Output (SD, CS)

Printer Host computer

A

B

Fig. 2-3 RS-422A interface circuit

– 9 –

Page 14

2-3. Connectors and Signals

RS-232C

Pin no. Signal name

1 F-GND — Frame ground

2 TXD OUT Transmitted data

3 RXD IN Received data

4 RTS OUT Data transmission request signal. This is al-

5 CTS IN This signal changes to “SPACE” when

6 N/C Not connected

7 S-GND — Signal ground

8 N/C Not connected

9-10 N/C This pin is used when using the optional

11 RCH OUT This signal changes to “SPACE” when the

12 N/C Not connected.

13 S-GND — Signal ground

14 FAULT OUT When printer error occurs (such as paper

15

16

Multi-printer TXD

Multi-printer DTR

17 to 19 N/C This pin is used when using the optional

20 DTR OUT Data terminal ready signal. When the printer

21-22 N/C Not connected

23 to 25 N/C This pin is used when using the optional

I/O

direction

ways “SPACE” when the printer is turned on.

host computer is ready to transmit data. (In

this instance, the printer does not check this

signal.)

interface board.

printer is ready to receive data. (The signal

line is same as pin 20.)

out, mechanical error, etc.), this signal is

set to “MARK”.

OUT Diode coupled TXD

OUT Diode coupled DTR

interface board.

is ready to receive data, this signal changes

to “SPACE”.

interface board.

Function

14

1

Fig. 2-4 Serial interface connector

– 10 –

25

13

Page 15

20 mA current loop (option)

Pin no. Signal name

9 TTY TXDR — Indicates the ground side of the data signal

10 TTY TXD OUT Transmitted data of 20 mA current loop.

17 TTY TXDR — Indicates the ground side of the data signal

18 TTY RXDR — Indicates the ground side of the data signal

19 TTY RXD IN Received data of 20 mA current loop.

23 TTY RXDR — Indicates the ground side of the data signal

24 TTY TXD OUT Transmission data of 20 mA current loop.

25 TTY RXD IN Reception data of 20 mA current loop.

I/O

direction

Function

of 20 mA loop current.

of 20 mA loop current.

of 20 mA loop current.

at 20 mA loop current.

RS-422A (option)

Pin no. Signal name

9 SD (+) OUT Transmitted data

10 SD (–) OUT Transmitted data

17 RD (+) IN Received data

18 RD (–) IN Received data

19 CS (+) IN When the host computer is set to standby

23 CS (–) IN When the host computer is set to standby

24 RS (+) OUT Data transmission request signal. When the

25 RS (–) OUT Data transmission request signal. When the

I/O

direction

Function

for data transmission, this signal changes to

“SPACE”.

(In this instance, the printer does not check

the signal.)

for data transmission, this signal changes to

“SPACE”.

(In this instance, the printer does not check

the signal.)

printer is ready to receive data, this signal

changes to “SPACE”.

printer is ready to receive data, this signal

changes to “SPACE”.

– 11 –

Page 16

2-4. Interface Connections

The following is a basic example of interface connections. (For interface

connections, refer to the specifications for the respective interface.) IBM PC type

serial port is shown as example.

F-GND

TXD

RXD

RTS

CTS

S-GND

FAULT

DTR

F-GND

TXD

RXD

RTS

CTS

S-GND

FAULT

DTR

Board side

1

2

3

4

5

7

14

20

Board side

1

2

3

4

5

7

14

20

Shield

IBM PC side

25Pin

1

2

3

4

5

6

7

8

20

IBM PC side

9 Pin

1

2

3

4

5

6

7

8

9

F-GND

TXD

RXD

RTS

CTS

DSR

S-GND

DCD

DTR

DCD

RXD

TXD

DTR

S-GND

DSR

RTS

CTS

RI

Fig. 2-5 Example of interface connections for IBM PC

– 12 –

Page 17

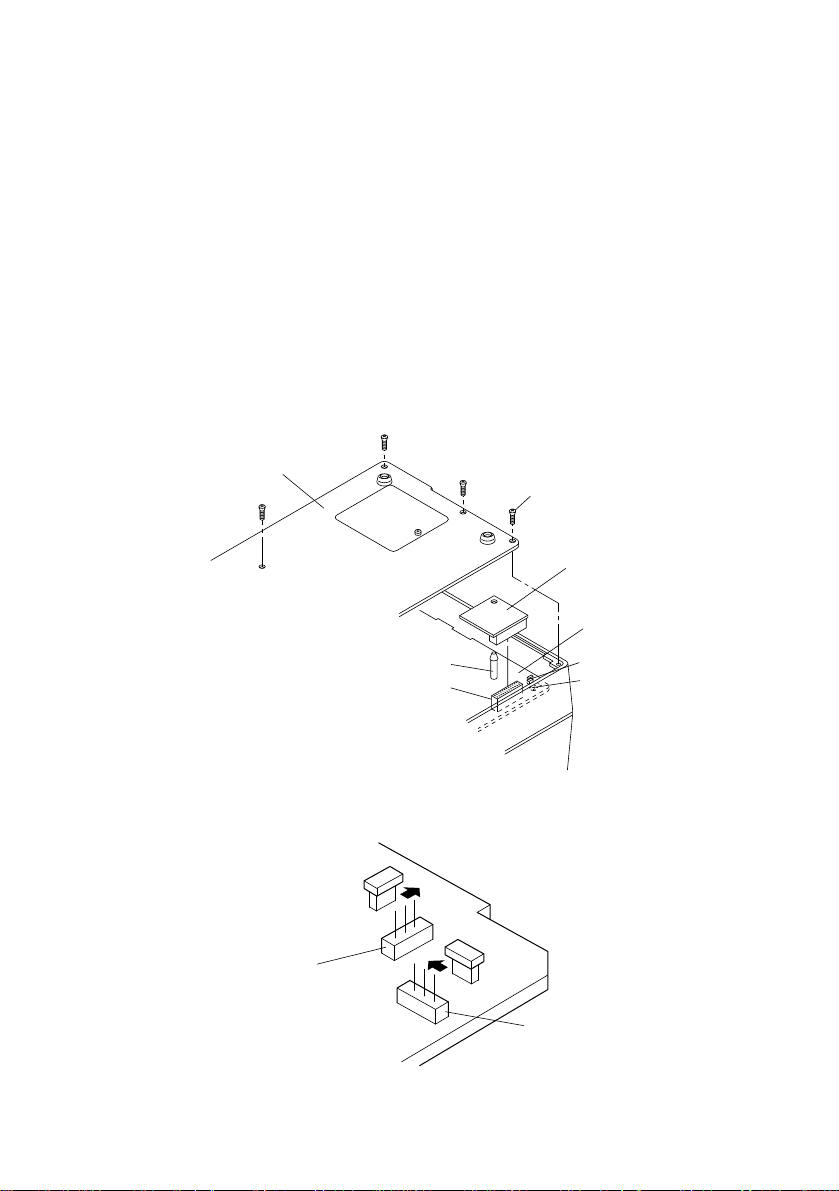

2-5. Installing the Optional Interface Board

Bottom cover

Screw

Optional interface board

Main logic board

SW5

SW6

Board support

CN9

When using the optional 20 mA current loop interface or the RS-422A interface,

the optional interface board must be mounted to the printer’s main logic board.

The following is the method of mounting the interface board to the printer’s main

logic board.

1 Remove the 6 screws on the bottom cover of the printer, then remove the

bottom cover.

2 Connect the optional interface board connector to connector CN9 on the

printer’s main logic board.

3 At the same time, insert the plastic board support of the main logic board into

the hole on the interface board.

4 Switch SW5 and SW6 on the main logic board from A-C to B-C.

5 Mount the bottom cover to the printer and fasten the 6 screws to fix it in place

on the printer.

Fig. 2-6 Installing the optional interface board

A C B

SW5

Fig. 2-7 Switch SW5 and SW6

A C B

– 13 –

SW6

Page 18

2-6. Data Structure

2-6-1.DTR mode

This mode is accessed when the DIP switch 3-5 is ON.

Signals are controlled using the DTR line as BUSY flag.

RXD

DTR

Printing

RXD

DTR

Printing

PAPER OUT signal

Power ON

When paper is out

Data Data Data

Buffer full Buffer empty

OFF LINE ON LINE

Paper out

Press the ON LINE switch after

loading paper.

Power ON

If a printer errors do not occur after the power is turned on, the DTR signal line

changes to “SPACE”.

When the host computer confirms that the DTR signal line is set to “SPACE”, the

host computer sends the data text via the RXD signal line to the printer. Also, the

printer will set the DTR signal line to “MARK” when the empty space in the data

buffer is below 256 bytes. After the host computer detects that the DTR signal line

is at “MARK”, transmission of the data text is sopped. In this instance, data can

still be received up until the data buffer becomes completely full.

When the empty space in the data buffer is increased following printing (when the

data in the data buffer is reduced to 256 bytes or less), the printer sets the DTR

signal line to “SPACE”.

– 14 –

Page 19

Data buffer

Full

Remainder

256 bytes

DTR “MARK” DTR “SPACE”

Near Full

Near Empty Empty

256 bytes

[Paper out]

When the “paper out’ detector senses the end of the paper, the printer stops

printing after printing a maximum of two more lines or on feeding the paper.

Immediately after a “paper out” condition is detected, the printer sets to OFF

LINE and the DTR changes to “MARK”. (To reset printer after a “paper out’, load

paper into the printer and press the ON LINE switch to set the printer to ON

LINE.)

[Mechanical error]

Mechanical errors are detected when the front cover is opened during printing, or

when the motor locks and the unit will not print. Immediately after a mechanical

error occurs, the printer sets the DTR to “MARK” and then sets the printer to OFF

LINE. To cancel a mechanical error, close the front cover properly and press the

ON LINE switch. If the buzzer sounds and the ALARM lamp flashes at this time,

then locate the cause of the error and turn the power for the printer off and back

on again to reset the printer.

[Status]

b7 b6 b5 b4 b3 b2 b1 b0

Constantly

set at “0”

– 15 –

Vertical parity error

1: error

Framing error

1: error

Mechanical error

1: error

Paper empty

1: empty

Buffer empty

1: empty

Buffer overflow

1: overflow

Compulsion switch

High level

(Switch is set to ON)

Page 20

[Framing error]

A framing error occurs when SPACE is detected at the stop bit. When a framing

error or a vertical parity error occurs for the data which is received, the printer

prints out a “?” mark to indicate that the error occurred.

[Compulsion switch]

When pin 6 of the peripheral unit drive circuit connector is set “HIGH”, status bit

7 becomes “1”.

2-6-2.X-ON/X-OFF mode

This mode accessed when the DIP switch 3-5 is OFF.

X–ON X–OFF X–OFF X–ON X–OFF X–OFF

X–OFF

TXD

X–OFF

X–ON

RXD

Printing

Paper out

signal

ON LINE

lamp

ON

OFF

Power ON Load paper and press

Data Data Data

Paper out

the ON LINE switch.

If printer errors do not occur after the power is turned on, the printer outputs an

X-ON (DC1 by control code; 11H by hexadecimal data) signal on the TXD signal

line which sends it to the host computer. When the host computer receives the XON signal, the host computer transmits the data to the RXD signal line for the

printer. If data text is not sent from the host computer (even after transmitting the

X-ON signal to the host computer), the printer outputs an X-ON signal at 3 second

intervals until the printer receives data.

The printer starts outputting an X-OFF (DC3, 13H) signal when the empty space

in the buffer reduces below 256 bytes. When the host computer receives the XOFF signal, it halts output of data. (however, the printer can continue receiving

data until the buffer becomes completely full.)

Output of the X-ON signal is resumed when the data in the buffer is printed out

and drops to below 256 bytes.

– 16 –

Page 21

Data buffer

Full

Remainder

256 bytes

X-OFF X-ON

Near Full

Near Empty Empty

256 bytes

[Paper out]

When the “paper out” detector senses the end of the paper, the printer stops

printing after printing a maximum of two more lines or on feeding the paper. The

printer will set the DTR to “MARK” and set the printer to OFF LINE five seconds

after a “paper out” condition is detected. To reset the printer after a “paper out”,

load a new roll of paper into the printer and press the OFF LINE switch to set the

printer ON LINE.

[Mechanical error]

Mechanical errors occur when the front cover is opened during printing and

printing stops or when the motor locks and printing stops. After the error occurs,

the printer outputs an X-OFF signal and stops printing. The printer sets the DTR

signal to “MARK” and sets to OFF LINE five seconds after a mechanical error

occurs. To reset the printer after a mechanical error occurs, close the front cover

properly and press the ON LINE switch. If a buzzer sounds and the ALARM lamp

flashes at this point, locate the cause of the error and turn the power off and then

back on to reset the printer.

– 17 –

Page 22

[Status]

b7 b6 b5 b4 b3 b2 b1 b0

0

Constantly

set at “0”

[Framing error]

A framing error occurs when SPACE is detected at the stop bit. When a framing

error or a vertical parity error occurs for the data which is received, the printer

prints out a “?” mark to indicate that the error occurred.

Vertical parity error

1: error

Framing error

1: error

Mechanical error

1: error

Paper empty

1: empty

Buffer empty

1: empty

Buffer overflow

1: overflow

Compulsion switch

High level

(Switch is set to ON)

[Compulsion switch]

When pin 6 of the peripheral unit drive circuit connector is set at “HIGH”, status

bit 7 becomes “1”.

– 18 –

Page 23

2-6-3.STX-ETX mode

This mode is accessed from whichever DTR mode or X-ON/X-OFF mode.

To set this mode, the data buffer must be empty.

The host computer sends an ENQ code to the printer and acknowledges the printer

status. Then, the host computer checks if the printer buffer is empty. After the host

computer detects that the buffer is empty, a STX code and data are transmitted.

After 1 block of data is transmitted, the host computer sends an ENQ code to the

printer and then receives the printer status and check byte (horizontal parity for

the printer.)

At this points, the host computer performs a status and horizontal parity check.

When the host computer determines that there was no error, it transmits an ETX

code which serves as text end code. After the printer receives the ETX code, data

in the data buffer is printed out. If an error occurs, a CAN code is transmitted by

the host computer. (In this instance, the data which was previously sent to the

buffer is cleared, thus, the host computer must retransmit the same data to the

printer.)

A flowchart of this operation is illustrated on the following page.

[Status]

b7 b6 b5 b4 b3 b2 b1 b0

0

Constantly

set at “0”

Vertical parity error

1: error

Framing error

1: error

Mechanical error

1: error

Paper empty

1: empty

Buffer empty

1: empty

Buffer overflow

1: overflow

Compulsion switch

High level

(Switch is set to ON)

[Framing error]

A framing error occurs when SPACE is detected at the stop bit. When a framing

error or a vertical parity error occurs for the data which is received, the printer

prints out a “?” mark to indicate that the error occurred.

– 19 –

Page 24

[Compulsion switch]

When pin 6 of the peripheral unit drive circuit connector is set at “HIGH”, status

bit 7 becomes “1”.

– 20 –

Page 25

Starts the

STX-ETX mode.

Sends an <ENQ>

Sends <ENQ>

Receives status byte.

NO

Is the data buffer

empty?

YES

Sends <STX>

Is an odd parity

check?

YES

(FF) H is set for the text

byte.

Acquires the exclusive OR of the content

of the text byte and the data to sent, then

it is used as the content of the test byte.

NO

The test byte is set at (0)H.

Receives status signal.

Receives a check byte.

Is the status an

error?

Horizontal

parity check

Ends the

STX-ETX mode.

NO

Check byte =

test byte?

YES

Sends <ETX>

(Printing)

YES

NO

Sends <CAN>

Transmits the data to

the printer.

NO

Is this the last data in

a block?

Is there a data block in

the STX-ETX mode?

YES

Check byte:

Horizotal parity of the printer.

Test byte:

Horrizontal parity of the host

computer.

YES

STX-ETX mode flow diagram for host computer

– 21 –

NO

RET

Page 26

3. PARALLEL INTERFACE

3-1. Interface Specifications

This printer has a parallel interface to communicate with the computer. The

operating specifications of the parallel interface are as follows.

(1) Data transfer rate : 1000 to 6000 characters per second

(2) Synchronization : Via externally supplied STROBE pulses

(3) Handshaking : ACK and BUSY signals

(4) Logic level : Compatible with TTL level

3-2. Interface T iming

A C K

About 9ms

Data

STROBE

BUSY

TTT

T:more than 0.5 microsec.

Fig. 3-1 Interface timing diagram

– 22 –

Page 27

Signal Name Circuit Example

74 HC Compatible4.7KW

DATA 1 – DATA 8

(To Printer)

4.7KW

INPUT

OUTPUT

STROBE

(To Printer)

BUSY, ACK

(From Printer)

74 HC Compatible4.7KW

100W

470pF

74 HC Compatible4.7KW

Fig. 3-2 Typical interface circuit

– 23 –

Page 28

3-3. Connectors and Signals

Pin no Signal name

1 STROBE IN Signals when data is ready to be read. Signal

2-9 DATA 1-8 IN These signals provide the information of the

10 ACK OUT A 9 microsecond LOW pulse acknowledges

11 BUSY OUT When this signal goes LOW, the printer is

12 PAPER OUT OUT This signal is normally LOW. It will go

13 SELECTED OUT This signal is HIGH when the printer is online.

14-15 N/C Unused

16

17

SIGNAL GND

CHASSIS GND

18 +5VDC +5VDC (Max 50mA)

19-30 GND Twisted pair return signal ground level.

31 RESET IN When this signal goes LOW, the printer is

32 ERROR OUT This signal is normally HIGH. This signal

33 EXT GND External ground.

34

COMPULSION

35-36 N/C Unused.

(19) (36)

Direction

goes from HIGH to LOW (for at least 0.5

microsec.) when data is available.

first to eighth bits of parallel data. Each signal

is at HIGH level for a logical 1 and at a LOW

level for a logical 0.

receipt of data.

ready to accept data. When the printer is in

one of the conditions below. “HIGH” is set.

1. Data being entered.

2. Off line.

3. Error condition.

HIGH if the printer runs out of paper.

Signal ground.

Chassis ground, isolated from logic ground.

reset to its power-on condition.

goes LOW to signal that the printer cannot

print due to an error condition.

Refer to Item 8-4 Emergency Suspension.

OUT Compulsion signal

Function

(1) (18)

Fig. 3-3 Parallel interface connector (printer side)

This connector mates with an

Amphenol 57-30360 connector

– 24 –

Page 29

4. EMERGENCY SUSPENSION

If any of the following errors is detected while the printer is operating, the printer

halts and ERROR signal turns to “LOW” level.

1 Mechanical errors

• Motor lock

• Defective of timing detector (signal not issued)

• Abnormal home position check.

• Defective cutter movement (paper jam, etc.)

• Timing error of Reset sig of the auto cutter during the auto cutter operation

(Auto-cutting models only)

• Abnormality of thermistor

To reset the emergency suspension, rectify the cause of trouble & adopt one of

the following 2 methods.

• Turn the printer power off and on again.

• Push ON LINE switch.

Even while in the status of no backed up RAM with DIP SW1-7, the RAM is

not cleared when power is turned OFF. Printing resumes from the line being

printed when the mechanism stopped. (Single Head Only)

2 If the front cover is opened while printing

If the front cover is opened while printing, the same operation as given in

above item “1 Mechanical errors” takes place. To restart printing, close the

front cover and push ON LINE switch.

3 CPU error

If CPU goes erratic due to external noise, etc., the printer halts, treating it as

CPU error. Normal operation can be resumed by turning ON the power supply

again, but the data contained in RAM gets cleared.

4 RAM Check Function

Before self-printing and when clearing the buffer, a RAM check is performed.

5 Procedures at Time of Power Interruption (Single Head Only)

When using the backed up RAM function in valid status, the data in the buffer

will be preserved even when there is a power interruption. When the power is

turned ON again, the power interruption message “

and printing will be resumed from the line where it was stopped.

– 25 –

” will be printed,

Page 30

5. VALIDATION PRINTING (Models with validation function only)

This printer can print one line of validation printing.

5-1. Operating Method

B

A

Adjust lever

A: Standard position (one sheet)

B: Validation printing or copying

Fig. 5-1 Position of the adjust lever

Rear cover

Front cover

1 Open the front cover, pull the adjust

lever one notch from standard position A toward the operation panel

side position B.

When you cannot find standard position A, push the lever as far as

possible toward the rear cover, and

pull it 2 notches after having pressed

it down. The lever is now in standard

position A.

2 Mount the front cover.

3 Set the printer for the validation

print mode. In this instance, the

buzzer gives tow short beeps.

4 Make sure that the ON LINE lamp

is flashing.

5 Align the right edge of paper with

the right end of the tear bar then

insert the paper from the top.

POWER

ALARM

ON LINE

FEED

Fig. 5-2 Loading the paper

6 The printer starts printing approx. 1

second after the paper is loaded.

7 When printing is completed, pull

the paper upward and remove it

from the printer.

Right end

of the tear bar

Note: When printing a roll paper, also

set the adjust lever at position B.

– 26 –

Page 31

5-2. Printing Format

Prints one line in 7 × 9 font normal printing.

32 columns (from the 5th to 36th columns)

Even if the setting for the paper width is changed by the DIP switch, the 32column format will not change.

5-3. Data format

<GS> <data> <LF>

5-4. Other

• The FEED and ON LINE switches will not operate normally during validation

printing.

• When the printer receives an immediate execution command for peripheral

units during validation printing, it executes the command when the validation

print mode is canceled.

• Modes in effect before the validation printing (such as emphasized printing,

inverted printing, expanded printing, and underlining) are invalid during

validation printing. But these become valid again after validation printing.

• Data received before a <GS> code is printed out when the printer receives the

<GS> code.

Paper sensor

position

Print area

52.8

100

Min. 120

Fig. 5-3 Print area

– 27 –

Approx.

17

Approx.

18

Approx.12

: m m

Min. 70

Page 32

6. AUTO CUTTER (Auto-cutting models only)

6-1. Cutting Method

Cuts recording paper into continuous forms connected at only one point remaining uncut between adjacent forms.

Only one sheet of paper can be cut each time.

6-2. Cutting position

The paper is cut approximately 21.7 mm above the printing head.

Center of printer

Partial cutting

with one uncut

point left

Fig. 6-1 Cutting method Fig. 6-2 Cutting position

Cutting position

Approx. 21.7mm

Printing head

position

6-3. Auto cutting control codes

<ESC> “d” “0” or <ESC> “d” <0>

<ESC> “d” “1” or <ESC> “d” <1>

Refer to the control codes of chapter 10.

6-4. Other position to be observed

1 When continuously cutting for more than 12 minutes, make a maximum of 10

cuttings per minute.

2 When using for a long time, paper dust will gather around the cutter.

Therefore, make sure to clean periodically. If paper dust is not removed,

normal paper feeding may become impossible.

– 28 –

Page 33

7. CONTROL CODES

Control Codes Used for Character Setting

Control codes

<ESC> “R” n 1B 52 n Select international character set 32

<ESC> “6” 1B 36 Select IBM character set #2 32

<ESC> “7” 1B 37 Select IBM character set #1 32

<ESC> “M” 1B 4D Select 7 × 9 (half dot) font 33

<ESC> “P” 1B 50 Select 5 × 9 (2 pulses + 1 dot) font 33

<ESC> “:” 1B 3A Select 5 × 9 (3 pulses + 1 dot) font 33

<SO> 0E Select expanded character mode 33

<DC4> 14 Cancel expanded character mode 34

<ESC> “W” “1” 1B 57 31

<ESC> “W” <1> 1B 57 31

<ESC> “W” “0” 1B 57 30

<ESC> “W” <0> 1B 57 30

<ESC> “E” 1B 45 Select emphasized print mode 34

<ESC> “F” 1B 46 Cancel emphasized print mode 34

<ESC> “-” “1” 1B 2D 31

<ESC> “-” <1> 1B 2D 01

<ESC> “-” “0” 1B 2D 30

<ESC> “-” <0> 1B 2D 00

<ESC> “_” “1” 1B 5F 31

<ESC> “_” <1> 1B 5F 01

<ESC> “_” “0” 1B 5F 30

<ESC> “_” <0> 1B 5F 00

<ESC> “4” 1B 34 Select highlighted print mode 35

<ESC> “5” 1B 35 Cancel highlighted print mode 36

<SI> 0F Select inverted print mode 36

<DC2> 12 Cancel inverted print mode 36

Hexadecimal

codes

Function Page

Select expanded character mode 34

Cancel expanded character mode 34

Select underline mode 35

Cancel underline mode 35

Select upperline mode 35

Cancel upperline mode 35

Control Codes Used for Line Spacing

Control codes

<LF> 0A Line feed 36

<CR> 0D Line feed (same as LF) 36

<ESC> “z” “1” 1B 7A 31

<ESC> “z” <1> 1B 7A 01

<ESC> “0” 1B 30 Set 1/8-inch line feed 37

<ESC> “a” n 1B 61 n Feed paper n lines 37

Hexadecimal

codes

Function Page

Set 1/6-inch line feed 36

– 29 –

Page 34

Control Codes Used for Page Layout

Control codes

<FF> 0C Page feed (form feed) 37

<ESC> “C” n 1B 43 n Set page length at n lines 37

<ESC> “C” <0> n 1B 43 00 n Set page length at n inches 37

<ESC> “B” n1 n2 1B 42 n1 n2 Set vertical tab positions 38

<VT> 0B Execute vertical tab 38

<ESC> “N” n 1B 4E n Set bottom margin 38

<ESC> “O” 1B 4F Cancel bottom margin 39

<ESC> “1” n 1B 6C n Set left margin 39

<ESC> “Q” n 1B 51 n Set right margin 39

<ESC> “D” n1 n2 1B 44 n1 n2 Set horizontal tab position 40

<HT> 09 Execute the horizontal tab 40

Hexadecimal

codes

Function Page

Control Code Used for Graphics Printing

Control codes

<ESC> “1” 1B 31 Set 7/72-inch line feed 41

<ESC> “A” n 1B 41 n Define n/72-inch line feed 41

<ESC> “2” 1B 32 Set n/72-inch line feed 41

<ESC> “J” n 1B 4A n One time line feed of n/72-inch 41

<ESC> “z” “0” 1B 7A 30

<ESC> “z” <0> 1B 7A 00

<ESC> “3” n 1B 33 n Set n/216-inch line feed simulation 42

<ESC> “y” n 1B 79 n Set n/144-inch line feed (Models with 1/44”

<ESC> “K” n1 <0> 1B 4B n1 00 8 dot single density bit image 42

<ESC> “L” n1 n2 1B 4C n1 n2 8 dot double density bit image 44

<ESC> “h” “1” 1B 68 31

<ESC> “h” <1> 1B 68 01

<ESC> “h” “0” 1B 68 30

<ESC> “h” <0> 1B 68 00

Hexadecimal

codes

Function Page

Set 1/12-inch line feed 41

-pitch paper feed mechanism only)

Select vertical expanded character mode 45

Cancel vertical expanded character mode 45

42

Control Codes Used for Download Characters

Control codes

<ESC> “&” <0> n1 n2 1B 26 00 n1 n2 Definition of down load characters 46

<ESC> “%” “1” 1B 25 31

<ESC> “%” <1> 1B 25 01

<ESC> “%” “0” 1B 25 30

<ESC> “%” <0> 1B 25 00

Hexadecimal

codes

Function Page

Enable download character set 47

Disable download character set 47

– 30 –

Page 35

Control Codes Used for Peripheral Units

Control codes

<ESC> <BEL> n1 n2 1B 07 n1 n2 Adjust drive pulse width for peripheral unit 1 49

<BEL> 07 Deferred drive command for peripheral unit 1 49

<FS> 1C Immediate drive command for peripheral unit 1 49

<SUB> 1A Immediate drive command for peripheral unit 2 50

<EM> 19 Immediate drive command for peripheral unit 1 50

Hexadecimal

codes

Function Page

Other Control Codes

Control codes

<RS> 1E Sound buzzer 50

<CAN> 18 Cancel print data in buffer & Initialize printer 50

<DC3> 13 Set deselect mode 51

<DC1> 11 Set select mode 51

<ESC> “U” “1” 1B 55 31

<ESC> “U” <1> 1B 55 01

<ESC> “U” “0” 1B 55 30

<ESC> “U” <0> 1B 55 00

<ESC> “@” 1B 40 Initialize printer 52

<ENQ> 05 Enquiry 53

<STX> 02 Enter STX-ETX mode 53

<ETX> 03 Terminate STX-ETX mode 53

<ESC> “d” “0” 1B 64 30

<ESC> “d” <0> 1B 64 00 Trigger auto-cutter drive

<ESC> “d” “1” 1B 64 31 (Auto-cutting models only)

<ESC> “d” <1> 1B 64 01

<GS>...<LF> 1D...0A Selection of validation characters

Hexadecimal

codes

Function Page

Select uni-directional print mode 52

Select bi-directional print mode 52

(Models with validation function only)

54

54

– 31 –

Page 36

7-1. Control Codes Used for Character Setting

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

FUNCTION

CODE

OUTLINE

NOTE

Select international character set

<ESC> “R” n

(1B)H (52)H n

(00)H n (08)H

Select the international character set corresponding to the

value set for n.

n =(00)

(01)

(02)

H: U.S.A. (03)H: England (06)H: Italy

H: France (04)H: Denmark (07)H: Spain

H: Germany (05)H: Sweden (08)H: Japan

The default international characters can also be set with DIP

switches, however, setting by control code takes priority over

setting by DIP switches.

Refer to chapter 11-5 “Code Table”

Select IBM character set #2

<ESC> “6”

H (36)H

(1B)

Selects IBM character set #2.

This code is only valid when the character code table set by

DIP switches 2-1 and 2-2 is IBM character set #1 or #2.

FUNCTION

CODE

OUTLINE

NOTE

Select IBM character set #1

<ESC> “7”

H (37)H

(1B)

Selects IBM character set #1.

This code is only valid when the character code table set by

DIP switches 2-1 and 2-2 is IBM character set #1 or #2.

– 32 –

Page 37

FUNCTION

CODE

Select 7 × 9 (half dot) font

<ESC> “M”

H (4D)H

(1B)

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

Selects 7 × 9 (half dot) font.

Refer to User’s manual for the maximum number of print

columns.

When the power of the printer is turned on, 7 × 9 (half dot)

printing is automatically selected.

This code valid only when received at the beginning of a line.

Select 5 × 9 (2 pulses = 1 dot) font

<ESC> “P”

H (50)H

(1B)

Selects 5 × 9 (2 pulses = 1 dot) font.

This code is valid only when received at the beginning of a

line.

Select 5 × 9 (3 pulses = 1 dot) font

<ESC> “:”

H (3A)H

(1B)

Selects 5 × 9 (3 pulses = 1 dot) font.

This code is invalid when using SP311F SP341F SP321S.

This code is valid only when received at the beginning of a

line.

FUNCTION

CODE

OUTLINE

Select expanded character mode

<SO>

H

(0E)

Data following this code is printed in double-width charac-

ters.

Same as <ESC> “W” “1” or <ESC> “W” <1>.

– 33 –

Page 38

FUNCTION

CODE

Cancel expanded character mode

<DC4>

H

(14)

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

Cancels expanded character mode set by <SO> or <ESC>

“W” “1” or <ESC> “W” <1> code. Data following this code

is printed out in normal size characters.

Same as <ESC> “W” “0” or <ESC> “W” <0>.

Select expanded character mode

<ESC> “W” “1” or <ESC> “W” <1>

H (57)H (31)H or (1B)H (57)H (01)H

(1B)

Data following this code is printed in double-width charac-

ters.

Same as <SO>.

Cancel expanded character mode

<ESC> “W” “0” or <ESC> “W” <0>

H (57)H (30)H or (1B)H (57)H (00)H

(1B)

Cancels expanded character mode set by <ESC> “W” “1” or

<ESC> “W” <1> or <SO> code. Data following this code is

printed out in normal size characters.

Same as <DC4>.

Select emphasized print mode

<ESC> “E”

H (45)H

(1B)

Data following this code is printed in the emphasized print

mode. In this mode, only uni-directional printing is performed.

FUNCTION

CODE

OUTLINE

Cancel emphasized print mode

<ESC> “F”

H (46)H

(1B)

Cancels emphasized print mode.

– 34 –

Page 39

FUNCTION

CODE

Select underline mode

<ESC> “-” “1” or <ESC> “-” <1>

H (2D)H (31)H or (1B)H (2D)H (01)H

(1B)

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

Data following this code is printed out underlined. (However,

the spaces generated by horizontal tab are not underlined.)

Cancel underline mode

<ESC> “-” “0” or <ESC> “-” <0>

H (2D)H (30)H or (1B)H (2D)H (00)H

(1B)

Cancels underlined mode.

Select upperline mode

<ESC> “_” “1” or <ESC> “_” <1>

H (5F)H (31)H or (1B)H (5F)H (01)H

(1B)

Data following this code is printed out with an upperline.

(However the spaces generated by horizontal tab are not

upperlined.)

Cancel upperline mode

<ESC> “_” “0” or <ESC> “_” <0>

H (5F)H (30)H or (1B)H (5F)H (00)H

(1B)

Cancels upperline mode.

Select highlighted print mode

<ESC> “4”

H (34)H

(1B)

OUTLINE

Prints with highlighted characters.

If an underline, upperline or inverted print command is input

while the highlighted print mode is in effect, the highlighted

mode will be canceled and the newly input command will be

executed. If a highlighted print command is received while

the underline, upperline or inverted print mode is in effect, the

previously set mode is canceled and the highlighted print

mode will be set.

– 35 –

Page 40

FUNCTION

CODE

Cancel highlighted print mode

<ESC> “5”

H (35)H

(1B)

OUTLINE

FUNCTION

CODE

OUTLINE

Cancels highlighted print mode.

Select inverted print mode

<SI>

H

(0F)

Data following this code is printed out in inverted characters.

This code is valid only when input at the beginning of a line,

thus, normal and inverted characters cannot be mixed in on

the same line.

FUNCTION

CODE

OUTLINE

Cancel inverted print mode

<DC2>

H

(12)

Cancels the inverted character mode. This code is valid only

when input at the beginning of a line.

7-2. Control Codes Used for Line Spacing

FUNCTION

CODE

OUTLINE

Line feed

<LF>

H

(0A)

Data in the line buffer is printed out and one line is fed. If data

does not exist before this code is received, the printer only

feeds one line.

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

Line feed (Same as LF)

<CR>

H

(0D)

Functions the same as an LF code.

When DIP SW 1-3 is set to ON, this code becomes invalid.

Set 1/6-inch line feed

<ESC> “z” “1” or <ESC> “z” <1>

H (7A)H (31)H or (1B)H (7A)H (01)H

(1B)

Line feed is set at 1/6-inch after this code is received.

– 36 –

Page 41

FUNCTION

CODE

Set 1/8-inch line feed

<ESC> “0”

H (30)H

(1B)

OUTLINE

FUNCTION

CODE

DEFINITION RANG

OUTLINE

Line feed is set at 1/8-inch after this code is received.

Feed paper n lines

<ESC> “a” n

H (61)H n

(1B)

1 n 127

After data in the line buffer is printed out, feeds the paper

n lines.

7-3. Control Codes Used for Page Layout

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

DEFINITION RANG

Page feed (form feed)

<FF>

H

(0C)

After data in the line buffer is printed out, feeds the paper to

the top of the next page.

Set page length at n lines

<ESC> “C” n

H (43)H n

(1B)

1 n 255 (default value friction: n =33

Sprocket: n =42)

OUTLINE

FUNCTION

CODE

DEFINITION RANG

OUTLINE

Sets page length at n lines.

Set page length at n inches

<ESC> “C” <0> n

H (43)H (00)H n

(1B)

1 n 127

Sets page length at n inches.

– 37 –

Page 42

FUNCTION

CODE

Set vertical tab positions

<ESC> “B” n1 n2...nk <0>

H (42)H n1 n2...nk (00)H

(1B)

DEFINITION RANGE

OUTLINE

NOTE

FUNCTION

CODE

OUTLINE

1 n1 < n2 < n3 <....< nk 255, 1 k 16

Cancels all current vertical tab positions and sets new vertical

tab positions at lines n1, n2, etc., where n1, n2, etc. are

numbers between 1 and 255. A maximum of 16 vertical tab

positions can be set. Tab positions must be specified in

ascending order; any violation of ascending order terminates

the tab position list. Standard termination is by the <0>

control code. Vertical tab positions are set in terms of the

current line spacing and do not move if the line spacing is

changed later.

If a tab set position <nk> is equivalent or smaller than

<nk–1> just preceding the tab set position, setting of vertical

tab is assumed as complete.

Execute vertical tab

<VT>

H

(0B)

Feeds the paper to the next vertical tab set position.

When a vertical tab is not set, line feed is not performed. If the

current line is at or below the last vertical tab set position, the

paper feeds to the top of the next page.

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

Page length

Set bottom margin

<ESC> “N” n

(1B)H (4E)H n

0 n 255 (Default n = 0)

Sets bottom margin to n lines.

Feeds the paper

automatically.

Bottom margin of n lines.

– 38 –

Page 43

FUNCTION

CODE

Cancel bottom margin

<ESC> “O”

H (4F)H

(1B)

OUTLINE

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

Cancels bottom margin.

Set left margin

<ESC> “1” n

H (6C)H n

(1B)

0 n (right margin –2)

Sets the left margin at column n in the current character pitch.

The left margin does not move if the character pitch is

changed later. The left margin must be at least two columns

to the left of the right margin and within the limits above.

Set right margin

<ESC> “Q” n

H (51)H n

(1B)

2 n (maximum no. of print columns)

Sets the right margin at column n in the current character

pitch. Column n becomes the last character position the line.

The right margin does not move if the character pitch is

changed later. The right margin must be within the limits

above.

Left end

Left margin n

Printing area

Right margin n columns

– 39 –

Page 44

FUNCTION

CODE

Set horizontal tab position

<ESC> “D” n1 n2...nk <0>

H (44)H n1 n2...nk (00)H

(1B)

DEFINITION RANGE

OUTLINE

NOTE

FUNCTION

CODE

OUTLINE

1 n1 < n2 < n3...< nk (Maximum print columns –1),

k 16

1

Cancels all current horizontal tab positions and sets new tab

positions at columns n1, n2, etc. in the current character pitch,

where n1, n2, etc. are numbers between 1 and (Maximum

print columns–1). The maximum number of horizontal tab

positions allowed is 16. The tab positions must be specified

in ascending order; any violation of ascending order terminates the tab position list. Standard termination is by the <0>

control code. To clear all tab positions, specify <ESC> “D”

<0>.

When the horizontal tab set position <nk> is equivalent or

smaller than <nk-1> which is the column just preceding the set

tab position, horizontal tab setting is assumed as complete.

Execute horizontal tab

<HT>

H

(09)

The print position skips to the next horizontal tab position in

line. If the current position is after the final horizontal tab

position that can be executed, this code is ignored. (Underlining and overlining do not take place in the spaces between

characters set with the horizontal tab function.)

– 40 –

Page 45

7-4. Control Codes Used for Graphics Printing

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

Set 7/72-inch line feed

<ESC> “1”

H (31)H

(1B)

Line feed is set at 7/72-inch after this code is received.

Define n/72-inch line feed

<ESC> “A” n

(1B)H (41)H n

0 n 85 (Default n = 12)

Line feed is defined at n/72-inch after this code is received.

This code sets the feed at n/72-inch with the <ESC> “2” code.

Set n/72-inch line feed

<ESC> “2”

H (32)H

(1B)

This code sets the line feed at a defined value with the <ESC>

“A” previously described.

One time line feed of n/72-inch

<ESC> “J” n

H (4A)H n

(1B)

DEFINITION RANGE

OUTLINE

FUNCTION

CODE

OUTLINE

1 n 255

This code activates the n/72-inch paper feed once.

Set 1/12-inch line feed

<ESC> “z” “0” or <ESC> “z” <0>

H (7A)H (30)H or (1B)H (7A)H (00)H

(1B)

Line feed is set at 1/12-inch after this code is received.

– 41 –

Page 46

FUNCTION

CODE

Set n/216-inch line feed simulation

<ESC> “3” n

H (33)H n

(1B)

DEFINITION RANGE

OUTLINE

1 n 255

Line feed is set at n/216-inch after this code is received.

According to the minimum paper feed pitch of the connected

mechanism, the amount of line feed is set as follows:

For 1/72”-pitch mechanisms: INT {(n/3)}/72-inch.

For 1/144”-pitch mechanisms: INT {(2n/3)+0.5}/144-inch.

FUNCTION

CODE

Set n/144-inch line feed

<ESC> “y” n

(1B)

DEFINITION RANGE

OUTLINE

1 n 255

Line feed is set at n/144-inch after this code is received.

* 1/72-inch type mechanism only

FUNCTION

CODE

8 dot single density bit image

<ESC> “K” n1 <0> m1 m2 ...

(1B)

DEFINITION RANGE

OUTLINE

1 n1 200

Excutes 8 dot bit image print determined by “n1”. The total

number of bit image data bytes in one line is equal to n1.

The printer ignores any data bytes over the specified amount

allowed in one line. When the bit image print is finished the

printer automatically returns to the character mode.

H (79)H n

H (4B)H n1 (00)H m1 m2 ...

Dot Position

1

2

3

4

5

6

7

8

9 (Not Used)

– 42 –

Image data

MSB LSB

D8D7D6D5D4D3D2D

1

Page 47

m1 m2 m3 m4 m5 m6 m7 m8 m9

m10 m11 m12 m13 m14 m15 m16 m17 m18 m19 m20 m21 m22 m23 m24 m25 m26 m27 m28 m29 m30

D8

D7

D6

D5

D4

D3

D2

D1

EXAMPLE

Actually, let us consider printing as a means of bit image. We

will create the design below using bit image.

Printing Samples

First, since the volume of data is 30, n1 = (1E)

H. If the data m1

~ m30 is converted to hexadecimal, it appears as shown

below.

Data Binary

Hexa-

decimal

m1 00000001 01

m2 00011110 1E

m3 00111110 3E

m4 01011111 5F

m5 00011111 1F

m6 01011110 5E

m7 00011110 1E

m8 00111111 3F

m9 00101111 2F

m10 00111110 3E

Data Binary

Hexa-

decimal

m11 00111110 3E

m12 00000010 02

m13 00000010 02

m14 00111110 3E

m15 00111110 3E

m16 00101111 2F

m17 00101111 2F

m18 00111110 3E

m19 00101110 2E

m20 00101110 2E

Data Binary

m21 00111110 3E

m22 00101110 2E

m23 00101110 2E

m24 00111110 3E

m25 00101111 2F

m26 00101111 2F

m27 00111110 3E

m28 00111110 3E

m29 00000010 02

m30 00000010 02

Hexa-

decimal

– 43 –

Page 48

FUNCTION

CODE

8 dot double density bit image

<ESC> “L” n1 n2 m1 m2...

H (4C)H n1 n2 m1 m2...

(1B)

DEFINITION RANGE

OUTLINE

NOTE

1 n1 + 256 × n2 400

Executes double density bit image printing (half-dot print-

ing) determined by “n1” and “n2”. The total number of bit

image data bytes in one line is equal to n1 + n2 × 256. Refer

to <ESC> K as to the relation between the dot position and the

bit number. The printer ignores any data bytes over the

specified amount allowed in one line.

The printer does not print adjacent dots. When the bit image

printing is finished, the printer automatically returns to the

character mode.

For double density bit image printing, dots cannot be printed

overlapping each other in the horizontal direction.

The following is an example of this.

Printing Possible

m2 m4 m6 m8 m10

m1 m3 m5 m7 m9m11

D

8

D

7

D

6

D

5

D

4

D

3

D

2

D

1

Printing not Possible

m2 m4 m6 m8 m10

m1 m3 m5 m7 m9m11

D

8

D

7

D

6

D

5

D

4

D

3

D

2

D

1

Over lapping

horizontally

Over lapping

horizontally

When printing one graphic image of a minimum of two lines

with <ESC> K or <ESC>L, feed the paper a minimum of one

line before printing so that the line spacing becomes identical

between the lines.

– 44 –

Page 49

FUNCTION

CODE

Select vertical expaned character mode

<ESC> “h” “1” or <ESC> “h” <1>

H (68)H (31)H or (1B)H (68)H (01)H

(1B)

OUTLINE

NOTE

FUNCTION

CODE

OUTLINE

Prints characters two times the normal vertical size after the

code is received.

However, the bit image mode <ESC> “K” and <ESC> “L”

are excluded.

(1) When combined with the <SO> code, this code enables

printing of the characters in two times the normal vertical

and horizontal size.

(2) This code is not combined with the inverted print mode

<SI> code.

(3) For the 6 × 12 dots IBM block graphic (the characters

code table (B0)

H-(DF)H and (F4)H-(F5)H of IBM charac-

ter set #1 and #2) of the font construction, vertical

enlargement is not available.

(4) The relationship of the vertically enlarged character and

the normal character is matched at the lower level.

(5) Feed the paper a minimum of one line before printing

with this code.

Cancel vertical expanded character mode

<ESC> “h” “0” or <ESC> “h” <0>

H (68)H (30)H or (1B)H (68)H (00)H

(1B)

Cancels vertical expanded character mode

– 45 –

Page 50

7-5. Control Codes Used for Download Characters

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

Pin No.

1

2

3

4

5

6

7

8

9

Definition of download characters

When the 7 × 9 (half dot) font is set (default setting):

<ESC> “&” <0> n1 n2 [m0 m1 m2 m3 m4 m5 m6 m7]

n2 – n1 + 1

(1B)H (26)H (00)H n1 n2 [m0 m1 m2 m3 m4 m5 m6 m7]

n2 – n1 + 1

When the 5 × 9 font is set:

<ESC> “&” <0> n1 n2 [m0 m1 m2 m3 m4 m5]

n2 – n1 + 1

(1B)H (26)H (00)H n1 n2 [m0 m1 m2 m3 m4 m5] n2 – n1 + 1

(21)H n1 n2 (7F)H, m0 = (00)H or m0 = (80)H

Defines download characters

Up to 10 download characters can be defined and the defined

character patterns can be stored in the printer’s RAM.

Defining of download characters begins with character code

n1 and completes with n2. When only one character is

defined, n1 = n2.

m0 indicates the relationship between the character pattern

and print head.

m1 = m2...Indicate the character pattern

When m0=(00)H

MSB

D8 D7 D6 D5 D4 D3 D2 D1

(Not Used)

LSB

Pin No.

1

2

3

4

5

6

7

8

9 (Not Used)

When m0=(80)H

MSB

D8 D7 D6 D5 D4 D3 D2 D1

LSB

NOTE

When the 7 × 9 (half dot) font is set (the default setting),

printing of adjacent horizontal dots is not allowed.

Printing possible

m2 m4 m6

m1 m3 m5 m7

D8

D7

D6

D5

D4

D3

D2

D1

– 46 –

Printing not possible

m2 m4 m6

m1 m3 m5 m7

D8

D7

D6

D5

D4

D3

D2

D1

Over lapping

horizontally

Over lapping

horizontally

Page 51

FUNCTION

CODE

Enable download character set

<ESC> “%” “1” or <ESC> “%” <1>

H (25)H (31)H or (1B)H (25)H (01)H

(1B)

OUTLINE

FUNCTION

CODE

OUTLINE

EXAMPLE

Enables the download character set

Download characters defined by the ESC & 0 code cannot be

printed until enabled by this command.

Disable download character set

<ESC> “%” “0” or <ESC> “%” <0>

H (25)H (30)H or (1B)H (25)H (00)H

(1B)

Disables the selected download character set and selects the

built-in character set. When the power of the printer is

initially turned on, the built-in character set is selected.

To print a download character when the 7 × 9 (half dot) font

character size is set.

(1) Design the download character to be used at code posi-

tions (21)

H, (22)H, and (23)H.

m2 m4 m6

m1 m3 m5 m7

D8

D7

D6

D5

D4

D3

D2

D1

Char. Code=(21)H Char. Code=(22)H Char. Code=(23)H

m1 m3 m5 m7

D8

D7

D6

D5

D4

D3

D2

D1

m2 m4 m6

m1 m3 m5 m7

D8

D7

D6

D5

D4

D3

D2

D1

m2 m4 m6

(2) Define the download characters.

When character codes where the download character is

written are specified as (21)H, (22)H, (23)H, n1 = (21)H, n2

H are obtained.

=(23)

If the relationship between the character pattern data and

printing head is specified to “not use pin 9”, m0 = (80)

H is

obtained. When data m1 to m7 are converted into hexadecimal data, they are indicated as follows.

– 47 –

Page 52

Data Binary

m1 10100000 A0

m2 00000000 00

m3 10100000 A0

m4 00011111 1F

m5 10100000 A0

m6 00000000 00

m7 10100000 A0

Example of transmitting data

Hexa-

Data Binary

decimal

m1 10011000 98

m2 01100100 64

m3 10000010 82

m4 00000001 01

m5 10000010 82

m6 01100100 64

m7 10011000 98

Hexa-

decimal

Data Binary

Hexa-

decimal

m1 00111000 3C

m2 01000010 42

m3 10100101 A5

m4 00000000 00

m5 10100101 A5

m6 01000010 42

m7 00111000 3C

Printing Samples

(1) Definition of down-

load characters

(2) Selecting the down-

load character set

(3) Character codes

(4) Canceling the down-

load character set

(5) Character codes

(1B)H (26)H (00)H (21)H (23)H (80)H

(A0)H (00)H (A0)H (1F)H (A0)H (00)H

(A0)H (80)H (98)H (64)H (82)H (01)H

(82)H (64)H (98)H (80)H (3C)H (42)H

(A5)H (00)H (A5)H (42)H (3C)H

(1B)H (25)H (31)H

(21)H (22)H (23)H (0A)H

H (25)H (30)H

(1B)

(21)H (22)H (23)H (0A)H

– 48 –

Page 53

7-6. Control Codes Used for Peripheral Units

ON

OFF

10 × n1 (ms) 10 × n2 (ms)

Printing and paper feed

are prohibited.

FUNCTION

CODE

DEFINITION RANGE

OUTLINE

NOTE

Adjust drive pulse width for peripheral unit 1

<ESC> <BEL> n1 n2

H (07)H n1 n2

(1B)

1 n1 127, 1 n2 127 (default setting n1 = n2 = 20)

Adjusts drive pulse width for peripheral devices requiring

other than standard 200 ms pulse time and delay time

Energizing time = 10 × n1 (ms)

Delay time = 10 × n2 (ms)

Executed by <BEL>, <FS> codes.

Adjustment is not necessary for standard cash drawers in the

U.S.A. market.

FUNCTION

CODE

Deferred drive command for peripheral unit 1

<BEL>

(07)

OUTLINE

FUNCTION

CODE

Executes drive pulse for peripheral unit 1 (deferred).

Immediate drive command for peripheral unit 1

<FS>

(1C)

OUTLINE

Executes drive pulse for peripheral unit 1 (immediate).

This code differs from the <BEL> code as follows:

When the printer receives an <FS> code, the command is

executed immediately. The <BEL> code is stored in the data

buffer in the same manner as other codes, and executed in the

order in which they are received.

H

H

– 49 –

Page 54

FUNCTION

CODE

Immediate drive command for peripheral unit 2

<SUB>

H

(1A)

OUTLINE

Drives peripheral unit 2. Pulse width is fixed at 200ms with

a fixed delay time of 200 ms.

When the printer receives a <SUB> code, the command is

executed immediately. Same as <EM>

NOTE

FUNCTION

CODE

OUTLINE

Peripheral units 1 and 2 cannot be driven simultaneously.

Immediate drive command for peripheral unit 2

<EM>

H

(19)

Dives peripheral unit 2. Pulse width is fixed at 200 ms with

a fixed delay time of 200 ms.

When the printer receives a <EM> code, the command is

executed immediately. Same as <SUB>.

NOTE

Peripheral units 1 and 2 cannot be driven simultaneously.

7-7. Other Control Codes

FUNCTION

CODE

OUTLINE

Sound buzzer

<RS>

H

(1E)

A short alarm is generated by the printer.

FUNCTION

CODE

OUTLINE

Cancel print data in buffer & Initialize printer

<CAN>

H

(18)

Clears the data buffer and line buffer and initializes (<ESC>

“@”) all commands already set. However, the following

parameters are not initialized: external device drive pulse

width setting, operation switch valid/invalid selection, online

switch valid/invalid selection.

For a serial interface printer, the select/deselect state for

addressable mode and DC1/DC3 mode is not affected.

In STX-ETX mode, this CAN code clears the data between

STX and ETX and the line buffer, but does not initialize the

commands.

– 50 –

Page 55

FUNCTION

CODE

Set deselect mode

<DC3>

H

(13)

OUTLINE

FUNCTION

CODE

(1) When using serial interface printer:

This function differs depending on the setting of DIP

switch 4.

a) When the DC1, DC3 invalid mode is set (DIP switches

4-1 to 4-4 are all set to ON), the printer ignores this code.

b) In the DC1, DC3 valid mode (with DIP switches 4-1

to 4-4 set to OFF), data following this code is ignored

when the printer receives a <DC3> code.

The deselect mode is canceled by <DC1> code.

c) If the printer receives a <DC3> code during an

addressable mode (with DIP switches 4-1 to 4-4 set to

settings other than a) and b) above,), the data following this code is ignored.

Deselect mode can be canceled by a <DC1> n code.

Note that addressable mode is valid only when the RS422A interface option is installed.

(2) When using parallel interface printer;

Data following this code is ignored when the printer

receives a <DC3> code.

The deselect mode is canceled by <DC1> code.

Set select mode

When using serial interface printer;

<DC1> or <DC1>n

H or (11)H n

(11)

When using parallel interface printer

<DC1>

H

(11)

OUTLINE

(1) When using serial interface printer;

This function differs depending on the setting of DIP

switch 4.

a) When the DC1, DC3 invalid mode is set (DIP switches

4-1 to 4-4 are all set to ON), the printer ignores this code.

b) In the DC1, DC3 valid mode (with DIP switches 4-1

to 4-4 set to OFF), when the printer receives a <DC1>

code, the deselect mode is canceled and data following this code is input to the buffer.

– 51 –

Page 56

c) If the printer receives a <DC1> n code (n is the DIP

switch controlled address) during the addressable

mode (with DIP switches 4-1 to 4-4 set other than

settings a) and b) above,), the deselect mode is canceled

and data following this code is input to the buffer.

Note that addressable mode is valid only when optional RS-422A interface is installed.

(2) When using parallel interface printer;

When the printer receives a <DC1> code, the deselect

mode is canceled and data following this code is input to

the buffer.

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

Select uni-directional print mode

<ESC> “U” “1” or <ESC> “U” <1>

H (55)H (31)H or (1B)H (55)H (01)H

(1B)

Prints only when the print head moves from left to right.

Select bi-directional print mode

<ESC> “U” “0” or <ESC> “U” <0>

H (55)H (30)H or (1B)H (55)H (00)H

(1B)

Returns to the standard bi-directional print mode. (This mode

is set automatically when the printer power is turned on.)

Initialize printer

<ESC> “@”

H (40)H

(1B)

Initializes all the commands already set. However the follow-

ing parameters are not initialized: eternal device drive pulse

width setting, operation switch valid/invalid selection, online

switch valid/invalid selection. Also, the line and data buffers

are not cleared and the DIP switches are not read in again.

For a serial interface printer, the select/deselect state for

addressable mode and DC1/DC3 mode is not affected.

– 52 –

Page 57

FUNCTION

CODE

Enquiry

<ENQ>

H

(05)

OUTLINE

NOTE

FUNCTION

CODE

OUTLINE

FUNCTION

CODE

OUTLINE

This code is valid when using serial interface printer.

Online in STX-ETX mode: The printer sends the status data

and the check byte to the host computer.

Online in any other mode: The printer sends only the status

data to the host computer.

Offline in any mode: The printer only sends the status data to

the host computer if there is a mechanical error in the status

bit, or if the paper out or power down bit is set.

When IBM character set #2 is selected by character code,

codes <ENQ> does not exist. (In this instance, select another

code.)

U.S.A. & Europe IBM #1 IBM #2 Japan

(05)H <ENQ> <ENQ> ♣ <ENQ>

Enter STX-ETX mode

<STX>

H

(02)

This code is valid when using serial interface printer.

STX-ETX mode is set.

Terminate STX-ETX mode

<ETX>

(03)H

This code is valid when using serial interface printer.

Terminates the STX-ETX mode and prints out the text data.

NOTE

When IBM character set #2 is selected by character code,

codes <ETX> does not exist. (In this instance, select another

code).

U.S.A. & Europe IBM #1 IBM #2 Japan

(03)H <ETX> <ETX> ♥ <ETX>

– 53 –

Page 58

FUNCTION

CODE

Trigger auto-cutter drive (Auto-cutting models only)

<ESC> “d” “0” or <ESC> “d” <0>

H (64)H (30)H or (1B)H (64)H (00)H

(1B)

<ESC> “d” “1” or <ESC> “d” <1>

H (64)H (31)H or (1B)H (64)H (01)H

(1B)

OUTLINE

FUNCTION

CODE

OUTLINE

NOTE

This code causes the printer to trigger auto-cutter.

Select validation printing (Models with validation function

only)

<GS> data <LF>

H data (0A)

(1D)

Prints up to 32 columns of the 7 × 9 (half dot) font size

characters on one line.

(1) Character data and immediate execution command

<CAN> <SUB> <LF> are valid for data.

(2) Printing modes (such as emphasized, inverted, expanded

character modes, etc.) which were set before validation

printing are invalid during validation printing. (These

modes become valid again after validation printing is

completed.)

(Refer to “5. VALIDATION PRINTING”)

– 54 –

Page 59

8. CHARACTER CODE TABLES

8.1 U.S.A. & Europe (DIP SW2-1: ON, SW2-2: ON)

– 55 –

Page 60

– 56 –

Page 61

8.2 IBM Character Set #1 (DIP SW2-1: OFF, SW2-2: ON)

– 57 –

Page 62

– 58 –

Page 63

8.3 IBM Character Set #2 (DIP SW2-1: ON, SW2-2: OFF)

– 59 –

Page 64

– 60 –

Page 65

8.4 JAPAN (DIP SW2-1:, OFF, SW2-2: OFF)

– 61 –

Page 66

– 62 –

Page 67

8.5 International Character Sets

– 63 –

Page 68

MEMO

Page 69

Page 70

ELECTRONIC PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinnya, Shimizu, Shizuoka,

424-0066 Japan

Tel: 0543-47-0112, Fax: 0543-48-5013

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

1150 King Georges Post Road, Edison,

NJ 08837-3729 U.S.A.

Tel: 732-623-5555, Fax: 732-623-5590

Please access the following URL

http://www.star-micronics.co.jp/service/frame_sp_spr_e.htm

for the lastest revision of the manual.

STAR MICRONICS U.K. LTD.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks, HP13 7DL, U.K.

Tel: 01494-471111, Fax: 01494-473333

Printed in Japan, 80872005

2000.11.30

Loading...

Loading...