Page 1

USER’S MANUAL

LC-500

DOT MATRIX PRINTER

CFA10EC 80826160

Page 2

Manufacturer’s Declaration of Conformity

CE

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the Electro

Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the European

Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

LC-500: Star Micronics Co., Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without

STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time

of going to press. However, should any errors be detected, STAR would greatly appreciate

being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

©

Copyright 2003 Star Micronics Co., LTD.

Page 3

Contents

1. Printer Setup .............................................. 1

Choosing a place for the printer ....................................................... 1

Unpacking the printer ....................................................................... 2

Printer Components .......................................................................... 3

Installing the paper guide ................................................................. 4

Opening the printer cover ................................................................. 4

Removing the printer cover .............................................................. 5

Connecting the Power Cord and turning the power ON and OFF.... 6

Installing the ribbon cassette ............................................................ 7

Removing the ribbon cassette ......................................................... 10

Connecting to your computer using the parallel cable ................... 10

Ferrite Core Installation ................................................................... 11

2. Paper Handling ........................................ 13

Selecting paper types ...................................................................... 13

Cut-sheet paper ............................................................................... 13

Fanfold paper .................................................................................. 13

ENGLISH

Loading cut-sheet paper.................................................................. 14

Printing on cut-sheet paper ............................................................. 17

Loading fanfold paper .................................................................... 18

Printing on fanfold paper ................................................................ 22

Parking fanfold paper ..................................................................... 23

Unparking fanfold paper................................................................. 23

3. Control Panel Operations ....................... 24

Switching between on-line and off-line.......................................... 25

Page 4

Control panel functions in on-line mode ........................................ 25

Control panel functions in off-line mode ....................................... 27

4. Using the EDS Mode................................ 30

About EDS Mode settings .............................................................. 30

Entering the EDS Mode.................................................................. 30

Selecting a EDS number ................................................................. 31

Selecting a bank .............................................................................. 31

Selecting a switch ........................................................................... 31

Changing a switch setting ............................................................... 31

Printing the current EDS settings ................................................... 31

Exiting the EDS Modes .................................................................. 31

5. Control Codes List................................... 42

< ESC/P-K mode> .......................................................................... 42

6. Troubleshooting ....................................... 45

Short test ......................................................................................... 45

Long test ......................................................................................... 46

Hexadecimal dump ......................................................................... 46

Adjusting the dot alignment ........................................................... 47

Troubleshooting guide .................................................................... 48

Appendix A. Specifications ............................... 53

Appendix B. Character Sets ............................. 56

Appendix C. Control Panel Operation Guide.... 67

Page 5

1. Printer Setup

This chapter contains important information on setting up your printer. Be sure

to read this chapter carefully before using the printer for the first time.

Choosing a place for the printer

Before unpacking the printer from the box, plan the installation location

of your printer. Consider the following points.

✓ Choose a firm, level surface where the printer will not be exposed to

vibr ation.

✓ The power outlet you plan to connect to for power should be nearby

and unobstructed.

✓ Make sure that the printer is close enough to your computer for you

to connect the two with your printer cable.

✓ Allow six inches (15 centimeters) of free space on either side and in

the back of the printer.

✓ Make sure that the printer is not exposed to direct sunlight.

✓ Make sure that the printer is well away from heaters.

✓ Make sure that the surrounding area is clean, dry, and free of dust.

✓ Make sure that the printer is connected to a reliable power outlet. It

should not be on the same electric circuit as copiers, refrigerators, or

other appliances that cause power spikes.

✓ Use a power outlet that matches the power rating noted on the label

affixed to the bottom of your printer.

✓ Make sure that the room where you are using the printer is not too

humid.

– 1 –

Page 6

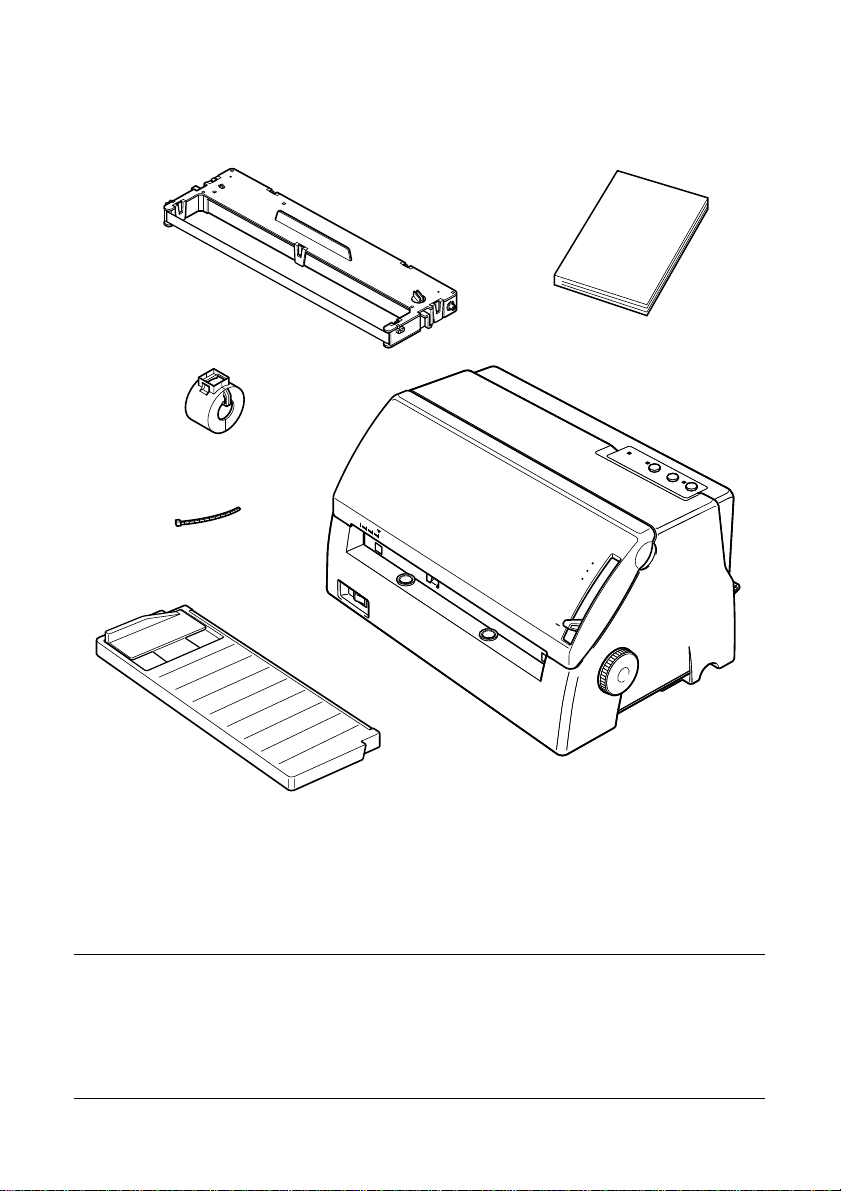

Unpacking the printer

Check that the package contains the following items.

ENGLISH

Ribbon cassette

Ferrite Core

Fastener

Printer

Paper guide

User,s manual

5

4

3

2

1

If any item is missing, contact the store where you bought the printer and

ask them to supply the missing part. Note that it is a good idea to keep the

original box and all packing materials in case you need to transport the

printer at a later date.

Important!

There are several versions of this printer designed for different

voltages. It is not possible to change the voltage of a printer. If the

voltage shown on the label on the back of your printer does not match

the voltage for your area, contact your dealer immediately.

– 2 –

Page 7

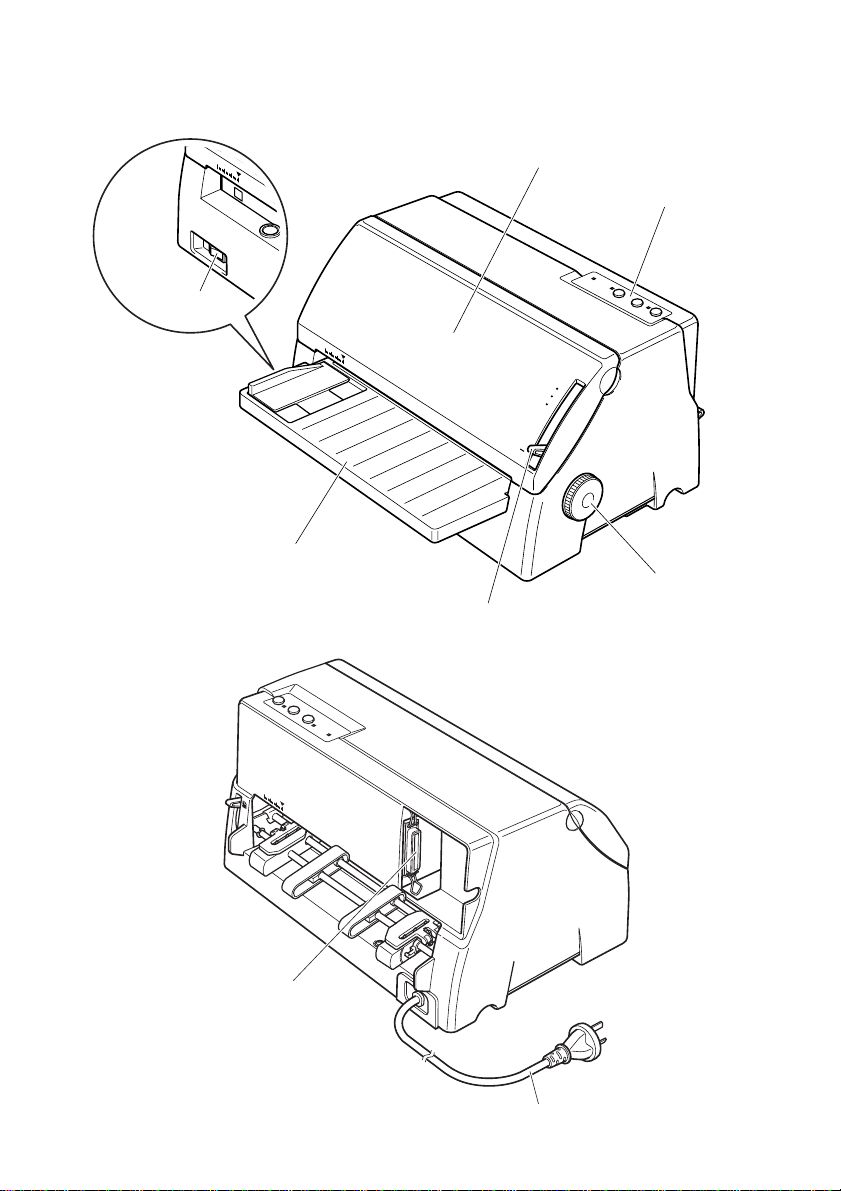

Printer Components

The following illustrations show the major components of your printer.

Power switch

Paper guide

Printer cover

5

4

3

2

1

Adjustment lever

Control panel

Platen knob

Parallel interface

connector

Power cord

– 3 –

Page 8

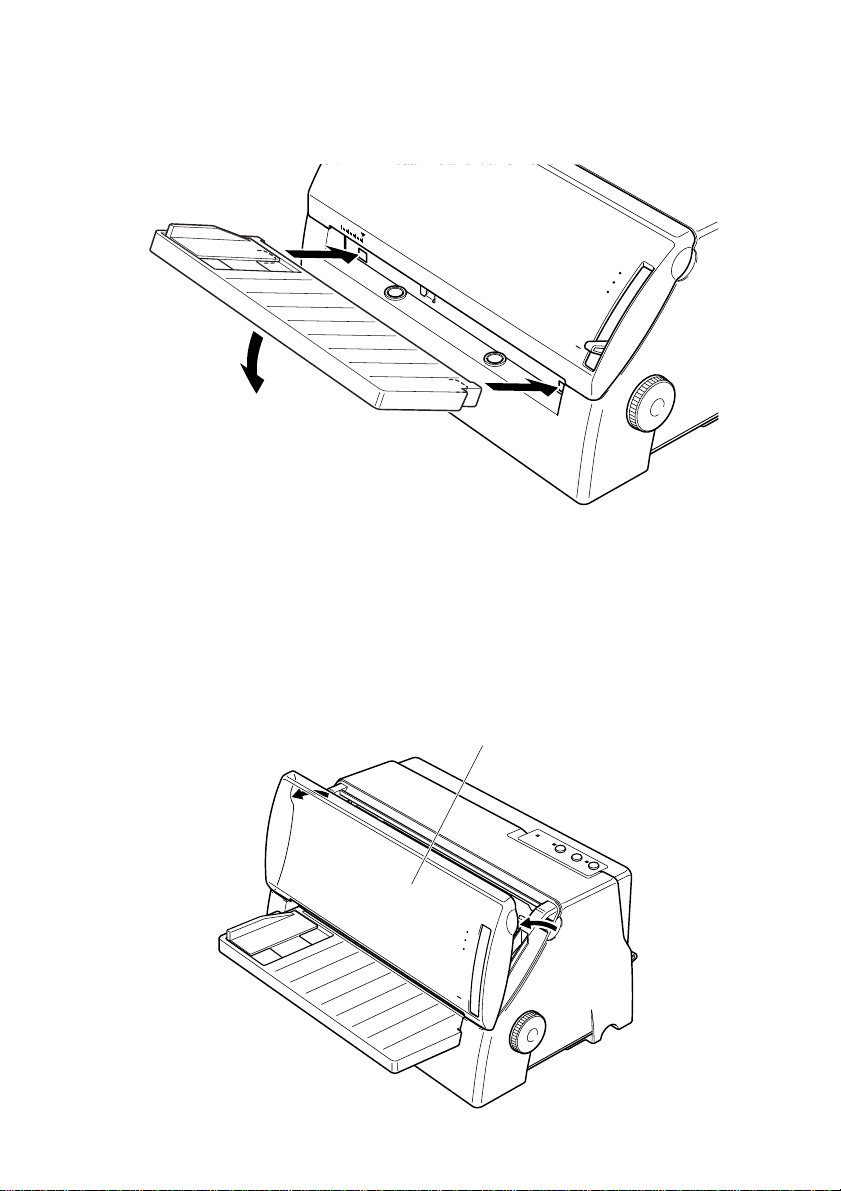

Installing the paper guide

4

5

1

2

3

1. Hold the paper guide at a slight angle and slide the two slots on either

side of the paper guide into the tabs provided on the printer case.

2. Press the paper guide firmly against the tabs until it clicks, and then

lower the table to a horizontal position.

Opening the printer cover

ENGLISH

Pull on the left and right corners of the printer cover to and swing it down

until it is fully open.

Printer cover

5

4

– 4 –

3

2

1

Page 9

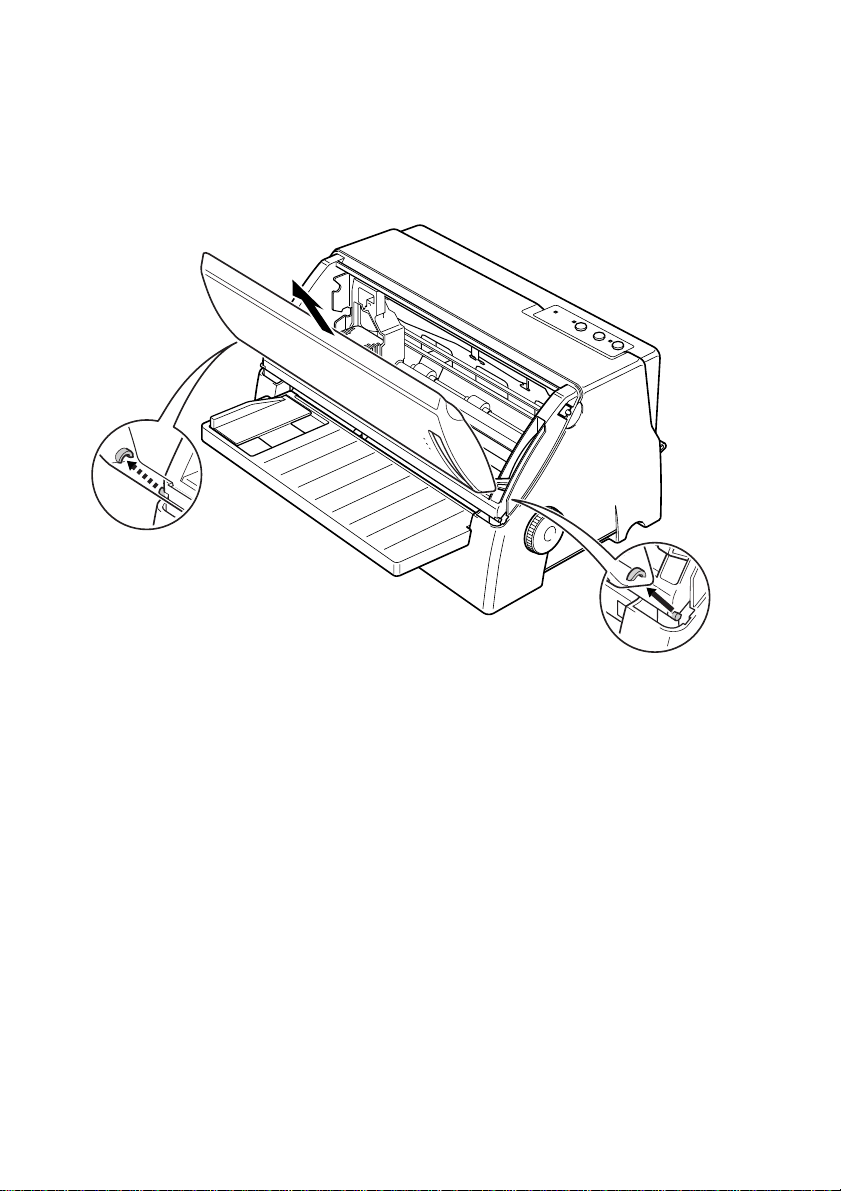

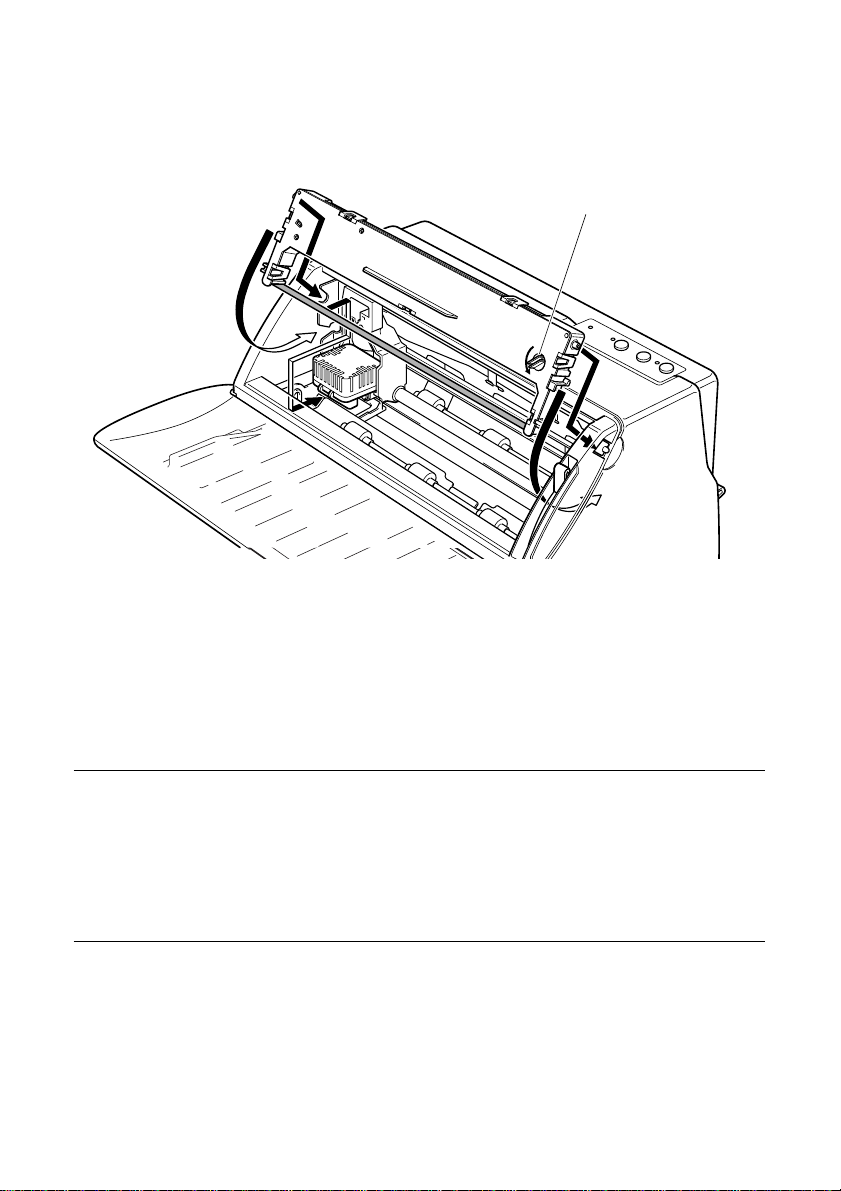

Removing the printer cover

4

5

1

2

3

Swing the printer cover so that it is at an angle as shown in the figure

below and lift the cover to remove it. To replace the printer cover, lower

the two slots on either side of the cover onto the tabs provided on the

printer case.

– 5 –

Page 10

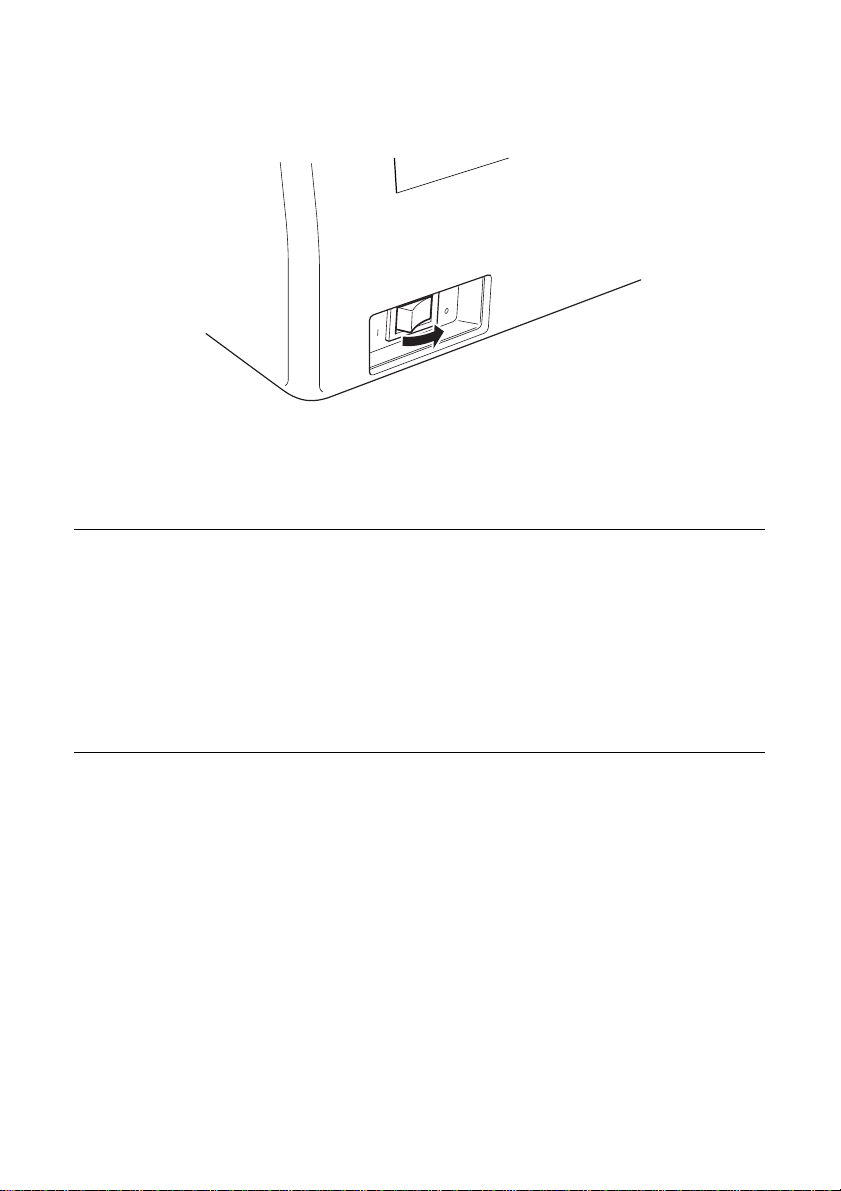

Connecting the Power Cord and turning the power ON and OFF

1. Check that the power switch on the front panel of the printer is in the

OFF position (O).

OFF

ON

2. Plug the power cord to a power outlet whose voltage matches the

power rating noted on the label affixed to the bottom of your printer.

Caution!

1. If the voltage marked on the rear of your printer does not match

the voltage from the outlet you are using, do not plug in the power

cord. Contact your dealer for assistance.

2. We recommend that you unplug the printer from the power outlet

whenever you do not plan to use it for long periods. Because of

this, you should locate the printer so that the power outlet it is

plugged into is nearby and easy to access.

ENGLISH

3. To turn the power on, press the power switch to the ON position (|);

to turn the power off, press the power switch to the OFF position (O).

– 6 –

Page 11

Installing the ribbon cassette

1. Turn the power on. The carriage moves to the left most position. You

will hear beeps when the carriage reaches this position.

Caution!

Do not move the carriage by hand while the printer is turned on.

Doing so can damage the printer.

If you have just finished printing, let the print head cool for a few

minutes before you touch it.

Carriage

2. Turn the power off.

– 7 –

Page 12

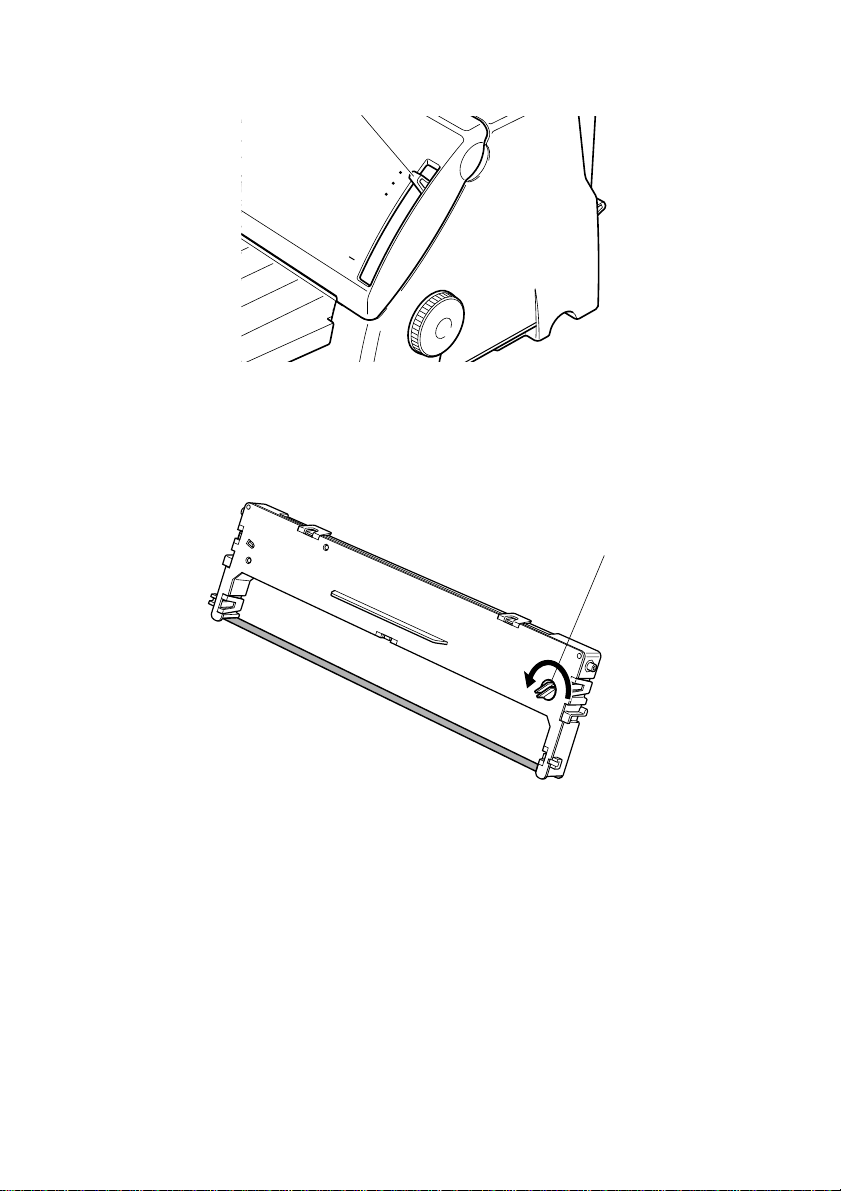

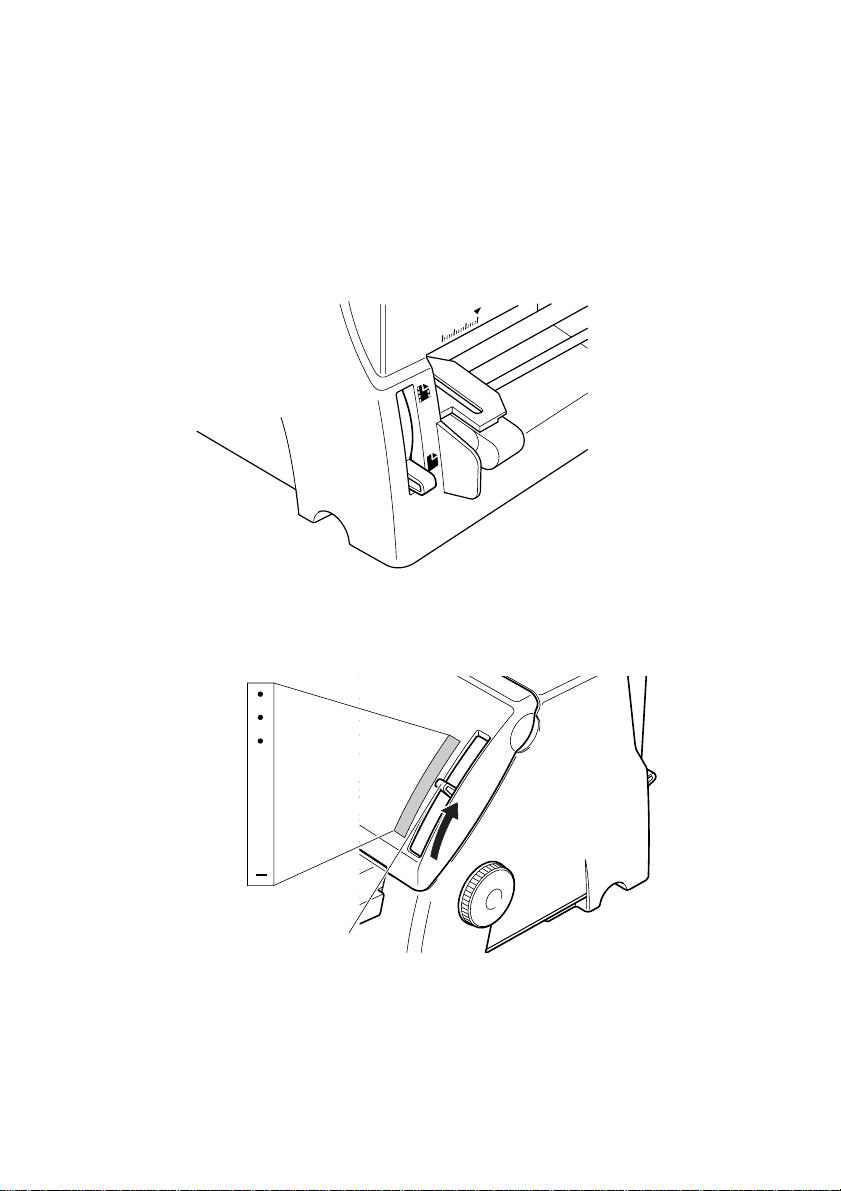

3. Set the adjustment lever to the highest position.

Adjustment lever

5

4

3

2

1

4. Open the printer cover.

5. Remove the ribbon cassette from the package and rotate the knob on

the cassette counterclockwise to take up any slack in the ribbon.

Knob

ENGLISH

– 8 –

Page 13

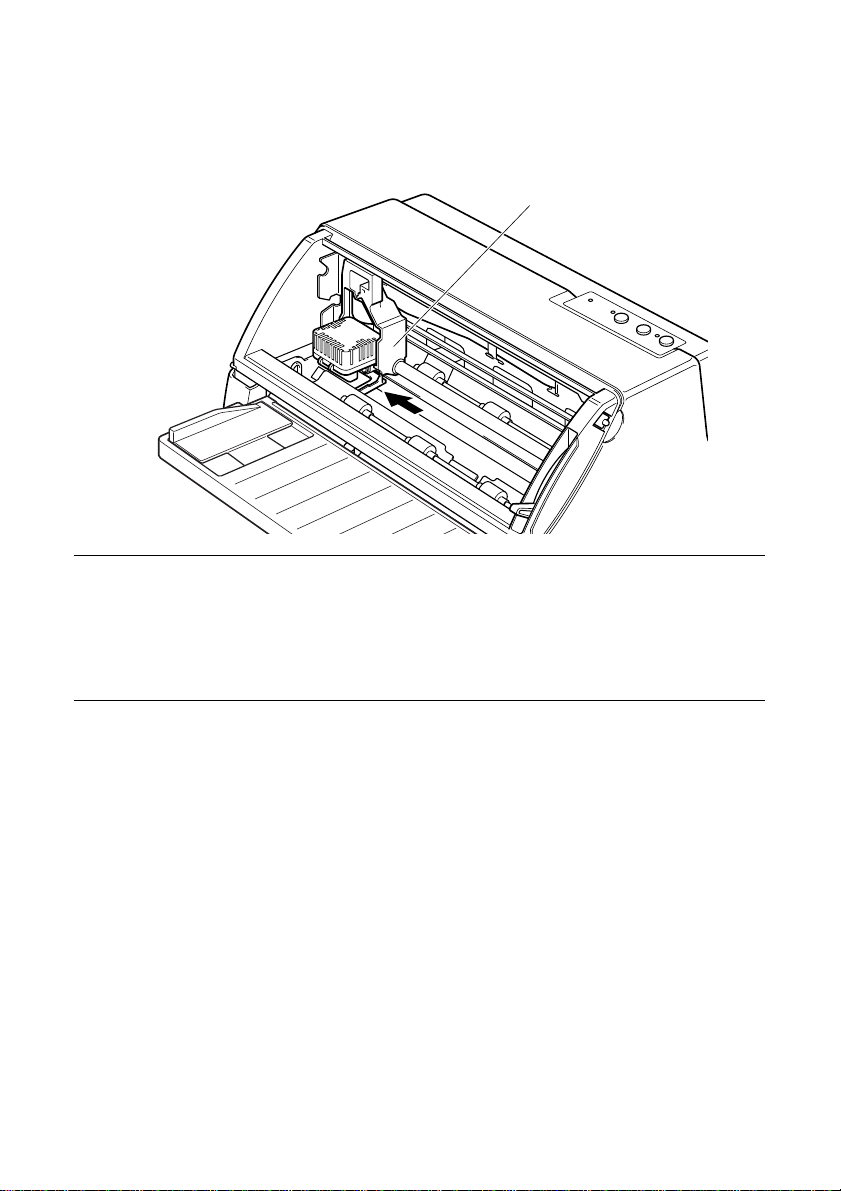

6. While holding the printer cassette at an angle, insert the two round

tabs on either side of the ribbon cassette into the two slots inside the

printer. Then, press the lower half of the cassette inward to a vertical

position until it snaps securely into place.

Knob

7. Rotate the knob on the cassette counterclockwise so that the ribbon

slides under the head.

8. Set the adjustment lever to position 1. Position 1 is for thin paper. You

may need to set the adjustment lever to another position, if you are

using a thick paper.

9. Close the printer cover.

Important!

Printing that is poor quality or too light is almost always due to a

ribbon that is simply worn out or “used up.” If you experience

problems with print quality, check the condition of the ribbon. If the

black part looks gray and well-worn, replace the ribbon with a new

one.

– 9 –

Page 14

Removing the ribbon cassette

When replacing the ribbon cassette, use the following procedure to

remove the old ribbon cassette from the printer.

1. Open the printer cover.

2. Turn the power on. The carriage moves to the left most position. You

will hear beeps when the carriage reaches this position.

Caution!

Do not move the carriage by hand while the printer is turned on.

Doing so can damage the printer.

If you have just finished printing, let the print head cool for a few

minutes before you touch it.

3. Turn the power off.

4. Pull the lower half of the cassette outward so that the ribbon slides out

from under the printer head. Then, lift up the cassette to remove it

from the printer.

Connecting to your computer using the parallel cable

ENGLISH

You printer comes equipped with a parallel port.

Since the printer does not come with cables, you must purchase an

appropriate cable that matches your computer. Below is an illustration of

a typical parallel cable.

Important!

The following instructions apply to the Centronics parallel cable that

is suitable for use with an IBM-compatible personal computer. Note

that they do not apply to all types of computers and cables. If you are

unsure about what type of cable you should use, consult your dealer.

For an IBM-compatible personal computer:

• Use a standard 36-pin Centronics parallel cable.

• The parallel cable should be no longer than six feet (two meters).

Longer cables can result in poor transfer of information.

– 10 –

Page 15

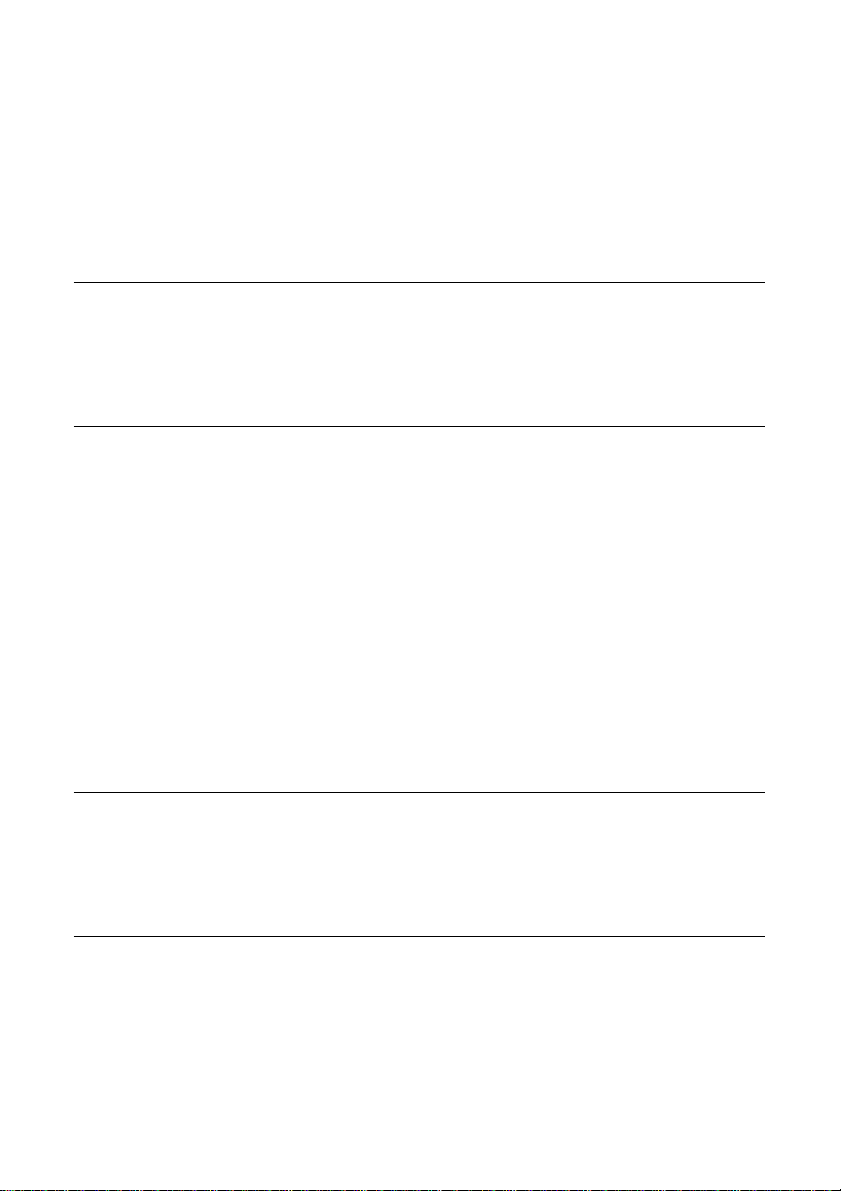

Ferrite Core Installation

1. Strap the fastener into the parallel interface cable as shown in the

illustration below.

2. Cut off the surplus part of the fastener.

Ferrite Core

12 to 15 cm

Fastener

3. With a regular screwdriver, unlatch and open the ferrite core.

4. Attach the ferrite core onto the cable as shown in the illustration

below.

Cable

Ferrite Core

– 11 –

Page 16

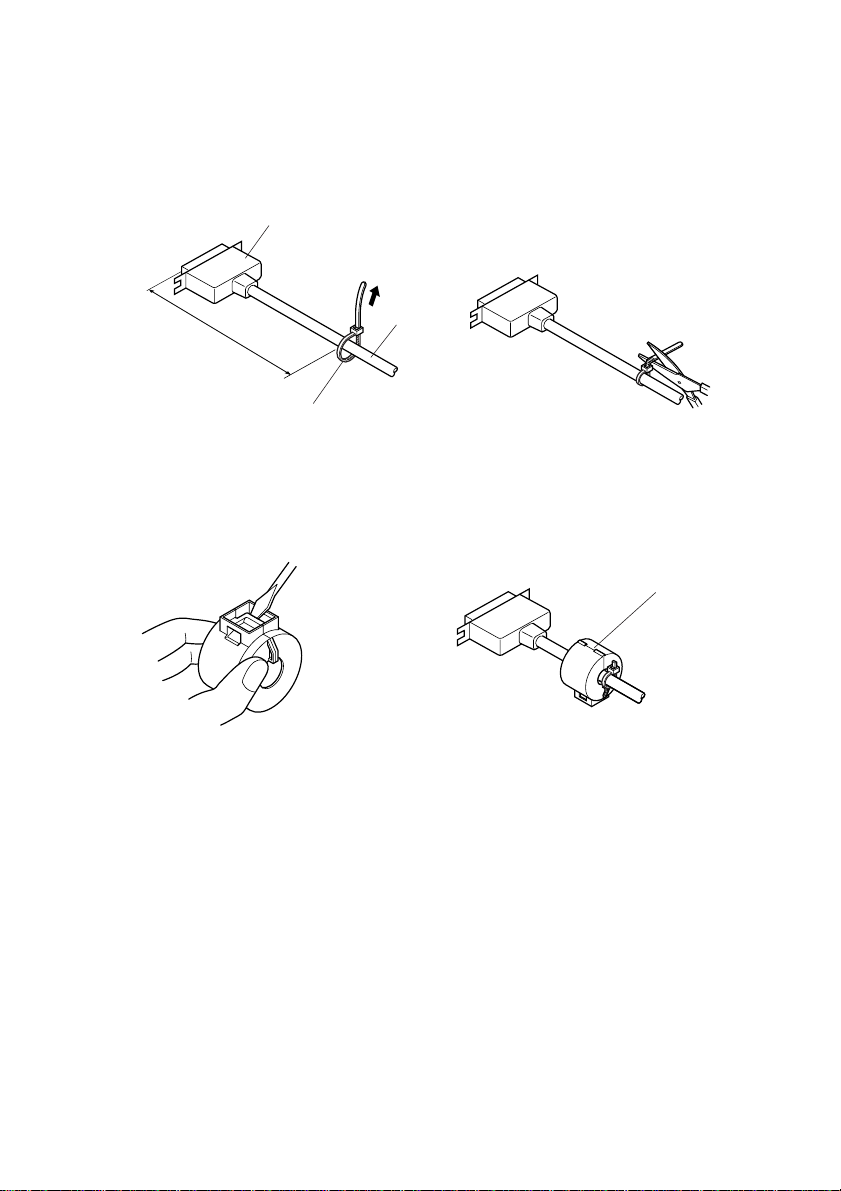

Important!

Make sure that the printer is unplugged from the AC outlet and that

the computer is turned off before connecting the parallel cable.

Note:

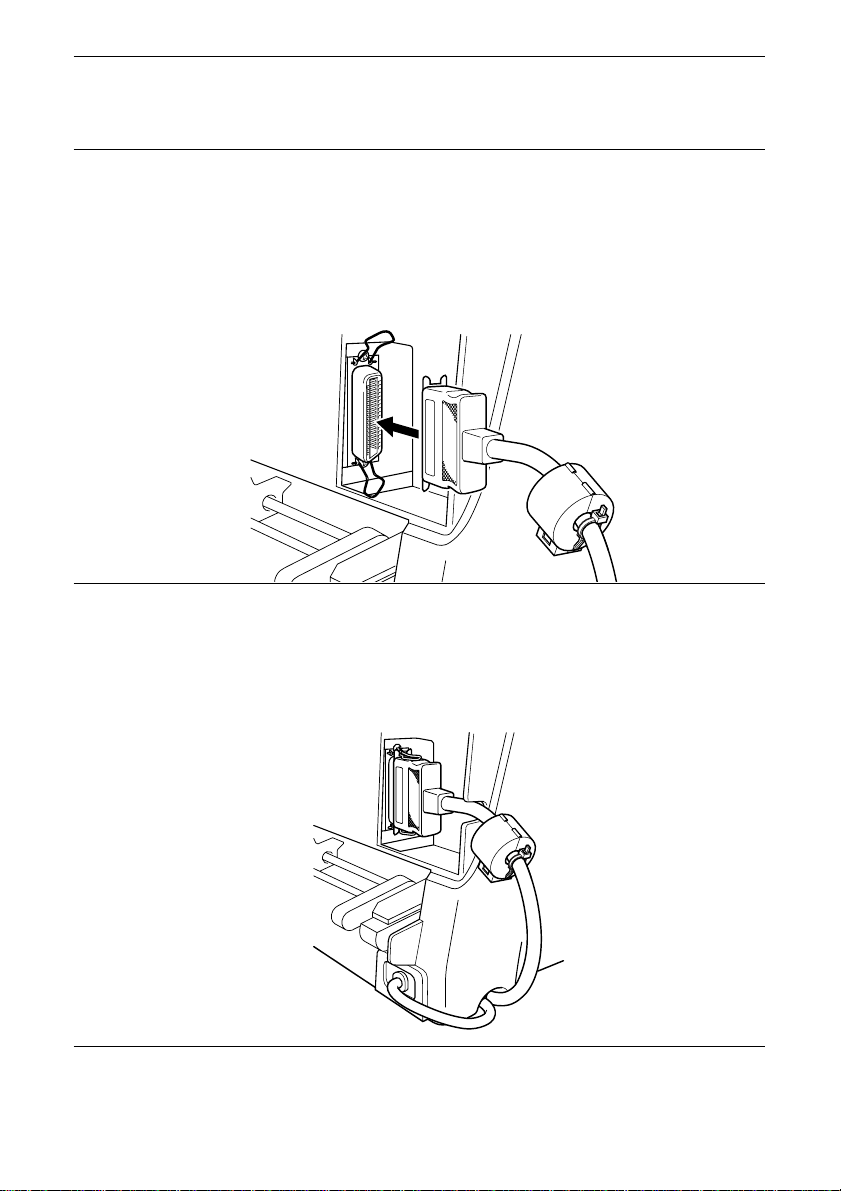

1. Connect one end of the parallel cable to the parallel port of your

computer. The parallel port is usually labeled “Printer,” “Parallel,”

“PRN,” “LPT1,” or something similar.

2. Connect the other end of the parallel cable into the socket on the back

of the printer and secure it in place with the clips.

If your computer is located to the right of the printer, run the cable

under the computer through the groove at the bottom of the printer.

This will prevent the cable from interfering with the fanfold paper.

You can also run the power cord under the printer.

ENGLISH

– 12 –

Page 17

This chapter describes the different types of paper you can print on and

how to setup the printer for each type.

Selecting paper types

Use the following information when selecting paper.

Cut-sheet paper

Width: 125 to 257 mm / 4.9 to 10.12 inches

Length: 85 to 364 mm / 3.3 to 14.33 inches

Paper Sizes: A6: 105 x 148 mm (Landscape)

Thickness

1-ply only: 0.05 to 0.18 mm

Multi-ply: 0.05 to 0.35 mm

Weight

1-ply only: 52 to 156 g/m

Multi-ply: 40 to 52 g/m

2. Paper Handling

B6: 128.5 x 182 mm (Portrait, Landscape)

A5: 148 x 210 mm (Portrait, Landscape)

B5: 182 x 257 mm (Portrait, Landscape)

A4: 210 x 297mm (Portrait)

B4: 257 x 364mm (Portrait))

Executive: 7.25 x 10.5 inches (Portrait)

Letter: 8.5 x 11 inches (Portrait)

Legal: 8.5 x 14 inches (Portrait)

2

/ 14 to 42 lbs / 45 to 135kg

2

/ 11 to 14 lbs / 34 to 45kg

Fanfold paper

Width: 139.7 to 254 mm / 5.5 to 10 inches

Length: Min. 5.5 inches

Thickness

1-ply only: 0.07 to 0.11 mm

Multi-ply: Max. 0.35 mm

Weight

1-ply only: 52 to 82 g/m

Multi-ply: 40 to 52 g/m

– 13 –

2

/ 14 to 22 lbs / 45 to 70kg

2

/ 11 to 14 lbs / 34 to 45kg

Page 18

Loading cut-sheet paper

This section describes the procedure for loading cut-sheet paper. You can

also use fanfold paper. For details on using fanfold paper, see “Loading

fanfold paper” on page 18. If the fanfold paper is currently loaded, first

park the fanfold paper using the procedures described in “Parking

fanfold paper” on page 23.

1. Set the release lever to the cut-sheet position.

2. Set the adjustment lever to the value that matches the thickness of the

paper you are using. The setting for normal paper is 1. Set the lever to a

larger value for thicker paper, or to a smaller value for thinner paper.

ENGLISH

5

4

3

2

1

Adjustment lever

4

3

2

1

– 14 –

5

Page 19

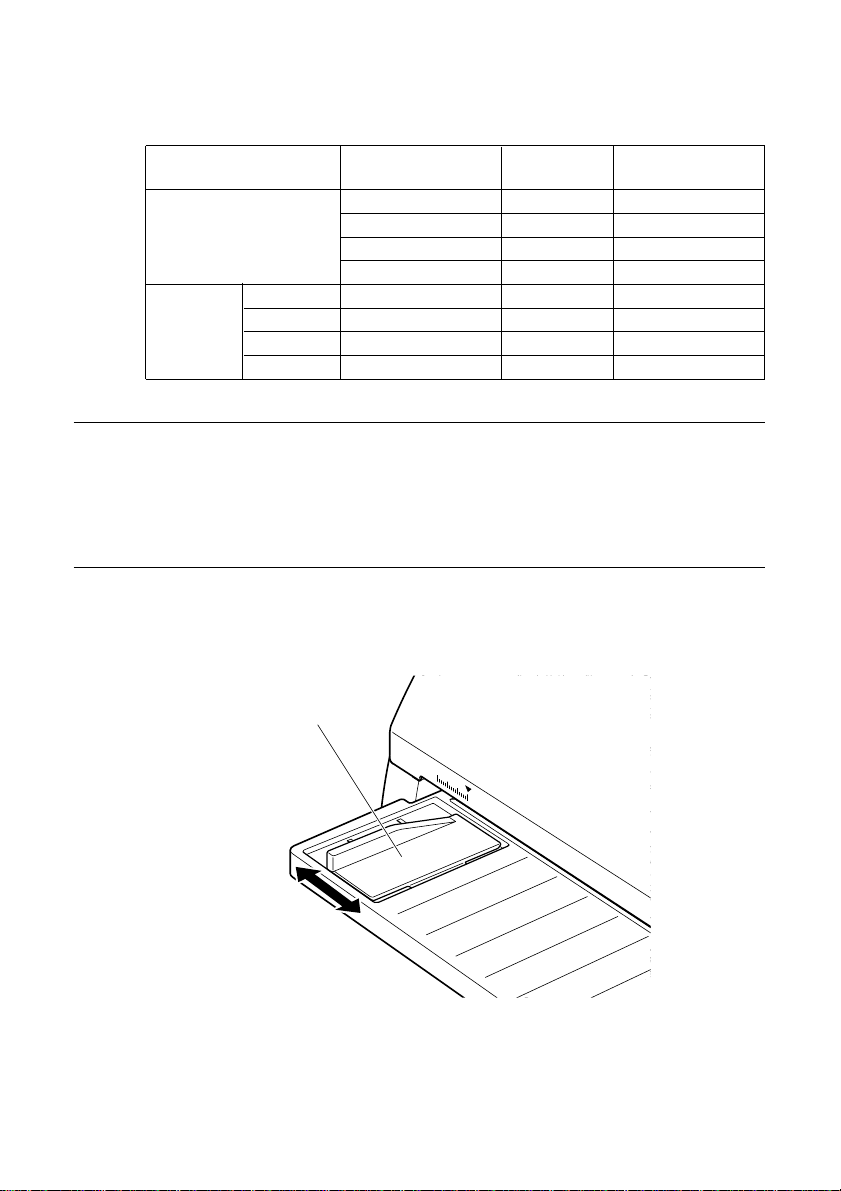

The following table provides a general guide for setting the adjustment

lever. Experiment with different settings until you find the one that gives

you the print quality you want.

Important!

Continuous use of the wrong adjustment lever setting can drastically

reduce the print head life. Position “–” is used only when the print

quality is too light. Setting the lever to position “–” when you are

using thin paper may damage the print head.

3. Adjust the paper edge to the desired position. The ▼ mark of the guide

Paper Type Weight Per Sheet Thickness

64 g/m

90 g/m

156 g/m

2

2

2

2

2

2

2

2

0.05 mm 1

0.08 mm 1

0.12 mm 1 to 2

0.19 mm 2

0.13 mm 2

0.20 mm 3

0.26 mm 5

0.32 mm 6

Single-sheet 30 g/m

Multi-part 2-ply 40 to 52 g/m

3-ply 40 to 52 g/m

4-ply 40 to 52 g/m

5-ply 40 to 52 g/m

indicates where the left margin of the printing will be.

Paper edge

Recommended

Position

– 15 –

Page 20

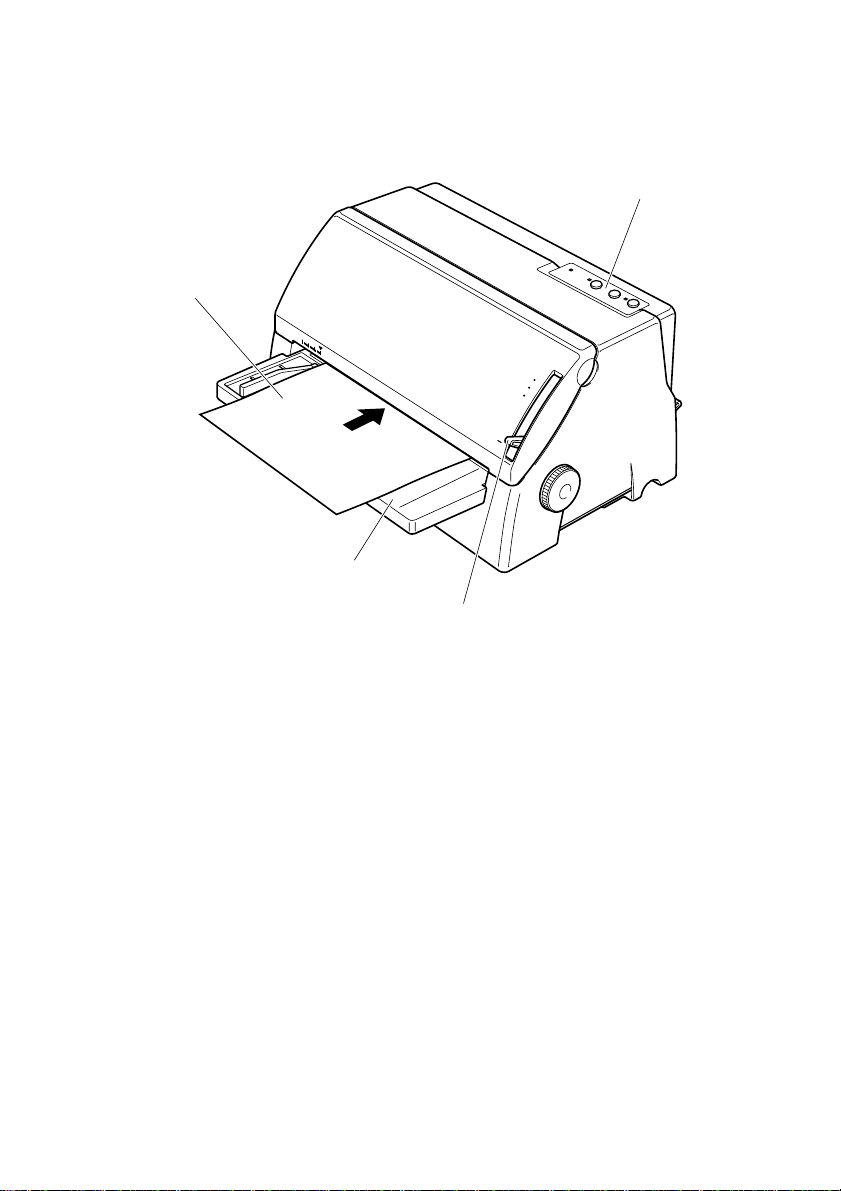

4. Insert the paper from the front of the printer as far as it will go, sliding

the left side of the paper against the paper edge. Insert the paper facing

up, with the top towards the printer.

Control panel

Paper

5

4

3

2

1

Peper guide

Adjustment lever

ENGLISH

The paper will automatically be fed into the printer.

5. Start the printing operation from your software application.

After the printing is complete, the paper is ejected from the same position

as you inserted the paper.

– 16 –

Page 21

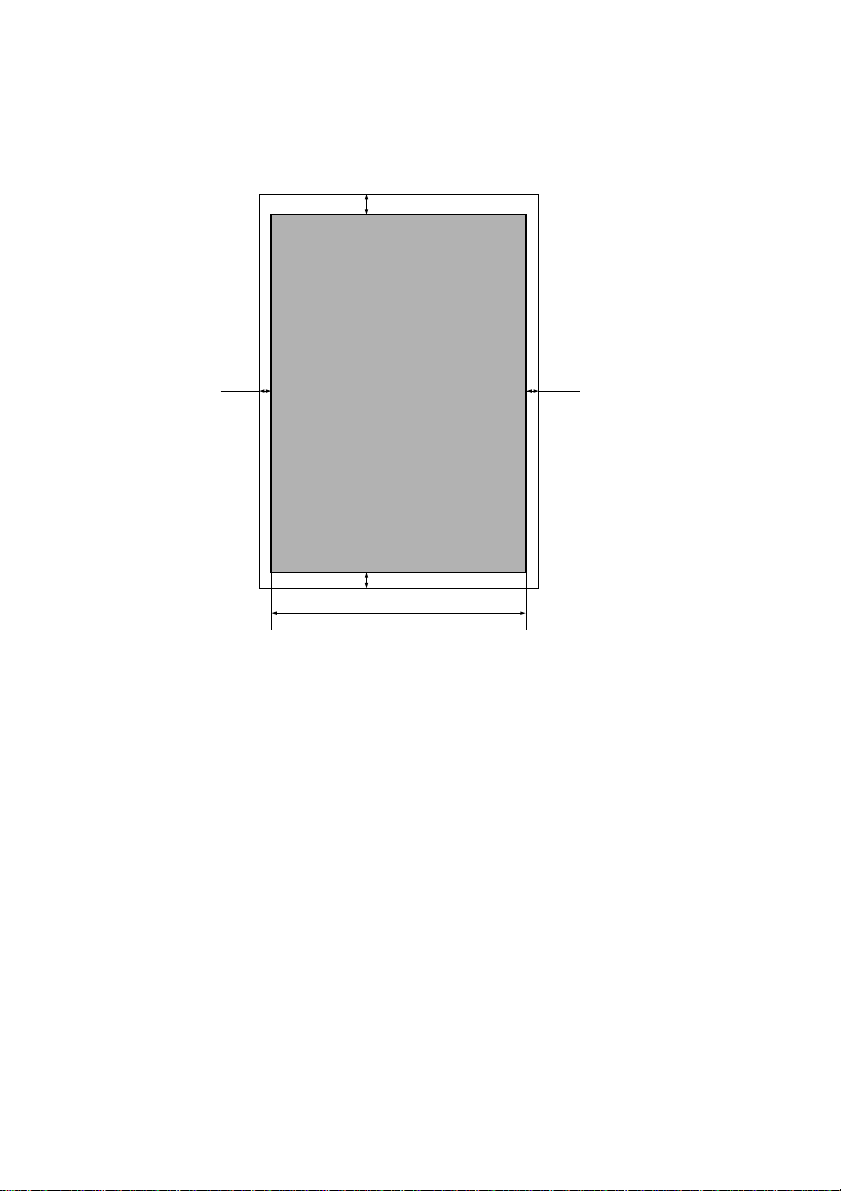

Printing on cut-sheet paper

The following shows the recommended print area for cut-sheet paper.

Cut-sheet paper

4.23 mm

3 mm

3 mm

6.35 mm

Max. 203.2 mm

(Max. 8 inches)

– 17 –

Page 22

Loading fanfold paper

This section describes the procedure for loading fanfold paper. You can

also use cut-sheet paper. For details on using cut-sheet paper, see

“Loading cut-sheet paper” on page 14.

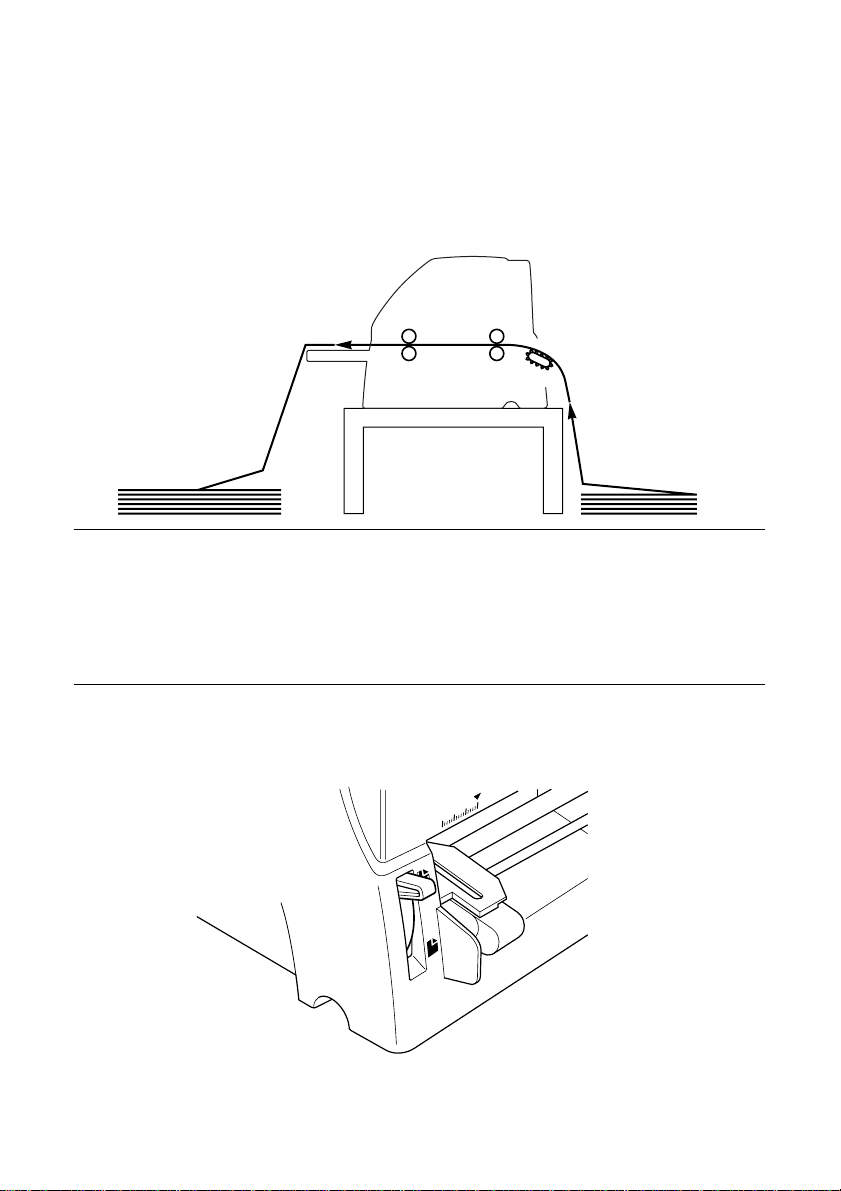

1. Position the stack of paper behind the printer. The following figure

Important!

To protect against paper jams, make sure that the fanfold paper is

stacked in a position that is lower than the printer.

To decrease paper jams, be sure that the perforations do not get

caught in anything in the paper path.

2. Make sure that the printer is turned off.

3. Set the release lever to the fanfold position.

ENGLISH

shows the correct path for fanfold paper.

– 18 –

Page 23

4. Set the adjustment lever to the value that matches the thickness of the

paper you are using. The setting for normal paper is 1. Set the lever

to a larger value for thicker paper, or to a smaller value for thinner

paper. See the table on page 15 for details.

5

4

3

2

1

Adjustment lever

5

4

3

2

1

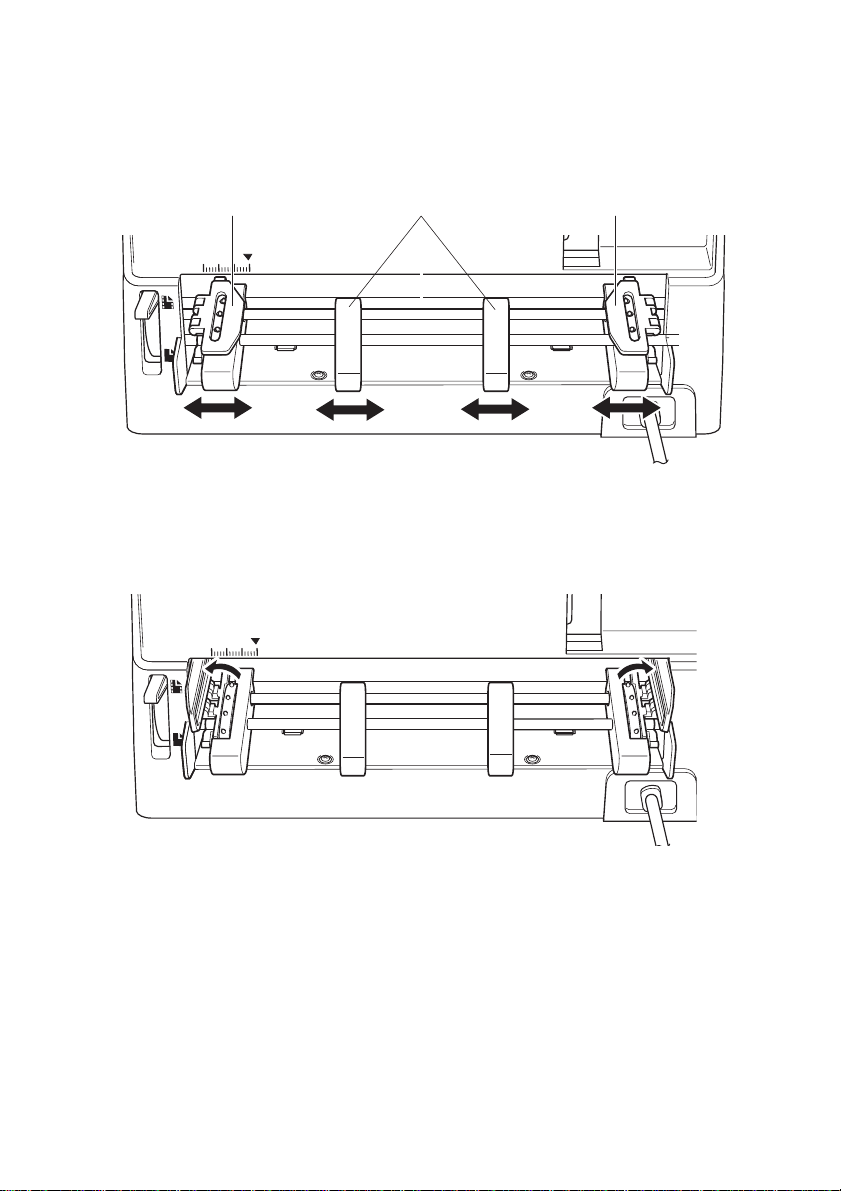

5. Unlock the tractor on the left (when viewing the printer from behind)

by pulling its gray lever up, and adjust the position of the left tractor.

Note that there is a guide inside the printer in front of the left tractor.

The ▲ mark of the guide indicates where the left margin of the

printing will be.

6. Once the left tractor is aligned the way you want it, push the gray lever

back down to lock it in place.

– 19 –

Page 24

7. Now move the tractor on the right to the approximate position of the

right side of the paper you are using. Pull its gray lever up to unlock

it, and push the lever back down to lock it into place. Also move the

sheet guide so that it is approximately halfway between the two

tractors.

Sheet guidesPin tractor Pin tractor

8. Open the covers of both tractors and align the paper so that at least

three pins on the tractors are inserted into the holes of the paper.

ENGLISH

– 20 –

Page 25

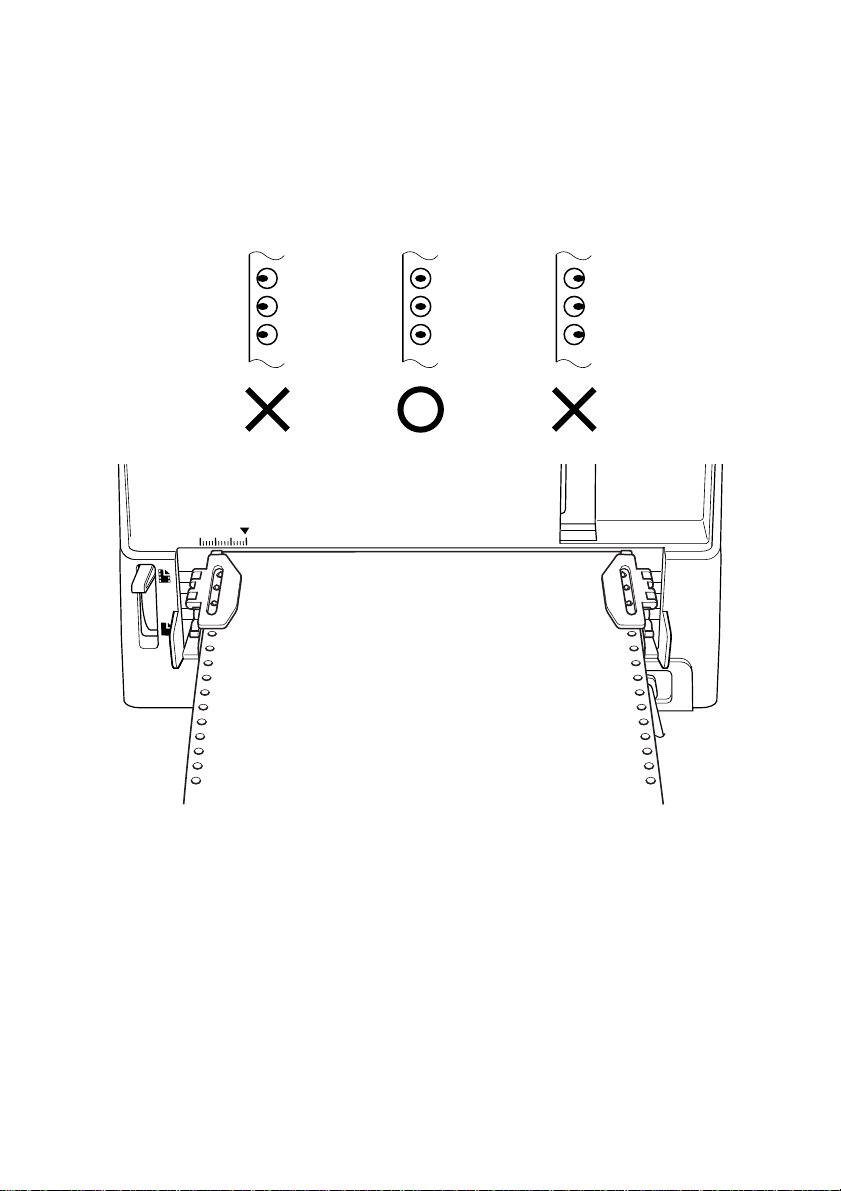

9. Close the tractor covers. At this point you can make final adjustments

to the paper position by releasing the gray levers and moving the

tractors. The paper should lie flat with no buckling or bulging (tractors

too close) or no stretching or elongation of the holes (tractors too far

apart). After making these adjustments, be sure that you re-lock the

tractors by pushing the gray levers back into their original positions.

10.Turn the power on.

11.Press the control panel’s SET/PARK/EJECT button and the paper

will feed to the starting position.

– 21 –

Page 26

Printing on fanfold paper

When printing on fanfold paper, take care not to print too close to the

perforations that separate each sheet. The following shows the

recommended print area for fanfold paper and cut-sheet paper.

4.23 mm

First page

3 mm

ENGLISH

Cut-sheet paperFanfold paper

4.23 mm

3 mm

Perforation

18 mm

Perforation

Bottom of

Form

4.23 mm

4.23 mm

4.23 mm

4.23 mm

142 mm

18 mm

Last page

6.35 mm

Max. 203.2 mm

(Max. 8 inches)

– 22 –

Page 27

Parking fanfold paper

It is not necessary to remove fanfold paper currently loaded in the printer

in order to print on cut-sheet paper. Instead, simply use the following

procedure to park the fanfold paper.

1. Press the control panel’s ON LINE button to put the printer off-line.

2. Press the control panel’s SET/PARK/EJECT button. The printer

automatically reverse feeds the fanfold paper until it is no longer in

contact with the platen, which is indicated by the printer beeping a

number of times. Also, the control panel’s POWER indicator starts to

flash because paper is not loaded.

You can now load cut-sheet paper into the printer using the procedures

described in “Loading cut-sheet paper” on page 14.

Unparking fanfold paper

After you are finished printing on cut-sheet paper, use the following

procedure to unpark fanfold paper and make it available for printing.

1. Remove all cut-sheet paper from the printer.

2. Set the release lever to the fanfold position.

3. Press the SET/PARK/EJECT button to feed the paper to the starting

position.

The printer automatically goes back on-line at this time.

– 23 –

Page 28

3. Control Panel Operations

The control panel gives you push-button control over the printer’s

operations. It also includes indicator lights, which tell you the current

status of the printer at a glance.

SET/PARK/EJECT button

LINE FEED button

ON LINE button

ENGLISH

POWER

P.E.

POWER indicator

MODE

SET/PARK

EJECT

MICRO FEED

PRINT MODE indicator

TEAR OFF

LINE FEED

ON LINE

FORM FEED

ON LINE indicator

This chapter describes control panel functions that can be performed

while the printer is turned on and either on-line or off-line. The buttons

perform different functions in the EDS and Dot Adjustment Modes.

Functions of control panel buttons in these modes are described in the

relevant sections covering them.

– 24 –

Page 29

Switching between on-line and off-line

• Press the ON LINE button to switch the printer between on-line and

off-line modes.

• When the printer is on-line, the ON LINE indicator is lit and the

printer can receive data from the computer. Make sure that the printer

is on-line whenever you are trying to print.

• When the printer is off-line, the ON LINE indicator is off, which

means that the printer cannot receive any data.

• Note that you can also press the ON LINE button while a printing

operation is in progress to stop the printing.

Control panel functions in on-line mode

Tear-off function (fanfold paper)

This procedure feeds fanfold paper to a position where it can be torn off

easily.

1. Press the LINE FEED button to feed the paper automatically so that

the perforation is just past the printer cover.

2. Tear the paper along the perforation.

When you resume printing, the printer reverse feeds the paper to its

former position.

Print mode selection

Press the SET/PARK/EJECT button to change the print mode selection.

When the print mode is changed, a short buzzer sounds. The mode

indicator tells you the current print mode as follows:

Print Mode Mode Indicator

LQ (Letter Quality) OFF

Draft ON

– 25 –

Page 30

Panel lock mode

When the printer is in the panel lock mode, the mode settings you make

on the control panel are used even if your software tries to override the

mode. Use the following procedure to enter the panel lock mode.

1. While holding down the SET/PARK/EJECT button, press the LINE

FEED button. A short buzzer sounds once.

To exit from the panel lock mode, press the LINE FEED button while

holding down the SET/PARK/EJECT button. A short buzzer sounds

twice.

Panel macro

The settings you make on the front panel are cleared when the printer is

turned OFF. To save the current control panel settings so that they are

used the next time the printer is turned ON, use the following procedure.

1. While holding down the SET/PARK/EJECT button, press the ON

LINE button. Keep both buttons held down until the printer beeps

twice.

This procedure saves the following settings.

To clear the panel macro, hold down SET/PARK/EJECT and ON LINE

until the printer beeps 3 times. If EDS2A-5 is OFF, this panel macro

function is ignored (see chapter 4).

ENGLISH

Print mode settings

Panel lock

– 26 –

Page 31

Control panel functions in off-line mode

Line feed

Press the LINE FEED button once to feed the paper one line. Holding

down the LINE FEED button continually feeds the paper, 1/6” (default)

at a time, until you release the button.

The line feed is executed using the current line feed value. In Self Test

mode, this button is ignored. While this button is held down, line feed is

executed up to 13 times. If the button is held down after 13 times of line

feed, the paper is continuously fed to the top of the next page. If the ON

LINE button is pressed while this button is held down, form feed is

executed.

Set/Park/Eject

Press the SET/PARK/EJECT button to set, eject, or park the paper.

If the paper is not loaded (paper end condition), paper loading is

executed. After the paper is loaded completely, the printer switches online mode. If the paper is loaded (not paper end condition), the paper is

parked when using fanfold paper or ejected when using cut-sheet paper.

After the paper is parked or ejected completely, the printer switches to

off-line mode.

Paper End Not Paper End

When using fanfold paper Paper load (Paper set) Paper park

When using cut-sheet paper Paper load (Paper set) Paper eject

Paper Condition

Form feed

While holding down the LINE FEED button, press the ON LINE button

to feed the paper to the top of the next page. If EDS2C-2 is ON (default)

when using cut-sheet paper, this function executes paper ejection.

– 27 –

Page 32

Micro paper feed

Use the following procedure to feed the paper in 1/60-inch increments. This

function can be used to align the print head exactly where you want it.

Press the LINE FEED button while holding down the ON LINE button

to execute micro paper feed. When Tear Off lifts the paper up, the micro

paper feed value is added to the tear off value. If the adjust value is over

1 inch, the micro paper feed is not executed.

Press the SET/PARK/EJECT button while holding down the ON LINE

button to execute micro reverse paper feed. When Tear Off lifts the paper

up, the micro reverse paper feed value is subtracted from the tear off

value. If the adjust value is over 1 inch, the micro reverse paper feed is

not executed.

Auto loading position change mode

While holding down the LINE FEED button, press the SET/PARK/

EJECT button. The printer enters the auto loading position change mode.

When the auto loading position change mode is entered, a short buzzer

sounds twice, and all LEDS turn ON. If paper is loaded (not paper end

condition), the paper is ejected when using cut-sheet paper or parked

when using fanfold paper. If the paper is not parked or ejected completely,

the printer exits from the auto loading position change mode, sounds a

short buzzer three times, and sets the LEDs back to the previous

condition. Below are the button assignments in auto loading position

change mode.

ENGLISH

Pressing the ON LINE button

If paper end condition, the printer executes paper loading.

If not paper end condition, the printer exits from the auto loading

position change mode and ignores the change.

Holding down the ON LINE button and pressing the LINE FEED button

The printer exits from the auto loading position change mode, and the

auto loading values are reset to factory default.

Holding down the ON LINE button and pressing the SET/PARK/EJECT

button

The printer exits from the auto loading position change mode, and the

change is effective until the next change (setting is kept in EEPROM).

– 28 –

Page 33

Pressing the LINE FEED button

The printer executes micro forward paper feed, and the auto loading

value is increased.

Pressing the SET/PARK/EJECT button

The printer executes micro reverse paper feed, and the auto loading

value is decreased.

The auto loading value must be greater than 0 inch. If the auto loading

value is less than 14/360 inch, the micro reverse paper feed is not

executed.

A micro paper feed moves the paper by 1/60 inch. When the printer exits

from the auto loading position change mode, a short buzzer sounds twice,

and all LEDs return to their previous conditions.

Set top of form (TOF)

While holding down the SET/PARK/EJECT button, press the LINE

FEED button. The vertical position is reset to the first line.

Buffer clear & All reset

While holding down the SET/PARK/EJECT button, press the ON LINE

button. Keep both buttons held down until the printer beeps once to clear

the data buffer. Continue to hold down both buttons until the printer

beeps again three times to reset all the settings.

After releasing the buttons, the printer is initialized in the same way as

a power-on reset.

– 29 –

Page 34

4. Using the EDS Mode

EDS stand for Electronic DIP Switches. Just like the small DIP switches

that are used by computers, printers, and other devices, the EDS lets you

configure the printer for your application.

This chapter describes how to enter the printer’s EDS Mode and provides

details about available settings and how to change them.

About EDS Mode settings

The EDS Mode of this printer actually consists of five sub-modes, named

EDS-1 to EDS-5. EDS settings are grouped among four “banks”

(representing banks of switches) that are identified by the letters A

through D. Each bank contains a number of “switches” numbered 1

through 7 that you can turn on and off to configure the printer.

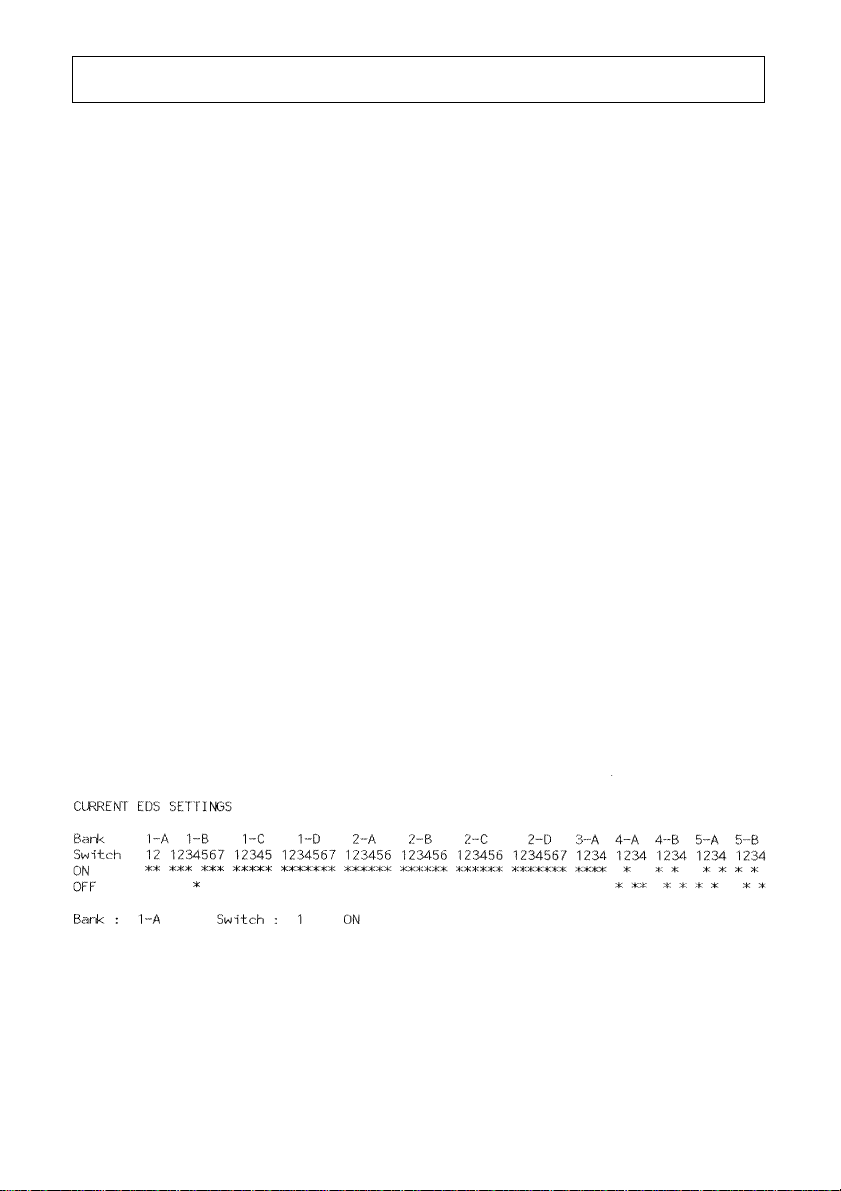

Entering the EDS Mode

1. Make sure that paper is loaded in the printer.

2. Turn off the printer.

3. To enter the EDS Mode, turn the printer on while holding down the

control panel’s LINE FEED, and ON LINE buttons.

ENGLISH

This causes the following message to be printed, which indicates the

printer is in the EDS Mode.

– 30 –

Page 35

Selecting a EDS number

In the EDS Modes , use the control panel’s LINE FEED button, while

holding down SET/PARK/EJECT button to select a EDS number.

When pressed the button, current setting of the bank is printed.

Selecting a bank

While in the EDS Modes , use the control panel’s SET/PARK/EJECT

button to select a bank. When pressed the button, current setting of the

bank is printed.

Selecting a switch

While in the EDS Modes , use the control panel’s LINE FEED button

to select a switch. When pressed the button, current setting of the is

switch printed.

Changing a switch setting

After selecting a bank and a switch, press the control panel’s ON LINE

button to turn the switch on and off. When pressed the button, changed

setting of the switch is printed.

Printing the current EDS settings

While holding down LINE FEED button, press the control panel’s ON

LINE button to print out the current switch settings. Asterisks on the

printout show whether a switch is turned on or off.

Exiting the EDS Modes

While holding down SET/PARK/EJECT button, press the control

panel’s ON LINE button to exit the EDS Modes.

– 31 –

Page 36

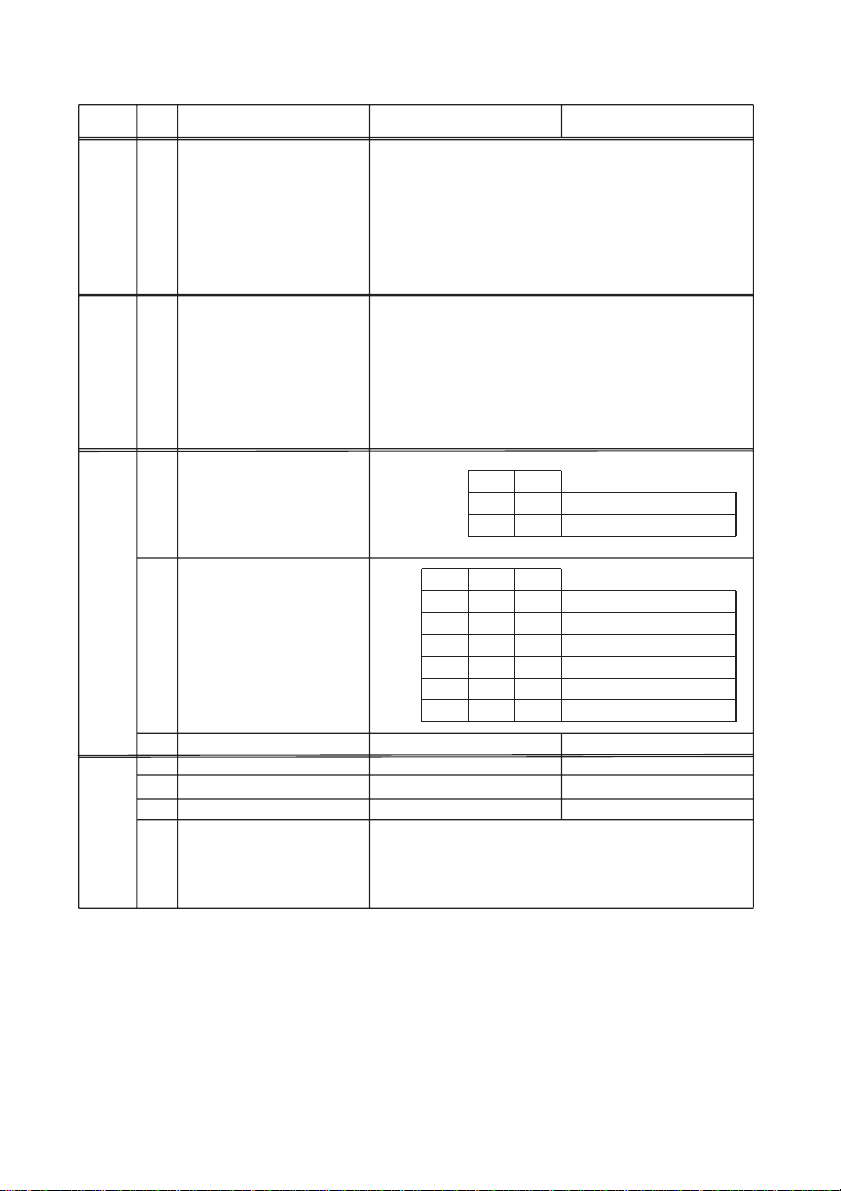

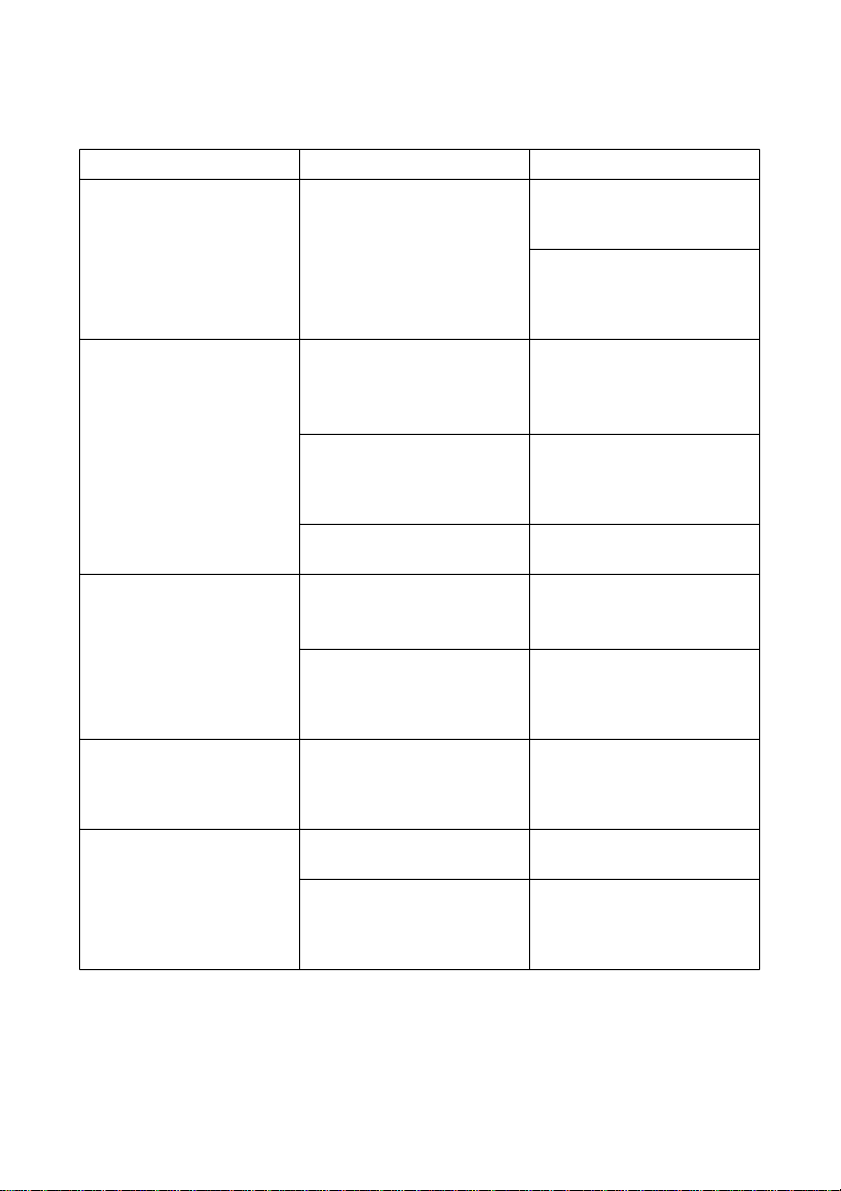

Use the information in the following table to change the EDS settings.

< EDS-1>

BANK

SW OFFONFUNCTION

( Reserved )

1

A

2

3

4

5

6

7

B

C

D

( Reserved )

1

2

3

4

5

6

7

Print mode

1

2

Character pitch

3

4

5

LQ Font

6

Character table

1

Character set

2

Zero style

3

4

( Reserved )

5

6

7

1 2

ON ON LQ (x1) *

OFF ON Draft (x3)

3 4 5

ON ON ON 10 CPI *

ON ON OFF 12 CPI

ON OFF ON 15 CPI

ON OFF OFF 17 CPI

OFF ON ON 20 CPI

OFF ON OFF Proportional

Roman*

IBM Graphics *

#2 *

Normal *

Sanserif

Italic

#1

Slashed zero

*: Default setting

ENGLISH

– 32 –

Page 37

Printer mode

The relation between the printer quality and the printer speed is as

follows:

Printer quality LQ > Draft

Printer speed Draft > LQ

The values inside the parentheses are print speed ratios with

respect to LQ.

Character table / IBM character set

See Appendix B, “Character set” for details.

– 33 –

Page 38

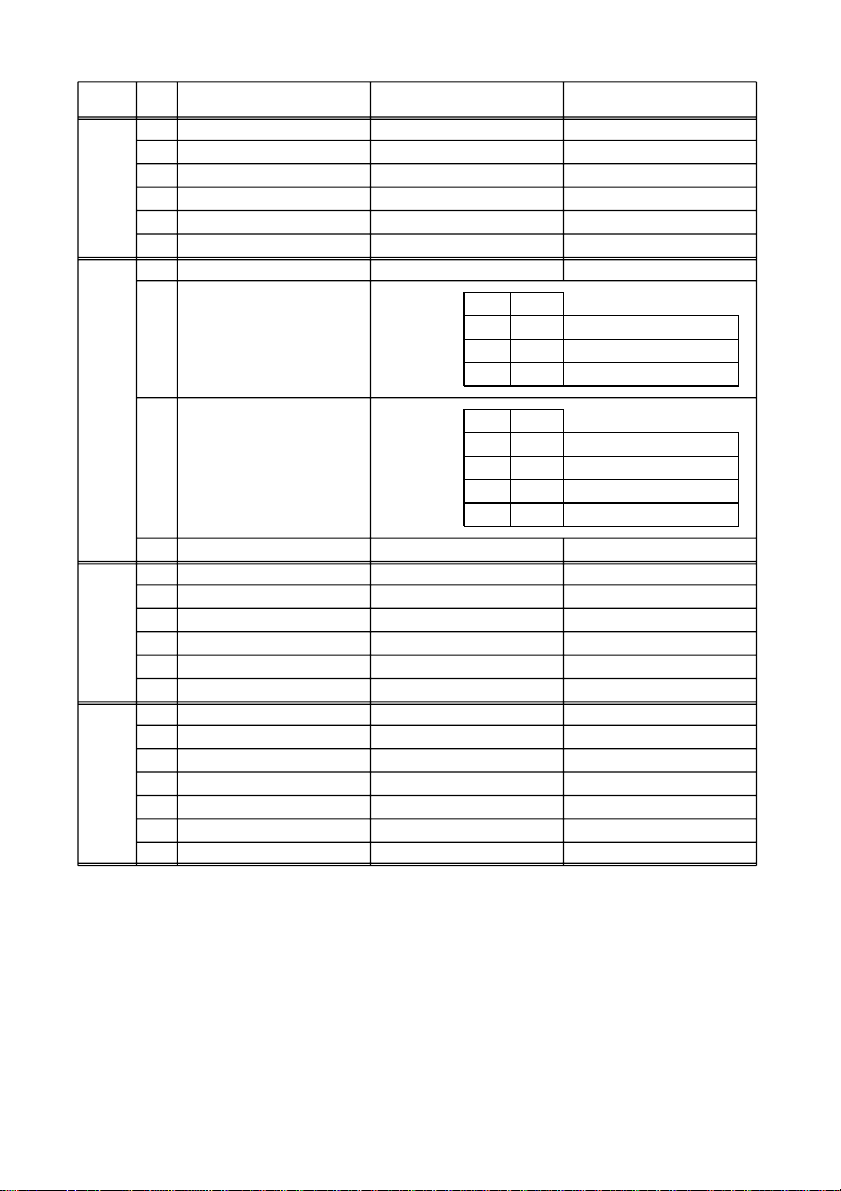

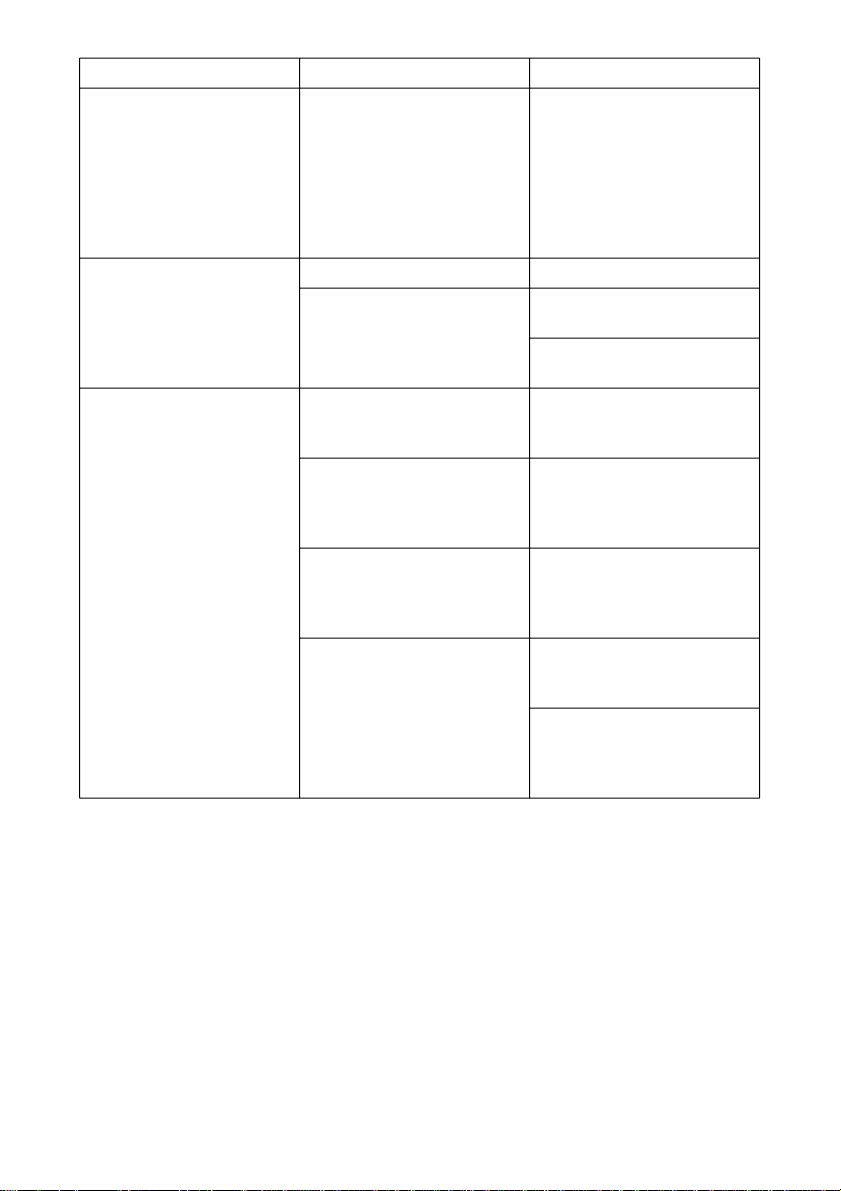

< EDS-2>

BANK

SW OFFONFUNCTION

A

B

C

D

Input buffer

1

Auto CR with LF

2

Auto LF with CR

3

Buzzer

4

Saving Control Panel Status

5

Quiet mode

6

Auto Tear-off

1

Multi-part mode

2

3

Waiting period for

4

Paper loading

5

75% Compress mode

6

Line spacing

1

FF command

2

Eject direction

3

Eject paper at Power ON

4

Skip over perforation

5

Paper out detector

6

Print direction

1

Print direction command

2

CR centering at top of form

3

CR wiping at top/bottom

4

2-pass printing at top/bottom

5

Strobe timing

6

ACK timing

7

Large ( 54.5 K bytes ) *

Enabled *

Disabled *

Enabled *

Panel Macro *

Disabled *

Disabled *

23

ON ON Auto selection *

ON OFF Multi-part mode

OFF ON Normal mode

45

ON ON 0.5 sec.

ON OFF 1.0 sec.

OFF ON 1.5 sec.

OFF OFF 2.0 sec.

Disabled *

1/6" *

Eject *

Front *

Enabled *

Disabled *

Enabled *

Bi-directional *

Disabled *

Disabled *

Disabled *

Disabled *

Normal *

Normal *

Small ( 1K byte )

Disabled

Enabled

Disabled

Auto Saving

Enabled

Enabled

Enabled

1/8"

Form Feed

Rear

Disabled

Enabled

Disabled

Uni-directional

Enabled

Enabled

Enabled

Enabled

Special

Special

*: Default setting

ENGLISH

– 34 –

Page 39

Auto CR with LF

When auto CR (carriage return) with LF (line feed) is enabled, the printer

automatically performs a carriage return whenever it receives a LF code

from the computer. This moves the print position to the beginning of the

next line. If the printer adds an extra line after every carriage return, select

OFF.

Auto LF with CR

When auto LF with CR is enabled (OFF), the printer automatically

performs a line feed whenever it receives a CR code from the computer.

When disabled (ON), the computer must send both a line feed code and

a carriage return code at the end of each line. Most computers and

applications send both.

Note the following check points when determining which setting to use.

• If you find that your output is double-spaced when it should not be,

turn this switch ON (disabled).

• If you find that lines are printing over each other, turn this switch OFF

(enabled).

Saving Control Panel Status

You can select either “Panel Macro” or “Auto Saving” to save the current

control panel settings. See “Panel macro” on page 26.

Quiet mode

When the Quiet Mode is enabled (OFF), the printer prints with less noise

than normal printing. Though the Quiet Mode prints more quietly, it also

takes considerably longer than normal printing.

Auto Tear-off

Specifies whether the printer’s auto tear-off feature is enabled (OFF) or

disabled (ON). Note that this setting controls the application software’s

tear-off function only. It does not affect the manual tear-off function that

is performed using the control panel buttons as described on page 25. The

manual tear-off function is always enabled.

– 35 –

Page 40

Multi-part mode

When the printer is in the Multi-part Mode, the print head prints with

greater impact. It should be noted, however, that printing in the Multipart Mode also reduces the life of the print head. Because of this, you

should use the Multi-part Mode only for printing on four or five-ply

paper. Use the Normal Mode for printing on one to three-ply paper. When

Auto (SW2: ON, SW3: ON) is selected, the printer automatically

switches between the Multi-part Mode and Normal Mode according to

the adjustment lever position. The Normal Mode is automatically selected when the adjustment lever is at any setting of 3 or less, while the

Multi-paper mode is selected for settings greater than 3.

Waiting period for Paper loading

This function sets the amount of wait time between paper insertion and

paper feeding. If the paper feeds before you can adjust the paper position

to your satisfaction, increase the wait time.

75% Compress mode

In the compression mode, the printer is able to receive print data for up

to 10.6-inch printing width. The print data is compressed from 10.6

inches to 8 inches (compression ratio of 75%).

ENGLISH

FF command / Eject direction

These functions are valid when the release lever is set to the cut-sheet

paper position.

Eject paper at Power ON

This function is valid when the release lever is set to the cut-sheet paper

position. This function selects whether to eject the cut-sheet paper when

a cut-sheet paper is on the paper guide at power on.

Skip over perforation

This function is valid only when fanfold paper is selected. When enabled,

the printer provides a one-inch margin between the last line printed on

one page and the first line printed on the next page.

– 36 –

Page 41

Print direction

This function selects bi-directional printing or uni-directional printing.

Printing is normally bi-directional, but uni-directional printing allows

for precise vertical printing alignment.

Print direction command

When disabled (ON), the preset printing direction overrides the print

direction commands sent by your software.

CR centering at top of form

This function is used to improve the paper feed precision when inserting

paper, ejecting paper, printing at the top or bottom edge of a paper, and

printing near the perforation of a fanfold paper. CR centering refers to the

operation of moving the carriage near the center of the paper. When

enabled (OFF), the printer performs CR centering at the positions

indicated above.

CR wiping at top/bottom

When enabled (OFF), the carriage moves to prevent a paper jam when the

printer inserts or ejects a curled paper.

2-pass printing at top/bottom

This function performs 2-pass printing when printing within 1/6 inch of

a perforation or 1/6 inch of the top or bottom edge of a paper. When

enabled (OFF), the printer performs 2-pass printing to prevent a paper

jam when printing at the positions indicated above.

Strobe timing

Selecting Normal (ON) allows the printer to receive data from the

computer when the parallel interface’s strobe signal falls. Selecting

Special (OFF) allows data receipt when the strobe signal rises.

ACK timing

Specifies the relation between the ACK (acknowledge) timing and the

BUSY timing. When set to Normal, the BUSY signal is activated while

ACK is being output. When set to Special, the BUSY signal is activated

after ACK is output.

– 37 –

Page 42

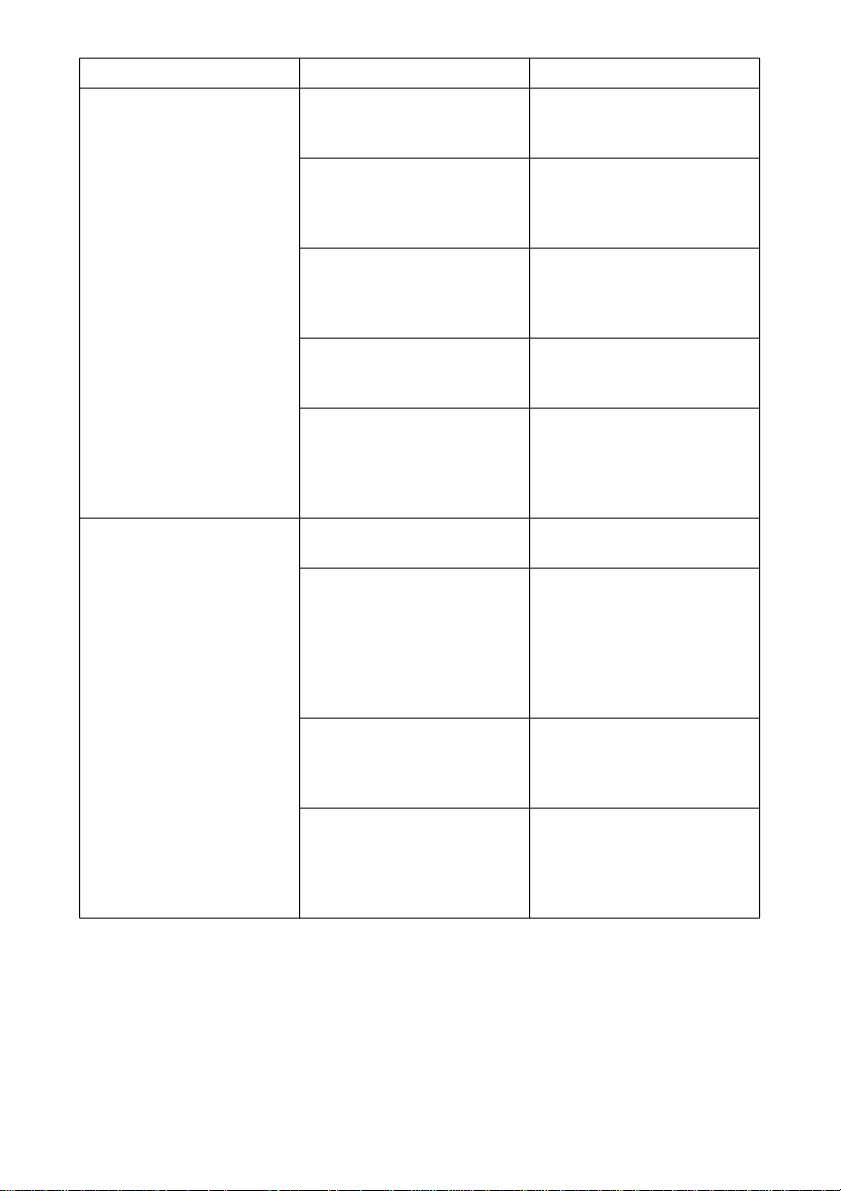

< EDS-3>

BANK

SW OFF ONFUNCTION

1

A

2

3

4

1

B

2

3

4

5

International character

set

Code Page

1 2 3 4 5

ON ON ON ON ON #437 U.S.A *

ON ON ON ON OFF #737 Greek

ON ON ON OFF ON #772 Lithuanian

ON ON ON OFF OFF #774 Lithuanian

ON ON OFF ON ON #850 Multi-lingual

ON ON OFF ON OFF #851 Greek

ON ON OFF OFF ON #852 Latin-2

ON ON OFF OFF OFF #858 Multi-lingual with Euro

ON OFF ON ON ON #860 Portuguese

ON OFF ON ON OFF #861 Icelandic

ON OFF ON OFF ON #863 Canada French

ON OFF ON OFF OFF #865 Nordic

ON OFF OFF ON ON #866 Russian

ON OFF OFF ON OFF #869 Greek

ON OFF OFF OFF ON #928 Greek

ON OFF OFF OFF OFF #1001 Arabic

OFF ON ON ON ON #2001 Lithuanian-KBL

OFF ON ON ON OFF #3001 Estonian-1

OFF ON ON OFF ON #3002 Estonian-2

OFF ON ON OFF OFF #3011 Latvian-1

OFF ON OFF ON ON #3012 Latvian-2

OFF ON OFF ON OFF #3021 Bulgarian

OFF ON OFF OFF ON #3031 Hebrew

OFF ON OFF OFF OFF #3041 Maltese

OFF OFF ON ON ON #3840 IBM-Russian

OFF OFF ON ON OFF #3841 Gost

OFF OFF ON OFF ON #3843 Polish

OFF OFF ON OFF OFF #3844 CS2

OFF OFF OFF ON ON #3845 Hungarian

OFF OFF OFF ON OFF #3846 Turkish

OFF OFF OFF OFF ON #3847 Brazil-ABNT

OFF OFF OFF OFF OFF #3848 Brazil-ABICOMP

1 2 3 4

ON ON ON ON U.S.A *

ON ON ON OFF France

ON ON OFF ON Germany

ON ON OFF OFF England

ON OFF ON ON Denmark-1

ON OFF ON OFF Sweden

ON OFF OFF ON Italy

ON OFF OFF OFF Spain-1

OFF ON ON ON Japan

OFF ON ON OFF Norway

OFF ON OFF ON Denmark-2

OFF ON OFF OFF Spain-2

OFF OFF ON ON Latin America

OFF OFF ON OFF Korea

OFF OFF OFF ON Ireland

OFF OFF OFF OFF Legal

ENGLISH

– 38 –

*: Default setting

Page 43

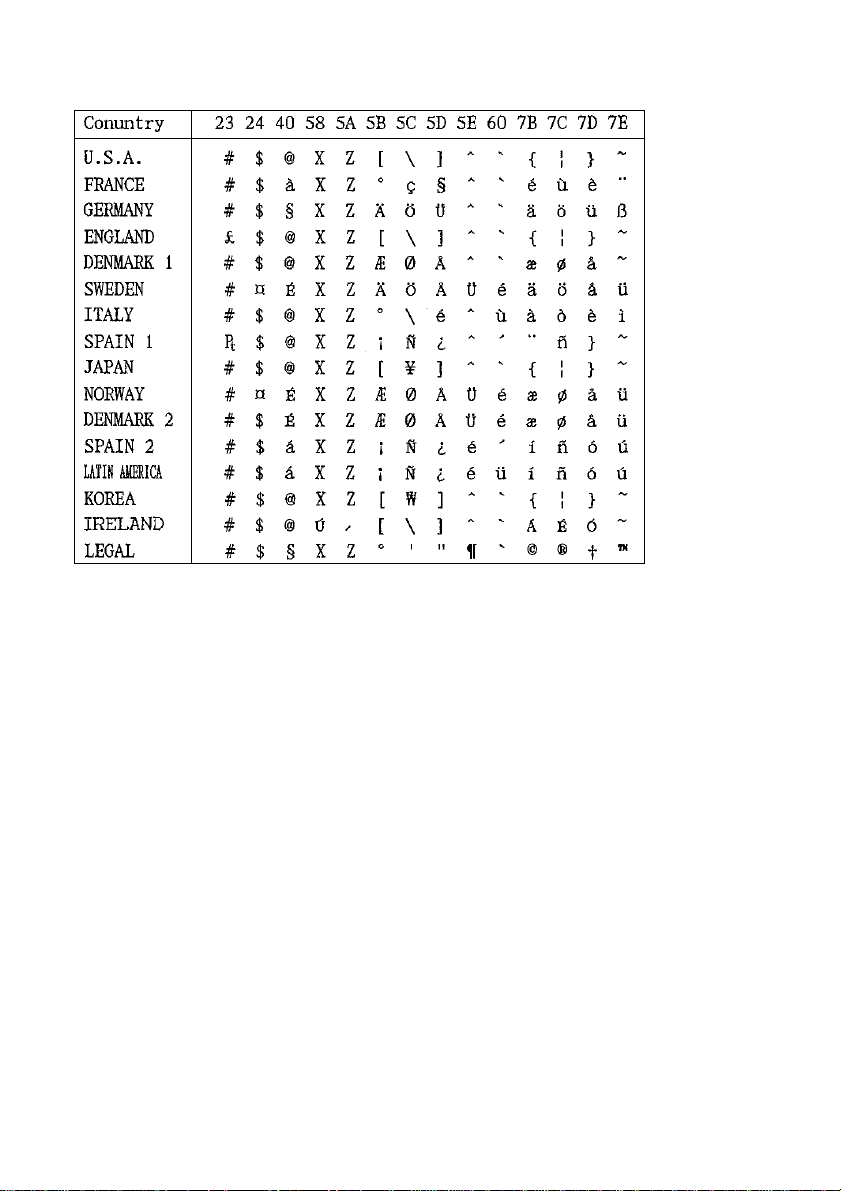

International character set

See Appendix C, “Character set” for details.

Code page

A code page is the set of symbols and characters that your printer can

print. Your printer converts ASCII hexadecimal data according to a code

page to print symbols and characters. By supporting different code

pages, the printer can print in a variety of different languages. The

following table shows detailed information about code pages.

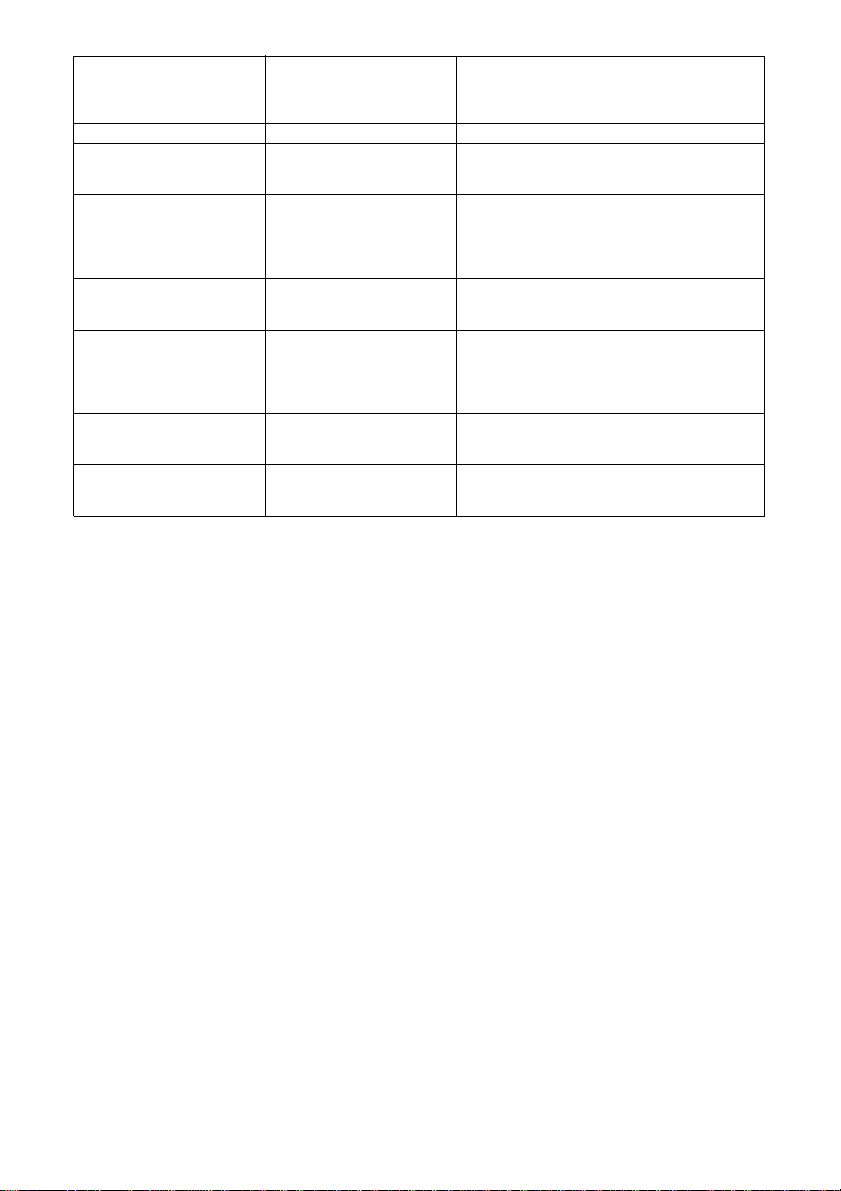

Code Page Name Country Remarks

#437 U.S.A United Kingdom, France, Germany, Italy,

#737 Greek Greece Almost 80%

#772 Lithuanian Lithuania New standard

#774 Lithuanian Lithuania

#850 Multi-lingual United Kingdom, France, germany, Italy, Preferred by Microsoft

#851 Greek Greece

#852 Latin-2 Croatia, Czech Republic, Hungary, Preferred by Microsoft

#858 Multi-lingual with Euro

#860 Portuguese Portugal

#861 Icelandic Iceland

#863 Canada French Canada

#865 Nordic Denmark, Finland, Norway, Sweden Preferred by Microsoft

#866 Russian Russia Preferred by Microsoft

#869 Greek Greece

#928 Greek Greece for UNIX

#1001 Arabic Egypt, Saudi Arabia Mainly in Arabic speaking

#2001 Lithuanian-KBL Lithuania Commonly used for DOS

#3001 Estonian-1 Estonia

#3002 Estonian-2 Estonia Most often used

#3011 Latvian-1 Latvia

#3012 Latvian-2 Latvia Government standard

#3021 Bulgarian Bulgaria

#3031 Hebrew Israel

#3041 Maltese Malta

#3840 IBM-Russian Russia, Bulgaria

#3841 Gost Russia Gost: government standard

#3843 Polish Poland Also called “Mazovia”

#3844 CS2 Czech Republic Also called “Kamenicky”

#3845 Hungarian Hungary

#3846 Turkish Turkey

#3847 Brazil-ABNT

#3848 Brazil-ABICOMP

Austria, Switzerland, United States, Spain

Austria, Switzerland, United States, Spain

Poland, Romania, Serbia, Slovak

Republic, Slovenia

countries

– 39 –

Page 44

< EDS-4>

BANK SW OFFONFUNCTION

Page length

1

A

(Cut-sheet paper)

2

3

4

1 2 3 4

ON ON ON ON ON ON ON OFF ON ON OFF ON 3.5 inch

ON ON OFF OFF 11/3 inch

ON OFF ON ON 4.0 inch

ON OFF ON OFF 5.5 inch

ON OFF OFF ON 6.0 inch

ON OFF OFF OFF 7.0 inch

OFF ON ON ON 8.0 inch

OFF ON ON OFF 8.5 inch

OFF ON OFF ON 11.0 inch

OFF ON OFF OFF 11.7 inch / A4 *

OFF OFF ON ON 12.0 inch

OFF OFF ON OFF 14.0 inch

OFF OFF OFF ON (17.0 inch)

ENGLISH

B

Top margin

1

(Cut-sheet paper)

2

Bottom margin

3

(Cut-sheet paper)

4

Page length (Cut-sheet paper)

The print quality for the values enclosed in parentheses (17.0 inch) is not

guaranteed.

1 2

ON ON 1.0 mm (1-pin)

ON OFF 1/6 inch * (1-pin)

OFF ON 9.24 mm (1-pin)

OFF OFF 1 inch (24-pin)

3 4

ON ON 1.0 mm (24-pin)

ON OFF 1/6 inch * (24-pin)

OFF ON 1/2 inch (24-pin)

*: Default setting

– 40 –

Page 45

< EDS-5>

BANK SW OFFONFUNCTION

Page length

1

A

(Fanfold paper)

2

3

4

1 2 3 4

ON ON ON ON ( 11/4 inch )

ON ON ON OFF ( 3.0 inch )

ON ON OFF ON ( 3.5 inch )

ON ON OFF OFF ( 11/3 inch )

ON OFF ON ON ( 4.0 inch )

ON OFF ON OFF 5.5 inch

ON OFF OFF ON 6.0 inch

ON OFF OFF OFF 7.0 inch

OFF ON ON ON 8.0 inch

OFF ON ON OFF 8.5 inch

OFF ON OFF ON 11.0 inch *

OFF ON OFF OFF 11.7 inch / A4

OFF OFF ON ON 12.0 inch

OFF OFF ON OFF 14.0 inch

OFF OFF OFF ON 17.0 inch

B

Top margin

1

(Fanfold paper)

2

Bottom margin

3

(Fanfold paper)

4

Page length (Fanfold paper)

The print quality for the values enclosed in parentheses (11/4 inch to 4.0

inch) are not guaranteed.

1 2

ON ON 1.0 mm (1-pin)

ON OFF 1/6 inch * (1-pin)

OFF ON 9.24 mm (1-pin)

OFF OFF 1 inch (24-pin)

3 4

ON ON 1.0 mm (24-pin)

ON OFF 1/6 inch * (24-pin)

OFF ON 1/2 inch (24-pin)

OFF OFF 1 inch (24-pin)

*: Default setting

– 41 –

Page 46

5. Control Codes List

< ESC/P mode>

Command HEX code Function

BEL 07 Beeper

BS 08 Backspace

HT 09 Tab horizontally

LF 0A Line feed

VT 0B Tab vertically

FF 0C Form feed

CR 0D Carriage return

SO 0E Select Double-width printing (1 line)

SI 0F Select Condensed printing

DC2 12 Cancel Condensed printing

DC4 14 Cancel Double-width printing (1 line)

CAN 18 Cancel line

DEL 7F Delete last character in buffer

ESC SO 1B 0E Select Double-width printing (1 line)

ESC SI 1B 0F Select Condensed printing

ESC SP n 1B 20 n Set inter character space

ESC ! n 1B 21 n Master select

n = 00 n = 00 10 CPI (ESC P)

01 01 12 CPI (ESC M)

02 02 Proportional (ESC p)

04 04 Condensed (SI)

08 08 Emphasized (ESC E)

10 10 Double-strike (ESC G)

20 20 Double-wide expanded (ESC W)

40 40 Italic (ESC 4)

ESC # 1B 23 Cancel MSB control

ESC $ nL n

ESC % n 1B 25 n Turn User-defined character on / off

ESC & 0 n m [ a0 a1 a2 d ... 1B 26 30 n m [ a0 a1 a2 d ... Define User-defined characters

ESC ( - nL nH m d1 d

ESC ( B nL nH k m s v1 v21B 28 42 nL nH k m s v1 v2Select Bar-code printing

ESC * m nL nH d1...d

ESC + n 1B 2B n Set n/360" line spacing

ESC - n 1B 2D n Turn under lining mode on / off

ESC / n 1B 2F n Select vertical tab channel

ESC 0 1B 30 Select 1/8" line spacing

ESC 2 1B 32 Select 1/6" line spacing

ESC 3 n 1B 33 n Select n/180" line spacing

ESC 4 1B 34 Select italic font

ESC 5 1B 35 Cancel italic font

ESC 6 1B 36 Enable printing of upper control codes

ESC 7 1B 37 Enable upper control codes

ESC 8 1B 38 Disable paper out detector

ESC 9 1B 39 Enable paper out detector

80 80 Underlining (ESC -)

H

1B 24 nL n

H

Set absolute horizontal print position

n = 00 n = 00 Turns User-defined character off

01 01 Turns User-defined character on

2

k

n = 00 n = 00 Turns underline off

01 01 Turns underline on

1B 28 2D nL nH m d1 d

1B 2A m nL nH d1...d

k

Select or cancel score

2

Select Bit-image mode

(Character set #2)

(Character set #1)

– 42 –

ENGLISH

Page 47

ESC : 0 n 0 1B 3A 30 n 30 Copy standard character ROM font into

RAM

ESC < 1B 3C Select Unidirectional mode (1 line)

ESC = 1B 3D Set MSB to 0

ESC > 1B 3E Set MSB to 1

ESC ? n m 1B 3F n m Reassign Bit-image mode

ESC @ 1B 40 Initialize Printer

ESC A n 1B 41 n Set n/60" line spacing

ESC B d1...dk NUL 1B 42 d1...dk 00 Set vertical tab

ESC C n 1B 43 n Set page length in lines

ESC C NUL n 1B 43 00 n Set page length in inches

ESC D n1...nk NUL 1B 44 n1...nk 00 Set horizontal tab

ESC E 1B 45 Select Bold mode

ESC F 1B 46 Cancel Bold mode

ESC G 1B 47 Select Double-strike printing

ESC H 1B 48 Cancel Double-strike printing

ESC J n 1B 4A n Advance print position vertically (n/180")

ESC K nL nH d1...d

ESC L nL nH d1...d

ESC M 1B 4D Select 12 CPI (Elite)

k

k

1B 4B nL nH d1...d

1B 4C nL nH d1...d

k

k

Select Single-density Bit-image mode

Select Double-density Bit-image mode

ESC N n 1B 4E n Set Skip over perforation

ESC O 1B 4F Cancel Skip over perforation

ESC P 1B 50 Select 10 CPI (Pica)

ESC Q n 1B 51 n Set right margin

ESC R n 1B 52 n Select international character set

n = 00 n = 00 #0 U.S.A.

01 01 #1 France

02 02 #2 Germany

03 03 #3 England

04 04 #4 Denmark I

05 05 #5 Sweden

06 06 #6 Italy

07 07 #7 Spain I

08 08 #8 Japan

09 09 #9 Norway

0A 0A #10 Denmark II

0B 0B #11 Spain II

0C 0C #12 Latin America

0D 0D #13 Korea

0E 0E #14 Ireland

40 40 #64 Legal

ESC S n 1B 53 n Select Superscript / Subscript printing

n = 00 n = 00 Superscript

01 01 Subscript

ESC T 1B 54 Cancel Superscript / Subscript printing

ESC U n 1B 55 n Turn Unidirectional mode on / off

n = 00 n = 00 Bi-directional

ESC W n 1B 57 n Turn Double-width printing on / off

01 01 Unidirectional

n = 00 n = 00 Turns off double-width

01 01 Turns on double-width

ESC Y nL nH d1...d

ESC Z nL nH d1...d

ESC \ nL n

ESC b m n1...nk NUL 1B 62 m n1...nk 00 Set vertical tab in VFU channels

k

k

H

1B 59 nL nH d1...d

1B 5A nL nH d1...d

1B 5C nL n

H

k

k

Select High-speed Double-density Bitimage mode

Select Quadruple-density Bit-image mode

Move relative horizontal print position

ESC g 1B 67 Select 15 CPI

ESC j n 1B 6A n Advance reverse feed (n/180")

– 43 –

Page 48

ESC k n 1B 6B n Select Type style family

n = 00 n = 00 Roman

01 01 Sanserif

ESC l n 1B 6C n Set left margin

ESC p n 1B 70 n Turn proportional mode on / off

ESC q n 1B 71 n Select character style

ESC s n 1B 73 n Select quiet mode

ESC t n 1B 74 n Select character table

ESC w n 1B 77 n Turn Double-high printing mode on / off

ESC x n 1B 78 n Select print mode (ANK)

05 05 OCR B

n = 00 n = 00 Returns to current fixed character pitch

01 01 Selects proportional spacing

n = 00 n = 00 Cancel shadow / outline printing

01 01 Set outline printing

02 02 Set shadow printing

03 03 Set shadow & outline printing

n = 00 n = 00 Prints at normal speed

01 01 Prints at low speed

n = 00 n = 00 Select italic character table

01 01 Select Codepage character table

02 02 Select Download character table

03 03 Select Codepage character table

n = 00 n = 00 Turns off double-high

01 01 Turns on double-high

n = 00 n = 00 Draft

01 01 LQ

ENGLISH

– 44 –

Page 49

6. Troubleshooting

The appendix will provide help if you experience problems with your printer. It

tells you how to test the printer, how to check system software settings, and how

to adjust the vertical alignment. In addition, there is information on actions to take

for specific problems, and on the meanings of printer beep tones.

Warning!

The printer uses high voltage. Do not attempt any other repair or maintenance

except as expressly recommended in this appendix. Unauthorized repair

and maintenance not only exposes you to the danger of electrical shock, it

also may damage your printer and void your warranty.

Short test

Use the following procedure to test the printer to make sure that

everything is working correctly.

1. Make sure that paper is loaded in the printer.

2. Turn off the printer.

3. While holding down the control panel’s ON LINE button, turn the

printer back on.

4. The short self-test prints the following information.

1) The version number of the software contained in the printer’s ROM.

2) All EDS settings.

If there is no paper at power on, self-printing starts after the paper is

loaded by the panel. In self-printing, only paper end detection is

available. All panel functions are ignored. After self-printing finishes,

the printer will reset.

– 45 –

Page 50

Long test

Use the following procedure to test the printer to make sure that

everything is working correctly.

1. Make sure that paper is loaded in the printer.

2. Turn off the printer.

3. While holding down the control panel’s LINE FEED button, turn the

printer back on.

4. The short self-test prints the following information.

1) Rolling ASCII 7 lines.

2) All ASCII characters.

Draft 10 cpi, 12 cpi, and 15 cpi

ROMAN 10 cpi, 12 cpi, and 15 cpi

3) All Kanji characters.

Note:

Test printing prints across the entire width of the carriage. Make sure

that the printer is loaded with the widest paper available in order to avoid

damage to the print head and platen.

Hexadecimal dump

ENGLISH

This procedure prints in hexadecimal format all codes (character codes

and control codes) that are sent to the printer by the computer. The printer

does not execute any control codes (such as 0A - linefeed), it just prints

them out. The hexadecimal dump is useful when you are writing

programs for printer control.

1. Make sure that paper is loaded in the printer.

2. Turn off the printer.

3. While holding down the control panel’s SET/PARK/EJECT button,

turn the printer back on to enter the Hex Dump Mode.

4. To exit the Hex Dump Mode, turn the printer off.

– 46 –

Page 51

Adjusting the dot alignment

You may never have to use the procedure described in this section, but after you

have been using your printer for some time you may find that the dots of some

graphics do not align correctly. For example, what should look like:

may come out looking like one of the following:

This is caused when mechanical parts of the printer get out of alignment. This

happens only rarely and you may never experience it at all throughout the life of

the printer. If you do have problems, use the following procedure to correct it.

1. Make sure that paper is loaded in the printer.

2. Turn off the printer.

3. While holding down the control panel’s SET/PARK/EJECT and

LINE FEED buttons, turn the printer back on to enter the Dot

Adjustment Mode.

The printer will print something like the following.

or like this

Note that the printer will feed the paper forward and back each time

during this operation so you can view the printout.

4. If the two lines do not align properly, use SET/PARK/EJECT to move

the lower line to the left or LINE FEED to move it to the right.

The above step performs alignment for Normal-density mode only.

You must make separate adjustments for the CRT graphics, Doubledensity, Draft-Text, Triple-density, CRT graphics II, Quadrupledensity, LQ Text modes as well.

5. Press ON LINE to change to the next printing mode.

Press LINE FEED while holding down ON LINE to change to the

previous printing mode.

6. Repeat the above steps for each printing mode, if necessary.

7. After making changes to the adjustments, press SET/PARK/EJECT

while holding down ON LINE to exit the Dot Adjustment Mode and

register your adjustments.

– 47 –

Page 52

Troubleshooting guide

Use the following table to help track down the causes of problems and to

determine the best solution to deal with them.

Problem Possible Cause Recommended Action

The ON LINE indicator does

not light.

Printer sounds like it is

printing, but it is not.

Printing is weak.

Printer test works, but printer

will not print out data from

the attached computer.

Printer test works, but printer

will not print out data from

the attached computer.

Printer does not feed paper

properly.

The printer is not receiving

power.

The ribbon is jammed,

twisted, or not set correctly

between the print head and

the print head shield.

The printer is not set up

correctly for the thickness of

paper you are using.

The ribbon is worn out or

"used up."

Your application program’s or

system software’s printer

selection is wrong.

The computer’s system

software is not set up

properly for the printer or for

the port you are using.

The interface cable is

connected incorrectly or

damaged.

Jamming paper.

The printer is not set up

correctly for the thickness of

paper being used.

Check whether the power

cord is correctly plugged into

the power outlet.

Check whether the power

outlet is working by

unplugging the printer and

plugging in another device.

Make sure that the ribbon

cassette is installed correctly.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Replace the ribbon with a

new one.

Check the printer selection of

your application software.

Check the system software

settings. Check the settings

for LPT1.

Check to make sure that the

printer interface cable is

connected correctly. If it is, try

a different cable.

Remove all paper from the

printer and then reload it.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

ENGLISH

– 48 –

Page 53

Problem Possible Cause Recommended Action

Line spacing is incorrect. Jamming paper.

The line spacing or leading

selected in your application

program is wrong.

Auto line feed with carriage

return is enabled.

Lines print over each other. Auto line feed with carriage

Incorrect number of lines are

printed on the page.

Text and graphics are

malformed.

Print quality is poor.

Forms are smudged.

Printing is too dark.

return is disabled.

Jamming paper.

Auto line feed with carriage

return is enabled.

The line spacing or leading

selected by your application

program is wrong.

Dot adjustment is not correct.

The ribbon is worn out or

"used up".

The printer is not set up

correctly for the thickness of

paper being used.

The print head is damaged.

The printer is not set up

correctly for the thickness of

paper being used.

The ribbon is jammed,

twisted, or not set correctly

between the print head and

the print head shield.

Print head shield is damaged

or missing.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Choose a different line

spacing or leading setting

from your application.

Use the EDS Mode to disable

auto line feed with carriage

return (page 32).

Use the EDS Mode to disable

auto line feed with carriage

return (page 32).

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Use the EDS Mode to disable

auto line feed with carriage

return (page 32).

Choose a different line

spacing or leading setting

from your application.

See "Adjusting the dot

alignment" on page 47.

Replace the ribbon with a

new one.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Return the printer to your

dealer for repair.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Make sure that the ribbon

cassette is installed correctly.

See "Installing the ribbon

cassette" on page 7.

Return the printer to your

dealer for repair.

– 49 –

Page 54

Problem Possible Cause Recommended Action

Printer case is hot. The printer’s air vents are

blocked or obstructed.

Printer makes excessive

noise.

Printer prints past the edge

of the paper.

The printer cover is removed.

The printer is vibrating.

Incorrect margin settings are

selected by your application

program.

The paper edge is not

positioned correctly.

The ribbon is jammed,

causing the print head to jam.

Paper is jamming, causing

the print head to jam.

Switch off the printer and let it

cool. Check the air vents on

the bottom of the printer to

see if they are blocked.

Remove the obstruction if

possible. If the problem

persists, return the printer to

your dealer for repair.

Replace the printer cover.

Move any objects that are

touching the printer.

Make sure that the printer is

on a level steady surface.

Choose different margin

settings from your application

program.

Remove the paper and adjust

the position of the paper

edge. Reload the paper and

try printing again.

Make sure that the ribbon

cassette is installed correctly.

See "Installing the ribbon

cassette" on page 7.

Remove all paper from the

printer and reload it. Try

printing again.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

ENGLISH

– 50 –

Page 55

Problem Possible Cause Recommended Action

Left margin moves to the

right during printing.

Some characters are printed

incorrectly.

The paper is not loaded

correctly, causing the print

head to jam.

The ribbon cassette is not

installed correctly, causing the

print head to jam.

The printer is not set up

correctly for the thickness of

paper being used.

Inappropriate settings are

selected by your application

program.

Static electricity caused by

interference from nearby

electrical devices or by lowlevel humidity is affecting

printer operation.

Panel Lock Mode is enabled.

Panel Lock Mode is enabled.

Panel Macro Mode is also

enabled.

The wrong character table,

code page, or international

character set is selected.

Static electricity caused by

interference from nearby

electrical devices or by lowlevel humidity is affecting

printer operation.

Remove all paper from the

printer and reload it. Try

printing again.

Make sure that the ribbon

cassette is installed correctly.

See "Installing the ribbon

cassette" on page 7.

Set up the printer for the

paper thickness you are using.

See "Adjusting for paper

thickness table" on page 15.

Choose different settings in

your application.

Make sure that the printer is

not too close to any devices

with electric motors or that

raise the humidity level.

Turn off the printer, and then

turn it back on.

While holding down

SET/PARK/EJECT button,

press ON LINE button to

clear Panel Macro Mode.

After three buzzer sounds,

turn off the printer, and then

turn it back on.

Use the EDS Mode to select

the correct character table,

code page, or international

character set (page 34).

Make sure that the printer is

not too close to any devices

with electric motors or that

raise the humidity level.

– 51 –

Page 56

Problem Possible Cause Recommended Action

Some characters are printed

incorrectly.

Printer behaves erratically.

Printing suddenly stops.

Inappropriate settings are

selected by your application

program.

Wires are missing from the

print head.

The interface cable is

connected incorrectly or

damaged.

Static electricity caused by

interference from nearby

electrical devices or by lowlevel humidity is affecting

printer operation.

Choose different settings in

your application.

Return the printer to your

dealer for repair.

Check to make sure that the

printer interface cable is

connected correctly. If it is, try

a different cable.

Make sure that the printer is

not too close to any devices

with electric motors or that

raise the humidity level.

ENGLISH

– 52 –

Page 57

Appendix A: Specifications

Printing System Serial Impact Dot-Matrix

Printing Speed (Character per Sec.) Draft LQ

(When using Normal mode) 10CPI 180 60

12CPI 216 72

15CPI 270 90

17.1CPI 154 103

20CPI 180 120

Print Direction Draft: Uni-directional/ bi-directional logic seeking

(selectable)

LQ: Uni-directional/ bi-directional logic seeking

(selectable)

Bit-Image: Uni-directional/ bi-directional logic seeking

(selectable)

Print Head Number of pins: 24

Life 200 million dots/pin (adjustment lever position 1 to 3)

100 million dots/pin (adjustment lever position4 to 8)

Line Spacing 1/6, 1/8, n/60, n/180, n/360

Environment Operating temperature: 41°F to 95°F (5°C to 35°C)

Storage temperature: -22°F to 149°F (-30°C to 65°C)

Operating humidity: 30% to 80% (non-condensing)

Storage humidity: 20% to 90% (non-condensing)

Emulation ESC/P

Interfaces Parallel Bi-directional IEEE-1284 nibble mode

Ribbon Type On-carriage, dedicated

Black ribbon

CS24 (Standard)

Ribbon Life 4.0 million characters (Draft,10CPI)

Dimensions and Weight Width: 14.3" / 363 mm

Depth: 9.6" / 244 mm

Height: 8.1"/ 205 mm

Weight: 13.0lbs. / 5.9 kg

Power Supply 220V±15% 50/60Hz

Power Consumption 55W during ASCII draft printing

10W during stand-by

APPENDIX

– 52 –

Page 58

Paper

Cut-sheet paper

Width: 125 to 257 mm / 4.9 to 10.12 inches

Length: 85 to 364 mm / 3.3 to 14.33 inches

Paper Sizes: A6: 105 x 148 mm (Landscape)

Thickness

1-ply only: 0.05 to 0.18 mm

Multi-ply: 0.05 to 0.35 mm

Weight

1-ply only: 52 to 156 g/m2 / 14 to 42 lbs / 45 to 135kg

Multi-ply: 40 to 52 g/m2 / 11 to 14 lbs / 34 to 45kg

Fanfold paper

Width: 139.7 to 254 mm / 5.5 to 10 inches

Length: Min. 139.7 mm / 5.5 inches

Thickness

1-ply only: 0.07 to 0.11 mm

Multi-ply: Max. 0.35 mm

Weight

1-ply only: 52 to 82

Multi-ply: 40 to 52

B6: 128.5 x 182 mm (Portrait, Landscape)

A5: 148 x 210 mm (Portrait, Landscape)

B5: 182 x 257 mm (Portrait, Landscape)

A4: 210 x 297mm (Portrait)

B4: 257 x 364mm (Portrait)

Executive: 7.25 x 10.5 inches (Portrait)

Letter: 8.5 x 11 inches (Portrait)

Legal: 8.5 x 14 inches (Portrait)

2

g/m

/ 14 to 22 lbs / 45 to 70kg

2

g/m

/ 11 to 14 lbs / 34 to 45kg

– 53 –

Page 59

Parallel Interface

Connector Signals

Pin Name Function

1 STROBE Goes low for ≥ 0.5µs when active.

2 DATA0

3 DATA1

4 DATA2

5 DATA3

6 DATA4

7 DATA5

8 DATA6

9 DATA7

10 ACK 10µs low to acknowledge receipt of data.

11 BUSY Printer sets line low when ready to receive data.

12 PAPER High when paper runs out.

13 SELECT High when printer is on-line.

14 AFXT This signal is used when the mode is nibble mode.

15 Not used.

16 SIGNAL GND Signal ground

17 CHASSIS Chassis ground (isolated from signal ground)

18 +5V +5V DC output from printer

19~30 GND Twisted pair ground return

31 RESET Printer is reset when this signal goes low.

32 ERROR Low when printing cannot continue due to error.

33 EXT GND External ground

34~35 Not used

36 SELECT IN This signal is used when the mode is nibble mode.

These signals represent information for the 1st

through 8th bit of parallel data, respectively. Each

signal is HIGH when data is logical 1, and LOW

when logical 0.

APPENDIX

– 54 –

Page 60

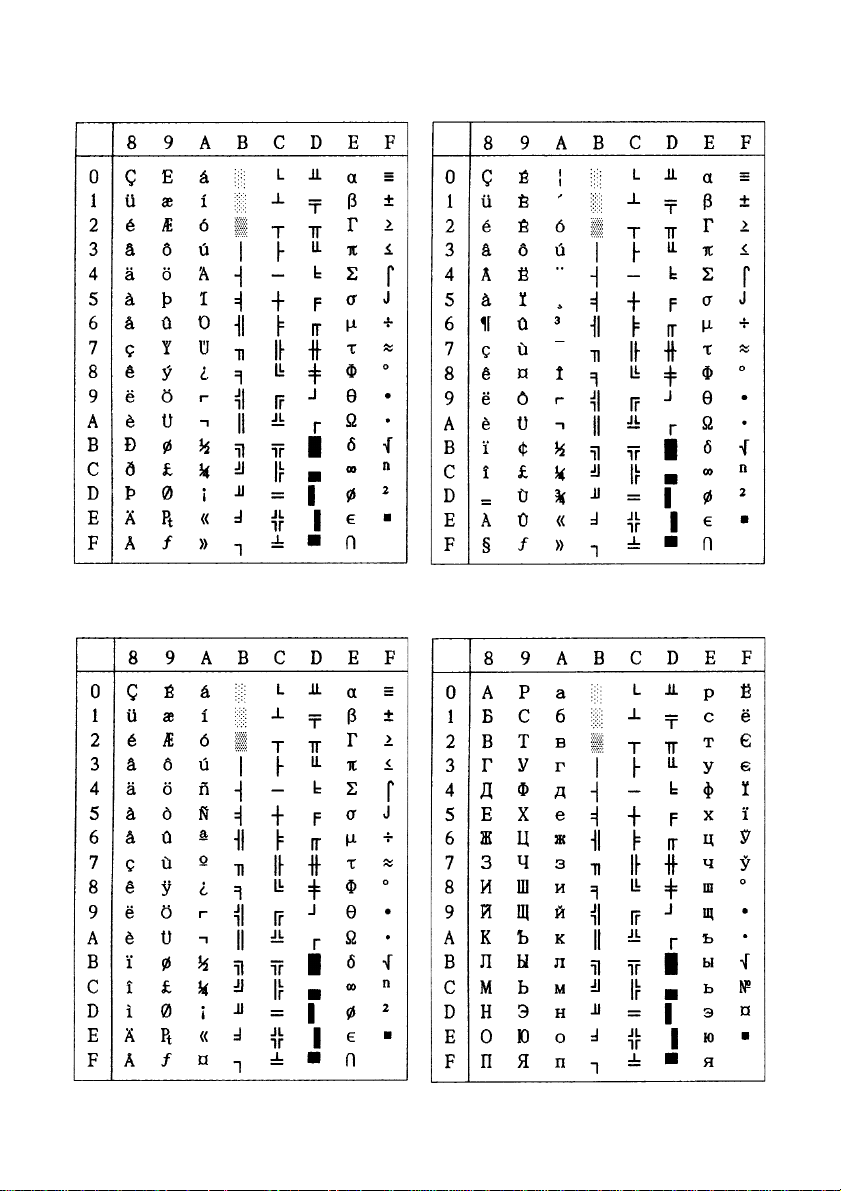

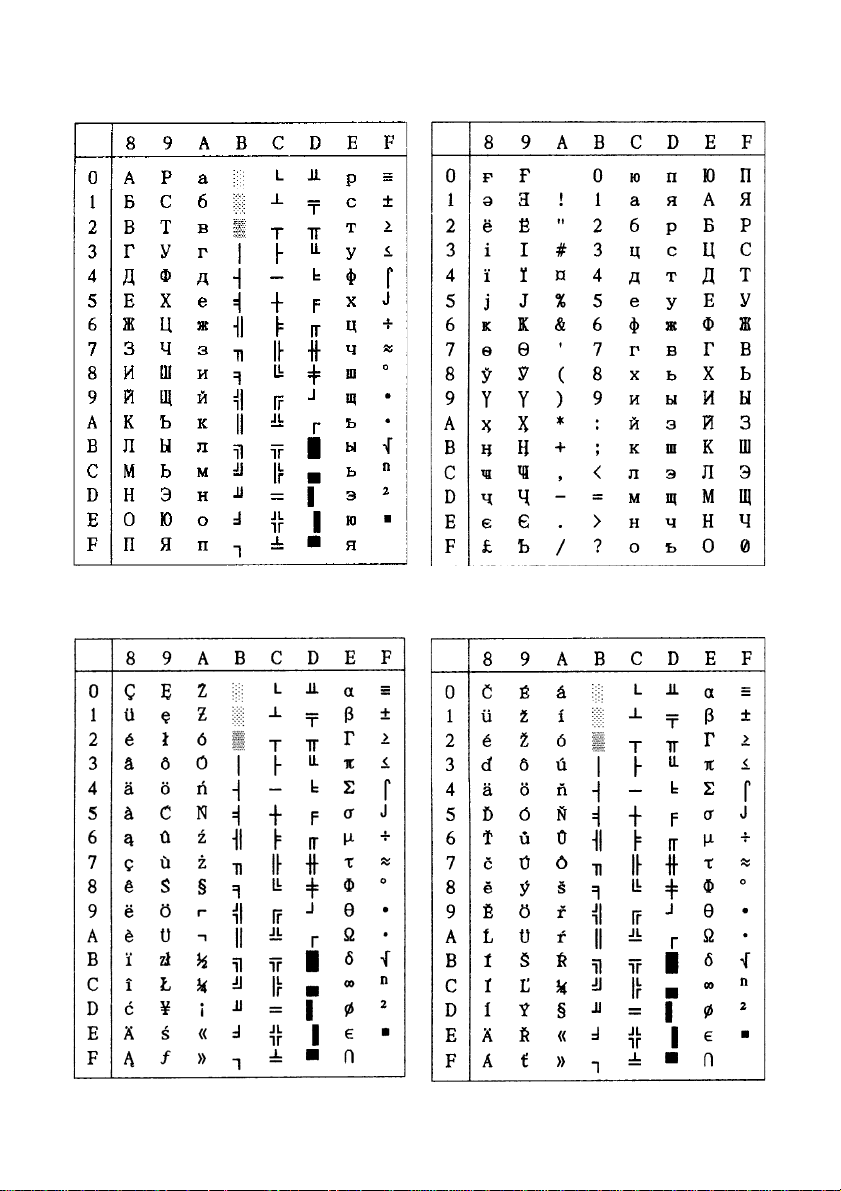

Appendix B: Character Sets

IBM Graphics Character Set #2

Code Page #437 (U.S.A.)

Italic Character Set #2

– 55 –

Page 61

IBM Graphics Character Set #1

Italic Character Set #1

– 56 –

APPENDIX

Page 62

Code Page #737 Code Page #772

Greek Lithuanian

Code Page #774 Code Page #850

Lithuanian Multi-lingual

Other characters are the same as those for Code Page #437.

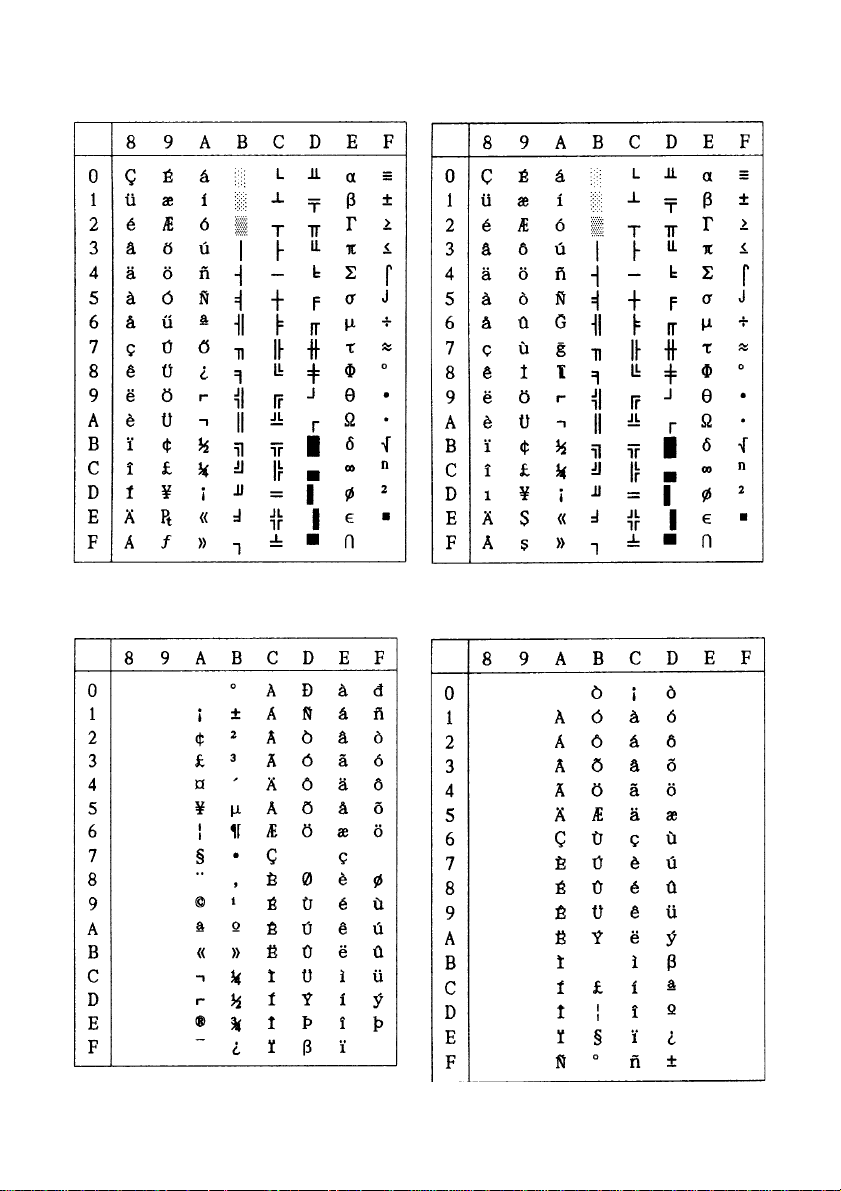

– 57 –

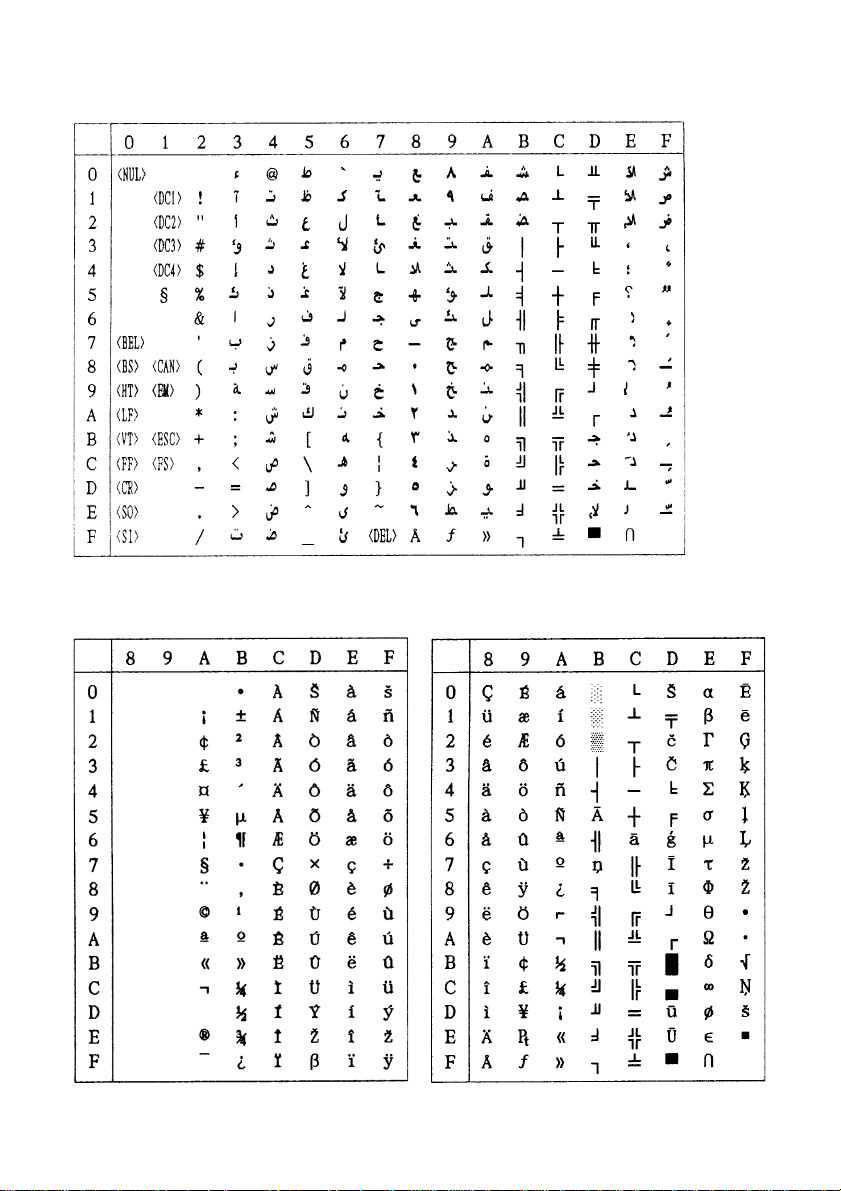

Page 63

Code Page #851 Code Page #852

Greek Latin-2

Code Page #858 Code Page #860

Multi-lingual with Euro Portuguese

Other characters are the same as those for Code Page #437.

– 58 –

APPENDIX

Page 64

Code Page #861 Code Page #863

Icelandic Canadian French

Code Page #865 Code Page #866

Nordic Russian

Other characters are the same as those for Code Page #437.

– 59 –

Page 65

Code Page #869 Code Page #928

Greek Greek

Code Page #2001 Code Page #3001

Lithuanian-KBL Estonian-1

Other characters are the same as those for Code Page #437.

– 60 –

APPENDIX

Page 66

Code Page #1001

Arabic

Code Page #3002 Code Page #3011

Estonian-2 Lavian-1

Other characters are the same as those for Code Page #437.

– 61 –

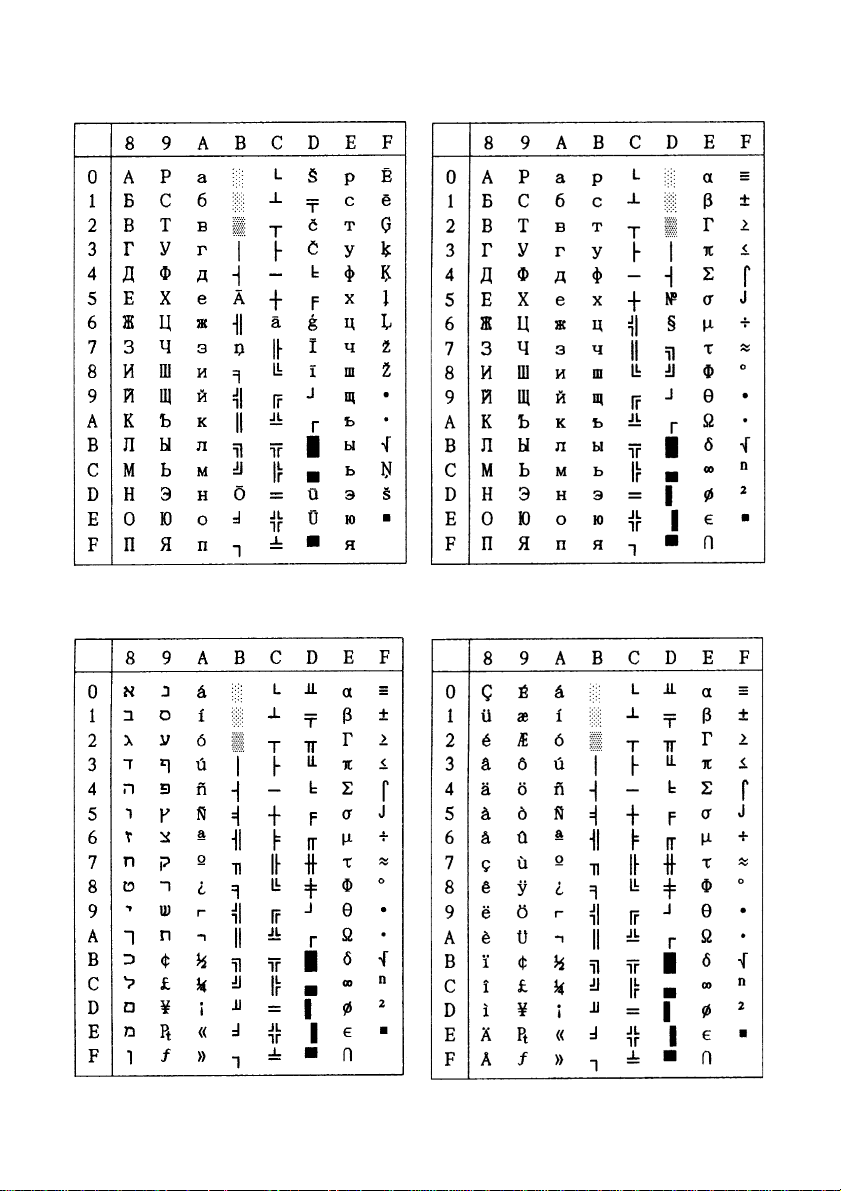

Page 67

Code Page #3012 Code Page #3021

Lavian-2 Bulgarian

Code Page #3031 Code Page #3041

Hebrew Maltese

Other characters are the same as those for Code Page #437.

– 62 –

APPENDIX

Page 68

Code Page #3840 Code Page #3841

IIBM-Russian Gost

Code Page #3843 Code Page #3844

Polish CS2

Other characters are the same as those for Code Page #437.

– 63 –

Page 69

Code Page #3845 Code Page #3846

Hungarian Turkish

Code Page #3847 Code Page #3848

Brazil-ABNT Brazil-ABICOMP

Other characters are the same as those for Code Page #437.

– 64 –

APPENDIX

Page 70

International Character Set

– 65 –

Page 71

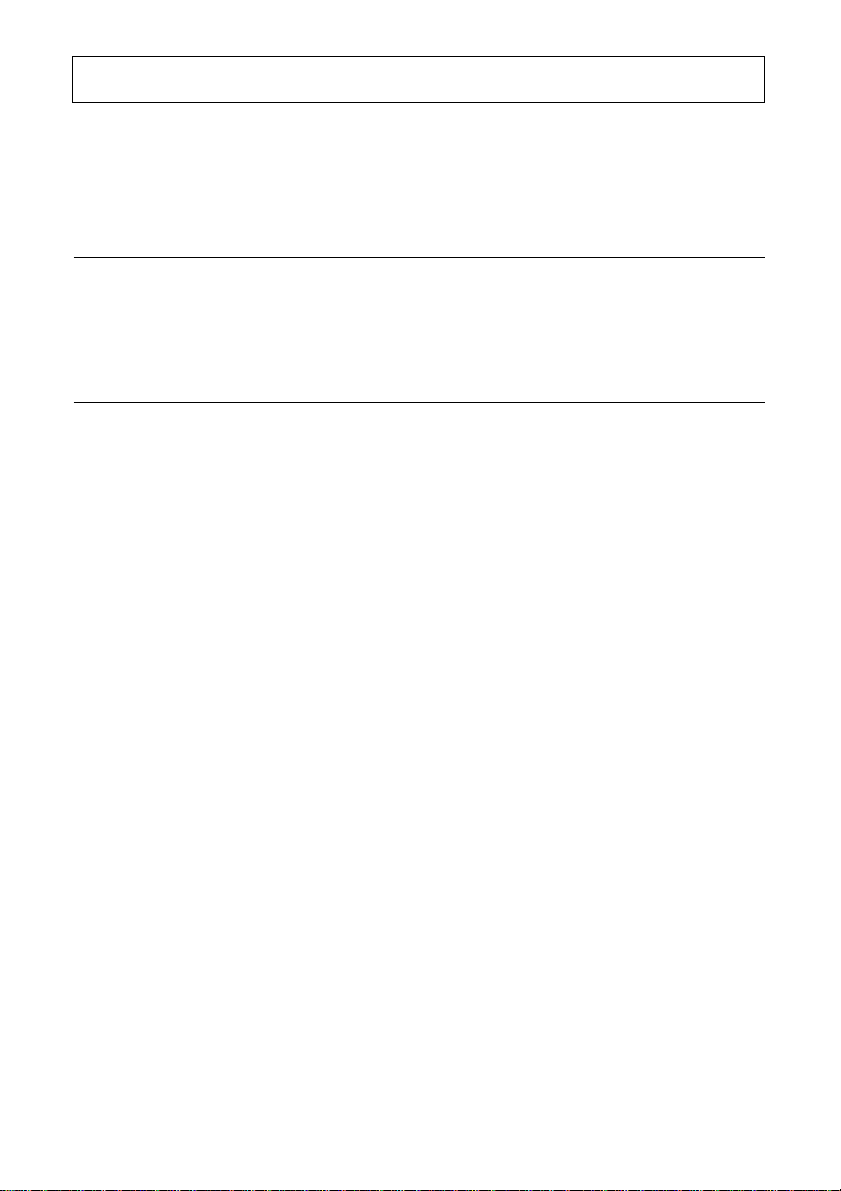

Appendix C. Control Panel Operation Guide

: Push

: Hold

ON-LINE

OFF-LINE

POWER-ON

POWER

P.E.

TEAR OFF

SET/PARK

EJECT

MICRO FEED

Print mode

Panel lock (Print mode)

Panel Macro (Print mode & Panel Lock)

Set / Park / Eject Line Feed ON-LINE

Reverse

AUTO LOADING POSITION CHANGE MODE

Set top of form (TOF)

Buffer clear (1 Beep) / All reset (3 Beeps)

Hex dump mode Self test (Long) Self test (Short)

DOT ADJUSTMENT MODE

LINE FEED

FORM FEED

Tear off (Page)

Form Feed

Forward

EDS MODE

ON LINE

OFF-LINE

< Micro Paper Feed >

ENGLISH

EDS MODE

DOT ADJUSTMENT MODE

AUTO LOADING POSITION CHANGE MODE

BANK SW

EDS No.

Left Right

Reverse feed Forward feed

Save & Exit

– 66 –

ON / OFF

Print

Exit

Next

Previous

Exit

Paper loading

Factory settings & Exit

Page 72

STAR MICRONICS ASIA LTD.

HEAD OFFICE

Rm. 1901-6, 19/F., Enterprise Square Two,

3 Sheung Yuet Road, Kowloon Bay, Hong Kong

EUROPEAN OFFICE

C.P. 58, CH-6914 Carona,

Ticino, Switzerland

TEL: +852-2796-2727

FAX: +852-2799-9344

E-mail: smh@starhkg.com.hk

Web site: http://www.starhkg.com.hk/

TEL: +41-91-630.62.08

FAX: +41-91-630.62.09

E-mail: Gaudenz.Juon@dial.eunet.ch

Loading...

Loading...