Page 1

DOT MATRIX PRINTER

NX-1000SERIES

LC-10SERIES

TECHNICAL MANUAL

[ NINTH EDITION ]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual

in any form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without

notice.

• All efforts have been made to ensure the accuracy of the

contents of this manual at the time of going to press.

However, should any errors be detected, STAR would

greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no respon-

sibility for any errors in this manual.

© Copyright 1987 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

This manual describes dot matrix printers as shown below.

It is intended for use as a reference for periodic inspections and maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

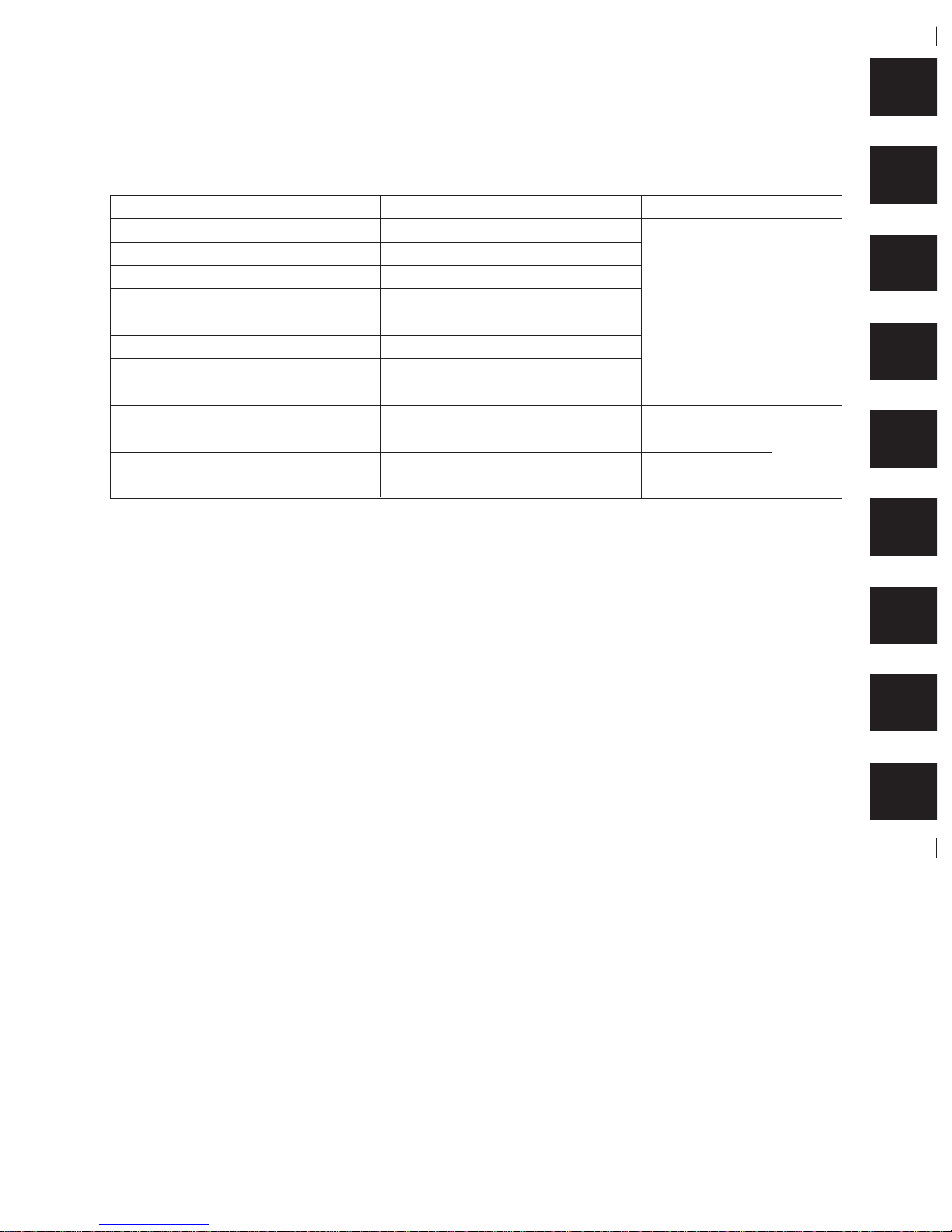

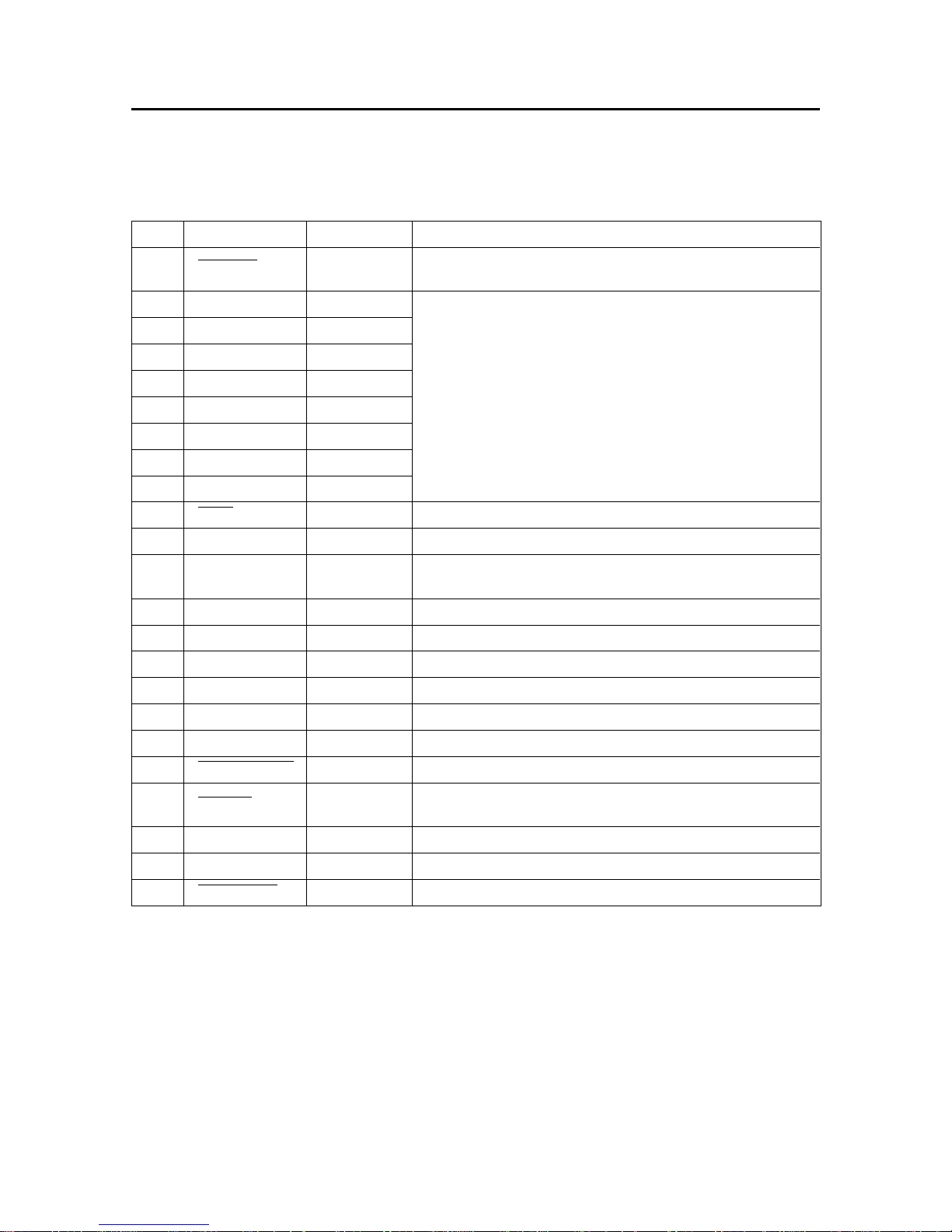

Model Interface Mono/Colour Destination Ver.

NX-1000MULTI-FONT PRINTER Parallel Type Monochrome

NX-1000CMULTI-FONT PRINTER Commodore Type Monochrome

NX-1000COLOUR PRINTER Parallel Type Colour

NX-1000C COLOUR PRINTER Commodore Type Colour

LC-10 MULTI-FONT PRINTER Parallel Type Monochrome

LC-10CMULTI-FONT PRINTER Commodore Type Monochrome

LC-10 COLOUR PRINTER Parallel Type Colour

LC-10C COLOUR PRINTER Commodore Type Colour

NX-1000 II MULTI-FONT PRINTER Parallel Type Monochrome

LC-10 II MULTI-FONT PRINTER Parallel Type Monochrome

• This manual is divided into the following sections:

Chapter 1 General Specifications

Chapter 2 Theory of Operation

Chapter 3 Adjustments

Chapter 4 Parts Replacement

Chapter 5 Maintenance and Lubrication

Chapter 6 Troubleshooting

Chapter 7 Parts List (Ver. 1 and Ver. 1.5)

Chapter 8 Parts List (Ver. 2)

Appendix Explanation of Principle ICs

• First edition : Nov. 1987 Only Monochrome Type

Second edition : Mar. 1988 Add Colour Type

Third edition : Dec. 1988 Add Ver. 1.5 of Parallel Type

Fourth edition : Jul. 1989 Add NX-1000 II and LC-10 II (Ver. 2 of Parallel Type)

Fifth edition : Apr. 1991

Sixth edition : Aug. 1993

Seventh edition :Sep. 1995

Eighth edition :Apr. 1996

Ninth edition :Aug. 1997

Except for

European market

For European

Market

For American

and Asian market

For European and

Pacific market

Ver. 1

and

Ver. 1.5

Ver. 2

1

2

3

4

5

6

7

8

APP.

Page 4

CHAPTER 1

GENERAL SPECIFICATIONS

1. General Specifications .........................................................................................3

1-1. Parallel Type............................................................................................................ 3

1-2. Commodore Type.................................................................................................... 4

2. External Appearance and Composition .............................................................. 7

2-1. Names of Parts........................................................................................................ 7

2-2. DIP switch settings ................................................................................................. 9

3. Connector Signals .............................................................................................. 11

3-1. Parallel Interface ................................................................................................... 11

3-2. Commodore Interface........................................................................................... 12

1

2

3

4

5

6

7

8

A

Page 5

– 2 –

GENERAL SPECIFICATIONS

Page 6

– 3 –

GENERAL SPECIFICATIONS

1. General Specifications

1-1. Parallel Type

Printing

Printing method Serial impact dot matrix

Printing speed 120 characters per second (in Draft pica for Ver. 1 and Ver. 1.5)

30 characters per second (in NLQ pica for Ver. 1 and Ver. 1.5)

150 characters per second (in Draft pice for Ver. 2)

38 characters per second (in NLQ pica for Ver. 2)

Data buffer 4K bytes (for monochrome type), 8K byte (for colour type) when not used for

download characters. 1-Line buffer when using download

Paper feed 2.7 inches/second (during page feed)

Friction and push-tractor feed

Printing direction Draft: bi-directional or unidirectional (selectable), logic seeking

NLQ and graphics: unidirectional, logic seeking

Character set

Standard character set 96 ASCII characters

IBM character set 244 characters (ASCII,international characters, symbols, block graphics)

Downloadable characters Max.192 (draft) or 78 (NLQ)

International character sets 14 sets (USA, France, Germany, England, Denmark I, Denmark II, Sweden,

Italy, Spain I, Spain II, Japan, Norway, Latin America, Denmark/Norway

Dot matrix size

Character matrix 9 × 9 dots (Draft pica)

18 × 23 dots (Courier and Orator pica)

18 × 18 dots (Sanserif pica,elite)

12 × 11 dots (IBM block graphics,pica)

18 × 19 dots (Courier and Orator elite)

18 × 12 dots (Condensed pica)

18 × 10 dots (Condensed elite)

Bit-image graphic 8 × 480 dots at 60 dpi (Single density)

9 × 480 dots at 60 dpi (Single density)

8 × 576 dots at 72 dpi (Plotter mode)

8 × 640 dots at 80 dpi (CRT I)

8 × 720 dots at 90 dpi (CRT II)

8 × 960 dots at 120 dpi (Double density)

9 × 960 dots at 120 dpi (Double density)

8 × 960 dots at 120 dpi (High speed)

8 × 1920 dots at 240 dpi (Quadruple density)

Line spacing 1/6 inch standard 1/8, n/72, or n/216 inch programmable

Column width 80, normal pica 96, normal elite

137, condensed pica 160, condensed elite

Paper

Single sheets 5.5 ~ 8.5 inches wide 0.07 ~ 0.10 mm thick

Fanfold paper 4 ~ 10 inches wide 0.07 ~ 0.10 mm thick (single-ply)

Max, 0.28mm thick (3-ply)

Page 7

– 4 –

GENERAL SPECIFICATIONS

Printer

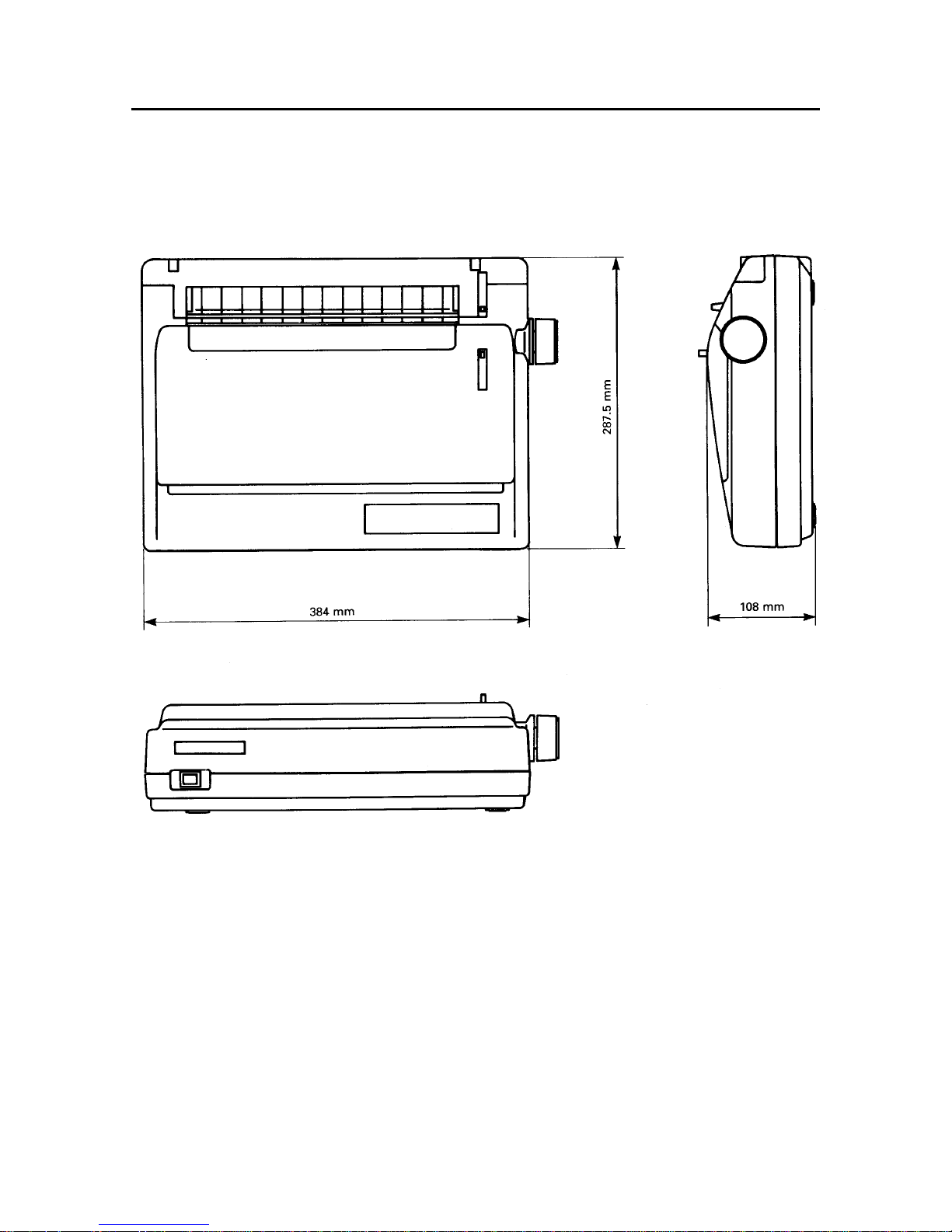

Dimensions Height 108 mm (4.3 inches) Width 384 mm (15.1 inches)

Depth 287.5 mm (11.3 inches)

Weight 4.7 kg (10.3 pounds)

Power 120 VAC±10%, 60Hz. 220 VAC±10%, 50/60Hz.

240 VAC±10%, 50/60Hz.

Power consumption Typ. 30W, Max. 60W

Environment Operating temperature: 5 to 40°C (41 to 104°F)

Operating humidity: 10 to 80%, non condensation

Storage temperature: –30 to 65°C (–22 to 149°F)

Storage humidity: 10% to 95% (at 40°C) (no condensation)

Print head 9 Pins

Life: 200 million dots

Ribbon Fabric ribbon cartridge

Monochrome type ........................... Black

Colour type ..................................... Black/cyan/magenta/yellow

Life: 1 million draft characters

Option Automatic sheet feeder

Parallel interface

Interface Centronics-compatible

Synchronization By external supplied strobe pulses

Handshaking By ACK or BUSY signals

Logic level TTL

Connector 57-30360 Amphenol

1-2. Commodore Type

Printing

Printing method Serial impact dot matrix

Print speed 120 characters per second (in Draft pica)

30 characters per second (in NLQ pica)

Data buffer 1-line buffer

Paper feed 2.7 inches/second (during page feed)

Friction and push-tractor feed

Printing direction Draft: bi-directional or unidirectional (selectable), logic seeking

NLQ and graphics: unidirectional, logic seeking

Commodore character sets

Standard graphics Upper-case letters, digits, punctuation and symbols, graphic characters

Standard business Lower- and upper-case letters, digits, punctuation and symbols, graphic charac-

ters

DIN graphics Upper-case letters, international letters, digits, punctuation and symbols, graphic

characters

DIN business Lower- and upper-case letters, international letters, digits, punctuation and

symbols, graphic characters

Downloadable characters Max. 192 (draft) or 80 (NLQ)

International characters sets 10 sets (England, USA, France, Germany, Denmark I, Denmark II, Sweden I,

Italy, Spain, Sweden II)

Page 8

– 5 –

GENERAL SPECIFICATIONS

Printing

Dot matrix size

Character matrix 9 × 9 dots (Draft pica)

18 × 23 dots (Courier and Orator pica)

18 × 18 dots (Sanserif pica,elite)

7 × 11 dots (Block graphics,pica)

18 × 19 dots (Courier and Orator elite)

18 × 12 dots (Condensed pica)

18 × 10 dots (Condensed elite)

Bit-image graphic 7 × 480 dots at 60 dpi (Single density)

8 × 480 dots at 60 dpi (Single density)

7 × 960 dots at 120 dpi (Double density)

8 × 960 dots at 120 dpi (Double density)

8 × 960 dots at 120 dpi (High speed)

8 × 1920 dots at 240 dpi (Quadruple density)

Line spacing 1/6 inch standard 1/8, n/72, or n/216 inch programmable

Column width 80, normal pica 96, normal elite

137, condensed pica 160, condensed elite

Paper

Single sheets 5.5 ~8.5 inches wide 0.07 ~ 0.10 mm thick

Fanfold paper 4 ~ 10 inches wide 0.07 ~ 0.10 mm thick (single-ply)

Max. 0.28mm thick (3 ply)

Printer

Dimensions Height 108 mm (4.3 inches) Width 384 mm (15.1 inches)

Depth 287.5 mm (11.3 inches)

Weight 4.7 kg (10.3 pounds)

Power 120 VAC±10%, 60Hz. 220 VAC±10%, 50/60Hz.

240 VAC±10%, 50/60Hz.

Power consumption Typ. 30W, Max. 60W

Environment Operating temperature: 5 to 40°C (41 to 104°F)

Operating humidity: 10 to 80%, no condensation

Storage temperature: –30 to 65°C (–22 to 149°F)

Storage humidity: 10% to 95% (at 40°C) (no condensation)

Print head 9 Pins

Life: 200 million dots

Ribbon Fabric ribbon cartridge

Monochrome type ........................... Black

Colour type ..................................... Black/blue/red/yellow

Life: 1 million draft characters

Option Automatic sheet feeder

Commodore interface

Interface Serial mode, for Commodore computers

Synchronization By external supplied clock (synchronous serial)

Logic level TTL

Connector 6-pin DIN

Page 9

– 6 –

GENERAL SPECIFICATIONS

Fig. 1-1 External Dimensions

Page 10

– 7 –

GENERAL SPECIFICATIONS

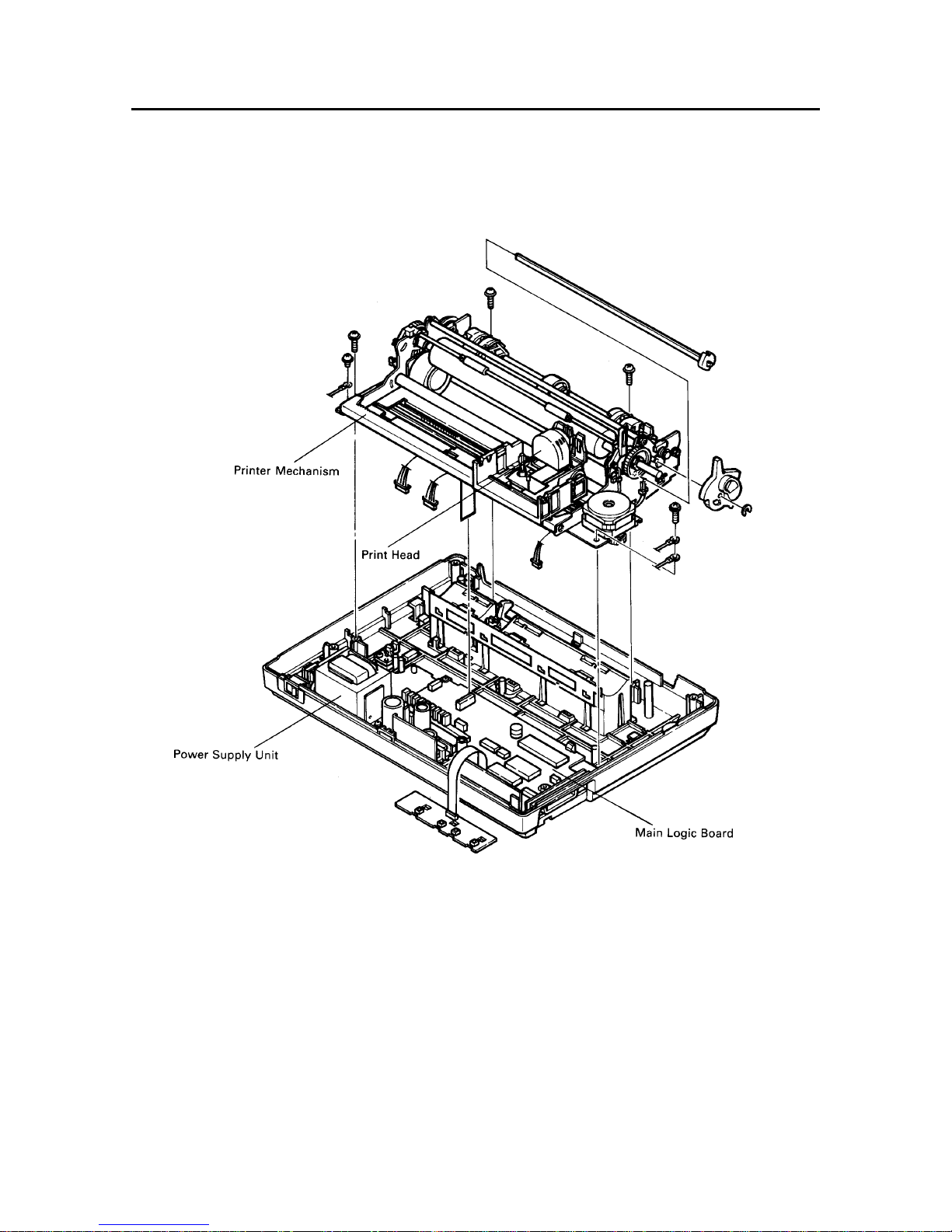

2. External Appearance and Composition

2-1. Names of Parts

Fig. 1-2 Front and rear views of the printer

Page 11

– 8 –

GENERAL SPECIFICATIONS

Fig. 1-3 Diagram of Internal Composition

Page 12

– 9 –

GENERAL SPECIFICATIONS

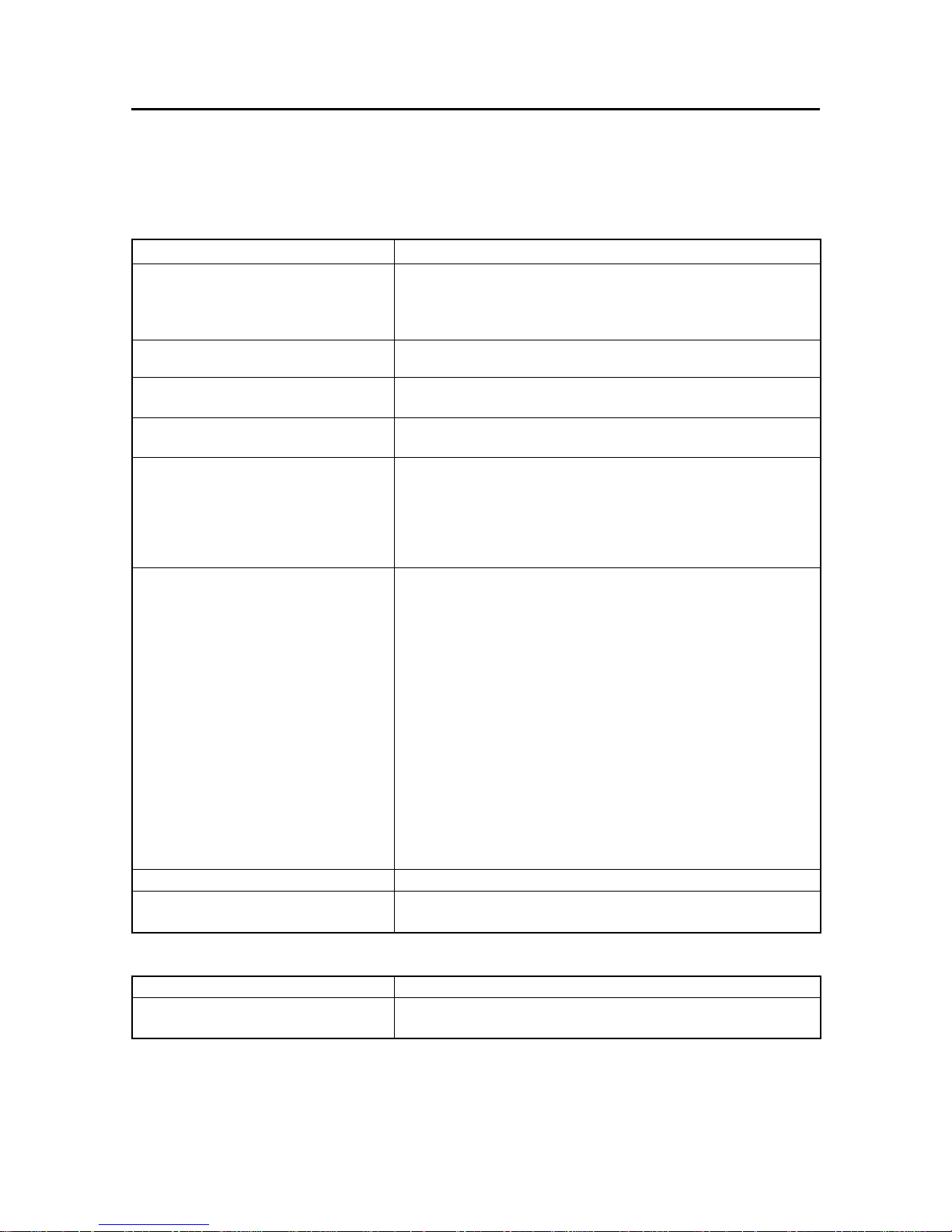

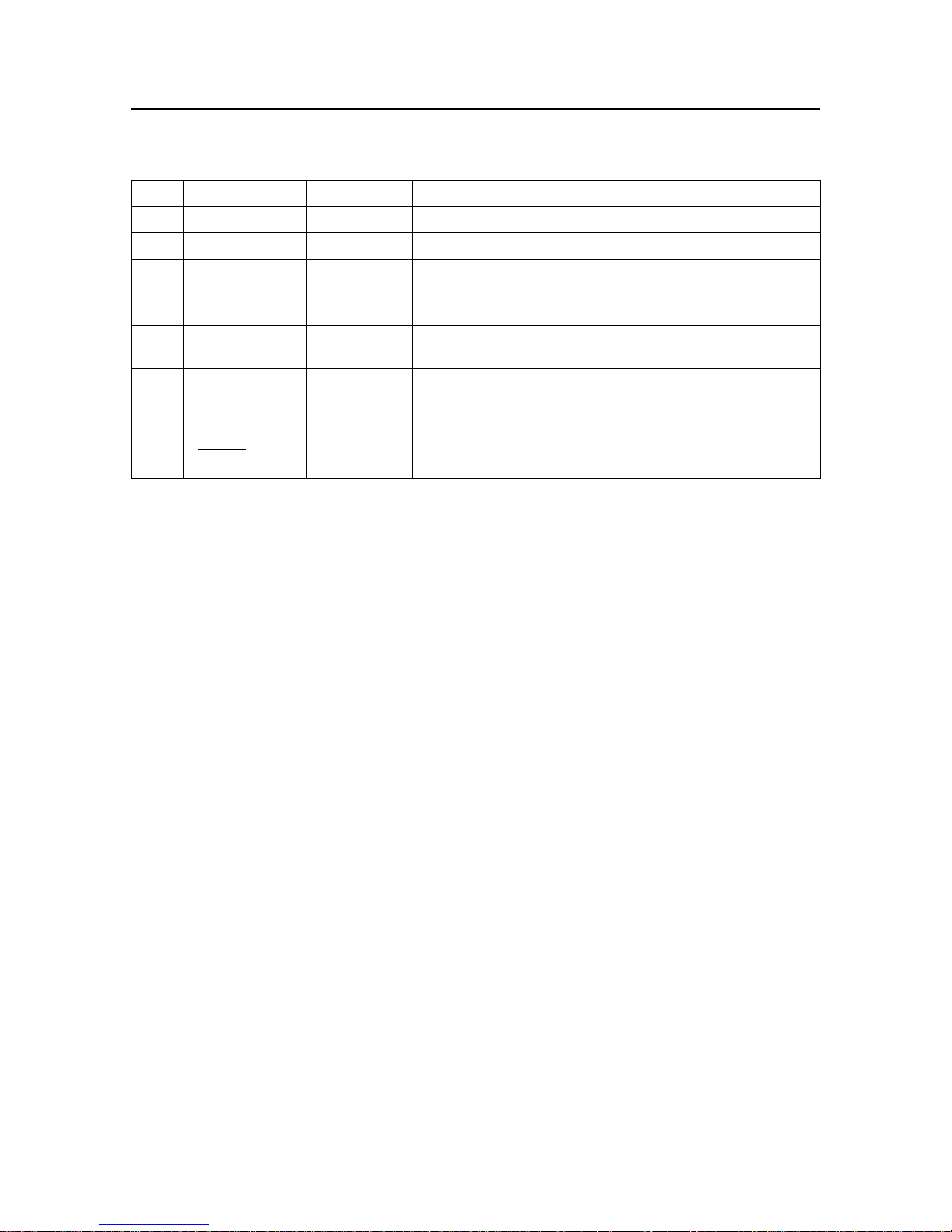

2-2. DIP Switch Settings

Parallel Type Commodore Type

Fig. 1-4 The DIP Switch is located under the Printer Cover

2-2-1. Parallel Type

Switch Function ON OFF Factory

1-1 Page length 11 inches 12 inches ON

1-2 Auto CR Yes No ON

1-3 Orator lower case Small caps Lower case ON

1-4 Auto sheet feeder Inactive Active ON

1-5 Paper-out detector Enabled Disabled ON

1-6 Printer mode Standard IBM ON

Character set (Std. Mode) Italics Graphics

Character set (IBM Mode) Set #2 Set #1

1-8 Auto LF No Yes ON

2-1 Usage of RAM Buffer Download ON

2-2 ON

2-3 International character set (See right) ON

2-4 ON

International character sets:

Country 2-2 2-3 2-4

U.S.A. ON ON ON

France OFF ON ON

Germany ON OFF ON

England OFF OFF ON

Denmark I * ON ON OFF

Sweden OFF ON OFF

Italy ON OFF OFF

Spain I OFF OFF OFF

* Denmark/Norway when switches 1-6

and 1-7 are both OFF.

A. Except for U.S.S.R. market

1-7 ON

Switch Function ON OFF Factory

1-1 Page length 11 inches 12 inches ON

1-2 Auto CR Yes No ON

1-3 Character set Standard IBM ON

1-4 Auto sheet feeder Inactive Active ON

1-5 Paper-out detector Enabled Disabled ON

1-6 Printer mode Standard IBM ON

1-7 Character set Set #1 Set #2 ON

1-8 Auto LF No Yes ON

2-1 Usage of RAM Buffer Download ON

2-2 Italic OFF ON ON

2-3 ESC 4/ESC 5 (*1) Italic MSB ON

2-4 Not used — — ON

*1 The switch 2-3 is valid only in the standard printer mode.

B. For U.S.S.R. market

Page 13

– 10 –

GENERAL SPECIFICATIONS

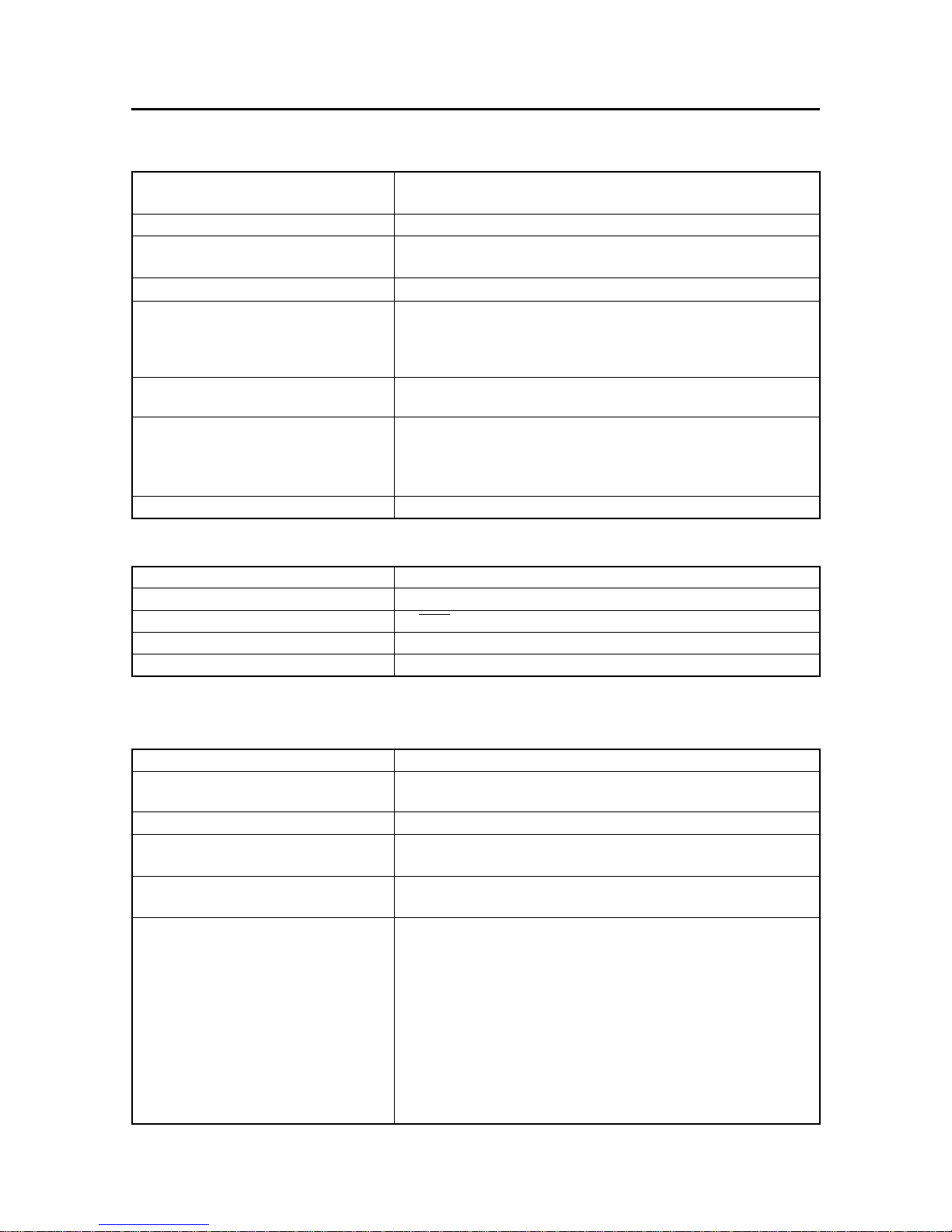

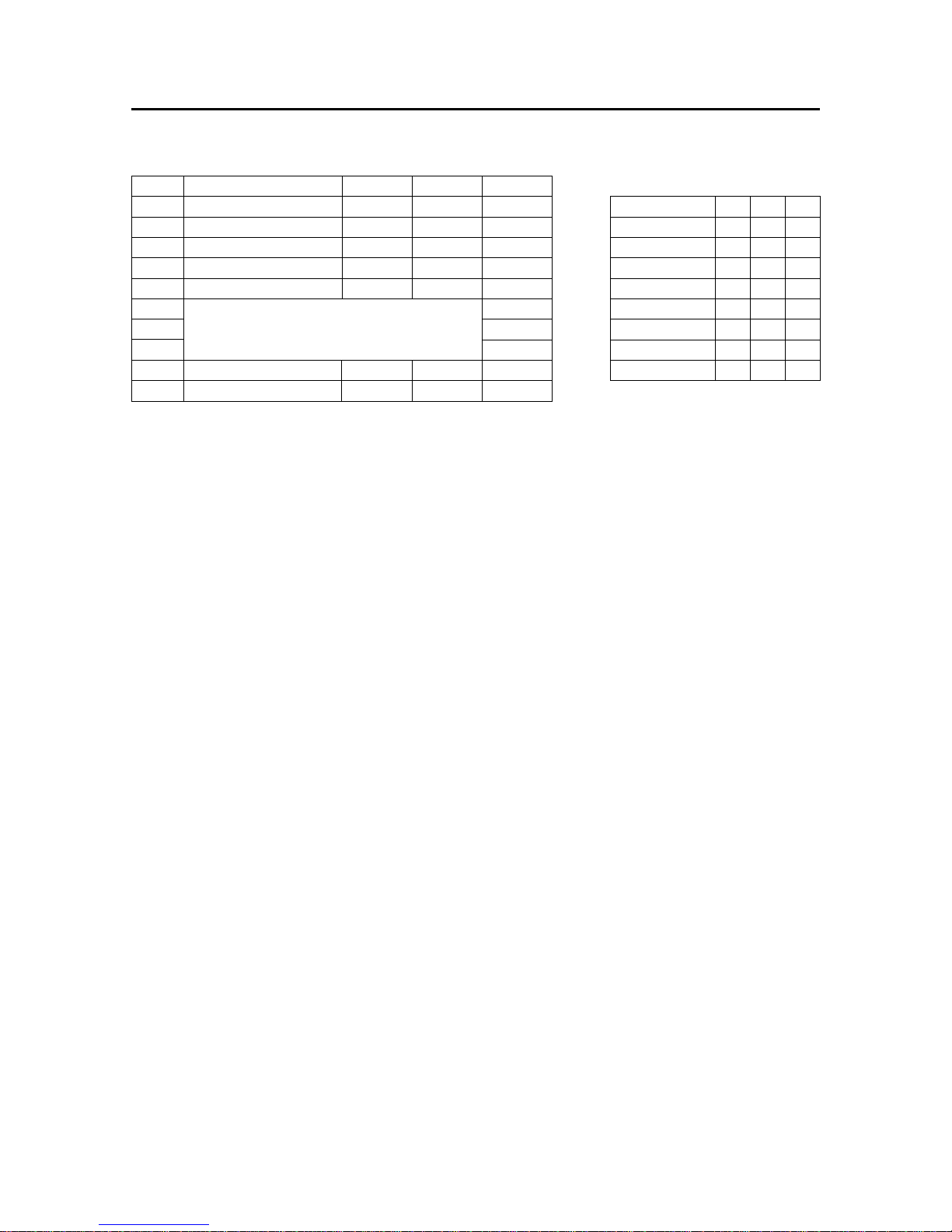

2-2-2. Commodore Type

Switch Function ON OFF Factory

1-1 Auto LF Yes No ON

1-2 Paper out detector Enable Disable ON

1-3 Device number No. 4 No. 5 ON

1-4 Page length 11 inches 12 inches ON

1-5 Operating mode

Commodore

ASCII ON

1-6 ON

1-7 International character set (See right) ON

1-8 ON

1-9 Commodore characters Standard DIN ON

1-10 Auto sheet feeder Inactive Active ON

International character sets:

Country 1-6 1-7 1-8

Commodore * ON ON ON

U.S.A. OFF ON ON

Germany ON OFF ON

Denmark I OFF OFF ON

France ON ON OFF

Sweden I OFF ON OFF

Italy ON OFF OFF

Spain OFF OFF OFF

* England (Switch 1-5 is OFF)

Page 14

– 11 –

GENERAL SPECIFICATIONS

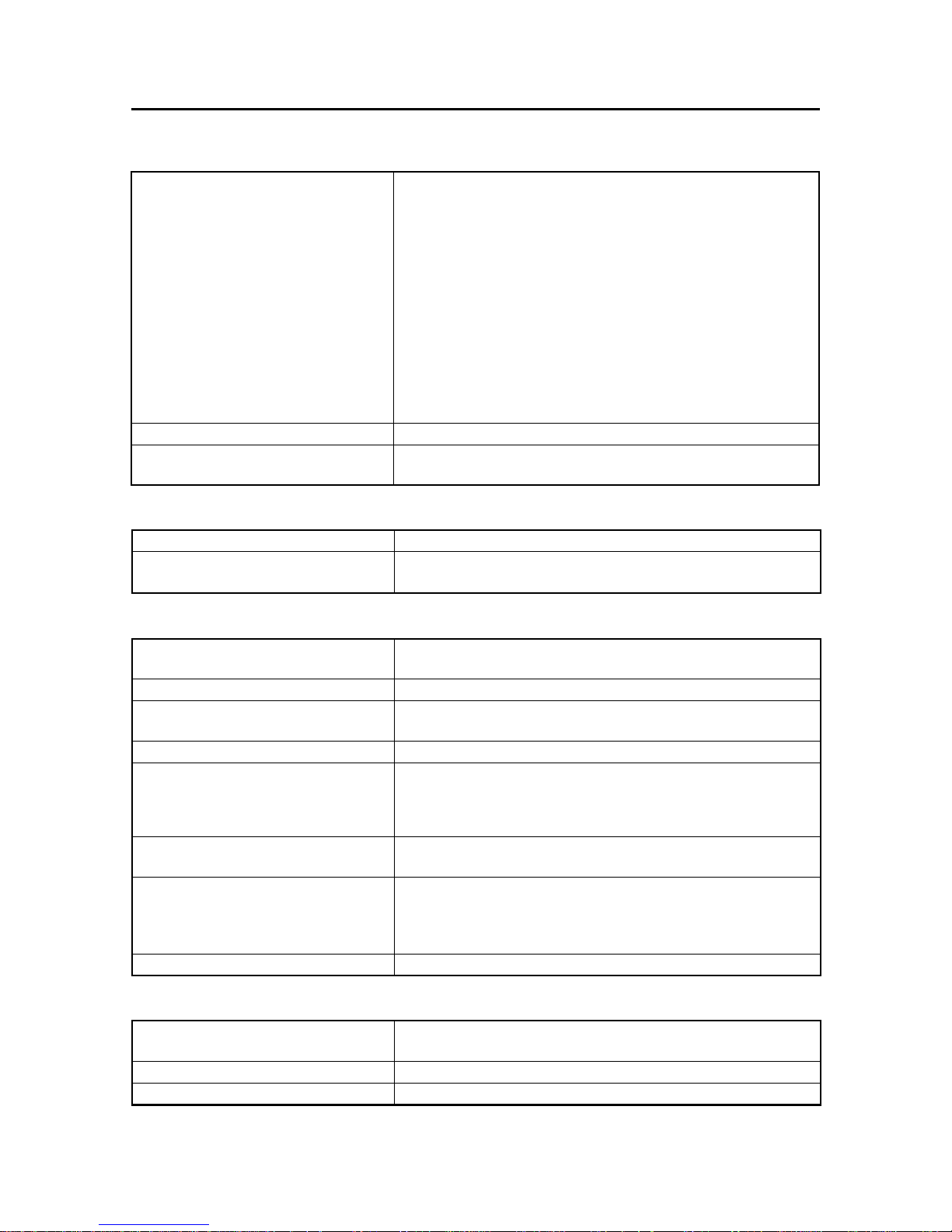

3. Connector Signals

3-1. Parallel Interface

Pin No. Signal Name Direction Functional Description

Goes from High to Low (for at least 0.5 microseconds) when data

are valid.

Eight-bit character data. DATA8 is the most significant bit; DATA

1 is the least significant bit.

High is logic 1 and Low is logic 0.

Approx.9-Microsecond Low pulse acknowledges receipt of data.

Low when the printer is ready to accept data.

Goes High if the printer runs out of paper.

Can be held Low permanently by turning DIP switch 1-5 off.

High when the printer is on-line.

Unused

Signal Ground

Printer’s chassis ground, isolated from signal ground.

External supply of +5V DC.

Twisted pair return signal ground level.

Low input resets the printer to its power-up condition.

Goes Low to signal that the printer cannot print due to an error

condition.

External ground

Unused

Always High.

1 STROBE IN

2 DATA 1 IN

3 DATA 2 IN

4 DATA 3 IN

5 DATA 4 IN

6 DATA 5 IN

7 DATA 6 IN

8 DATA 7 IN

9 DATA 8 IN

10 ACK OUT

11 BUSY OUT

12 PAPER OUT OUT

13 SELECTED OUT

14, 15 (NC)

16 SIGNAL GND

17 CHASSIS GND

18 +5VDC OUT

19 ~ 30 GND

31 INPUT-PRIME IN

32 ERROR OUT

33 EXT GND

34, 35 (NC)

36 SELECT-IN IN

Page 15

– 12 –

GENERAL SPECIFICATIONS

3-2. Commodore Interface

Pin No. Signal Name Direction Functional Description

1 SRQ OUT

2 GND

3 ATN IN

4 CLK IN

5 DATA IN/OUT

6 RESET IN

Not used.

Signal ground.

Serial Attention In

High.....................Signifies the data transfer mode.

Low .....................Signifies the command transfer mode.

Serial Clock In

The printer begins reading data on the rising edge of this signal.

Serial Data In/Out

IN: Conveys commands and data from the computer to the printer

OUT: High indicates printer ready Low indicates printer busy.

When this signal level goes low, the printer is initialized

and the memory buffer is cleared.

Page 16

CHAPTER 2

THEORY OF OPERATION

1. Block Diagram ..................................................................................................... 15

2. Main Logic Board ................................................................................................ 16

2-1. Data Input Operation............................................................................................. 16

2-1-1. Parallel Interface ............................................................................................... 16

2-1-2. Commodore Interface.......................................................................................17

2-2. General Flow Chart ............................................................................................... 19

2-2-1. Editing ............................................................................................................... 20

2-2-2. Print Head Driving Circuit ................................................................................ 20

2-2-3. Carriage Motor Driving Circuit......................................................................... 20

2-2-4. Carriage Motor Speed Control......................................................................... 21

2-2-5. Paper Feed Motor Driving Circuit.................................................................... 22

2-3. Reset Circuit .......................................................................................................... 23

2-4. Reset by +5V Line Voltage Detection .................................................................. 24

2-5. Protection Circuit .................................................................................................. 24

3. Power Supply Unit .............................................................................................. 24

4. Mechanisms......................................................................................................... 25

4-1. Print Head Mechanism.......................................................................................... 25

4-2. Print Head Carrying Mechanism .......................................................................... 25

4-3. Ink Ribbon Feed Mechanism................................................................................ 26

4-4. Paper Feed Mechanism ........................................................................................ 27

4-5. Detectors ............................................................................................................... 28

1

2

3

4

5

6

7

8

A

Page 17

– 14 –

THEORY OF OPERATION

Page 18

– 15 –

THEORY OF OPERATION

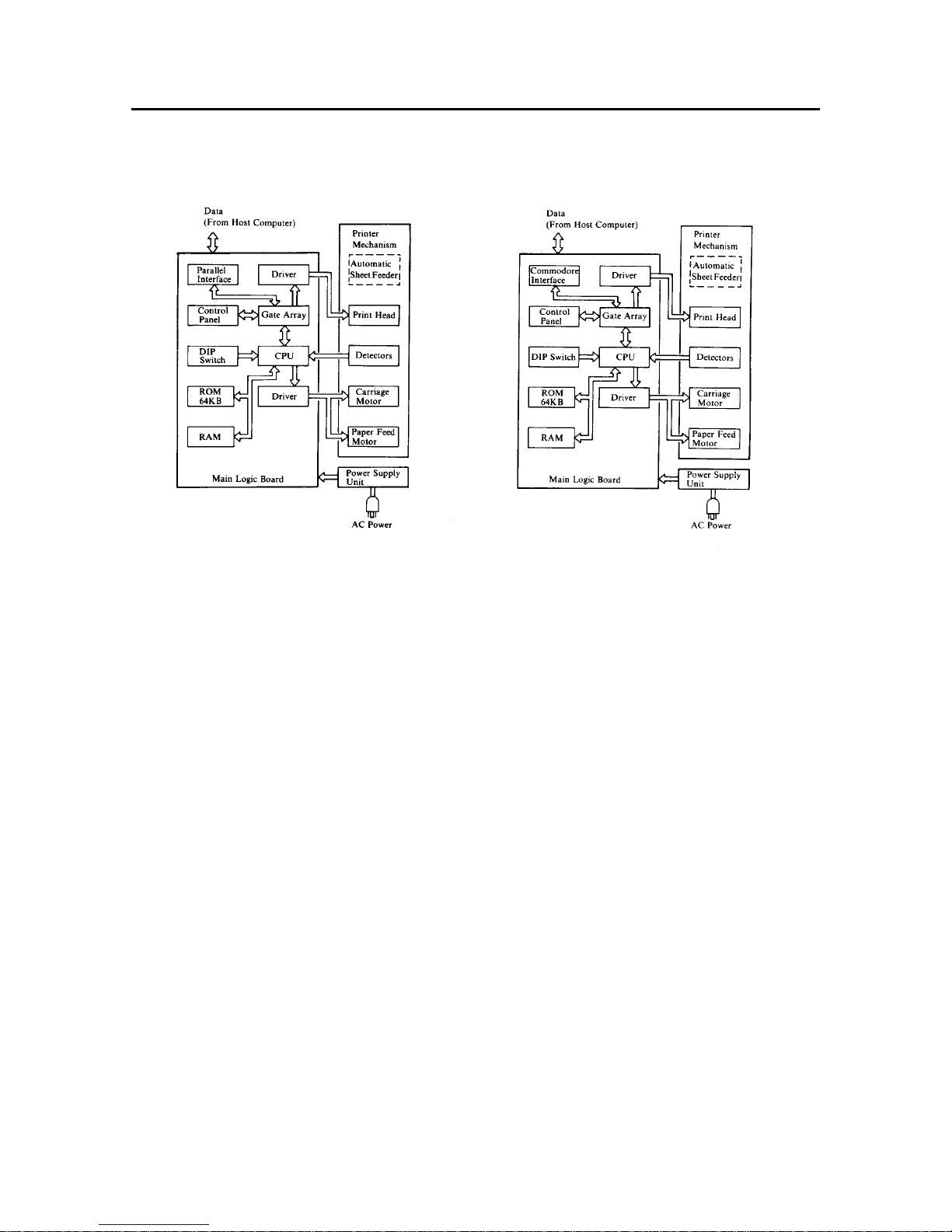

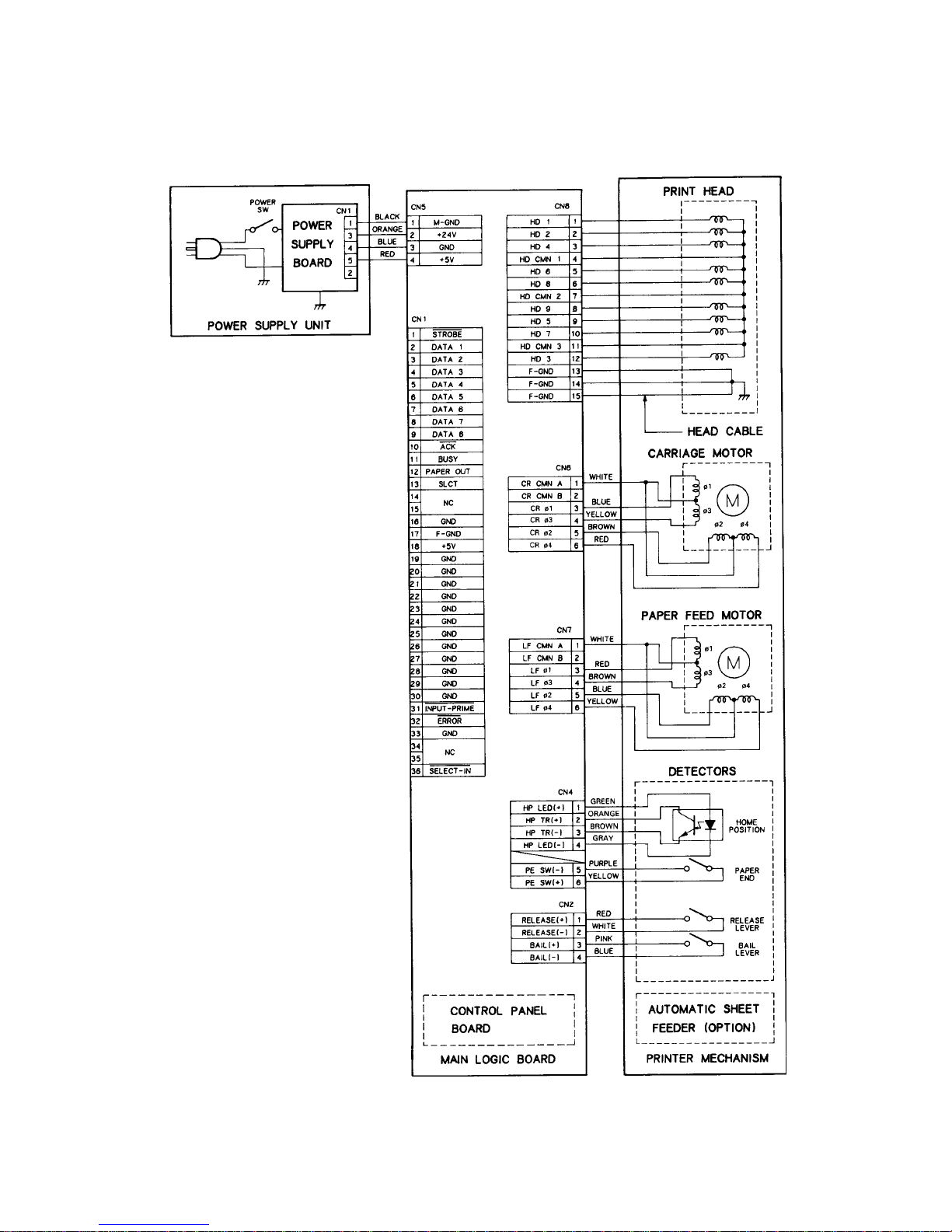

1. Block Diagram

The block diagram of this printer is shown in Fig. 2-1.

Parallel Type Commodore Type

Fig. 2-1 Block Diagram

(1) Main Logic Board

This board receives data from the host computer and stores it in the RAM in the order of arrival. The CPU on this

board reads the data from the RAM and edits it according to the program stored in the ROM.

When the editing is completed, various drive signals from the CPU are sent to the printer mechanism to perform

printing.

<Explanation>

1 CPU M50734SP

• Controls this printer.

2 ROM µPD27C512 64K-byte

• Contains the program which executes control of the printer.

3 RAM 8K-byte (Monochrome type), 32K-byte (Colour type)

• Used as stack area, work area and data buffer of the CPU.

4 Parallel interface (Parallel type only)

5 Commodore interface (Commodore type only)

6 Gate array (custom IC)

• Inputs or outputs several signals.

7 Driver

• The data edited by the CPU and gate array are sent to the printer mechanism after conversion to the signal

for the print head drive, carriage motor drive, and paper feed motor drive respectively.

8 Control Panel Circuit

This panel circuit is for manual operation of the printer.

(2) Printer Mechanism

The printer mechanism consists of a print head, carriage motor, paper feed motor, and detectors.

(3) Power Supply Unit

AC power is converted to DC24V and DC5V.

Page 19

– 16 –

THEORY OF OPERATION

2. Main Logic Board

2-1. Data Input Operation

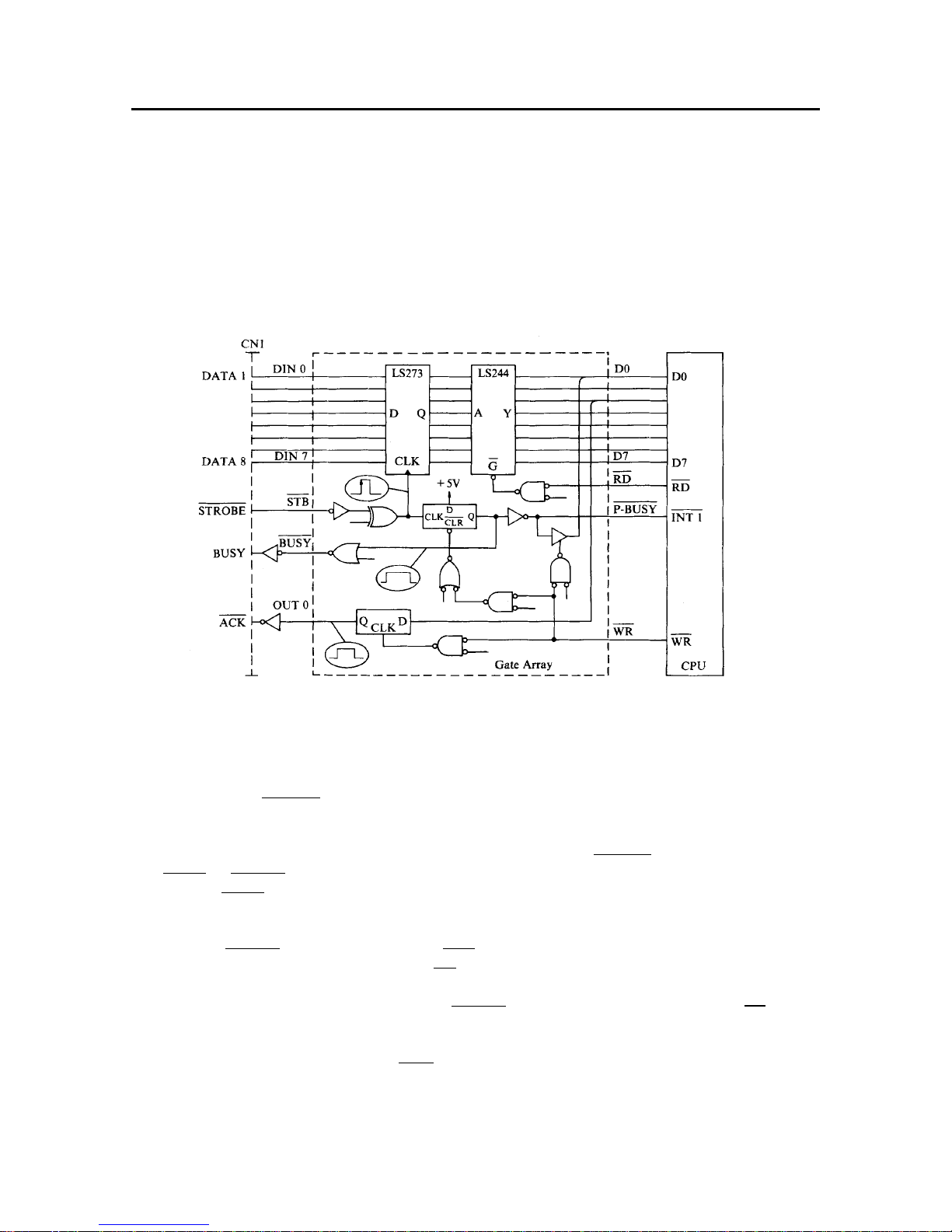

2-1-1. Parallel Interface (Parallel type only)

Communications between the host computer and this printer are facilitated via parallel connectors. This section explains

the handshake of this interface.

The data input circuit of this interface is shown in Fig. 2-2.

Fig. 2-2 Data Input Circuit with Parallel Interface

The following is an explanation of this handshake.

(1) When the BUSY signal is LOW (Ready), the host computer outputs 8- bit data 1 through 8 to the connector CN1.

Pin 1 carries the STROBE pulse signal from the host computer to the printer.

This signal is normally held HIGH by the host computer. When the host computer has data ready for the printer,

it sets this signal to LOW for at least 0.5 µS.

(2) The gate array of the main logic board reads data 1 through 8 at the time of STROBE signal fall, and then turns the

BUSY and P-BUSY signals to low.

(3) When the BUSY signal of the gate array is set to LOW, the BUSY signal of connector CN1 will be turned to HIGH,

notifying the host computer that data cannot be accepted.

(4) Ver. 1 Board

When the P-BUSY signal goes LOW, the CPU INT1 signal also goes LOW, causing a CPU interrupt.

If such an interrupt occurs in the CPU, set the RD signal to LOW, and read the gate array into the CPU.

Ver. 1.5 Board and Ver. 2 Board

The CPU is informed via the D0 data line that the P-BUSY terminal is LOW. Because of this, set the RD signal to

LOW and read the gate array into the CPU.

(5) Upon completion of the data reading, the CPU notifies the host computer of the data receivable state by setting the

BUSY signal of connector CN1 and the ACK signal to LOW for a certain period of time.

This concludes the explanation of the parallel interface handshake. The following chart describes the timing chart

of the handshake.

Page 20

– 17 –

THEORY OF OPERATION

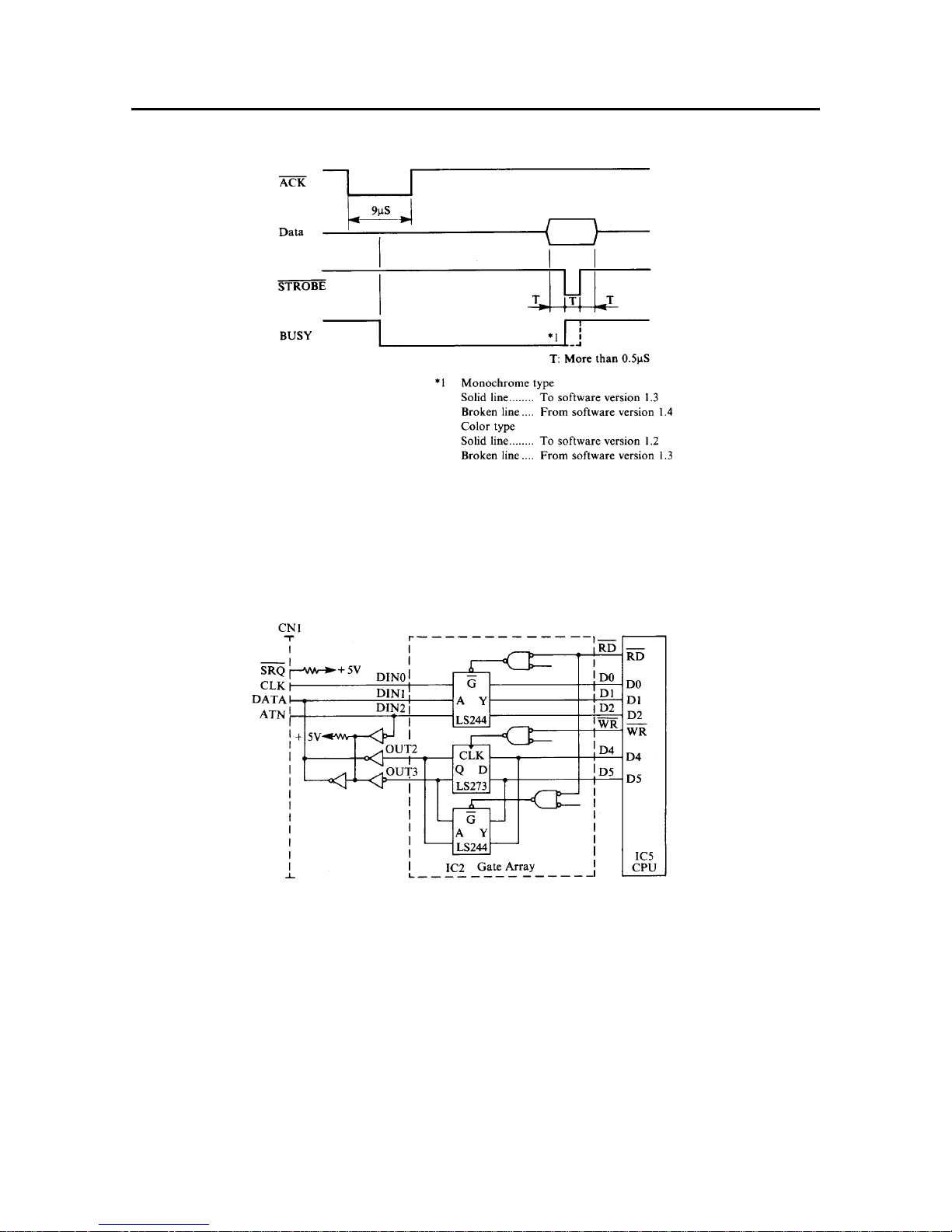

Fig. 2-3 Timing Chart of Parallel Interface

2-1-2. Commodore Interface (Commodore type only)

The commodore interface is a serial interface which can be connected to COMMODORE network host computers.

The data input circuit with a Commodore interface is shown in Fig. 2-4.

Fig. 2-4 Data Input Circuit with Commodore Interface

Two types of the handshake mode are used with this Commodore interface:

Non-EOI handshake and EOI handshake. The timing chart of the Non-EOI handshake mode is shown in Fig. 2-5, and that

of the EOI handshake mode in Fig.2-6.

Page 21

– 18 –

THEORY OF OPERATION

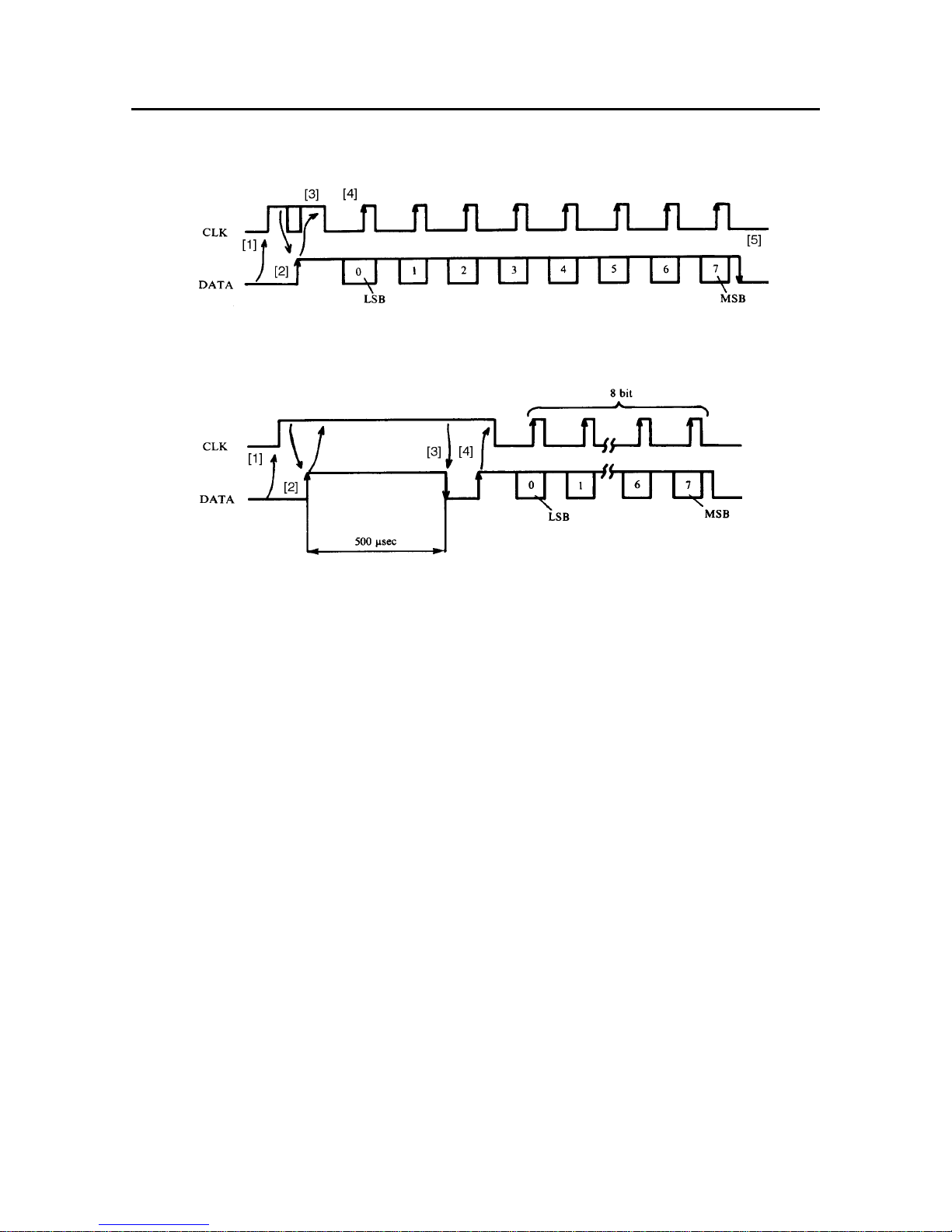

Fig. 2-5 Timing Chart of Non-EOI Handshake Mode

Fig. 2-6 Timing Chart of EOI Handshake Mode

(1) Non-EOI handshake

This is a regular data transmission handshake.

1. The host computer acknowledges that the DATA line is low (data reception is completed), raises the CLK, and

notifies the printer that the host computer is ready to send (data or commands).

2. The printer sends information to the host computer by raising the DATA line to show that the printer is ready

to receive more data.

3. The host computer sends information to the printer that data is available after the next raising of the CLK, by

lowering the CLK.

4. After storing data, the host computer indicates that the data is available by raising the CLK.

The printer reads the data at the rising edge of the CLK. Then the host computer lowers the CLK and opens

the DATA line, acknowledging that the printer is in READY mode (DATA line is high), and moves to the next

bit handshake.

5. Sending 8-bit data is the same as above. When transmission is completed, the printer sends information to the

host computer that the receiving of data is finished by lowering the DATA line.

(2) EOI handshake

This handshake is used to show that the next data bytes are the last data.

1. The host computer acknowledges that the DATA line is LOW (receiving data is finished), and sends

information to the printer that the host computer is ready to send data (including commands) by raising the

CLK.

2. The printer sends information to the host computer that the printer is ready to receive data by raising the DATA

line.

At the rising edge the 500 µs timer starts.

(Until now this has been operating the same as the Non-EOI handshake.) From the starting of the timer, the

host computer keeps the CLK high for more than 500 µs to indicate EOI.

3. If the CLK does not fall within 500 µs, the printer acknowledges the EOI, and lowers the DATA line to LOW.

4. The printer sends information to the host computer that it is ready to receive data by raising the DATA line

again.

To send 8-bit data, follow the preceding Non-EOI handshake procedure.

Page 22

– 19 –

THEORY OF OPERATION

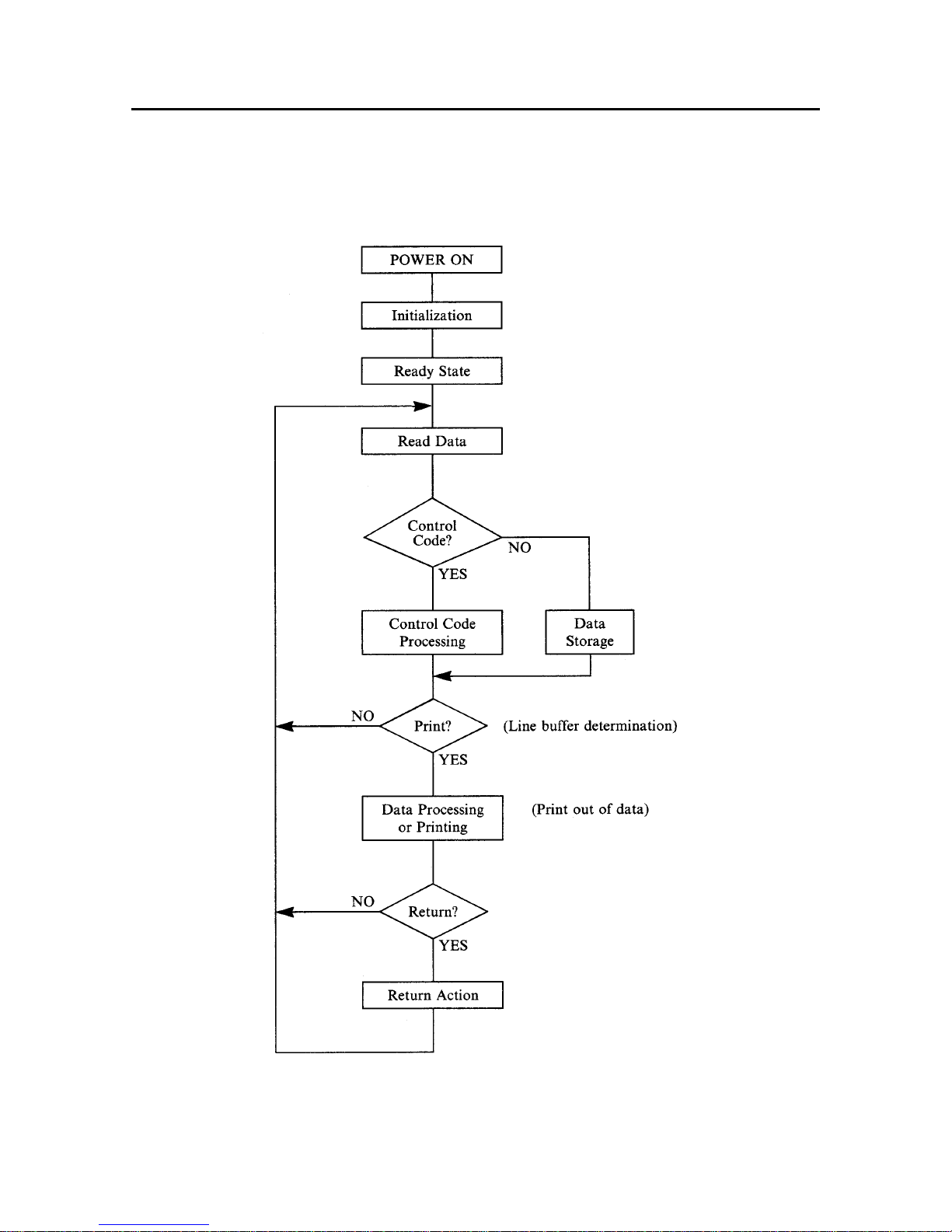

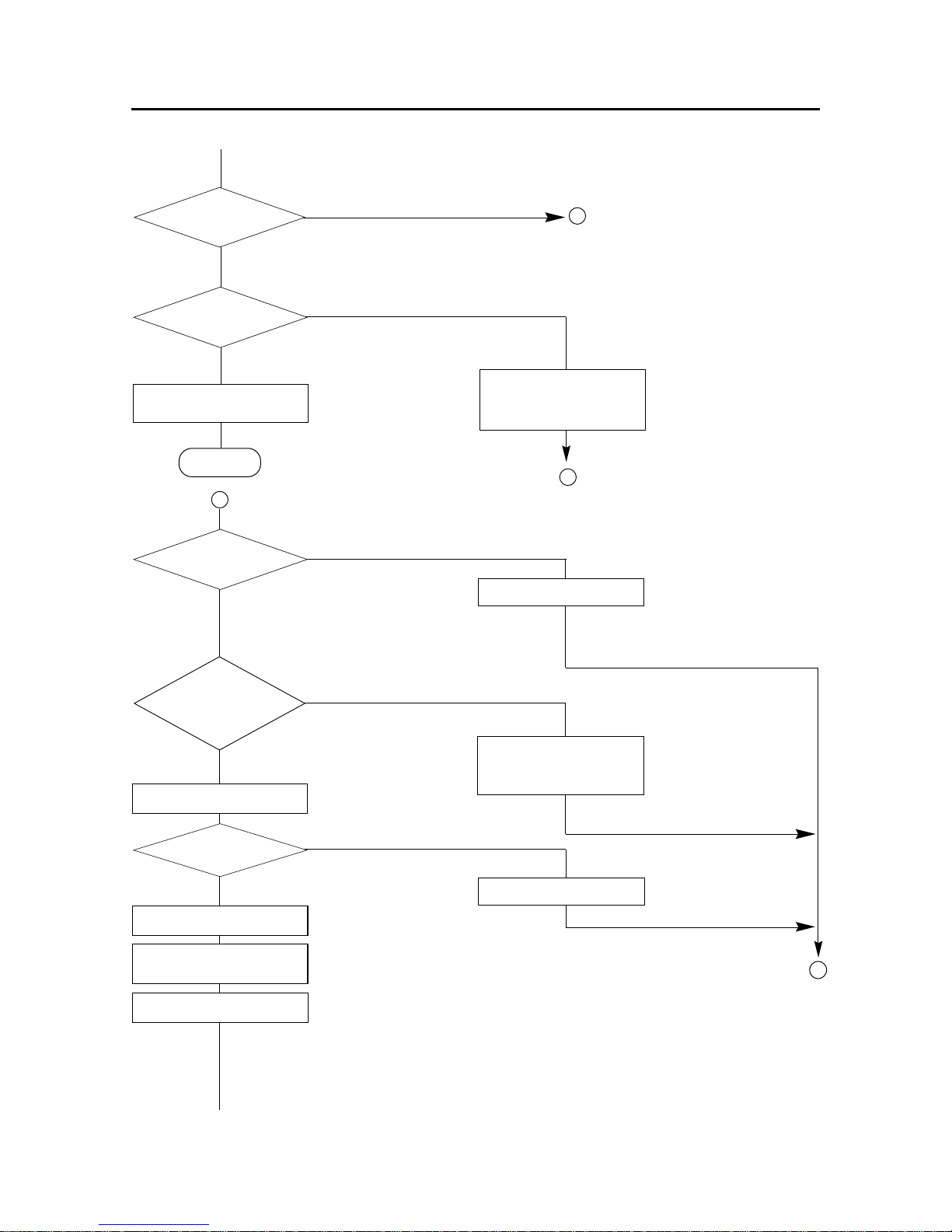

2-2. General Flow Chart

A general flow chart of editing and printing operations is presented in Fig. 2-7.

Fig. 2-7 General Flow Chart of Editing and Printing

Page 23

– 20 –

THEORY OF OPERATION

2-2-1. Editing

Data stored in the RAM is read out sequentially by the CPU and then edited according to a function code that has been

specified in advance.

This editing takes places until the CR or CR + LF code appears or the line buffer becomes full.

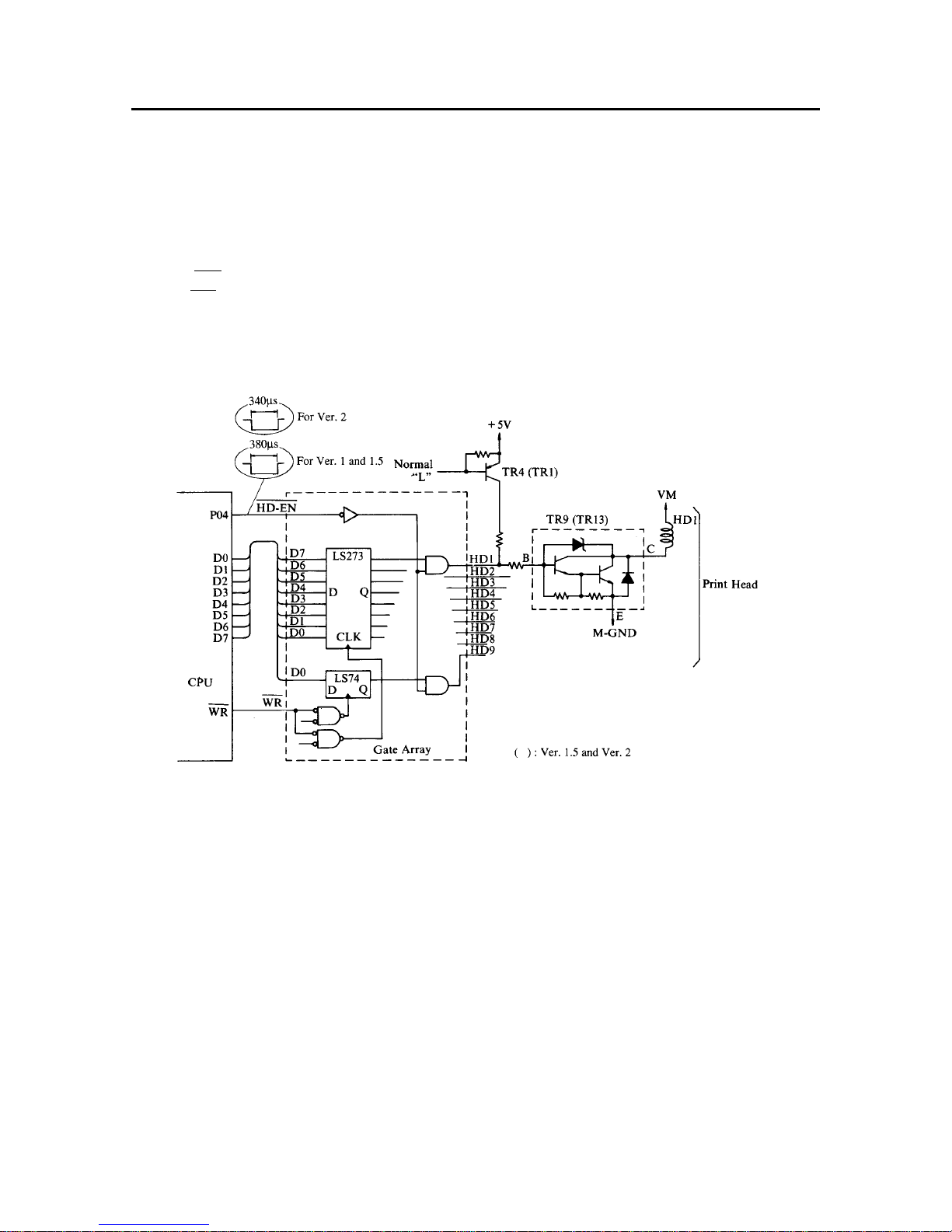

2-2-2. Print Head Driving Circuit

Edited print data is output to terminal Q of LS273 in the gate array through the CPU data bus, as regulated by the issue

timing of a WR signal. However, as for pin 9 (HD9) of the print head, the data is output to the same terminal upon issue

of the next WR signal. When all the data is received for printing, an energized time control signal is output from port PO4

of the CPU. This allows the print data to be output to HD-1 ~ 9 of the gate array. When the print data is HIGH, the transistor

TR9 will be turned ON for 380 µS (Ver 1 and 1.5), 340 µs (Ver 2), energizing the print head solenoid to drive the print

head.

Fig. 2-8 Print Head Driving Circuit

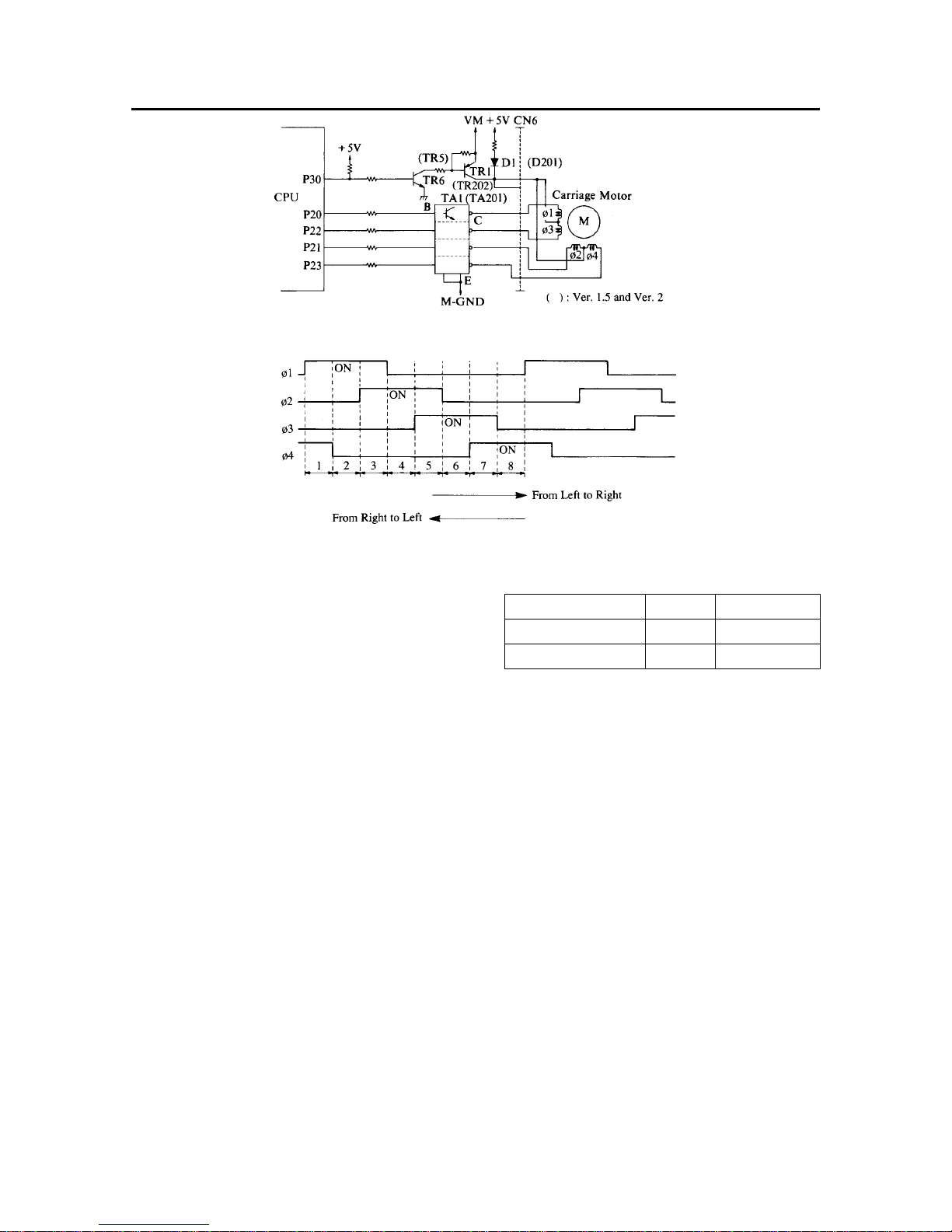

2-2-3. Carriage Motor Driving Circuit

This printer employs a stepping motor as the carriage motor. Unlike regular motors on the market, this stepping motor

will not operate just by connecting it to a power source. The motor operates only when a drive pulse is fed to it, but even

then, it turns only a certain angle.

This stepping motor is characterized by 4-phase stepping. Control of the motor is facilitated by phase 1-2 excitation. The

following is the description of the carriage motor drive circuit and the control signal generated by the phase 1-2 excitation

method.

Page 24

– 21 –

THEORY OF OPERATION

Fig. 2-9 Carriage Motor Driving Circuit

Fig. 2-10 Carriage Motor Driving Signals

The utilization of voltage applied to the carriage motor is

described below:

Voltage applied to the carriage motor is changed by setting port

P30 of the CPU to HIGH or LOW and by turning transistors

TR6 and TR1 ON or OFF.

When TR1 is ON, +24V is supplied to the carriage motor and

when TR1 is OFF, +5V is supplied to the motor via diode D1.

2-2-4. Carriage Motor Speed Control

Since the carriage motor is a stepping motor, the carriage can be stopped at a desired position by controlling acceleration

and deceleration. The carriage can also move backward.

The rotational speed of the carriage motor is set by the number of pulses per time unit. The character pitch (horizontal

character size) in each print mode is determined by changing this rotational speed (or carriage transfer speed).

(1) At start-up of the motor:

The number of pulses input to the motor increase in steps (36 altogether), reaching a certain frequency.

(2) To stop the motor:

The number of pulses input to the motor decreases in steps (36), in order to gradually bring the motor to a halt.

(3) When printing is carried out:

Pulses of a uniform pulse width are supplied for printing.

Mode Voltage Application

Operation: +24V Motor Drive

Standby: +5V Holding Bias

Page 25

– 22 –

THEORY OF OPERATION

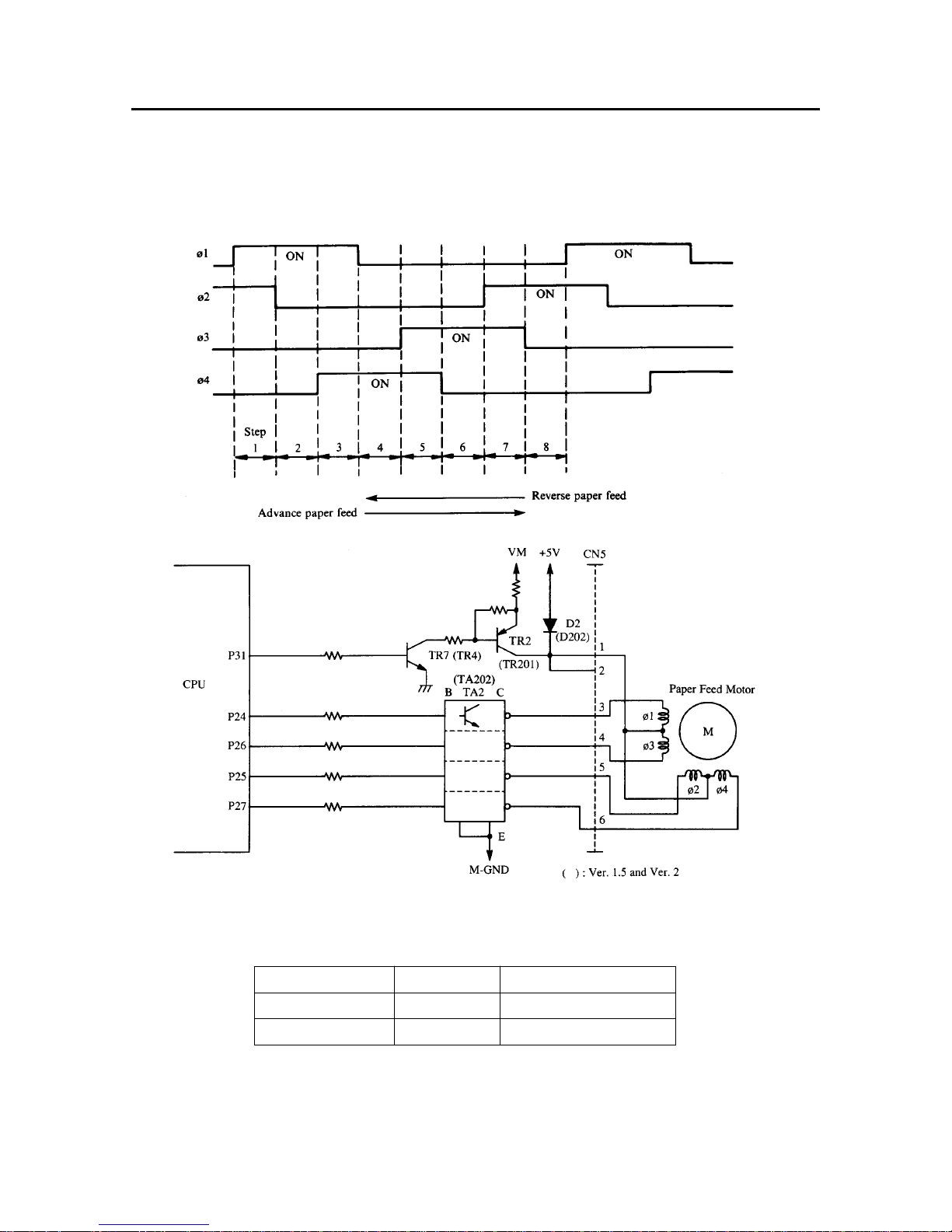

2-2-5. Paper Feed Motor Driving Circuit

Again, a stepping motor is employed as the paper feed motor, which turns a certain angle only when a drive pulse is

received. This 4-phase stepping motor is controlled by the phase 1-2 excitation method. The following is the description

of the paper feed motor drive circuit and the control signal generated by the phase 1-2 excitation method.

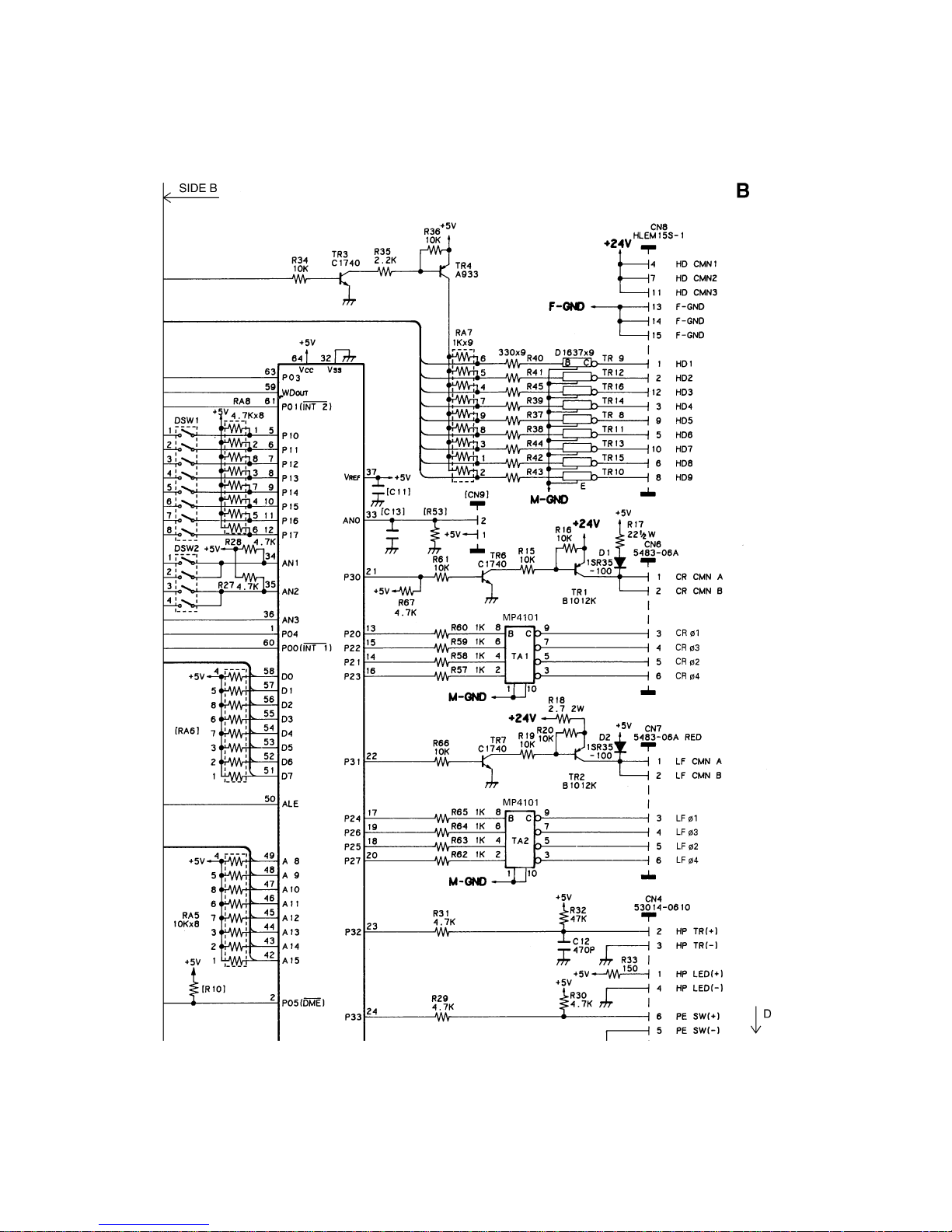

Fig. 2-11 Paper Feed Motor Driving Circuit

Fig. 2-12 Paper Feed Motor Driving Signals

The utilization of voltage applied to the paper feed motor is described as follows.

Mode Voltage Application

Operation +24V Motor Drive

Standby: +5V Holding Bias

Voltage to the paper feed motor is changed by setting CPU port P31 to LOW or HIGH and by turning transistors TR7 and

TR2 ON or OFF.

When TR2 is turned on, +24V is applied to the paper feed motor.

When TR2 is turned off, +5V is supplied to the motor via diode D2.

Page 26

– 23 –

THEORY OF OPERATION

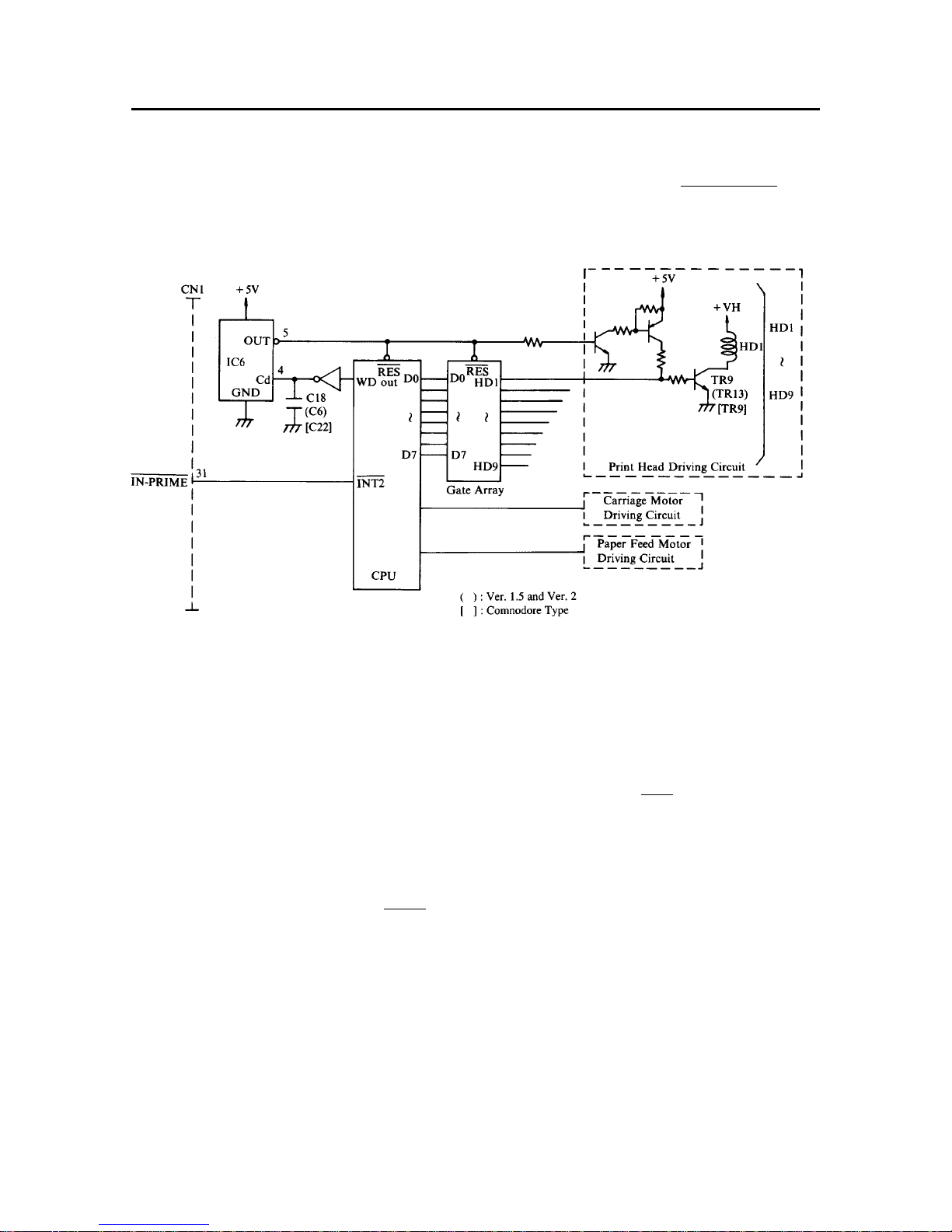

2-3. Reset Circuit

The RESET signal initializes the circuit elements and prevents operation errors when the power is turned on.

The RESET signal is output for approx. 34ms. when the power is turned on, or while the RESET ( INPUT-PRIME ) signal

is being output from the host computer.

Fig. 2-13 Reset Circuit and Protection Circuit.

• Power On Reset

1 When the power is turned on, the RESET signal output from Pin 5 of IC6 (M51953BL) for approx. 34 msec. This time

length is determined by external capacitor C18 (0.1µF), and it can be calculated by the following formula.

T = 0.34 × C18 (pF) µsec.

2 This LOW signal triggers RESET command to the CPU and the RESET terminal ( RES ) of the gate array.

3 Resetting the CPU and the gate array will ignore all the drive signals for the carriage motor, the paper feed motor and

the print head, preventing operation errors at power ON.

• Reset by Input Prime Signal from Host Computer

1 The input prime signal from the host computer is output to pin 31 of the connector CN1.

2 This output signal will set the terminal INIT 2 of the CPU to LOW, executing interruption. Then, the CPU will be

initialized.

Page 27

– 24 –

THEORY OF OPERATION

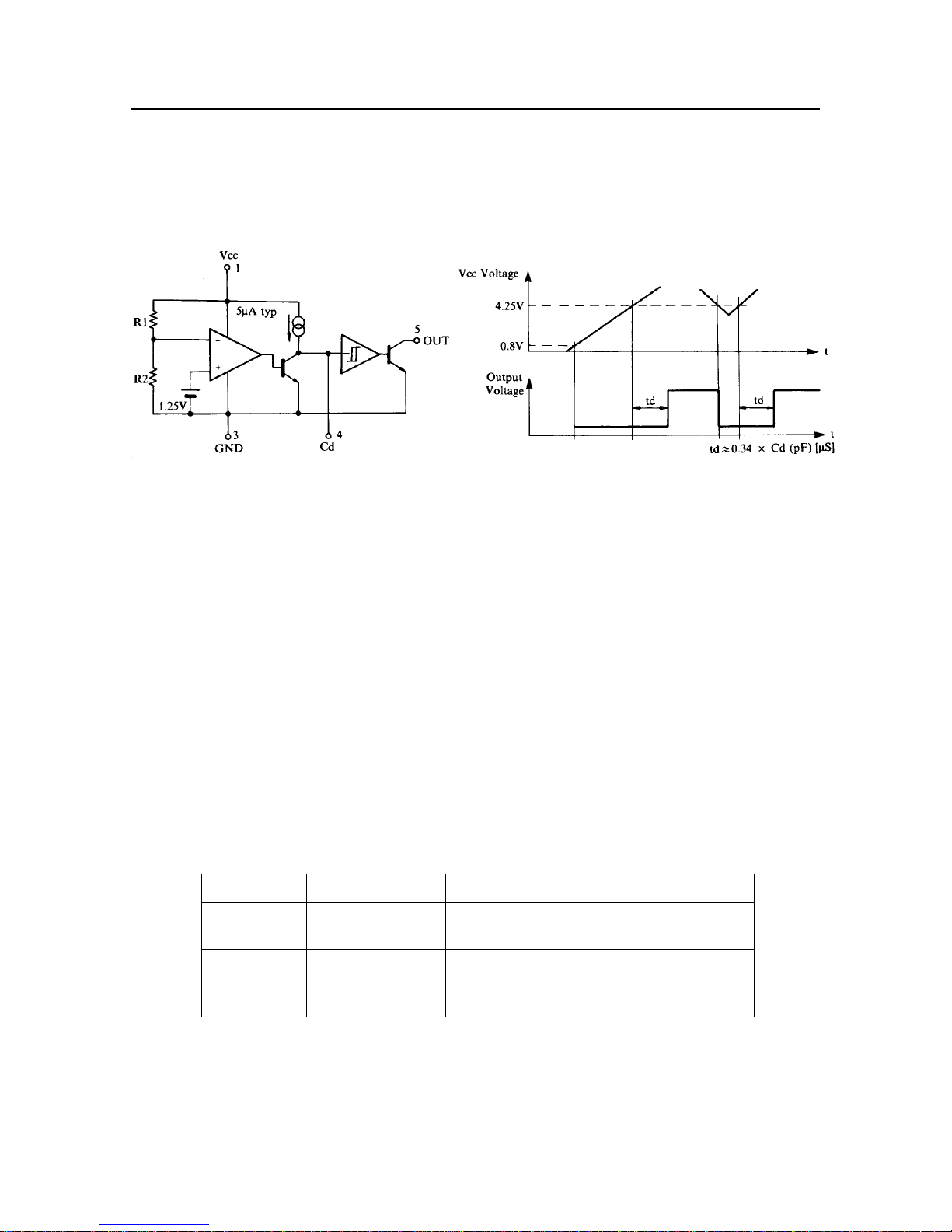

2-4. Reset by +5V Line Voltage Detection

A voltage-detecting IC (IC6 in Fig.2-13) detects momentary drops in voltage or unstable voltage supply (due to power

failures, etc.) on the +5V line. If the voltage on the +5V line falls below 4.25V, the RESET signal appears at the output

terminal of the voltage-detecting IC.

Fig. 2-14 Equivalent Circuit of Fig. 2-15 Operational Timing Chart

Voltage-Detecting IC

2-5. Protection Circuit

This printer is provided with a protection circuit which shuts off the print head and motor driving circuits in the event of

a CPU malfunction. (Refer to Fig.2-13)

The CPU normally outputs a LOW level signal from the terminal (WD OUT).

However, if the CPU malfunctions, it can not output this signal.

When the LOW level signal is not output from the CPU, the input terminal (Cd) of the voltage-detecting IC goes to LOW

and the RESET signal is output from the output terminal (OUT) of the voltage-detecting IC. By this signal, the CPU and

the gate array are reset and the print head, the carriage motor and paper feed motor driving signals are ignored, protecting

the printer from the CPU runaway.

3. Power Supply Unit

The power supply circuit converts the incoming AC power to DC voltages, +5V and +24V.

Voltage Tolerance Application

+24V DC24V±5% To drive print head, carriage motor, paper feed

motor.

+5V DC5V±2.5% To supply power to CPU, ROM, RAM, TTL

and ICs and to retain carriage motor and paper

feed motor.

Page 28

– 25 –

THEORY OF OPERATION

4. Mechanism

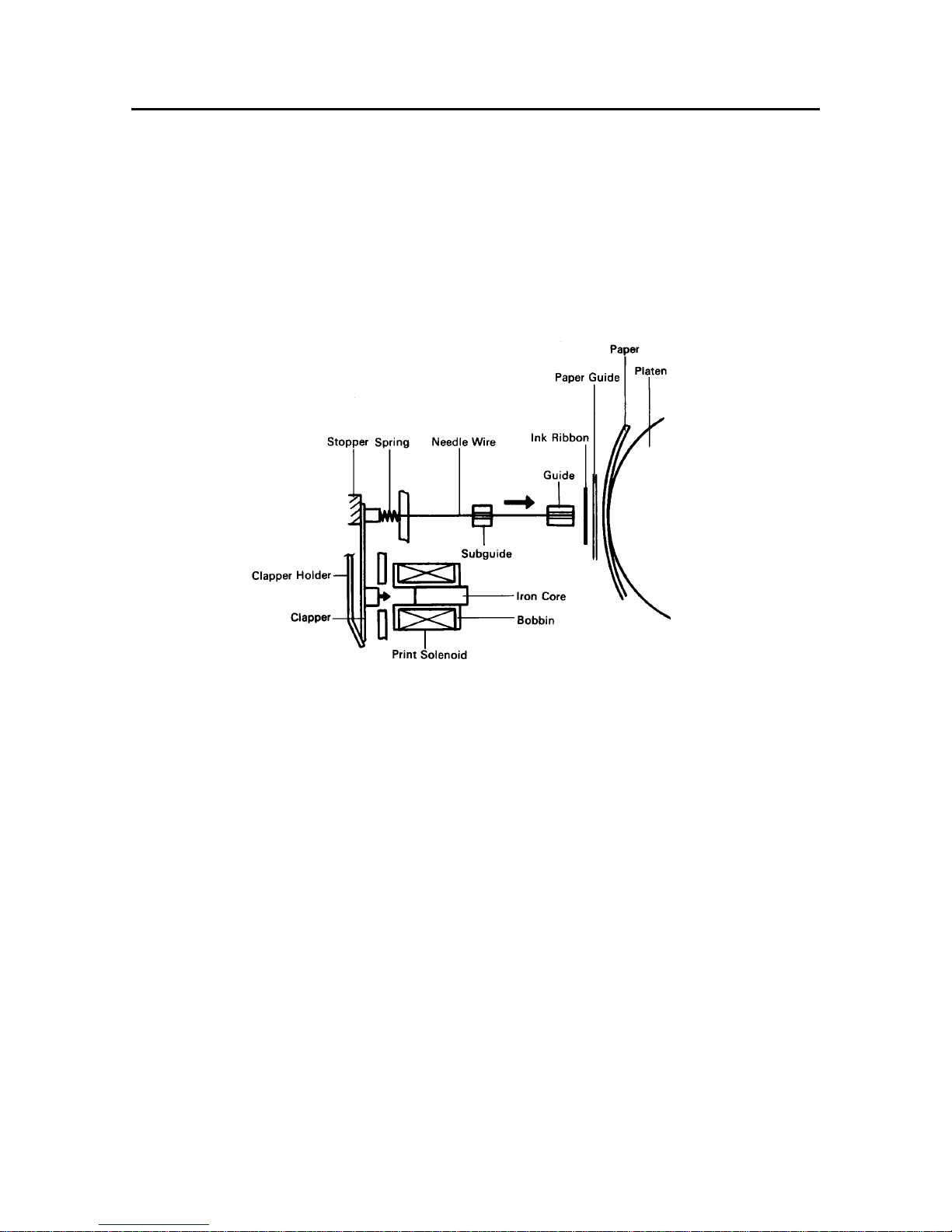

4-1. Print Head Mechanism

The print head consists of 9 needle wires and 9 print solenoids.

The following explains how each needle wire operates during printing.

(1) When the print solenoid is energized, the clapper is attracted by the iron core and the needle wire is driven toward

the platen.

(2) This needle wire hits the platen via the ink ribbon and paper. A single dot is printed on the paper.

(3) When the print solenoid is de-energized, the needle wire is returned to its original position by rebound energy and

spring and clapper holder (leaf spring) force.

Fig. 2-16 Outline of Print Head Mechanism

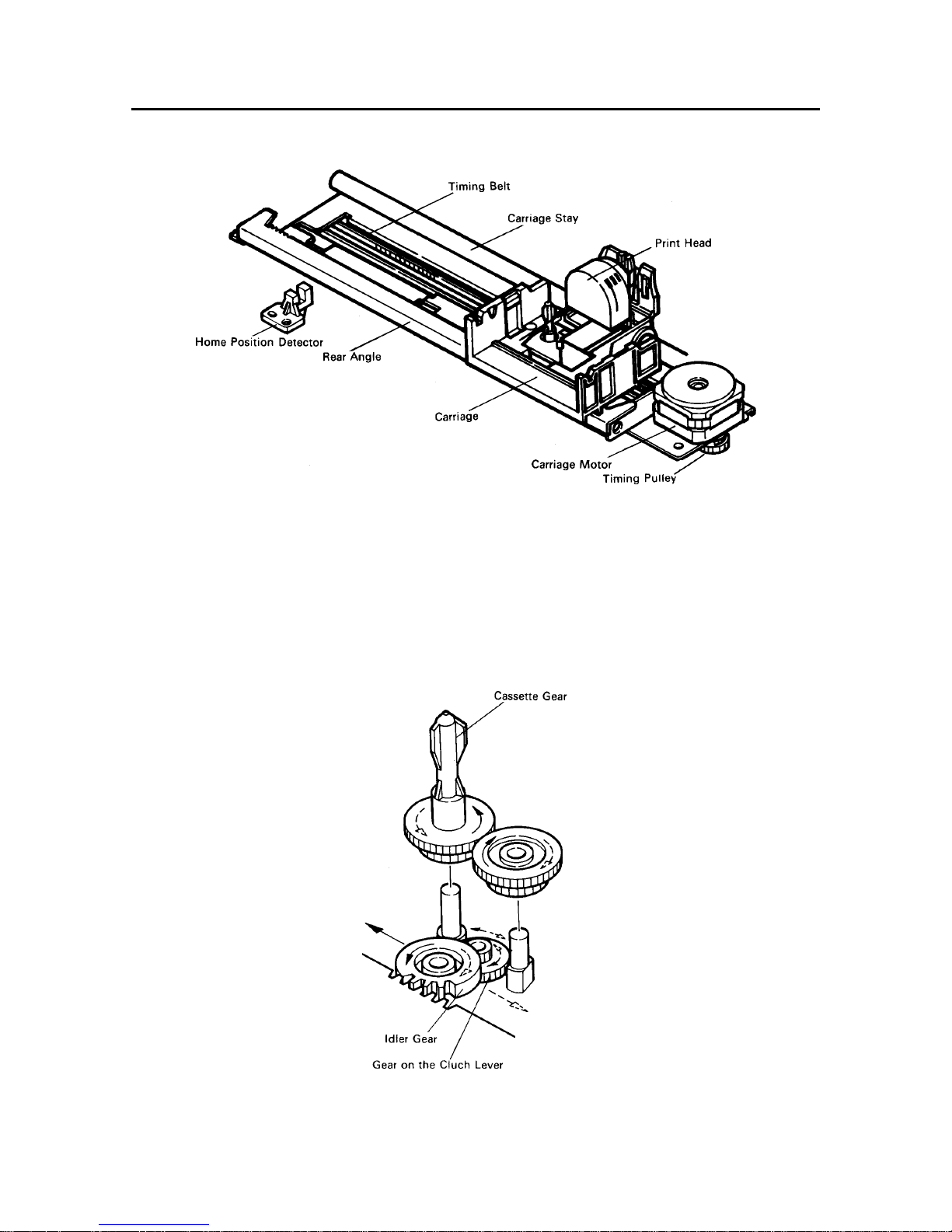

4-2. Print Head Carrying Mechanism

The print head carrying mechanism consists mainly of a carriage, timing belt, carriage motor, and home position detector.

(1) Carriage

The carriage is supported horizontally by means of the carriage stay and rear angle, and it moves from side to side

with the print head mounted above it. A timing belt is clamped to the base of the carriage and a shield plate is mounted

at the base for home position detection.

(2) Timing Belt

The timing belt is suspended between the timing pulley of the carriage motor and the timing pulley of the tension

lever, and it maintains a constant tension.

The timing belt is also clamped to the base of the carriage so that it can move the carriage accurately with driving

force from the carriage motor.

(3) Carriage Motor

The carriage motor is a PM (Permanent Magnet) type, four-phase and 48-pole pulse motor, which is driven by pulse

signals from the control circuit. The rotational rate depends on the number of pulses per unit time. By varying this

rotational rate (that is, the carriage carrying rate), the size of the horizontal letters can be changed in each print mode.

Page 29

– 26 –

THEORY OF OPERATION

Fig. 2-17 Print Head Carrying Mechanism

4-3. Ink Ribbon Feed Mechanism

The ink ribbon feed mechanism is linked to the print head carrying mechanism described previously so that the ink ribbon

is wound up automatically while the carriage moves left or right.

The ribbon feed mechanism is driven by torque from the carriage motor, and carriage movement allows the idler gear to

rotate.

This rotation is conveyed sequentially to the gears that work to wind the ribbon. The carriage is equipped with a clutch

lever so that the direction of cassette gear rotation remains constant regardless of the direction of the idler gear rotation.

Fig. 2-18 Ribbon Feed Mechanism

Page 30

– 27 –

THEORY OF OPERATION

Not Linked

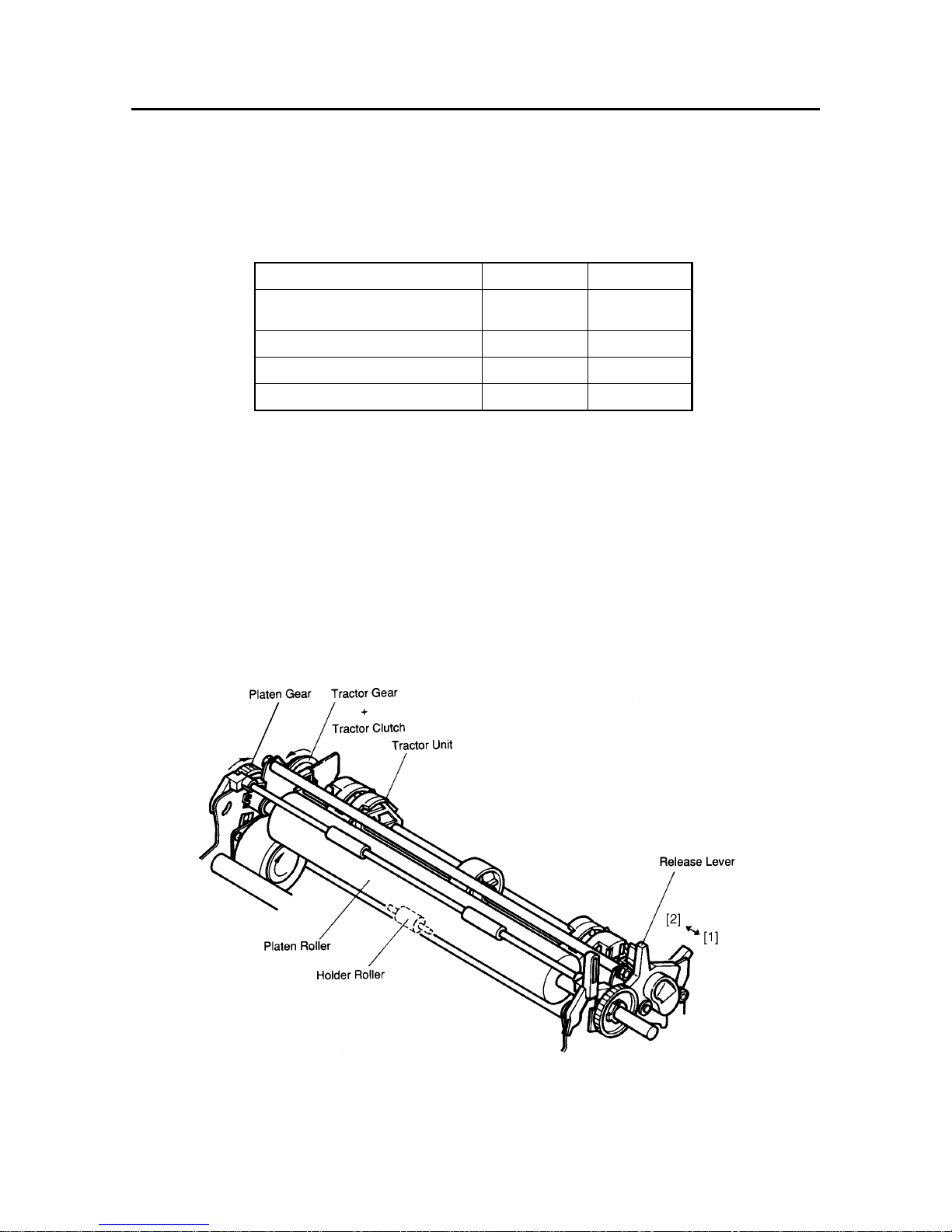

4-4. Paper Feed Mechanism

The paper feed motor is a PM type, four-phase and 48-pole pulse motor.

Minimum paper feed is set at 1/216 inch.

There are two ways of feeding paper available with this printer: Friction method and Tractor method. You can select one

of the two methods, using the release lever.

Position of release lever [1] [2]

Linkage between tractor

gear and tractor clutch

Platen roller and holder roller Pressured Not

Release lever position detector Closed Open

Paper feeding method Friction Tractor

(1) Friction Method

Friction method is selected when the release lever is position [1].

With this method, paper is pressed between the platen roller and the holder roller therefore, paper is fed as the rollers

turn.

As the paper feed motor is driven, the motor gear, through the idler gear, turns the platen gear in the paper feeding

direction. However, since the tractor gear and the tractor clutch are not linked at this time, the tractor unit will not

be driven.

(2) Tractor Method

Tractor method is selected when the release lever is position [2].

As described below, paper feeding is facilitated by rotation of the sprocket pin of the tractor unit. When the tractor

method is selected, the tractor gear is linked to the tractor clutch, enabling the drive force generated by the paper

feed motor to be transferred to the tractor unit via the idler gear and the platen gear.

Fig. 2-19 Paper Feed Mechanism

Page 31

– 28 –

THEORY OF OPERATION

4-5. Detectors

(1) Home Position Detector

A photo-interrupter is used in the home position detector, which is set at the left side of the frame unit.

ON/OFF signals are generated according to the position of the shield plate mounted at the base of the carriage, and

the printing position is determined by these signals.

(2) Paper Out Detector

A paper out detector is located at the paper insertion slit. When paper is present, the reed switch of the sensor is

OPEN. As soon as paper runs out, the switch is set to CLOSE, outputting a paper empty signal.

Fig. 2-20 Home Position Detector Fig. 2-21 Paper Out Detector

(3) Bail Lever Position Detector

Upon detecting the position of the bail lever, the auto loading operation will be activated.

The leaf switch is open when the bail roller is in contact with the platen roller, and it is closed when the bail roller

is separated from the platen roller.

(4) Release Lever Position Sensor

The leaf switch is closed when the release lever is in the Friction position, and is open in the Tractor position.

Fig. 2-22 Bail Lever Position Detector Fig. 2-23 Release Lever Position Detector

Page 32

CHAPTER 3

ADJUSTMENTS

This printer has undergone various adjustments so that it will achieve standard performance. In this chapter,

a brief explanation is given of the methods of adjustments.

Please check this explanation when making maintenance inspections or when replacing parts to correct

malfunctions.

1. Gap Adjustment Between Print Head and Platen ............................................ 31

1-1. Measuring Gap Between Print Head and Platen.................................................31

1-2. Adjusting Gap Between Print Head and Platen.................................................. 31

2. Adjustment of Timing Belt Tension................................................................... 32

3. Adjustment of Home Position (Colour Type only) ........................................... 33

3-1. Measuring Gap Between Home Position Detector and Frame..........................33

3-2. Adjusting Gap Between Home Position Detector and Frame ...........................33

4. Adjustment of Colour Ribbon Holder (Colour Type only)............................... 34

1

2

3

4

5

6

7

8

A

Page 33

ADJUSTMENTS

– 30 –

Page 34

ADJUSTMENTS

– 31 –

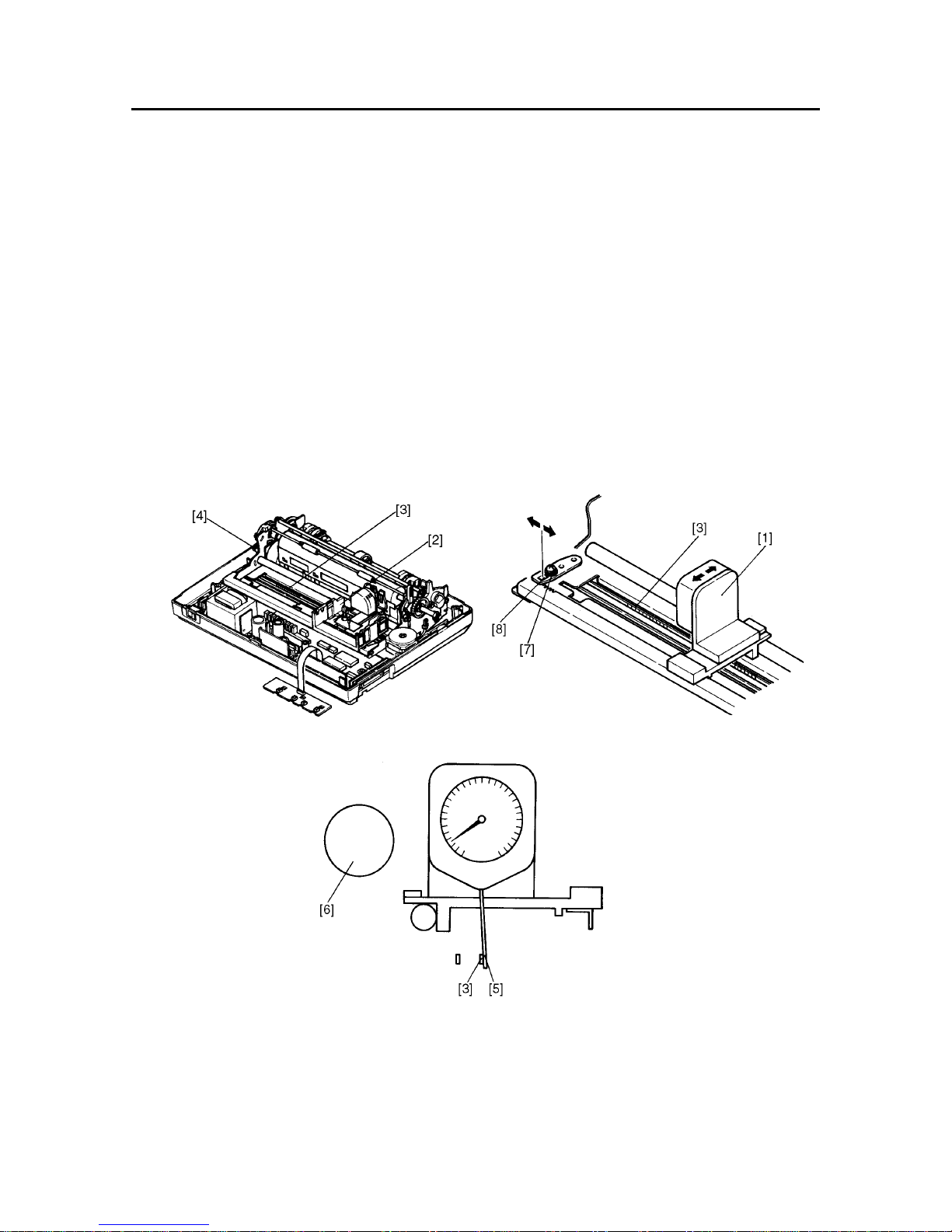

1. Gap Adjustment Between Print Head and Platen

1-1. Measuring Gap Between Print Head and Platen

(1) Remove the upper case unit according to procedures

described in chapter 4.

(2) Set the adjustment lever [1] at step two.

(3) Remove the ribbon guide [2].

(4) Insert a thickness gauge [3] between the print head[4]

and the platen [5], and measure the gap.

(5) This measurement must be carried out at the center

[C].

(6) The standard gap value is 0.30 to 0.40 mm.

(7) If the gap does not lie within this range, adjust it by

following the procedure in item 1-2.

Fig. 3-2 Position of Adjustment Lever Fig. 3-3 Gap Measurement

1-2. Adjusting Gap Between Print Head and Platen

If the gap does not lie within the standard range, adjust it by

carrying out the following procedures.

(1) Remove the printer mechanism according to the

procedures described in chapter 4.

(2) Loosen the nut [6].

(3) Insert the shaft in the ø2.5 hole [7].

Adjust the gap by rotating the carriage stay [8] with

the shaft.

When the shaft is lowered to the platen side, the gap

is reduced, and when lowered to the opposite side,

the gap is expanded.

(4) After adjusting, set the adjustment lever [1] to the

position shown in Fig. 3-2 and tighten the nut [6].

(Note) When tightening the nut [6], make sure that the

carriage stay [8] does not move.

Fig. 3-1 Gap Adjustment

Fig. 3-4 Gap Adjustment

Page 35

ADJUSTMENTS

– 32 –

2. Adjustment of Timing Belt Tension

The timing belt tension should be set to 16±2 g for MONO type (20±3 g for CL type).

(The belt tension must be measured with the designated tension gauge [1].)

After the belt has been used for a long time, however, it may be difficult to maintain prescribed tension because of belt

deterioration or wear. In these cases, make adjustments by following the procedures listed below.

(1) Remove the upper case unit according to the procedures described in chapter 4.

(2) Move the carriage unit [2] right and left two or three times in order to familiarize yourself with the timing belt [3].

(3) Set the adjustment lever [4] to step 2 as shown in Fig. 3-2.

(4) Move the carriage unit [2] to the right end.

(5) Set the arm [5] of the tension gauge [1] 152 mm from the frame L.

(6) Move the tension gauge [1] in the direction of the platen [6] until it stops. Then place the arm [5] of the tension gauge

on the timing belt [3].

(7) Loosen the screw [7].

(8) Insert a flat-blade screwdriver into the square hole of the tension arm [8] and adjust the belt tension by moving the

tension arm [8] left or right.

(9) When the belt has been adjusted to the prescribed tension, tighten the setting screw [7].

(10) If the belt cannot be adjusted to the prescribed tension, replace it with a new timing belt [3].

Fig. 3-5 Adjustment of Timing Belt Tension

Fig. 3-6 Tension Measurement

Page 36

ADJUSTMENTS

– 33 –

3. Adjustment of Home Position (Colour Type only)

3-1. Measuring Gap Between Home Position Detector and Frame

(1) Remove the printer cover [1] .

(2) Measure gap between home position detector [2] and frame [3] .

(3) The standard gap value is 2.4 to 3.0 mm.

(4) If the gap does not lie within this range, adjust it by following the procedure in item 3-2.

Fig. 3-7 Position of Home Position Fig. 3-8. Gap Adjustment

3-2. Adjusting Gap Between Home Position Detector and Frame

If the gap does not lie within the standard range, adjust it by carrying out the following procedures.

(1) Remove the upper case according to procedures described in chapter 4.

(2) Loosen the four screws [4] .

(3) Move the printer mechanism.

(4) Insert the thickness gauge (2.7 mm) between the home position detector [2] , and frame [3] .

(5) Tighten the four screws [4] .

Fig. 3-9 Position of Four Screws

Page 37

ADJUSTMENTS

– 34 –

4. Adjustment of Colour Ribbon Holder (Colour Type only)

This adjustment requires use of the carriage unit to fix the position of the color ribbon holder on older parts (see drawings

no. 1-24 and 1-25, chapter 7, part 3-3-2). However, newer parts (nos. 1-30 and 1-31) do not require use of the carriage

unit.

Adjustment of the colour ribbon holder properly positions the ink ribbon cartridge vertical to the print head when the

cartridge is installed on the colour ribbon holder. (Refer to Fig. 3-10.) Failure to perform this adjustment may cause some

kinds of defective printing such as printing in “YELLOW” ink when printing should be done in “RED” ink.

The following is the adjustment procedure.

(1) Execute Self Printing [1].

(2) Judging from the print sample printed just now, decide if the ink ribbon cartridge should be moved upward or

downward of the print head.

(3) Remove the printer cover and ink ribbon cartridge [1] .

(4) Turn the adjusting screws A [2] and B [3] (brass parts)

counter-clockwise to move the ribbon cartridge upward.

clockwise to move the ribbon cartridge downward.

(5) Install the ink ribbon cartridge and printer cover.

(6) Execute self printing.

(7) Check the printing condition on the print sample.

If additional adjustment is required, repeat the procedure from (2) to (7).

*1 Self printing

1. Insert the paper.

2. With power off, press the On Line switch on the control panel and hold it down.

3. Still holding the On Line switch down, turn the printer’s power on.

Fig. 3-10 Needle Wire Position of Print Head

Fig. 3-11 Position of Adjusting Screws Fig. 3-12 Adjusting of Colour Ribbon Holder

Page 38

CHAPTER 4

PARTS REPLACEMENT

This chapter explains disassembly and reassembly of the printer.

Note the following precautions during disassembly and reassembly.

1. Disconnect the printer from the wall outlet before servicing it.

2. Assembly is the reverse of disassembly unless otherwise specified.

3. After reassembly, coat the screw heads with locking sealant.

4. Lubrication information is not provided in this chapter. Refer to item 2 in chapter 5.

1. Upper Case Unit ..................................................................................................37

2. Printer Mechanism .............................................................................................. 37

3. Main Logic Board ................................................................................................ 38

4. Power Supply Unit .............................................................................................. 39

5. Fuses .................................................................................................................... 40

6. Print Head ............................................................................................................41

7. Carriage Motor Unit............................................................................................. 42

8. Platen Unit ........................................................................................................... 43

9. Tractor Unit.......................................................................................................... 43

10. Detector Unit........................................................................................................ 44

1

2

3

4

5

6

7

8

A

Page 39

PARTS REPLACEMENT

– 36 –

Page 40

PARTS REPLACEMENT

– 37 –

1. Upper Case Unit

(1) Turn off the power switch [1] .

(2) Remove

• Printer cover

• Rear cover

• Platen knob [2]

• Four screws [3]

(3) Move the Carriage Unit [4] over to the right so that

it aligns with the cut-out of the upper case unit [5] .

(4) Remove

• Upper case unit [5]

Clasp the back side of the upper case unit, and

gently push it further forward.

• Control panel board [6]

2. Printer Mechanism

(1) Remove

• Upper case unit according to the procedure de-

scribed in item 1.

• Stop ring [1]

• Release lever [2]

• Gear lever [3]

• Four tapping screws [4]

• Screw [5]

• Connector cover [6]

Lift up the tab of the connector cover, and slide it

to the right for removal.

• Printer head cable [7]

• Three connectors [8]

• Printer mechanism [9]

Caution in assembly:

Align the the ∆ mark on the Release lever [2] with

the ∆ mark on the Release gear [3] to install the

Release lever [2] .

Page 41

PARTS REPLACEMENT

– 38 –

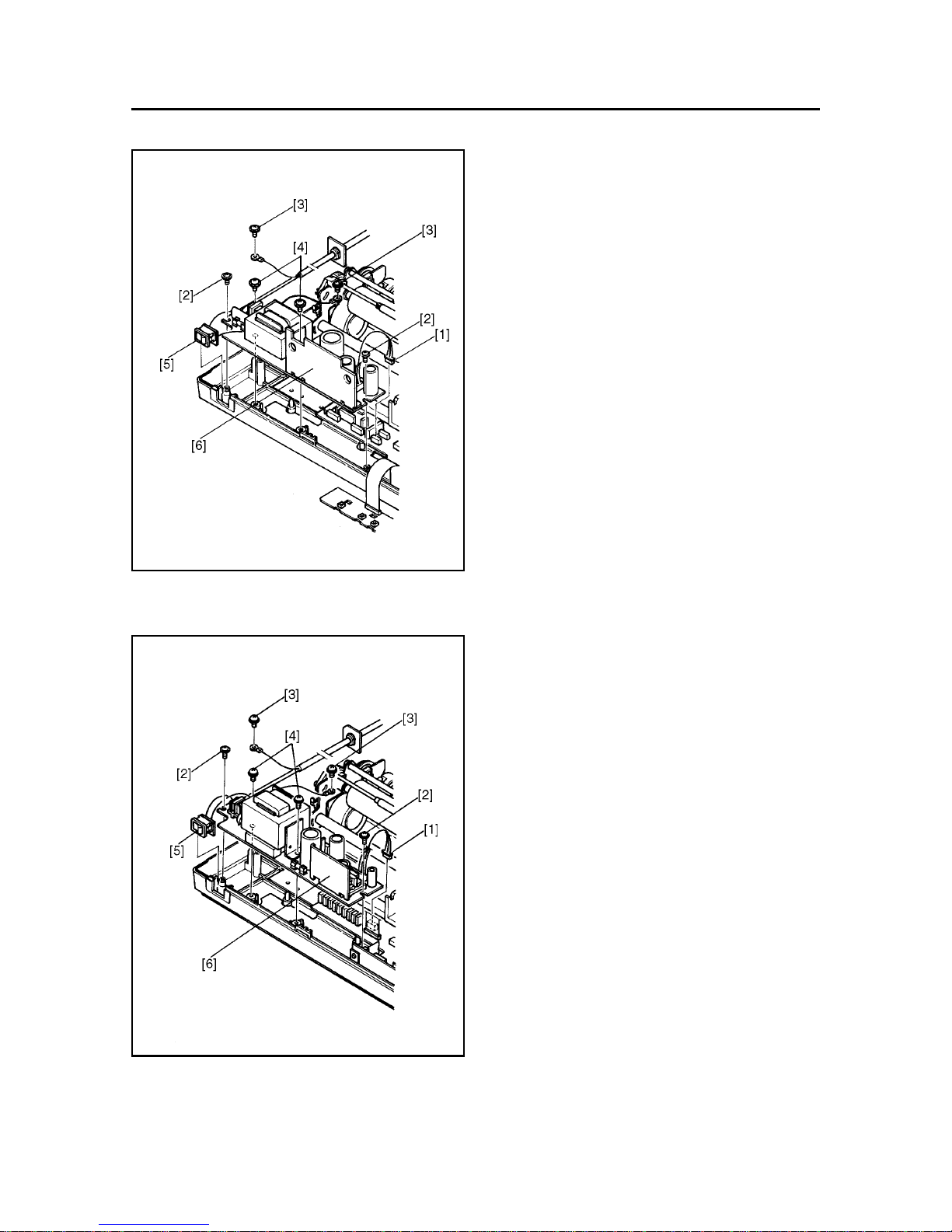

3. Main Logic Board

(1) Remove

• Printer mechanism according to the procedure

described in item 2.

• Two connectors [1]

• Two tapping screws [2]

• Two screws [3]

• Main logic board [4]

For Ver. 1

For Ver. 1.5 For Ver. 2

Page 42

PARTS REPLACEMENT

– 39 –

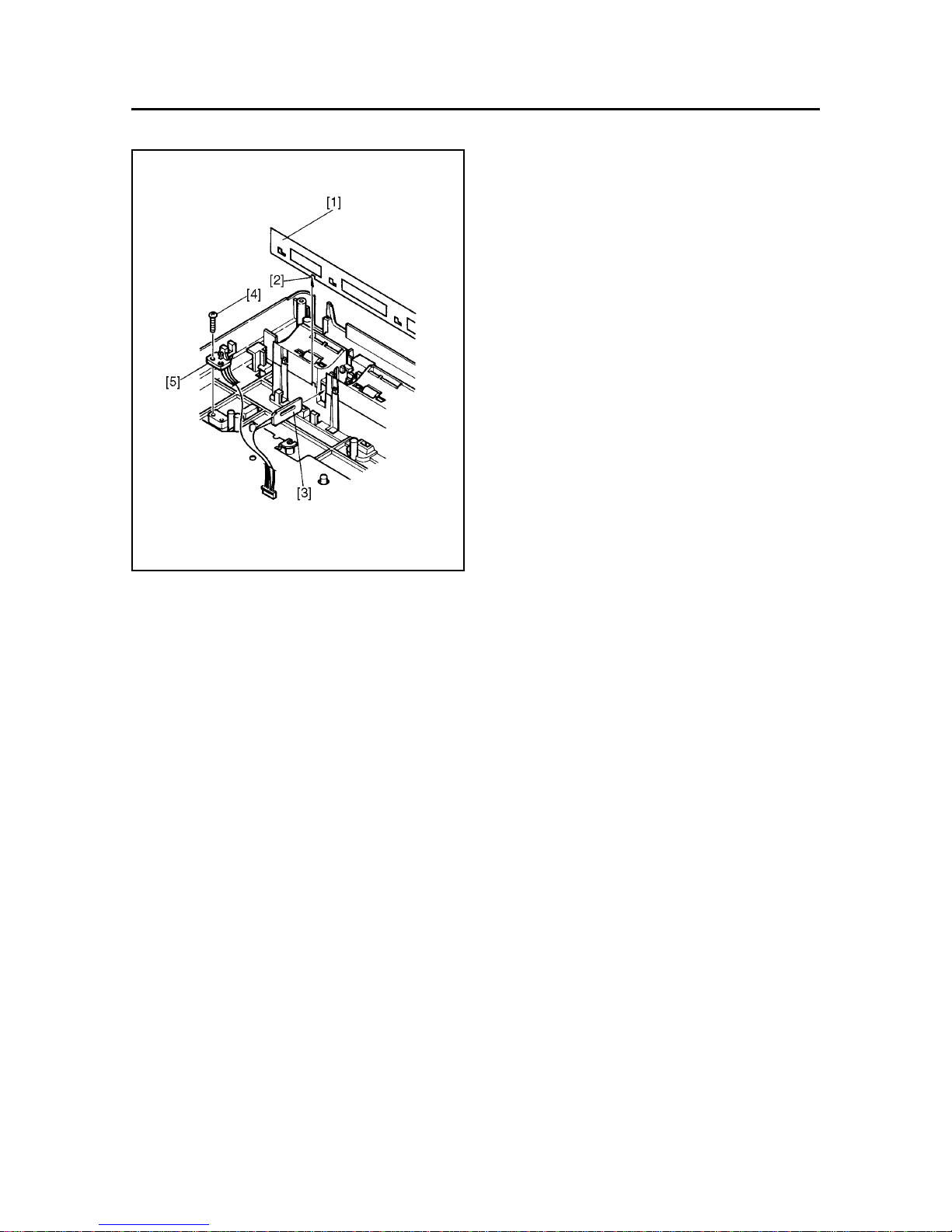

4. Power Supply Unit

(1) Remove

• Upper case unit according to the procedure de-

scribed in item 1.

• Connector [1]

• Two tapping screws [2]

• Two tapping screws [3]

• Two screws [4]

• Power switch [5]

• Power supply unit [6]

For Ver. 1 and 1.5

For Ver. 2

Page 43

PARTS REPLACEMENT

– 40 –

5. Fuses

For Ver. 1 and Ver. 1.5

(1) Remove

• Upper case unit according to the procedure de-

scribed in item 1.

(2) Inspect

• Fuse F1 [1]

• Fuse F2 [2]

• Fuse F3 [3] (For 120V only)

Defective→ Replace fuse as follows:

AC Voltage F1 (F3)

120V 5TT1A 5MT3.0

220V/240V 630mA –

The Destination Countries F2

EC, WG, NBR, SC, SU EAK2.0

US, TW, HK, UK, AS, MAS, UE 5MT2.0

New fuse blown → Inspect circuit

For Ver. 2

(1) Remove

• Upper case unit according to the procedure de-

scribed in item 1.

(2) Inspect

• Fuse F1 [1]

• Fuse F2 [2]

Defective → Replace fuse as follows:

AC Voltage F1

120V 5TT1A

220V/240V 630mA

The Destination Countries F2

EC, WG, NBR, SC, SU EAK3.15A

US, TW, HK, UK, AS, MAS, UE 5TT3A

New fuse blown → Inspect circuit

For Ver. 1 and 1.5

For Ver. 2

Page 44

PARTS REPLACEMENT

– 41 –

6. Printer Head

(1) Remove

• Printer cover

• Ink ribbon cartridge

• Connector cover [1]

• Gear Cover [2] (Colour type only)

• Two tapping screws [3]

• Head cable [4]

• Print head [5]

WARNING:

The print head becomes hot after printing so wait

for it to cool before removing it.

(2) Adjust

• Gap between print head and platen

Refer to item 1 of Chapter 3.

For Ver. 1 and 1.5

For Ver. 2

Page 45

PARTS REPLACEMENT

– 42 –

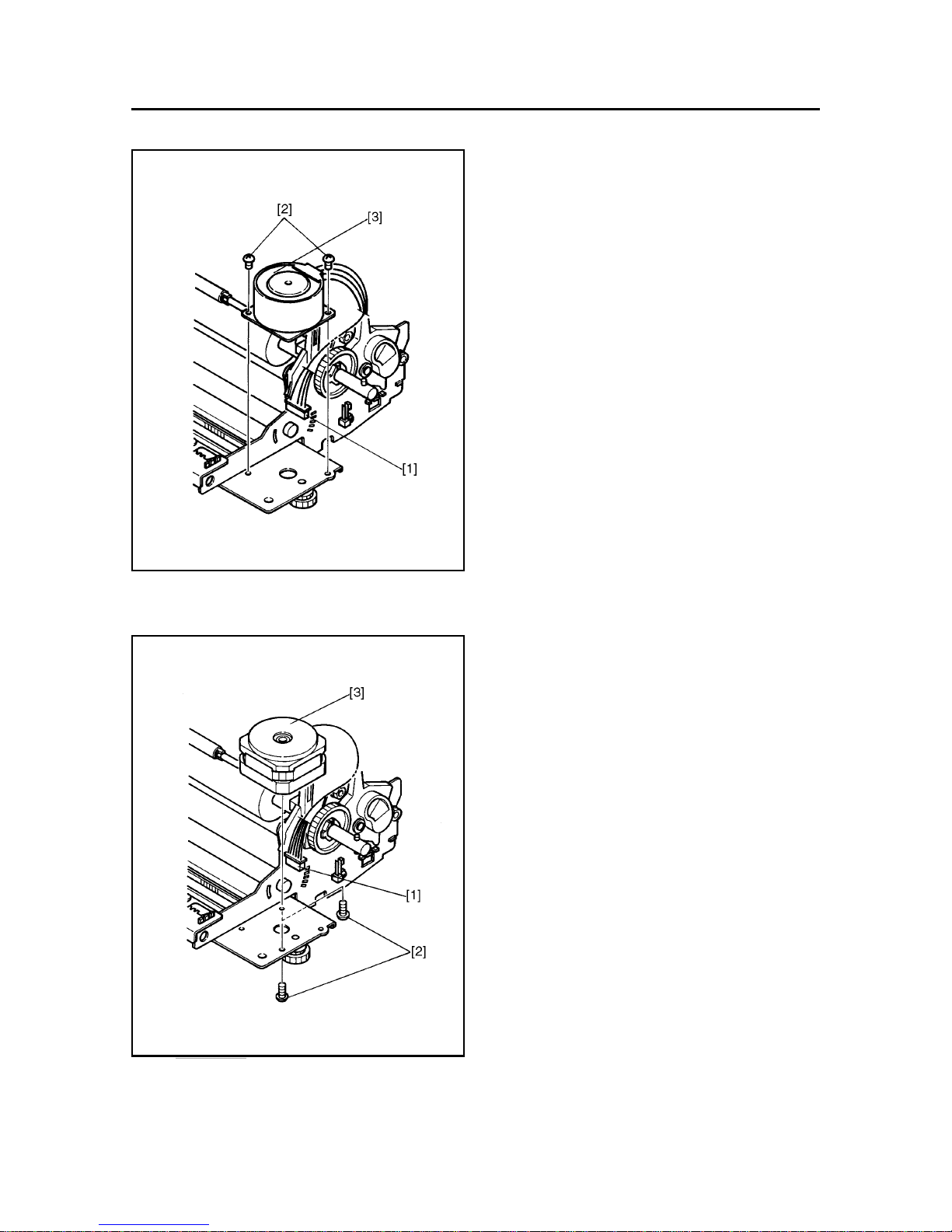

7. Carriage Motor Unit

(1) Remove

• Printer mechanism according to the procedure

described in item 2.

• Cord fastener binding the lead wires

• Connector [1]

• Two screws [2]

• Carriage motor unit [3]

For Ver. 1 and 1.5

For Ver. 2

Page 46

PARTS REPLACEMENT

– 43 –

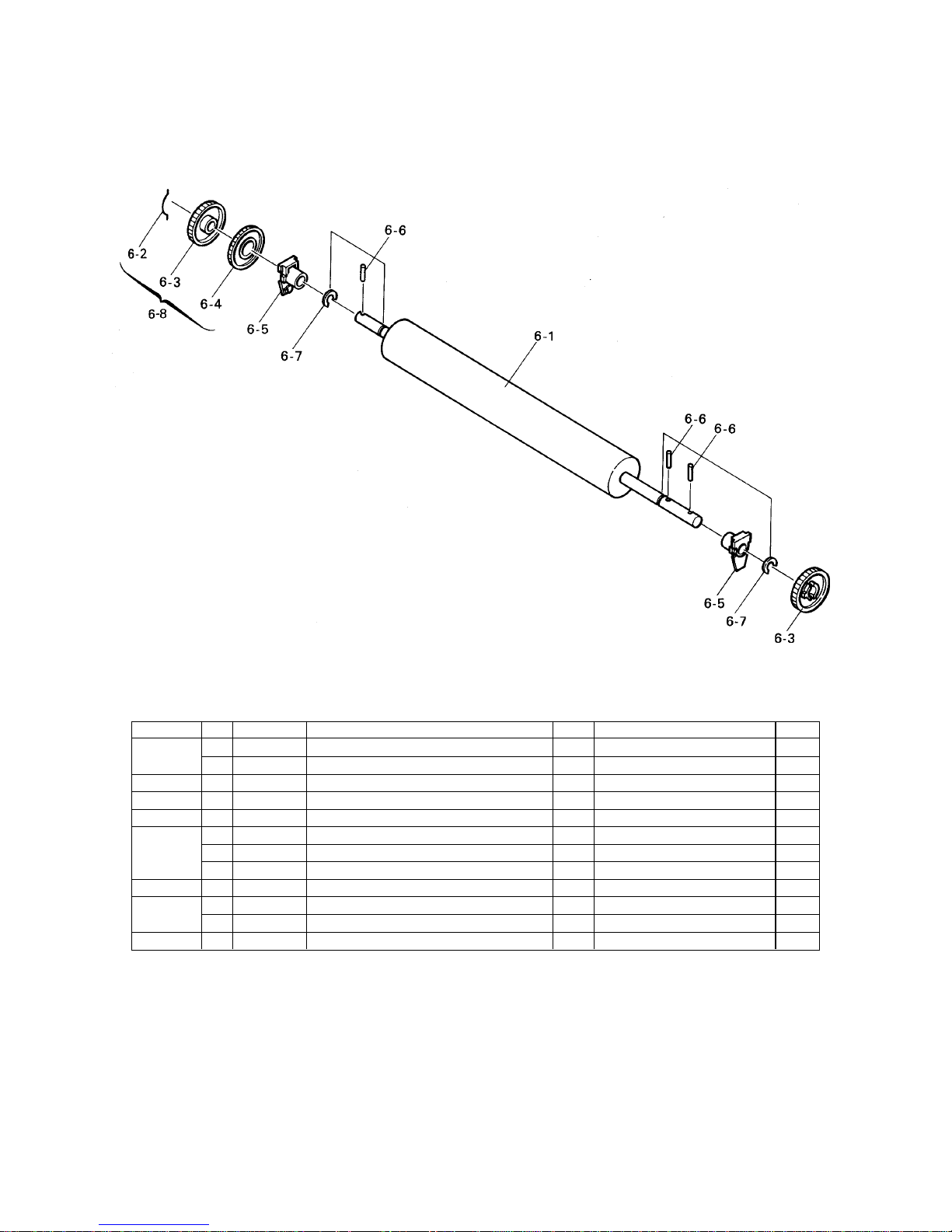

8. Platen Unit

(1) Remove

• Printer mechanism according to the procedure

described in item 2.

• Two nuts [1]

• Tractor stay [2]

• Stop ring [3]

• Ground contact spring [4]

• Platen holder R [5]

• Platen holder L [6]

Lift the tabs [7] of platen holders R and L to allow

removal of platen holders R and L from the frame.

• Platen unit [8]

Caution in assembly:

When assembling the platen gear assembly [9] on the

idler gear, align the teeth of gear A and gear B (be

sure to align the holes [10] in the two gears.)

(2) Adjust

• Gap between print head and platen

Refer to item 1 of Chapter 3.

9. Tractor Unit

(1) Remove

• Upper case unit according to the procedure de-

scribed in item 1.

• Stop ring [1]

• Release lever [2]

• Two nuts [3]

• Two tractor bushings [4]

Lift the tab [5] of the tractor bush to allow

removal of the tractor bush from the frame.

• Tractor unit [6]

Caution in assembly:

• For reassembly, hold the sheet guide [7] at the

center of the tractor shaft and push the guide into

the printer.

• Aligen the mark ( or ) on the release lever [2]

with the mark ( or ) on the release gear [8] to

install the release lever [2].

Page 47

PARTS REPLACEMENT

– 44 –

10. Detector Unit

(1) Remove

• Printer mechanism according to the procedure

described in item 2.

• Cord fastener binding the lead wires

• Sub guide [1]

Lift the notched part [2] and slide sub guide [1]

to the left to remove.

• PE detector [3]

• Screw [4]

• Home position detector [5]

Page 48

CHAPTER 5

MAINTENANCE AND LUBRICATION

1. Maintenance ........................................................................................................ 47

1-1. Cleaning ................................................................................................................. 47

1-2. Checks ................................................................................................................... 47

2. Lubrication...........................................................................................................48

2-1. Lubricant................................................................................................................ 48

2-2. Lubricating Method ............................................................................................... 48

2-3. Lubricated Areas................................................................................................... 48

1

2

3

4

5

6

7

8

A

Page 49

– 46 –

Page 50

– 47 –

MAINTENANCE AND LUBRICATION

1. Maintenance

In order to maintain the optimum performance of this printer and to prevent trouble, maintenance must be carried out

according to the following items.

1-1. Cleaning

(1) Removal of dirt

Wipe off dirt with a soft cloth soaked in alcohol or benzine.

*Note: Do not use thinner, trichlene or ketone solvents because they may damage plastic parts. Also during

cleaning, be careful not to moisten or damage electronic parts, wiring, or mechanical parts.

(2) Removal of dust, pile, etc.

Vacuum cleaning (with an electric cleaner) is preferred. Remove all dust, etc., inside the printer.

*Note: After cleaning, check the oil level. If it is not adequate due to cleaning, replenish it.

1-2. Checks

Checks must be carried out at two levels: “daily check” which the operator can easily carry out during operation, and

“periodic check” which an expert should carry out.

(1) Daily check

When the printer is used on a daily basis, check to be sure that the printer is being used properly. Make sure that

the printer is operating under the best conditions.

• Is any paper stuck in the paper box or printer case?

• Is the cartridge ribbon set to the right position?

• Is there any foreign matter inside the printer? (Remove.)

• Is the print head getting excessively dirty?

(2) Periodic check

After 6 months or printing 1,000,000 lines, the periodic check and lubrication must be carried out.

• Check for deformation of springs.

• Check the gap between the platen and the print head.

• Remove dust, dirt, etc., from near each detector.

Page 51

– 48 –

MAINTENANCE AND LUBRICATION

2. Lubrication

Lubrication is very important to maintain optimum performance and to prevent trouble.

2-1. Lubricant

The type of lubricant greatly affects the performance and durability of the printer, especially in a low temperature

environment. We recommend use of the grease and lubrication oils listed below for this printer

Product name Maker

FLOIL GB-TS-0 and FLOIL GB-100 Kanto Chemicals Co., Ltd.

KF96-1000CS and KF96-SP Shinetsu Chemical Industry

Mobil 1 Mobil oil

2-2. Lubricating Method

When lubrication is carried out in assembly and disassembly, wash parts well to remove dust and dirt before lubrication.

Lubrication must be carried out regularly once every 6 months or after 1 million lines have been printed. Lubrication is

necessary irrespective of the regular lubrication whenever lubricant becomes deficient after cleaning or whenever parts

have been disassembled or replaced.

2-3. Lubricated Areas

NO. Lubrication Product Name

[1] Rubbing surfaces of idler gear 16 × 72 × 0.5 and idler gear shaft GB-TS-0

[2] Rubbing surfaces of gear 40 × 0.5 and gear shaft GB-TS-0

[3] Rubbing surfaces of adjusting lever and frame GB-TS-0

[4] Rubbing surfaces of timing pulley and pulley shaft GB-TS-0

[5] Rubbing surfaces of rear angle and carriage GB-TS-0

[6] Rubbing surfaces of bushing and carriage stay Mobil 1

[7] Rubbing surfaces of timing pulley and stop ring GB-TS-0

[8] Rubbing surfaces of release shaft and frame GB-TS-0

[9] Rubbing surfaces of release lever and tractor shaft GB-TS-0

[10] Rubbing surfaces of two tractor bushings and tractor shaft GB-TS-0

[11] Rubbing surfaces of tractor holder and tractor cover KF96-1000CS

[12] Rubbing surfaces of bail roller and shaft KF96-SP

[13] Rubbing surfaces of timing pulley and pulley bushing GB-100

[14] Rubbing surfaces of lift cam and ribbon change lever GB-TS-0

[15] Rubbing surfaces of lift cam and carriage shaft GB-TS-0

[16] Rubbing surfaces of ribbon change lever and carriage KF96-1000CS

[17] Rubbing surfaces of idler gear 16 × 1 – 40 × 0.3 GB-TS-0

[18] Rubbing surfaces of lift lever assy and carriage shaft KF96-1000CS

[19] Rubbing surfaces of lift lever assy and carriage GB-TS-0

[20] Rubbing surfaces of lift lever assy and lift cam KF96-1000CS

[21] Rubbing surfaces of ribbon cassette gear and carriage shaft GB-TS-0

[22] Rubbing surfaces of rear angle and idler gear 16 × 1 – 40 × 0.3 GB-TS-0

[23] Rubbing surfaces of idler gear 43 × 6.3 × 0.3 and carriage shaft GB-TS-0

[24] Rubbing surfaces of idler 43 × 6.3 × 0.3 and gear cover GB-TS-0

[25] Rubbing surfaces of idler gear 17 × 41 × 0.3 and clutch lever GB-TS-0

[26] Rubbing surfaces of idler gear 16 × 1 – 40 × 0.3 and carriage shaft GB-TS-0

[27] Rubbing surfaces of lift cam and gear cover GB-TS-0

[28] Rubbing surfaces of wave washer and poly-slider GB-TS-0

Page 52

– 49 –

MAINTENANCE AND LUBRICATION

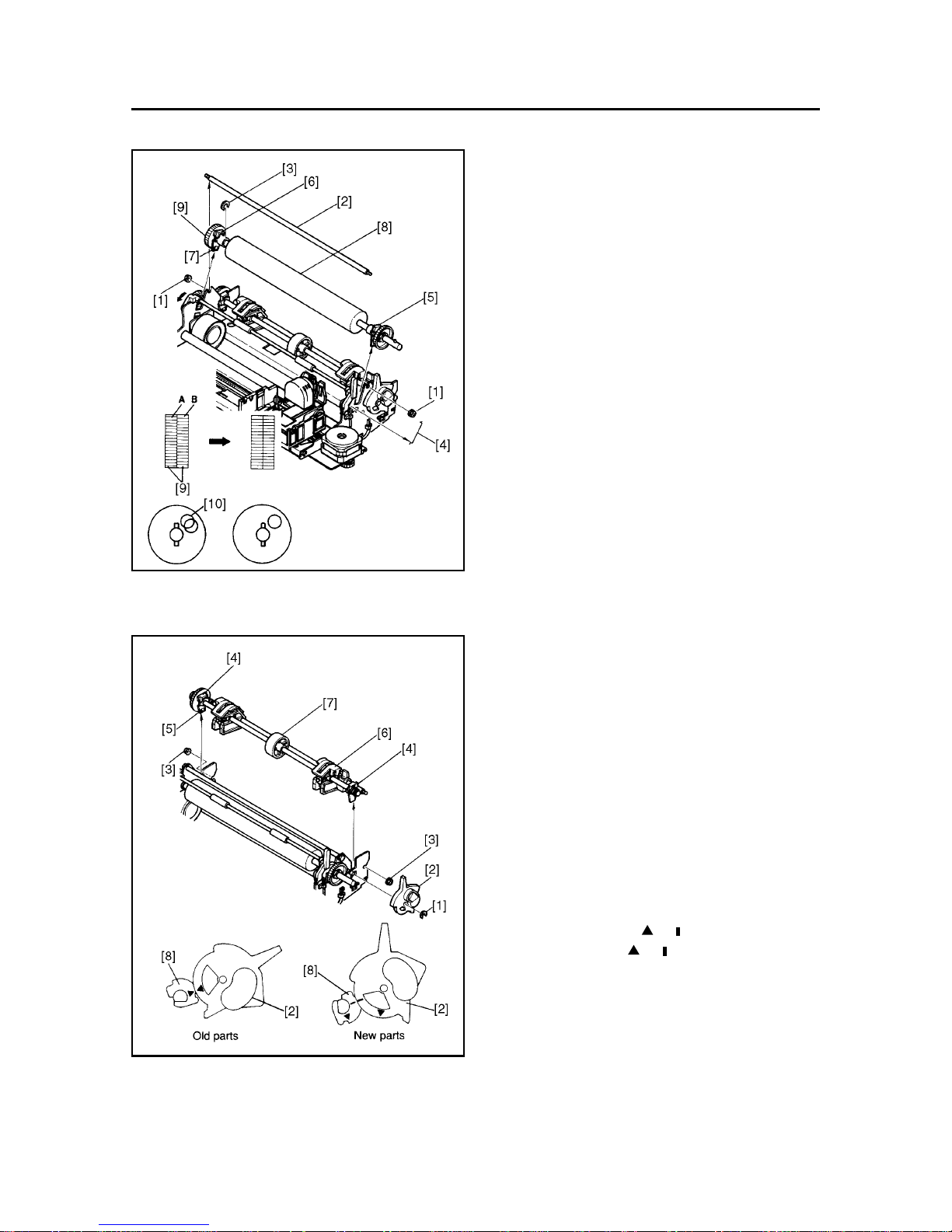

Fig. 5-1 Lubricated Areas

Detail-B (Monochrome Type)

Detail-B (Colour Type)

Page 53

– 50 –

Page 54

– 51 –

CHAPTER 6

TROUBLESHOOTING

1. Troubleshooting Procedures ............................................................................. 53

2. Unit Replacement Flow Chart ............................................................................ 54

3. Repair by Unit Replacement .............................................................................. 55

4. Repair by Replacement of Parts ........................................................................ 61

4-1 Does not Operate at ALL with Power on.............................................................61

4-2 Power Supply Unit Abnormal...............................................................................62

4-3 Defective Motor Operation ................................................................................... 63

4-4 Defective Print Head Operation ........................................................................... 64

4-5 Defective Interface Operation .............................................................................. 65

1

2

3

4

5

6

7

8

A

Page 55

– 58 –

REPLACEMENT AND ADJUSTMENT OF PARTS

Page 56

– 53 –

TROUBLESHOOTING

1. Troubleshooting Procedures

Troubleshooting is never easy because various problems arise depending upon the particular location of the breakdown,

but the following procedures should be adhered to in making repairs.

(1) At the first stage, conduct repairs through unit replacements.

The two display codes appearing in the flow chart are defined as follows: 1) indicates main logic board replacement

and 2) indicates printer mechanism replacement, to be carried out if the problem has not been corrected.

1) Main Logic Board Replacement

2) Printer Mechanism Replacement

Check again at this time whether the replaced unit is malfunctioning. (This is done to rule out trouble caused by improper

contact of connectors.)

Replaceable units consist of the following:

• Power supply unit

• Main logic board

• Printer mechanism

In replacing these units, always refer to the unit replacement flow chart.

(2) At the second stage, use the flow chart for repair by parts replacement to replace defective elements inside a

particular unit.

(Note 1) Before starting to repair, be sure to check visually the contact of the connector and the mounting of the IC

in the IC socket.

(Note 2) Always turn off power source and remove power plug before replacing any units or parts.

(Note 3) If any check items appear on the flow chart, be sure to always check them. Otherwise, newly mounted parts

or units may become damaged.

(Note 4) If, in the process of making repairs, there is any confusion about proper procedures, start to do the job again

from the beginning.

(Note 5) Refer to the oscilloscope waveforms presented in Chapter 7 when repairing boards.

(Note 6) Be careful to avoid injury from static electricity when handling ICs and main logic boards.

(3) The following relate to the “*” marks in the flow chart.

*1 See (6) and (7) waveform in Item 7 of Chapter 7 or Chapter 8 and Fig. 2-10 ~ 17 in Chapter 2.

*2 See (8) and (9) waveform in Item 7 of Chapter 7 or Chapter 8.

*3 See (4) and (5) waveform in Item 7 of Chapter 7 or Chapter 8.

*4 See 3. Power Supply unit in Chapter 2.

*5 See 2-1. Data Input Operation in Chapter 2 and (10) or (11) waveform in Item 7 of Chapter 7 or Chapter 8.

*6 See (2) RESET waveform in Item 7 of Chapter 7 or Chapter 8.

*7 See (1) Crystal waveform in Item 7 of Chapter 7 or Chapter 8.

Page 57

– 54 –

TROUBLESHOOTING

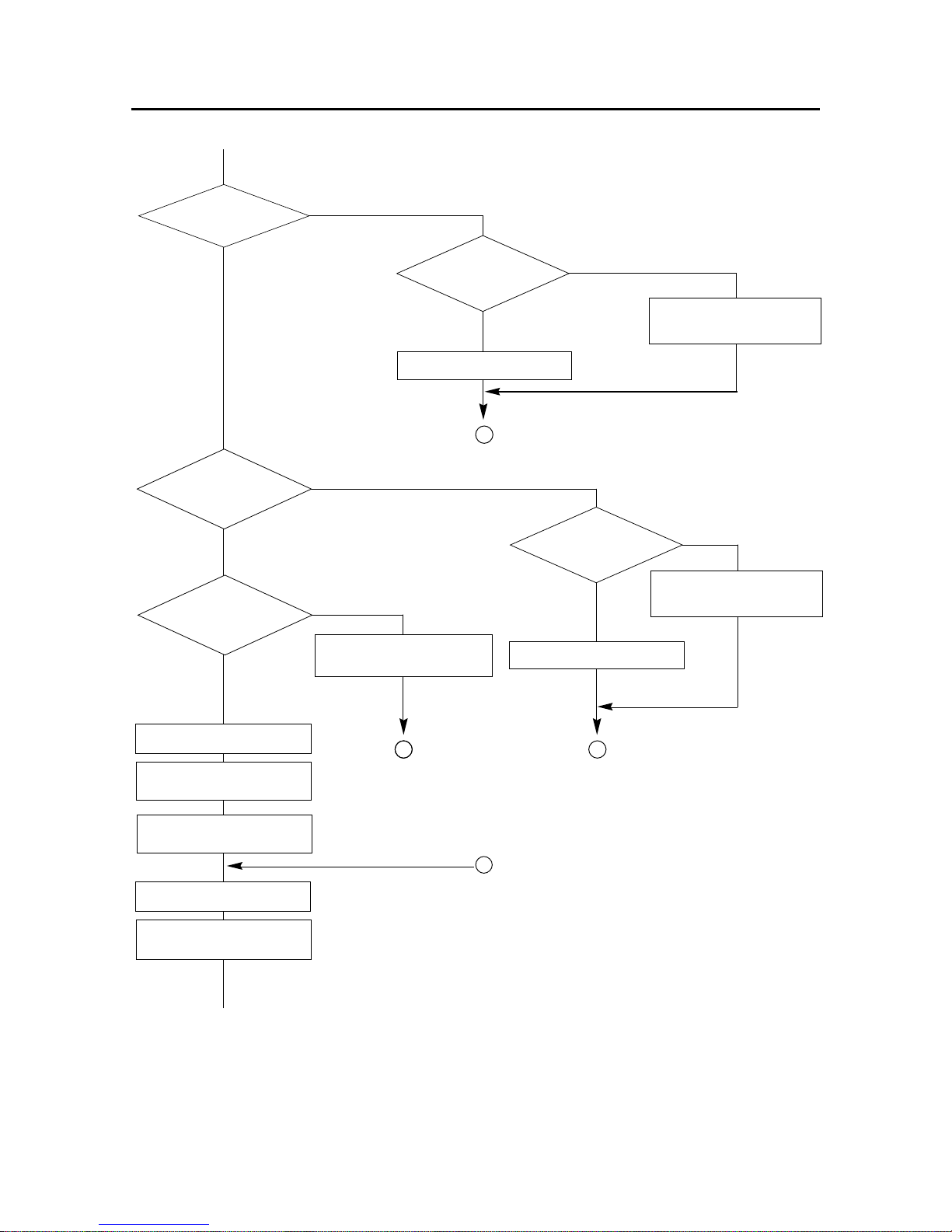

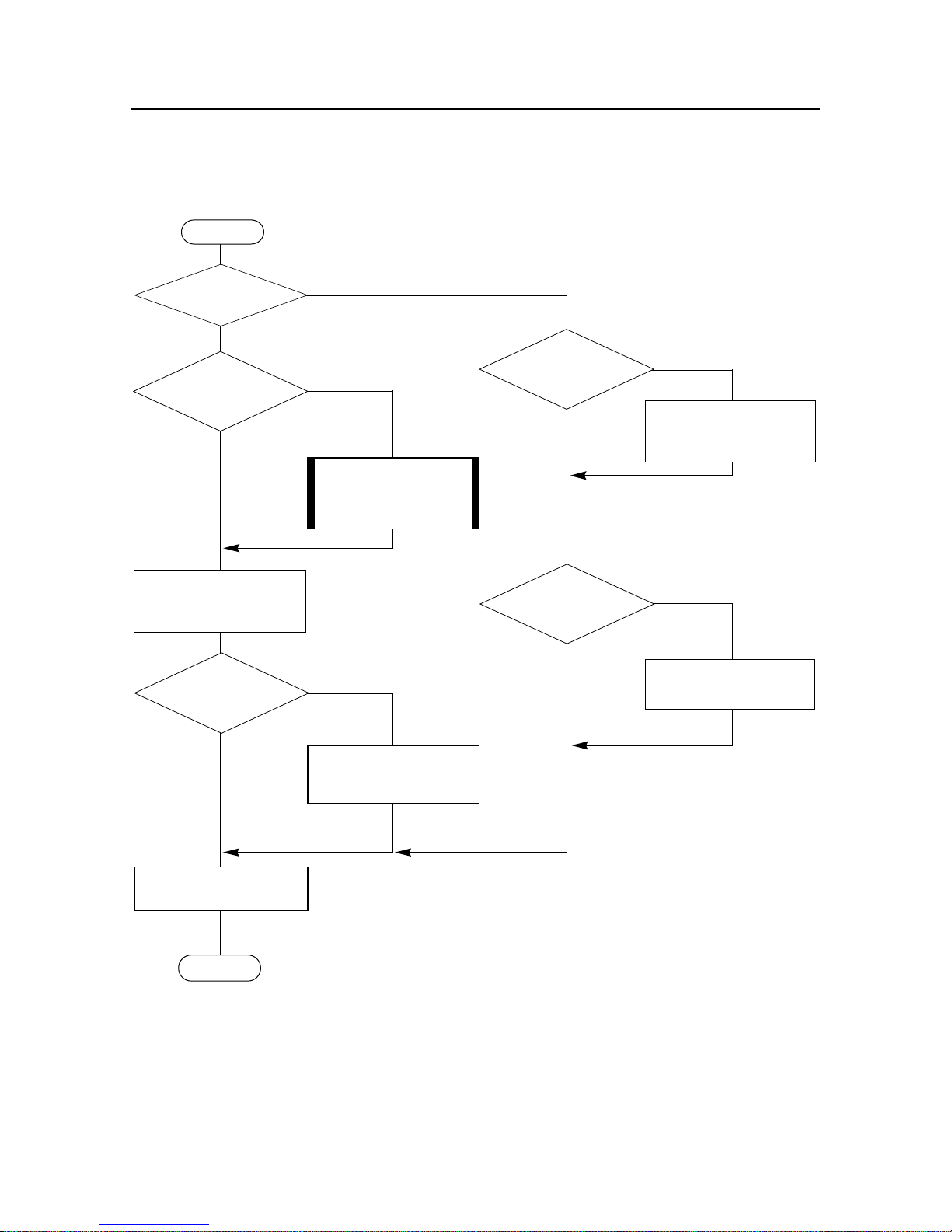

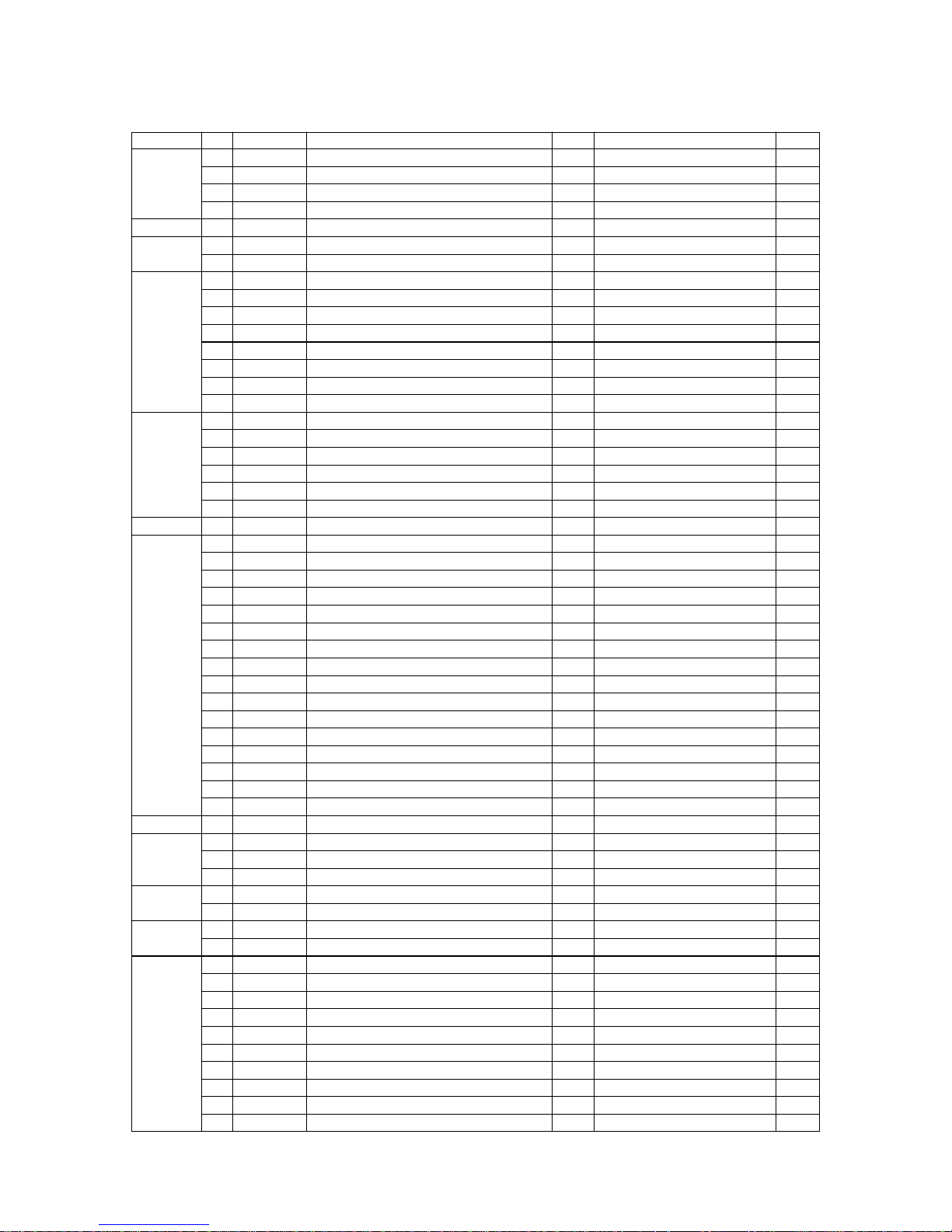

2. Unit Replacement Flow Chart

Unit Exchange Sequence

Power

supply unit

Problem

Details

Category Remarks

Specific display

lamp only will

not glow

Specific switch

only cannot be

input

Buzzer does not

sound (sound

volume

inadequate)

Strange sounds

during operation

No motor

holding power

(power very

weak)

Dots skipped

Print is too light

Ink ribbon

entanglement

(wire sticks out)

Absence of paper

not detected

Lever position

not detected

Incorrect printing

Ink ribbon not

forwarded

No operation at

DIP switch

setting

Faulty operation

when power is

turned on/off

Abnormal motor

operating speed

(slow)

Fuse blown

during operation

2

3

Ink ribbon

Gap check

Check I/F cable

Note: The figures 1, 2 and 3 mean the priority of replacement.

Operation related

Motor related

Print head

related

Detector

related

Interface related and others

Printer

mechanism

2

1

1

1

1

2

1

2

2

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

Main

logic board

Check setting of

DIP switch

Page 58

– 55 –

TROUBLESHOOTING

3. Repair by Unit Replacement

1) Replace main logic

board.

2) Replace printer

mechanism.

Carriage motor

operating waveform is

normal? *1

YES

Replace printer mechanism.

A

NO

NO

A

NO

1) Replace main logic

board.

2) Replace printer

mechanism.

A

NO

NO

Home position

switch signal is

normal?

YES

Replace main logic board.

START

* Turn power off.

* Remove I/F cable.

* Mount ink ribbon.

* Set paper.

* Move carriage to center.

Turn power on.

Carriage

Movement?

YES

Carriage operates

normally?

YES

Carriage stops at

home position?

YES

B

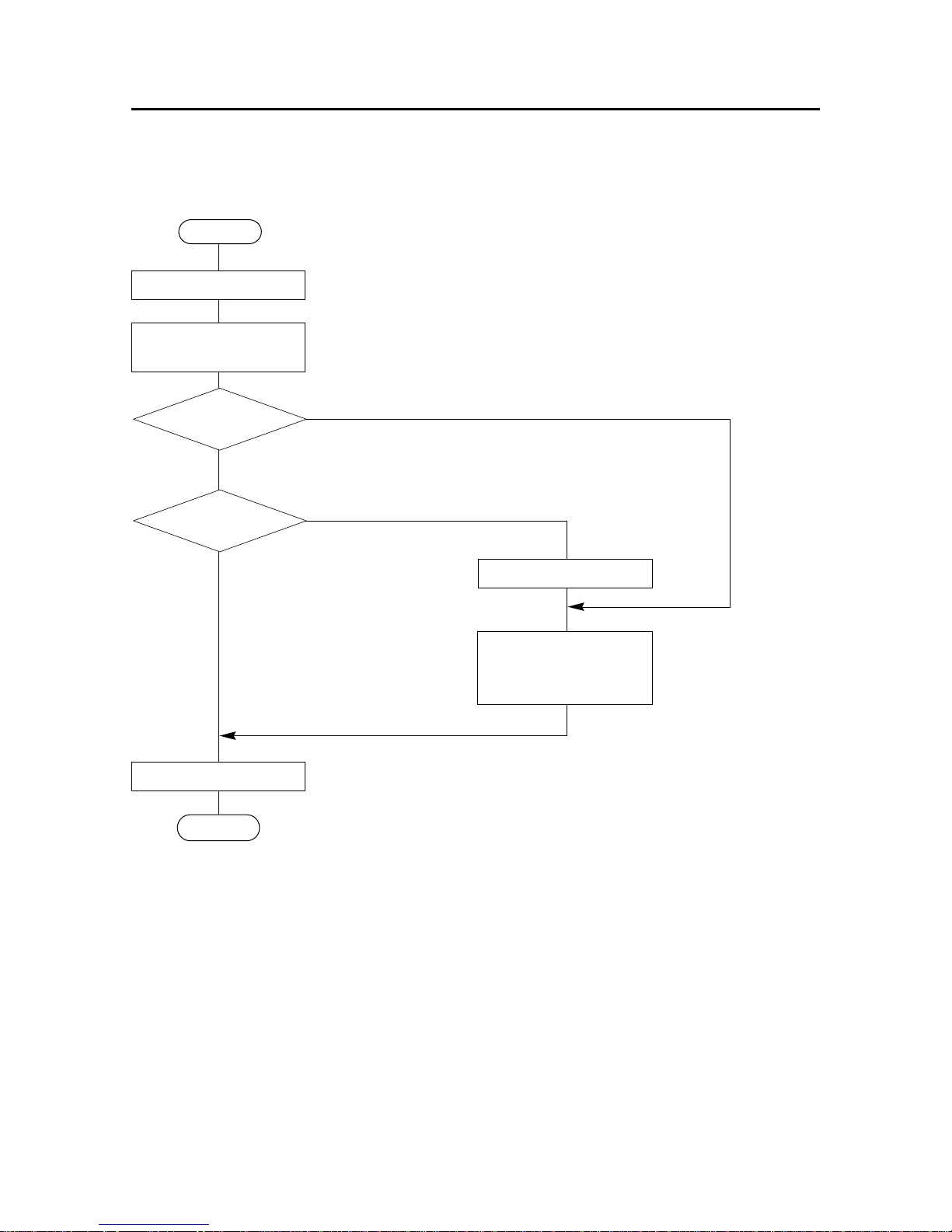

Page 59

– 56 –

TROUBLESHOOTING

1) Replace main logic board.

2) Replace printer mechanism.

NO

1) Replace main logic board.

2) Replace printer mechanism.

A

NO

NO

Paper feed

motor drive waveform

is normal? *2

YES

Replace printer mechanism.

A

Self

printing:

Carriage motor

drive waveform is

normal? *1

YES

Replace printer mechanism.

Printer lamps light?

YES

On line switch in on.

(Take Off Line)

On line lamp is out?

YES

Paper feed switch is on.

Paper feed switch

operation is normal?

YES

Power is off.

Power source is on while

pressing paper feed switch.

Carriage operates

normally?

YES

NO

NO

NO

Replace main logic board.

A

Replace main

logic board.

Page 60

– 57 –

TROUBLESHOOTING

1) Replace main logic board.

2) Replace printer mechanism.

A

NO

Print head

drive signal waveform is

normal? *3

YES

Replace printer mechanism.

NO

C

NO

1) Replace main logic board.

2) Replace printer mechanism.

NO

NO

1) Replace ink ribbon.

2) Replace printer mechanism.

AA

A

Replace printer mechanism.

Paper feed

motor drive waveform is

normal? *2

YES

Printing operation

is normal?

YES

Paper feed

operation is

normal?

YES

Ribbon feed

operation is

normal?

YES

Self printing terminates.

Check host computer

connection.

Power is off and I/F cable is

connected.

Power is on.

Print program operation

begins from host computer.

Page 61

– 58 –

TROUBLESHOOTING

1) Replace I/F cable.

2) Replace main logic board.

3) Check host computer.

Replace printer mechanism.

Replace power supply unit.

C

D

NO

NO

NO

YES

NO

Printing begins?

YES

Printing

operation normal?

YES

Printer is normal; host

computer print program stops.

END

Works with

carriage hand?

YES

Output

(+24V, +5V)

of power supply unit is

normal? *4

NO

Power source is off.

Fuse blows out?

YES

Replace fuse.

Remove connector CN5[CN6]

of main logic board.

Power source is on.

B

[ ]: Commodore type

1) Replace main logic board.

2) Replace printer

mechanism.

A

Page 62

– 59 –

TROUBLESHOOTING

NO

NO

A

[ ]: Commodore type

Output of

power supply unit is

normal? *4

YES

Power source is off.

Connect connector

CN5[CN6] of

main logic board.

Power source is on.

Fuse blows out?

YES

Replace fuse

1) Replace main logic board.

2) Replace printer mechanism.

Page 63

– 60 –

TROUBLESHOOTING

YES

NO

YES

YES

1) Replace I/F cable.

2) Replace main logic board.

D

NO

NO

E

A

C

A

I/F signal is

normal? *5

NO

Ready condition?

YES

There is data

transmission?

NO

Hardware check or check

of host computer print

program.

On line switch

goes ON/OFF?

YES

On line lamp

drive signal is

normal?

YES

Replace main logic board.

I/F mode set

up properly?

NO

I/F mode set up changed.

① Replace control panel board.

➁ Replace main logic board.

Page 64

– 61 –

TROUBLESHOOTING

4. Repair by Replacement of Parts

4-1. Does not Operate at All with Power on

DC Power abnormal.

Check RESET circuit;

replace parts.

Check crystal circuit;

replace parts.

1) Replace CPU or ROM.

2) Check relevant circuit.

NO

NO

NO

NO

See 4-2. Power Supply

Unit Abnormal.

START

+24V

and +5V are

supplied? *4

YES

RESET

signal becomes

HIGH? *6

YES

Crystal

waveform is

normal? *1

YES

ROM OE

signals become

LOW?

YES

Carriage motor abnormal.

Check operation.

END

Page 65

– 62 –

TROUBLESHOOTING

4-2. Power Supply Circuit Abnormal

(1) Remove connector CN5 (CN6 for Commodore type) of the main logic board.

YES

Replace Fuse F1

Fuse is

blown again?

NO

START

Fuse F1

is blown?

NO

Fuse F2 or F3

is blown?

NO

Check operation.

END

Replace

1) Transformer

2) IC1

YES

F3 is for AC120 only

YES

YES

YES

NO

Replace

Fuse F2 or F3

Fuse is

blown again?

NO

ACS1

and ACS2 are

supplied?

NO

Replace

transformer

The no load voltages are below:

ACS2 AC29.9V

ACS1 AC8.5V

Check or replace

1) D1~D4

2) IC1

NO

Check or replace

1) DB1

2) TR1, TR3

+5V line

is supplied?

YES

+24V line

is supplied?

YES

Page 66

– 63 –

TROUBLESHOOTING

4-3. Defective Motor Operation

NO

NO

NO

NO

START

START

LF-CMN

signal is normal?

*2

YES

LF-ø1,

ø2, ø3, ø4 are

normal? *2

YES

Replace

LF-motor

Check operation

END

Check or replace

1) TR1(TR202)

2) TR6(TR5)

3) CPU

Check or replace

1) TA1(TA201)

2) CPU

CR-CMN

signal is normal?

*1

YES

CR-ø1,

ø2, ø3, ø4 are

normal? *1

YES

Replace

CR-motor

Check operation

END

Check or replace

1) TR2(TR201)

2) TR7(TR4)

3) CPU

Check or replace

1) TA2(TA202)

2) CPU

( ): Ver. 1.5 and Ver. 2

( ): Ver. 1.5 and Ver. 2

( ): Ver. 1.5 and Ver. 2

( ): Ver. 1.5 and Ver. 2

Page 67

– 64 –

TROUBLESHOOTING

4-4. Defective Print Head Operation

Check or replace

1) TR8~TR16

(TR6~TR14)

Adjust gap

(Refer to chapter 3.)

Power supply

unit abnormal.

(Refer to item 4-2.)

Check or replace

1) Gate array

2) CPU

YES

YES

( ): Ver. 1.5 and Ver. 2

( ): Ver. 1.5 and Ver. 2

START

Does not

print at all?

YES

+24V

line is

supplied?

YES

Check or replace

1) TR4(TR1)

2) Gate array

Head

energizing control

signal is normal?

*3

YES

Check or replace

1) Print mechanism

END

NO

NO

NO

A specific

pin does not

work?

NO

Print is light

as whole?

NO

Page 68

– 65 –

TROUBLESHOOTING

4-5. Defective Interface Operation

NO

YES

START

Set at on line

Start print program

of host computer.

Is I/F

signal normal? *5

YES

Incorrect print

generated?

NO

Check operation

END

Check I/F cable.

Check or replace

1) IC2 (IC5)[IC1]

2) Gate array

3) CPU

( ) : Ver. 1.5 and Ver. 2

[ ] : Commodore type

Page 69

– 66 –

Page 70

CHAPTER 7

PARTS LIST (For Ver. 1 and Ver. 1.5)

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Part that have been added in the revised edition are indicated with “#”.

Part that have been abolished in the revised edition are indicated with “*”. For example,

#1 :First edition→Second edition *1 :First edition→Second edition

(3) PARTS NO.

Parts numbers must be indicated when ordering replacement parts.

(4) PARTS NAME

Parts names must be indicated when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

When there are differences in the specifications of the fuse, destinations, etc., the differences are described in

words or indicated by two letters.

US ..........U.S.A. EC ....... EC (220V) AS .............Australia

MAS .......Mass Merchant WG ...... Germany NBR..........No Brand

(NX MALTI TYPE) SC ........ Scandinavia SU .............Russia

TW .........Taiwan HK....... Hong Kong MONO......Monochrome

UE ..........EC (120V) UK ....... United Kingdom CL.............Color Type

The seal number of ROM is described in this column. The “**” mark of a seal number is variable depending

on the software version.

(7) RANK

Parts marked “S” are service parts. Service parts are recommendable for maintenance.

1. Pringer Assembly............................. 68

1-1. Disassembly Drawing....................68

1-2. Parts List......................................... 69

2. Printer Mechanism ............................. 71

2-1. Disassembly Drawing....................71

2-2. Parts List......................................... 72

3. Sub-Assembly .................................. 73

3-1. Upper Case Unit ............................. 73

3-2. Lower Case Unit.............................74

3-3. Frame Unit ...................................... 75

3-3-1. Monochrome Type ................ 75

3-3-2. Colour Type ........................... 76

3-4. Tractor Unit..................................... 78

3-5. Platen Unit ...................................... 79

4. Wiring Scheme of Printer ................ 80

4-1. Parallel Type................................... 80

4-2. Commodore Type .......................... 81

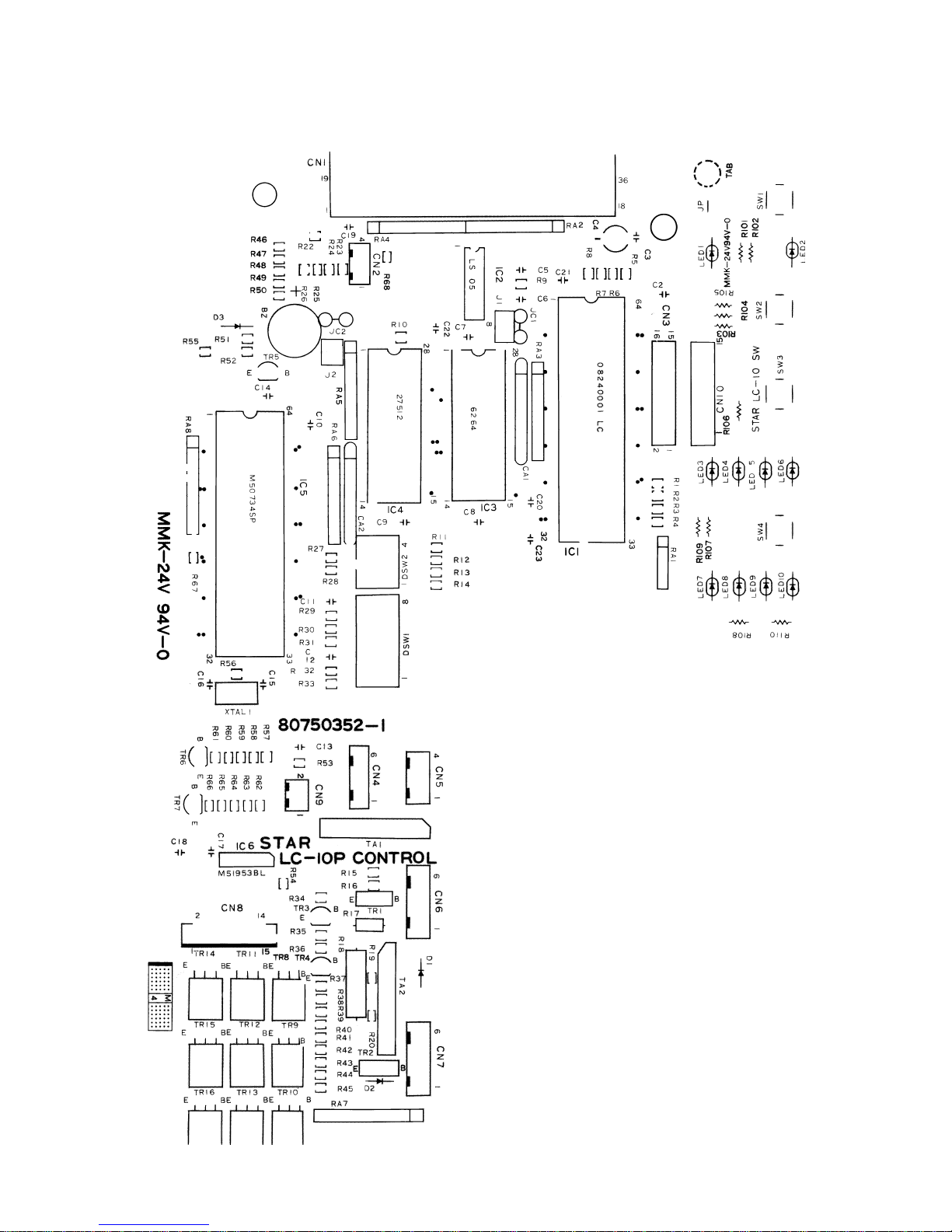

5. Main Logic Board ............................. 82

5-1. Parallel Type (Ver.1)....................... 82

5-1-1. Component Layout................ 82

5-1-2. Parts List ................................ 84

5-1-3. Circuit Diagram...................... 88

5-2. Parallel Type (Ver.1.5).................... 92

5-2-1. Component Layout................ 92

5-2-2. Parts List ................................ 94

5-2-3. Circuit Diagram...................... 98

5-3. Commodore Type ........................ 102

5-3-1. Component Layout.............. 102

5-3-2. Parts List .............................. 104

5-3-3. Circuit Diagram.................... 106

6. Power Supply Unit ......................... 110

6-1. Circuit Diagram ............................ 110

6-2. Component Layout ...................... 110

6-3. Parts List....................................... 111

7. Waveform with Oscilloscope ........ 112

1

2

3

4

5

6

7

8

A

Page 71

– 68 –

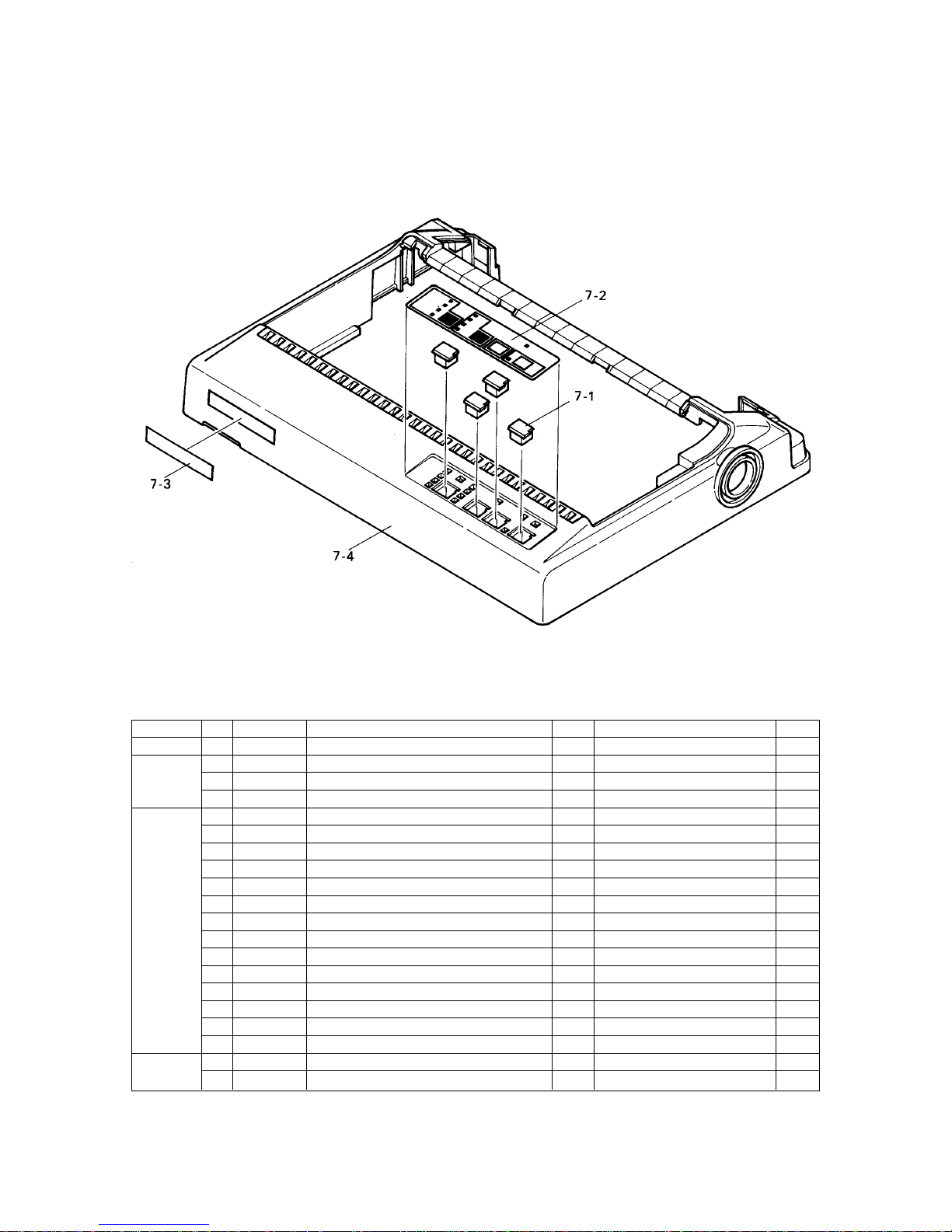

1. Printer Assembly (Ver. 1 and 1.5)

1-1. Disassembly Drawing

Page 72

– 69 –

1-2. Parts List Printer Assembly (Ver .1 and 1.5)

Printer Assembly (Ver. 1 and 1.5)

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK

1 89060010 PRINTER MECHANISM DP891 1 FOR MONO(VER.1.0) S

#2 89060050 PRINTER MECHANISM DP891D 1 FOR MONO(VER.1.5) S

#1 89060020 PRINTER MECHANISM DP891CL 1 FOR CL(VER.1.0) S

#2 89060060 PRINTER MECHANISM DP891DCL 1 FOR CL(VER.1.5) S

2 89130010 PRINT HEAD DP8901 1 S

3 87291010 LOWER CASE UNIT NX-1000 1 FOR VER.1.0 S

#2 87291050 LOWER CASE UNIT NX-1000D 1 FOR VER.1.5 S

4 87292010 MAIN LOGIC BOARD UNIT NX-1000 1 MONO(1.1),PARALLEL S

#2 87292090 MAIN LOGIC BOARD UNIT NX-1000D 1 MONO(1.5),PA. EX. HK S

#3 87292110 MAIN LOGIC BD UNIT NX-1000D HK 1 MONO(1.5),PA. FOR HK S

#1 87292030 MAIN LOGIC BOARD UNIT NX1000CL 1 CL(1.0),PARALLEL S

#2 87292100 MAIN LOGIC BD UNIT NX-1000DCL 1 CL(1.5),PA. EX. HK S

#3 87292140 MAIN LOGIC BD UNIT NX1000DCLHK 1 CL(1.5),PA. FOR HK S

87292020 MAIN LOGIC BOARD UNIT NX-1000C 1 FOR MONO,COMMODORE S

#1 87292040 MAIN LOGIC BD UNIT NX-1000C CL 1 FOR CL,COMMODORE S

5 87293060 POWER SUPPLY UNIT NX-1000 US 1 FOR US,UE,TW,MAS S

87293070 POWER SUPPLY UNIT NX-1000 EC 1 FOR EC,WG,NBR,SU S

87293100 POWER SUPPLY UNIT NX-1000 HK 1 FOR HK S

#2 87293180 POWER SUPPLY UNIT NX-1000 SC 1 FOR SC S

87293080 POWER SUPPLY UNIT NX-1000 UK 1 FOR UK S

87293090 POWER SUPPLY UNIT NX-1000 AS 1 FOR AS S

6 82040070 SUB-GUIDE 891 1 S

7 #2 87290160 UPPER CASE UNIT NX-1000 MAS 1 FOR MAS :NX-1000 S

87290010 UPPER CASE UNIT NX-1000 1 EXCEPT MAS :NX-1000 S

87290080 UPPER CASE UNIT LC-10NBR 1 FOR NBR :LC-10 S

87290030 UPPER CASE UNIT LC-10 1 EXCEPT FOR NBR:LC-10 S

87290020 UPPER CASE UNIT NX-1000C 1 :NX-1000C S

87290080 UPPER CASE UNIT LC-10NBR 1 FOR NBR :LC-10C S

87290040 UPPER CASE UNIT LC-10C 1 EXCEPT NBR :LC-10C S

#1 87290050 UPPER CASE UNIT NX-1000CL US 1 FOR US :NX-1000CL S

#2 87290170 UPPER CASE UNIT NX-1000CL MAS 1 FOR MAS :NX-1000CL S

#1 87290070 UPPER CASE UNIT NX-1000 CL 1 TW,HK,AS :NX-1000CL S

#4 87290390 UPPER CASE UNIT NX-1000CL SU 1 FOR SU :NX-1000CL S