Page 1

Page 2

Declaration of Conformity

Manufacturer’s Name : Japan CBM Corporation

Manufacturer’s Address : CBM Bldg., 5-68-10, Nakano, Nakano-ku,

Tokyo 164-0001 Japan

Declare the Product

Product Name Terminal Slip Printer

Model Number(s) CBM-820

(CBM-820R, CBM-820P)

(S. No.9890001 - )

Conform to the following Standards

LVD : EN60950 : A4:1997

EMC : EN55022

: EN61000-3-2

: EN61000-3-3

: EN50082-1

: EN61000-4-2

: EN61000-4-3

: ENV50204

: EN61000-4-4

: EN61000-4-5

: EN61000-4-6

: EN61000-4-8

: EN61000

Supplementary Information

“The product complies with the requirements of the Low Voltage Directive 73/23/EEC,

93/68/EEC and the EMC Directive 89/336EEC, 92/31/EEC, 93/68EEC”

: 1994 Class B

: 1995

: 1995

: 1997

: 1995 ±4KV CD, ±8KV AD

: 1995 3V/m, 80MHz-1000MHz AM 1KHz 80%

: 1995 3V/m,895MHz-905MHz

(Pulse 200Hz,duty cycle50%)

: 1995 ±1.0KV(

: 1995

: 1996 3V, 0.15MHz-80MHz AM 1KHz 80%

: 1993 50Hz, 3A/m

-4-11

: 1991-80%, 10ms/-60%,100ms/-100%, 5000ms

AC Mains

1KV Differential mode, 2KV Common mode

), ±0.58KV (

Signal Lines

)

Place

: Tokyo, Japan

Date :August.1998 Full Name : Mikio Moriya

European Contact :

Norco Declaration AB

Box 7146 S-250 07 Helsingborg Sweden

This declaration is applied only for 230V model.

Signature

Position : General Manager

R & D Department

Page 3

IMPORTANT SAFETY INSTRUCTIONS

• Read all of these instructions and save them for future reference.

• Follow all warnings and instructions marked on the product.

• Unplug this product from the wall outlet before cleaning. Do not use liquid or aerosol cleaners.

Use a damp cloth for cleaning.

• Do not use this product near water.

• Do not place this product on an unstable cart, stand or table. The product may fall, causing serious

damage to the product.

• Slots and openings on the back or bottom of the case are provided for ventilation. To ensure reliable

operation of the product and to protect it from overheating, do not block or cover these openings.

The openings should never be blocked by placing the product on a bed, sofa, rug of other similar

surface. This product should never be placed near or over a radiator or heater. This product should

not be placed in an built-in installation unless proper ventilation is provided.

• This product should be operated from the type of power source indicated on the marking label. If

you re not sure of the type of power available, consult your dealer or local power company.

• Do not allow anything to rest on the power cord. Do not place this product where the cord will be

walked on.

• If an extension cord is used with this product, make sure that the total of the ampere ratings of the

products plugged into the extension cord does not exceed the extension cord ampere rating. Also,

make sure that the total of all products plugged into the wall outlet does not exceed 15 amperes.

• Never push objects of any kind into this product through cabinet slots as they may touch dangerous

voltage points or short out parts that could result in a risk of fire or electric shock. Never spill liquid

of any kind on the product.

• Except as explained elsewhere in this manual, do not attempt to service this product by yourself.

Opening and removing the covers that are marked “Do Not Remove” may expose you to dangerous

voltage points or other risks. Refer all servicing on those compartments to service personnel.

• Unplug this product from the wall outlet and refer servicing to qualified service personnel under

the following conditions:

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the product.

C. If the product has been exposed to rain or water.

D. If the product does not operate normally when the operating instructions are followed. Adjust

only those controls that are covered be the operating instructions since improper adjustment of

other controls may result in damage and will often require extensive work by a qualified

technician to restore the product to normal operation.

E. If the product has been dropped or the cabinet has been damaged.

F. If the product exhibits a distinct change in performance, indicating a need for service.

• Please keep the poly bag which this equipment is packed in away from children or throw it away to

prevent children from putting it on. Putting it on may cause suffocation.

Page 4

WICHTIGE SICHERHEITSANWEISUNGEN

• Lesen Sie die nachfolgenden Anweisungen sorgfältig durch und bewahren Sie sie auf.

• Befolgen Sie alle auf dem Drucker vermerkten Hinweise und Anweisungen. Vor dem Reinigen

grundsätzlich Stecker aus der Steckdose ziehen. Keine Flüssigkeiten oder Aerosolreiniger

benutzen. Nut mit einem feuchten Tuch abwischen.

• Der Drucker darf nicht in der Nähe von Wasser aufgestellt werden.

• Drucker nicht auf einem unstabilen Wagen, Stand oder Tisch aufstellen. Der Drucker könnte

herunterfallen und dabel beschädigt werden.

• Schlitze und Öffnungen im Gehäuse, in der Rückwand und im Boden dienen der Belüftung. Sie

dürfen keinesfalls zugedeckt oder blockiert werden, da sich der Drucker sonst überhitzt. Drucker

nicht auf ein Bett, Sofa, Teppich oder dergleichen stellen. Drucker nicht in der Nähe eines

Heizkörpers aufstellen. Drucker darf nicht eingebaut werden, falls nicht für ausreichende

Belüftung gesorgt ist.

• Drucker nur mit der auf dem Typschild angegebenen Spannung betreiben. Wenn Sie sich nicht

sicher sind, fragen Sie ihren Händler oder ihr zuständiges Elektrizitätswerk.

• Nichts auf das Stromanschlußkabel stellen. Kabel muß so verlegt werden, daß man nicht

darauftreten kann.

• Ein etwaiges Verlängerungskabel muß der Stromstärke aller daran angeschlossenen Geräte

entsprechen.

• Keine Gegenstände in die Gehäuseschlitze schieben.

• Drucker darf nur da gewartet werden, wo im Handbuch angegeben, Öffnen und. Abnehmen von

Abdeckungen, die mit “Do not remove” gekennzeichenet sind, könnte gefährliche spannungführende Stellen oder sonstige Gefahrenpunkte freilegen. Die Wartung solcher Stellen darf

grundsätzlich nur von besonders ausgebildetem Fachpersonal vorgenommen werden.

A. Wenn das Stromanschlußkabel oder der Stecker beschädigt oder durch-gescheuert ist.

B. Wenn Flüssigkeit auf dem Drucker verschüttet wurde.

C. Wenn der Drucker im Regen gestanden hat oder Wasser darauf verschüttet wurde.

D. Wenn der Drucker trotz genauer Befolgung der Betriebsvorschriften nicht richtig arbeitet. Nur

die in der Bedienungsanleitung angegebenen Einstellungen vornehmen. Ein Verstellen anderer

Bedienungselemente könnte den Drucker beschädigen und macht umständliche Arbeiten eines

qualifizierten Technikers erforderlich, um den Drucker Wieder auf den normalen Betrieb

einzustellen.

E. Wenn der Drucker heruntergefallen ist oder das Gehäuse beschädigt wurde.

F. Wenn der Drucker in seiner Leistung nachläßt.

• Bitte halten Sie den Kunststoffbeutel, in den die Ware verpackt ist, von Kindern entfernt, oder

werfen Sie ihn weg, damit er nicht in die Hande von Kindern gerät. Das Überstülpen des Beutels

kann zum Ersticken führen.

Lärmemission kleiner 70 dBA

Page 5

IMPORTANT:

installed and used in accordance with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A computing

device pursuant to Subpart J of Part 15 off FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the interference.

This equipment generates, uses, and can radiate radio frequency energy and if not

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Grät angebracht und leicht zugänglich

sein.

For Uses in Canada

This digital apparatus does not exceed the class A limits for radio noise emissions from digital,

apparatus, as set out in the radio interference regulations of the Canadian department of

communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les émissions de bruit radio

émanant d'appareils numériques, tel que prévu dans les réglements sur l'interférence radio du

départment Canadien des communications.

Page 6

< CAUTIONS >

1. Prior to using the equipment, be sure to read this User’s Manual thoroughly. Please keep it handy for

reference whenever it may be needed.

2. The information contained herein may be changed without prior notice.

3. Reproduction of part or all of this User’s Manual without permission is strictly prohibited.

4. Never service, disassemble, or repair parts that are not mentioned in this User’s Manual.

5. Note that we will not be responsible for damages attributable to a user’s incorrect operation/ handling or

an improper operating environment.

6. Operate the equipment only as described in this User’s Manual; otherwise accidents or problems may

result.

7. Data are basically temporary; they cannot be stored or saved permanently or for a long time. Please note

that we will not be responsible for damages or losses of profit resulting from losses of the data

attributable to accidents, repairs, tests, and so on.

8. If you have any questions or notice any clerical errors or omissions regarding the information in this

manual, please contact our office.

9. Please note that, notwithstanding Item 8 above, we will not be responsible for any effects resulting from

operation of the equipment.

Note:

• Citizen and Citizen logo are registered trademarks of Citizen Watch Co., Ltd.

• ESC/POS and TM-295 are trademarks of Seiko Epson Co., Ltd.

• Auto Side Loading™ is a trademark of Star Micronics Co., Ltd.

• Windows codepage is a registered trademark of Microsoft Corporation.

Page 7

SAFETY PRECAUTIONS ----- BE SURE TO OBSERVE

In order to prevent hazards to an operator or other persons and damage to property, be sure to observe the

following precautions.

●

The following describes the degrees of hazard and damages that can occur if the given instructions are

neglected or the equipment is incorrectly operated.

WARNING

CAUTION

This is an illustration mark used to alert your attention.

This is an illustration mark used to indicate such information as an instruction or the like.

Negligence of this precaution may result in death or serious injury.

Negligence of this precaution may result in injury or damage to

property.

Page 8

WARNING

●

Never handle the equipment in the following manners, as it may break, become out of order, or

overheat causing smoke and resulting in fire or electric shock.

If the equipment is used in an abnormal condition, such as when broken, then problems, smoke

emission, abnormal odor/noise, and fire can result. If an abnormal condition exists, be sure to

disconnect the power plug from a plug socket, and contact our dealer. Never repair the equipment

on your own - it is very dangerous.

• Do not allow the equipment to receive a strong impact or shock, such as kicking, stomping, hitting,

dropping, and the like.

• Install the equipment in a well-ventilated place. Do not use it in such a manner that its ventilation

port will be blocked.

• Do not install the equipment in a place like a laboratory where chemical reactions are expected, or

in a place where salt or gases are contained in the air.

• Do not connect/disconnect a power cord or a data cable, while holding the cable. Do not pull,

install, use, or carry the equipment in such a manner that force will be applied to the cables.

• Do not drop or insert any foreign substances, such as clips or pins, into the equipment.

• Do not spill any liquid or spray any chemical-containing liquid over the equipment. If any liquid

is spilled on it, turn off the power, disconnect the power cable and power cord from the plug socket,

and so on, and contact our dealer.

• Never disassemble or remodel the equipment. Negligence of this may cause fire or electric shock.

• Use the equipment only with the specified commercial power supply and AC adapter. Negligence

of this may result in fire, electric shock, or problems.

• If you drop or break the AC adapter, or if water or the like gets inside it, unplug it immediately from

the socket and contact your dealer.

• Do not damage, break, process, bend/pull by force, twist, or head an AC adapter cord. Also, do not

put a heavy substance on it or heat it. The AC adapter cord could be broken, resulting in fire,

electric shock, or trouble. If the AC adapter cord is damaged, contact our dealer.

• Do not connect/disconnect the AC adapter with wet hands.

• Do not overload a single electrical outlet, using a table tap or a current tap socket.

●

An equipment packing bag must be discarded or kept away from children. A child can suffocate

if the bag is placed over the head.

Page 9

PRECAUTIONS FOR INSTALLATION

• Do not use or store the equipment in a place exposed to fire, moisture, or direct sunshine, or in a

place near a heater or thermal device where the prescribed operating temperature and humidity are

not met, or in a place exposed to much oil, iron powder, or dust. The equipment may become out

of order, emit smoke, or catch fire.

• Do not install or use the equipment in a place like a laboratory where chemical reactions are

expected, or in a place where salt or gases are contained in the air. There is a danger of fire or

electric shock.

• Install the printer on a flat, stable desk or table that is free from vibration, in a well-ventilated place.

• Do not install the printer at a location where its operation could be hindered.

• Do not place anything on the printer or leave small objects, like a clip or pin, around it. A foreign

object could cause trouble if it gets inside.

• Do not use any sharp-pointed object, such as a pen, for example, to touch the operation panel of the

printer. It could cause trouble.

• Do not use the equipment near a radio or TV receiver. Do not share the power from a plug socket

a radio or TV receiver is connected to. It may cause a reception problem.

• Use the equipment only at the specified power supply, voltage and frequency. Otherwise, it may

emit smoke and catch fire or cause other problems.

• Connect only the specified power source. Use of an unspecified power source could cause trouble

or smoke/fire.

• Confirm that a plug socket used for connection has sufficient capacity.

• Avoid connecting a power cable to a plug socket shared by other devices or extending the wiring

too far. It may result in the cable catching fire or a power outage. Also, do not step on or apply an

excessive force (Pull, load) to the cable, and do not use the printer with such a force applied to it.

• Never connect a grounding cable (Frame ground) to a gas pipe. There is a danger of explosion.

When connecting or disconnecting the grounding cable, be sure to disconnect the power cable and

the power plug from the plug socket.

• When connecting/disconnecting the cables, be sure to turn off the power first, including the

connected side, and then connect/disconnect them, holding a plug and a connector. Pulling the

cable itself could cause it to snap or become damaged.

• Connect a power cable or a connector cable securely. If a reverse-polarity connection is made,

internal elements may be broken or a mating device may be adversely affected.

• Use a shielding wire or twisted pair wire for a signal line, in order to minimize noise effect. Do not

route the cable too long or connect it to a noisy device. Connection to a noisy device could cause

erroneous printing due to corrupt data, and so on.

• Use the equipment in an environment where there is a plug socket near the main body and you can

easily disconnect the power plug from it, to shut off the power.

• When the equipment will not be used for a long period of time, unplug it and remove the paper roll

from it.

• When transporting the equipment, remove the paper roll from the paper holder.

Page 10

PRECAUTIONS FOR HANDLING

Do not handle the equipment in the following manners, because problems may result.

• Do not use any other power source besides the accessory AC adapter. Also, do not use the AC

adapter for other purposes.

• Do not print without paper.

• Do not drop or put any foreign object, such as a clip, pin, or the like, inside the printer.

• Do not spill any liquid or spray any chemical-containing liquid over the equipment.

• Never use a pointed object, such as a pen, to operate the operation panel.

• Do not use Scotch tape to fasten paper together for continuous use. It could damage the printing

head.

• Never pull the set paper forcibly. When opening/closing the printer cover, take care that the paper

will not be caught. It could cause the paper to jam.

• Be sure to use the specified paper. Use of other paper could deteriorate the print quality or cause a

problem with the printing head.

To Prevent Injury and Spreading of Damage

• Never touch the printing head, motor, or paper cutting blade. Your finger may be cut.

• During power-on or immediately after printing, do not touch electrical parts or moving parts, such

as the mechanism, motor, internal gear, etc. They may be very hot and can burn your hand/finger.

• Be careful to avoid bodily injure or damaging other objects with an edge of sheet metal.

• Should any error occur while operating the equipment, stop it immediately and disconnect the

power plug from the plug socket.

• Only a qualified serviceman is allowed to disassemble or repair the printer.

• Should a problem occur, leave solving it to our serviceman. Do not disassemble the equipment on

your own.

• When opening/closing the printer cover, and so on, be careful not to catch your hand or finger on

the equipment.

• After using the equipment, turn off the power switch and unplug the AC adapter from a plug socket.

Page 11

DAILY MAINTENANCE

• At the time of maintenance, be sure to turn off the power switch of the printer and unplug it from

the socket.

• Use a dry soft cloth to wipe off stains and dust from the surfaces of the main body case. For severe

soiling, dip the cloth in water and wring it, for wiping off the soil. Never use organic solvents, such

as alcohol, thinner, trichlene, benzene, ketone, or chemical dusters.

• If the equipment is contaminated with paper powder, use a soft brush to clean it. Be careful not to

damage the printing head.

CAUTION :

The printing head and motor are very hot. Be careful not to touch them

immediately after printing. Do not touch the heating surface of the head

with a bare hand or metal.

Page 12

1. Printer Setup

This chapter contains important information on setting up your printer. Be sure

to read this chapter carefully before using the printer for the first time. In this

chapter you will learn about:

Choosing a place for the printer

❏

Unpacking and setting up the printer

❏

Installing the ribbon cassette

❏

Connecting to a host computer

❏

Inserting paper

❏

1.1 Choosing a place for the printer

Before actually unpacking the printer, you should take a few minutes to think

about where you plan to use it. Remember the following points when doing this.

✓

Choose a firm, level surface where the printer will not be exposed to

vibration.

The power outlet you plan to connect to for power should be nearby and

✓

unobstructed.

✓

Make sure that the printer is close enough to your host computer for you to

connect the two.

✓

Make sure that the printer is not exposed to direct sunlight.

✓

Make sure that the printer is well away from heaters and other sources of

extreme heat.

Make sure that the surrounding area is clean, dry, and free of dust.

✓

Make sure that the printer is connected to a reliable power outlet. It should

✓

not be on the same electric circuit as copiers, refrigerators, or other

appliances that cause power spikes.

✓

Use a power outlet that matches the power rating noted on the label affixed

to the bottom of your printer.

Make sure that the room where you are using the printer is not too humid.

✓

– 1 –

Page 13

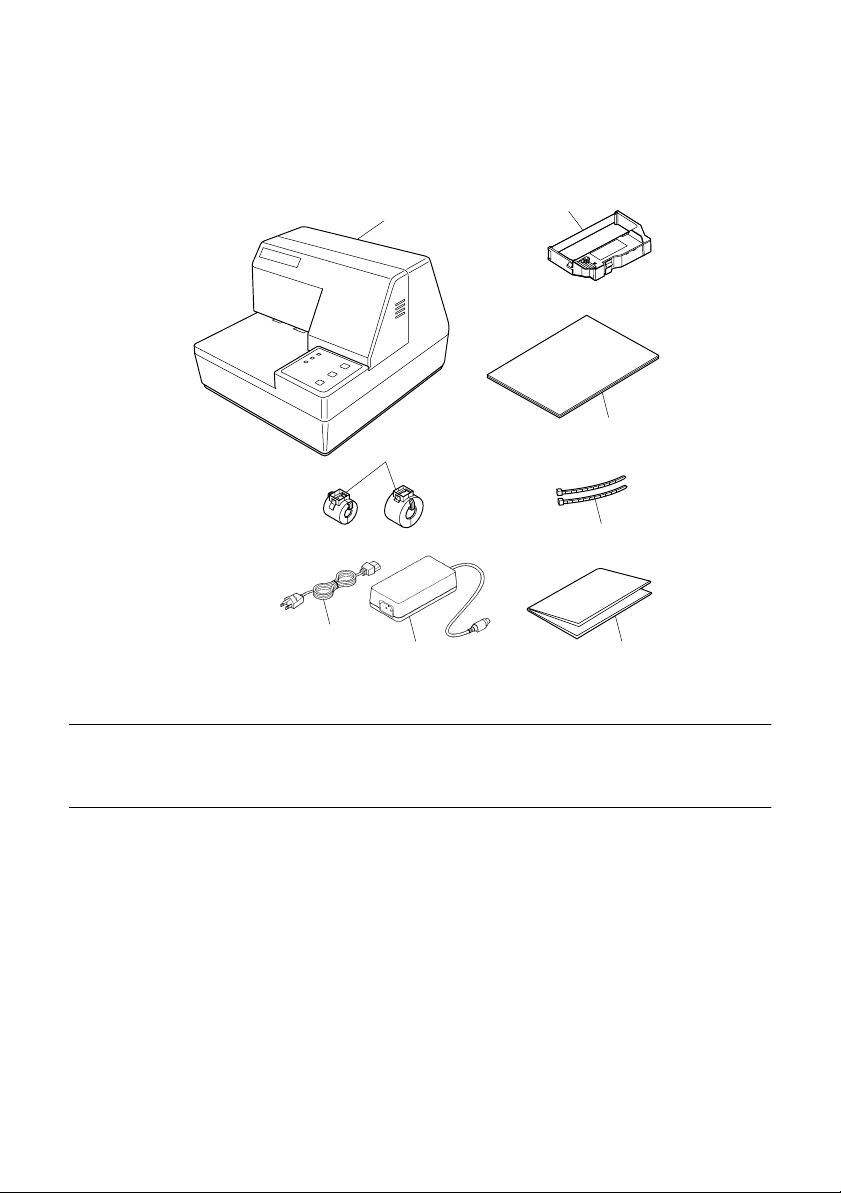

1.2 Unpacking the printer

Check to make sure that the carton contains each of the items shown in the

following illustration.

Printer

Ferrite core

Ribbon cassette

User’s Manual

Fastener

Note:

AC Cable

AC Adapter

Notes of the AC adapter

The AC adapter is accompanied by Notes. Be sure to read this document prior

to using the AC adapter, and keep it together with this manual.

If anything is missing, contact the dealer where you bought the printer and ask

them to supply the missing part. Note that it is a good idea to keep the original

box and all the packing materials just in case you need to pack the printer up

again and send it somewhere at a later date.

Always keep the Instruction Manual and Notes near the printer, for ready

reference whenever necessary.

– 2 –

Page 14

1.3 Removing the protective materials

Four protective materials are inserted into the printer to protect components

during shipping. Before using the printer, be sure to remove all protective

materials as shown in the illustration.

tape

tape

– 3 –

Page 15

2. Specifications

2.1 General Specifications

Printing System Serial impact dot-matrix

Number of Head Pins 9 wires

Printing Speed 3.1 lines/sec maximum

Number of Print Columns 35

Total dots 210

Printing width 63 mm

Dot spacing Horizontal: 0.30mm

Vertical: 0.35mm

Paper Width 80mm to 182mm

Sensors Paper out top-of-form, bottom-of-form sensors

Command Modes ESC/POS mode (TM-295 emulation)

Interface Serial (RS-232C standard)

Data Buffer 2 K bytes / 35 bytes

(Can be selected by DIP switch)

Reliability Mechanism (MCBF): 2.5 million lines

Printer head life: 70 million characters

Operating Environment

Temperature 41°F to 104°F (5°C to 40°C)

Humidity 10% to 80% RH at 40°C (non-condensing)

Storage Environment

Temperature -4°F to 140°F (-20°C to 60°C)

Humidity 5% to 90% RH at 40°C (non-condensing)

Reliability

Printable lines MCBF 2,500,000 lines

Head life 70,000,000 characters

Ink Ribbon

Type Cartridge cassette

Color Purple

Ribbon Material Nylon # 40 denier

Life 2.2 million characters

Important!

Use only the specified type of ribbon. Use of another type of ribbon can cause

malfunction of and damage to the printer.

Applicable Standards

115 V model: UL, C-UL, FCC Class-A

230 V model: TÜV, CE Marking

Those standards are applicable when our exclusive AC adapter (31AD series) is used.

✳

– 4 –

Page 16

2.2 Printing Specifications

Character Set

Character Matrix

Character Dimensions

Codepage PC437 (USA, European Standard)

Codepage Katakana (Japanese)

Codepage PC850 (Multilingual)

Codepage PC860 (Portuguese)

Codepage PC863 (Canadian-French)

Codepage PC865 (Nordic)

Codepage PC852 (Eastern Europe)

Codepage PC866 (Russian)

Codepage PC857 (Turkish)

Windows Codepage

Codepage PC858 (Multilingual II)

7 × 9 (half), 42 columns

5 × 9, 35 columns

7 × 9 font (half): 1.2 (W) × 2.42 (H) mm

5 × 9 font (2 pulses per dot): 1.5 (W) × 2.42 (H) mm

5 × 9 font (3 pulses per dot): 2.1 (W) × 2.42 (H) mm

2.3 Paper Specifications and Print Area

Paper Width

Paper Length

Copies

Paper Thickness

Copy Offset

Binding

Print Area

80 to 182mm / 3.15″ to 7.17

80 to 257mm / 3.15″ to 10.8

Original + 2

1-ply: 0.09 to 0.2mm / 0.0035″ to 0.0079

Duplicates 0.12 mm (minimum for 2-ply forms) to 0.25 mm/0.0047″ to 0.0098

<Maximum 0.2 mm when printing graphics>

1.5mm maximum/15 lines (between top sheet and bottom sheet)

Top or left

Distance from first printed line (Head #1) to top of form (form stopper): 28.6 mm

Distance from first printed line (Head #1) to TOF sensor: 26.0 mm

(However, with the automatic start position operation, this distance is set to 26.5 mm.

The automatic start position operation can be enabled or disabled with the memory

switches.

When the top-of-form sensor is disabled, a command can be used to perform a reverse

paper feed enabling printing to begin at approximately 20 mm from the top of the paper.)

Distance from last printed line (Head #9) to bottom of form (BOF sensor): 38.1 mm

When the BOF sensor is disabled, printing can continue to 14.0 mm from the bottom of

the paper.

Right margin: 5.1 mm

Print area width: 62.7 mm

″

″

(Printing may continue to 27.3 mm from the bottom of the paper.)

″

″

– 5 –

Page 17

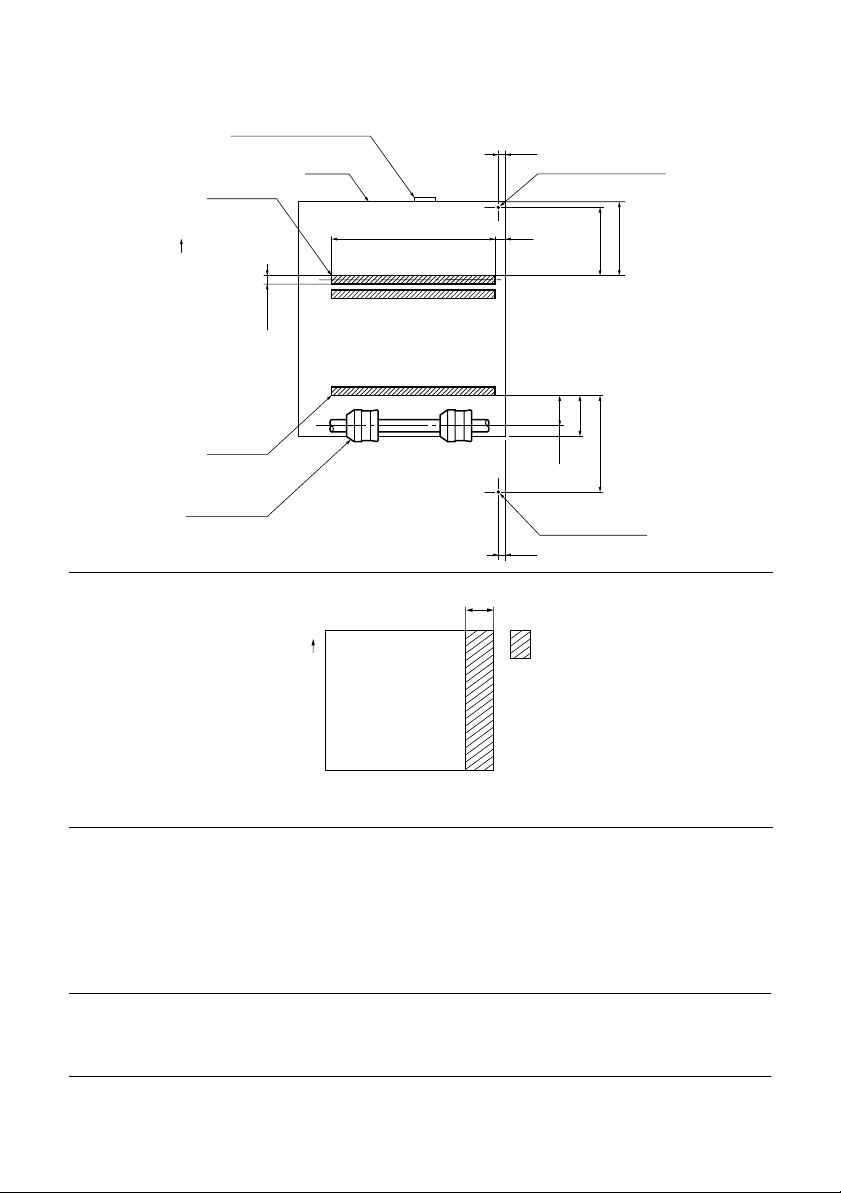

Form stopper (fixed)

Head #1

Paper

3.2

TOF sensor (fixed)

62.7

Paper feed direction

2.82

Head #9

Paper feed

roller

First printed line

Last printed line

Print Position

Paper feed

direction

Do not use paper with perforations within the shaded area. Perforations may cause the

paper sensor to erroneously report an out of paper condition.

Paper Feed

Drive Stepping motor

Pitch Adjustable in n/60″ units (approximate)

Speed (while printing) 3.5″ per second

Speed (while ejecting) 4.5″ per second

8 mm

5.1

14

11.9

BOF sensor (fixed)

3.2

No holes in this area

26.0

38.1

28.6

Important!

Slip paper must be flat, smooth, and free of curls, bends, wrinkles and folds, all

of which can cause jamming and soiling by ink.

– 6 –

Page 18

2.4 Power Supply Specifications

Power Supply

AC Adaptor 31AD, switching type

Input AC100 to 240V 50/60Hz

Output DC 24V ± 5%, 1.9A

Plug TCP8927-83-1100 (Hoshiden brand or equivalent.)

Consumption Current

Conditions: DC 24V, excluding external equipment driving

Operating

(approximate averages)

Stand-by

(approximate averages)

Important!

• When using a printer power supply other than the specified AC adaptor

(31AD), be sure that the following cautions are observed.

• Use a power supply of DC 24 V ±5% and more than 1.9 A.

• Be careful about installing the printer in an area where there is noise. Take the

appropriate measures to protect against electrostatic AC line noise, etc.

Continuous ASCII printing + paper feed: 0.6A

Solid block printing + paper feed: 1.0A

Solid block printing: 1.9A

Peak (solid printing): 3.1A

Paper release deactivated: 0.24 A

Paper release activated: 0.07A

– 7 –

Page 19

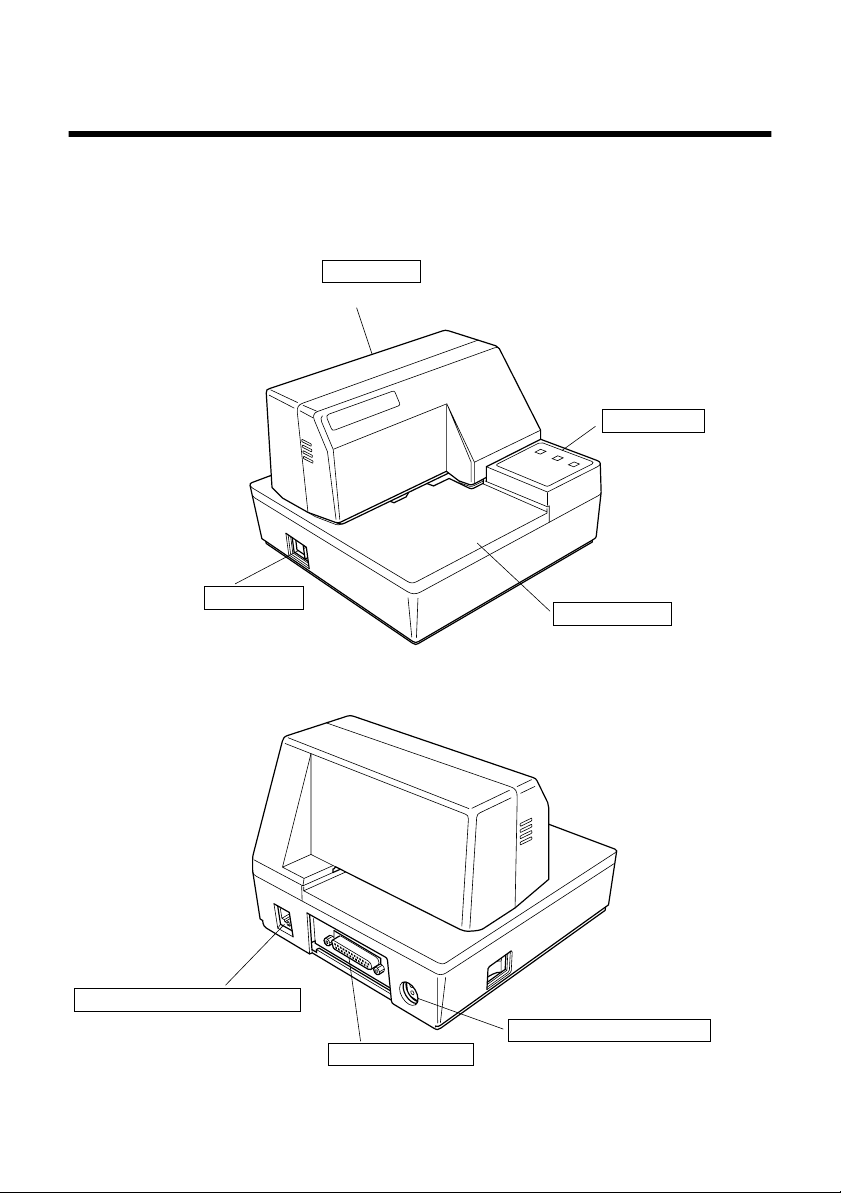

3. Outer Appearance and Component Parts

3.1 General guide

The following illustrations describe the major components, buttons, and

connectors of your printer.

Printer cover

Protects internal components.

Control panel

Three indicators show

the printer status, and

two switches provide

control over printer

functions.

Power switch

Turns printer

power on and off.

Peripheral unit connector cover

Covers a modular jack for

connection of a cash drawer or

other peripheral.

Do not connect a telephone line

to this connector.

Interface connector

For connection

to a host computer.

– 8 –

Document table

Supports the paper fed

into the printer.

AC adapter cable connector

For connection of the AC adapter.

Never unplug the AC adapter

while the printer is on.

Page 20

4. Operation

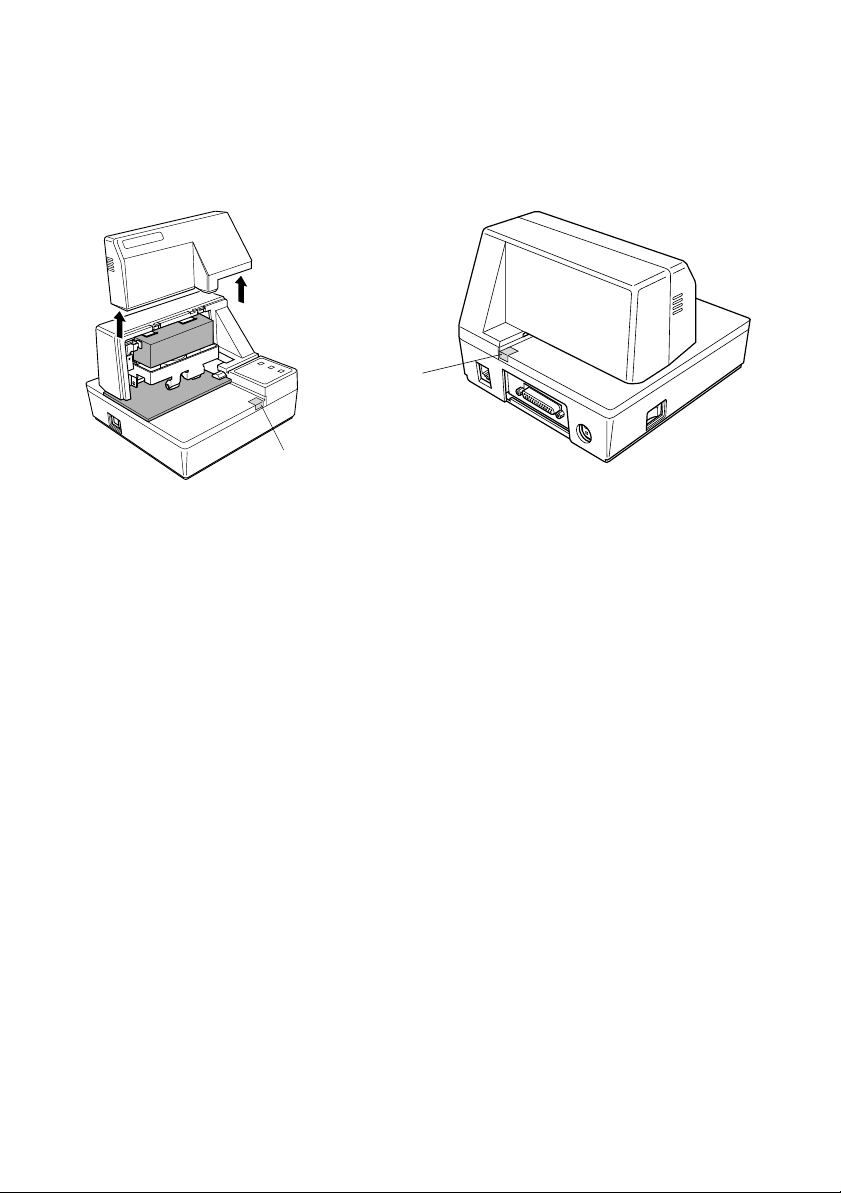

4.1 Removing the printer cover

Push straight up on the ridged locations on the sides of the printer cover to

❏

remove it from the printer.

T o replace the cov er , slide it back do wn into position. Gently press do wn on

❏

the cover until you hear it click securely into place.

4.2 Installing the ribbon cassette

❏

Make sure that the printer's paper release is activated (the paper is not held

in place by the paper feed roller). If it cannot be determined whether or not

the paper release is activated, turn on the printer and check if the

RELEASE

press the

Make sure that the printer is turned off and unplugged from its power

❏

outlet.

Remove the printer cover.

❏

indicator on the control panel is lit. If the indicator is not lit,

RELEASE

button until the indicator lights up.

– 9 –

Page 21

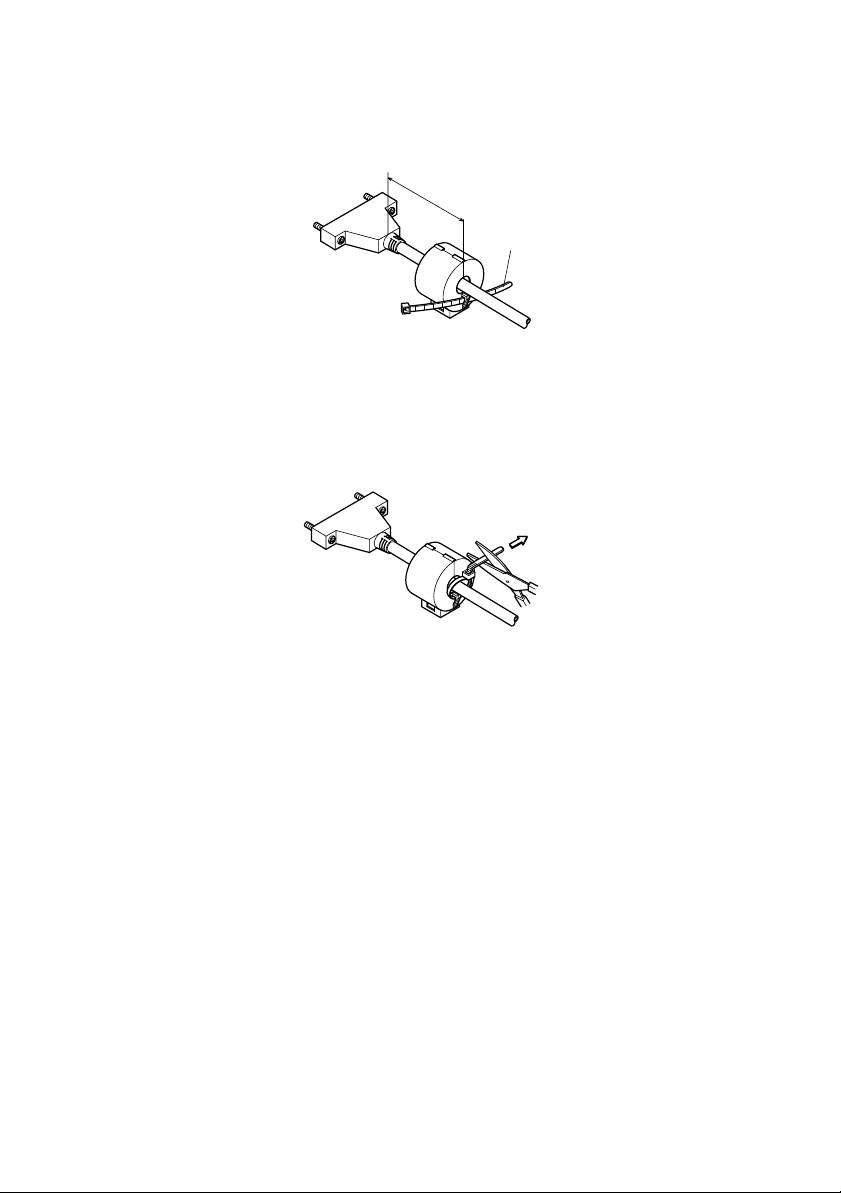

❏

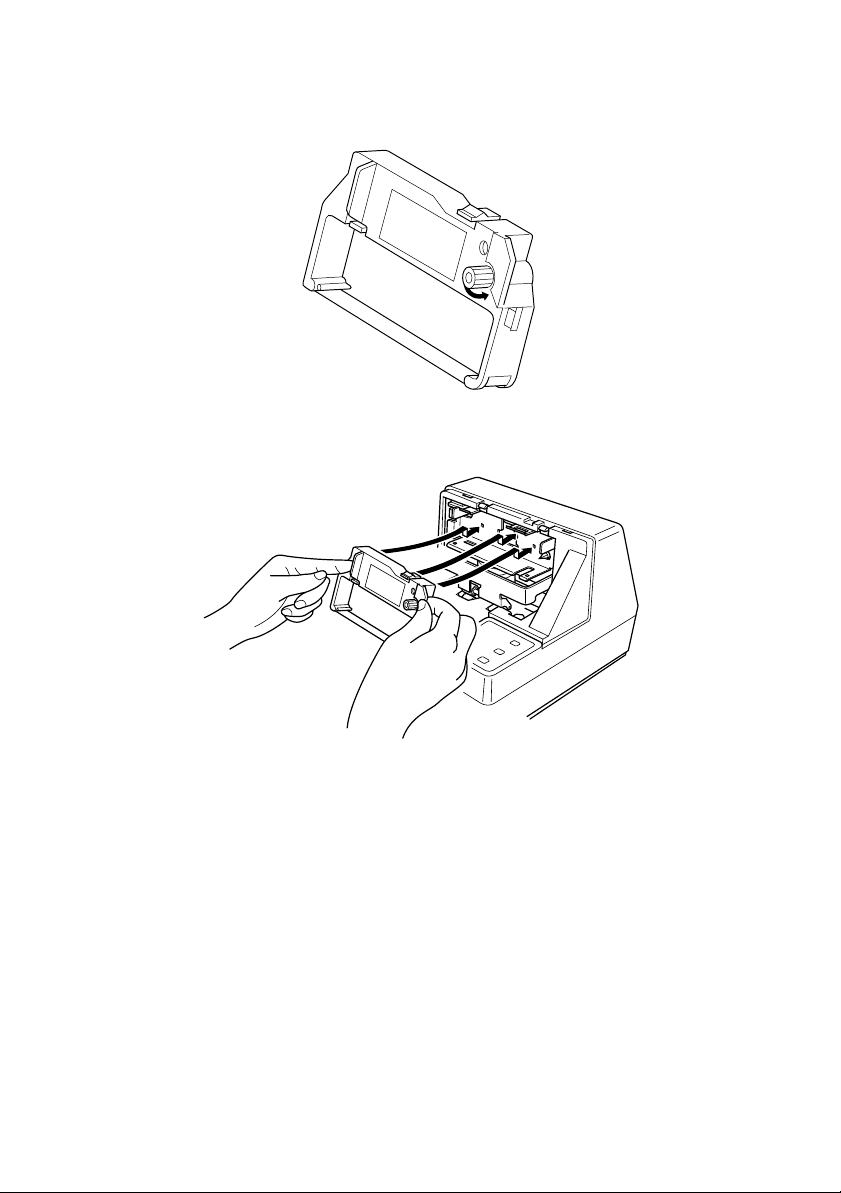

Remove the ribbon cassette from its packaging, and turn its knob in the

direction indicated by the arrow to take up any slack in the ribbon.

❏

Holding the ribbon cassette so that the ribbon is facing down, install the

cassette into the slip printer as shown in the illustration.

❏

Press gently but firmly on the cassette until it snaps securely into place.

❏

Rotate the knob on the cassette again to take up any slack.

❏

Replace the printer cover.

– 10 –

Page 22

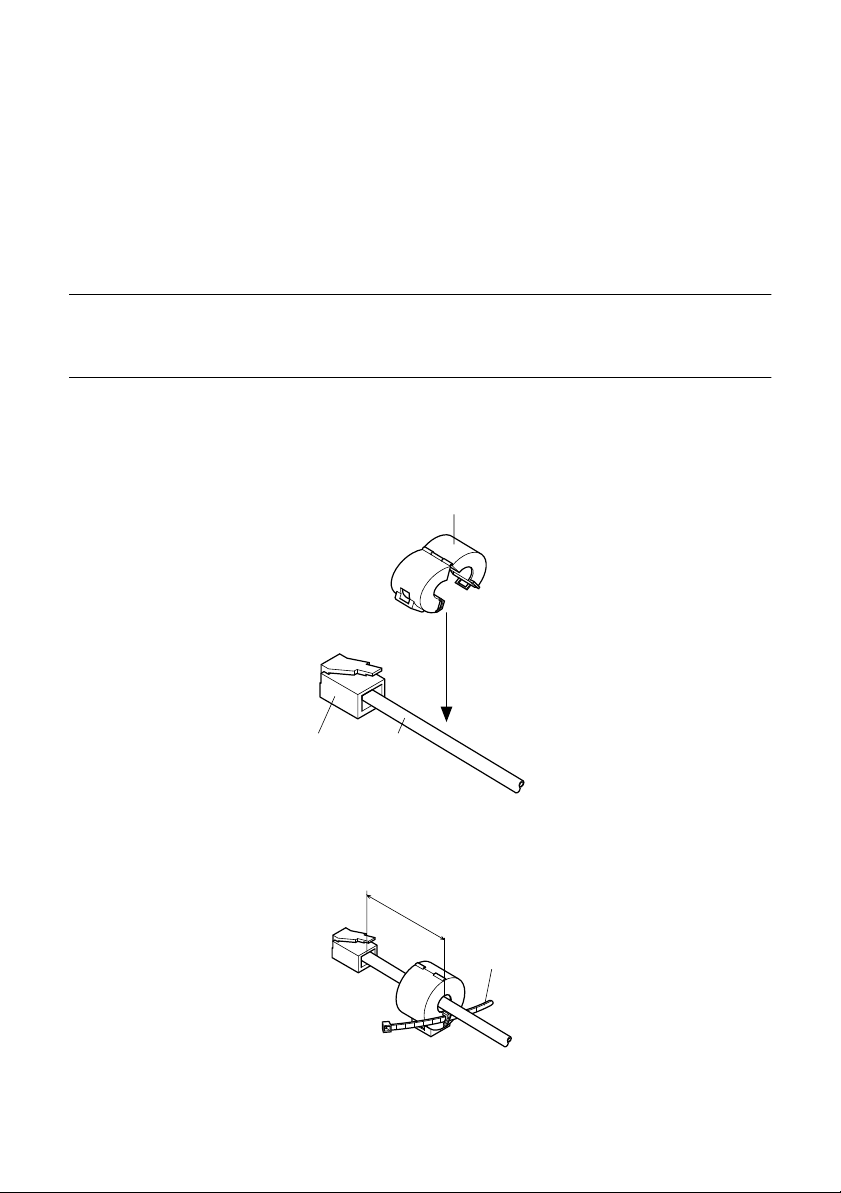

4.3 Removing the ribbon cassette

Use the following procedure to remove the ribbon cassette from the slip printer

when you want to replace it with a new one.

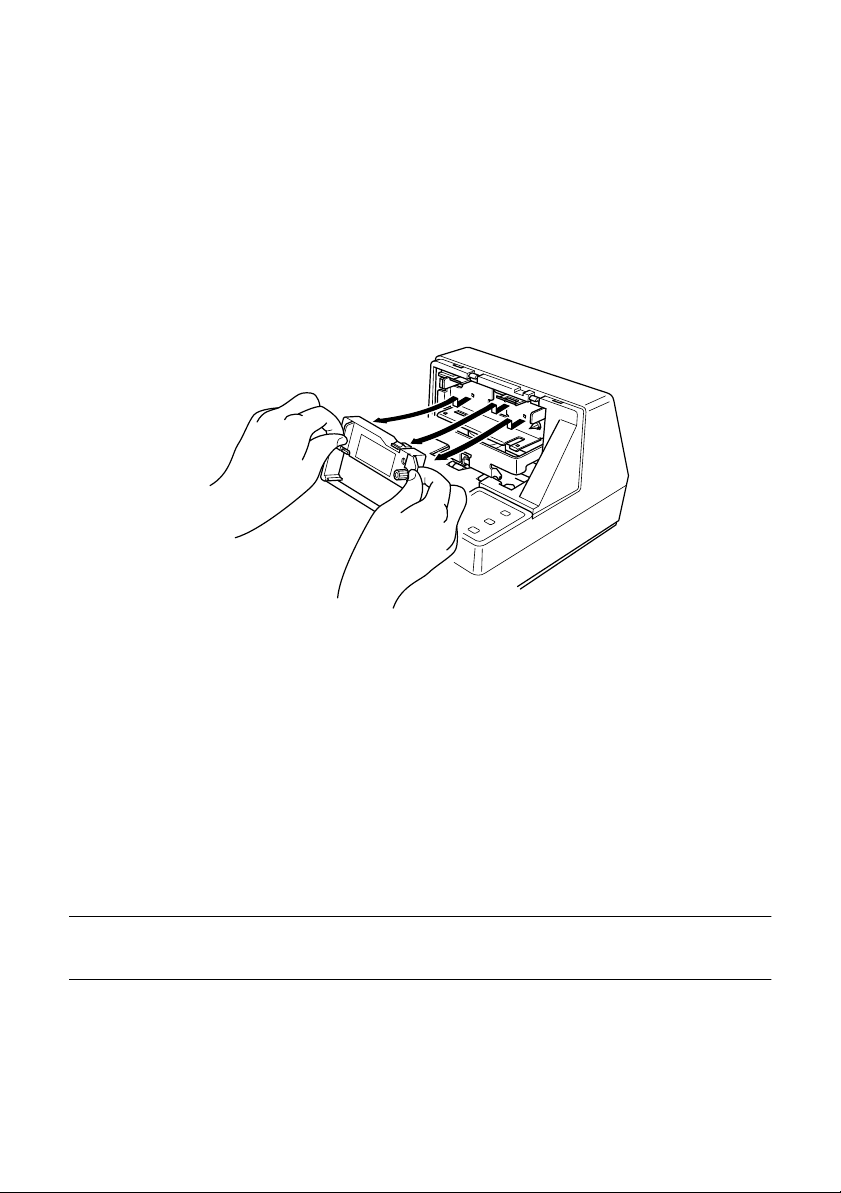

Make sure that the printer is turned off and unplugged from its power

❏

outlet.

Remove the printer cover.

❏

Grasping the ribbon cassette as shown, gently pull it away from the printing

❏

mechanism.

Use the procedure under “Installing the ribbon cassette” on page 9 to install

❏

a new cassette.

4.4 Connecting to a power outlet and turning power on and off

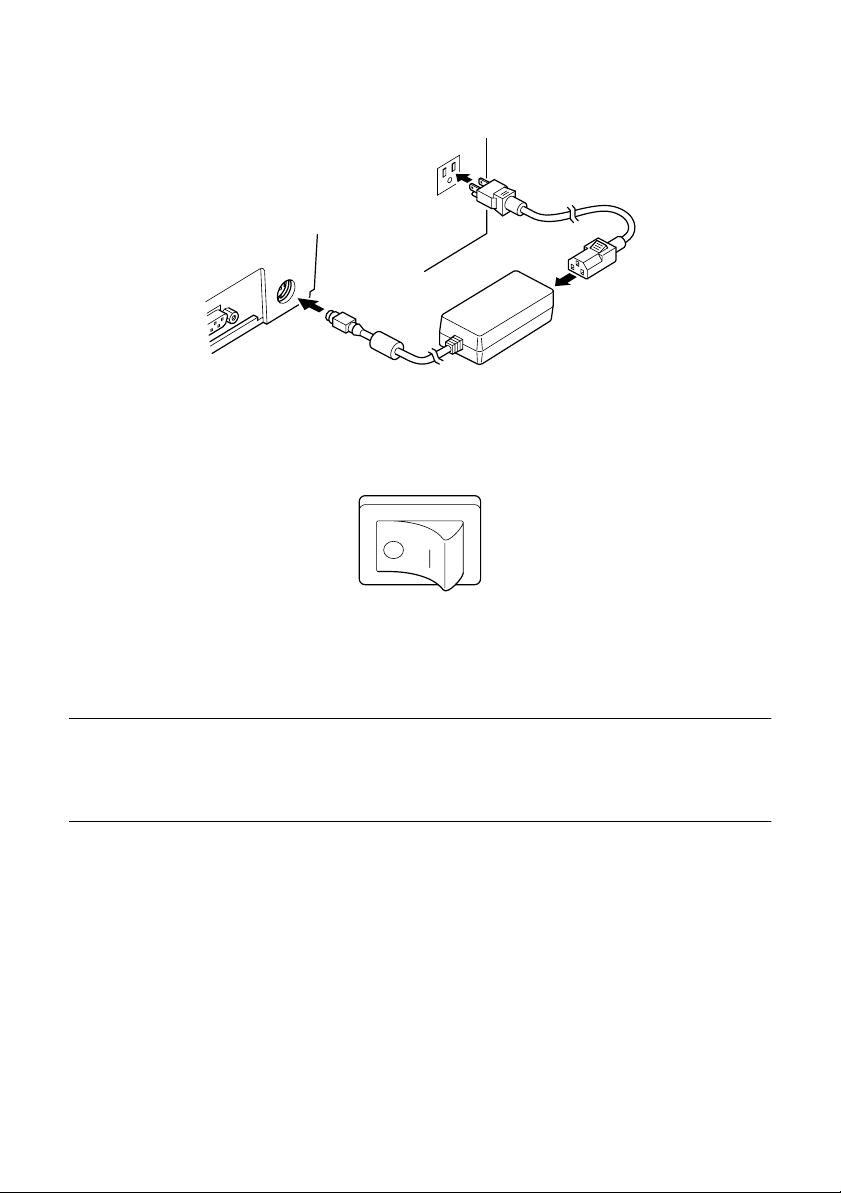

❏

Make sure that the printer is turned off.

❏

Plug the AC adapter that comes with the printer into the printer’s AC

adapter cable connector.

Connect a three-prong grounded power cord to the power cord connector of

❏

the AC adapter.

Note:

The printer does not come with a power cord, so you must pr o vide one yourself .

– 11 –

Page 23

❏

Plug the other end of the power cord to a standard household wall outlet.

❏

Use the power switch on the left side of the printer to turn power on and of f.

Important!

W e recommend that you unplug the printer from the power outlet whenever you

do not plan to use it for long periods. Because of this, you should locate the

printer so that the power outlet it is plugged into is nearby and easy to access.

At this point you may want to perform a test of the printer to make sure it is

working properly. See page 20 for details on how to test the printer.

– 12 –

Page 24

4.5 Connecting to your host computer

The computer sends data to the printer through a cable to the printer’s standard

serial interface (Connector Type: D-sub 25-pin). This printer does not come

with a cable, so it is up to you to obtain one that suits your needs.

Important!

• The following instructions apply to the interface cable that is used with an

IBM-compatible personal computer. Note that they do not apply to all types of

computers and cables. If you are unsure about what type of cable you should

use to connect with your computer, consult your dealer.

• Make sure that the printer is turned off and unplugged from the AC outlet and

that the computer is turned off before connecting them.

❏

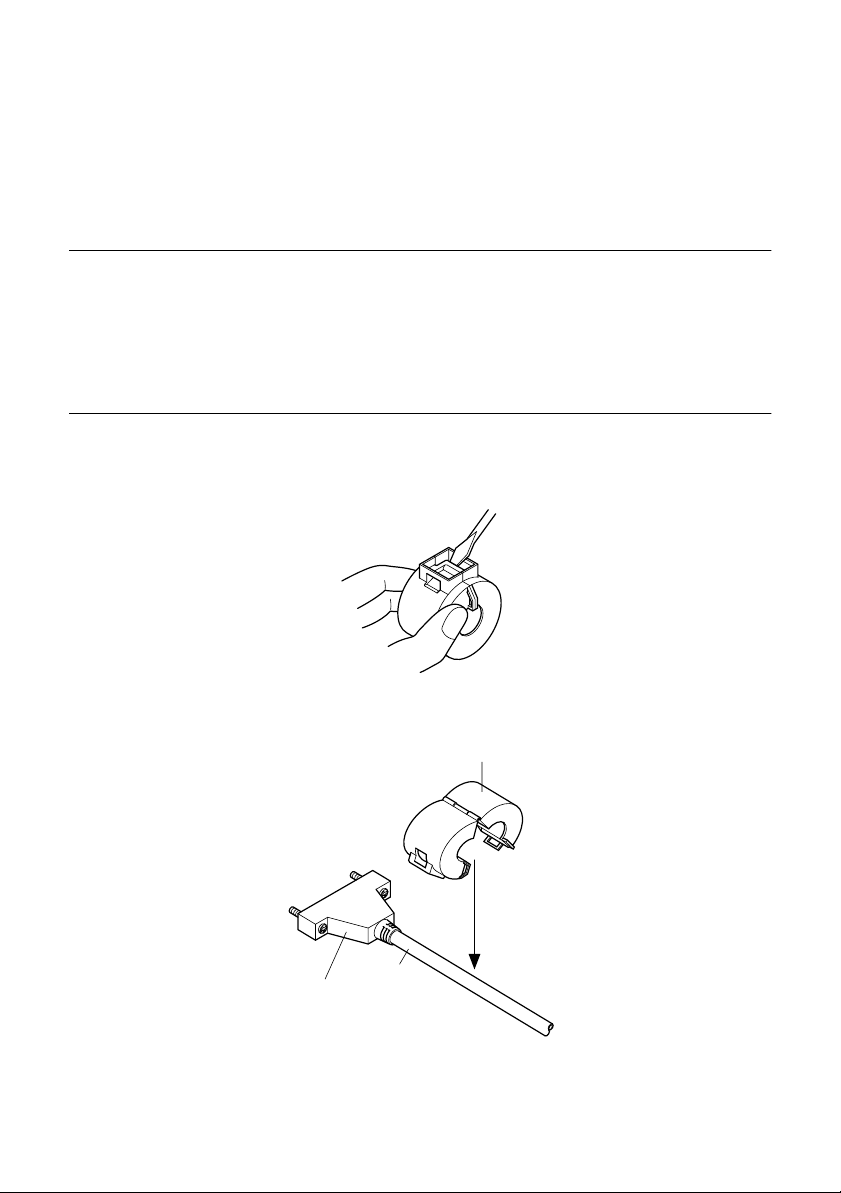

Affix the larger ferrite core onto the interface cable as shown in the

illustration below.

Interface

Ferrite core (28 mm diameter)

Cable

– 13 –

Page 25

Pass the fastener through the ferrite core.

5 cm

maximum

Fastner

Loop the fastener around the cable and lock it. Use scissors to cut off any

excess.

Pull and cut

Plug one end of the serial cable into the serial port of your computer, and

❏

the other end of the cable into the socket on the back of the printer. Secure

both connectors in place with the screws that are provided.

– 14 –

Page 26

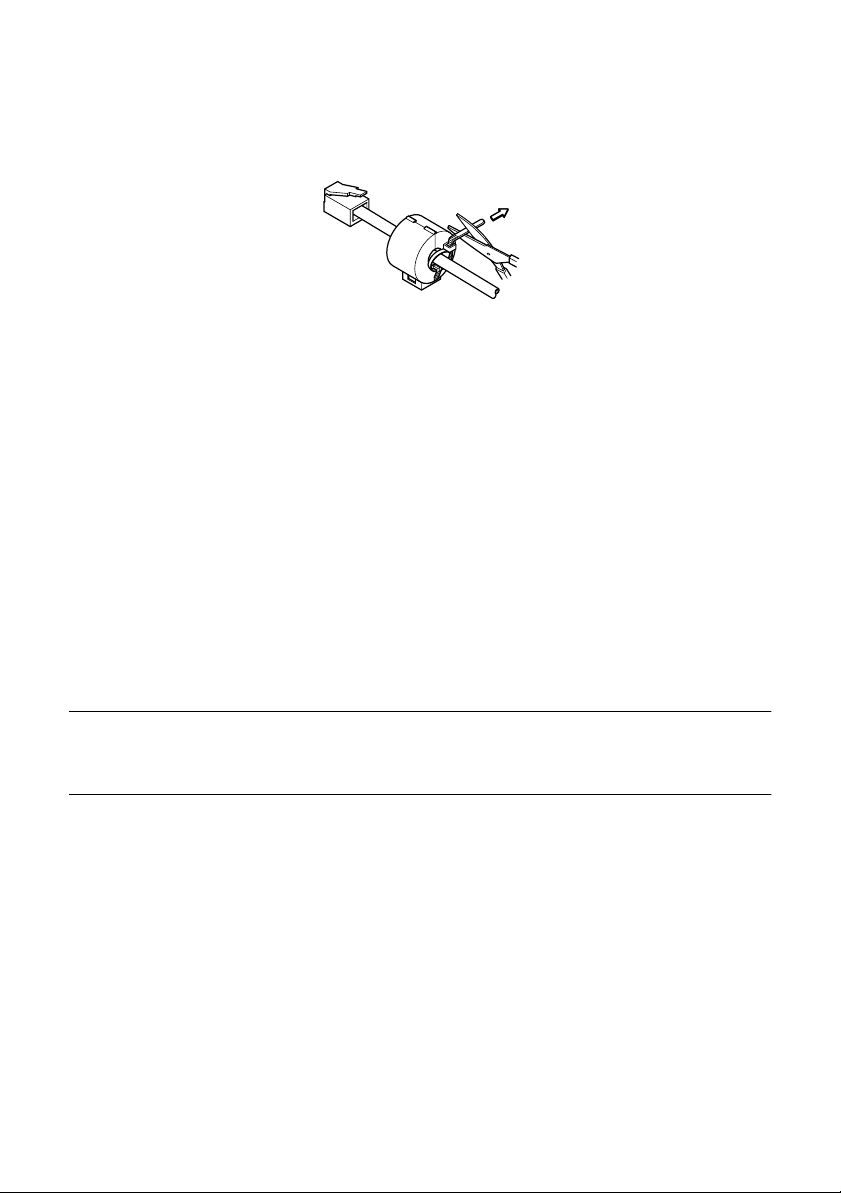

4.6 Connecting to a peripheral unit

You can connect a peripheral unit to the printer using a modular plug. The

following describes how to install the ferrite core and make the actual

connection. See “Modular plug” on page 31 for details about the type of

modular plug that is required. Note that this printer does not come with a

modular plug or wire, so it is up to you to obtain one that suits your needs.

Important!

Make sure that the printer is turned off and unplugged from the AC outlet and

that the computer is turned off before making connections.

❏

Affix the smaller ferrite core onto the modular wire as shown in the

illustration below.

Ferrite core (20 mm diameter)

Connector

Cable

Pass the fastener through the ferrite core.

5 cm

maximum

Fastner

– 15 –

Page 27

Loop the fastener around the cable and lock it. Use scissors to cut off any

excess.

❏

Plug one end of the modular cable into the modular jack of the peripheral.

❏

Remove the modular jack cover from the back of the printer and plug the

other end of the modular cable into the jack of the printer.

4.7 Inserting the paper into the printer

Use only the specified type of paper for this printer. Do not use inappropriate

types of paper, or it could cause malfunction or damage of the printer.

The following procedure describes how to print on paper. Before trying to print,

be sure to install a ribbon cassette into the printer using the procedure under

“Installing the ribbon cassette” on page 9.

❏

Make sure that the printer is plugged in and turned on.

❏

Check that the

indicator is not lit, press the

RELEASE

indicator on the control panel is lit. If the

RELEASE

Pull and cut

button until the indicator lights up.

Important!

Insertion and removal of paper should be done only when the printer is

released condition (the paper is not held by paper feed roller).

– 16 –

Page 28

❏

Place a piece of the paper onto the printer’s document table and slide its

right edge into the printer. Printing will be performed on the side of the

paper that is facing up (the one you can see), starting from the top of the

paper.

Important!

Do not use wrinkled or curled paper. In case of multiple paper, neatly align the

sheets.

Though paper can be inserted either from the front or side of the printer, front

paper insertion may result in paper jams, depending on the condition of the

paper. Because of this, it is recommended that you always insert paper from the

side.

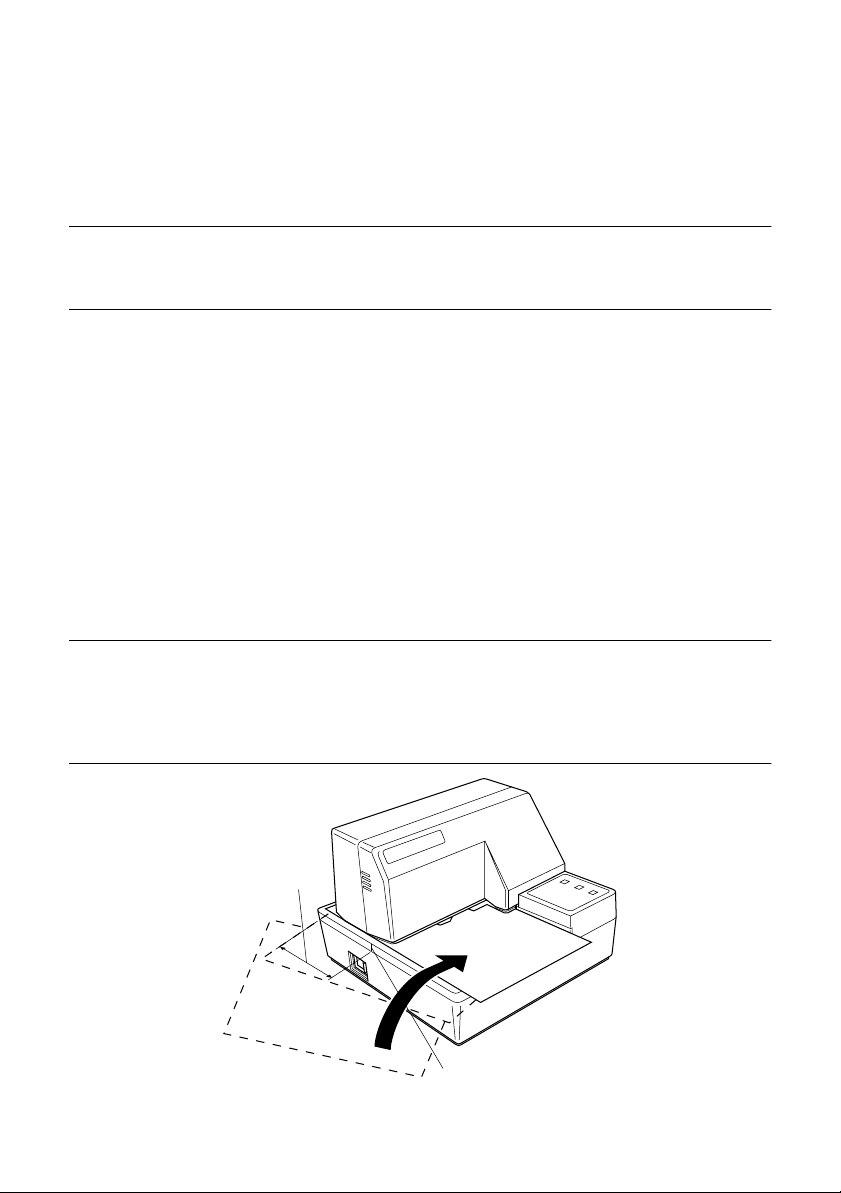

4.8 AutoSide Loading™

This printer is equipped with paper sensors, so you do not have to perform any

special procedure to align the location from which printing should start. Simply

insert the paper into the printer and the sensor locates the top of the paper. The

paper will be moved automatically into position for printing.

Important!

When inserting the paper into the printer, make sure that there ar e at least 3 cm

between the top edge of the paper and the print start position mark on the

printer. Otherwise the paper sensor may not be able to correctly locate the top

of the paper.

At least 3 cm

Print start position mark

– 17 –

Page 29

❏

Push the right edge of the paper into the printer until it stops. At that time,

the

PAPER OUT

automatically align the paper for printing from the top.

Send data from your host computer to be printed on the paper.

❏

After printing, press the

❏

paper.

indicator will go out, and the printer mechanism will

RELEASE

button to automatically release the

– 18 –

Page 30

4.9 Control Panel Operations

The control panel gives you some push-button control over the slip printer

operation. It also includes indicator lights, which tell you the current status of

the printer at a glance.

POWER

RELEASE

PAPER

OUT

FORWARD

REVERSE

RELEASE

4.9.1 Indicator lights

The following table describes the meaning of indicator lights when it is on, off,

or flashing.

Indicator Light Off On Flashing

POWER

PAPER OUT

RELEASE

Power off Power on Dot Alignment Adjust

Paper inserted No paper Insert paper prompt

Slip paper engaged Slip paper released Mechanical error

4.9.2 Buttons

The following table describes the function of the three control buttons of the

control panel.

Mode

Button Description

FORWARD

REVERSE

RELEASE

Feeds the slip paper forward, toward the back of the printer. One press

feeds one line, holding down performs continuous feed.

Feeds the slip paper back, toward the front of the printer. One press

feeds one line, holding down performs continuous feed.

Activates the printer's paper release (the paper is not held in place by

the paper feed roller).

Clears recoverable errors.

– 19 –

Page 31

4.9.3 Producing a test print

The following procedure can be used at any time to test the printer.

Turn on the printer and insert a piece of paper (page 11, 16).

❏

Turn off printer power.

❏

While holding down

❏

depressed for a few moments until the printer beeps and the printer test

print starts.

The printer test will continue until it reaches the end of the paper.

4.9.4 Adjusting the dot alignment

You may never have to use the procedure described in this section, but after you

have been using your printer for some time you may find that the dots of some

graphics do not align correctly. For example, what should look like:

may come out looking like one of the following:

RELEASE

, turn printer back on. Keep

or like this

RELEASE

– 20 –

Page 32

This is caused when mechanical parts of the printer get out of alignment. This

happens only rarely and you may never experience it at all throughout the life

of the printer. If you do have problems, use the following procedure to correct it.

❏ Turn on the printer and insert a piece of paper.

❏ Turn off printer power.

❏ While holding down the control panel’s FORWARD and REVERSE

buttons, turn the printer back on to enter the Dot Alignment Adjust Mode,

which is indicator by a flashing POWER indicator flashes.

Entering the Dot Alignment Adjust Mode causes seven blocks to be printed,

each of which indicates a dot alignment setting, as shown below. An asterisk

to the left of the blocks indicates which block is currently selected.

❏ Use FORWARD to specify the block that appears to have the best aligned

characters. Press FORWARD once to specify the first block, twice to

specify the second block, and so on up to seven times to specify the sev enth

block.

Warning beep will sound if you press FORWARD more than seven times.

❏ After specifying a block, press REVERSE to register your selection and

exit the Dot Alignment Adjust Mode.

– 21 –

Page 33

The dots alignment adjustment setting you selected is stored in printer memory

and a pattern is printed using the selected setting followed by the message

“Adjust Complete!” The printer ejects the paper after printing is complete.

Note:

You setting is not registered if you turn off printer power before pressing

REVERSE to exit the Dot Alignment Adjust Mode.

If a paper feed error occurs during this mode, the printer ejects the paper and

this mode is cancelled.

4.9.5 Hexadecimal dump

This procedure prints in hexadecimal format all codes (character codes and

control codes) that are sent to the printer by the computer. The printer does not

execute any control codes (such as 0A - linefeed), it just prints them out. The

hexadecimal dump is useful when you are writing programs for printer control.

❏ Turn on the printer and insert a piece of paper.

❏ Turn off printer power.

❏ While holding down the control panel’s FORWARD buttons, turn the

printer back on to enter the Hex Dump Mode.

❏ To exit the Hex Dump Mode, turn the printer off.

Note:

The printer will not responde to any commands you send it while it is in the

Hex Dump Mode.

– 22 –

Page 34

4.9.6 Errors

There are three types of errors: recoverable errors that require some action by

you before they clear, non-recoverable errors that require servicing by an

authorized service provider, and a data receive error. Errors are indicated by and

audible buzzer and the indicators.

(1) Recoverable Errors

Error Type

Paper jam

Indicators

Recovery

POWER RELEASE PAPER OUT

Carriage motor lockup

Flashing

Abnormal home position signal

Abnormal timing signal

(2) Non-recoverable Errors

Indicators

Error Type

POWER RELEASE PAPER OUT

RAM read/write

Off On On

CPU lockup

(3) Data Receive Error

This type of error is caused whenever a problem is encountered during data

receipt. The method used by the printer to recover from a data receive error

depends on the current command mode.

Data Receive Error Recover Procedure

Memory switch 4-0=0 : The printer prints a question mark.

Memory switch 4-0=1 : The printer discards the received data.

Correct the cause of the problem and

then press RELEASE.

Recovery

Turn off the printer, then after waiting a

few minutes, turn the printer back on. If

the printer does not recover, contact

your nearest service provider.

– 23 –

Page 35

4.10 Paper Sensors

The following paper sensors are available.

❏ TOF Sensor

This top-of-form sensor detects the leading edge of the paper.

When enabled, the TOF sensor detects when there is no paper present and

stops printing.

❏ BOF Sensor

This bottom-of-form sensor detects the trailing edge of the paper. When

enabled, the BOF sensor detects when there is no paper present and printing

is interrupted.

When the TOF or BOF sensor detects that no paper is present, the printer stops

its motor after printing of 0 to a maximum of two more lines.

The BOF sensor detects a paper out condition whenever the distance between

print head pin #9 and the trailing edge of the paper becomes 38.1 mm or less.

The print stop operation is not entered until the distance between print head pin

#9 and the trailing edge of the paper becomes 27.3 mm or less.

When the auto clamp is enabled with Memory Switch 5-1, the auto clamp

operation is performed about 1.0 second (Initial value is approximately

1 second) after the presence of paper is detected both by the TOF and BOF

sensors, following a paper out condition. The auto clamp function is not affected

by whether the TOF or BOF sensor is enabled or disabled.

The top of form positioning function is enabled with Memory Switch 5-0. Even

if the auto clamp function is disabled, auto top of form positioning is performed

if the paper is clamped when printing starts.

The PAPER OUT lamp flashes to request insertion of paper when the sensors

detect there is no paper (when a sensor enabled by command detects no paper)

after data is received by the printer. At that time, the user inserts paper, and

printing begins after the sensor detects that paper is present.

– 24 –

Page 36

5. Making DIP Switch Settings

The printer’s DIP switches let you specify communications parameters, receive

buffer size, and emulation. This “5. Making DIP Switch Settings” explains the

settings you can make and tells you how to actually change DIP switch settings.

5.1 Accessing the DIP switches

The DIP switches are located inside the printer, underneath the document table.

Use the following procedure to remove the document table so you can operate

the DIP switches.

❏ Make sure that the printer is turned off and unplugged from its wall outlet.

❏ Remove the printer cover.

❏ While using a screwdriver or other similar instrument to press down at the

location marked (a) in the illustration below, carefully slide the document

table in the direction indicated by the arrow until it is out of the way.

a

– 25 –

Page 37

It is not necessary to remove the document table completely, just move it

enough so you can get at the DIP switches inside.

ON

OFF

ON

Note:

Note:

OFF

12345678910

If the document table seems to be getting caught on the rollers, it means that

you are not pressing down at point (a) enough. Pressing at point (a) should

separate the rollers to the document table can slide freely.

❏ After the document table is opened sufficiently, use a thin flat-blade

screwdriver or some other similar object to change DIP switch settings.

See the following section for details on available DIP switch settings.

❏ After making the settings you want, slide the document table back into

place while pressing down at point (a). Make sure that the document table

is correctly seated in place before releasing point (a).

❏ Replace the printer cover.

– 26 –

Page 38

5.2 Available DIP switch settings

The following table shows all the possible settings for the DIP switch. The

factory default settings are ON for switches 1 through 7 and OFF for switches

8 through 10.

Switch Parameter ON OFF

1

2

3 Data Length 8 bits 7 bits

4 Parity Check Disabled Enabled

5 Parity Odd Even

6 Handshake DTR/DSR XON/XOFF

7 Receive Buffer Size 2K bytes 35 bytes

8 Character Code Set Japanese (Katakana) International (PC437)

9 Pin 6 (DSR) Reset Signal Enabled Disabled

10 Pin 25 (INIT) Reset Signal Enabled Disabled

Baud Rate Switch 1 Switch 2

1200BPS OFF OFF

2400BPS ON OFF

4800BPS OFF ON

9600BPS ON ON

Baud Rate See table below

– 27 –

Page 39

5.3 Memory Switch Settings

Each memory switch is a 16-bit word store in EEPROM. For details on the

functions and settings of memory switches, see the “9. Print Control Functions

(ESC#)”.

The table below shows the factory settings for the memory switches.

Memory Switch Hexadecimal Code

# 0 –

# 1 –

# 2 –

# 3 –

# 4 0000

# 5 0000

Warning!

Changing the memory switch settings can cause the printer to fail to operate

correctly.

– 28 –

Page 40

6. Interface

This appendix provides detailed specifications for the printer’s standard serial

interface.

13

25

6.1 Pins and Signal Names

Pin

Signal

No.

1FG — Frame ground

2 TXD OUT Transmission data

3 RXD IN Receive data

4 RTS OUT Same as DTR signal

5 N.C. Not connected

6 DSR IN • DIP Switch 9 = OFF

Direction Function

Name

In DTR/DSR communication mode when Memory Switch4-5 = 0, indicates whether data

receive from host is enabled or disabled.

Space: Receive enabled

Mark: Receive disabled

This signal is not checked in the X-ON/X-OFF communication mode.

1

14

• DIP Switch 9 = ON

This signal used for external reset. Printer is reset whenever signal is in mark state with

pulse width of 1mS or more.

7 SG Signal ground

8 -19 N.C. Not connected

– 29 –

Page 41

Pin

Signal

No.

20 DTR OUT Indicates whether data receive from host is enabled or disabled.

21 - 24 N.C. Not connected

25 INIT IN • DIP Switch 10 = OFF

Direction Function

Name

DTR/DSR Communication Mode

Space when receive is enabled.

X-On/X-Off Communication Mode

Always space, except during following conditions:

• Period between reset and communication enabled

• During self-test printing and dot alignment adjustment

This signal not used.

• DIP Switch 10 = ON

This signal becomes reset signal. Printer is reset whenever signal is in mark state with

pulse width of 1mS or more.

6.2 Interface Connections

Refer to the interface specifications of the host for details on connecting to its

interface connector. The following illustration shows a typical connection

configuration.

(D-sub 25 pin)

F-GND

TXD

RXD

RTS

DSR

S-GND

DTR

INIT

Printer side

1

2

3

4

6

7

20

25

– 30 –

1

2

3

4

5

6

7

8

20

IBM PC side

9 pin25 pin

F-GND

3

TXD

2

RXD

7

RTS

8

CTS

DSR

6

5

S-GND

1

DCD

4

DTR

Page 42

7. Peripheral Unit Driver Circuit

This printer is equipped with a circuit for driving peripheral units, such as cash

drawers. A 6-pin modular connector for connection of the peripheral unit is

located on the back of the printer. To connect to the drive circuit, connect the

peripheral unit to the modular connector using a cable supplied by you like that

one shown in the figure below.

Important!

Never connect any other type of plug to the peripheral unit connector.

7.1 Modular plug

Modular plug: MOLEX 90075-0007,

AMP641337, or JAPAN BURNDY B-66-4

16

Shield

Wire lead

– 31 –

Page 43

7.2 Drive circuit

The recommended drive unit is shown below.

Drive output: 24V, 1.0A max.

F.G

TR1

M-GND

M-GND

TR3

Notes

+24V

TR2

+5V

• Peripheral Units 1 and 2 cannot be driven simultaneously.

• For continuous driving, do not use drive duty greater than 20%.

• Compulsion switch status is available as status data.

• Minimum resistance for coils L1 and L2 is 24Ω.

• Absolute maximum ratings for diodes D1 and D2 (Ta = 25°C) are:

Average Rectified Current Io = 1A

Maximum forward surge current (60Hz, 1-cycle sine wave) I

• Absolute maximum rating for transistors TR1 and TR2 (Ta = 25°C) are:

Collector current Ic = 2A

Collector loss Pc = 1.2W

R2

D1

7824

D2

R1

Printer side User side

1

2

3

4

5

6

With shield

L1

L2

Peripheral

unit 2

Frame

ground

Peripheral

unit 1

R3

4.7kΩ

1/4W

Compulsion

switch

FSM

= 40A

– 32 –

Page 44

8. Maintenance and Service

For theinformationon maintenanceand service,pleasecontact

our dealeror atthefollowingaddress.

North America Other Areas

CBM America Corporation Japan CBM Corporation

Service Center Information Systems Division

365 Van Ness Way CBM Bldg., 5-68-10, Nakano,

Suite 510 Nakano-ku, Tokyo 164-0001

Torrance, CA 90501, U.S.A Japan

TEL +1-310-781-1460 TEL +81-3-5345-7540

FAX +1-310-781-9157 FAX +81-3-5345-7541

– 33 –

Page 45

9. Print Control Functions

This printer supports one command mode: the ESC/POS mode.

The ESC/POS mode emulates the Epson TM-295 slip printer.

This chapter provides you with all of the commands supported by this printer.

9.1 List of ESC/POS Commands

Command Function Code

HT Horizontal T ab 09H

LF Line Feed 0AH

FF Prints and Ejects Single Sheet, and Prints and

Returns in Paper Mode

DLE EOT Sends Status at Real Time 10H 04H n

CAN Cancels Print Data in Page Mode 18H Disabled

ESC SP Sets Space Size to Right of Characters 1BH 20H n

ESC ! Selects Print Mode in Batch 1BH 21H n

ESC # Sets Memory Switch

(Unique Extension Command)

ESC % Selects/Deselects Download Character Set 1BH 25H n

ESC & Defines Download Characters 1BH 26H y c1 c2

ESC

ESC 2 Sets 1/6-inch Line Feed 1BH 32H

ESC 3 Sets n/60-inch Line Feed (Approximate Value) 1BH 33H n

ESC = Selects Peripheral Device 1BH 3DH n

ESC @ Initializes Printer 1BH 40H

ESC C Sets Single Sheet Ejection Length 1BH 43H

ESC D Sets Horizontal Tab Position 1BH 44H

ESC F Selects/Deselects Ejection of Single Sheet in

ESC J Print and n/60-inch Paper Feed

ESC K Print and n/60-inch Reverse Paper Feed

ESC L Selects Page Mode 1BH 4CH n (Line) Disabled 57

ESC R Selects International Characters 1BH 52H n

ESC T Selects Character Print Direction in Page Mode 1BH 54H n (Set)

Selects Bit Image Mode 1BH 2AH m

Reverse Direction

(Approximate Value)

(Approximate Value)

0CH

1BH 23H N

n1 n2 n3 n4

1BH 46H n

1BH 4AH n

1BH 4BH n

Standard

Mode

Page

Mode

Disabled 56

Page

¢

37

37

38

39

42

42

43

44

46

47

49

51

51

52

53

53

54

55

55

58

59

– 34 –

Page 46

Command Function Code

ESC W Sets Print Area in Page Mode 1BH 57H (Set)

ESC c4 Selects No-paper Sensor Valid for Print Stop 1BH 63H 34H n

ESC c5 Enables/Disables Panel Switch 1BH 63H 35H n

ESC d Print and N-line Paper Feed 1BH 64H n

ESC e Print and N-line Reverse Paper Feed 1BH 65H n

ESC f Sets Single Sheet Waiting Time 1BH 66H t1 t2

ESC p Generates Specified Pulses 1BH 70H m t1 t2

ESC q Release 1BH 71H

ESC t Selects Character Code Table 1BH 74H n

ESC u Sends Peripheral Device Status 1BH 75H n

ESC v Sends Paper Sensor Status 1BH 76H

ESC { Selects/Deselects Inverted Print 1BH 7BH n (Line) (Set) 69

GS I Sends Printer ID 1DH 49H n

GS a Enables/Disables Automatic Status Sending 1DH 61H n

GS r Sends Status 1DH 72H n

:

Enabled

Standard

Mode

Page

Mode

Disabled 63

Disabled 65

74

(Line) : Enabled only at the head of the line

(Set) : Only setting is enabled

:

Only part of setting is enabled

¢ :

Ignores partially Disabled: An argument is processed as next data

Page

60

61

62

62

63

64

66

67

68

70

71

– 35 –

Page 47

9.2 Command Details

9.2.1 Description of Each Items

XXXX

[Function] Shows a command function.

[Code] Shows a sequence of code consisting the command; ASCII represents the ASCII code and [ ]k

a repeat count of k-times.

[Range] Shows a settable range of an argument.

[Outline] Outlines the command.

[Caution] Describes a caution for the command as required.

[Default] Describes an initial value for the command, if accompanied by an argument.

[See Also] Describes other associated commands in using the command.

[Example] Describes an example of using the command.

< >H: Denotes a hexadecimal number.

< >B: Denotes a binary number. < >: Denotes a decimal number.

Notes Of "Enabled only at the head of the line" in Section 9.1, the "head of the line" refers to the

case when the following condition is satisfied.

(1) There is no print data (space and skipping portion by HT included) in the current

print buffer.

– 36 –

Page 48

9.2.2 Command Details

[Function] Horizontal Tab

[Code] ASCII HT

Hexadecimal 09

Decimal 9

[Outline] This command shifts a printing position to the next horizontal tab position.

[Caution] • The horizontal tab position is set by ESC D.

• The command is ignored if the next horizontal tab position has not been set.

• Initial setting of the horizontal tab position is every 8 characters of the 5 × 7 font(9th, 17th,

25th character, and so on)

[See Also] ESC D

LF

[Function] Line Feed

[Code] ASCII LF

Hexadecimal 0A

Decimal 10

[Outline] This command prints the data in the print buffer and feeds the paper by a set line feed amount.

[Caution] • The head of the line is assumed to be the next printing start position.

[See Also] ESC 2, ESC 3

HT

– 37 –

Page 49

FF

[Function] Prints and Ejects Single Sheet, and Prints and Returns in Paper Mode

[Code] ASCII FF

Hexadecimal 0C

Decimal 12

There is the following difference between the standard mode and page mode:

<Standard Mode>

[Outline] This command prints the data in the print buffer and ejects a single sheet.

[Caution] • If a single sheet ejection length by ESC C has not been set, the paper will be ejected

completely. If it has been set, the paper will be ejected by a set amount. If the no-paper

condition is detected halfway ejection, the printer will stop paper ejection even before

reaching the set ejection amount.

• The single sheet ejecting direction is specified by ESC F.

[See Also] ESC F, ESC C

<Page Mode>

[Outline] Prints in batch the data developed across the print area and returns to the standard mode.

When this is done, all the developed data are erased after printing. The paper is not ejected.

[Caution] • The head of the line is assumed to be the next printing position.

[See Also] ESC L

– 38 –

Page 50

DLE EOT n

[Function] Sends Status at Real Time

[Code] ASCII DLE EOT n

Hexadecimal 10 04 n

Decimal 16 4 n

[Range] 1 n 3, n = 5

[Outline] This command sends the n-specified status at real time.

n Description

1 Sends the printer status.

2 Sends the off-line factor status.

3 Sends the error factor status.

5 Sends the slip status.

[Caution] • For the status sent, see the tables on the following pages.

• This command runs processing upon its reception.

• When sending the status, only one byte is sent without confirming the DSR signal status.

• The command is executed in the off-line state, reception buffer full state, and error state as

well.

• The user should note that the operation of this command is also executed when a data

sequence of <10>H<04>H<n> (1 n 3, n = 5) is received, other than this command.

<Example>

d1 = <10>H, d2 = <04>H, d3 = <1> in ESC * m nL nH [d]nL + 256 × nH

• This command must not be used by interrupting the code sequence of other command

consisting of 2 bytes or more.

<Example>

If DLE EOT 3 is sent after sending up to ESC 3, attempting to send ESC 3 n from the host, it will

be processed as ESC 3 n = <10>H. Therefore, the use should take heed of this.

• If ASB has been enabled by GS a, it is necessary to distinguish the status by this command

from that of ASB. See “6. Interface” for how to distinguish them

• If n is beyond the range, this command will be ignored.

– 39 –

Page 51

n = 1: Printer status

Bit Description Hexadecimal Decimal

0 Unused 00 0

1 Unused 02 2

2 Status of the drawer kick connector No. 3 pin = L 00 0

Status of the drawer kick connector No. 3 pin = H 04 4

3 On-line status 00 0

Off-line status 08 8

4 Unused 10 16

5 Undefined ––

6 Undefined ––

7 Unused 00 0

n = 2: Off-line factor status

Bit Description Hexadecimal Decimal

0 Unused 00 0

1 Unused 02 2

2 Undefined ––

3 Not feeding the paper by the Paper Feed switch 00 0

Feeding the paper by the Paper Feed switch 08 8

4 Unused 10 16

5 No print stop because of no paper. 00 0

Print stop because of no paper. 20 32

6 No error 00 0

Error 40 64

7 Unused 00 0

Bit 5 : If there is no paper when the TOF or BOF sensor enables no-paper print stop by ESC c 4, the printer

will stop printing, resulting in 32 (print stopping).

– 40 –

Page 52

n = 3: Error factor status

Bit Description Hexadecimal Decimal

0 Unused 00 0

1 Unused 02 2

2 Undefined ––

3 Undefined ––

4 Unused 10 16

5 No irrecoverable error 00 0

Irrecoverable error 20 32

6 Undefined ––

7 Unused 00 0

n = 5: Slip status

Bit Description Hexadecimal Decimal

0 Unused 00 0

1 Unused 02 2

2 The slip has been selected 00 0

3 Slip insertion non-waiting status 00 0

Slip insertion waiting status 08 8

4 Unused 10 16

5 Paper set in the BOF sensor 00 0

No paper set in the BOF sensor 20 32

6 Paper set in the TOF sensor 00 0

No paper set in the TOF sensor 40 64

7 Unused 00 0

Bit 3 : Detects a slip of paper and results in 0 immediately before starting the operation (not waiting for

insertion)

Bits 5, 6 : Send the current status of the TOF and BOF sensors.

[See Also] ESC u, ESC v, GS a, 6. Interface

– 41 –

Page 53

CAN

[Function] Cancels Print Data in Page Mode

[Code] ASCII CAN

Hexadecimal 18

Decimal 24

[Outline] This command erases all the print data in the current print area in the page mode.

[Caution] • This command is valid only in the page mode.

[See Also] ESC W

• Even the print data in the previously set print area is erased, if it is extended over the currently

set print area.

ESC SP n

[Function] Sets Space Size to Right of Characters

[Code] ASCII ESC SP n

Hexadecimal 1B 20 n

Decimal 27 32 n

[Range] 0 n 32

[Outline] This command sets the right space size of the characters.

[Caution] • In the double width mode, the right space size is doubled.

• The space size is set in increments of half dot.

• In the page mode, the space size may be shifted a half dot from a set value.

• There are two set values for the standard and page modes, respectively.

[Default] n = 0

– 42 –

Page 54

ESC ! n

[Function] Selects Print Mode in Batch

[Code] ASCII ESC ! n

Hexadecimal 1B 21 n

Decimal 27 33 n

[Range] 0 n 32

[Outline] This command specifies the print mode.

[Caution] • The underline is drawn across the print character width, not the blank skipped by HT.

[Default] n = 0

Each bit has the following meaning.

Bit Description Hexadecimal Decimal

0 Character font 5 × 7000

Character font 7 × 7011

1 Undefined ––

2 Undefined ––

3 Undefined ––

4 Deselects double height 00 0

Selects double height 10 16

5 Deselects double width 00 0

Selects double width 20 32

6 Undefined ––

7 Deselects underline 00 0

Selects underline 80 128

• If both double height and double width are specified, the characters will be quadrupled.

• For selection of the underline and 7 × 7 font in the page mode, only their setting is enabled.

– 43 –

Page 55

ESC #

[Function] Sets Memory Switch

[Code] <ESC> "#N, n1 n2 n3 n4" <LF> <NUL>

N : Memory switch segment number (4 and 5 only)

n1 n2 n3 n4 : Set data

[Range] 0 n 255

[Outline] The memory switch is stored in the nonvolatile EEPROM memory. To change this setting, send

a command from the host side. After setting with the command, turn on the power again, or

reset with the following reset command, to enable setting. (If reset with the command, selfprinting will be implemented.)

Reset command: <ESC> <CAN> <LF> <NUL>

[Caution] The EEROM has a data-writing life. Do not execute this command every time. Note that if the

EEROM’s life is running out due to frequent use of this command, printer operation cannot be

guaranteed.

The memory switch segment numbers other than 3 to 5 do not have relevant setting items, but

they actually exist. Therefore, use of other numbers besides 3 to 5 will be valid as a command

and change the data in the EEROM. If this is the case, operation will not be guaranteed.

Exercise full care when using this command.

[Default]

[Example]

1) Memory Switch 4 (MSW4)

The setting upon shipment from the factory is indicated with “ ”.

Bit Description 0 1

F

E

D

C

B

A

9

8

7

6

5 DSR signal check at status

4

3

2

1

0 Data reception Prints "?"

( : Denotes setting enabled)

(Note) X-ON/X-OFF output timing: Setting whether to output the X-ON code every 3 seconds

sending time

Checks

Does not check

Ignores

– 44 –

Page 56

2) Memory Switch 5 (MSW5)

The setting upon shipment from the factory is indicated with “ ”.

Bit Description

F

E

D <ESC> "q" command function See Table 4-3

C <ESC> "q" command function See Table 4-3

B

A

9

8

7

6

5

4

3

2

1 Automatic clamp function Enabled

0 Automatic head search function Enabled

MSW5-D MSW5-C <ESC> “q” Command Function

0

1 0 Implements releasing

0 1 Implements releasing after discharging all in the forward direction

1 1 Implements releasing after discharging all in the reverse direction

0

Implements releasing

(far side).

(near side).

01

Disabled

Disabled

– 45 –

Page 57

ESC % n

[Function] Selects/Deselects Download Character Set

[Code] ASCII ESC % n

Hexadecimal 1B 25 n

Decimal 27 37 n

[Range] 0 n 255

[Outline] This command selects or deselects the download character set. n is valid only for the least

[Default] n = 0

[See Also] ESC &

significant bit.

• At n = <

internal character set).

• At n = <

0>B, the command deselects the download character set(selects an

1>B, the command selects the download character set.

– 46 –

Page 58

ESC & y c1 c2 [x[d]yxx]c2-c1+1

[Function] Defines Download Characters

[Code] ASCII ESC & y c1 c2 [x [d] y × x]c2-c1+1

Hexadecimal 1B 26 y c1 c2 [x [d] y × x]c2-c1+1

Decimal 27 38 y c1 c2 [x [d] y × x]c2-c1+1

[Range] y = 1

32 c1 c2 126

0 x 6 (When the 5 × 7 font is selected)

0 x 10 (When the 7 × 7 font is selected)

0 d1 ... d y × x 255

[Outline] This command defines the font of the alphanumeric or Kana download characters.

• y denotes the number of vertical bytes.

• c1 denotes the start character code and c2, end character code, respectively. When de fining

only one character, set c1 = c2.

• The definable character code is the 95 ASCII code characters from <20>H to <7E>H.

• x denotes the number of horizontal dots to be defined.

• d denotes the data to be defined; a horizontal x dots pattern from the left. The right remaining

pattern results in spaces.

[Caution] • Once the download characters are defined, they will remain valid until they are redefined,

ESC @ is executed, the printer is reset, or the power is turned off.

• If y, c1, c2, or x is beyond the range, this command will be ignored, processing the

subsequent data as normal one.

• In case of the 7 × 7 font, define the data so that the horizontally adjacent dots will not be

contained, because they cannot be printed.

[Default] Identical pattern with the internal character set

[See Also] ESC %

– 47 –

Page 59

[Example]

• When selecting the 5 × 7 font

p1 p2 p3 p4 p5 p6

When defining the pattern above to the code 20H

ESC& y c1c2 x p1p2p3p4p5

Code (hex.) 1B 26 01 20 20 05 3E 48 88 48 3E

• When selecting the 7 × 7 font

p1 p2 p3 p4 p5 p6 p7 p8 p9 p10

MSB

LSB

MSB

When defining the pattern above to the code 20H

ESC& y c1c2 x p1p2p3p4p5p6p7

Code (hex.) 1B 26 01 20 20 07 1E 20 48 80 48 20 1E

– 48 –

LSB

Page 60

ESC * m nL nH [d]k

[Function] Selects Bit Image Mode

[Code] ASCII ESC

Hexadecimal 1B 2A m nL nH [d] k

Decimal 27 42 m nL nH [d] k

[Range] m = 0, 1

0 nL 255

0 nH 3

0 d 255

k = nL nH × 256

[Outline] • This command specifies the bit image of the m-mode as to the number of dots specified with

nL and nH.

• nL and nH denote the number of horizontal dots of the bit image to be printed, resulting in [nL

+ nH × 256] dots.

• If the bit image data is input beyond the dot position printable in one line, the surplus data will

be discarded.

• d denotes the bit image data. Set "1" in the corresponding bit when printing, and "0" when not

printing.

• The following table lists the bit image mode selected with m.

m Mode

0 8-dots single density 8 210

1 8-dots double density 8 420

1: The total number of horizontal dots in the page mode differs depending on the printing area

secured with ESC W and printing direction specified with ESC T.

m nL nH [d] k

Vertical Direction Horizontal Direction ( 1)

Dots Max. Dots

[Caution] • If a value of m or nH goes beyond the range, this command will be ignored, processing the

subsequent data as normal one.

• Normal data processing is restored after printing the bit image.

• The following page shows the relations between the bit image data and the dots printed.

• The double density bit image is invalidated in the page mode.

– 49 –

Page 61

• The following shows the relations between the bit image data and the dots printed.

76543210

Bit Image Data

High

Low

Print Data

– 50 –

Page 62

ESC 2

[Function] Sets 1/6-inch Line Feed

[Code] ASCII ESC 2

Hexadecimal 1B 32

Decimal 27 50

[Outline] This command sets a line feed amount per line to 1/6 inch.

[Caution] There are two kinds of line feed amounts for the standard mode and page mode.

• For the standard mode: Set to 1/6 inch.

• For the page mode: Set to 10 dots (10/72 inch)

[See Also] ESC 3

ESC 3 n

[Function] Sets Line Feed Amount

[Code] ASCII ESC 3 n

Hexadecimal 1B 33 n

Decimal 27 51 n

[Range] 0 n 255

[Outline] This command sets a line feed amount per line to n/60 inch.

[Caution] There are two kinds of set values for the standard mode and page mode. Since the printer has

the minimum paper feed pitch of 1/144 inch, the line feed amount of n/60 inch is treated as

follows:

• For the standard mode: Set an approximate value of INT((6n+5)+0.5)/72 inch.

• For the page mode: Set n/72 inch(n coordinate).

[Default] n = 10 (1/6 inch for the standard mode and 10 dots (10/72 inch for the page mode))

[See Also] ESC 2

– 51 –

Page 63

ESC = n

[Function] Selects Peripheral Device

[Code] ASCII ESC = n

Hexadecimal 1B 3D n

Decimal 27 61 n

[Range] 0 n 3

[Outline] This command selects a peripheral device which validates the subsequent data, depending on

[Caution] • Even if Printer Disabled has been selected, the printer may be made off-line by operating it.

[Default] n = 1

a value of n.

• Each bit has the following different meanings.

• If Printer Disabled has been selected, the printer will discard all the received data until Printer

Enabled is selected with this command.

Bit Peripheral Device Hexadecimal Decimal

0 Printer Disabled 00 0

Printer Enabled 01 1

1 Undefined ––

2 Undefined ––

3 Undefined ––

4 Undefined ––

5 Undefined ––

6 Undefined ––

7 Undefined ––

– 52 –

Page 64

ESC @

Fnction] Initializes Printer

[Code] ASCII ESC @

Hexadecimal 1B 40

Decimal 27 64

[Outline] This command clears the data in the print buffer to initialize various settings.

[Caution] • The setting of the DIP switch is not re-read.

• The data in the reception buffer is not cleared.

ESC C n

[Function] Sets Single Sheet Ejection Length

[Code] ASCII ESC C n

Hexadecimal 1B 43

Decimal 27 67

[Range] 0 n 127

[Outline] This command sets a single sheet ejection length to n lines.

• If n = 0, the ejection length will not be set

[Caution] • Even if the line feed amount is changed after setting the ejection length, the latter will not

change

• The ejection length set here is meaningful only when FF is executed

[Default] n = 0

[See Also] FF

– 53 –

Page 65

ESC D [n]k NUL

[Function] Sets Horizontal Tab Position

[Code] ASCII ESC D [n] k NUL

Hexadecimal 1B 44 [n] k 00

Decimal 27 68 [n] k 0

[Range] 1 n 255

0 k 32

[Outline] This command sets a horizontal tab position.

• n denotes the number of columns from the head of the line to the horizontal tab setting

position. n is equal to the setting column position - 1, and if the horizontal tab is to be set in

the 9th column, for example, set n = 8.

• k denotes the number of horizontal tab positions to be set.

• The tab position is set to the position at a distance of the character width × n from the head of

the line. This character width includes the right space size of the character, and if double

width is selected, the character width will be doubled. A horizontal magnification selection is

followed even in the page mode.

• The data, <n>k, which denotes a setting position is input in the ascending order and ends

with <00>H.

• ESC D NUL clears all the set tab positions. After clearing, HT is ignored.

[Caution] • If the data <n>k is equal to or smaller than the preceding data <n>k-1, it is assumed that

horizontal tab setting has been finished. If this is the case, the subsequent data will be

processed as normal one.

• Up to 32 tab positions can be set. The data exceeding this limit is processed as normal data.

• If HT is executed, a move to the tab position beyond the print area will be made to the

position of the print area + 1 dot.

• Even if the character width is changed after setting the horizontal tab position, the latter will

not change.

• There are two kinds of right space sizes of the characters; for the standard mode and page

mode. To set the horizontal tab position in the respective modes, set the right space size of

the characters in the very mode you are in.

[Default] Every 8 characters of the 5 × 7 font (9th, 17th, 25th character, and so on)

[See Also] HT

– 54 –

Page 66

ESC F n

[Function] Selects/Deselects Ejection of Single Sheet in Reverse Direction

[Code] ASCII ESC F n

Hexadecimal 1B 46 n

Decimal 27 70 n

[Range] 0 n 255

[Outline] This command selects or deselects single sheet ejection in the reverse direction with FF.

• n is valid only for the least significant bit.

[Default] n = 0

[See Also] FF

At n = <

At n = <

forward directional ejection).

1>B, the command selects reverse directional ejection.

0>B, the command deselects reverse directional ejection(selects

ESC J n

[Function] Print and Paper Feed

[Code] ASCII ESC J n

Hexadecimal 1B 4A n

Decimal 27 74 n