Page 1

Delta User’s Manual

1

:

i’

THE PDWER BEHINDTHE PRINTED WORD.

_ _ __

NOT INTENDED FOR SALE

Page 2

Federal Communications Commission

Radio Frequency Interference Statement

This equipment generates and uses radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause

interference to radio and television reception. It has been type tested and found to comply

with the limits for a Class B computing device in accordance with the specifications in

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

l Reorient the receiving antenna

l Relocate the computer with respect to the receiver

l Move the computer away from the receiver

l Plug the computer into a different outlet so that computer and receiver are on

different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may find the following booklet prepared by the

Federal Communications Commission helpful: “How to Identify and Resolve Radio-TV

Interference Problems.” This booklet is available from the U.S. Government Printing

Office, Washington, D.C., 20402, Stock No. 004~080-00345-4.

A note about the programs in this manual:

This manual contains several programs that help to demonstrate the versatility of the

Delta printers. Star Micronics has made every effort to insure that the programs are functional and accurate. However, Star Micronics cannot guarantee their accuracy or suitabil-

ity to any particular application.

Trademark Acknowledgement

Delta-lo, Delta-18 grafstar, UniversaUAtari Parallel Interface, Universal/Commodore

Parallel Interface: Star Micronics

Apple, Apple II, Apple II + , Apple IIe, Applesoft: Apple Computer Inc.

Atari 400, Atari 800, Atari 850: Atari Inc., a Warner Communications Company

Commodore, VIC-20, C-84: Commodore Business Machines, Inc.

Compaq: Compaq Computer Corporation

CPIM: Digital Research

EasyWriter: Information Unlimited Software, Inc.

IBM Personal Computer, IBM PC, IBM XT: International Business Machines Corp.

Kaypm: Kaypro Computer Corporation

Microsoft BASIC: Microsoft Corporation

Osborne 1: Osborne Computer Corporation

SuperCalc: Sorcim Corporation

TRS-80: Radio Shack, a division of Tandy Corporation

WordStar: MicroPro International Corporation

- -

@Copyright 1983 Star Micronics, Inc.

Page 3

c.

i

i.

L

L-

to the New Owner

‘L

Your new Delta printer and this manual are both setting new

A Special Message

c

standards for the computer printer industry - and you’re part of

it! Congratulations, and welcome aboard!

First, about this manual. It’s another first in our industry the first to be truly written not just for the person who does his

own programming, but for the first-time user or anyone else who

prefers to leave the programming to others, and simply inserts his

store-bought programs (software) into his computer/printer system. Someone very much like you, perhaps . . .

You’ll find using this manual easy and pleasant. We’ve gone to

great lengths to make it so, as it’s master-minded by solid experts

in the arcane art of computer science, and written by equally proficient practitioners in the art of Plain English!

Page 4

iv

Delta User’s Manual

As a first example, look over the Table of Contents and you’ll

see what we mean, Whether you’re a greenhorn or a wizard, everybody will find what they need to know to fulfill their expectations. We suggest that each new owner/user, before you even

unpack the box, read or at least scan Chapters 1 and 2 - “A Closer

Look” and “Getting Started with Delta” - as well as Appendix A,

“Unpacking and Installation.”

Now you can unpack the box and

start putting things together.

When you’re ready to connect up your computer to your

Delta, look at Appendices B through G for directions applying to

your make of computer. Remember, Delta has both serial and parallel interfaces, so there’s nothing extra to buy!

Which leads naturally to a few words of praise for some other

special features that make the new Delta so satisfactory to own.

Features like the high speed leOcharacter per second printout,

the capability to design your own characters, do your own plotting, your own infinite variety of dot graphics patterns and densities. You’ll have a ball! For you, Chapters 3 through 8 are a must,

and of course everybody should look at Chapter 10 which tells

how to maintain your Delta for a long and carefree life.

We’ll end this as we began, with congratulations for your wise

buying, and a most cordial welcome to the wonderful world of

Delta printing. . . fast, clean and beautiful!

‘-

Page 5

Table of Contents

i

L..

i.

L

i.

L.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

A Closer Look

Components and Controls

Paper Selection and Loading

Loading single sheets

Loading roll paper

Loading sprocket-feed paper

Bottom feeding Delta-15

Ribbon Installation

Adjusting the Gap

Self-Test

Getting Started With Delta

Using Commercial Software

First, some terminology

Using Delta with SuperCalc

Using Delta with word processors

Using this book without learning BASIC

Some Basics about BASIC

Establishing communications

The CHR$ function

Control codes

The escape code

Some problem codes

Printing Text With Delta

Changing the print pitch

Expanded print

Making Delta print darker

Some Special Kinds of Text

Italic printing

Underlining

Superscripts and subscripts

Mixing modes

Summary

Line Spacing and Forms Control

Starting New Lines

1

17

29

43

Page 6

vi

Chapter 5

Chapter 6

Chapter 7

Delta User’s Manual -

Changing Line Spacing

Moving down the page without a

carriage return

Forms Controls

Form feed

Changing the Page Length

Top and Bottom Margins

Summary

Formatting Your Output

A one-shot tab command

Setting Left and Right Margins

Using Vertical Tabs

A one-shot vertical tab command

Summary

Special Features of the Delta Printer

Now hear this

Initializing Delta

Putting Delta to sleep

Printing to the bottom of the sheet

Unidirectional printing

Backspace and delete

The seven bit dilemma

Block graphics characters and

special symbols

International character sets

The macro control code

Summary

Creating Your Own Characters

Dot Matrix Printing

The Print Matrix

Defining Your Own Characters

Rule 1: Download characters are seven

dots high

Rule 2: Dots cannot overlap

Add up each column of dots

Assigning a value to your character

Download character definition

command

Printing Download Characters

Proportional Characters

Defining proportional characters

Printing proportional characters

Connecting characters

55 .--

- -

61

73

-

Page 7

. .

c-.

‘se-

Table of Contents

vii

Mixing Print Modes with Download

Characters

A Utility Program

Summary

Chapter 6

Printing With Dot Graphics

99

Comparing dot graphics with download

characters

Using the Dot Graphics Commands

Specifying the number of columns of

dots

Specifying the graphics data

Combining text and graphics

Printing a Design or Logo

Plotting with Delta

How the program works

Using Delta for business graphics

High Resolution Graphics

If You Have Problems wi:h BASIC

Summary

Chapter 9

Chapter 10

Getting It All Together

Maintenance

119

123

Cleaning Delta

Removing the Upper Case

Replacing a Fuse

Replacing the Print Head

Appendix A

Setting Up Delta

131

Where shall we put it?

What have we here?

Removing the shipping screws

Removing the packing from inside the printer

Installing the platen knob

Removing the tractor unit

Attaching the paper separator and paper

guide

Installing the ribbon

‘L-

Installing the printer cover

Connecting Delta to your computer

L..

Appendix B

IBM Personal Computer and Compaq

139

Recommended DIP switch settings for

IBM-PC

BASIC programming

I.

-.

Page 8

9..

Vlll

Delta User’s Manual

Listing programs

Program listings

Appendix C

Apple II Computers

Setting the switches

Applesoft BASIC

Listing programs

Program listings

Chart program

Special character chart program

Macro program

Bridge hand program

Numeral program

Download utility program

Delta plot program

Pie chart program

Appendix D TRS-60 Computers

Recommended DIP switch settings for

TRSSO

TRSSO BASIC

Chart program

Special character chart program

Macro program

Bridge hand program

Numeral program

Download utility program

Delta plot program

Pie chart program

Appendix E Osborne, Kaypro and CP/M Computers

Setting the switches

Using MBASIC

Program listings

Chart program

Special character chart program

Macro program

Bridge hand program

Numeral program

Download utility program

Delta plot program

Pie chart program

Appendix F

Atari 400/800 Computers

Setting the switches

Using Atari BASIC

Listing programs

143 _

- -

161 .-.

177

193

Page 9

Table of Contents

Program listings

Chart program

Special character chart program

Macro program

Bridge hand program

Numeral program

Download utility program

Delta plot program

Pie chart program

Appendix G Commodore VIC-20 and C-64 Computers

Setting the switches

Using Commodore BASIC

Listing programs

Program listings

Chart program

Special character chart program

Macro program

Bridge hand program

Numeral program

Download utility program

Delta plot program

Pie chart program

Appendix H DIP Switch Settings

Switch Functions

Appendix I ASCII Codes

Appendix J Character Style Charts

Appendix K Function Code Reference

Commands to Control Print

Style

Font style controls

Font pitch controls

Special print modes

Commands to Control Vertical Position of Print

Head

Line feed controls

Form feed controls

Vertical tabs

Commands to Control Horizontal Position of

Print Head

Download Character Commands

Commands to Control Graphics

Macro Instruction Commands

Other Commands

ix

211

227

233

239

251

Page 10

X

Delta User’s Manual

Appendix L

Appendix M

Command Summary in Numeric Order

ASCII Code Conversion Chart

Appendix N Technical Specifications

Appendix 0 The Parallel Interface

Functions of the Connector Signals

Appendix P Serial Interface Specifications

Configuring the Serial Interface

Delta’s Serial Protocols

Serial busy protocols

XONlXOFF protocol

ACK protocol

Index

Consumer Response

DIP Switch Quick Reference

Warranty

Command Quick Reference

279

283

291

293

297

303

309

311

Inside back cover

Inside back cover

Page 11

Table of Tables

Table 3-1

Table 3-2

Table 3-3

Table 3-4

Table 3-5

Table 3-6

Table 4-l

Table 4-2

Table 4-3

Table 5-1

Table 6-1

Table 6-2

Table 6-3

Table 6-4

Table 6-5

Table 6-6

Table 6-7

Table 7-l

Table 7-2

Table 7-3

Table 8-l

Table 8-2

Table B-l

Table H-l

Table H-2

Table O-l

Table P-l

Table P-2

Table P-3

Table P-4

Print pitch commands

Expanded print commands

Print emphasis commands

Italic commands

Underline commands

Superscript and subscript commands

Line spacing commands

Form length commands

Top and bottom margin commands

Left and right margin commands

Bell commands

Some miscellaneous commands

Printing direction

Eighth bit controls

International character set commands

International character sets

Macro instruction commands

Download character definition commands

Download character printing commands

Mixing download characters with various

print modes

Calculating nl and n2 for graphics

Dot graphics commands

IBM serial switch settings

DIP switch settings

International character sets

Delta parallel interface

Serial interface pin functions

DIP switch 3

Handshaking protocols

Data transfer rates

30

32

33

34

35

36

46

49

50

57

62

63

64

66

68

69

69

88

91

95

101

115

141

228

231

295

298

298

300

300

Page 12

xii

Delta User’s Manual

Page 13

.-

1.

i.

i.

N.

.

i

i

\..

‘L.

_.

L,

*I-

i.

Chapter I

A Closer Look

._

In this chapter, we’ll introduce you to your Delta printer. We’ll

cover:

l Components and controls

l Paper selection and loading

l Adjusting the gap-for different paper thickness

l Self-test-print-out of available characters

Components and Controls

First, the components. You saw most of these when you

unpacked your printer. Now we’ll give you a brief explanation of

Page 14

2

Delta User’s Manual

what they do. (For directions on how to set up Delta, see Appen-

dix A.)

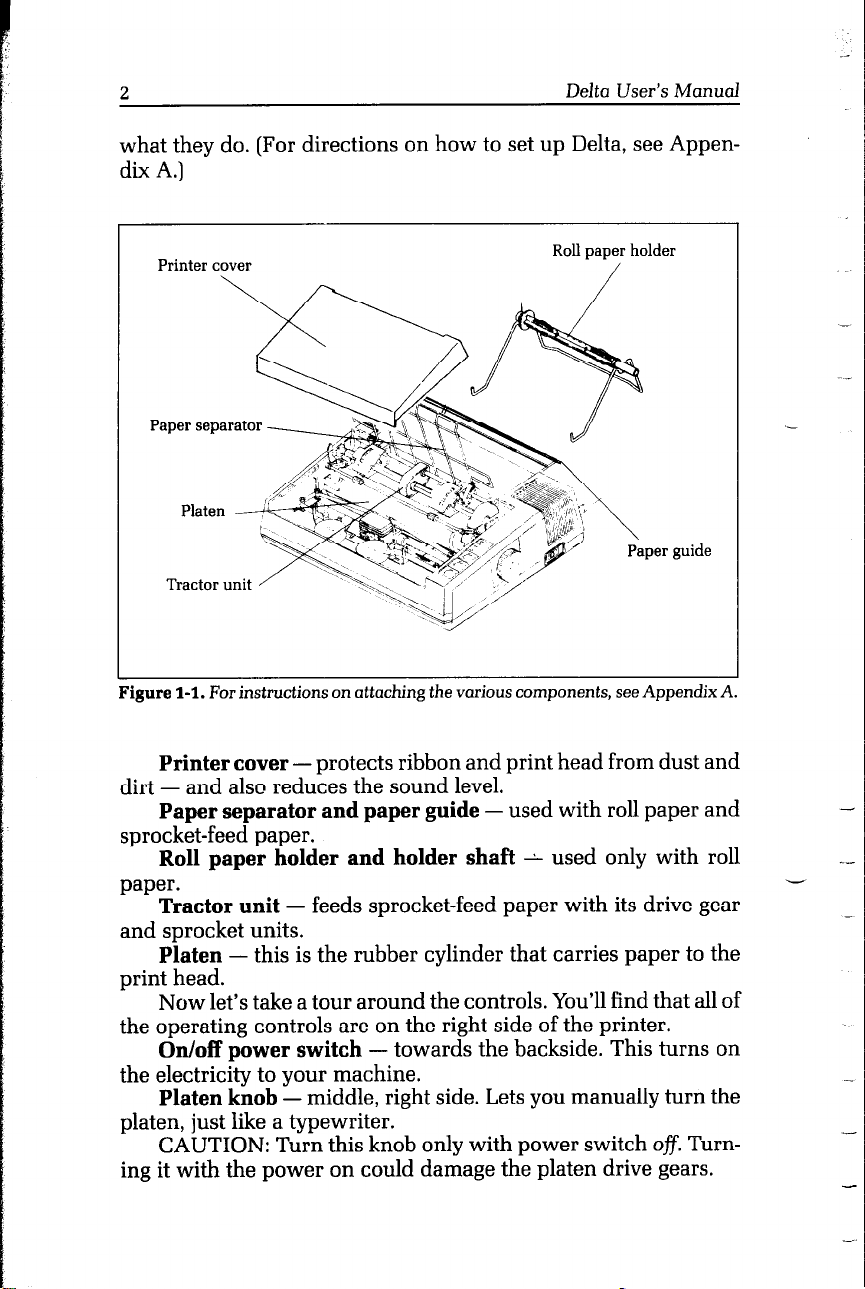

Printer cover

‘igure l-l. For instructions on attaching the various components, see Appendix A.

Roll paper holder

/

guide

Printer cover - protects ribbon and print head from dust and

dirt - and also reduces the sound level.

Paper separator and paper guide - used with roll paper and

sprocket-feed paper.

Roll paper holder and holder shaft - used only with roll

paper.

Tractor unit - feeds sprocket-feed paper with its drive gear

and sprocket units.

Platen - this is the rubber cylinder that carries paper to the

print head.

Now let’s take a tour around the controls. You’ll find that all of

the operating controls are on the right side of the printer.

On/off power switch - towards the backside. This turns on

the electricity to your machine.

Platen knob - middle, right side. Lets you manually turn the

platen, just like a typewriter.

CAUTION: Turn this knob only with power switch ofi. Turn-

ing it with the power on could damage the platen drive gears.

-

--

-

-.

Page 15

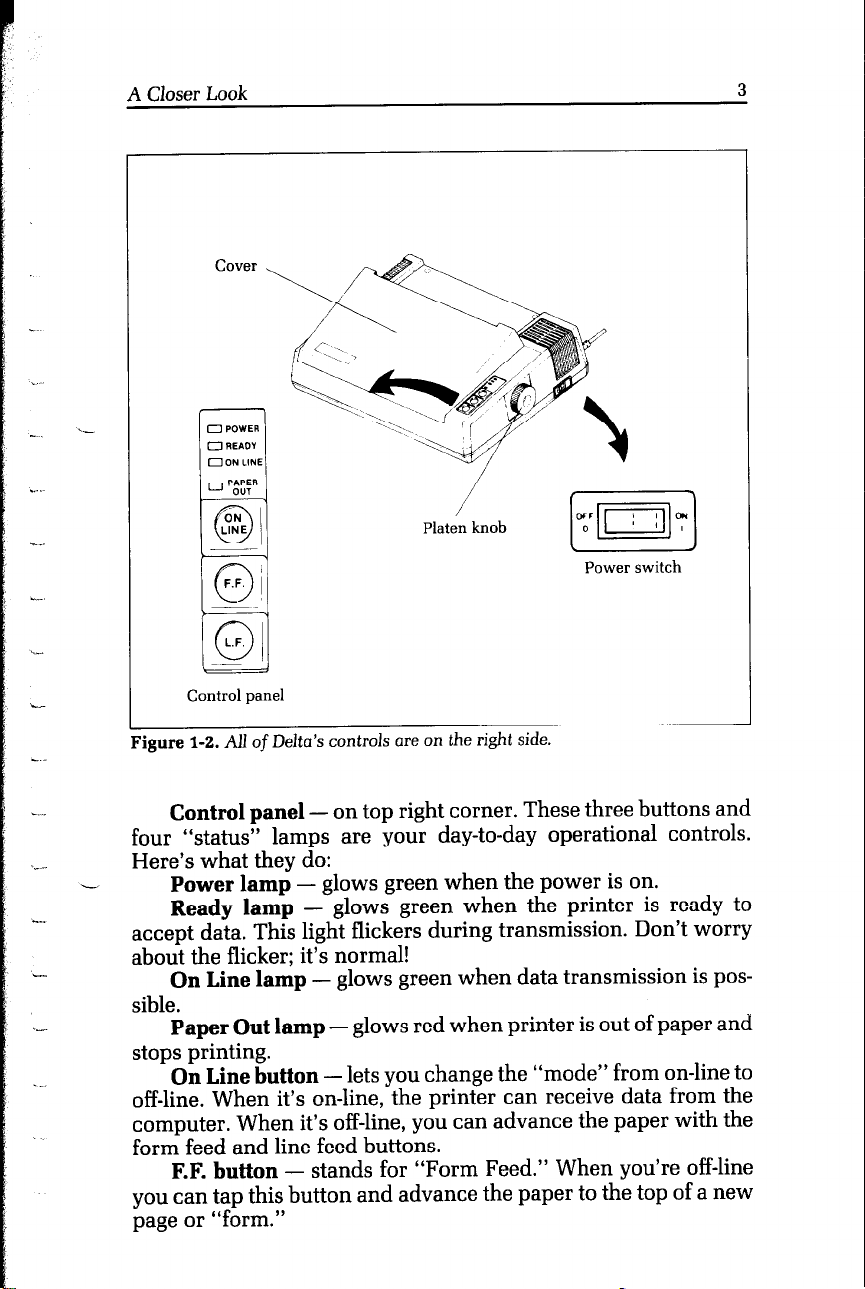

Cover ,

_~

.-

I-

-

_. .~

*_.

Platen knob

[ml

Power switch

..-

i_-

i_-

h...

.

Control panel

‘igure 1-2. All of Delta’s controls are on the right side.

Control panel - on top right corner. These three buttons and

four “status” lamps are your day-to-day operational controls.

II-

Here’s what they do:

Power lamp - glows green when the power is on.

--.

Ready lamp - glows green when the printer is ready to

accept data. This light flickers during transmission. Don’t worry

about the flicker; it’s normal!

On Line lamp - glows green when data transmission is possible.

.-

Paper Out lamp - glows red when printer is out of paper and

stops printing.

. -.

On Line button - lets you change the “mode” from on-line to

off-line. When it’s on-line, the printer can receive data from the

computer. When it’s off-line, you can advance the paper with the

form feed and line feed buttons.

F.F. button - stands for “Form Feed.” When you’re off-line

you can tap this button and advance the paper to the top of a new

page or “form.”

Page 16

4 Delta User’s Manual

L.F. button - stands for “Line Feed.” When you’re off-line this

allows you to advance the paper one line at a time. If you hold the

button down, you’ll get multiple line feeds, one after the other.

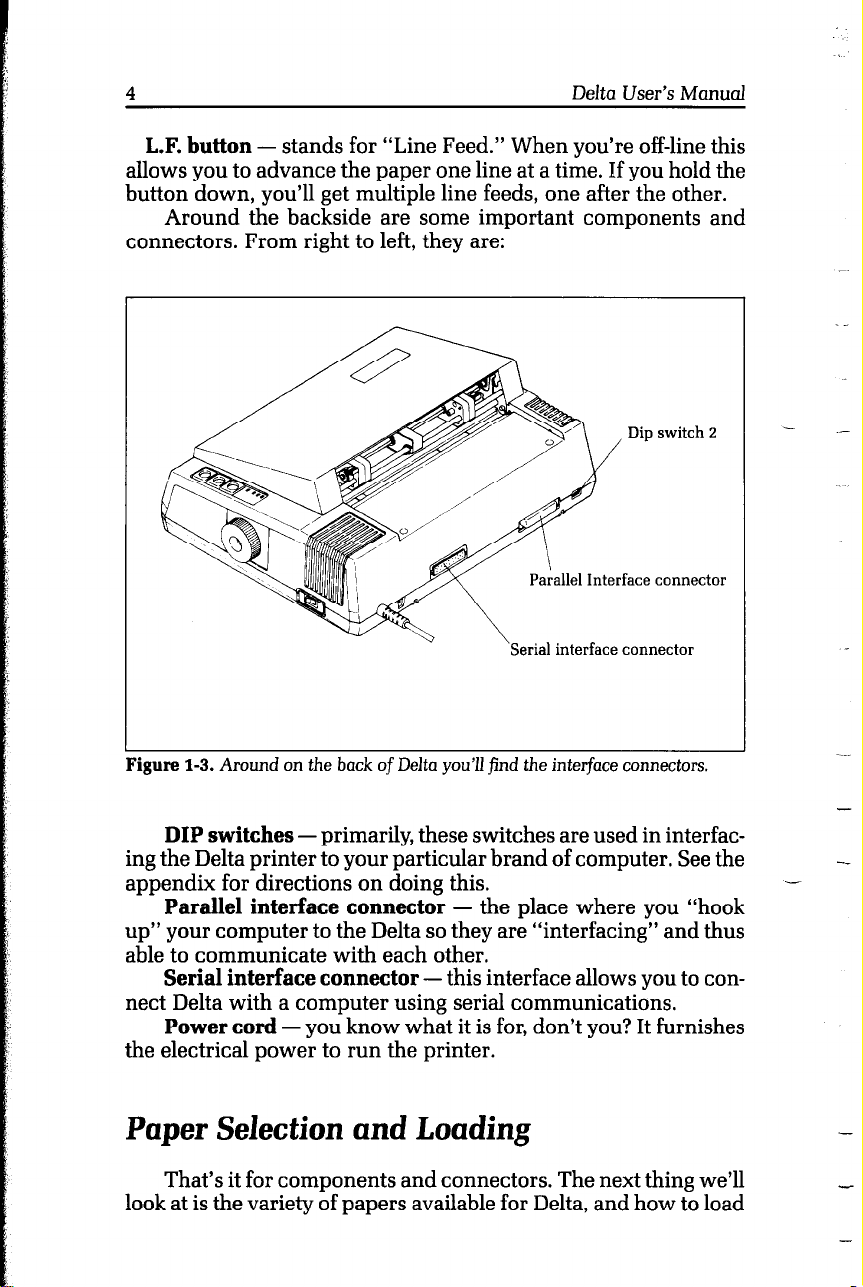

Around the backside are some important components and

connectors. From right to left, they are:

.-

Figure 1-3. Around on the back of Delta you’ll find the interface connectors.

DIP switches - primarily, these switches are used in interfacing the Delta printer to your particular brand of computer. See the

appendix for directions on doing this.

Parallel interface connector - the place where you “hook

up” your computer to the Delta so they are “interfacing” and thus

able to communicate with each other.

Serial interface connector - this interface allows you to con-

nect Delta with a computer using serial communications.

Power cord - you know what it is for, don’t you? It furnishes

the electrical power to run the printer.

Paper Selection and Loading

That’s it for components and connectors. The next thing we’ll

look at is the variety of papers available for Delta, and how to load

-

-_

1

-

-

Page 17

A Closer Look

them, ready to print. For starters, Delta can handle single sheetswhether standard-size stationery, envelopes, multi-part carbonless business forms, or almost any other kind of individual sheets.

You can also print on continuous paper-either in rolls or fanfolded perforated paper.

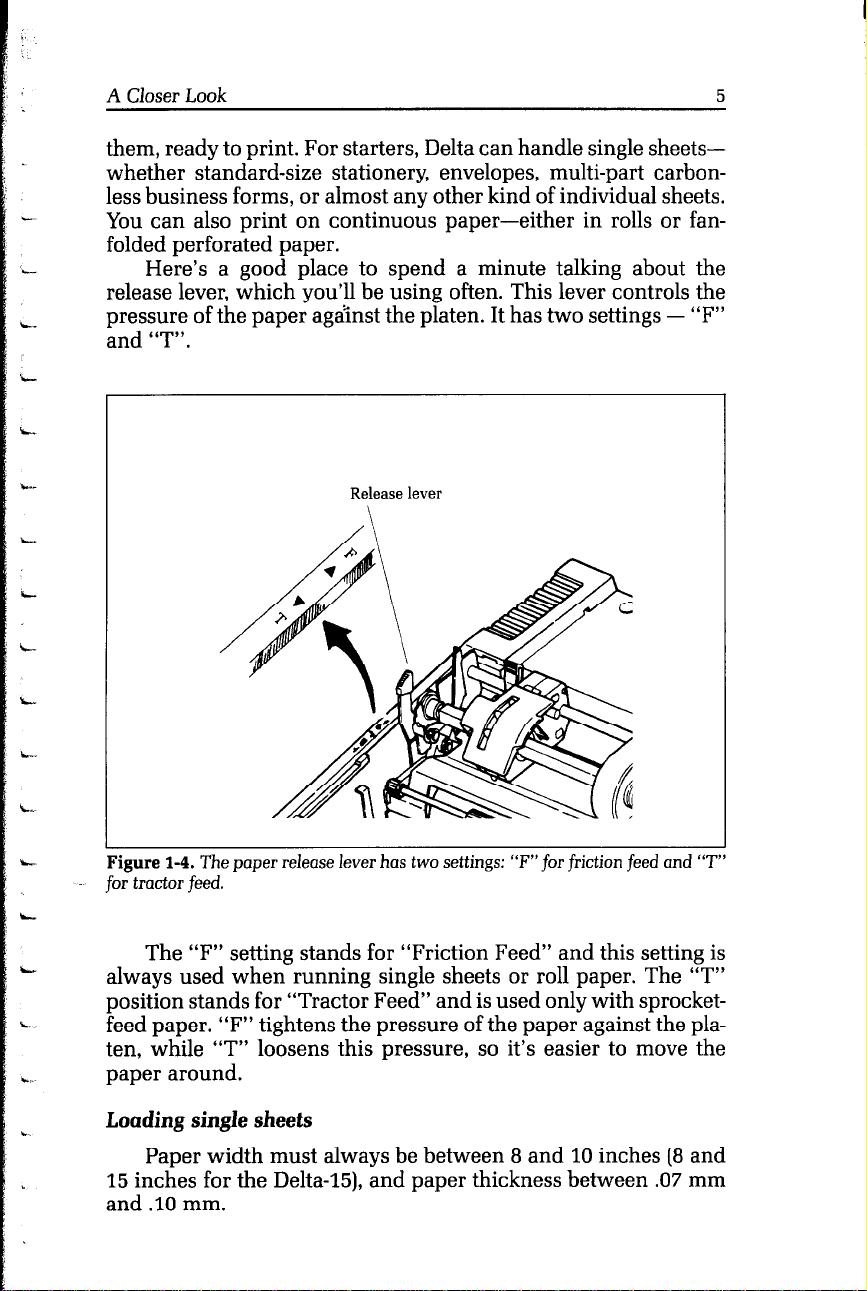

Here’s a good place to spend a minute talking about the

release lever, which you’ll be using often. This lever controls the

pressure of the paper against the platen. It has two settings - “F”

and “T”.

Release lever

\

5

Figure 1-4. The paper release lever has two settings: “F”for friction feed and “T

for tractor feed.

The “F” setting stands for “Friction Feed” and this setting is

always used when running single sheets or roll paper. The “T”

position stands for “Tractor Feed” and is used only with sprocketfeed paper. “F” tightens the pressure of the paper against the platen, while “T” loosens this pressure, so it’s easier to move the

paper around.

Loading single sheets

Paper width must always be between 8 and 10 inches (8 and

15 inches for the Delta-15), and paper thickness between .O7 mm

and .lO mm.

Page 18

6

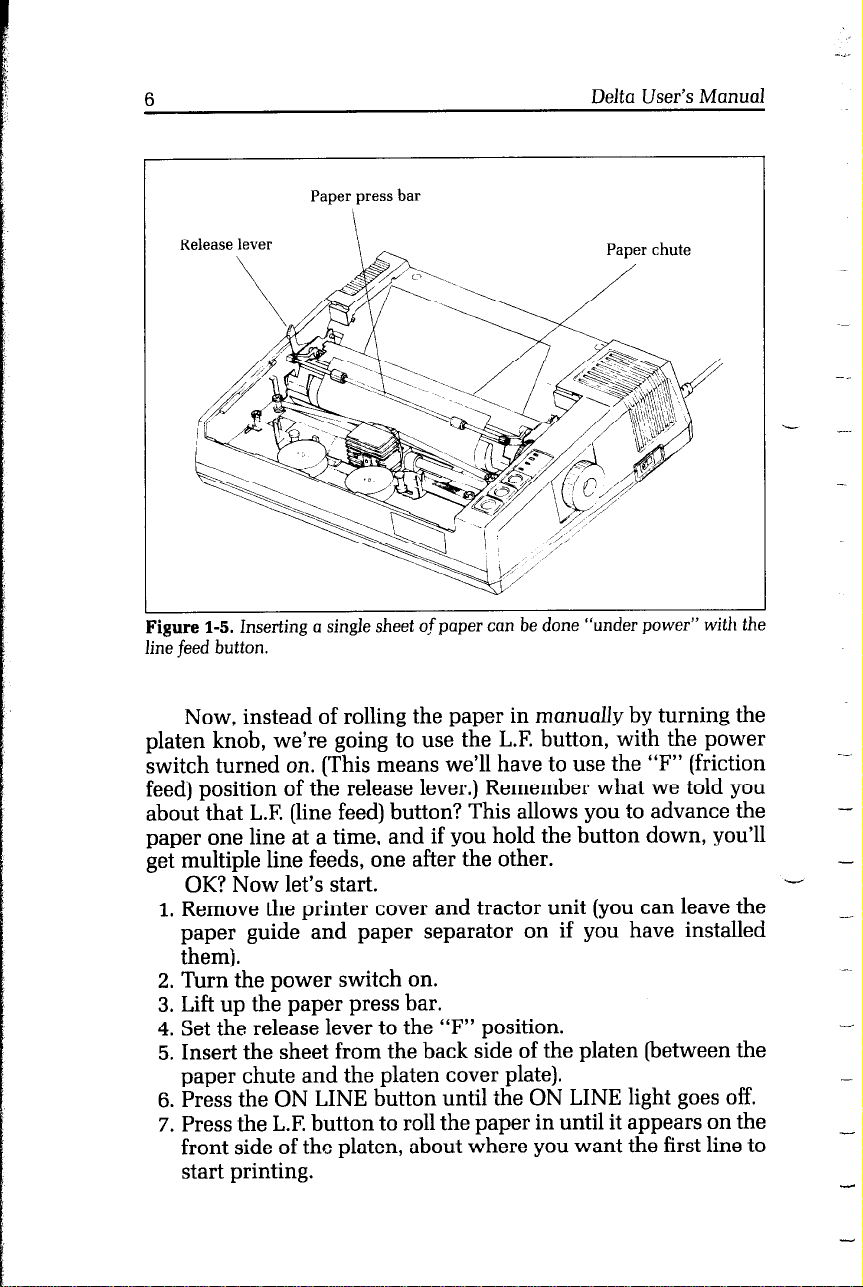

Paper press bar

\

Release lever

‘igure l-5. Inserting a single sheet ofpaper can be done “under power” with the

ne feed button.

Delta User’s Manual

‘- __

Now, instead of rolling the paper in manually by turning the

platen knob, we’re going to use the L.F. button, with the power

switch turned on. (This means we’ll have to use the “F” (friction

feed) position of the release lever.) Remember what we told you

about that L.F. (line feed) button? This allows you to advance the

paper one line at a time, and if you hold the button down, you’ll

get multiple line feeds, one after the other.

OK? Now let’s start.

1. Remove the printer cover and tractor unit (you can leave the

paper guide and paper separator on if you have installed

them).

2. Turn the power switch on.

3. Lift up the paper press bar.

4. Set the release lever to the “F” position.

5. Insert the sheet from the back side of the platen (between the

paper chute and the platen cover plate).

6. Press the ON LINE button until the ON LINE light goes off.

7. Press the L.F. button to roll the paper in until it appears on the

front side of the platen, about where you want the first line to

start printing.

--

-

-

_

__

-

_

Page 19

A Closer Look

NOTE: To straighten paper (if it’s in crooked):

l Move the release lever to “T” position.

l Position the sheet where you want it, moving right or left if

necessary to get the paper located between the margins of

the printing area.

l Move release lever back to “F” position.

8. Push the paper press bar back to its original position, flush

against the paper.

9. Replace the printer cover.

10. Presto! You’re ready to start printing!

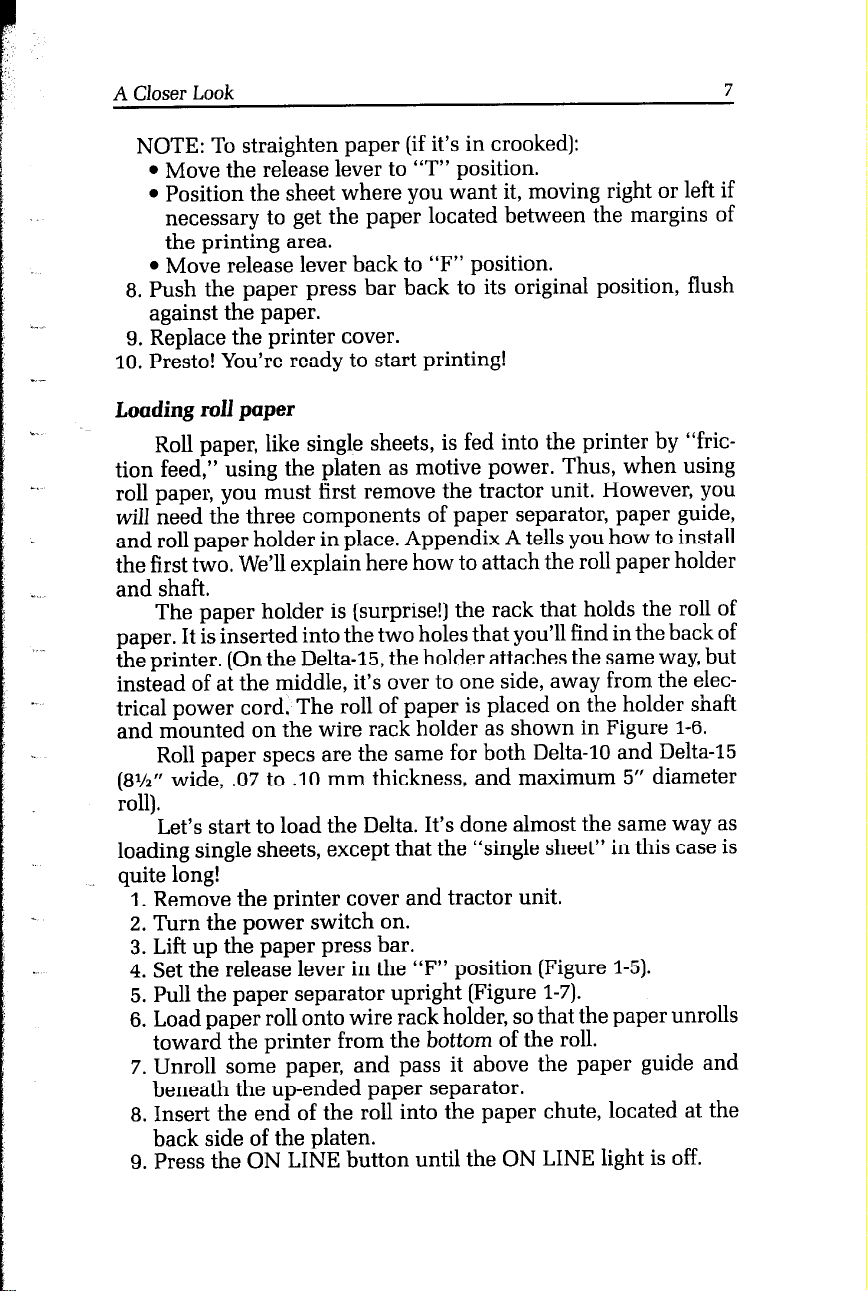

Loading roll paper

Roll paper, like single sheets, is fed into the printer by “friction feed,” using the platen as motive power. Thus, when using

roll paper, you must first remove the tractor unit. However, you

will need the three components of paper separator, paper guide,

and roll paper holder in place. Appendix A tells you how to install

the first two. We’ll explain here how to attach the roll paper holder

and shaft.

The paper holder is [surprise!) the rack that holds the roll of

paper. It is inserted into the two holes that you’ll find in the back of

the printer. (On the Delta-X, the holder attaches the same way, but

instead of at the middle, it’s over to one side, away from the electrical power cord, The roll of paper is placed on the holder shaft

and mounted on the wire rack holder as shown in Figure l-6.

Roll paper specs are the same for both Delta-10 and Delta-15

(8% ” wide, .CV to .lO mm thickness, and maximum 5” diameter

roll).

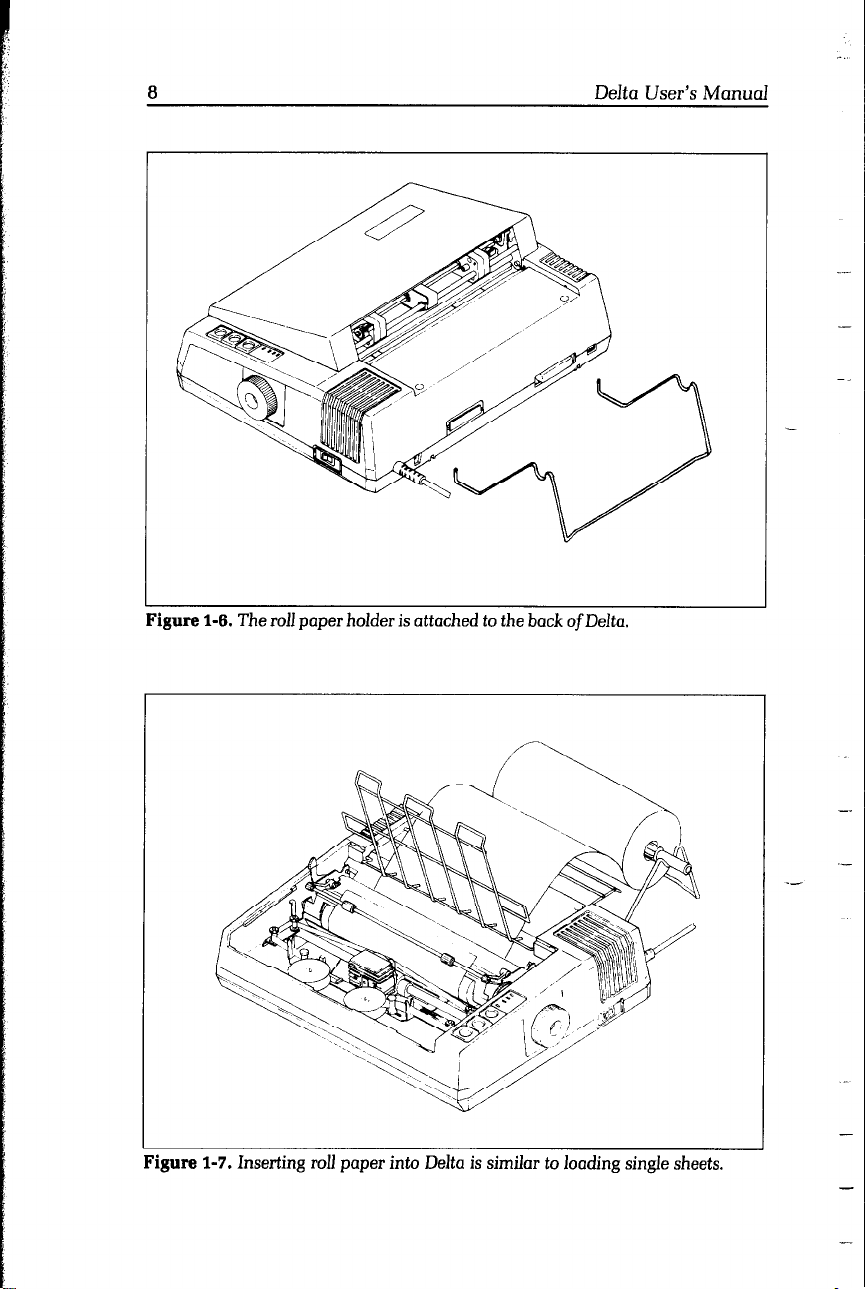

Let’s start to load the Delta. It’s done almost the same way as

loading single sheets, except that the “single sheet” in this case is

quite long!

1. Remove the printer cover and tractor unit.

2. Turn the power switch on.

3. Lift up the paper press bar.

4. Set the release lever in the “F” position (Figure 1-5).

5. Pull the paper separator upright (Figure l-7).

6. Load paper roll onto wire rack holder, so that the paper unrolls

toward the printer from the bottom of the roll.

7. Unroll some paper, and pass it above the paper guide and

beneath the up-ended paper separator.

8. Insert the end of the roll into the paper chute, located at the

back side of the platen.

9. Press the ON LINE button until the ON LINE light is off.

7

Page 20

-.

8

igure l-6. The roll paper holder is attached to the back of Delta.

Delta User’s Manual

Figure 1-7. Inserting roll paper into Delta is similar to loading single sheets.

-_

.-

Page 21

--

..“.

L

..*. --

A Closer Look

10. Press the L.F. button to move the paper in until the leading

edge appears on the front side of the platen, about where you

want the first line to start printing.

NOTE: To straighten roll paper (if it’s in crooked):

l Move the release lever to the “T” position.

l Position the sheet where you want it, moving it right or left if

necessary to get the paper located between the margins of

the printing area.

l Move the release lever back to “F” position.

11. Push the paper press bar back to its original position, flush

against the paper.

12. Replace the printer cover.

13. Presto! You’re ready to start printing!

9

L

L

L.

Loading sprocket-feed paper

This is the familiar perforated paper, with the holes along both

sides, also called sprocket, punched, fan-fold, or just plain “computer paper.” It can be as narrow as 3”, and up to 10” wide (5” to

15%” on Delta-15).

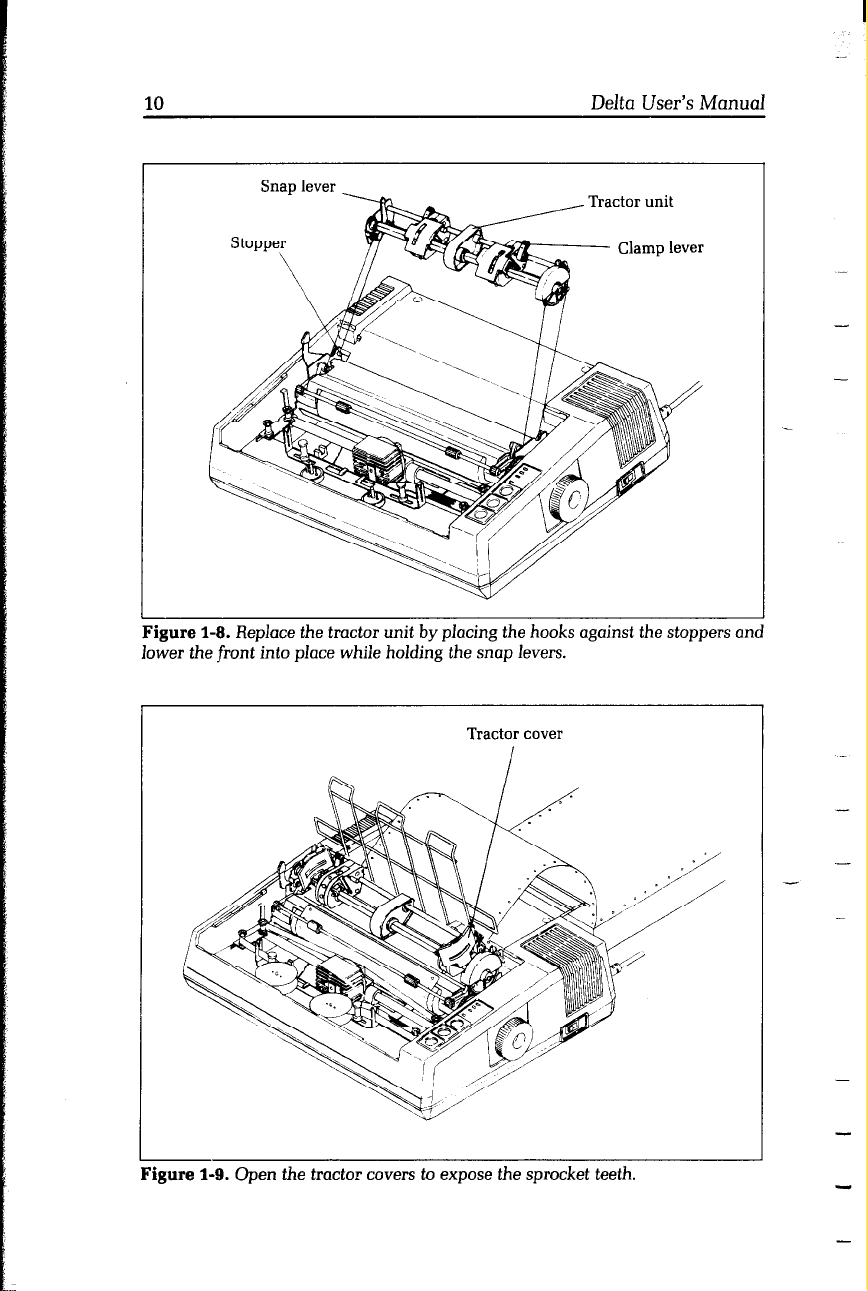

To use this kind of paper, you’ll need to install the tractor unit,

i

with its two “sprocket” wheels to carry the paper along.

To install the tractor, identify the two “snap levers” shown in

c.

Figure 1-8. At the same time, identify the two “stoppers,” nickel-

plated bars over which the hooked or cut-out bottom edge of the

L-

i

tractor frame fits.

OK? Now pick up the tractor unit. While depressing the two

snap levers, guide it down to the two stoppers; when the hooks

slide over the stopper bars, let go of the snap levers to lock it in

place.

L

Next, if you haven’t already, install the paper separator and

- paper guide (see Appendix A), and we’re ready to start loading.

L

1. Turn the power switch off and remove the printer cover.

2. Pull the release lever (on left side) to position “T”.

L

L

3. Raise the paper press bar; lift the paper separator upright.

4. Place the stack of fan-fold paper behind the printer.

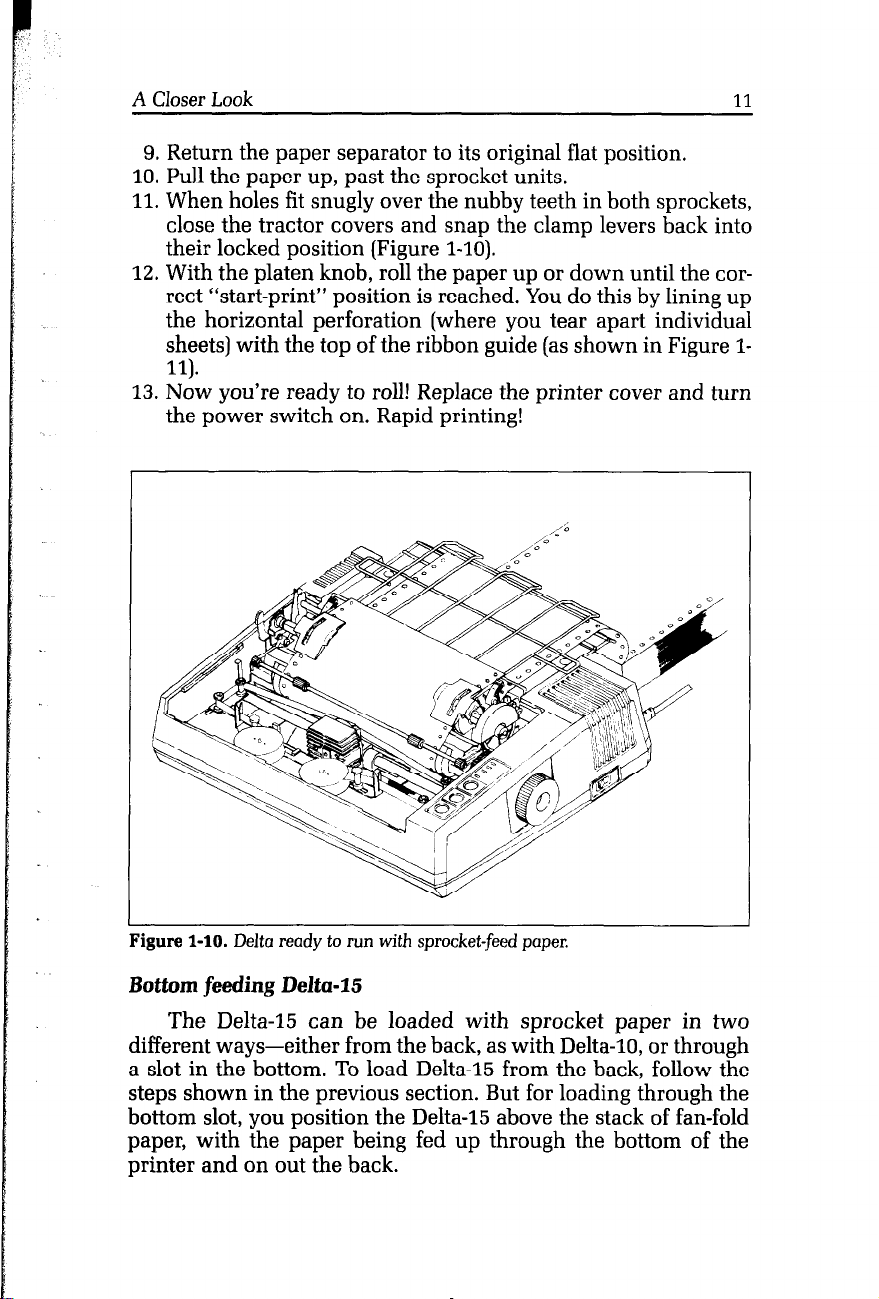

5. Open the tractor covers, atop the right and left sprocket units,

as shown in Figure 1-9.

6. Flip the clamp levers forward. This allows the two sprocket

units to move freely right and left, so you can align them with

the holes in the paper.

L

7. Pick up the top sheet, and feed it between the paper chute and

platen cover plate.

8. Push the paper down and forward, so it wraps around the platen.

Page 22

10

Figure 1-8. Replace the tractor unit by placing the hooks against the stoppers am

lower the front into place while holding the snap levers.

Delta User’s Manual

.-

-

-

-

Tractor cover

Figure 1-9. Open the tractor covers to expose the sprocket teeth.

-

-

-

Page 23

A Closer Look

11

9. Return the paper separator to its original flat position,

10. Pull the paper up, past the sprocket units.

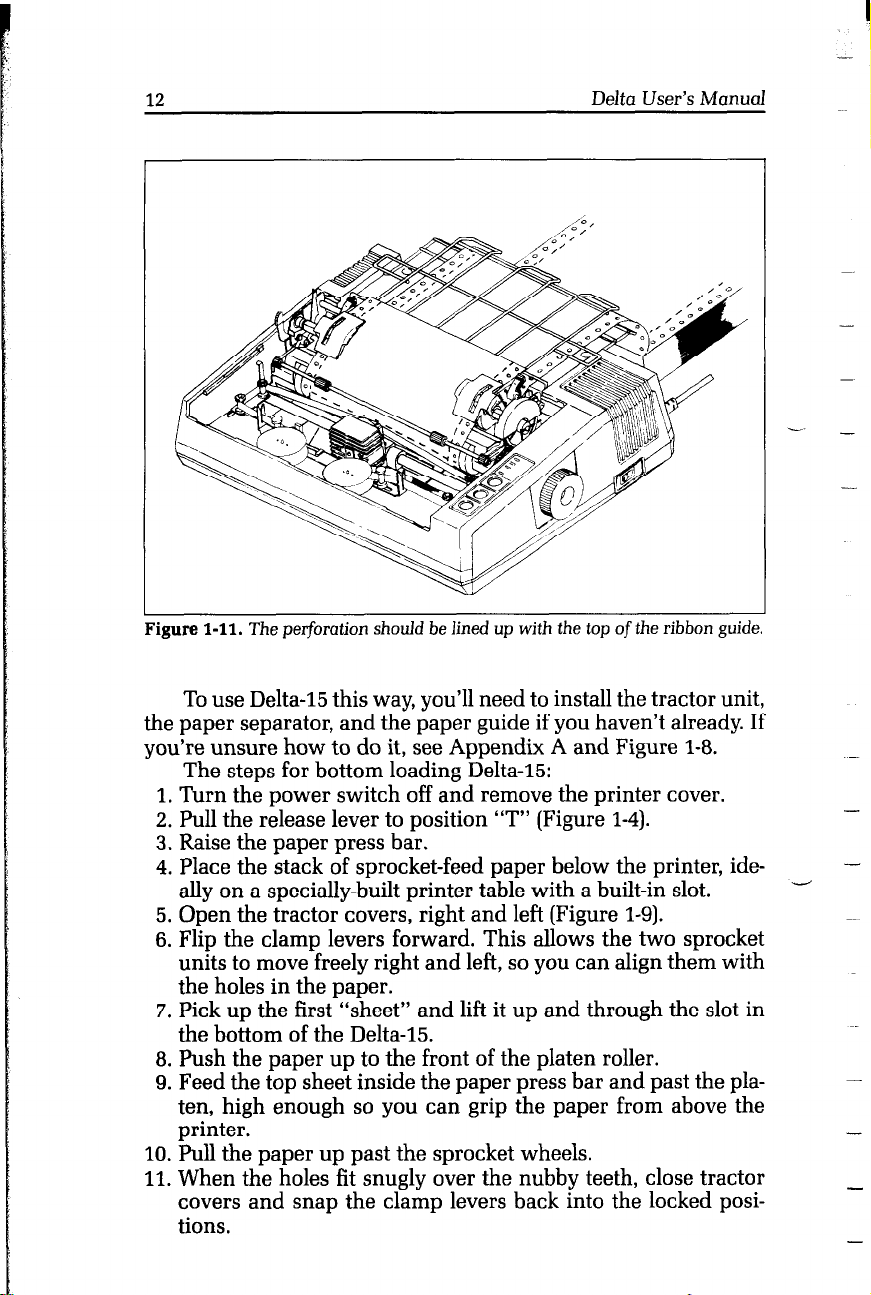

11. When holes fit snugly over the nubby teeth in both sprockets,

close the tractor covers and snap the clamp levers back into

their locked position (Figure l-10).

12. With the platen knob, roll the paper up or down until the correct “start-print” position is reached. You do this by lining up

the horizontal perforation (where you tear apart individual

sheets] with the top of the ribbon guide (as shown in Figure Ill).

13. Now you’re ready to roll! Replace the printer cover and turn

the power switch on. Rapid printing!

Figure I-10. Delta ready to run with sprocket-feed paper.

Bottom feeding Delta-15

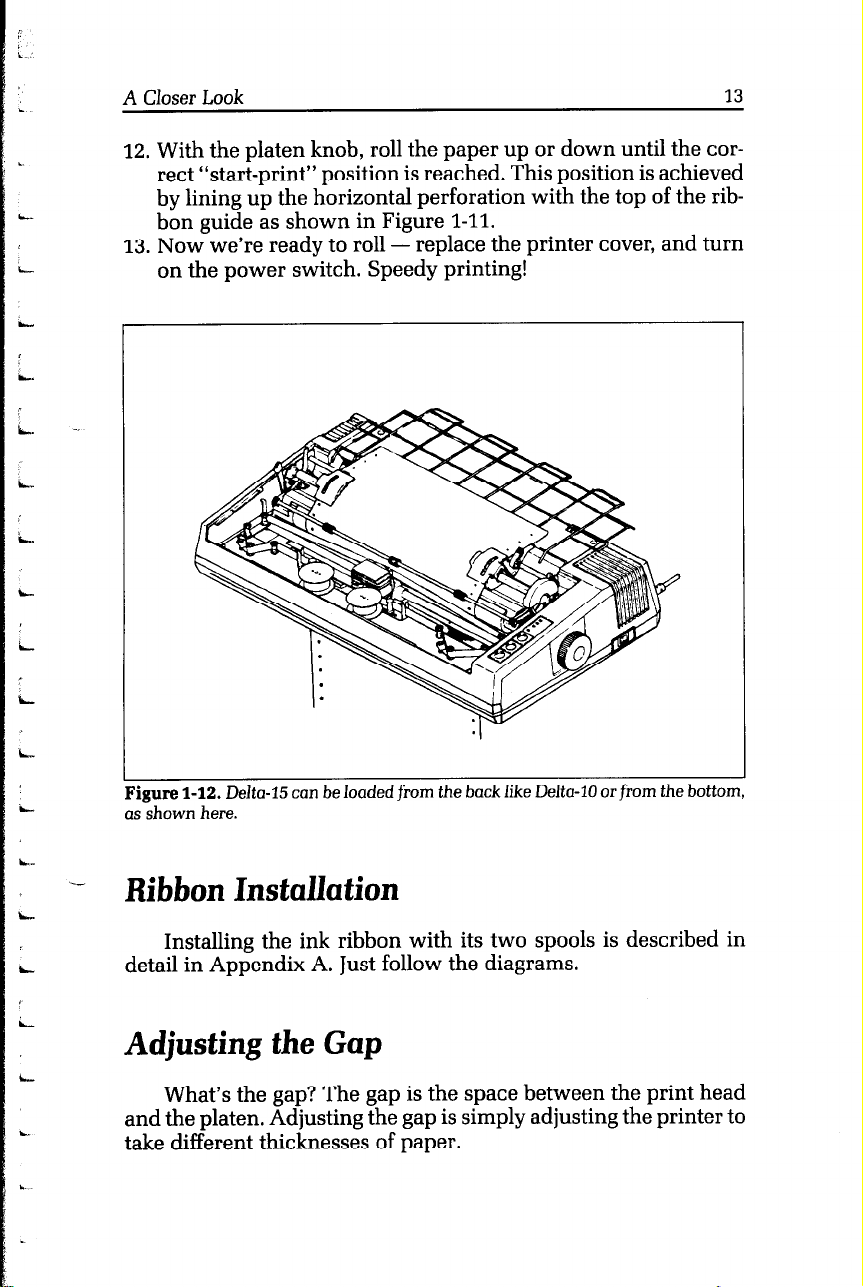

The Delta-15 can be loaded with sprocket paper in two

different ways-either from the back, as with Delta-lo, or through

a slot in the bottom. To load Delta-15 from the back, follow the

steps shown in the previous section. But for loading through the

bottom slot, you position the Delta-15 above the stack of fan-fold

paper, with the paper being fed up through the bottom of the

printer and on out the back.

Page 24

12

Figure l-11. The perforation should be lined up with the top of the ribbon guide.

Delta User’s Manual

.~

-

-- -

-

To use Delta-15 this way, you’ll need to install the tractor unit,

the paper separator, and the paper guide if you haven’t already. If

you’re unsure how to do it, see Appendix A and Figure l-8.

The steps for bottom loading Delta-15

1. Turn the power switch off and remove the printer cover.

2. Pull the release lever to position “T” (Figure l-4).

3. Raise the paper press bar.

4. Place the stack of sprocket-feed paper below the printer, ide- ally on a specially-built printer table with a built-in slot. -

5. Open the tractor covers, right and left (Figure l-9).

6. Flip the clamp levers forward. This allows the two sprocket

units to move freely right and left, so you can align them with

the holes in the paper.

7. Pick up the first “sheet” and lift it up and through the slot in

the bottom of the Delta-15.

8. Push the paper up to the front of the platen roller.

9. Feed the top sheet inside the paper press bar and past the platen, high enough so you can grip the paper from above the

printer.

10. Pull the paper up past the sprocket wheels.

11. When the holes fit snugly over the nubby teeth, close tractor

covers and snap the clamp levers back into the locked posi-

tions.

-

-

-

_

-

Page 25

A Closer Look

13

12. With the platen knob, roll the paper up or down until the correct “start-print” position is reached. This position is achieved

by lining up the horizontal perforation with the top of the ribbon guide as shown in Figure l-11.

13. Now we’re ready to roll - replace the printer cover, and turn

on the power switch. Speedy printing!

L

Figure 1-12. Delta-15 con be loaded from the bock like Delta-10 or from the bottom,

OS shown here.

Ribbon Installation

Installing the ink ribbon with its two spools is described in

detail in Appendix A. Just follow the diagrams.

Adjusting the Gap

What’s the gap? The gap is the space between the print head

and the platen, Adjusting the gap is simply adjusting the printer to

take different thicknesses of paper.

Page 26

14

Thickness adjustment lever

Delta User’s Manual

I

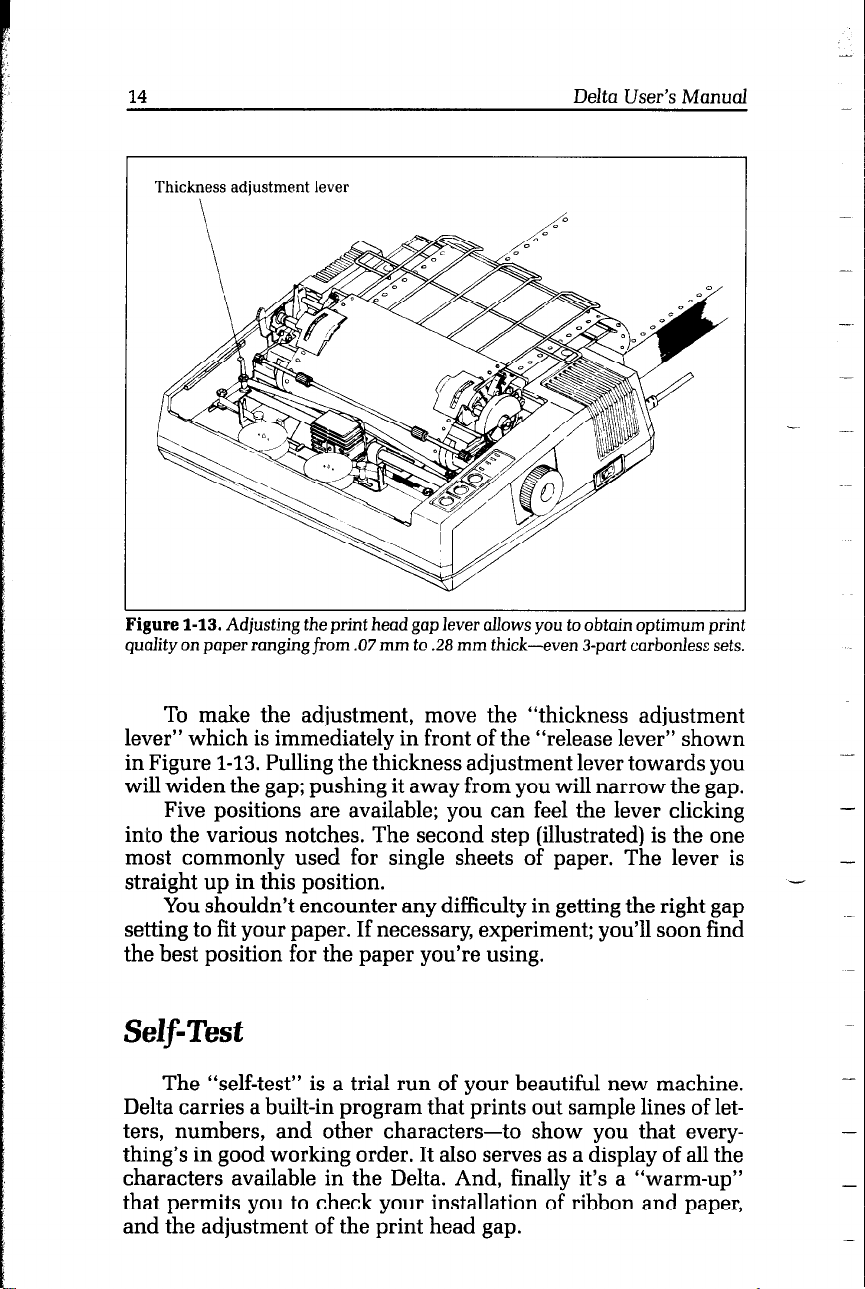

Figure l-13. Adjusting the print head gap lever allows you to obtain optimum print

quality on paper rongingfrom .07 mm to 28 mm thick-even ~-part carbonless sets.

To make the adjustment, move the “thickness adjustment

lever” which is immediately in front of the “release lever” shown

in Figure l-13. Pulling the thickness adjustment lever towards you

will widen the gap; pushing it away from you will narrow the gap.

Five positions are available; you can feel the lever clicking

into the various notches. The second step (illustrated) is the one

most commonly used for single sheets of paper. The lever is

straight up in this position.

You shouldn’t encounter any difficulty in getting the right gap

setting to fit your paper. If necessary, experiment; you’ll soon find

the best position for the paper you’re using.

Self-Test

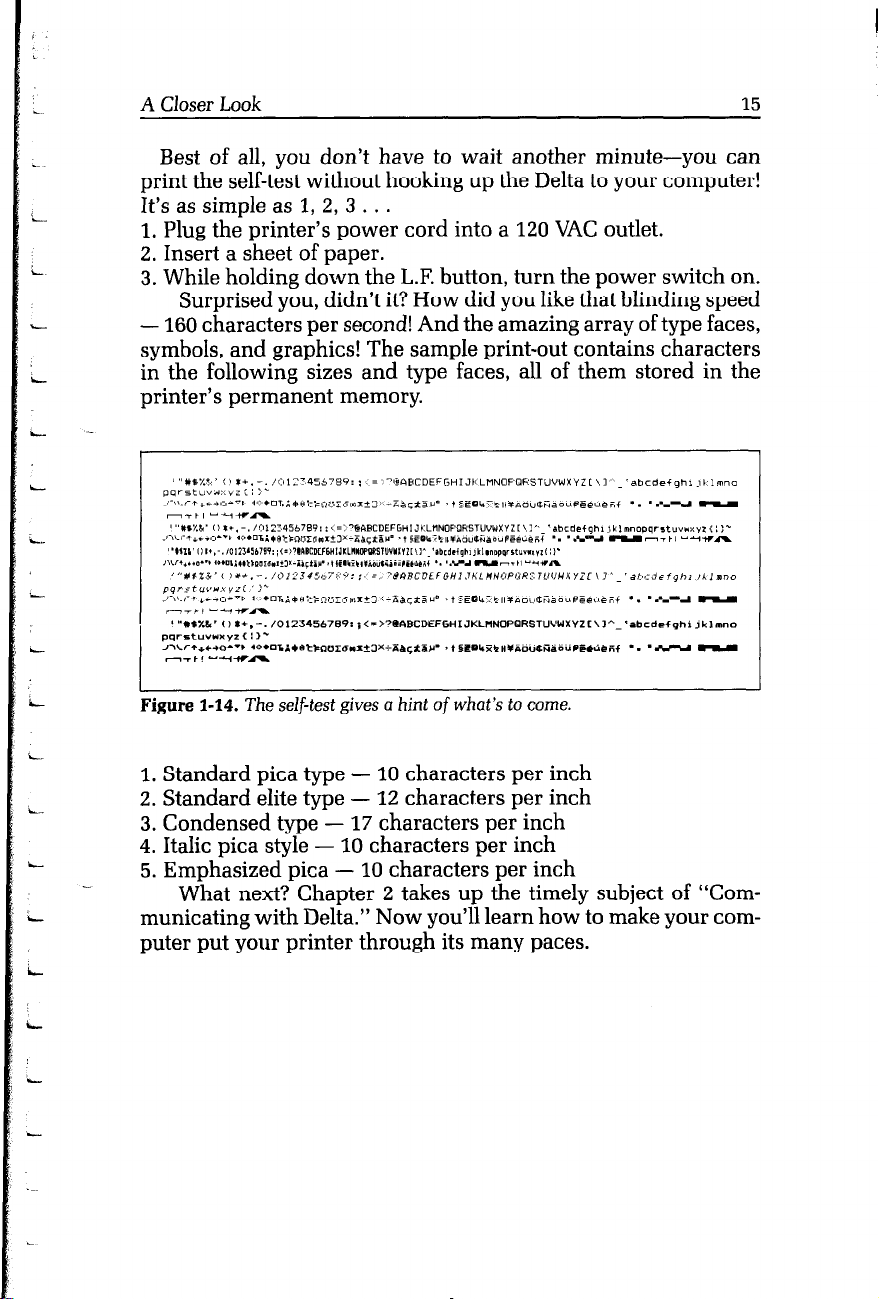

The “self-test” is a trial run of your beautiful new machine.

Delta carries a built-in program that prints out sample lines of let-

ters, numbers, and other characters-to show you that everything’s in good working order. It also serves as a display of all the

characters available in the Delta. And, finally it’s a “warm-up”

that permits you to check your installation of ribbon and paper,

and the adjustment of the print head gap.

I

1

-

-

-

-

Page 27

A Closer Look

15

Best of all, you don’t have to wait another minute-you can

print the self-test without hooking up the Delta to your computer!

It’s as simple as 1, 2, 3 . . .

1. Plug the printer’s power cord into a 120 VAC outlet.

2. Insert a sheet of paper.

3. While holding down the L.F. button, turn the power switch on.

Surprised you, didn’t it? How did you like that blinding speed

- 160 characters per second! And the amazing array of type faces,

symbols, and graphics! The sample print-out contains characters

in the following sizes and type faces, all of them stored in the

printer’s permanent memory.

‘igure l-14. The self-test gives o hint of what’s to come.

1. Standard pica type - 10 characters per inch

2. Standard elite type - 12 characters per inch

3. Condensed type - 17 characters per inch

4. Italic pica style - 10 characters per inch

5. Emphasized pica -

10 characters per inch

What next? Chapter 2 takes up the timely subject of “Com-

municating with Delta.” Now you’ll learn how to make your computer put your printer through its many paces.

Page 28

16

Delta User’s Manual

.-

-

-

-

-

-

Page 29

Chapter 2

Getting Started With Delta

You have assembled and tested your printer, and seen a quick

sample of Delta’s capabilities in the self-test. Now it’s time to do

what you bought Delta to do: print information from your computer.

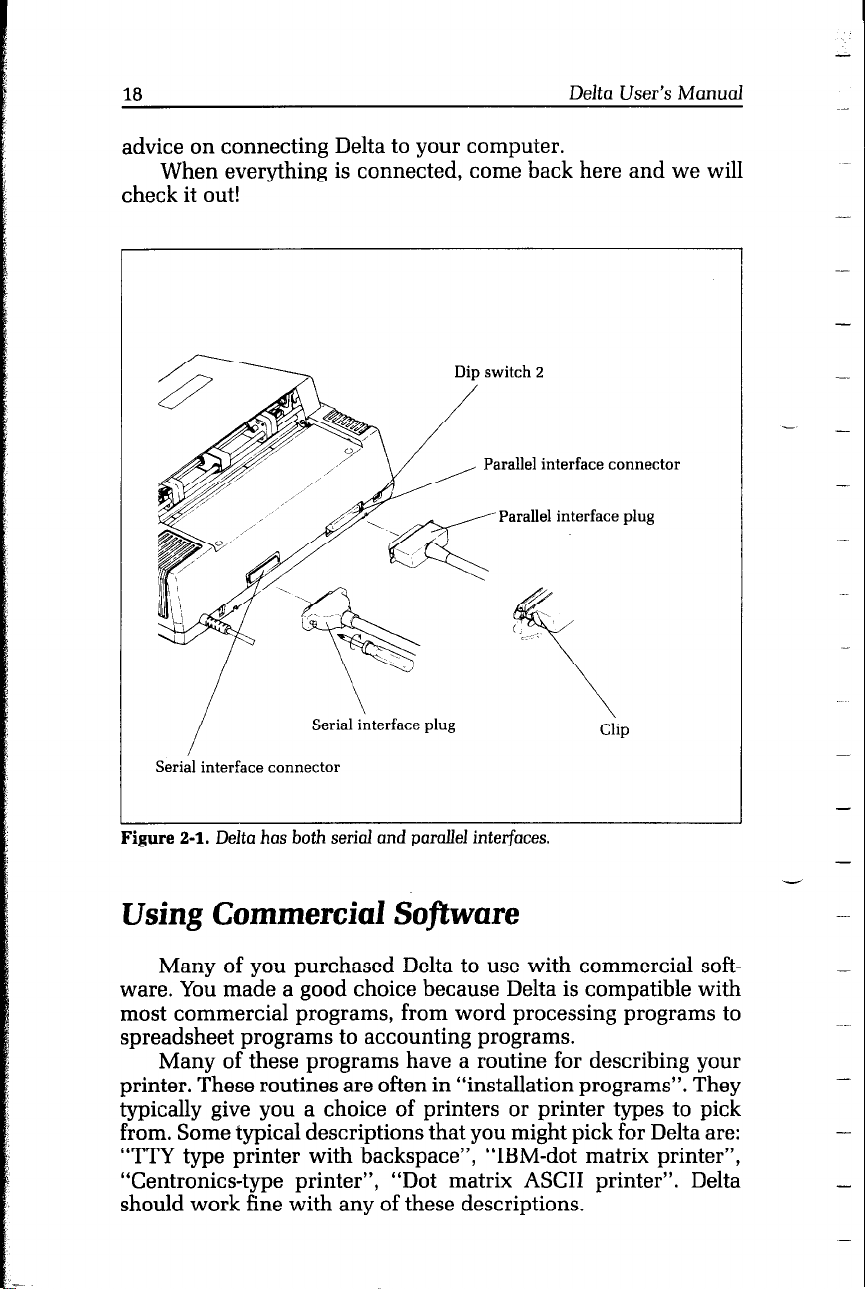

But first you need to connect Delta to your computer. Figure

2-l shows where the cables connect, but there’s more that you

need to know. Complete instructions for connecting Delta to

many popular computers are given in the appendix. Find the

appendix that covers your computer and follow the instructions

for connecting Delta and for setting the DIP switches. If your computer isn’t listed in the appendix, then ask your Star dealer which

computer that is listed is most like yours. If none of the listed computers are similar to yours, then your Star dealer will give you

Page 30

18

Delta User’s Manual

advice on connecting Delta to your computer.

When everything is connected, come back here and we will

check it out!

-

-

Dip switch 2

Parallel interface connector

Parallel interface plug

Serial interface plug

/

Serial interface connector

Figure 2-1. Delta has both serial and parallel interfaces.

Using Commercial Sojtware

-

- -

-

\

Clip

-

-

Many of you purchased Delta to use with commercial software. You made a good choice because Delta is compatible with

most commercial programs, from word processing programs to

spreadsheet programs to accounting programs.

Many of these programs have a routine for describing your

printer. These routines are often in “installation programs”. They

typically give you a choice of printers or printer types to pick

from. Some typical descriptions that you might pick for Delta are:

“TTY type printer with backspace”, “IBM-dot matrix printer”,

“Centronics-type printer”,

“Dot matrix ASCII printer”. Delta

should work fine with any of these descriptions.

-

-

-

Page 31

‘.

Getting Started With Delta

19

Many of these lists of printers are not very clear, and may not

include anything that you think describes Delta. If you can’t

decide which description best fits Delta, we recommend that you

narrow the list to two or three choices (you can quickly eliminate

ail the daisy-wheel printer types) and then experiment. You won’t

hurt anything if you guess wrong; it just won’t work right. This

should quickly tell you if your guess is right. If ail else fails,

though, your Star dealer will be happy to give you some advice.

Some programs don’t ask you what kind of printer you have,

but instead they ask some questions about what your printer can

do. Here are the answers to the “most asked” questions. Delta can

do a “backspace”.

Delta can do a “hardware form feed”.

With these questions answered, you are ready to start printing. Read the manual that came with your commercial software to

see how to make it send information for Delta to print. This is ail

you need to know to use Delta as a regular printer. But Delta isn’t

just a regular printer. Delta has many capabilities that your commercial software isn’t aware of. A little later we will see what it

takes to use some of Delta’s advanced features with commercial

software.

First, some terminology

Delta knows what to print because it knows how to interpret

the codes that the computer sends to it. These codes are numbers

that the computer sends to Delta. Both the computer and Delta

know the meaning of these codes because they are a set of standard codes used by almost ail microcomputers. This set of codes is

the American Standard Code for Information Interchange, which is

usually referred to as ASCII (pronounced ask-key). There are

ASCII codes for all the letters of the alphabet, both lower case and

capital, the numbers from 0 to 9, most punctuation marks, and

some (but not all) of Delta’s functions.

ASCII codes are referred to in several different ways, depending on the way they are used. Some times these codes are treated

as regular numbers. For example, the letter “A” is represented by

the number 65 in ASCII. Appendix M shows ail of the ASCII

codes.

In BASIC, ASCII codes are used in the CHR$ function. This

function is used to print the character that is represented by the

number in the CHR$ function. The BASIC statement PRINT

CHR$(65) will print an “A” on the terminal.

In some other programming languages, ASCII codes are

referred to by their hex value.

“Hex” is short for hexadecimal

which is a base-16 number system. (Our usual numbers are base-

Page 32

20

10) Since hex needs 16 digits, it uses the numbers 0 through 9 and

Delta User’s Manual

then it uses the letters A through F for digits. The ASCII code for

the letter “A” is 41 in HEX.

Of course, most of the time we don’t even need to think about

this code system. Our computers are smart enough to know that

when we press the “A” key on our keyboard we want to print the

letter “A”. The computer takes care of all the rest.

But there are a number of ASCII codes that don’t have keys on

the keyboard. The most important of these codes are the codes

that have ASCII values below 32. These codes control many of

Delta’s functions. Even though there aren’t keys for these codes,

most keyboards can send these codes. It’s done by holding down

the “control” key (many times marked CTRL) and simultaneously

pressing a letter key. The particular letter key that is pressed determines what code is sent. Control and A sends ASCII code 1, con-

trol and B sends ASCII code 2, and so on. Because of the way they

are created, these codes are often referred to as “control-A” etc.

So there are four common ways of referring to the same set of

codes: the character or name of the code, the decimal ASCII

value, the hexadecimal ASCII value, and the “control-” value.

For example, the code that causes Delta to advance the paper

one line is ASCII 10 (decimal). This code is commonly referred to

by all the following names:

-

line feed

(LF) -

ASCII 10

ASCII OAH

CHR$(lO)

- its name

the abbreviation of its name

-

its decimal value

- its hex value (the H signifies hex)

- the way it’s used in BASIC

control-J - the way you send it from a keyboard.

There’s a chart in Appendix M that shows these side-by-side so

that you can convert back and forth.

The reason that we are telling you all this about ASCII codes

is that people are not very consistent about how they describe

ASCII codes. We are going to help you use Delta with commercial

software, but we don’t know what its documentation is going to

call the various codes. So if you know all the different things that

the codes might be called it will be easier to figure out what it is

trying to tell you.

Now, armed with the knowledge of what to look for, you can

delve into the manuals of your commercial software and dig out

the secrets of how to send “control codes” to your printer. When

Page 33

L

Getting Started With Delta

21

you find the method that your program uses, then you can shop

through this manual to find the function that you want to use. By

translating the codes from the system that we use, to the system

that your commercial software uses, you should be able to use

many of Delta’s advanced features. It may help, however if we

look at a couple of examples.

Using Delta with SuperCalc

SuperCalc is typical of the many spreadsheet programs that

are now available. It has the capability of using several of the

advanced features of Delta. Perhaps the most often used feature

with spreadsheet programs is compressed printing. Let’s see how

to use compressed printing with SuperCalc.

In SuperCalc, the /Output command provides output to the

printer. One of the options of the /Output command is S(etup).

This option provides you with a menu of functions to configure

SuperCalc to match your printer. You can change the number of

characters that SuperCalc will print on a line and the number of

lines that will print on a page. You should be sure that these values

match your printer. Delta-lo’s print 80 characters per line of pica

type, or 136 characters of condensed type. Delta-15 can print 136

characters per line of pica type, or 233 characters per line of condensed type. One of the other options on this menu is “send setup

codes to printer”.

This is how we tell Delta that we want to use

condensed print. The code to switch Delta into condensed print is

ASCII 15, or control-O. So to switch on condensed type, use the

/Output command and, after selecting D(isplay) and entering the

range to print, select the S(etup) option, and the S(etup)-“Manual

setup codes” sub option, Then, at the prompt that says “Enter

codes (CR when done)“, type control-O. Remember, to enter con-

-- trol-0 you hold down the CTRL key while you press the 0 key

(That’s the letter Oh, not the number zero]. Then just press return

and select P(rint) to print your report.

,You only need to go through this procedure once each time

you use SuperCalc because Delta will stay in compressed print

until it’s turned off or reset.

You might also wish to use some of Delta’s other features with

SuperCalc. Find the code for the feature you wish to use in Appendix K and use the same procedure given here. Remember that

Appendix M can be used to translate between the different names

for the codes.

c

Using Delta with word processors

Not many word processing programs recognize the advanced

Page 34

22

Delta User’s Manual

features of printers like Delta. They usually provide for some

method of making bold characters and underlining. But Delta can

do much more than that. The people that write word processing

programs do, however, know that there are a lot of different printers on the market, and so they usually, (but not always) provide a

way of sending special codes to a printer. We will study one example of this to see how a typical word processor handles it. Once

you understand the concept you should be able to use your program manual to figure out how your word processor does it.

The program that we will study is the EasyWriter word processor for the IBM Personal Computer. This uses a fairly typical

method of handling special codes. Generally, word processing

programs don’t want you to put non-printing codes in the file. They “know” that they won’t print anything, and so they “protect” you by not letting you use them. But the non-printing codes

are the ones that you need to use Delta’s features. So EasyWriter

provides a way to override this protection. If you precede a special code with a “control-O” then EasyWriter will accept the next

non-printing code.

Let’s look at a specific example. Suppose you want to print the

title of a book in italic. The code sequence to select italic type is

Escape 4 (that’s two separate characters). Entering the 4 is no

problem; it’s a printing character so EasyWriter won’t object

(although in this case it’s not going to print). The Escape, however,

is a non-printing character so it requires special handling. To

enter the Escape code first enter control-0 (hold the Ctrl key while

you press the letter 0). Then press the Esc key. The Escape character shows on the screen as a left pointing arrow. Now just type the

number 4 and you’re done.

When you want to end the italic, you need to enter Escape 5.

Use the same procedure: enter control-O, Esc, and then 5.

You can use many of Delta’s features this way. Find the codes that you need in Appendix K, and then if necessary, use Appendix

M to translate the codes into the form your word processor uses.

A note to WordStar users: WordStar is probably the most popular word processing program in the world. But it provides no

way to enter special printer control codes from the keyboard.

WordStar does, however, provide you with a way to use some of

Delta’s advanced features. WordStar has four special commands

that you can use to access Delta’s features. These are called “user

printer controls” and are control-P Q, control-P W, control-P E,

and control-P R. You might use two of these to turn italic on and

off and the other two for some other function. The process of setting up these codes is called “patching” and is done with the

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

Page 35

Getting Started With Delta 23

install program that comes with WordStar. The procedure is fairly

involved, but it is explained in the WordStar manual. If you have

trouble figuring it out, ask for assistance where you bought WordStar.

Using this book without learning BASIC

._

Throughout most of this book we will be teaching you how to

use Delta’s features using the BASIC programming language in

our examples. This is because it is easy to communicate with

Delta from BASIC and because, despite its shortcomings, BASIC

is the nearest thing to a universal language among users of per-

sonal computers. But it’s not the only way to communicate with

Delta, as we have already seen. Even if you don’t know BASIC,

you can learn how to use Delta’s features by reading on. When

you find a function that you want to use, just apply what you

already know about translating from one name for codes to

another. The examples will still show you how the commands are

used, even if you are not using BASIC.

Some Basics About BASIC

Probably the simplest thing to do with your printer in BASIC

is to list a program on the printer. But in this world of proliferating

microcomputers even this presents a problem. It seems that every

computer uses a different system of communicating with the

printer. We are going to tell you about some of the more common

ways, and hope that between this and your computer’s BASIC

manual you will be able to stay with us.

First on our list is Microsoft BASIC’s way of communicating

with the printer. They just add an “L” to the beginning of the LIST

and PRINT commands, making them LLIST and LPRINT. This

method is used by more computers than any other and so we will

use it throughout this book, after telling the rest of you how to

follow along.

Microsoft BASIC is used by TRSSO computers, IBM-PC com-

puters, many CPlM computers, and many other computers. (Look

in your BASIC manual; it will probably say if it’s Microsoft

BASIC.)

Next we need to talk about Apple II computers. They have a

real simple system. To list a program that you have loaded into

Page 36

24 Delta User’s Manual

-

memory, just type:

PR#l

LIST

PR#g

The PR#l says “send everything to the printer”, the LIST

sends it, and the PR#O says “Ok, back to the screen now”. (There

are some slightly different versions of these commands in Appendix C.)

Some other computers require you to open the printer as a numbered device, and then direct the output to that device. For

example, to list a program on the printer with a Commodore C-64

computer you type the following:

OPEN4,4

CMD4

LIST

PRINT#4

This says that the printer is device 4, directs the output to it,

lists the program, and finally closes device 4.

The appendix gives more information about listing programs

on various computers. Find the appendix that tells how your computer works, and try it.

Now that we all know how our computers address the printer,

let’s try listing a BASIC program. Load a BASIC program and

LLIST it (or however your computer does it).

We’ve crossed the first major hurdle-learning how to list pro-

grams on Delta. Now we are ready to jump into the world of programming with Delta. But first, there are a few fundamentals that

we need to cover.

Establishing communications

: CLOSE4

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

We’ve learned something about communicating with our

printer. Now we need to adapt what we know to printing in a

BASIC program. Generally, computers use about the same procedure for printing in a program as they do to list a program. Again

take a few moments to look at the appendix that relates to your

computer. We’ll continue when you have it all figured out.

_

-

-

Page 37

Getting Started With Delta

Welcome back. Let’s try what we learned. Type the following:

25

L

i

c

i

i

L

L

L

i

NEW

18 LPRINT "TESTING"

RUN

Remember-we use LPRINT, you may have to use something

else!

At any rate, you should have the word “TESTING” on your

printer. Quite an achievement, isn’t it? Let’s get done with this

simple stuff so that we can go on to something interesting.

The CHR$ function

We mentioned CHR$ earlier as one way to express ASCII

codes. We are going to use it a lot in communicating with Delta.

Delta uses many of the ASCII codes that don’t represent letters

and numbers. The CHR$ function gives us an easy way to send

these codes to the printer. Try this to see how the CHR$ function

works:

NEW

18 LPRINT CHR$(68)

RUN

I,

L

i

L

6

:

L

That should print a “D” for Delta. If you check the chart in

Appendix I you will see that 68 is the ASCII code for “D”.

.-

Control codes

Delta uses many of the non-printing ASCII codes for control

codes. These codes perform a function rather than printing a character. Let’s try an easy one right now:

NEW

18 LPRINT CHR$(7)

RUN

Who made that noise? That’s Delta’s bell. We will learn more

Page 38

26

Delta User’s Manual

about it in Chapter 6. We just wanted to illustrate a code that

causes Delta to perform a function.

The escape code

There’s one particular ASCII code that we are going to be

using more than all the rest. This is ASCII 27, which is called

escape. In BASIC it’s CHR$(27). With all of Delta’s advanced features, there weren’t enough single ASCII codes to go around. So

escape is used to start sequences of control codes that open a

wider range of functions to us.

While you must call this code CHR$(27) in BASIC, we are

going to refer to it as (ESC) in this book. This will make it much

easier to recognize when we use it.

A typical escape code sequence starts with (ESC) which is

followed by one or more CHR$ codes. As an example, the escape

code sequence to turn on italic print is:

(ESC) CHR$(52)

In a program, this would look like this:

NEW

18 LPRINT CHR$(27) CHR$(52);

2$3 LPRINT "TESTING"

RUN

-

-

-

-

-

-

-

-

-

-

Try this program, it will print the word TESTING in italic. -

Some of you fast students may have noticed that CHR$(52) is

the same as “4”. That’s right, the program will work just as well if

line 10 is changed like this:

lpi LPRINT CHR$(27) "4";

That’s just another form of the same ASCII code, and it’s all

the same to Delta.

Here’s another shortcut for BASIC programmers: since

(ESC) is used so often, assign it to a variable. In a long program,

typing ESC$ is much easier than typing CHR$(27) each time! Now

-

-

-

Page 39

Getting Started With Delta

27

our program looks like this:

5 ESC$=CHR$(27)

l@ LPRINT ESC$ “4”;

.

\..-

L..

Turn your printer off and back on now, or you will be printing

in italic for quite a while!

Some problem codes

Before we go too far we need to mention some codes that may

cause you problems. Like most of the subjects in this chapter, we

have to be a little vague because of the differences in computers.

Nearly all BASICS change some of the ASCII codes between

your BASIC program and your printer. Some turn CHR$(lO) (a

line feed) into a CHR$(13) (

a carriage return) before sending it on.

Some other problem codes are 0, and 9 through 13. Once again we

refer you to the appendix about your computer, where some more

specific information awaits.

That’s it for the basics. You are ready to learn how to use the

many features of Delta.

Page 40

28

Delta User’s Manual

-

- -

-

-

-

-

-

-.

Page 41

Chapter 3

Printing Text With Delta

Beginning with this chapter we will be exploring all the features of Delta. All our examples will be given in Microsoft BASIC

as used by the IBM Personal Computer, but remember that you

don’t need to know BASIC to use Delta’s features. Just use the

same ASCII codes as we do in our examples.

If your computer doesn’t use Microsoft BASIC, look in the

appendix to see what changes you need to make for your BASIC.

The appendix tells you how to change the short example programs, and gives complete listings of the longer programs,

already converted for your computer.

You have already printed a few lines on your Delta printer.

Now it’s time to start looking at the many variations of printing

style that you have available to you. The first technique that we

Page 42

30 Delta User’s Manual

will investigate is changing the width of the characters that Delta

prints.

Changing the print pitch

In “printer talk,” character width is called pitch. Normally,

Delta prints 10 characters per inch. This is called pica pitch

because it’s the same spacing as a standard pica typewriter.

Delta can also print 12 characters per inch. This is called elite

pitch because it is the same spacing as an elite typewriter.

Condensed print is approximately 17 characters per inch

(actually it’s 17.14 characters per inch). Condensed pitch allows

you to get 136 columns of printing on an 8% inch page.

You tell Delta which pitch you want to use with the (ESC)

“B” command. The table below shows the three options of this

command.

._

Table 3-l

Print pitch commands

Pitch

Pica

Elite

Condensed

Characters/inch

10

12

17

Control code

(ESC) “B” CHR$(l)

(ESC) “B” CHR$(2)

‘, ESC) “B” CHR$(3)

Let’s see how these three pitches look. Try this program:

NEW

18 LPRINT CHR$(27) "B" CHR$(2)

2@ LPRINT "THIS IS ELITE PITCH PRINTING"

30 LPRINT CHR$(27) "B" CHR$(3)

40 LPRINT "CONDENSED IS THE NARROWEST PITCH"

50 LPRINT CHR$(27) "B" CHR$(l)

60 LPRINT "NOW WE ARE BACK TO PICA PITCH PRINTING"

When you run this program you should get this:

THIS IS ELITE PITCH F’HiNTING

-

--.

-

-

-

-

.-.

-

CONDENSED IS THE NARROWEST PITCH

NOW WE ARE BACK TO FICA PITCH F’RINTING

-

Page 43

c

‘L

i..

L

L.

L *

Printing Text With Delta

31

Line 10 turns on elite pitch with ( ESC > “B” CHR$(2). Line 20

prints a line at 12 characters per inch. The (ESC) “B” CHR$(3) in

line 30 changes Delta to condensed pitch and line 40 prints a line

in condensed pitch. Line 50 resets Delta to pica pitch and line 60

prints a line in pica pitch.

Pica pitch and condensed pitch can be set with “shortcut”

codes. Instead of using (ESC) “B” CHR$(n), you can set them

with a single code. CHR$(18) sets pica pitch and CHR$(15) sets

condensed pitch. You can not set elite pitch with a single code.

Expanded print

Each of Delta’s three print pitches can be enlarged to twice its

normal width. This is called expanded print. Try this program to

see how it works:

i..

L

L

L

i

L.

L

c

NEW

18 LPRINT CHR$(lh) "THIS LINE IS EXPANDED"

2@ LPRINT "BUT THIS LINE IS NOT"

T-HIS

L~INlzEI IS

BUT THIS LIME IS NO-r

Expanded print set with CHR$(14) is automatically canceled

at the end of the line. This is convenient in many applications,

such as for one line titles. Note that you don’t need to put an

(ESC) in front of the CHR$(14), although (ESC) CHR$(14) works

just the same.

Sometimes you may wish to stay in expanded print for more

than one line. Change your program to this:

E x l==‘aNwER

18 LPRINT CHR$(27) "W" CHR$(l) "THIS LINE IS

EXPANDED"

2fl LPRINT "AND SO IS THIS ONE"

39 LPRINT CHR$(27) "W" CHR$(@) "NOW WE'RE BACK TO

NORMAL"

Now the results look like this:

‘L

-l-H I s LINE

6rNR su IS

NOW WE’ RE BACK TO NCIRMAL

I s

ECXF-‘RNlDEr)

-l-H153 CBNE

Page 44

32 Delta User’s Manual

When you turn on expanded print with (ESC) “W” CHR$(l) it

stays on until you turn it off with (ESC) “W” CHR$(O). That’s

what we added line 30 for.

Table 3-2

Expanded print commands

1 Function

I

One line expanded

Expanded ON

ExDanded OFF

1 Control code

I

CHR$(14)

(ESC) “W” CHR$(l)

‘,ESC) “W” CHR$fOI

By combining expanded print with the three pitches, Delta

has six different character widths available.

Enter this program to see how the print pitches and expanded

print can be combined:

18 LPRINT CHR$(llt) "EXPANDED PICA PITCH"

2@ LPRINT CHR$(27) "B" CHR$(2)

38 LPRINT CHR$(14) "EXPANDED ELITE PITCH"

48 LPRINT CHR$(27) "B" CHR$(j)

58 LPRINT CHR$(14) "EXPANDED CONDENSED PITCH"

6@ LPRINT CHR$(27) "B" CHR$(l)

79 LPRINT "NOW WE ARE BACK TO UNEXPANDED PICA

PRINTING"

I

-.-

-

- -

-

-

Here’s what you should get from this program:

EXF19NRED ELITE PITCH

EXPANDED CONDENSED PITCH

NOW WE ARE BACK TQ UNEXF’ANDED PICA PRINTING

Making Delta print darker

Delta has very good print density when it’s just printing regularly. But sometimes you may want something to stand out from

the rest of the page. Delta provides two ways to do this: doublestrike and emphasized print. Both of these go over the characters

-

-

Page 45

Printing Text With Delta

33

twice, but they use slightly different methods to darken the characters. Let’s try them and see what the difference is.

The following table shows the control codes for getting into

and out of double-strike and emphasized modes.

Table 3-3

L.

i

Function

Double-strike ON

Double-strike OFF

Print emDhasis commands

Emphasized ON

c

Emphasized OFF

a

Control code

‘, ESC) “G”

(ESC) “H”

(ESC) “E”

(ESC) “F”

Try them now with this little program:

~

j L.

I

) IN...

I

NEW

18 LPRINT CHR$(27) "G"

28 LPRINT "THIS IS DOUBLE-STRIKE PRINTING"

3p LPRINT CHR$(27) "H" CHR$(27) "E";

4@ LPRINT "THIS IS EMPHASIZED PRINTING"

5!2 LPRINT CHR$(27) "G";

69 LPRINT "AND THIS IS BOTH AT ONCE"

7pI LPRINT CHR$(27) "H" CHR$(27) "F"

Run this program. The results will look like this:

THIS IS DOUBLE-STRIKE PRINTING

THIS IS EMPHASIZED PRINTING

AND THIS IS BOTH AT ONCE

Line 10 turns on double-strike with (ESC) “G” and line 20

prints a line of text. In line 30 double-strike is turned off with

(ESC) “H” and then emphasized is turned on with (ESC) “E”.

Line 40 prints a line of emphasized text. Line 50 then turns double-strike back on so that line 60 can print in both at once. Finally,

line 70 turns both off, so that Delta is set for normal printing.

Look closely at the different lines of printing. In the line of

double-strike printing each character has been printed twice, and

they are moved down just slightly the second time they are

Page 46

34 Delta User’s Manual

printed. In emphasized printing, they are moved slightly to the

right the second time Delta prints. The last line combined both of

these so that each character was printed 4 times. Now that’s pretty

nice printing, isn’t it?

Some Special Kinds of Text

We’re just getting started on the kinds of text that Delta can

print. Still to come are italic characters, underlined characters,

superscripts and subscripts.

Italic printing

Italic letters are letters that are slanted to the right. Delta can

print all the kinds of letters that we have seen so far in italic as well

as the roman (standard) letters we have been using. Italics can be

used to give extra emphasis to certain words. The command

codes to turn italic on and off are shown in Table 3-4.

Table 3-4

Italic commands

Function

Italic ON

Italic OFF

Control code

(ESC) “4”

(ESC) “5”

-.

-

Use this program to see italic characters:

NEW

18 LPRINT CHR$( 27) “4”;

2p LPRINT “THIS LINE IS PRINTED IN ITALIC”

3g LPRINT CHR$(27) “5”;

4pl LPRINT “THIS LINE IS NORMAL PRINTING”

Here is what you should get:

THIS LINE IS PRINTED IN ITALIC

THIS LINE IS NORMAL PRINTING

-

-.

-.

Page 47

Printing Text With Delta

35

This program is easy; line 10 turns italic on with (ESC) “4”,

and line 30 turns it off with (ESC) “5”.

UnderJining

Not only can Delta print all the styles of printing that we have

seen in both roman and italic, but it can underline them too. The

control codes are shown in Table 3-5.

Table 3-S

Underline commands

Function

Underline ON

Underline OFF

Control code

(ESC) “-" CHR$(l)

(ESC) “-"CHR$(O)

Again, that’s simple. Let’s try it with this program:

NEW

18 LPRINT CHR$(27) '-' CHR$(l);

2g LPRINT "THIS IS UNDERLINED";

3@ LPRINT CHR$(27) 11-u CHR$(a);

49 LPRINT v AND THIS IS NOT"

It should come out like this:

TtiIS IS UNDERLINED AND THIS IS NOT

__-_-_.-- -.-..._.-- ------“--_--

In this program underline is turned on in line 10 with (ESC)

“

- ” CHR$(l), and then off in line 30 with (ESC) “ -” CHR$(O).

There’s a new little wrinkle in this program, though. It all printed

on one line. The semicolons at the end of the first three lines told

BASIC that those lines were to be continued. Therefore, BASIC

didn’t send a carriage return and line feed at the end of those lines.

We just did this to illustrate that all these control codes can be used

in the middle of a line. It’s easy to underline or italicize only part of

a line.

Superscripts and subscripts

We have seen how Delta can print in 6 different widths. Delta

Page 48

36

Delta User’s Manual

can also print in two different heights of characters. The smaller

characters are called superscripts and subscripts and are half the

height of normal characters. Superscripts print even with the tops

of regular printing while subscripts print even with the bottom of

regular printing. They are frequently used to reference footnotes,

and in mathematical formulas.

Table 3-6 has the codes for using superscripts and subscripts.

Table 3-6

Superscript and subscript commands

Function

Superscript ON

Subscript ON

Super & subscript OFF (ESC) “T”

Control code

(ESC) “S” CHR$(O)

(ESC > “S” CHR$(l)

Try this program to see them work:

NEW

18 LPRINT "THIS LINE USES";

28 LPRINT CHR$(27) "S" CHR$(@);

3pI LPRINT 11 SUPERSCRIPTS";

48 LPRINT CHR$(27) "T";

5pI LPRINT " AND";

6p LPRINT CHR$(27) "S" CHR$(l);

7pI LPRINT " SUBSCRIPTS";

88 LPRINT CHR$(27) "T";

90 LPRINT t~ BOTH"

-

-

THIS LINE USES *UPER-CRxPTa FIND BIU~~SCRIPT(B BOTH

Here line 20 turns on superscripts with ( ESC > “S” CHR$(O).

It’s turned off in line 40 with (ESC) “T”. Then, between printing

text, subscripts are turned on in line 60 with (ESC) “S” CHR$(l),

and finally off in line 80. Again, everything prints on one line

because of the semicolons.

Mixing modes

We have learned how to use Delta’s many different printing

modes individually. Now let’s see how we can combine these

Page 49

Printing Text With Delta

modes for even more printing effects. Condensed, italic, doublestrike, underlined subscripts are something that you are probably

just itching to print!

There are 288 “theoretical” combinations of the modes that

we have learned. Of these, a mere 112 will work! (Some combinations, like expanded superscripts, just don’t work.) Instead of try-

ing to list all the combinations that work, we have a program that

prints a chart showing all the combinations. There is a sample of

each of the 112 possible combinations on the chart. (The dots just

indicate the few combinations that don’t work.) Enter the follow-

ing program and run it to make your own chart.

37

lplpl WIDTH "LPTl:", 255

'CANCEL AUTO CR & LF AFTER

80 CHAR'S

110 GOSUB 1$30$3 'BUILD INSTRUCTION SET REQUIRED

120 GOSUB 20&J 'PRINT HEADING

130 LPRINT "*REGULAR*"

140 GOSUB 3000 'PRINT FOUR LINES REGULAR

150 LPRINT "*DOUBLE STRIKE*"

160 LPRINT DOUBLE.STRIKE$;

170 GOSUB 3000 'PRINT FOUR LINES DOUBLE STRIKE

180 LPRINT "*EMPHASIZED*"

190 EMPHASIZED = TRUE

200 GOSUB 3000 'PRINT FOUR LINES EMPHASIZED

210 LPRINT "*DOUBLE STRIKE & EMPHASIZED*"

220 LPRINT DOUBLE.STRIKE$ EMPHASIZED$;

230 GOSUB 3000

'PRINT DOUBLE STRIKE & EMPHASIZED

240 END

250 ~******************************************

260 '*****XttXXtffXXXttf***********************

lllllllllll1llll1fIllllIllllllllllflllI,lll

1000

lpll0 ' '

1020 ’

1030 ’ ’

flll1rrflllllllllllrllllllllllllllllllIllfl

1040

BUILD INSTRUCTION SET '

1059 """FONT (CHARACTER) STYLES"""""""

1060 ITALIC$ = CHR$(27) + CHR$(52)

1070 ROMAN$ = CHR$(27) + CHR$(53)

@,Qj ll,llIllllI'PITCH ~~~~~IllllllllIlllIlfllll

1090

ENLARGED$ = CHR$(27) + CHR$(87) + CHR$(l)

1100 NOT.ENLARGED$ = CHR$(27) + CHR$(87) + CHR$(@)

1110 PICA$

1120 ELITE$

1130

CONDENSED$ = CHR$(27) + CHR$(66) + CHR$(j)

= CHR$(27) + CHR$(66) + CHR$(l)

= CHR$(27) + CHR$(66) + CHR$(2)

Page 50

.-

38

Delta User’s Manual

1140 fllllll'SP~CIA~ PRINT ~~~~~Ill,llllllllllIt

1151a

EMPHASIZED$

116g NOT.EMPHASIZED$

11.7g

DOUBLE.STRIKE$ = CHR$(27) + CHR$(71)

= CHR$(27) + CHR$(69)

= CHR$(27) + CHR$('I@)

1180 NOT.DOUBLE.STRIKE$ = CHR$(27) + CHR$(72)

1190

UNDERLINED$ = CHR$(27) + CHR$(45) +

CHR$(l)

12pl0 NOT.UNDERLINED$ = CHR$(27) + CHR$(45) +

CHR$(0)

1210 SUPERSCRIPT$ = CHR$(27) + CHR$(83) +

CHR$(0)

1220 SUBSCRIPT$ = CHR$(27) + CHR$(83) +

CHR$(l)

1230 NOT.SCRIPTED$ = CHR$(27) + CHR$(84)

1240 RESET.ALL$ = NOT.EMPHASIZED$ + NOT.UNDERLINED$

+ NOT.DOUBLE.STRIKE$

1250 RESET.ALL$ = RESET.ALL$ + ROMAN$ + PICA$ +

NOT.ENLARGED$

1260 IlllllllllltlllI~~~~~~~~~l"ll"l,lf'll"l,'

1270 TRUE = 1 :FALSE = 0

1280 REGULAR.HEADING$ = STRING$(27,"*") + "REGULAR"

+ STRING$(27,"*")

1290 RETURN

,r,,,11l1,lll,111l111llr1l1ll,l1l,,r11lf1111

2000

2010 I

2020 1

2030 ’

,,1l,,11l111r1111l111ll11ll1!1l11,11l111rlll

2040

1

PRINT HEADING '

1

2050 LPRINT RESET.ALL$

2060 LPRINT ENLARGED$ lr

NORMAL ENLARGED lr

2070 LPRINT RESET.ALL$;

2080 LPRINT UNDERLINED$;

2090 LPRINT CONDENSED$ "CONDENSED I';

2100 LPRINT ELITE$

2110 LPRINT PICA$

" ELITE I';

" PICA I';

2120 LPRINT CONDENSED$ "CONDENSED ";

2130 LPRINT ELITES " ELITE 'I;

2140 LPRINT PICA$

" PICA "

2150 LPRINT RESET.ALL$

2160 RETURN

,,ll,1llrl,11,l,l11l1ll,l1l,1l1l11r11,1,1fl

3000

3010 ' '

3020 '

3030 ' '

,111,l,,,,,,,ll,,,1!1~1111,1111,1l1111f1111

3040

PRINT FOUR LINES

,

-

-.

-

-

-

-

Page 51

Printing Text With Delta

39

3050 ITALICS = FALSE

3060 UNDERLINED = FALSE

:LPRINT ROMAN$;

:LPRINT

NOT.UNDERLINED$;

3070 ENLARGED = FALSE

:LPRINT NOT.ENLARGED$;

3080 PICA = FALSE

3090 IIIIII~~~II~~~RINT PI~CHESftlfl~fff~~flfffl

3100 LPRINT CONDENSED$;

..

b.

3110 GOSUB 3500 'PRINT AS REQUIRED

3120 LPRINT ELITE$;

3130 GOSUB 3500 'PRINT AS REQUIRED

3140 LPRINT PICA$; :PICA = TRUE

3150 GOSUB 3500 'PRINT AS REQUIRED

i

3160 '~~"""SEE WHAT HAS BEEN D0NE""""""

3170 IF ENLARGED = TRUE THEN LPRINT :GOTO 3190

'CHECK IF UNDERLINED

3180 LPRINT ENLARGED$; :ENLARGED = TRUE :GOTO 3080

i

'ELSE CONTINUE LINE

3190 IF UNDERLINED = TRUE THEN LPRINT :GOTO 3210

'CHECK IF ITALICS

3200 LPRINT UNDERLINED~; :UNDERLINED = TRUE :G0~0

. .

3070

3210 IF ITALICS = TRUE THEN LPRINT RESET.ALL$

'ELSE PRINT UNDERLINE

:RETURN

1.

3220 LPRINT ITALICS; :ITALICS = TRUE :GoTo 3060

'REPEAT WITH ITALICS

111!1l1ll111111ll,1l1ll11ff111ll1ll11l1lflll

3500

3510 ’

3520 ’

3530 '

l1l1ll111!rl11ll11llllllllll1ll1lllll11111l1

3540

3550 BLANK$ = STRING$(6,32)

1

PRINT AS REQUIRED

I

1

:FOUR.DOT$ = "...."

3560 IF EMPHASIZED = FALSE THEN LPRINT "ABcd";

:GOTO 3610

3570 IF PICA = FALSE THEN LPRINT FOUR.DOT$;

:GOTO 3590

3580 LPRINT EMPHASIZED$ "ABcd" ;

3590 IF ENLARGED = TRUE THEN LPRINT 11 ";

:ELSE LPRINT BLANK$;

3600 RETURN

3610 llllft~~lfl~~~~~~~~~~ = FA~SElf"llllflll"

3620 IF ENLARGED = TRUE THEN LPRINT v ";

:RETURN

3630 LPRINT SUPERSCRIPT$; "Xx";

3640 LPRINT SUBSCRIPT$;

"YY " ;

3650 LPRINT NOT.SCRIPTED$;

3660 RETURN

Page 52

an

Here is the chart it produces:

Delta User’s Manual

NOKMF=lL

CONDENSED

tHEtULARX

bBcd%, APcdX”v, ABcdX” vy

h&d%, ABcd-‘v, ABcd”“v, ABcd FIEcd

fEMF’HAS1 ZEDt

.,.a

. . . .

ELITE

. . . .

,...

--F’ICA

-

ABcd

ABcd

ENL-eRGED

CONDENSED

ABcd CIRcd

..I. m--m

..I. m--w

ELITE

---P I CA

ABcd

e..=cd -

FlBcd

FlBcd

*IfOUHLE STRIKE % EMPHAS I ZEDlr

III.

I”’

. . . .

.,,.

ABcd

. . . . .m.m cSEcd

ABcd . . . . I

Summary

Control code

(ESC) “B” CHR$(l)

(ESC) “B” CHR$(2)

(ES0 “B” CHR$(3)

CHR$(18)

Function

Sets pica pitch

Sets elite pitch

Sets condensed pitch

Sets pica pitch

-

EC

-

Page 53

Printing Text With Delta

41

CHR$(15)

CHR$(14)

(ESC) CHR$(14)

(ESC) “W” CHR$(l)

(ESC) “W” CHR$(O)

(ESC) “G”

( ESC) “H”

(ESC) “E”

(ESC) “F”

(ESC) “4”

(ESC) “5”

(ESC) “ - ” CHR$(l)

(ESC) “ - ” CHR$(O)

(ESC) “S” CHR$(O)

(ESC) “S” CHR$(l)

(ESC) “T”

Sets condensed pitch

One line expanded

One line expanded

Expanded on

Expanded off

Double-strike on

Double-strike off

Emphasized on

Emphasized off

Italic on

Italic off

Underline on

Underline off

Superscript on

Subscript on

Super & subscript off

Page 54

42

Delta User’s Manual

Page 55

Chapter 4

Line Spacing and Forms Control

We have learned how to print in many different ways, but so

far we haven’t looked at how to position the printing on the page.

In this chapter we will learn how to change the vertical spacing

and the length of the page.

Starting New Lines

Up until now the only time we have thought about printing on

a new line is when we didn’t want it to happen. We learned that

putting a semicolon (;) at the end of a BASIC line will not end the

line of printing. So somehow, the computer is telling the printer

Page 56

44

Delta User’s Manual

when to end one line and start another.

There are two codes that are used to end one line and start

another. They are carriage return (CHR$(13)) and line feed

(CHR$(lO)). The codes are simple, but their action is a little confusing (especially with BASIC). Carriage return is the easiest. Each

time that the printer receives a CHR$(13) it returns the print head

to the left margin. It does not advance the paper (if DIP switch 2-4

is off; see below).

Line feed is more complicated. Each time the printer receives

a CHR$(lO) it both advances the paper one line and returns the

print head to the left margin, ready to start a new line.

Now to add a little confusion-most (but not all) versions of

BASIC add a line feed (CHR$(lO)) to every carriage return (CHR$(13)) that they send. If your version of BASIC doesn’t do

this, then you should turn DIP switch 2-4 on so that Delta will add

the line feed for you. When you have DIP switch 2-4 on the printer

will do the same thing when it receives a carriage return as it does

when it receives a line feed.

If you find that your printer double spaces when it should

single space, then you probably need to turn DIP switch 2-4 off.

Changing Line Spacing

When you turn Delta on the line spacing is set to 6 lines per

inch (or 8 lines per inch if DIP switch l-5 is off). This is fine for

most printing applications, but sometimes you may want something different. Delta makes it easy to set the line spacing to whatever value you want.

Try this program to see how easy it is to change the line spat-

ing:

NEW

$2 FOR I = 1 TO 25

29 IF I = 13 THEN 51a

38 LPRINT CHR$(27) "A" CHR$(I);

4g LPRINT "DELTA HAS VARIABLE LINE SPACING"

5p NEXT

6pl LPRINT CHR$(27) "2"

-.

_

_

-

-

-

Page 57

Line Spacing and Forms Control

This is what you will get:

45

i--

i L

j L

i or

: c-

DELTA HAS VARIABLE

DELTA HAS VARIABLE

DELTA HAS VAR I ABLE

DELTA HAS VAR I ABLE

DELTA HAS VARIABLE

DELTA HAS VARIABLE

DELTA HAS VARIABLE

DELTA HAS VARIAELE

DELTA HAS VARIABLE LINE SPACING

DELTA HAS VARIABLE LINE SFACI NG

DELTA HAS VARIABLE LINE SPACING

DELTA HAS VARIABLE LINE SPACING

DELTA HAS VARIABLE LINE SF’ACING

DELTA HAS VARIABLE LINE SPACING

DELTA HAS VARIABLE LINE SPACING

LINE

LINE

LINE

LINE

LINE

LINE

LINE

LINE

SF-AC I NG