Page 1

Dot Matrix Printer

DP8340R SERIES

[

SERIAL INTERFACE

USERS MANUAL

]

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

is equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. ese limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. is equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded cable.

is statement will be applied only for the printers marketed in U.S.A.

Statement of

e Canadian Department of Communications

Radio Interference Regulations

is Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

e above statement applies only to printers marketed in Canada.

Trademark acknowledgments

DP8340: Star Micronics Co. Ltd.

Notice

All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s

•

express permission is forbidden.

e contents of this manual are subject to change without notice.

•

All eorts have been made to ensure the accuracy of the contents of this manual at the time of going to

•

press. However, should any errors be detected, STAR would greatly appreciate being informed of them.

e above notwithstanding, STAR can assume no responsibility for any errors in this manual.

•

© Copyright 1986-2008 Star Micronics Co., Ltd.

Page 3

TABLE OF CONTENTS

1. OUTLINE ........................................................................................... 1

2. UNP

2-1. Unpacking ............................................................................................. 2

2-2. Installation of Paper Holders and Re-Roll

Prevention Guard ................................................................................ 3

2-4. Maintenance ......................................................................................... 5

3. PART IDENTIFICATION AND NOMENCLATURE ..................... 6

3-1. Power Supply Unit ............................................................................... 6

3-2. Printer ................................................................................................... 7

4. INSTALLATION OF INK RIBBON AND PAPER ..........................9

4-1. Installation of Ink Ribbon................................................................... 9

4-2. Removal of Ink Ribbon ..................................................................... 10

4-3-1. For Roll Paper ..............................................................................11

4-3-2. Roll Paper Installation

(When using the optional Printer Cover 8340R) ....................

4-4. Roll Paper Removal ........................................................................... 13

5. CONTROL CODES ......................................................................... 14

ACKING AND INSTALLATION ............................................. 2

2-3. Handling Notes .................................................................................... 4

3-3. Part Functional Description ............................................................... 8

4-3. Paper Insertion ................................................................................... 11

12

4-3-3. Validation Option Installation ...................................................13

6. GENER

NTERFACE FOR MODEL DP8340RM

7. I

MODULAR JACK CONNECTOR ......................................................... 19

7-1. Interface Specications ..................................................................... 19

7-2. Interface Circuit ................................................................................. 19

7-3. Setting of the DIP Switches .............................................................. 20

7-3-1. DIP-SW 1 ......................................................................................20

7-3-2. DIP-SW2 .......................................................................................20

7-4. Connectors and Signals..................................................................... 21

7-5. Interface Connections ....................................................................... 22

7-6. Peripheral Unit Drive Circuit ........................................................... 23

7-6-1. Cable Connection ........................................................................23

7-6-2. Peripheral Drive Circuit .............................................................24

AL SPECIFICATIONS ....................................................... 15

7-6-3. Control Codes ..............................................................................24

Page 4

8. INTERFACE FOR MODEL DP8340RD

DSUB 25 PIN CONNECTOR ..................................................... 25

8-1. Interface Specications ..................................................................... 25

8-2. Interface Circuit ................................................................................. 26

8-2-1. RS-232C ........................................................................................26

8-2-2. Current Loop ................................................................................26

8-3. Setting of the DIP Switches .............................................................. 27

8-3-1. DIP-SW 1 ......................................................................................27

8-3-2. DIP-SW 2 ......................................................................................27

8-4. Jumper Setting .................................................................................... 28

8-4-1. Removal of the Bottom Cover ...................................................28

8-4-2. Setting of Jumper .........................................................................28

8-5. Connectors and Signals..................................................................... 29

8-6. Interface Connections ....................................................................... 30

8-7. Peripheral Unit Drive Circuit ........................................................... 31

8-7-1. Cable Connection ........................................................................31

8-7-2. Peripheral Drive Circuit .............................................................32

8-7-3. Control Codes ..............................................................................32

9. DATA STRUCTURE AND CONTROL .......................................... 33

9-1. DTR Mode (1 BLOCK) ..................................................................... 33

9-2. X-ON/X-OFF Mode .......................................................................... 34

9-3. STX-ETX Mode ................................................................................. 36

10. CHARACTER CODE LIST ........................................................... 38

11. WHEN POWER IS SUPPLIED BY THE USER ........................... 41

Page 5

1. OUTLINE

DP8340 R M

Interface

Printer Type

D: D-sub 25 Pin Connector

( RS-232C / 20mA Current Loop )

M: Modular Jack Connector

( Only RS-232C )

R: R Type Printer

(3.25 inch paper)

e DP8340R series of serial dot matrix printers is for use in ECR, POS, electronic instruments, banking machines and computer peripheral equipment.

e DP8340R series include the following features;

1) 2 color printing (Red and Black)

2) High-speed bidirectional printing (2 line/sec, 29 or 44 columns per line)

3) 9-pin print head

4) The interface conforms to RS-232C in M type, and to RS-232C/20mA

Current Loop in D type.

5) Commands for expanded characters, inverted characters, emphasized

characters, red and black printing, and 10CPI or 15CPI characters etc. are

provided, which makes the printer very versatile.

6) Simultaneous Data Communication and Printing

7) Error Checking Protocol

8) Peripheral Driver

9) One line validation printing (Option)

Model Name Notation

– 1 –

Page 6

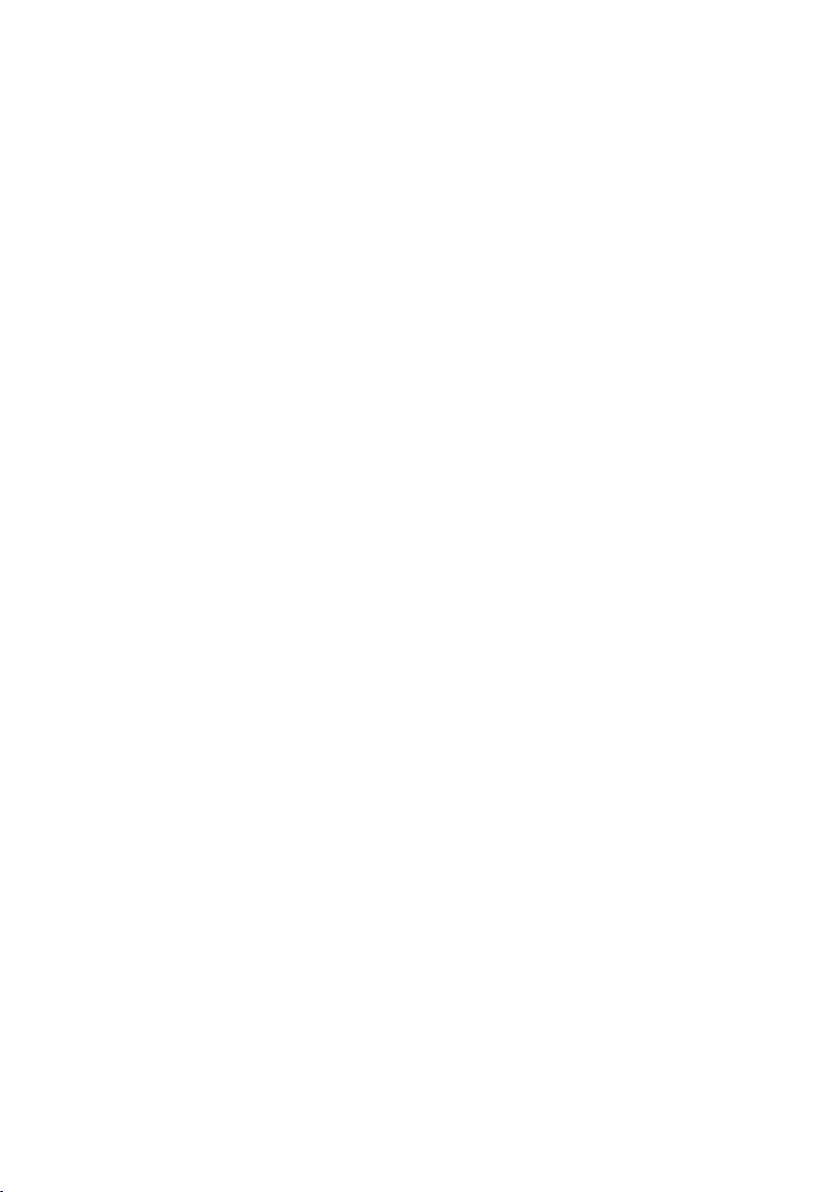

2. UNpackINg aNd INsTaLLaTION

1

2-1. Unpacking

Aer opening the box, check if all necessary accessories are included.

(A) Printer

Printer

1

User’s Manual

2

Paper Holders

3

4

5

6

(B) Power Supply Unit (Option: PS8340A)

Power Supply Unit

1

User’s Manual

2

Figure 2-1. Unpacking

– 2 –

Re-Roll Prevention Guard

Ink Ribbon

DIP Switch Cover

Page 7

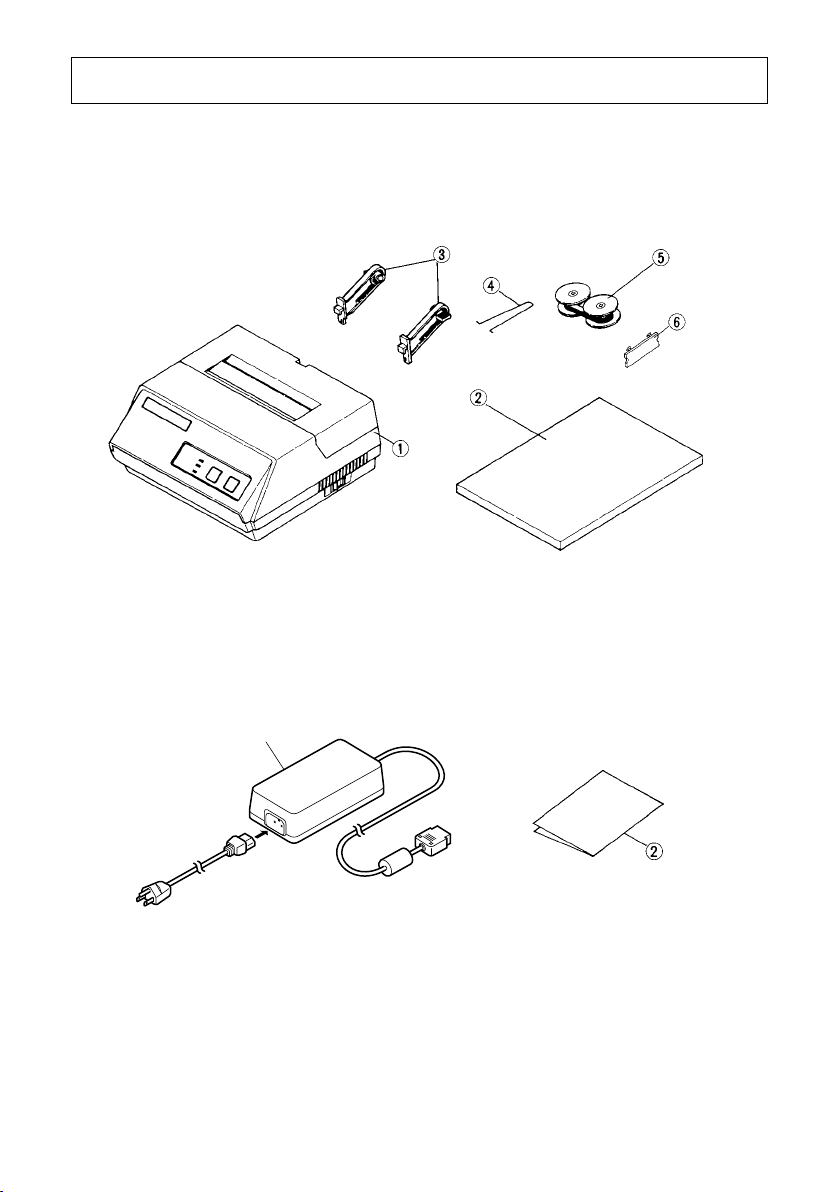

2-2.

Installation of Paper Holders and Re-Roll Prevention Guard

Install the Paper Holders in the intermost holes in the rear of the printer.

Figure 2-2. Installation of Paper Holders

Install the Re-Roll Prevention Wire in the holes of the printer cover. Twisting the

Wire as shown in the gure below, will make the installation easier.

Figure 2-3. Installation of Re-Roll Prevention

– 3 –

Page 8

2-3. Handling Care

1. Be careful not to drop paper clips, pins or other foreign matter into the unit

as these cause

2. Do not attempt to print when either paper or ribbon cartridge is not located

in the printer, otherwise the print head can be damaged.

Do not open the cover while printing.

3.

4. Do not touch the print head immediately aer printing as it gets very hot.

5. Use only roll paper that is not glued to the core.

6. When the paper end mark appears on the paper, replace the roll paper before

it runs out.

the printer to malfunction.

WARNING

P

Shut down your equipment immediately if it produces smoke, a strange

odor, or unusual noise. Immediately unplug the equipment and contact

your dealer for advice.

P

Never attempt to repair this product yourself. Improper repair work can be

dangerous.

P

Never disassemble or modify this product. Tampering with this product

may result in injury, re, or electric shock.

P

During and immediately aer printing, the area around the print head is

very hot. Do not touch it, as you could be burned.

CAUTION

P

We recommend that you unplug the printer from the power outlet

whenever you do not plan to use it for long periods. Because of this, you

should locate the printer so that the power outlet it is plugged into is

nearby and easy to access.

P

If the voltage shown on the label on the of your printer does not match the

voltage for your area, contact your dealer immediately.

P

Make sure that the printer is turned o and unplugged from the AC outlet

and that the computer is turned o before making connections.

P

Do not connect a telephone line into the modular connector.

P

Do not pull out paper while the printer cover is closed.

P

If liquids, foreign objects (coins and paper clips), and so on enter the

printer, turn o the printer, unplug it from the AC outlet, and contact your

dealer for advice. Continued use could cause a short circuit, which may

result in re or electric shock.

– 4 –

Page 9

2-4. Maintenance

Essentially, your printer is a robust piece of equipment, but should be treated

with a modicum of care in order to avoid malfunctions. For example:

Keep your printer in a “comfortable” environment. Roughly speaking, if you

1.

feel comfortable, then the environment is suitable for your printer.

Do not subject the printer to physical shocks or excessive vibration.

2.

3. Avoid over-dusty environments. Dust is the enemy of all precision

mechanical devices.

4.

To clean the exterior of the printer, use a cloth barely dampened with either

water with a little detergent or a little alcohol, but do not allow any liquid to

fall inside the printer.

5.

The interior of the printer may be cleaned with a small cleaner or a

compressed-air aerosol (sold for this purpose). When performing this

operation, be sure not to bend or damage any cable connections or electronic

components.

– 5 –

Page 10

3.

parT IdENTIfIcaTION aNd NOmENcLaTUrE

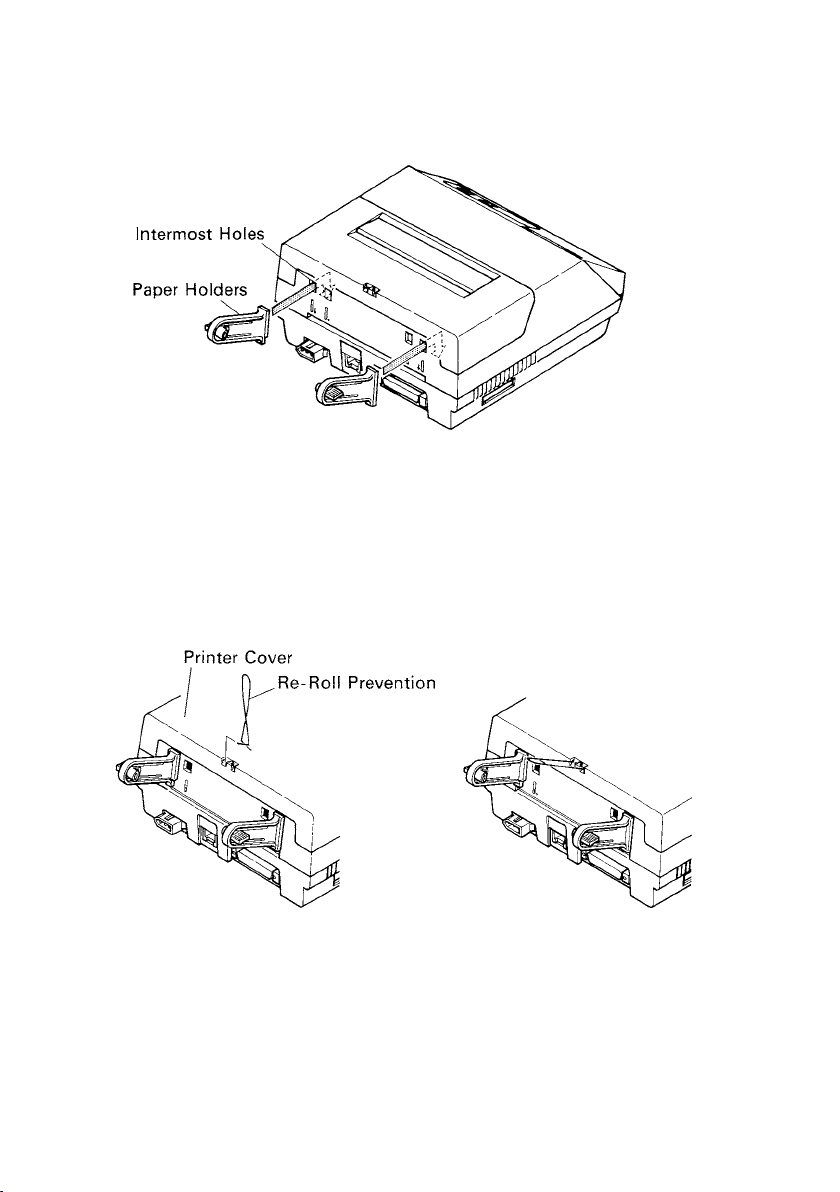

3-1. Power Supply Unit (Option)

Model name : PS8340A

Input : 100 to 240V AC, 50/60 Hz 6.0A

Output : DC12V 5% 2.0A

DC Power Connector (Output)

Shape of AC Power plug will

vary according to destinations.

Figure 3-1. Power Supply Unit

– 6 –

Page 11

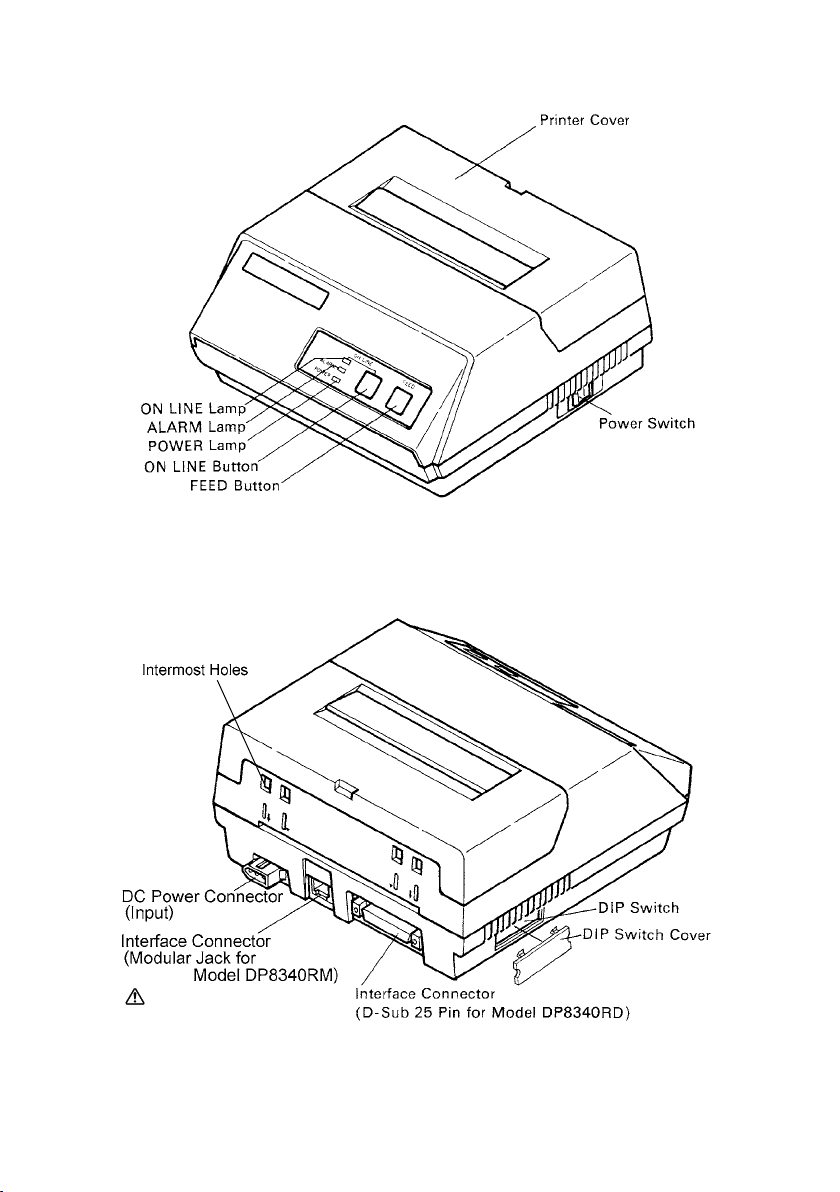

3-2. Printer

Figure 3-2. Printer: Front View

Do not connect this to a

telephone.

Figure 3-3. Printer: Rear View

– 7 –

Page 12

3-3. Part Functional Description

(1) AC Power Plug : Connect to an outlet of the specied voltage.

(2) DC Power Outlet : Supplies DC 12V power to the printer.

(3) Printer Cover : Protects the printer against dust and reduces noise.

(4) POWER Lamp : Lights up (green LED) when power is on.

(5) ON LINE Lamp : Lights up (green LED) when the unit is in the online

mode.

(6) AL

(7) ON LINE Button : Toggles between the on-line and off-line modes.

(8) FEED Button : Momentary operation of this button provides one

(9)

(10)

ARM Lamp : Lights up (red LED) when printer operation is not

normal, or the printer is out of paper. It is necessary

to install paper into the printer and press the ON

LINE Button to recover from paper empty status.

Turn o the printer power in order to recover from

abnormal operation.

e printer will go on-line aer turning power on.

line feed. Pressing this button continuously will

cause continuous paper feed. If power is turned on

while pressing this button, self printing*1 will be

performed.

Interface Connector : Connects the printer to host computers. Check that

both computer and printer are o before connect

ing.

DIP Switches : Allows for setting of various functions according to

user requirements.

-

*1 Self Printing is printer has another convenient function, the

Automatic Test Printing. With the ink ribbon and

paper properly installed in the printer, turn the pow

e

r ON while holding down the Feed switch. Test

printing will start and stop again automatically.

– 8 –

-

Page 13

4.

INsTaLLaTION Of INk rIbbON aNd papEr

4-1. Installation of Ink Ribbon

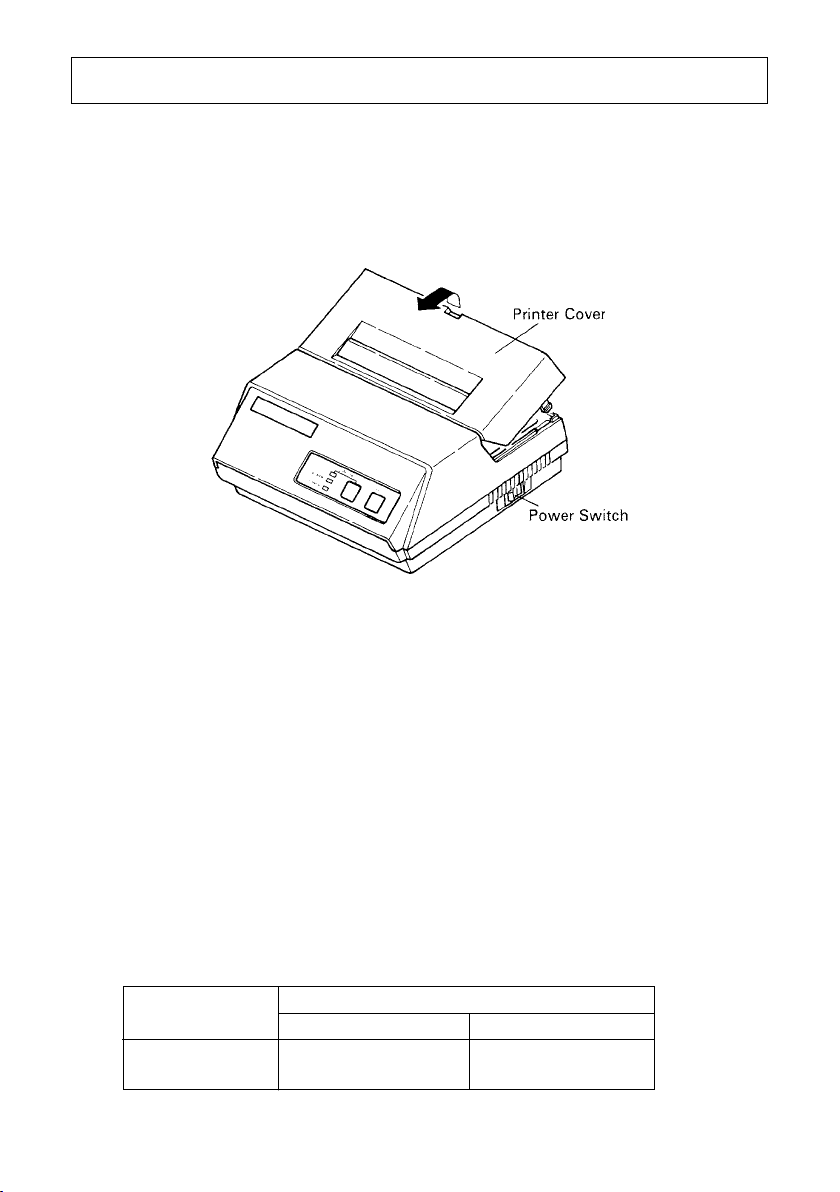

(1) Turn power o, li the Printer Cover up and remove it.

Note: Be careful not to touch the print head immediately after printing,

because it can get very hot.

Figure 4-1. Printer Cover Removal

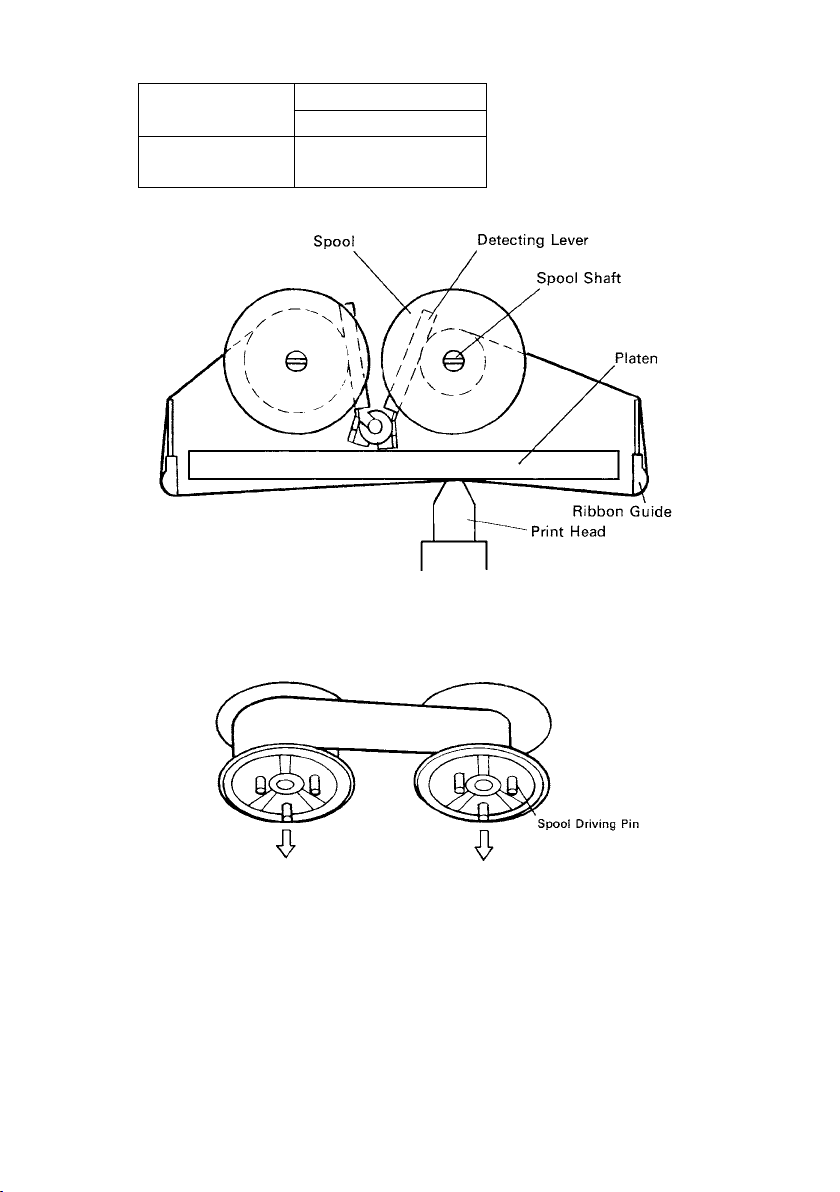

(2) Unwind ribbon so that the spools are separated as shown in Figure 4-3.

Hold the ribbon taut as shown with the drive pins facing down and slide the

ribbon between the print head and the platen. While keeping the ribbon

taut, wrap one side around the black ribbon guide on the end of the platen

and drop one spool on the spool sha. As you move the spool downwards,

move the detecting lever aside to allow the spool to drop into place. Make

sure the spool drive pins engage with the spool drive holes. As the spool

drops into place there will be a click.

(3) While continuing to hold the ribbon taut, install the remaining ribbon spool

in a similar fashion.

(4) Turn the spool that rotates freely to take up the ribbon slack.

R

ibbon Life

Description

SF-03BR

0.8 million characters 0.4 million characters

Ap

prox. Approx.

Black Red

Ribbon life

– 9 –

Page 14

Ribbon Life

Description

SF-03B

Ap

Ribbon life

Black

prox.

0.8 million characters

Figure 4-2. Installation of Ink Ribbon

Figure 4-3. Ribbon Spools

4-2. Removal of Ink Ribbon

Hold the spool and li gently, rotating it until the ribbon sags. Push the ribbon

detecting lever out, li the spool until it comes o the sha. Remove the second

spool in a similar manner.

(Do not apply excessive force when liing spools.)

– 10 –

Page 15

4-3. Paper Insertion

4-3-1. For Roll Paper

(1) Cut the Roll Paper end straight and square. Hold the roll so that the paper

comes from the bottom.

(2) Attach the Roll Paper to the Holders Paper by slipping one side of the roll

onto the Hub and pulling the other Hub out to allow the roll to slip in place.

(3) Insert the paper evenly into the Paper Insertion Slot.

(4) Turn the Power Switch “ON”, and press the FEED Button. e paper will be

fed into the unit.

Figure 4-4. Paper Insertion (1)

Figure 4-5. Paper Insertion (2)

– 11 –

Page 16

4-3-2.

Roll Paper Installation (When using the optional Printer Cover 8340R)

When installing roll paper with the optional “Ptinter Cover 8340R”, please use

the following procedure.

(1) Turn power o, li the Printer Cover up and remove it.

Note: Be careful not to touch the print head immediately after printing

because it can get very hot.

(2) Insert paper into the printer, and feed the paper so it extends 3 inches or

more above the top surface of the printer.

(3) Insert the paper into the slot in the “Printer Cover 8340R”.

(4) Install the “Printer Cover 8340R” on the printer.

Figure 4-6. Replace the Printer Cover

Figure 4-7. Printer Cover 8340R

– 12 –

Page 17

4-3-3. Validation Option Installation

e validation printing requires the optional printer cover 8340R. Refer to item

4-3-2 for the installation.

(1) Turn power ON.

(2) Enter the printer the validation mode.

(Refer to the control code “GS” in Chapter 5.)

(3) Insert the material to be validated against the right side of the slot in the

Printer Cover 8340R.

Figure 4-8. Insertion of Material to be validated

4-4. Roll Paper Removal

Cut the paper close to the slot and use the feed button until paper has passed

completely through the printer.

Note: Do not try to remove the paper by hand as it could become crooked and

get jammed inside the printer.

– 13 –

Page 18

5. cONTrOL cOdEs

Character Code List

Character Code Function

1 LF (0A)H Print and line feed instruction

2 CR (0D)H Print and line feed instruction

(same as LF)

3 SO (0E)H Expanded character instruction

4 DC4 (14)H Expanded character release

5 ESC-1 (1B)H (2D)H(01)H Underline instruction

(1B)H (2D)H (31)H

6 ESC-0 (1B)H (2D)H(00)H Underline release

(1B)H (2D)H (30)H

7 SI (0F)H Inverted print instruction

8 DC2 (12)H Inverted print release

9 ESC E (1B)H (45)H Emphasized print instruction

(o

10 ESC F (1B)H (46)H Emphasized print release

11 ESC 4 (1B)H (34)H Red character print instruction

12 ESC 5 (1B)H (35)H Red character print release

13 ESC a n (1B)H (61)H n n-line feed instruction

14 ESC C n (1B)H (43)H n Sets page length in lines

1 n 120 (default n = 42)

15 ESC N n (1B)H (4E)H n Set bottom margin in lines

16 ESC O (1B)H (4F)H Cancel Bottom margin

17 FF (0C)H Form feed

18 ESC @ (1B)H (40)H Printer initialization instruction

19 ESC BEL (1B)H (07)H Set peripheral unit drive pulse duration

1 n2

n

20 BEL (07)H Trigger peripheral unit drive (Deferred)

21 FS (1C)H Trigger peripheral unit drive

22 ENQ (05)H Enquiry

23 STX (02)H Start of text enter STX-ETX mode

24 ETX (03)H End of text end STX-ETX mode

25 CAN (18)H Clears print buer

26 ESC P (1B)H (50)H Select 10 CPI

27 ESC M (1B)H (4D)H Select 15 CPI (Default value)

28 GS (1D)H Validation printing instruction

n1 n2

ne-way printing)

n 120 (default n = 0)

0

1

1 n

127, 1 n2 127

1

efault n

(d

(Immediate)

= n2 = 20)

– 14 –

Page 19

6. gENEraL spEcIfIcaTIONs

Printing method : Serial impact dot matrix printing,

9 wires

Number of print columns : 29 columns (10CPI), 44 columns (15CPI)

Print speed : Approx. 2 lines/sec

Print direction : Bi-directional

Line spacing : 1/6 inch

Paper feed method : Friction Feed

Paper feed speed : Approx. 12 lines/sec

Character set : ASCII 96 characters

Special 64 characters

Block graphics* 64 characters

Font conguration : 10CPI Ordinary characters 5

Block graphics* 6 ×

15CPI Ordinary characters 7 ×

Block graphics* 5 ×

* Graphic Feed Not Available

Character size : 10CPI 2.00 (H) ×

15CPI 1.32 (H) ×

Character spacing : 10CPI 2.55 mm (1/10 inch)

15CPI 1.70 mm (1/15 inch)

Dot spacing : 10CPI H=0.425 mm V=0.353 mm

15CPI H=0.340 mm V=0.353 mm

Gross dot : 10CPI 174 dots/wire/line

15CPI 220 dots/wire/line

Print area : 10CPI 73.53 mm

15CPI 74.46 mm

Print Buer : Approx. 1.5 KB

Peripheral drive : 1 output (1A max. at 12V)

Serial Interface :

Model DP8340-RM Only RS-232C

Model DP8340-RD RS-232C/20mA Current Loop

External dimensions :

(Printer) 202(W)

(without paper holder, DC Power Connector)

(Power supply unit) 54(W) ×

Weight :

(Printer) Approx. 1.9 kg

(Power supply unit) Approx. 0.3 kg (without AC cable)

200(D) × 98(H) mm

×

114(D) × 36(H) mm (without AC cable)

2.42 (V) mm

2.42 (V) mm

9 dots

×

6 dots

9 half dots

6 dots

– 15 –

Page 20

Power supply unit :

Four supplies available with following ratings

Input Output

C 100 to 240 V DC 12.0 V ± 5%

50/60 H

A

z

0.6 A

2.0 A

Paper specication :

Paper type Ordinary and carbonless copy paper

Size Paper width 82.55

Roll diameter 80 mm outer diameter (Max)

ickness (single) 0.07 mm (52.3 g/m

±

0.5mm (3.25 inches)

2

) to 0.09 mm (64g/m2)

(2 copy) One copy and one original (max 0.13 mm)

Paper end Paper should not be attached to the core

One line validation Check (Refer to Fig. 6-2)

Paper width 70 to 90 mm

ickness 0.1 to 0.15 mm

* Requires the optional Printer Cover 8340R

Ink ribbon specication :

olor Black and red / Black only

C

Ribbon material Nylon (#40 denier)

Ribbon size 13mm × 6m

S

pool 13mm (width), 35mm in diameter (two spool)

Recommended ribbon SF-03BR (Black and red), SF-03B (Black)

Operating conditions : Temperature +5˚C to +40˚C

Humidity 10% to 80%RH

Storage conditions : Temperature –20˚C to +70˚C

Humidity 5% to 95%RH (+40˚C)

Head life : 70 million characters

Printer reliability : 5.0 million lines MCBF (except head life)

– 16 –

Page 21

Figure 6-1. Roll Paper and Print Area

Figure 6-2. Material to be validated and One Line Validation Printing

– 17 –

Page 22

Figure 6-3. External Dimensions (Printer)

114 mm 2.0 m36 mm

54 mm

Shape of AC Power plug will

vary according to destinations.

Figure 6-4. External Dimensions (Power Supply Unit)

– 18 –

Page 23

7. INTErfacE fOr mOdEL dp8340rm

(

mOdULar Jack cONNEcTOr

7-1. Interface Specications

(1) Synchronization system : Asynchronous

(2) Baud rate : 150, 300, 600, 1200, 2400, 4800, 9600 bps

(Selectable)

(3) Word length :

Start bit: 1 bit

Data bit: 7 or 8 bits (Selectable)

Parity bit: Odd, Even, or None (Selectable)

Stop bit: 1 or 2 bit length (Selectable)

(4) Signal polarity :

RS-232C MARK : Logic “1” (–3V to –25V)

SPACE : Logic “0” (+3V to +25V)

(5) Handshaking :

1 DTR Mode (1 block)

2 X-ON/X-OFF Mode

3 STX-ETX Mode

Note: STX-ETX Mode may use DTR or X-ON/X-OFF, selected by DIP SW 1-5.

See Chapter 9. for details.

)

7-2. Interface Circuit

Input (RXD, CTS)

Output (DTR, FAULT, TXD, RTS)

Figure 7-1. RS-232C Interface

– 19 –

Page 24

7-3. Setting of the DIP Switches

7-3-1. DIP-SW 1

Switch O

1-1 O

1-2 Data transfer rate — see below (*1) ON

1-3 O

1-4 Stop bit 1 Stop bit 2 ON

1-5 DTR MODE (1 BLOCK) X-ON/X-OFF MODE ON

1-6 8 data bits 7 data bits ON

1-7 No parity Parity checked ON

1-8 Odd parity Even parity ON

N OFF

Factory

setting

N

N

(*1)

Baud rate SW1-1 SW1-2 SW1-3

150 OFF OFF OFF

300 OFF OFF ON

600 OFF ON OFF

1200 OFF ON ON

2400 ON OFF OFF

4800 ON OFF ON

9600 ON ON ON/OFF

(*2) DIP Switch 2-3 should

be set to ON when you

use a 2-color ribbon for

2-color printing.

It should be set to OFF

when a m onochrome

ribbon is used.

7-3-2. DIP-SW2

actory

Switch ON

nternational character set :

I

U

.S.A

Always ON ON

2-1

2-2

2-3(*2) 2-color Ribbon Monochrome Ribbon ON

2-4 CR Invalid CR Valid ON

OFF

s

FRANCE

Note: DIP switches are only read by the

controller at power turn on.

DIP switch changes should be

made with power off, or after

changing switch setting, turn the

power o and on again.

F

etting

ON

– 20 –

Figure 7-2. Setting of DIP Switch

Page 25

7-4. Connectors and Signals

Signal

Pin No.

Name

1

2 GND — Frame Ground

3 TXD

(Return channel)

4 RXD IN is pin carries data to the printer.

5 RTS OUT is is SPACE when the printer power is ON.

6

(Refer to Error Condition Alarm Mode *1.)

7 GND — Signal ground.

8 DTR OUT

GND — Shield Ground

FAULT OUT

Direction

is pin carries data from the printer.

OUT

is is MARK when the printer is abnormal.

r there is a paper error.

O

is printer turns this pin SPACE when

t is ready to receive data.

i

Function

Figure 7-3. Modular Jack Connector

*1 Error Condition Alarm Mode

If an error condition is detected during operation, the printer will stop

printing and cause the FAULT signal to go MARK. All solenoides &

motors will be de-energized. It is necessary to turn the printer power

o and on again in order to recover from the alarm mode.

is printer can detect the following error coditions:

a. Motor Lock

b. Defective timing detector

c. Micro-proccessor out of program sequence

– 21 –

Page 26

7-5. Interface Connections

For interface connections, refer to the instructions for interface of the host computer. e following gives basic examples.

Figure 7-4. Interface Connections using Modular/D-Sub 25 Adapter to IBM PC

(Use with straight through cable wiring)

Before selecting interface cable wiring, it is necessary to know the wiring of the

modular interconnect cable. Figure 7-5. below shows the way to determine if the

cable is straight connected, or cross connected. Cross connected wiring is not

suitable for shielded cable.

Figure 7-5.

– 22 –

Page 27

Figure 7-6. Wiring of cable for direct connection between DP8340

and IBM PC serial part

7-6. Peripheral Unit Drive Circuit

e Control Board of this unit is equipped with a circuit for driving a peripheral

unit (Paper Cutter, Take-Up Device, Cash Drawer, etc.)

e Control Board Connector (CN3) is used to connect the Peripheral Unit to the

Drive Circuit. When using this circuit connect the peripheral unit cable to the CN3

Connector (cable is not included). Use a cable with the following specications:

Note: Do not run cable near devices generating large amounts of electrical noise.

Figure 7-7. Cable Specications

7-6-1. Cable Connection

Remove the printer Bottom Cover and connect the cable to the CN3 Connector.

Pass the cable around the control board as shown and through grommetted hole

in bottom cover. (Grommet may have to be cut)

– 23 –

Page 28

Figure 7-8. Cable Connection

+12V

CN3 Connector

D1

TR

2A

1 OU TPUT(+)

2 OU TPUT(

-

)

3 S- GND

7-6-2. Peripheral Drive Circuit

Absolute Ratings (Ta = 25˚C)

D1 Voltage Breakdown 400V

Output

Drive

12V

, MAX. 1A

Forward Current 1A

Figure 7-9. Drive Circuit

Caution: Do not use external power supply with peripheral drive circuit.

To drive them continuously, set the duty cycle ratio to 20% or less.

7-6-3. Control Codes

Codes for Drive Circuit control are ESC BEL n1 n2, BEL and FS. Refer to the

Control Codes in Chapter 5.

– 24 –

Page 29

8. INTErfacE fOr mOdEL dp8340rd

(

d-sUb 25 pIN cONNEcTOr

8-1. Interface Specications

(1) Synchronization system : Asynchronous

(2) Baud rate : 150, 300, 600, 1200, 2400, 4800, 9600 bps

(S

(3) World length :

Start bit: 1 bit

Data bit: 7 or 8 bits (Selectable)

Parity bit: Odd, Even, or None (Selectable)

Stop bit: 1 or 2 bit length (Selectable)

(4) Signal polarity :

RS-232C MARK : Logic “1” (–3V to –25V)

SPACE : Logic “0” (+3V to +25V)

Current Loop MARK : Logic “1” (Current ON)

SPACE : Logic “0” (Current OFF)

electable)

)

Start bit

1

Data bits

2

Parity bit

3

Stop bit

4

(5) Handshaking :

1 DTR Mode (1 block)

2 X-ON/X-OFF Mode

3 STX-ETX Mode

Note: STX-ETX Mode may use DTR or X-ON/X-OFF, selected by DIP SW 1-5.

See Chapter 9. for details.

– 25 –

Page 30

8-2. Interface Circuit

8-2-1. RS-232C

Input (RXD, CTS)

Output (DTR, FAULT, TXD, RCH, RTS)

Figure 8-1. RS232-C Interface

8-2-2. Current Loop

Input (TTY-RXD, TTY-RXDR)

Output (TTY-TXD, TTY-TXDR)

Note: Resistance should be set so that Current Loop is restricted to the range of

10 ~ 20 mA.

Figure 8-2. Current Loop Interface

– 26 –

Page 31

8-3. Setting of the DIP Switches

8-3-1. DIP-SW 1

Switch O

1-1 O

1-2 Data transfer rate — see below (*1) ON

1-3 O

1-4 Stop bit 1 Stop bit 2 ON

1-5 DTR MODE (1 BLOCK) X-ON/X-OFF MODE ON

1-6 8 data bits 7 data bits ON

1-7 No parity Parity checked ON

1-8 Odd parity Even parity ON

N OFF

Factory

setting

N

N

(*1)

Baud rate SW1-1 SW1-2 SW1-3

150 OFF OFF OFF

300 OFF OFF ON

600 OFF ON OFF

1200 OFF ON ON

2400 ON OFF OFF

4800 ON OFF ON

9600 ON ON ON/OFF

(*2) DIP Switch 2-3 should

be set to ON when you

use a 2-color ribbon for

2-color printing.

It should be set to OFF

when a monochrome

ribbon is used.

8-3-2. DIP-SW 2

F

Switch ON

nternational character set :

I

U

.S.A

Always ON ON

2-1

2-2

2-3(*2) 2-color Ribbon Monochrome Ribbon ON

2-4 CR Invalid CR Valid ON

OFF

s

FRANCE

Note: DIP switches are only read by the

controller at power turn on.

DIP switch changes should be

made with power off, or after

changing switch setting, turn the

power o and on again.

actory

etting

ON

– 27 –

Figure 8-3. Setting of DIP Switch

Page 32

8-4. Jumper Setting

e serial interface is set to the RS-232C mode upon shipment from the factory.

When using in the 20mA current loop mode, it is necessary to set the jumpers.

e jumpers built into the Control Board allow for setting of functions shown in

the table. However, the Bottom Cover must be removed to perform this setting.

For setting the Jumper, disconnect the power source beforehand.

8-4-1. Removal of the Bottom Cover

Figure 8-4. Removal of the Bottom Cover

8-4-2. Setting of Jumper

Jumper

No.

OPEN RS-232C

J3

SHORT Current Loop

A-C

J7

B-C

Setting F

Selection of Current Loop Output

(between TTY-T XD and T T YTXDR) Signal Polarity (inversion

possible) Consult STAR MICRONI

CS for details.

unction

– 28 –

F

actory

Setting

Page 33

8-5. Connectors and Signals

Signal Direction

Pin No.

1 GND — Frame Ground

2 TXD

3

4 RTS OUT is is SPACE when the printer power is ON.

5

6 DSR IN

7 GND — Signal ground.

8 N/C Unused.

9 T

10 T

11

12 N/C Unused.

13 GND — Signal ground.

14

15 ~ 16 N/C Unused.

17 T

18 T

19 T

20

21 ~ 22 N/C Unused.

23 T

24 T

25 T

Name

is pin carries data from the printer.

OUT

RXD IN is pin carries data to the printer.

CTS IN

TY TXDR —

TY TXD OUT

RCH OUT

FAULT OUT

TY TXDR —

TY RXDR —

TY RXD IN

DTR OUT

TY RXDR —

TY TXD OUT

TY RXD IN

(R

eturn channel)

is pin is SPACE when the computer is ready to send

data. e printer does not check this pin.

is pin is SPACE when the computer is ready to send

data. e printer does not check this pin.

is pin is the return path for data transmitted from

the printer on the 20mA current loop.

is pin carries data from the printer on the 20mA

current loop.

is pin is SPACE when the printer is ready to receive

data. is line carries the same signal as pin 20.

is is MARK when the printer is abnormal. (Refer to

Error Condition Alarm Mode *1.) Or there is a paper

error.

is pin is the return path for data transmitted from

the printer on the 20mA current loop.

is pin is the return path for data transmitted to the

printer on the 20mA current loop.

is pin carries data to the printer on the 20mA cur-

rent loop.

is printer turns this pin SPACE when it is ready to

receive data.

is pin is the return path for data transmitted to the

printer on the 20mA current loop.

is pin carries data from the printer on the 20mA

current loop.

is pin carries data to the printer on the 20mA cur-

rent loop.

Function

– 29 –

Page 34

Figure 8-5. D-Sub 25 Pin Connector

*1 Error Condition Alarm Mode

If an error condition is detected during operation, the printer will stop printing

and cause the FAULT signal to go MARK. All solenoides & motors will be deenergized. It is necessary to turn the printer power o and on again in order to

recover from the alarm mode.

is printer can detect the following error coditions:

a. Motor Lock

b. Defective timing detector

c. Micro-proccessor out of program sequence

8-6. Interface Connections

For interface connections, refer to the instructions for interface of the host computer. e following gives one basic example of connections.

Figure 8-6. Interface Connections

with D-Sub 25 Pin Connector to IBM PC

– 30 –

Page 35

8-7. Peripheral Unit Drive Circuit

e Control Board of this unit is equipped with a circuit for driving a peripheral

unit (Paper Cutter, Take-Up Device, Cash Drawer, etc.)

e Control Board Connector (CN3) is used to connect the Peripheral Unit to the

Drive Circuit. When using this circuit connect the peripheral unit cable to the CN3

Connector (cable is not included). Use a cable with the following specications:

Note: Do not run cable near devices generating large amounts of electrical

noise.

Figure 8-7. Cable Specications

8-7-1. Cable Connection

Remove the printer Bottom Cover and connect the cable to the CN3 Connector.

Pass the cable around the control board as shown and through grommetted hole

in bottom cover. (Grommet may have to be cut)

– 31 –

Page 36

+12V

CN3 Connecto r

D1

TR

2A

1 OUTPUT(+ )

2 OUTPUT(

-

)

3 S-GND

Figure 8-8. Cable Connection

8-7-2. Peripheral Drive Circuit

D1

Caution: Do not use external power supply with peripheral drive circuit.

To drive a peripheral unit continuously, set the duty cycle to 20% or

8-7-3. Control Codes

Codes for Drive Circuit control are ESC BEL n1 n2, BEL and FS. Refer to the

Control Codes in Chapter 5.

Absolute Ratings (Ta = 25˚C)

V

oltage Breakdown 400V

P

eak Forward Current 1A

less.

Figure 8-9. Drive Circuit

– 32 –

Output

Drive

12V

, MAX. 1A

Page 37

9. daTa sTrUcTUrE aNd cONTrOL

9-1. DTR Mode (1 BLOCK)

Controls Data Transfer by using DTR line as BUSY FLAG

(a)

(b)

In case of Paper Empty

Paper Empty

When the paper out detector indicates end of paper, the printer stops printing aer

a maximum of two lines of printing or paper feed. e printer goes OFF LINE and

sets the DTR to “MARK” status immediately aer occurrence of a paper empty. It

is necessary to install paper into the printer and press the ON LINE BUTTON to

light the ON LINE LAMP in order to recover from paper empty status.

Machine Error

A machine error may be generated by paper jamming or when the printer is unable

to print data. When a machine error occurs the printer stops printing. e printer

goes OFF LINE and sets the DTR to “MARK” status immediately aer the occur-

ence of Machine Error. It is necessary to turn the printer power o and on again

r

in order to recover from Machine Error.

– 33 –

Page 38

9-2. X-ON/X-OFF Mode

e printer transmits an X-ON (Control Code; DC1, Hexadecimal Value; 11H,)

signal aer power is turned on, if there is no printer error being generated. When

this signal is received by the host computer, the host computer transmits the data

to the printer. e X-ON signal is output intermittently every three seconds until

the host computer receives and responds to this signal.

e X-OFF (DC3, 13H) signal outputting begins when the amount of empty space

in the buer becomes less than 256 bytes. When the computer receives the X-OFF

signal, it will halt data transmission as soon as it can. However even at this time

the printer can receive data until the buer is completely full. An X-ON signal is

output when the contents of the buer goes below 256 bytes. e increase of the

empty area in the buer is caused by printing. If the computer causes a buer over

ow, a ag bit in the status register will be set. (See Status)

e X-OFF signal will continue to be output at a 3-second interval until the data

buer becomes near empty (less than 256 bytes).

– 34 –

Page 39

Paper Empty

When the paper out detector indicates end of paper, the printer stops printing

aer a maximum of two lines of printing or paper feed. e host computer can

receive the printer status by transmitting an ENQ code to the printer. e printer

goes OFF LINE and sets the DTR to “MARK” status in 5 seconds aer occur-

ence of a paper empty. It is necessary to install paper into the printer and press

r

the ON LINE BUTTON to light the ON LINE LAMP in order to recover from

paper empty status.

Machine Error

A machine error may be generated by paper jamming or when the printer is unable to print data. When a machine error occurs the printer stops printing. In the

X-ON/X-OFF mode, the printer outputs an X-OFF signal immediately. At this

time the host computer can receive the printer status aer transmitting an ENQ

code to printer. e printer goes OFF LINE and sets the DTR to “MARK” status

within 5 seconds aer the occurrence of Machine Error. It is necessary to turn

the printer power o and on again in order to recover from Machine Error.

STATUS

Parity

In DTR mode and X-ON/X-OFF mode parity check is done on vertical parity

only.

Framing Error

Framing Error occurs when SPACE signal is detected at STOP Bit time. Framing

error and vertical parity error will be indicated by printing “?”.

– 35 –

Page 40

9-3. STX-ETX Mode

e start of the STX-ETX mode should occur with a totally empty print buer.

is can be achieved by sending an ENQ code to the printer and checking the

status until the status code indicates an empty buer. At that point, the STX code

is sent by the host computer followed by a data block. While receiving the data

block, the printer generates a horizontal parity check character. Aer the data

block is sent, the host computer sends an ENQ which causes the printer to return

2 characters, one would be the normal status character, and the second would be

the horizontal parity check character that was generated by the printer while the

data block was received.

e host computer checks the status character to determine if any vertical par

i

ty errors or other errors occurred during block transmission, and checks the

horizontal parity character against a character generated in the host computer

while the data was transmitted. If there are no errors, ETX causes the buer to

be printed, but if an error is detected, CAN code clears the buer and the data is

transmitted again. Any control codes transmitted to the printer during the STXETX mode will be ignored as control codes, but will be included in the check

character. is is done to prevent a control code received in error from causing

printing of erroneous data.

STATUS

-

Parity

Vertical and horizontal parity check is executed in STX-ETX mode.

Framing Error

Framing Error occurs when SPACE signal is detected at STOP Bit time. Framing

error or even vertical parity error will be indicated by printing “?”.

– 36 –

Page 41

STX-ETX Mode Flow Diagram

– 37 –

Page 42

10. characTEr cOdE LIsT

– 38 –

Page 43

– 39 –

Page 44

International Character Sets

– 40 –

Page 45

11. WhEN pOWEr Is sUppLIEd by ThE UsEr

+12V

GND

GND

Note : The optional AC adapter (PS8340A) has been designed specically for

this unit(DP8340).

Other AC adapters may not meet the EMC technical standards.

When printer power is supplied by the user rather than through the accessory

power source unit, please be careful of the following points.

Note 1: An electrolytic capacitor (C = 4700µF/25V to 6800µF/25V) must be

connected across the output of the power supply. Use a power supply

of DC 12 V ± 5% and more than 2.0 A with SELV output and LPS or Class

2 (double-insulation structure) output approved by IEC60950.

Note 2: A DC power plug is available as an option.

Note 3: Be careful about installing the printer in an area where there is noise.

Take the appropriate measures to protect against electrostatic AC line

noise, etc.

– 41 –

Page 46

SPECIAL PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinya, Shimizu-ku, Shizuoka,

424-0066 Japan

Tel: (int+81)-54-347-0112

Fax: (int+81)-54-347-0409

Please access the following URL

http://www.star-m.jp/eng/dl/dl02.htm

for the latest revision of the manual.

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

1150 King Georges Post Road, Edison, NJ 08837-3729 U.S.A.

Tel: (int+1)-732-623-5500, Fax: (int+1)-732-623-5590

STAR MICRONICS EUROPE LTD.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks, HP13 7DL, U.K.

Tel: (int+44)-1494-471111, Fax: (int+44)-1494-473333

STAR MICRONICS ASIA LTD.

Rm. 1901-5, 19/F., Enterprise Square Two,

3 Sheung Yuet Road, Kowloon Bay, Hong Kong

Tel : (int+852)-2796-2727, Fax : (int+852)-2799-9344

Printed in Japan, 80870186

2008.07.18

Loading...

Loading...