Page 1

DOT MATRIX PRINTER

SP200F SERIES

USERS MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a

shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

Manufacturer’s Declaration of Conformity

CE

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the

Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the

European Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

SP200F Series: Star Micronics Co. Ltd.

VeriFone: VeriFone, Inc.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 1994, 1999 Star Micronics Co., LTD.

Page 3

TABLE OF CONTENTS

1. Outline ...............................................................................................................1

2. Unpacking and Installation................................................................................2

2-1. Unpacking ..............................................................................................2

2-2. Locating the printer ................................................................................3

2-3. Handling Care ........................................................................................3

2-4. Maintenance ........................................................................................... 3

3. Parts Identification and Nomenclature ..............................................................4

4. Loading the Ribbon Cartridge and Paper ..........................................................6

4-1. SP210 type .............................................................................................6

4-2. SP240 type .............................................................................................9

4-3. Removing the Paper .............................................................................14

4-4. Connecting the Interface Cable............................................................14

5. Control Panel ...................................................................................................16

5-1. Basic Operation....................................................................................16

5-2. Switch Operation (Combined Switch Operation) ................................17

6. Control Codes ..................................................................................................19

STAR mode..................................................................................................19

6-1. Control Codes Used in Character Setting ............................................19

6-2. Control Codes Used in Print Mode Setting..........................................19

6-3. Control Codes Used in Line Spacing...................................................19

6-4. Control Codes Used for Peripheral Units ............................................20

6-5. Auto Cutter Control .............................................................................20

6-6. Other Control Codes ............................................................................20

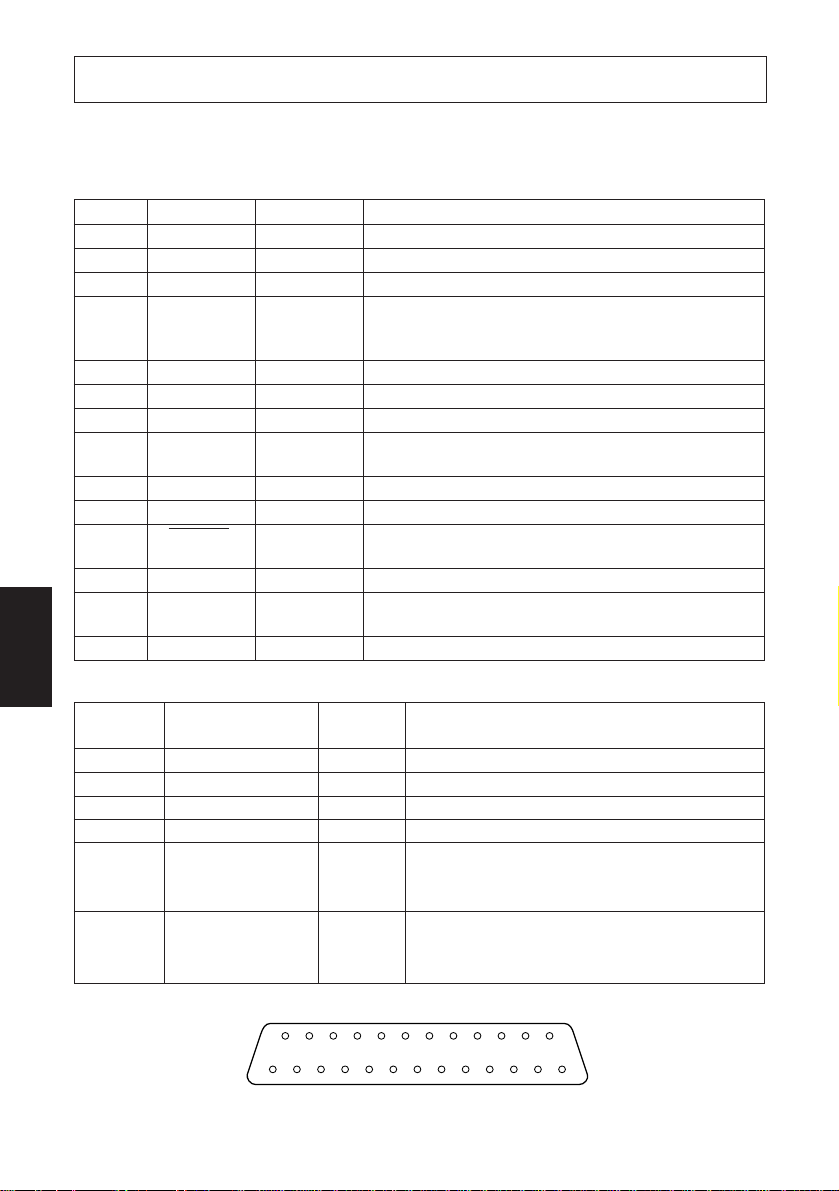

Appendix A: Serial Interface...............................................................................87

A-1. Connectors and Signals ........................................................................87

A-2. Interface Connections ..........................................................................88

A-3. Dip Switch Setting ...............................................................................89

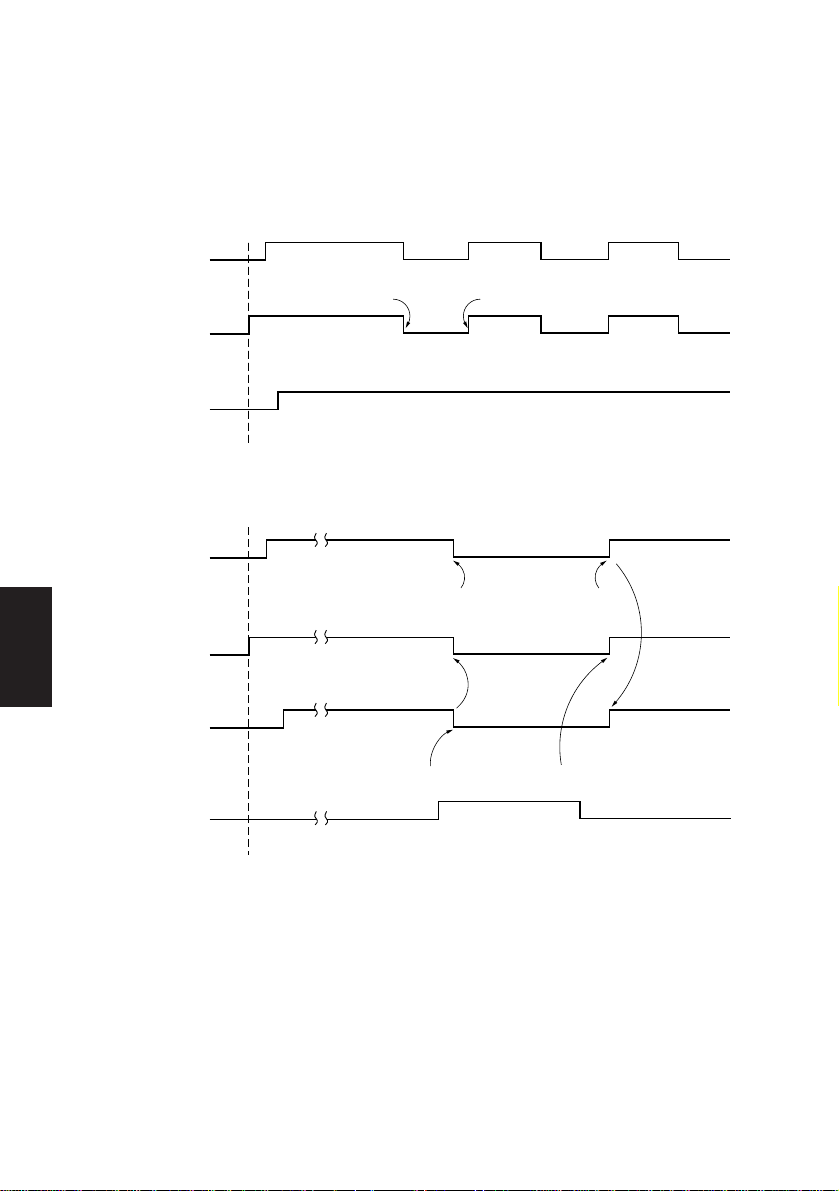

A-4. Communication Protcol .......................................................................90

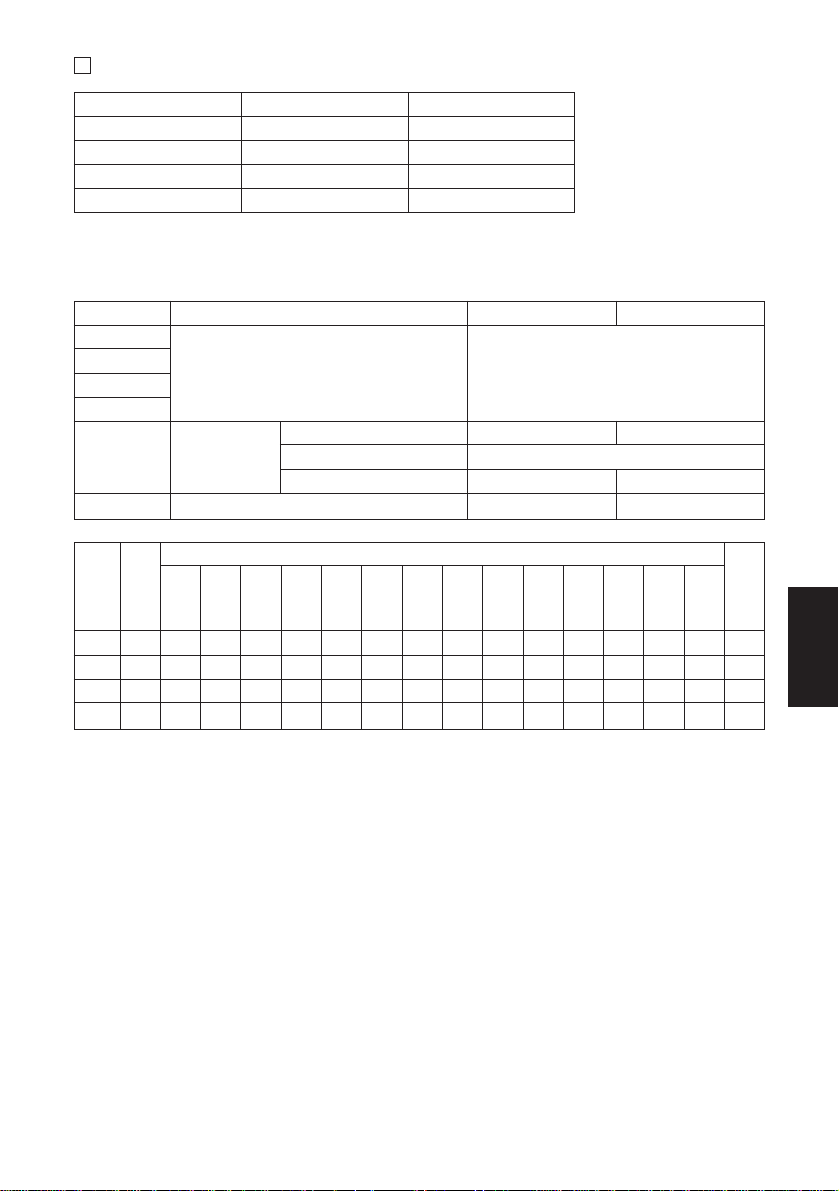

Appendix B: Parallel Interface ............................................................................92

B-1. Interface Specifications........................................................................92

B-2. Interface Timing...................................................................................92

B-3. Connectors and Signals ........................................................................93

B-4. Dip Switch Setting ...............................................................................94

Appendix C: Peripheral Unit Drive Circuit.........................................................95

Appendix D: General Specifications ...................................................................97

Appendix E: Character Font Table....................................................................100

E-1. U.S.A..................................................................................................100

E-2. Europe ................................................................................................102

E-3. International Character Sets ...............................................................104

E-4. VeriFone ............................................................................................105

Page 4

1. Outline

ENGLISH

The SP200 Series Serial Impact Dot Matrix Printer is designed for use with

electronic instruments such as POS, banking equipment, computer peripheral

equipment, etc.

The major features of the SP200 Series are as follows:

1. Bi-directional printing at approx. 2.5 lines/sec.

2. Serial interface or Parallel interface.

3. The data buffer allows the unit to receive print data even during printing.

4. Peripheral unit drive circuit enables control of external devices such as cash

drawers.

SP2 1 2 F D 42 – 120

Voltage

120 : 120VAC

230 : 230VAC

240 : 240VAC

No. of print columns

42 : 42 columns (16 CPI)

Interface

D : Serial interface (RS-232C)

K : Serial interface (RS-422A)

C : Parallel interface

Paper feed

F : Friction paper feed method

Mechanism

2 : Single color, 42 columns (16 CPI)

6 : Two color, 42 columns (16 CPI)

Printer type

1 : Standard type

4 : Auto cutter equipped type

SP200 Series printer

– 1 –

Page 5

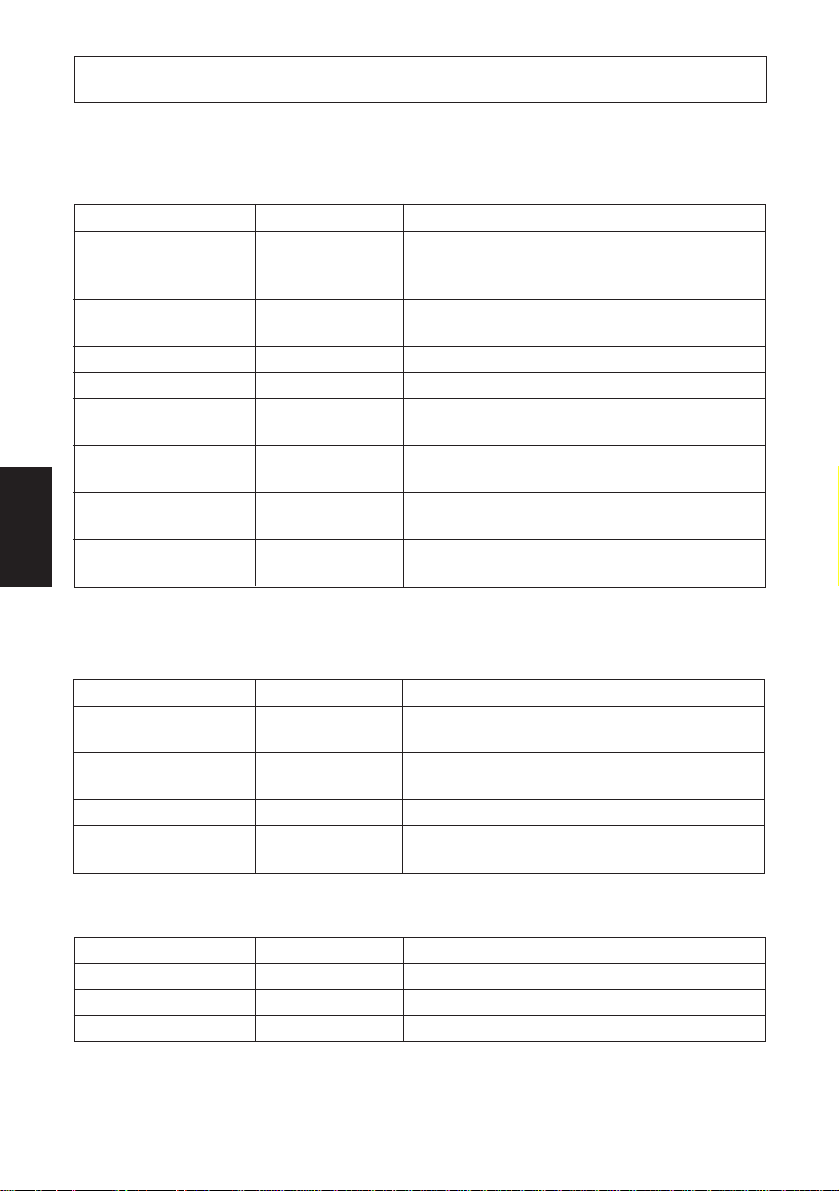

2. Unpacking and Installation

2-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in

the package.

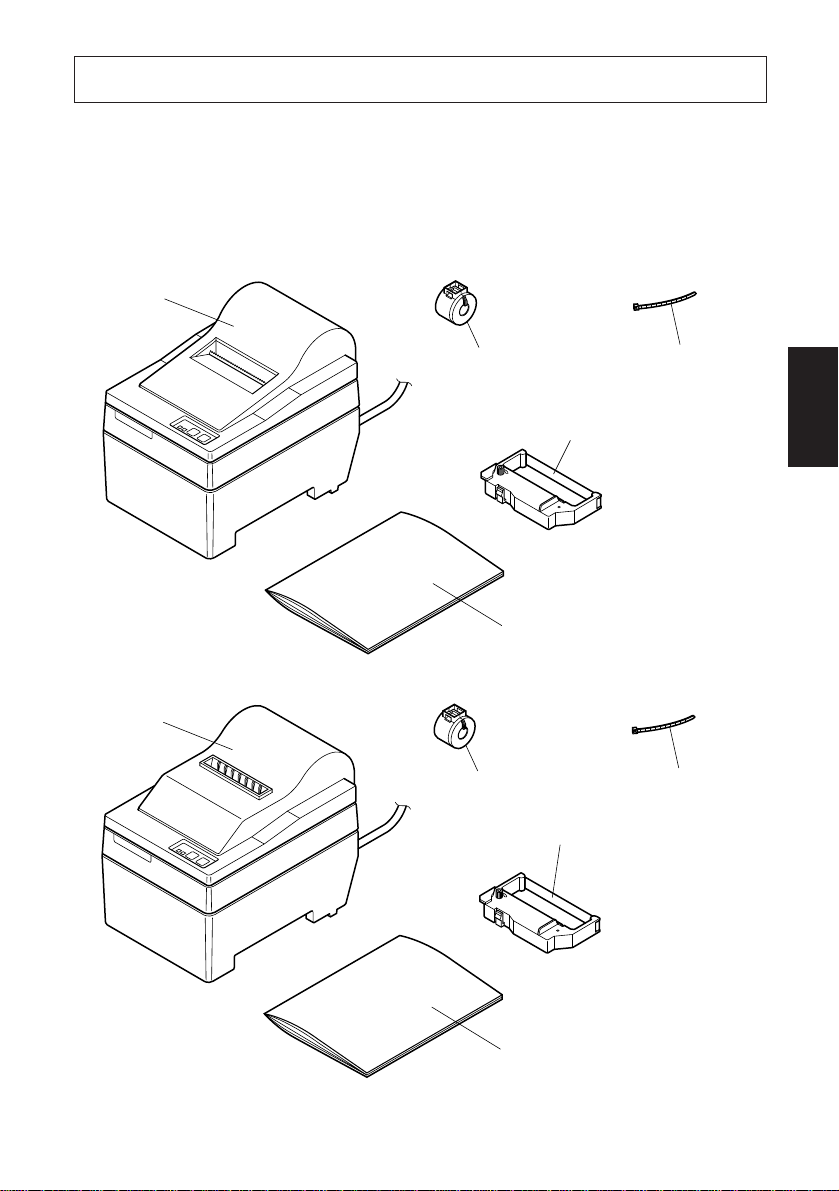

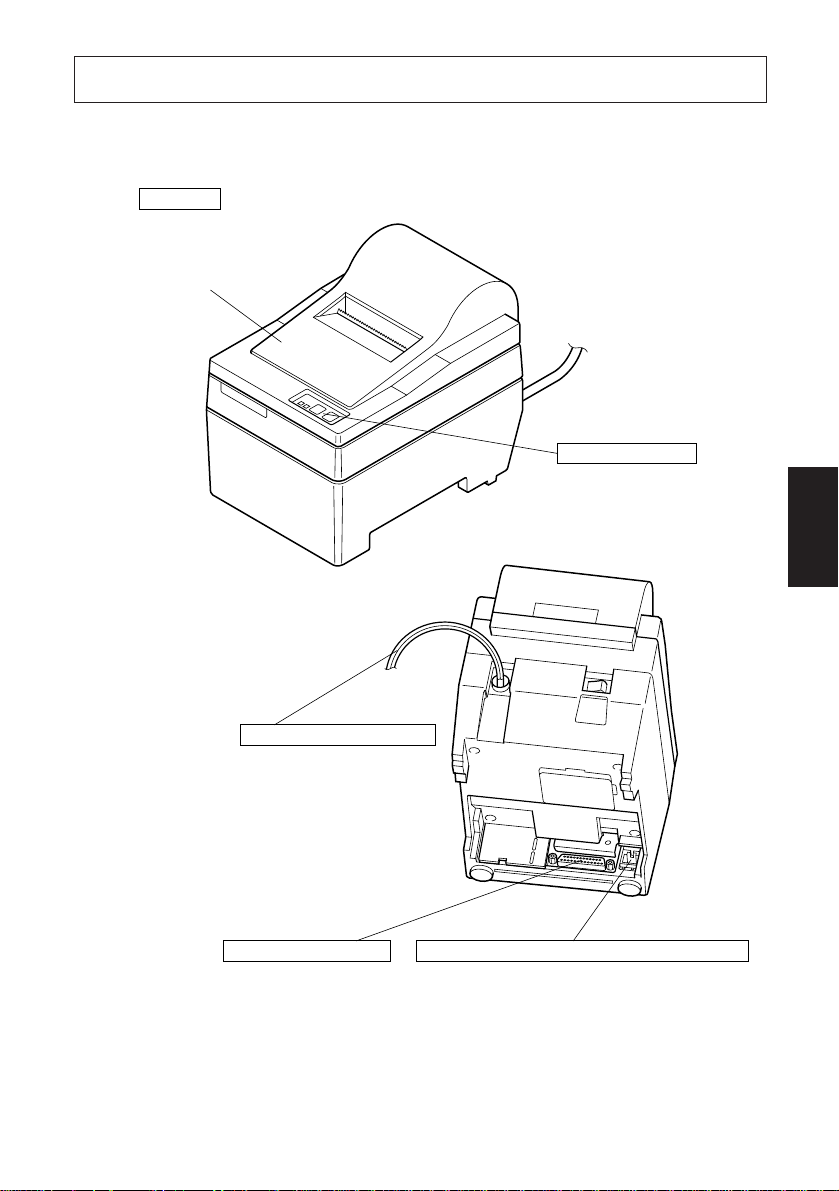

SP210 type

Printer

ENGLISH

SP240 type

Printer

Ferrite core

(EU only)

User´s manual

Ferrite core

(EU only)

Fastener

(EU only)

Ribbon cartridge

Fastener

(EU only)

Ribbon cartridge

Fig. 2-1 Unpacking

– 2 –

User´s manual

Page 6

2-2. Locating the printer

When you locate your printer, keep the following tips in mind:

ENGLISH

1. Protect your printer from excessive heat such as direct sunlight or heaters, and

keep it away from moisture and dust.

2. Place the printer on a firm, level surface which is fairly vibration-free.

3. A steady power supply that is not subject to power surges should be connected

to the printer.

For example, do not connect it to the same circuit as a large, noise-producing

appliance such as a refrigerator or an air conditioner.

4. Make sure the line voltage is the voltage specified on the printer’s identification plate.

5. To disconnect the printer, the plug has to be disconnected from the wall socket,

which has to be located close to the printer, and easy to access.

2-3. Handling Care

1. Be careful not to drop paper clips, pins or other foreign matter into the unit as

these cause the printer to malfunction.

2. Do not attempt to print when either paper or ribbon cartridge is not located in

the printer, otherwise the print head can be damaged.

3. Do not open the cover while printing.

4. Do not touch the print head immediately after printing as it gets very hot.

5. Use only roll paper that is not glued to the core.

6. When the paper end mark appears on the paper, replace the roll paper before

it runs out.

2-4. Maintenance

Essentially, your printer is a robust piece of equipment, but should be treated with

a modicum of care in order to avoid malfunctions. For example:

1. Keep your printer in a “comfortable” environment. Roughly speaking, if you

feel comfortable, then the environment is suitable for your printer.

2. Do not subject the printer to physical shocks or excessive vibration.

3. Avoid over-dusty environments. Dust is the enemy of all precision mechanical devices.

4. To clean the exterior of the printer, use a cloth barely dampened with either

water with a little detergent or a little alcohol, but do not allow any liquid to

fall inside the printer.

5. The interior of the printer may be cleaned with a small cleaner or a compressed-air aerosol (sold for this purpose). When performing this operation,

be sure not to bend or damage any cable connections or electronic components.

– 3 –

Page 7

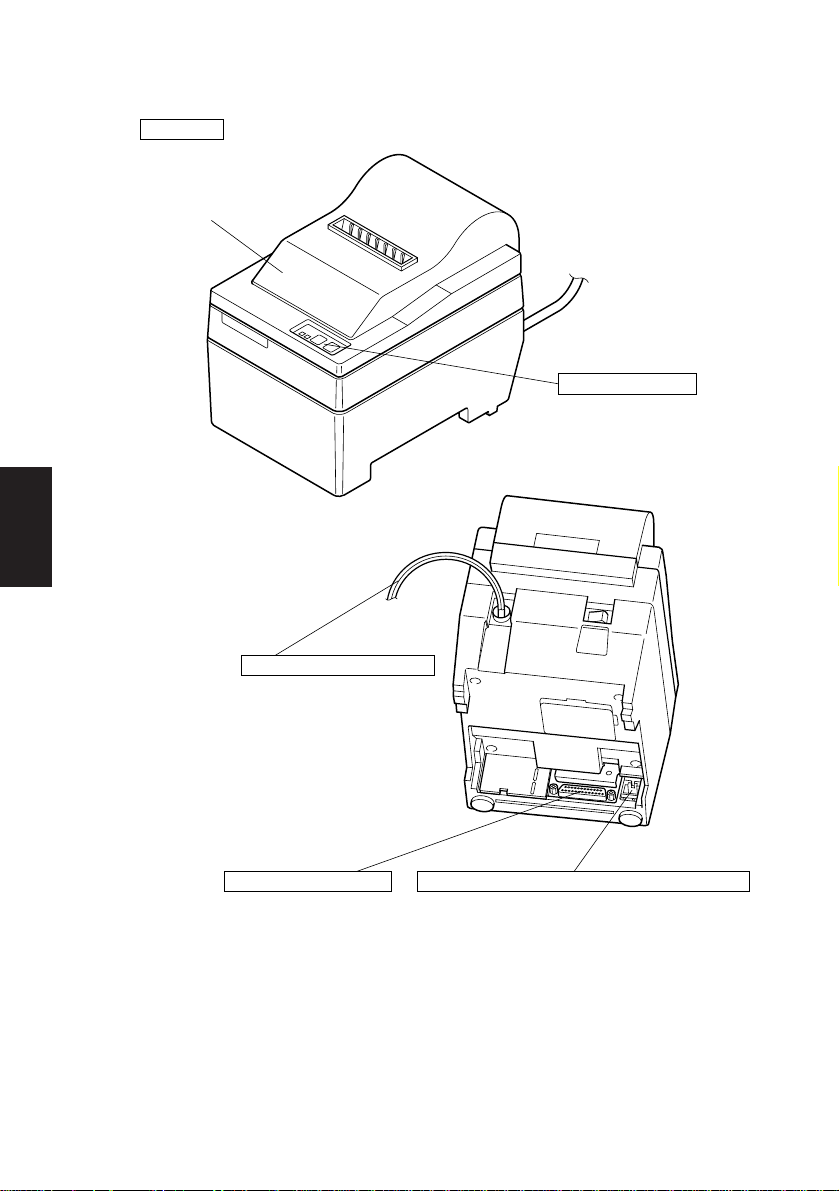

SP210 type

3. Parts Identification and Nomenclature

Cover

Protects the printer from

dust and reduces noise.

Do not open the cover

while printing.

AC power cord

Plugs into an outlet of

the specified voltage.

Shape of AC power plug

will vary according to

destinations.

ENGLISH

Control panel

Features two control

switches and two

indicators to indicate

printer status.

Interface connector

Connects the printer

with host computer.

Peripheral unit drive circuit connector

Connects to peripheral units such

as cash drawers, etc.

Do not connect this to a telephone.

Fig. 3-1 External view of the printer (SP210 type)

– 4 –

Page 8

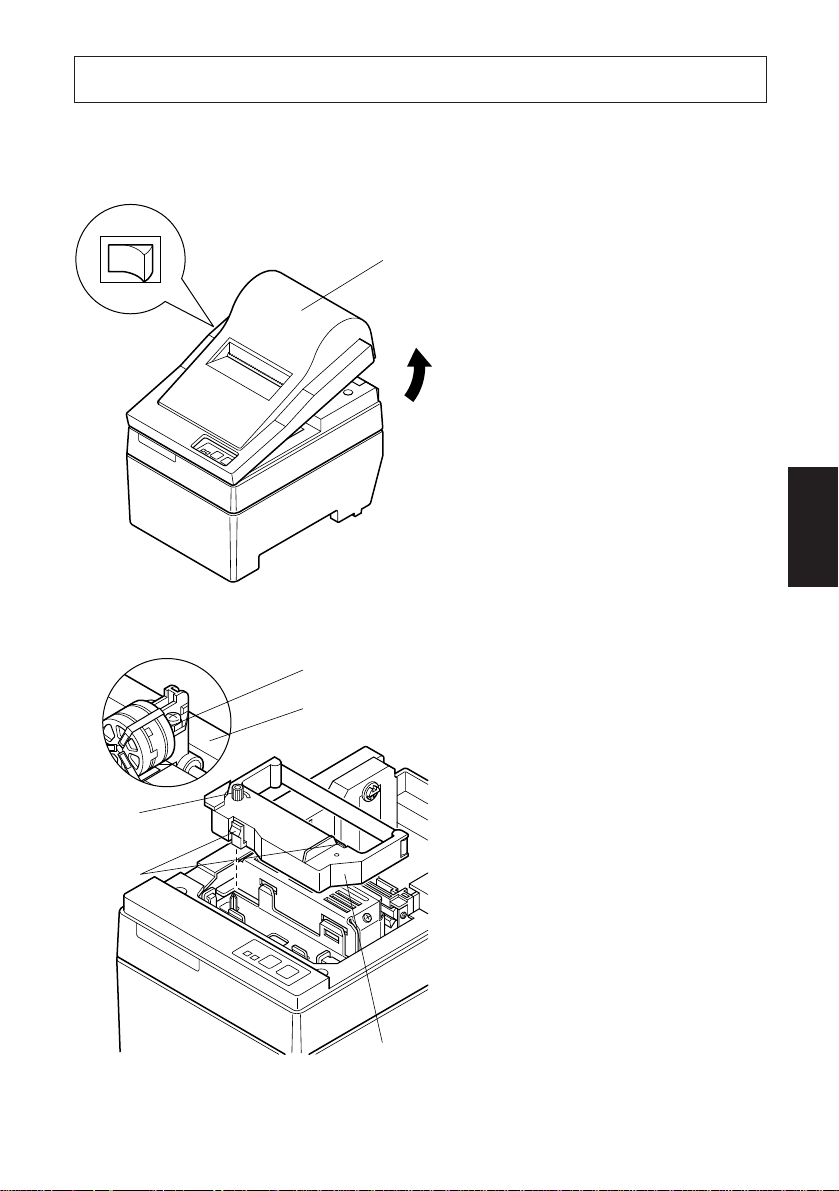

SP240 type

ENGLISH

Cover

Protects the printer from

dust and reduces noise.

Do not open the cover

while printing.

Control panel

Features two control

switches and two

indicators to indicate

printer status.

AC power cord

Plugs into an outlet of

the specified voltage.

Shape of AC power plug

will vary according to

destinations.

Interface connector

Connects the printer

with host computer.

Peripheral unit drive circuit connector

Connects to peripheral units such

as cash drawers, etc.

Do not connect this to a telephone.

Fig. 3-2 External view of the printer (SP240 type)

– 5 –

Page 9

4. Loading the Ribbon Cartridge and Paper

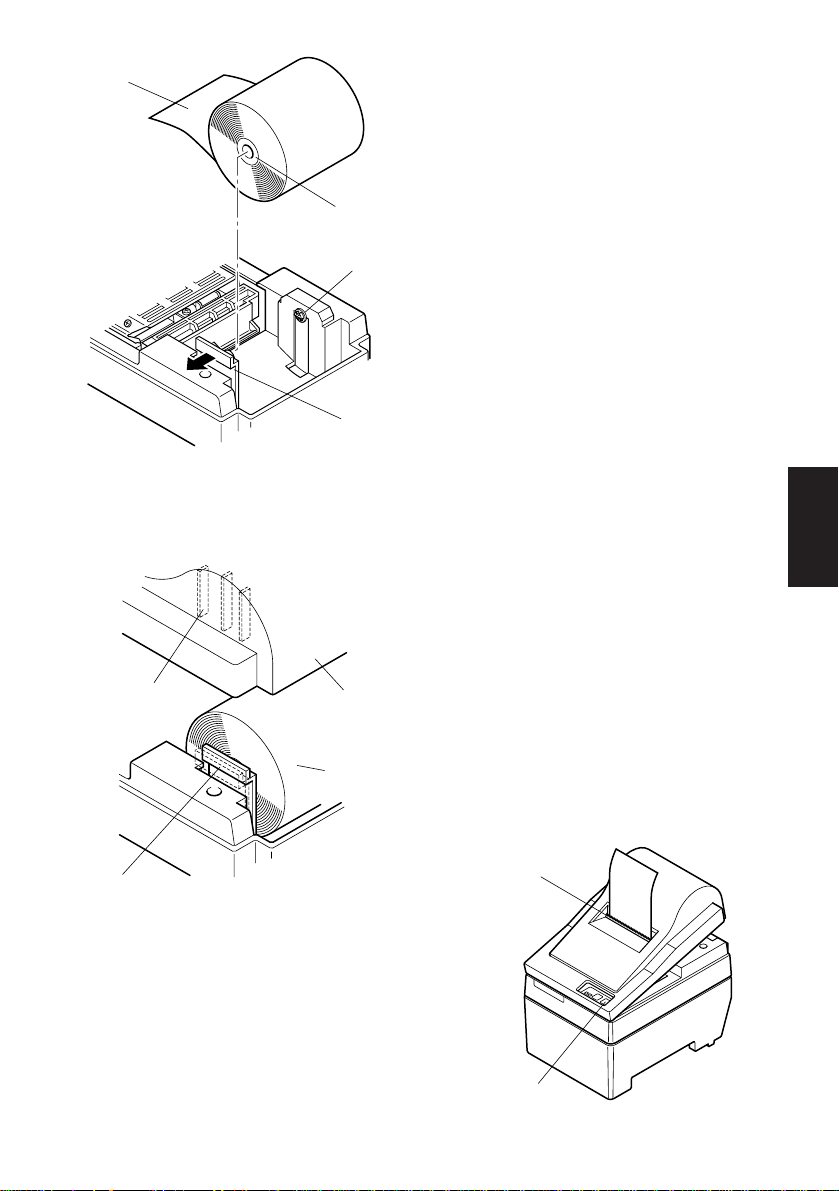

4-1. SP210 type

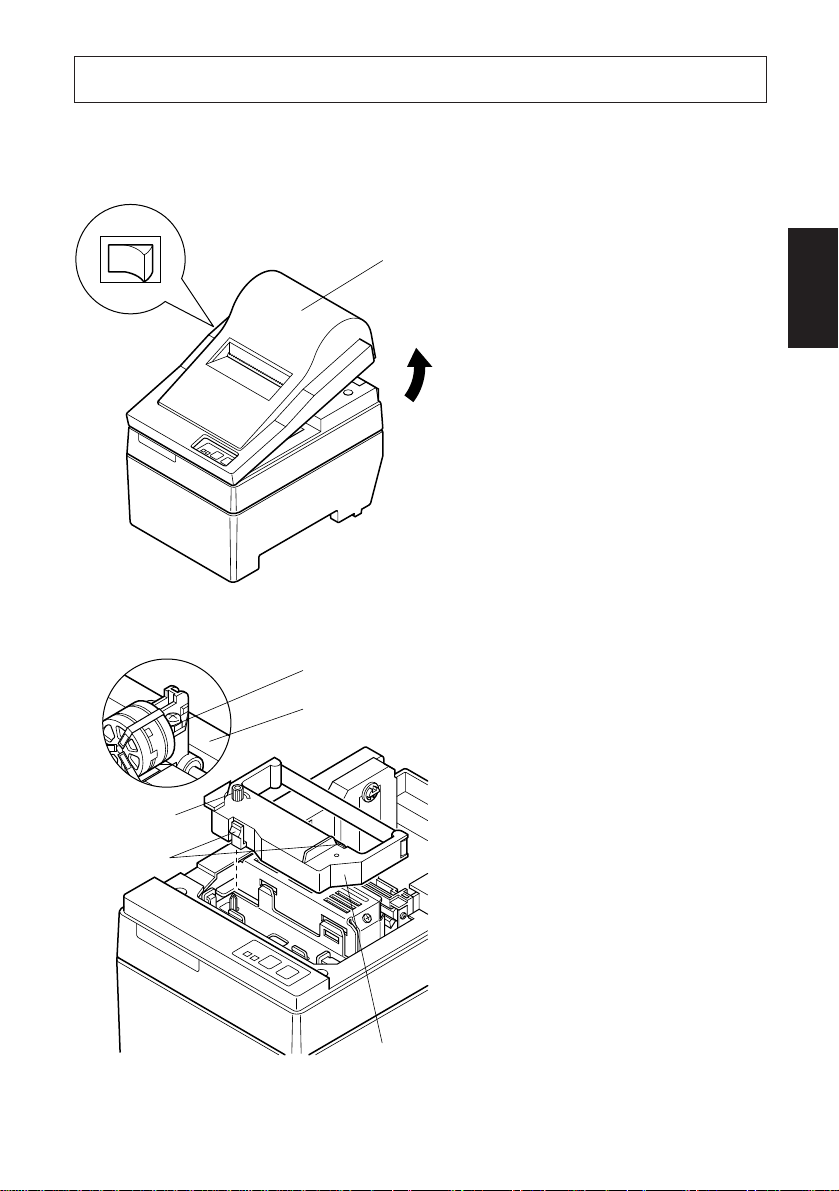

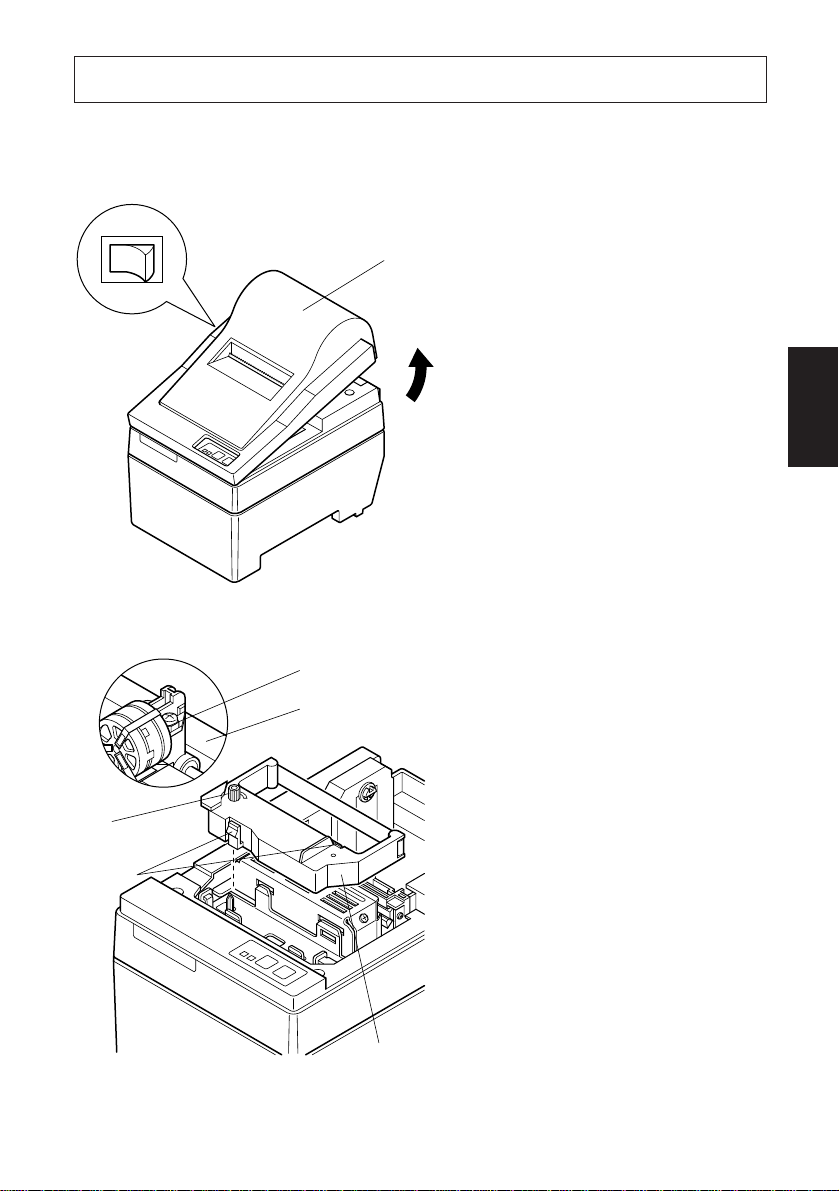

4-1-1.Loading the Ribbon Cartridge

Cover

Power off

1 Turn off power to the printer.

2 Lift the cover up approx. 3 cm.

Hold the cover tilted at this angle, then pull it toward you to

remove it.

3 Place the ribbon cartridge in the

direction shown in Fig. 4-2 and

press it down to load it. If loading

of the ribbon cartridge is not satisfactory, press down the cartridge while rotating the ribbon

feed knob in the direction of the

arrow.

ENGLISH

Fig. 4-1 Removing the cover

Print head

Ink ribbon

Ribbon feed

knob

Notched

part

Ribbon cartridge

Fig. 4-2 Loading the ribbon cartridge

4 Turn the ribbon feed knob of the

ribbon cartridge in the direction

of the arrow to remove slack in

the ribbon.

5 Mount the cover by reversing the

procedure outlined in step 2

above.

– 6 –

Page 10

ENGLISH

A

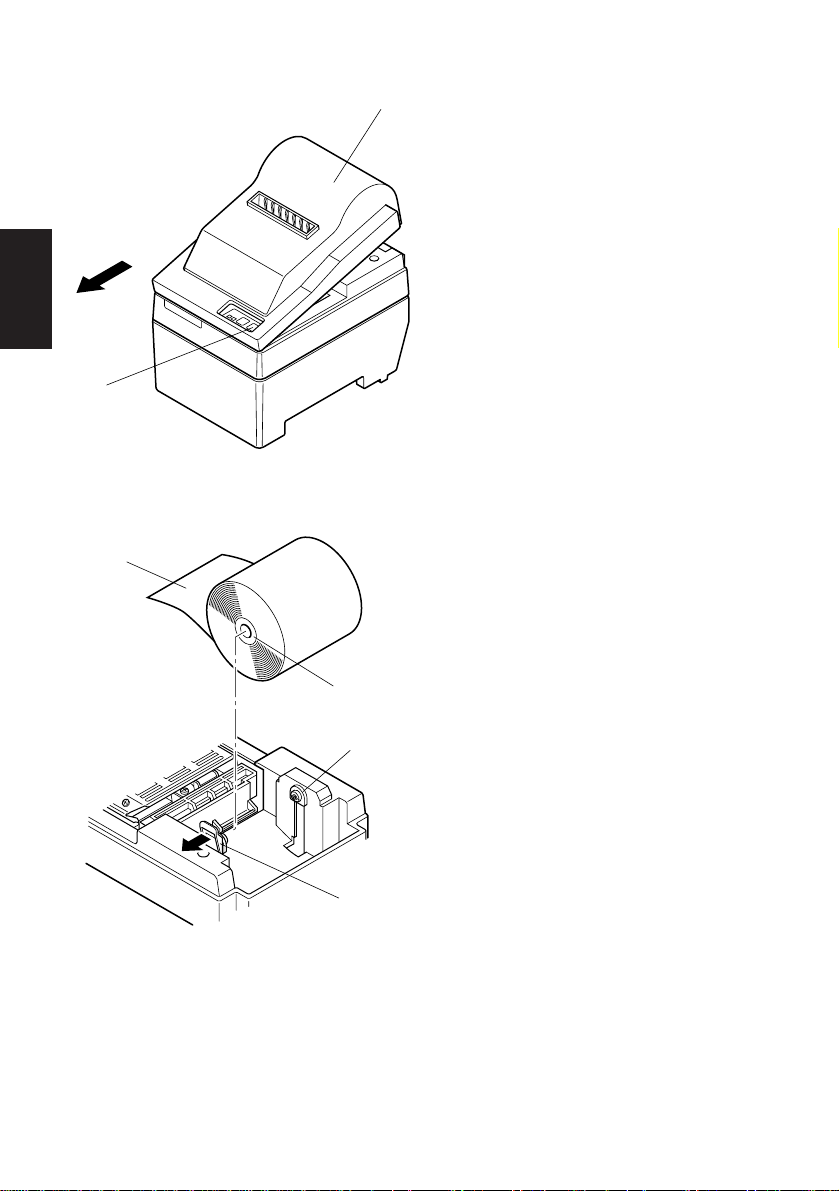

4-1-2.Loading the Paper

Note: When removing the ribbon car-

tridge, raise the A section and

then remove it by holding the B

section as shown in Fig. 4-3.

B

Fig. 4-3

FEED

switch

Fig. 4-4 Removing the cover

Cover

1 Lift the cover up approx. 3cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

– 7 –

Page 11

Roll paper

Fig. 4-5 Loading the paper

Positioning rib

Core

Axis

Paper roll holder

Cover

Roll paper

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

4 While observing the direction of the

roll paper, insert the top end of the

paper beneath the paper guide as far as

it will go. If the roll paper is installed,

the top end of the paper automatically

comes out from the paper exit.

5 Move the paper roll holder in the

direction of the arrow, and insert the

roll so that the holes in the core align

with the axes of the paper roll holder.

Release the paper roll holder to secure the paper.

6 If the paper roll core has not been

properly aligned with the paper roll

holder, the cover cannot to properly

seated until the paper position is

corrected.

7 Press the FEED (paper feed) switch to

feed the paper approximately 10cm.

8 Insert the top edge of the paper into

the tear bar slot, then mount the cover

by reversing the procedure for removing the cover in step 1 above.

Note: When the paper end mark ap-

pears on the paper, replace the

roll paper before it runs out.

ENGLISH

Paper roll holder

Fig. 4-6

– 8 –

Tear bar

FEED switch

Fig. 4-7

Page 12

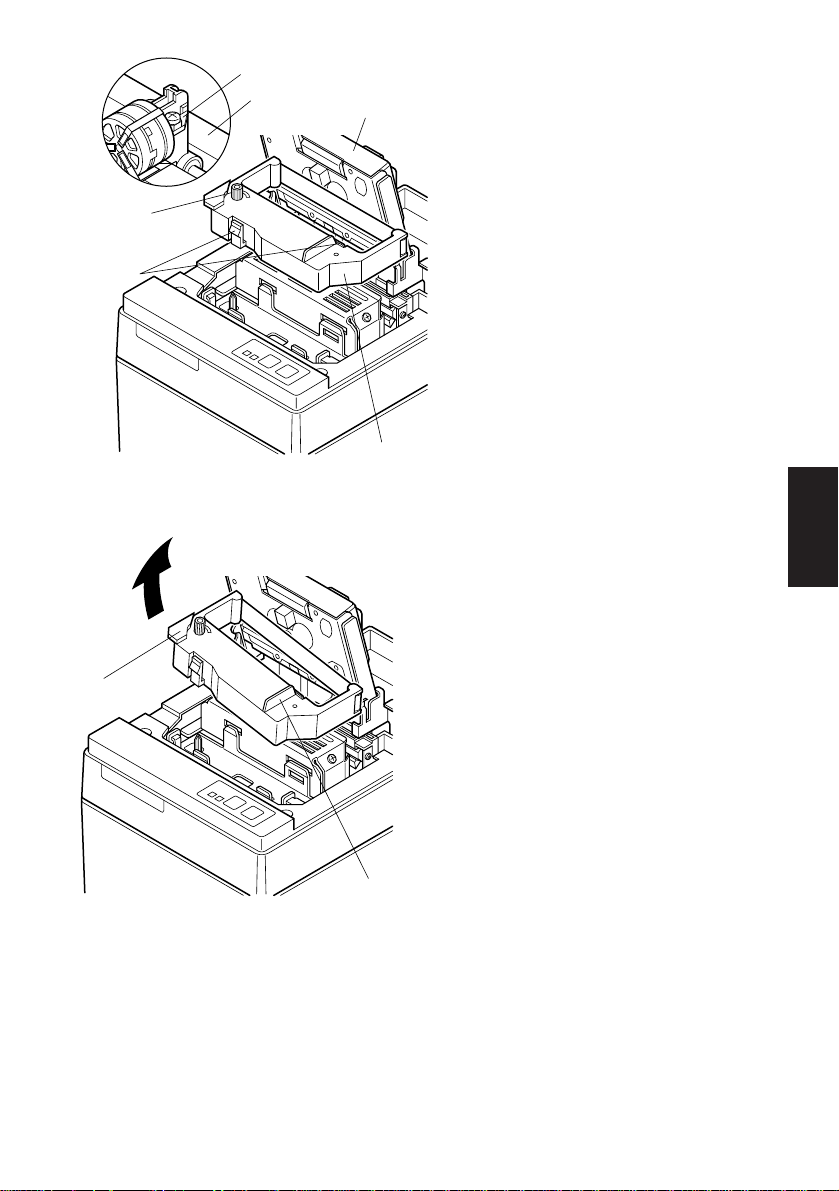

4-2. SP240 type

r

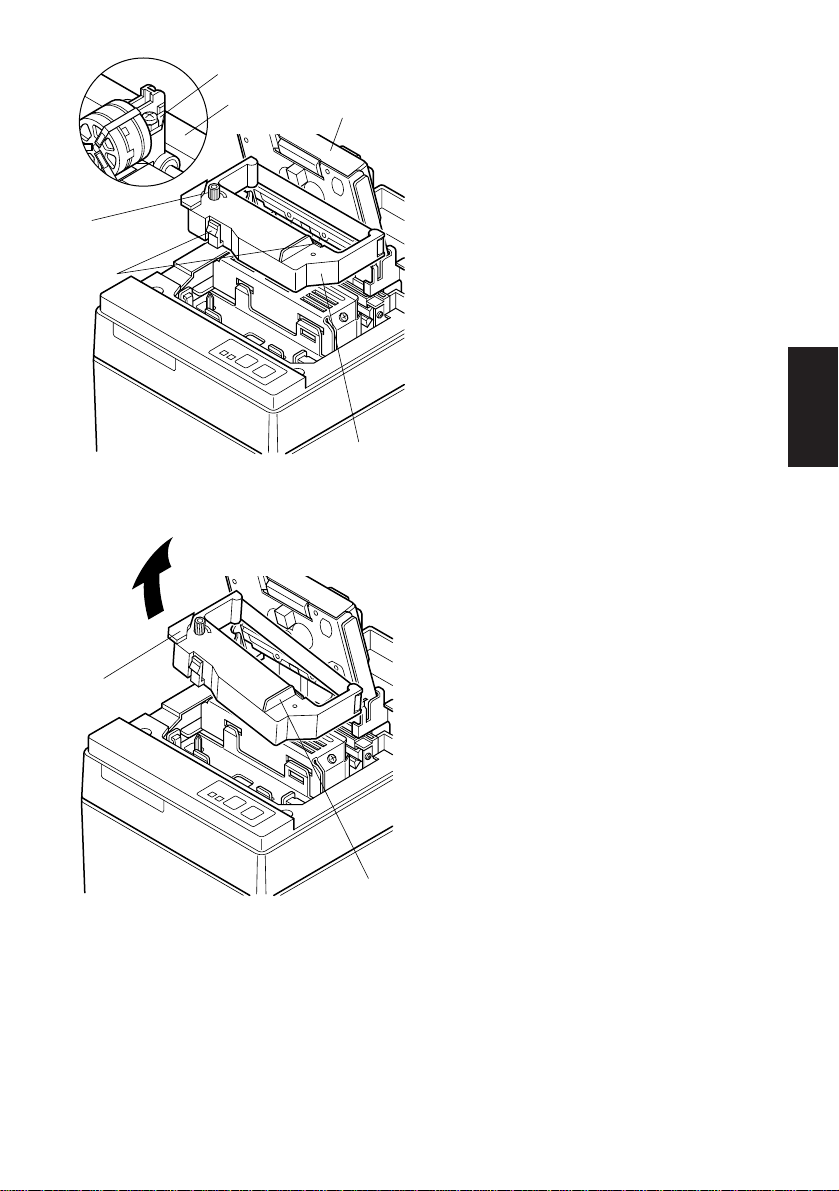

4-2-1.Loading the Ribbon Cartridge

ENGLISH

Power off

Fig. 4-8 Removing the cover

Auto cutter

Cove

1 Turn off power to the printer.

2 Lift the cover up approx. 3 cm.

Hold the cover tilted at this angle, then pull it toward you to

remove it.

3 Lift up the auto cutter and put it in

a vertical position, as shown in

Fig. 4-9.

Fig. 4-9 Raise the auto cutter

– 9 –

Page 13

Ribbon feed

knob

Notched

part

Print head

Ink ribbon

Auto cutter

4 Place the ribbon cartridge in the

direction shown in Fig. 4-10 and

press it down to load it. If loading

of the ribbon cartridge is not satisfactory, press down the cartridge while rotating the ribbon

feed knob in the direction of the

arrow.

5 Turn the ribbon feed knob of the

ribbon cartridge in the direction

of the arrow to remove slack in

the ribbon.

ENGLISH

Ribbon cartridge

Fig. 4-10 Loading the ribbon cartridge

A

B

Fig. 4-11

6 Close the Auto Cutter.

7 Mount the cover by reversing the

procedure outlined in step 2

above.

Note: When removing the rib-

bon cartridge, raise the A

section and then remove

it by holding the B section

as shown in Fig. 4-11.

– 10 –

Page 14

4-2-2.Loading the Paper

ENGLISH

FEED

switch

Fig. 4-12 Removing the cover

Cover

1 Lift the cover up approx. 3cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

Roll paper

Fig. 4-13 Loading the paper

Core

Axis

Paper roll holder

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

4 While observing the direction of the

roll paper, insert the top end of the

paper beneath the paper guide as far as

it will go. If the roll paper is installed,

the top end of the paper automatically

comes out from the paper exit. After

2cm of paper are fed out, the paper

is automatically cut off.

5 Move the paper roll holder in the

direction of the arrow, and insert the

roll so that the holes in the core align

with the axes of the paper roll holder.

Release the paper roll holder to secure the paper.

6 If the paper roll core has not been

properly aligned with the paper roll

holder, the cover cannot to properly

seated until the paper position is

corrected.

– 11 –

Page 15

7 Press the FEED (paper feed) switch

to feed the paper approximately

10cm.

Positioning rib

Paper roll holder

Cover

Roll paper

Fig. 4-14

Auto

Paper

insertion

slit

cutter

Fig. 4-15 Insertion of the paper into

the auto cutter

ENGLISH

8 Insert the tip of the roll paper in the

auto cutter paper slit.

• When using copying paper, insert

only the original (the upper paper)

into the slit of the auto cutter. Insert

the paper which is to be copied (the

lower paper) between the platen and

the auto cutter.

– 12 –

Page 16

ENGLISH

Paper insertion

slit

Auto cutter

Upper paper

Upper

paper

Print head

Lower paper

Fig. 4-16 Insertion of the paper into the auto cutter

(When using copying paper)

Paper

outlet

Auto cutter

Fig. 4-17 Paper outlet of the front

cover

Paper insertion

slit

Platen

9 Pull on the edge of the paper to

0 Insert the paper through the paper

Lower paper

Print head

Platen

remove any slack and then lower the

auto cutter.

outlet and then replace the cover by

reversing the removal steps.

Note: When the paper end mark ap-

pears on the paper, replace the

roll paper before it runs out.

– 13 –

FEED switch

Fig. 4-18

Page 17

4-3. Removing the Paper

Remove the cover, then cut off the paper near the rear of the paper guide and press

the FEED switch to feed out the paper remaining in the unit.

When the paper runs out, the POWER lamp will blink.

Note 1. Remove the paper remaining in the printer by pressing the FEED

switch.

2. When the paper end mark appears on the paper, replace the roll

paper before it runs out.

3. When removing the core of the roll paper, open the roll paper

holder.

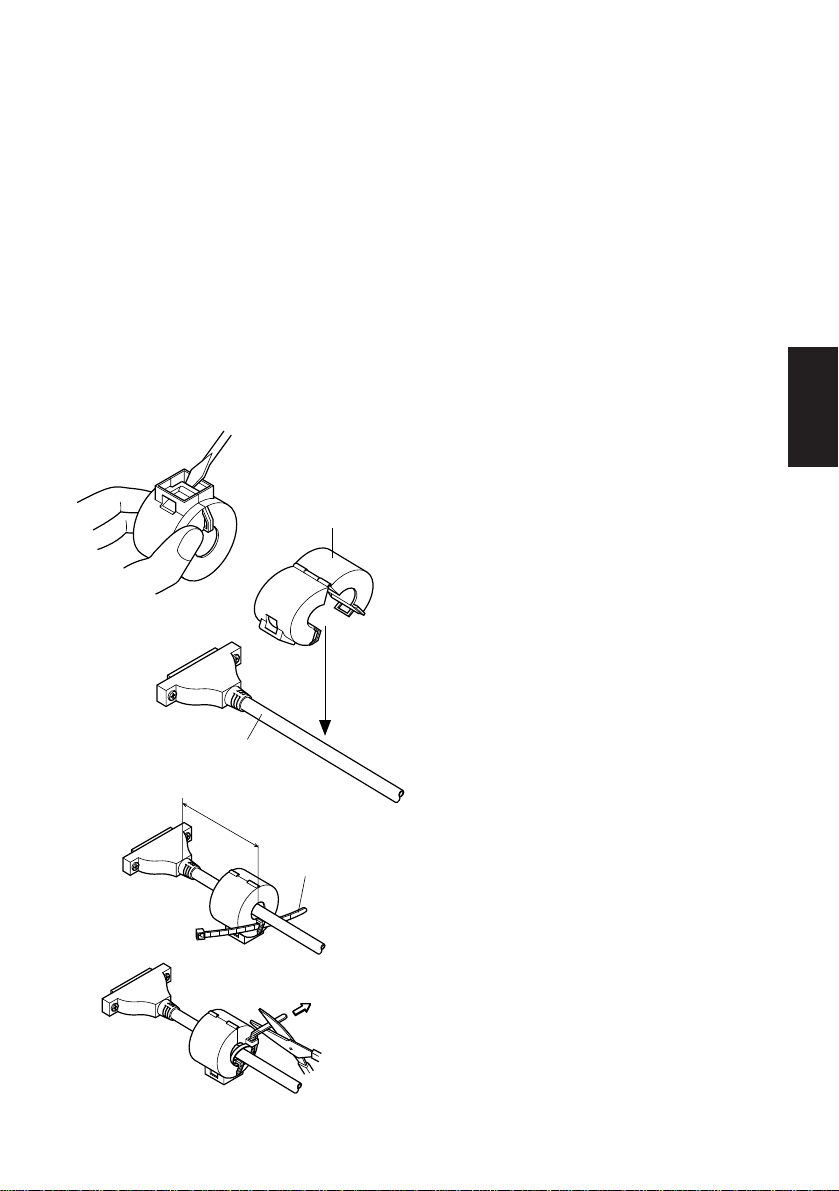

4-4. Connecting the Interface Cable

4-4-1.Ferrite core installation (EU only)

1 Affix the ferrite core onto the serial/

parallel interface cable as shown in

Ferrite core

Interface cable

the illustration.

If a ferrite core is not open, use a

screw driver to pry it apart, taking

care not to damage the core or lock.

2 Pass fastener through ferrite core.

3 Pass fastener around cable and lock

it.

Cut off excess with scissors.

Attach the ferrite core only to the

cables of printers sold in the EU.

ENGLISH

5cm

maximum

Fig. 4-19

Fastener

Pull and cut

– 14 –

Page 18

4-4-2.Serial Interface Cable

ENGLISH

Ferrite core

(EU only)

Screwdriver

Fig. 4-20 Connecting the interface

cable

4-4-3.Parallel Interface Cable

Fig. 4-21 Connecting the parallel

interface cable

Screws

Ferrite core

(EU only)

1 Turn off power to both the host

computer and the printer.

2 Insert the connector at one end of

the interface cable into the connector on the printer and the other connector into the connector for the

host computer.

3 Next, fasten the right and left screws

for the respective interface connectors to fix them in place on the

connectors.

1 Turn off power to both the host

computer and the printer.

2 Insert one terminal of the interface

cable into the printer’s connector,

as shown in the diagram, and fasten

it there with the clasp.

3 Insert the other terminal of interface

cable into the host computer’s connector, and again fasten it with the

clasp.

– 15 –

Page 19

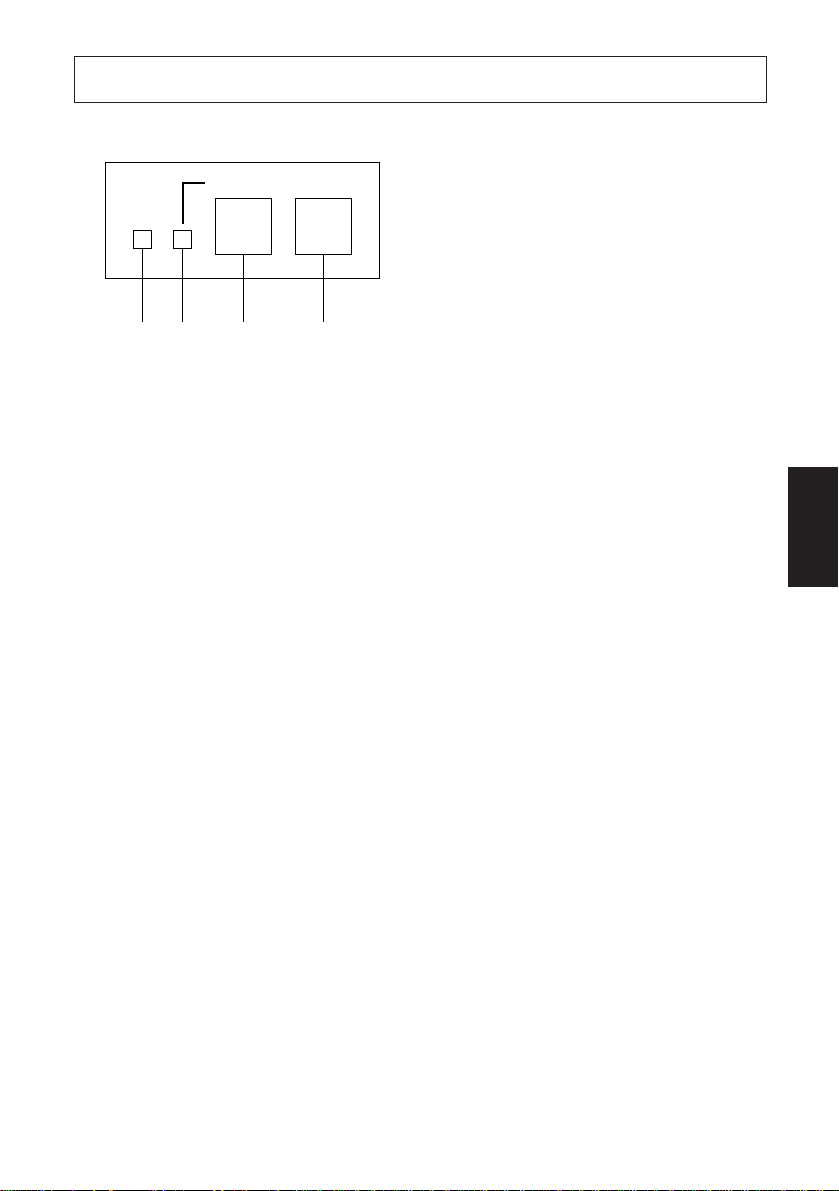

5-1. Basic Operation

5. Control Panel

ON LINEPOWER FEED

1 ON LINE switch

Switches the printer between ON

LINE and OFF LINE. ON LINE

and OFF LINE switching is possible only when paper is loaded in the

printer.

3 4 1 2

2 FEED switch

• When this switch is pressed and

Fig. 5-1 Control panel

then released within 0.5 sec., the

paper feeds on line.

• When this switch is held depressed

for more than 0.5 sec., the paper

feeds continuously.

(The above paper feed operation is

possible for both ON LINE and OFF

LINE modes.)

3 POWER lamp (green LED)

• Lights when the power to the printer is on.

• Flashes when paper is out, mechanical error occurs, when there is an alarm due

to head temperature detection, or when a CPU error has occurred.

• If the paper is out, load new paper and press the ON LINE switch.

• When the POWER lamp flashes due to occurrence of a mechanical error, turn

off the power and remove the cause of a mechanical error and then turn on the

power again to reset the printer.

• If the POWER lamp flashes due to the alarm of the head temperature detection,

the printer will be set automatically when the head temperature becomes low.

4 ON LINE lamp (green LED)

LED lit: Printer is ON LINE

LED off: Printer is OFF LINE

LED flashes: CPU error

ENGLISH

When the POWER lamp and ON LINE lamp light simultaneously, a CPU

error has occurred.

– 16 –

Page 20

5-2. Switch Operation (Combined Switch Operation)

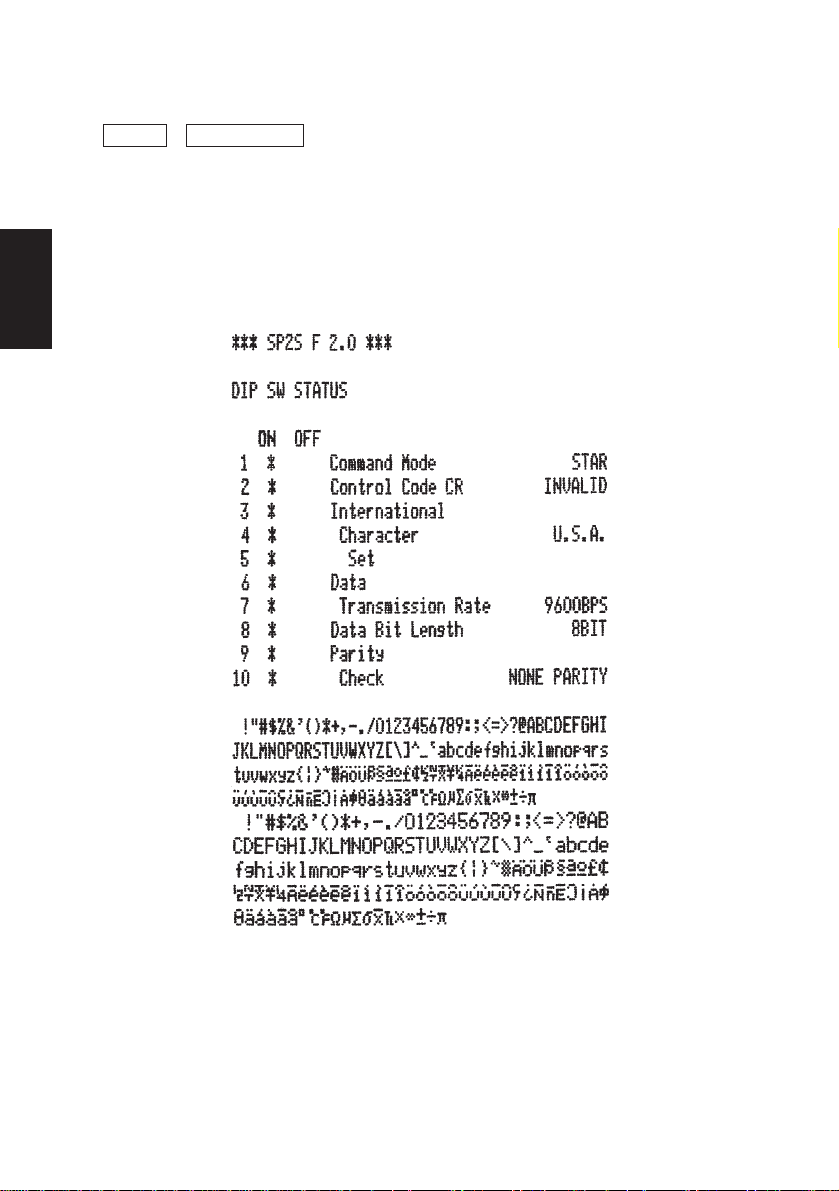

1 <SELF PRINTING>

ENGLISH

FEED + POWER ON (Turn the power on while holding the FEED switch

depressed.)

Self-printing will be performed according to the VER. NO., DIP switch

settings and character order. When the FEED switch is held continuously or

when the FEED switch is depressed at the time of the end of self-printing, only

the characters will be printed out repeatedly.

Fig. 5-2 Self printing sample (when using serial interface RS-232C printer)

– 17 –

Page 21

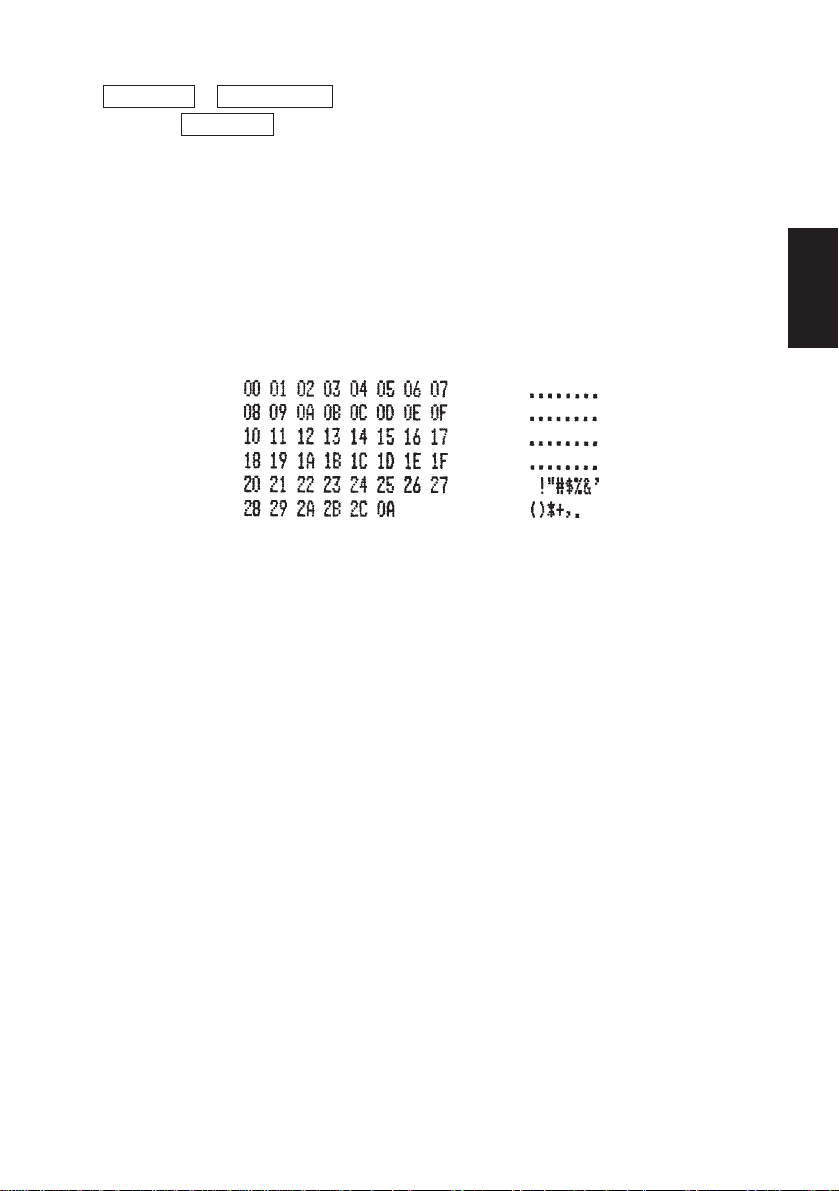

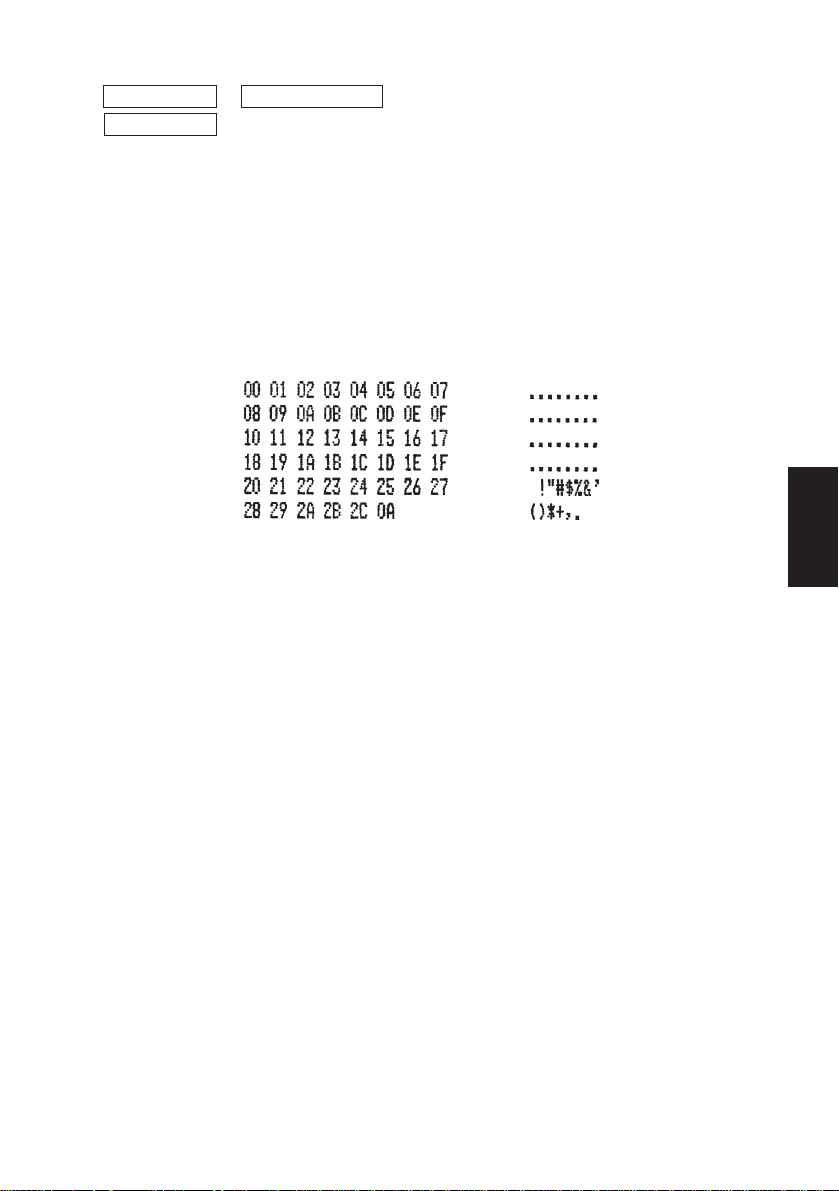

2 <Hexadecimal dump mode>

ON LINE + POWER ON (Turn the power on while holding the ON LINE

switch depressed.)

Each of the signals sent from the computer to the printer will be printed out in

hexadecimal code.

This function allows you to check if a control code sent to the printer by the

program being used is correct or not. The last line is not printed if its data is

less than one full line. However, if the ON LINE switch is pressed to set the

off line mode, the last line will be printed. To turn off the mode, it is necessary

to turn off the printer completely.

Fig. 5-3 Hexadecimal dump printing sample

ENGLISH

– 18 –

Page 22

6. Control Codes

ENGLISH

STAR mode

6-1. Control Codes Used in Character Setting

Control codes Hexadecimal codes Function

<ESC> “R” n 1B 52 n Select international character set. Default is accord-

ing to the dip switch settings 3, 4 and 5.

<ESC> “M” 1B 4D Select 7 × 7 (Half dots) character size (Default

setting)

<ESC> “P” 1B 50 Select 9 × 7 (Half dots) character size

<SO> 0E Select expanded character mode

<SI> 0F Cancel expanded character mode

(Default setting)

<DC4> 14 Cancel expanded character mode

(Default setting)

<ESC> “W” “1” 1B 57 31 Select expanded character mode

<ESC> “W” <1> 1B 57 01

<ESC> “W” “0” 1B 57 30 Cancel expanded character mode

<ESC> “W” <0> 1B 57 00 (Default setting)

6-2. Control Codes Used in Print Mode Setting

Control codes Hexadecimal codes Function

<ESC> “4” 1B 34 Red color print selection (enable for SP216/246)

<ESC> “5” 1B 35 Red color print deselection (enable for SP216/246)

(Default setting)

<ESC> “E” 1B 45 Emphasized print mode selection

<ESC> “F” 1B 46 Emphasized print mode deselection (Default set-

ting)

6-3. Control Codes Used in Line Spacing

Control codes Hexadecimal codes Function

<LF> 0A Line feed

<CR> 0D Line feed (same as LF)

<ESC> “a” n 1B 61 n Feed paper n lines

– 19 –

Page 23

6-4. Control Codes Used for Peripheral Units

Control codes Hexadecimal codes Function

<ESC> <BEL> n1 n2 1B 07 n1 n2 Adjust drive pulse width for peripheral unit (Default

setting)

<BEL> 07 Deferred drive command “A” for peripheral unit 1

<FS> 1C Immediate drive command “B” for peripheral unit 1

6-5. Auto Cutter Control (SP240 type only)

Control codes Hexadecimal codes Function

<ESC> “d” “0” 1B 64 30 Full-cut command to the auto cutter

<ESC> “d” <0> 1B 64 00

<ESC> “d” “1” 1B 64 31 Partial-cut command to the auto cutter

<ESC> “d” <1> 1B 64 01

<ESC> “d” “2” 1B 64 32 Full-cut command to the auto cutter

<ESC> “d” <2> 1B 64 02 after paper feed

<ESC> “d” “3” 1B 64 33 Partial-cut command to the auto cutter after paper

<ESC> “d” <3> 1B 64 03 feed

6-6. Other Control Codes

Control codes Hexadecimal codes Function

<CAN> 18 Cancel print data in buffer

<ENQ> *

<DC1> *

<DC3> *

<ESC> “@” 1B 40 Initialize printer

<ESC> “e” “0” 1B 65 30 ON LINE/FEED switch valid

<ESC> “e” <0> 1B 65 00 (Default setting)

<ESC> “e” “1” 1B 65 31 ON LINE/FEED switch invalid

<ESC> “e” <1> 1B 65 01

<ESC> “f” “0” 1B 66 30 ON LINE switch valid

<ESC> “f” <0> 1B 66 00 (Default setting)

<ESC> “f” “1” 1B 66 31 ON LINE switch invalid

<ESC> “f” <1> 1B 66 01

1 05 Enquiry

1 11 Set select mode

1 13 Deselect printer

ENGLISH

*1: Valid for the RS-422A only.

– 20 –

Page 24

ENGLISH

– 21 –

Page 25

TABLE DES MATIERES

1. Introduction .....................................................................................................23

2. Déballage et Inspection ...................................................................................24

2-1. Déballage .............................................................................................24

2-2. Emplacement de l’imprimante .............................................................25

2-3. Précautions de manipulation ................................................................25

2-4. Entretien ...............................................................................................25

3. Identification des Pièces et Nomenclature ......................................................26

4. Installation d’une cartouche à ruban et chargement du papier ........................28

4-1. Modèle SP210 ......................................................................................28

4-2. Modèle SP240 ......................................................................................31

4-3. Enlèvement d’un rouleau de papier .....................................................36

4-4. Connexion du câble d’interface ...........................................................36

5. Panneau de Commande ...................................................................................38

5-1. Fonctionnement de base.......................................................................38

5-2. Utilisation des touches (Utilisation combinée des touches) ................39

6. Codes de contrôle ............................................................................................41

Mode STAR .................................................................................................41

6-1. Commandes utilisées pour le réglage des caractères ...........................41

6-2. Commandes utilisées pour le réglage du mode d’impression..............41

6-3. Commandes utilisées pour l’espacement des lignes ............................41

6-4. Commandes utilisées pour le pilotage des appareils périphériques.....42

6-5. Commandes de pilotage de l’unité de découpage automatique

(Modèle SP240 seulement) ..................................................................42

6-6. Autres commandes ...............................................................................42

APPENDICE .......................................................................................................87

FRANÇAIS

L’appendice n’est pas traduit.

– 22 –

Page 26

1. Introduction

L’imprimante série à impact et matrice de points est conçue pour une utilisation

avec des instruments électroniques tels que des terminaux points de vente, du

matériel bancaire, du matériel périphérique pour ordinateurs, etc.

Les caractéristiques principales des modèles de la série SP200 sont les suivantes:

FRANÇAIS

1. Impression bi-directionnelle à 2,5 lignes/sec. environ.

2. Interface série ou parallèle.

3. Tampon de données permettant à l’appareil de recevoir des données d’impression même pendant le travail d’impression.

4. Circuit de contrôle d’appareils périphériques permettant la commande de

dispositifs extérieurs tels que des tiroirs-caisses.

SP2 1 2 F D 42 – 120

Tension

120 : 120V CA

230 : 230V CA

240 : 240V CA

Nombre de colonnes d’impression

42 : 42 colonnes (16 ccp)

Interface

D : Interface série (RS-232C)

K : Interface série (RS-422A)

C : Interface parallèle

Alimentation de papier

F:

Alimentation de papier par friction

Mécanisme

2:

Une couleur, 42 colonnes (16 ccp)

6:

Deux couleurs, 42 colonnes (16 ccp)

Type d’imprimante

1 : Type standard

4 : Type avec unité de découpage

automatique

Imprimante de la série SP200

– 23 –

Page 27

2. Déballage et Inspection

2-1. Déballage

Après avoir déballé l’appareil, vérifiez si tous les accessoires nécessaires se

trouvent dans la boîte.

Modèle SP210

Imprimante

Tore de ferrite

(UE seulement)

Cartouche à ruban

Mode d’emploi

Attache

(UE seulement)

FRANÇAIS

Modèle SP240

Imprimante

Tore de ferrite

(UE seulement)

Fig. 2-1 Déballage

– 24 –

Attache

(UE seulement)

Cartouche à ruban

Mode d’emploi

Page 28

2-2. Emplacement de l’imprimante

Pour installer correctement l’imprimante, gardez à l’esprit les conseils suivants:

1. Mettez l’imprimante à l’abri de températures excessivement élevées comme en plein

soleil ou à proximité d’un appareil de chauffage, et à l’abri de l’humidité et de la

poussière.

2. Installez l’imprimante sur une surface stable et de niveau sur laquelle l’imprimante

FRANÇAIS

ne sera pas soumise à des vibrations.

3. Veillez à ce que l’imprimante soit branchée sur une source secteur stable.

Par exemple, ne pas brancher l’imprimante sur la prise secteur d’un circuit alimentant

déjà un appareil électroménager gros consommateur de courant et producteur de

parasites, tel qu’un réfrigérateur ou un climatiseur.

4. Veillez à ce que la tension du secteur corresponde bien à la tension spécifiée sur la

plaque d’identification de l’imprimante.

5. Pour débrancher l’imprimante, la fiche doit être débranchée de la prise murale, et

celle-ci doit être située à proximité de l’imprimante et facile d’accès.

2-3. Précautions de manipulation

1. Faites attention à ne pas laisser tomber de trombones, punaises ou autres objets dans

l’imprimante. Un dysfonctionnement pourrait en résulter.

2. Ne pas essayer d’imprimer quand il n’y a pas de papier ou de cartouche à ruban dans

l’imprimante. La tête d’impression pourrait être endommagée.

3. Ne pas ouvrir le capot pendant l’impression.

4. Ne pas toucher la tête d’impression immédiatement après un travail d’impression car

elle devient très chaude.

5. Utilisez seulement un rouleau de papier dont l’extrémité n’est pas collée au tube

central.

6. Quand le repère de fin de papier apparaît sur le papier, remplacez le rouleau de papier

avant qu’il soit terminé.

2-4. Entretien

Avant tout, cette imprimante est un appareil robuste, mais un minimum de précautions

sont à prendre pour éviter les dysfonctionnements. Par exemple:

1. Laissez l’imprimante dans un environnement “confortable”. En gros, si vous êtes à

l’aise, l’environnement sera acceptable pour l’imprimante.

2. Ne pas soumettre l’imprimante à des chocs ou à des vibrations excessives.

3. Évitez les environnements excessivement poussiéreux. La poussière est l’ennemi de

tous les appareils mécaniques de précision.

4. Pour nettoyer l’extérieur de l’imprimante, utilisez un chiffon légèrement imbibé

d’eau ou d’alcool, mais ne laissez aucun liquide pénétrer à l’intérieur de l’imprimante.

5. L’intérieur de l’imprimante peut être nettoyé avec une petite brosse de nettoyage ou

un aérosol à air comprimé (vendu à cet effet). Pendant cette opération, veillez à ne pas

plier ni endommager les connexions ou les composants électroniques.

– 25 –

Page 29

3. Identification des Pièces et Nomenclature

Modèle SP210

Capot

Protège l’imprimante de la

poussière et réduit le bruit.

Ne pas ouvrir le capot

pendant l’impression.

FRANÇAIS

Panneau de commande

Comprend deux

commutateurs de

commande et trois témoins

indiquant le statut de

l’imprimante.

Cordon d’alimentation secteur

A brancher sur la sortie

correspondant à la tension

spécifiée. La présentation

de la fiche du cordon

d’alimentation secteur

varie selon les pays.

Connecteur d’interface

Ce connecteur vous

permet de raccorder

l’imprimante à

l’ordinateur hôte.

Connecteur de pilotage d’appareils périphériques

Ce connecteur vous permet de

raccorder l’imprimante à des appareils

périphériques tels que des tiroirs-caisses, etc.

Ne pas raccorder à un téléphone.

Fig. 3-1 Vue externe de l’imprimante (Modèle SP210)

– 26 –

Page 30

Modèle SP240

FRANÇAIS

Capot

Protège l’imprimante de la

poussière et réduit le bruit.

Ne pas ouvrir le capot

pendant l’impression.

Panneau de commande

Comprend deux

commutateurs de

commande et

deux témoins

indiquant le statut

de l’imprimante.

Cordon d’alimentation secteur

A brancher sur la sortie

correspondant à la tension

spécifiée. La présentation

de la fiche du cordon

d’alimentation secteur varie

selon les pays.

Connecteur d’interface

Ce connecteur vous

permet de raccorder

l’imprimante à

l’ordinateur hôte.

Connecteur de pilotage d’appareils périphériques

Ce connecteur vous permet de

raccorder l’imprimante à des appareils

périphériques tels que des

tiroirs-caisses, etc.

Ne pas raccorder à un téléphone.

Fig. 3-2 Vue externe de l’imprimante (Modèle SP240)

– 27 –

Page 31

4. Installation d’une cartouche à ruban et chargement du papier

4-1. Modèle SP210

4-1-1. Installation d’une cartouche à ruban

1 Mettez l’imprimante hors tension.

Capot

Hors tension

Fig. 4-1. Dépose du capot

2 Soulevez le capot d’environ 3

cm. Tout en tenant le couvercle

incliné à cet angle, tirez-le vers

vous pour l’enlever.

3 Mettez la cartouche à ruban en

place dans le sens indiqué dans la

figure 4-2 et appuyez légèrement

sur la cartouche afin qu’elle se

mette en place. Si la mise en

place de la cartouche n’est pas

satisfaisante, appuyez sur la cartouche tout en faisant tourner le

bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

FRANÇAIS

Tête d’impression

Ruban encreur

Bouton

d’alimentation

du ruban

Parties avec

encoches

Cartouche à ruban

Fig. 4-2 Mise en place de la cartouche à

ruban

4 Pour tendre le ruban, faites tour-

ner le bouton d’alimentation du

ruban de la cartouche dans le

sens de la flèche.

5 Pour remettre en place le capot,

suivant la procédure décrite à

l’étape 2 dans le sens inverse.

– 28 –

Page 32

A

FRANÇAIS

Fig. 4-3

4-1-2.Chargement du papier

Remarque: Pour enlever la cartouche à

ruban, soulevez la partie A,

puis enlevez la cartouche en la

tenant par la partie B comme

indiqué dans la figure 4-3.

B

Touche

d’avance

de papier (FEED)

Fig. 4-4 Dépose du capot

Capot

1 Soulevez le capot d’environ 3 cm.

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

– 29 –

Page 33

Rouleau de papier

Support de rouleau

de papier

Fig. 4-5 Chargement du papier

Nervure de

positionnement

Tube central

Axe

Capot

Rouleau

de papier

2 Coupez l’extrémité du papier

perpendiculairement.

3 Vérifiez si l’imprimante est bien sous

tension.

4 Insérez l’extrémité du papier sous le

guide de papier aussi loin que possible

en faisant attention au sens du rouleau.

Lorsque le rouleau est en place, le papier ressort automatiquement par la fente

de sortie de l’imprimante.

5 Déplacez le support de rouleau de pa-

pier dans le sens de la flèche, et insérez

le rouleau de telle façon que les orifices

du tube s’alignent sur les axes du support de rouleau de papier. Relâchez le

support de rouleau de papier pour maintenir en place le papier.

6 Si le tube du rouleau de papier n’a pas

été aligné correctement sur le support

de rouleau de papier, le capot ne pourra

pas être bien refermé. Pour pouvoir

refermer le capot, vous devrez corriger

la position du papier.

7 Appuyez sur la touche d’avance FEED

pour faire avancer le papier de 10 cm

environ.

8 Insérez l’extrémité du papier dans la

fente de sortie où se trouve la barre de

découpage, puis remettez le capot en

place en suivant la procédure de dépose

du capot décrite à l’étape 1 ci-dessus

dans le sens inverse.

Remarque: Quand le repère de fin de

papier apparaît sur le papier, remplacez le rouleau

de papier avant qu’il soit

terminé.

FRANÇAIS

Support de rouleau de papier

Fig. 4-6

Barre de

découpage

Touche d’avance FEED

– 30 –

Fig. 4-7

Page 34

4-2. Modèle SP240

4-2-1.Installation d’une cartouche à ruban

FRANÇAIS

Hors tension

Fig. 4-8 Dépose du capot

Unité de découpage

automatique

Capot

1 Mettez l’imprimante hors tension.

2 Soulevez le capot d’environ 3

cm. Tout en tenant le couvercle

incliné à cet angle, tirez-le vers

vous pour l’enlever.

3 Soulevez l’unité de découpage

automatique pour la mettre en

position verticale, comme indiqué dans la figure 4-9.

Fig. 4-9 Redressement de l’unité de

découpage automatique

– 31 –

Page 35

Bouton

d’alimentation

du ruban

Parties avec

encoches

Tête d’impression

Ruban encreur

Cartouche à ruban

Unité de

découpage

automatique

4 Mettez la cartouche à ruban en

place dans le sens indiqué dans la

figure 4-10 et appuyez légèrement sur la cartouche afin qu’elle

se mette en place. Si la mise en

place de la cartouche n’est pas

satisfaisante, appuyez sur la cartouche tout en faisant tourner le

bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

5 Pour tendre le ruban, faites tour-

ner le bouton d’alimentation du

ruban de la cartouche dans le

sens de la flèche.

FRANÇAIS

Fig. 4-10 Mise en place de la cartouche à

ruban

A

B

Fig. 4-11

6 Refermez l’unité de découpage

automatique.

7 Pour remettre en place le capot,

suivez la procédure décrite à

l’étape 2 dans le sens inverse.

Remarque: Pour enlever la cartou-

che à ruban, soulevez

la partie A, puis enlevez la cartouche en la

tenant par la partie B

comme indiqué dans la

figure 4-11.

– 32 –

Page 36

4-2-2.Chargement du papier

FRANÇAIS

Touche

d’avance

de papier (FEED)

Capot

1 Soulevez le capot d’environ 3 cm.

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

Fig. 4-12 Dépose du capot

Rouleau de papier

Support de

rouleau de papier

Fig. 4-13 Chargement du papier

Tube central

Axe

– 33 –

2 Coupez l’extrémité du papier

perpendiculairement.

3 Vérifiez si l’imprimante est bien

sous tension.

4 Insérez l’extrémité du papier sous le

guide de papier aussi loin que possible en faisant attention au sens du

rouleau. Lorsque le rouleau est en

place, le papier ressort automatiquement par la fente de sortie de

l’imprimante. Après la sortie de 2

cm de papier, le papier est automatiquement coupé.

5 Déplacez le support de rouleau de

papier dans le sens de la flèche, et

insérez le rouleau de telle façon que

les orifices du tube s’alignent sur les

axes du support de rouleau de papier. Relâchez le support de rouleau

de papier pour maintenir en place le

papier.

6 Si le tube du rouleau de papier n’a

pas été aligné correctement sur le

support de rouleau de papier, le capot

ne pourra pas être bien refermé. Pour

pouvoir refermer le capot, vous devrez corriger la position du papier.

Page 37

7 Appuyez sur la touche d’avance

FEED pour faire avancer le papier

de 10 cm environ.

Nervure de

positionnement

Support de rouleau de papier

Fig. 4-14

Unité de

Fente

d’insertion

du papier

découpage

automatique

Fig. 4-15 Insertion du papier dans

l’unité de découpage automatique

Capot

Rouleau

de papier

FRANÇAIS

8 Insérez l’extrémité du papier dans

la fente de l’unité de découpage

automatique.

• Quand vous utilisez du papier pour

copie, insérez seulement l’original

(feuille supérieure) dans la fente de

l’unité de découpage automatique.

Insérez le papier de copie (feuille

inférieure) entre le cylindre et l’unité

de découpage automatique.

– 34 –

Page 38

Feuille

supérieure

FRANÇAIS

d’impression

Tête

Fente

d’insertion

du papier

Cylindre

Fente d’insertion

du papier

Unité de découpage

automatique

Feuille supérieure

Feuille inférieure

Feuille inférieure

Tête

d’impression

Cylindre

Fig. 4-16 Insertion du papier dans l’unité de découpage automatique

(avec utilisation de papier pour copie)

Sortie

de papier

9 Tirez sur l’extrémité du papier afin

de tendre le papier, puis rabaissez

l’unité de découpage automatique.

0 Insérez le papier dans la sortie de

papier, puis remettez le capot en

place en suivant la procédure de

Unité de

découpage

automatique

Fig. 4-17 Fente de sortie du cache

avant

dépose du capot dans le sens inverse.

Remarque: Quand le repère de fin de

papier apparaît sur le papier, remplacez le rouleau

de papier avant qu’il soit

terminé.

– 35 –

Touche

d’avance FEED

Fig. 4-18

Page 39

4-3. Enlèvement d’un rouleau de papier

Retirez le capot, puis coupez le papier juste derrière le guide de papier et appuyez

sur la touche d’avance FEED afin de faire sortir le reste du papier qui se trouve

toujours dans l’imprimante.

Quand tout le papier est sorti, le témoin POWER clignote.

Remarques 1. Enfoncez la touche d’avance FEED pour retirer le reste du papier

qui se trouve dans l’imprimante.

2. N’attendez pas que le rouleau de papier soit épuisé avant de le

remplacer. Remplacez-le dès que le repère de fin de rouleau

apparaît.

3. Pour enlever le tube du rouleau de papier, ouvrez le support de

rouleau de papier.

4-4. Connexion du câble d’interface

4-4-1.Installation du tore de ferrite (UE seulement)

1 Mettez le tore de ferrite en place sur

le câble d’interface série/parallèle

comme indiqué dans l’illustration.

Tore de ferrite

Interface câble

5 cm

maximum

Attache

Si le tore de ferrite n’est pas ouvert,

utilisez un tournevis pour l’ouvrir,

en prenant soin de ne pas endommager le tore de ferrite ou le dispositif

de fermeture en plastique.

2 Faites passer l’attache dans le tore

de ferrite.

3 Faites passer l’attache autour du

câble et fermez-la.

Coupez toute partie qui dépasse avec

des ciseaux.

Attachez le tore de ferrite uniquement sur les câbles des imprimantes

vendues dans les pays de l’UE.

FRANÇAIS

Tirer et couper

Fig. 4-19

– 36 –

Page 40

4-4-2.Câble d’interface série

Tore de ferrite

(UE seulement)

FRANÇAIS

Tournevis

Fig. 4-20 Connexion du câble

d’interface série

4-4-3.Câble d’interface parallèle

Tore de ferrite

(UE seulement)

Fig. 4-21 Connexion du câble

d’interface parallèle

Vis

1 Mettez l’ordinateur hôte et

l’imprimante hors tension.

2 Insérez un des connecteurs du câble

d’interface dans la prise de

l’imprimante et l’autre dans la prise

de l’ordinateur hôte.

3 Serrez ensuite les vis droite et gau-

che des connecteurs pour les fixer

aux prises.

1 Mettez l’ordinateur hôte et

l’imprimante hors tension.

2 Insérez un des connecteurs du câble

d’interface dans la prise de

l’imprimante comme indiqué dans

le schéma, et fixez-le avec les fermoirs

3 Insérez l’autre connecteur du câble

d’interface dans la prise de l’ordinateur hôte, puis fixez-le également

avec les fermoirs.

– 37 –

Page 41

5. Panneau de Commande

5-1. Fonctionnement de base

ON LINEPOWER FEED

1 Touche ON LINE

Cette touche permet de mettre

l’imprimante en ligne ou hors ligne.

Vous ne pouvez effectuer cette

commutation que si du papier est

chargé dans l’imprimante.

3 4 1 2

2 Touche d’avance FEED

• Si vous appuyez sur cette touche,

Fig. 5-1 Panneau de commande

puis la relâchez moins de 0,5 seconde après, le papier avancera

d’une ligne à la fois.

• Si vous maintenez la pression sur

cette touche pendant plus de 0,5

seconde, le papier avancera de façon continue.

(Cela est valable que l’imprimante

soit en ligne ou hors ligne.)

3 Témoin d’alimentation POWER (DEL verte)

• Ce témoin s’allume quand l’imprimante est sous tension.

• Ce témoin clignote quand il n’y a plus de papier dans l’imprimante, quand une

erreur mécanique ou une surchauffe de la tête d’impression est détectée, ou

quand une erreur s’est produite au niveau de l’unité centrale de traitement.

• Si le papier est épuisé, mettez en place un nouveau rouleau, puis appuyez sur

la touche ON LINE.

• Si le témoin POWER clignote en raison d’une erreur mécanique, mettez

l’imprimante hors tension, puis éliminez la cause de l’erreur mécanique et

remettez l’imprimante sous tension pour la réinitialiser.

• Si le témoin POWER clignote après avoir détecté une surchauffe de la tête

d’impression, l’imprimante sera réinitialisée automatiquement quand la température de la tête d’impression aura baissé.

4 Témoin ON LINE (DEL verte)

DEL allumée : L’imprimante est en ligne

DEL éteinte : L’imprimante est hors ligne

DEL clignotante : Erreur de l’unité centrale

FRANÇAIS

Quand les témoins POWER et ON LINE s’allument simultanément, une

erreur s’est produite au niveau de l’unité centrale de traitement.

– 38 –

Page 42

5-2. Utilisation des touches (Utilisation combinée des touches)

1 <Test d’impression>

FEED + POWER ON (Mettez l’imprimante sous tension tout en maintenant

la touche FEED enfoncée.)

Le test d’impression sera effectué conformément au réglage du numéro de

FRANÇAIS

vérification, des commutateurs DIP et de l’ordre des caractères. Si vous

maintenez la pression sur la touche FEED ou si vous appuyez sur la touche

FEED à la fin du test d’impression, seuls les caractères seront imprimés à

plusieurs reprises.

Fig. 5-2 Exemple d’impression d’essai (quand l’imprimante est utilisée avec

l’interface RS-232C série)

– 39 –

Page 43

2 <Vidage hexadécimal>

ON LINE + POWER ON (Mettez l’imprimante sous tension tout en maintenant

la touche ON LINE enfoncée.)

Chacun des signaux envoyés de l’ordinateur à l’imprimante sera imprimé en

code hexadécimal.

Cette fonction vous permet de vérifier si un code de contrôle envoyé à

l’imprimante par le programme utilisé est correct ou non. La dernière ligne

n’est pas imprimée si les données correspondantes ne remplissent pas une

ligne complète. Néanmoins, si vous appuyez sur la touche ON LINE pour

mettre l’imprimante hors ligne, la dernière ligne sera imprimée. Pour sortir de

ce mode, il est nécessaire de mettre l’imprimante hors tension.

Fig. 5-3 Exemple d’impression d’essai avec vidage hexadécimal

FRANÇAIS

– 40 –

Page 44

6. Codes de contrôle

Mode STAR

6-1. Commandes utilisées pour le réglage des caractères

Code de contrôle Code hexadécimal Fonction

FRANÇAIS

<ESC> “R” n 1B 52 n Sélection du jeu de caractères internationaux. Le

réglage par défaut est fonction du réglage des commutateurs DIP 3, 4 et 5.

<ESC> “M” 1B 4D Sélection du format de caractère 7 × 7 (demi points)

(réglage par défaut)

<ESC> “P” 1B 50 Sélection du format de caractère 9 × 7 (demi points)

<SO> 0E Sélection des caractères élargis

<SI> 0F Annulation de la sélection des caractères élargis

(réglage par défaut)

<DC4> 14 Annulation de la sélection des caractères élargis

(réglage par défaut)

<ESC> “W” “1” 1B 57 31 Sélection des caractères élargis

<ESC> “W” <1> 1B 57 01

<ESC> “W” “0” 1B 57 30 Annulation de la sélection des caractères élargis

<ESC> “W” <0> 1B 57 00 (réglage par défaut)

6-2. Commandes utilisées pour le réglage du mode

d’impression

Code de contrôle Code hexadécimal Fonction

<ESC> “4” 1B 34 Sélection de la couleur d’impression rouge (valide

pour la SP216/246)

<ESC> “5” 1B 35 Annulation de la sélection de la couleur d’impression

rouge (valide pour la SP216/246) (réglage par défaut)

<ESC> “E” 1B 45 Sélection du mode d’impression avec mise en valeur

<ESC> “F” 1B 46 Annulation de la sélection du mode d’impression

avec mise en valeur (réglage par défaut)

6-3. Commandes utilisées pour l’espacement des lignes

Code de contrôle Code hexadécimal Fonction

<LF> 0A Avance ligne par ligne

<CR> 0D Avance ligne par ligne (comme avec LF)

<ESC> “a” n 1B 61 n Avance du papier sur n lignes

– 41 –

Page 45

6-4. Commandes utilisées pour le pilotage des appareils

périphériques

Code de contrôle Code hexadécimal Fonction

<ESC> <BEL> n1 n2 1B 07 n1 n2 Réglage de la largeur d’impulsion d’entraînement

du périphérique (réglage par défaut)

<BEL> 07 Commande d’entraînement différé “A” de l’appa-

reil périphérique 1

<FS> 1C Commande d’entraînement immédiat “B” de l’ap-

pareil périphérique 1

6-5. Commandes de pilotage de l’unité de découpage

automatique (Modèle SP240 seulement)

Code de contrôle Code hexadécimal Fonction

<ESC> “d” “0” 1B 64 30 Commande de découpage complet adressée à l’unité

<ESC> “d” <0> 1B 64 00 de découpage automatique

<ESC> “d” “1” 1B 64 31 Commande de découpage partiel adressée à l’unité

<ESC> “d” <1> 1B 64 01 de découpage automatique

<ESC> “d” “2” 1B 64 32 Commande de coupe complè te au couteau

<ESC> “d” <2> 1B 64 02 automatique après une avance de papier.

<ESC> “d” “3” 1B 64 33 Commande de d’ecoupe partielle au mécanisme

<ESC> “d” <3> 1B 64 03 automatique après une avance de papier.

6-6. Autres commandes

Code de contrôle Code hexadécimal Fonction

<CAN> 18 Effacement des données d’impression dans la mé-

moire tampon

<ENQ> *

<DC1> *

<DC3> *

<ESC> “@” 1B 40 Initialisation de l’imprimante

<ESC> “e” “0” 1B 65 30 Validation de la combinaison de touches ON LINE/

<ESC> “e” <0> 1B 65 00 FEED (réglage par défaut)

<ESC> “e” “1” 1B 65 31 Annulation de la combinaison de touches ON LINE/

<ESC> “e” <1> 1B 65 01 FEED

<ESC> “f” “0” 1B 66 30 Validation de la combinaison de touches ON LINE

<ESC> “f” <0> 1B 66 00 (réglage par défaut)

<ESC> “f” “1” 1B 66 31 Annulation de la touche ON LINE

<ESC> “f” <1> 1B 66 01

1 05 Interrogation

1 11 Réglage du mode de sélection

1 13 Désélection de l’imprimante

FRANÇAIS

1 : Valable pour la RS-422A uniquement.

*

– 42 –

Page 46

FRANÇAIS

– 43 –

Page 47

INHALTSVERZEICHNIS

1. Kurzbeschreibung............................................................................................45

2. Auspacken und Aufstellen...............................................................................46

2-1. Überprüfen ...........................................................................................46

2-2. Wahl eines Aufstellungsorts für den Drucker......................................47

2-3. Hinweise zum Umgang ........................................................................47

2-4. Wartung................................................................................................47

3. Beschreibung und Bezeichnung der Geräteteile..............................................48

4. Einlegen von Farbbandkassette und Papier .....................................................50

4-1. Typ SP210............................................................................................50

4-2. Typ SP240............................................................................................53

4-3. Entfernen des Rollenpapiers ................................................................58

4-4. Anschließen des Schnittstellenkabels ..................................................58

5. Bedienfeld........................................................................................................60

5-1. Grundlegender Betrieb .........................................................................60

5-2. Tastenbedienung (kombinierte Tastenbedienung) ...............................61

6. Steuercodes......................................................................................................63

STAR-Modus ...............................................................................................63

6-1. Steuercodes für Zeicheneinstellung .....................................................63

6-2. Steuercodes für Druckmoduseinstellung .............................................63

6-3. Steuercodes für Zeilenabstand .............................................................63

6-4. Steuercodes für Peripheriegeräte .........................................................64

6-5. Steuerung für Schneidwerk (nur Typ SP240) ......................................64

6-6. Andere Steuercodes .............................................................................64

ANHANG............................................................................................................87

DEUTSCH

Der Anhand dieser Bedienungsanleitung ist nur in englischer Sprache.

– 44 –

Page 48

1. Kurzbeschreibung

Der serielle Nadeldrucker der Serie SP200 ist zur Verwendung mit elektronischen Instrumenten wie POS, Bankgeräte, Computerzubehör, etc. gedacht.

Die wichtigsten Merkmale der Serie SP200 sind:

1. Bidirektioneller Druck mit ca. 2,5 Zeilen/s

2. Serielle oder parallele Schnittstelle

3. Pufferspeicher erlaubt, Druckdaten auch während des Druckvorgangs zu

empfangen.

4. Peripherie-Steuerschaltung zur Steuerung von externen Geräten wie Registrier-

DEUTSCH

kassen:

SP2 1 2 F D 42 – 120

Spannung

120 : 120 V AC

230 : 230 V AC

240 : 240 V AC

Anzahl der Druckspalten

42 : 42 Spalten (16 cpi)

Schnittstelle

D : Serielle Schnittstelle (RS-232C)

K : Serielle Schnittstelle (RS-422A)

C : Parallele Schnittstelle

Papiervorschub

F : Walzenvorschub

Mechanismus

2 : Einfarbig, 42 Spalten (16 cpi)

6 : Zweifarbig, 42 Spalten (16 cpi)

Druckertyp

1 : Standardtyp

4 : Mit automatischem Schneidwerk

Drucker Serie SP200

– 45 –

Page 49

2. Auspacken und Aufstellen

2-1. Überprüfen

Sie den Kartoninhalt, und vergewissern Sie sich, daß alle unten abgebildeten

Teile vorhanden sind.

Typ SP210

Drucker

Typ SP240

Drucker

Ferritkern

(nur EU)

Ferritkern

(nur EU)

Befestigungsband

(nur EU)

Farbbandkassette

DEUTSCH

Bedienungsanleitung

Befestigungsband

(nur EU)

Farbbandkassette

Abb. 2-1 Auspacken

– 46 –

Bedienungsanleitung

Page 50

2-2. Wahl eines Aufstellungsorts für den Drucker

Bevor Sie den Drucker auspacken, sollten Sie einige Minuten damit verbringen,

einen geeigneten Aufstellungsort auszusuchen. Denken Sie dabei an die folgenden

Punkte:

1. Den Drucker vor Hitzequellen wie direktem Sonnenlicht oder Heizkörpern

schützen und von Feuchtigkeit und Staub fernhalten.

2. Den Drucker auf einem flachen, aber festen Untergrund aufstellen, wo keine

Vibrationen vorhanden sind.

3. Sicherstellen, daß der Drucker an eine einwandfreie Stromzufuhr angeschlossen ist.

Er sollte nicht an Steckdosen angeschlossen werden, an denen bereits Geräte mit

möglichen Netzstörungen wie Kopierer, Kühlschränke u.a. angeschlossen sind.

4. Die Versorgungsspannung muß dem Spannungswert auf dem Typenschild an der

DEUTSCH

Unterseite des Druckers entsprechen.

5. Die verwendete Steckdose soll in der Nähe und frei zugänglich sein.

2-3. Hinweise zum Umgang

1. Achten Sie darauf, keine Papierclips oder anderen Fremdkörper in den Drucker

fallen zu lassen. Diese können Betriebsstörungen oder Schäden am Gerät hervorrufen.

2. Versuchen Sie nicht zu drucken, wenn kein Papier oder keine Farbbandkassette

eingelegt ist, da sonst der Druckkopf beschädigt werden kann.

3. Öffnen Sie nicht die Frontabdeckung während des Druckens.

4. Berühren Sie nicht den Druckkopf sofort nach dem Druckvorgang, da dieser sehr

heiß wird.

5. Verwenden Sie nur Rollenpapier, das nicht am Rollenkern festgeklebt ist.

6. Wenn die Papierende-Markierung erscheint, tauschen Sie die Papierrolle aus,

bevor sie ganz verbraucht ist.

2-4. Wartung

Ihr Drucker ist ein robust gebautes Gerät, sollte aber trotzdem mit einem gewissen

Maß an Vorsicht behandelt werden, um Fehlfunktionen zu vermeiden. Zum Beispiel:

1. Stellen Sie den Drucker in einer “komfortablen” Betriebsumgebung auf. Als

Faustregel gilt: Wo Sie sich wohlfühlen, fühlt sich der Drucker ebenfalls wohl.

2. Setzen Sie den Drucker keinen Erschütterungen oder starken Vibrationen aus.

3. Vermeiden Sie sehr staubige Umgebungen. Staub ist der Erzfeind aller Präzisionsgeräte.

4. Zum Reinigen des Gehäuses verwenden Sie einen nur leicht mit Wasser, sehr

milder wässriger Seifenlösung oder ein wenig Alkohol angefeuchteten Lappen.

Lassen Sie auf keinen Fall Flüssigkeiten in das Innere des Druckers geraten.

5. Das Innere des Druckers kann mit einem kleinen Reiniger oder einem Luftspray

(in Fachgeschäften erhältlich) gereinigt werden. Bei dieser Arbeit darauf achten,

keine Kabelverbindungen oder elektronische Bauteile zu verbiegen oder zu

beschädigen.

– 47 –

Page 51

3. Beschreibung und Bezeichnung der Geräteteile

Typ SP210

Abdeckung

Schüzt den Drucker vor

Staub, und reduziert das

Betriebsgeräsch. Nicht die

Frontabdeckung würend

des Druckens öfnen.

Netzkabel

Zum Anschluß an eine

Netzbuchse. Der Stecker

ist je nach Bestimmungsland

unterschiedlich ausgelegt.

Schnittstellenbuchse

Zum Anschluß des

Druckers an den

Hostcomputer.

Bedienfeld

Hat zwei

Bedienungstasten

und zwei Anzeigen

zur Anzeige des

Druckerzustands.

Peripheriegerät-Steueranschluß

Zum Anschluß an Peripheriegeräte

wie Registrierkassen etc. Nicht zum

Anschluß an ein Telefon!

DEUTSCH

Abb. 3-1 Außenansicht des Druckers (Typ SP210)

– 48 –

Page 52

Typ SP240

DEUTSCH

Abdeckung

Schützt den Drucker vor

Staub, und reduziert das

Betriebsgeräusch. Nicht die

Frontabdeckung während

des Druckens öffnen.

Bedienfeld

Hat zwei

Bedienungstasten und

zwei Anzeigen zur

Anzeige des

Druckerzustands.

Netzkabel

Zum Anschluß an eine

Netzbuchse. Der Stecker

ist je nach Bestimmungsland

unterschiedlich ausgelegt.

Schnittstellenbuchse

Zum Anschluß des

Druckers an den

Hostcomputer.

Peripheriegerät-Steueranschluß

Zum Anschluß an Peripheriegeräte

wie Registrierkassen etc. Nicht zum

Anschluß an ein Telefon!

Abb. 3-2 Außenansicht des Druckers (Typ SP240)

– 49 –

Page 53

4. Einlegen von Farbbandkassette und Papier

4-1. Typ SP210

4-1-1.Einlegen der Farbbandkassette

Frontabdeckung

Netzschalter aus

1 Den Netzschalter am Drucker in

Aus-Stellung stellen.

2 Zum Abnehmen der Frontab-

deckung diese ca. 3 cm anheben,

und nach vorne ziehen.

3 Die Farbbandkassette in der Rich-

tung einsetzen wie in der Abbildung 4-2 gezeigt und eindrücken,

bis sie hörbar einrastet. Wenn die

Farbbandkassette nicht richtig

sitzt, eingedrückt halten und

gleichzeitig den Farbbandknopf

in Pfeilrichtung drehen.

DEUTSCH

Abb. 4-1 Abdeckung abnehmen

Druckkopf

Farbband

Farbbandzuführknopf

Kerbteil

Farbbandkassette

Abb. 4-2 Einlegen der Farbbandkassette

4 Um Schlaufen im Farbband auf-

zuwickeln, den Farbbandzuführknopf der Farbbandkassette in

Pfeilrichtung drehen.

5 Zum Anbringen der Frontab-

deckung die Ausbauschritte wie

in 2 oben beschrieben in umgekehrter Reihenfolge ausführen.

– 50 –

Page 54

A

DEUTSCH

4-1-2.Einlegen von Papier

Hinweis: Beim Entfernen der Farbband-

kassette den Teil A anheben und

dann die Kassette an Teil B halten und Abziehen wie in Abbildung 4-3 gezeigt.

B

Abb. 4-3

Abdeckung

FEEDTaste

Abb. 4-4 Entfernen der Abdeckung

1 Die Abdeckung um etwa 3 cm anhe-

ben. Die Abdeckung in diesem Winkel halten, und dann zum Entfernen

nach vorne ziehen.

– 51 –

Page 55

Rollenpapier

Abb. 4-5 Papier einlegen

Positionierungsrippe

Kern

Achse

Papierrollenhalter

Abdeckung

Rollenpapier

2 Schneiden Sie die Vorderkante des Rollen-

papiers in einer geraden Linie ab.

3 Bestätigen Sie, daß der Drucker einge-

schaltet ist.

4 Unter Beachtung der Richtung des Rollen-

papiers führen Sie die Vorderkante des

Papiers unter der Papierführung so weit

wie möglich ein. Wenn die Rolle einglegt

ist, kommt das Vorderende des Papiers

automatisch aus dem Papierauslaufschlitz.

5 Bewegen Sie den Papierrollenhalter in

Pfeilrichtung und setzen Sie die Role so

ein, daß die Löcher in der Kernführung

mit den Achsen des Papierrollenhalters

übereinstimmen.

Lassen Sie den Papierrollenhalter los, um

das Papier festzuhalten.

6 Wenn der Papierrollenkern nicht richtig

mit dem Papierrollenhalter ausgerichtet

ist, kann die Abdeckung nicht richtig geschlossen werden, bevor die Papierposition korrigiert ist.

7 Drücken Sie die FEED-Taste

(Papiervorschub), um das Papier um ca.

10 cm vorzuschieben.

8 Führen Sie die Oberkante des Papiers in

den Abreißkantenschlitz ein, und bringen

dann die Abdeckung an, indem Sie die

Ausbauschritte von Schritt 1 oben in

umgekehrter Reihenfolge ausführen.

Hinweis: Wenn die Papierendmarkie-

rung auf dem Papier erscheint,

das Rollenpapier austauschen,

bevor es zu Ende geht.

DEUTSCH

Papierrollenhalter

Abreißschlitz

Abb. 4-6

FEED-Taste

Abb. 4-7

– 52 –

Page 56

4-2. Typ SP240

4-2-1.Einlegen der Farbbandkassette

Netzschalter aus

DEUTSCH

Abb. 4-8 Abdeckung abnehmen

Frontabdeckung

1 Stellen Sie den Netzschalter am

Drucker in Aus-Stellung.

2 Zum Abnehmen der Frontab-

deckung heben Sie diese ca. 3 cm

an, und ziehen sie dann nach vorne.

Schneidwerk

Abb. 4-9 Anheben des Schneidwerks

3 Heben Sie das Schneidwerk an

und stellen es in senkrechte Stellung, wie in Abbildung 4-9 gezeigt.

– 53 –

Page 57

Farbbandknopf

Kerbteil

Druckkopf

Farbband

Schneidwerk

4 Die Farbbandkassette in der Rich-

tung einsetzen wie in der Abbildung 4-10 gezeigt und

eindrücken, bis sie hörbar einrastet. Wenn die Farbbandkassette nicht richtig sitzt, eingedrückt halten und gleichzeitig

den Farbbandknopf in Pfeilrichtung drehen.

5 Um Schlaufen im Farbband auf-

zuwickeln, den Farbbandzuführknopf der Farbbandkassette in

Pfeilrichtung drehen.

Farbbandkassette

Abb. 4-10 Einlegen einer Farbband-

kassette

A

B

Abb. 4-11

6 Das Schneidwerk schließen.

7 Zum Anbringen der Frontab-

deckung die Ausbauschritte wie

in 2 beschrieben in umgekehrter Reihenfolge ausführen.

Hinweis: Beim Entfernen der

Farbbandkassette den

Teil A anheben und dann

die Kassette an Teil B halten und Abziehen wie in

Abbildung 4-11 gezeigt.

DEUTSCH

– 54 –

Page 58

4-2-2.Einlegen von Papier

DEUTSCH

FEEDTaste

Abdeckung

1 Die Abdeckung um etwa 3 cm anhe-

ben. Die Abdeckung in diesem Winkel halten, und dann zum Entfernen

nach vorne ziehen.

Abb. 4-12 Entfernen der Abdeckung

Rollenpapier

Kern

Papierrollenhalter

Abb. 4-13 Einlegen des Papiers

Achse

2 Schneiden Sie die Vorderkante des

Rollenpapiers in einer geraden Linie ab.

3 Bestätigen Sie, daß der Drucker ein-

geschaltet ist.

4 Unter Beachtung der Richtung des

Rollenpapiers führen Sie die Vorderkante des Papiers unter der

Papierführung so weit wie möglich

ein. Wenn die Rolle einglegt ist,

kommt das Vorderende des Papiers

automatisch aus dem Papierauslaufschlitz. Nachdem etwa 2 cm Papier

ausgeschoben sind, wird das

Papier automatisch abgeschnitten.

5 Bewegen Sie den Papierrollenhalter

in Pfeilrichtung und setzen Sie die

Role so ein, daß die Löcher in der

Kernführung mit den Achsen des

Papierrollenhalters übereinstimmen.

Lassen Sie den Papierrollenhalter

los, um das Papier festzuhalten.

6 Wenn der Papierrollenkern nicht rich-

tig mit dem Papierrollenhalter ausgerichtet ist, kann die Abdeckung n

icht richtig geschlossen werden, bevor die Papierposition korrigiert ist.

– 55 –

Page 59

7 Drücken Sie die FEED-Taste

(Papiervorschub), um das Papier um

ca. 10 cm vorzuschieben.

Positionierrippe

Papierrollenhalter

Abdeckung

Rollenpapier

Abb. 4-14

Schnei-

Papiereinführschlitz

dwerk

Abb. 4-15 Einführen des Papiers in das

Schneidwerk

DEUTSCH

8 Führen Sie die Oberkante des Pa-

piers in den Schlitz des PapierSchneidwerks ein.

• Bei Verwendung von Durchschlagpapier führen Sie nur das Original

(den oberen Teil) in den Schlitz des

Schneidwerks ein. Führen Sie das

zu kopierende Papier (das untere

Papier) zwischen Druckwalze und

Schneidwerk ein.

– 56 –

Page 60

Oberes

Papier

Druckkopf

Papiereinführschlitz

Druckwalze

Papiereinführschlitz

Schneidwerk

Oberes Papier

Unteres Papier

DEUTSCH

Abb. 4-16 Einführen des Papiers in das Schneidwerk

(bei Verwendung von Durchschlagpapier)

Papierauslaß

Abb. 4-17 Papierauslaß an der Front-

abdeckung

Unteres Papier

Schneidwerk

Druckkopf

Druckwalze

9 Ziehen Sie die Kante des Papiers-

tau, um Schlaufen zu beseitigen,

und senken Sie dann das

Schneidwerk ab.

0 Führen Sie das Papier durch den

Papierauslaß, und setzen Sie dann

die Abdeckung wieder auf, indem

Sie die Ausbauschritte in umgekehrter Reihenfolge ausführen.

Hinweis: Wenn die Papierendmarkie-

rung auf dem Papier erscheint, das Rollenpapier

austauschen, bevor es zu

Ende geht.

– 57 –

FEED-Taste

Abb 4-18

Page 61

4-3. Entfernen des Rollenpapiers

Nehmen Sie die Abdeckung ab, und schneiden Sie das Papier in der Nähe der

Papierführung ab. Dann drücken Sie die FEED-Taste, um den Rest des Papiers

auszugeben, der noch in der Einheit ist.

Wenn das Papier verbraucht ist, blinkt das Lämpchen POWER.

Hinweis 1. Durch Drücken der FEED-Taste wird der Rest des noch im Drucker

befindlichen Papiers ausgegeben.

2. Wenn die Papier-Verbraucht-Markierung auf dem Papier erscheint,

tauschen Sie die Rolle aus, bevor das Papier ganz zu Ende ist.

3. Beim Entfernen des Kerns der Papierrolle den Rollenpapierhalter öffnen.

4-4. Anschließen des Schnittstellenkabels

4-4-1.Anbringen des Ferritkerns (nur EU)

Schnittstelle kabel

Maximum

5 cm

Befestigungsband

Ziehen und abschneiden

Ferritkern

1 Bringen Sie den Ferritkern am

seriellen/parallelen Schnittstellenkabel an wie in der Abbildung gezeigt. Wenn ein Ferritkern nicht offen ist, hebeln Sie ihn mit einem

Schraubenzieher auf, achten aber

darauf, den Kern oder die

Verriegelung nicht zu beschädigen.

2 Führen Sie das Befestigungsband

durch den Ferritkern.

3 Führen Sie das Befestigungsband

um das Kabel und sperren Sie es.

Schneiden Sie überschüssiges Band

mit einer Schere ab. Bringen Sie

den Ferritkern nur an im Gebiet der

EU verkauften Druckern an.

DEUTSCH

Abb. 4-19

– 58 –

Page 62

4-4-2.Serielles Schnittstellenkabel

Ferritkern

(nur EU)

Schraubenzieher

DEUTSCH

Abb. 4-20 Anschließen des Schnittst-

ellenkabels

4-4-3.Paralleles Schnittstellenkabel

Ferritkern

(nur EU)

Abb. 4-21 Anschließen des parallelen

Schnittstellenkabels

Schrauben

1 Schalten Sie sowohl den

Hostcomputer als auch den Drucker

aus.

2 Stecken Sie den Stecker des

Schnittstellenkabels in die entsprechenden Buchsen am Drucker und

am Hostcomputer ein.

3 Ziehen Sie die linken und rechten

Schrauben an den Steckern fest, um

den festen Sitz des Steckers zu sichern.

1 Schalten Sie sowohl den

Hostcomputer als auch den Drucker

aus.

2 Stecken Sie einen Stecker des

Schnittstellenkabels in die parallele

Schnittstellenbuchse am Drucker,

und klemmen Sie ihn mit den Haltebügeln fest.

3 Stecken Sie den anderen Stecker

des Schnittstellenkabels in die parallele Schnittstellenbuchse am

Hostcomputer, und klemmen Sie ihn

mit den Haltebügeln fest.

– 59 –

Page 63

5. Bedienfeld

5-1. Grundlegender Betrieb

ON LINEPOWER FEED

1 Taste ON LINE

Schaltet den Drucker zwischen Online und Off-line Betrieb um. Umschalten ist nur möglich, wenn Papier im Drucker eingelegt ist.

2 FEED-Taste

3 4 1 2

• Wenn diese Taste gedrückt und dann

innerhalb von 0,5 s losgelassen wird,

Abb. 5-1 Bedienfeld

wird das Papier um eine Zeile vorgeschoben.

• Wenn diese Taste länger als 0,5 s

gedrückt gehalten wird, wird das

Papier kontinuierlich vorgeschoben.

(Der obige Vorschubvorgang ist sowohl im On-line als auch im Offline Betrieb möglich.)

3 Netzlämpchen POWER (grüne LED)

• Leuchtet auf, wenn der Drucker mit Netzstrom versorgt wird.

• Blinkt, wenn das Papier verbraucht ist, eine mechanische Störung vorliegt,

wenn ein Alarm aufgrund von hoher Druckkopftemperatur ausgelöst wurde

oder ein CPU-Fehler aufgetreten ist.

• Wenn das Papier verbraucht ist, neues Papier einlegen und die Taste ON LINE

drücken.

• Wenn das Netzlämpchen POWER aufgrund eines mechanischen Fehlers

blinkt, den Drucker ausschalten und die mechanische Störung beheben. Dann

den Drucker wieder einschalten, um einen Reset auszuführen.

• Wenn das Netzlämpchen POWER aufgrund von hoher Druckkopftemperatur

blinkt, wird der Drucker automatisch wieder aktiviert, wenn die Kopftemperatur absinkt.

4 Lämpchen ON LINE (grüne LED)

LED leuchtet: Drucker im On-line-Betrieb

LED erloschen: Drucker im Off-line-Betrieb

LED blinkt: CPU-Fehler.

DEUTSCH

Wenn die Lämpchen POWER und ON LINE gleichzeitig leuchten, liegt ein

CPU-Fehler vor.

– 60 –

Page 64

5-2. Tastenbedienung (kombinierte Tastenbedienung)

1 <SELBSTDRUCK>

FEED + POWER ON (Gerät einschalten, während die Taste FEED gedrückt

gehalten wird.)

Der Selbstdruck wird entsprechend der VER.NO. DIP-Schaltereinstellung

und der Zeichenfolge ausgeführt. Wenn die Taste FEED kontinuierlich

gedrückt gehalten wird oder wenn FEED am Ende des Selbstdrucks gedrückt

wird, werden nur die Zeichen wiederholt ausgedruckt.

DEUTSCH