Page 1

DOT MATRIX PRINTER

SP317/347F

USERS MANUAL

GUIDE D’UTILISATION

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

For compliance with Federal Noise Interference Standard, this equipment requires a shielded

cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

Manufacturer’s Declaration of Conformity

Statement of

CE

(EC Council Directive 89/336/EEC of 3 May 1989)

This product has been designed and manufactured in accordance with the International

Standards EN50081-1/01.92 and EN50082-1/01.92 following the provisions of the

Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

NOTICE

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 1996 Star Micronics Co., LTD.

Page 3

TABLE OF CONTENTS

1. LOADING THE RIBBON CARTRIDGE ..........................................2

1-1. SP317 ...........................................................................................2

1-2. SP347 ...........................................................................................3

2. LOADING THE PAPER.....................................................................5

2-1. SP317 ...........................................................................................5

2-2. SP347 ...........................................................................................7

2-3. Removing the Roll Paper ...........................................................10

3. CONTROL PANEL .......................................................................... 11

APPENDIX .............................................................................................49

Page 4

1. LOADING THE RIBBON CARTRIDGE

ENGLISH

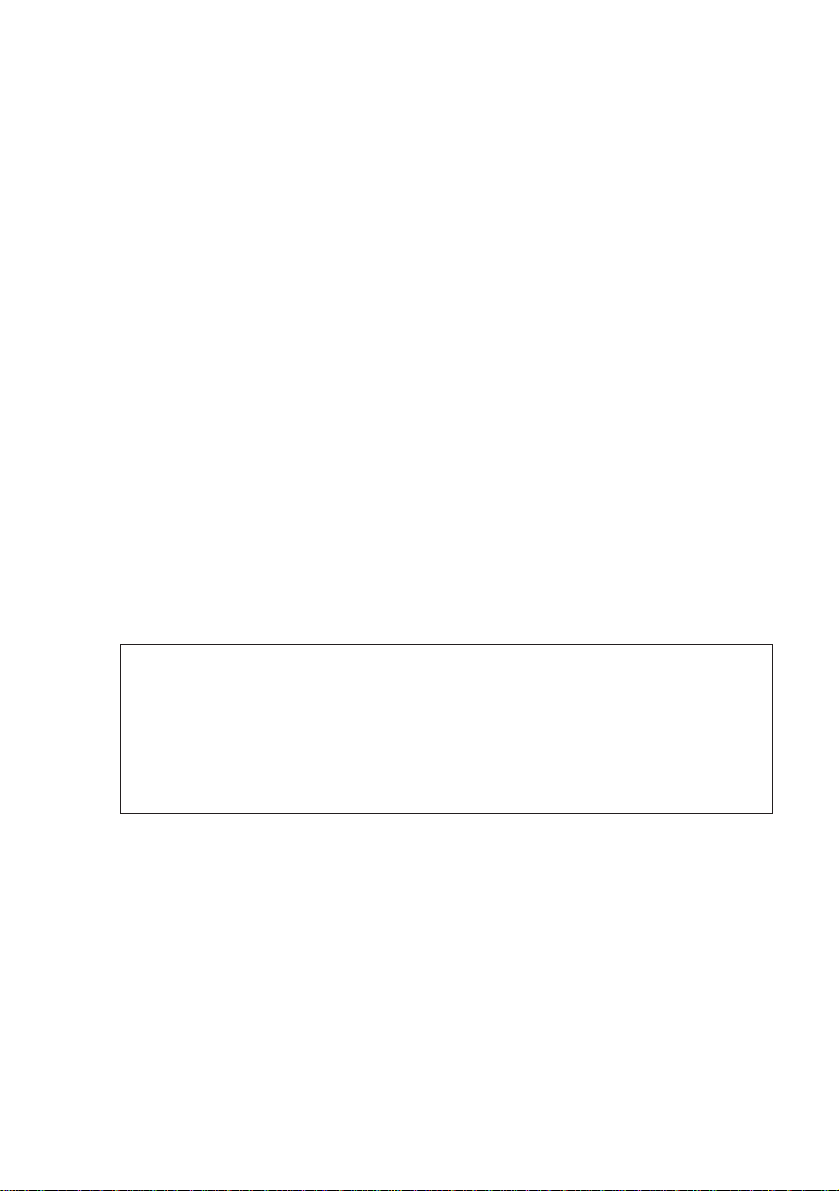

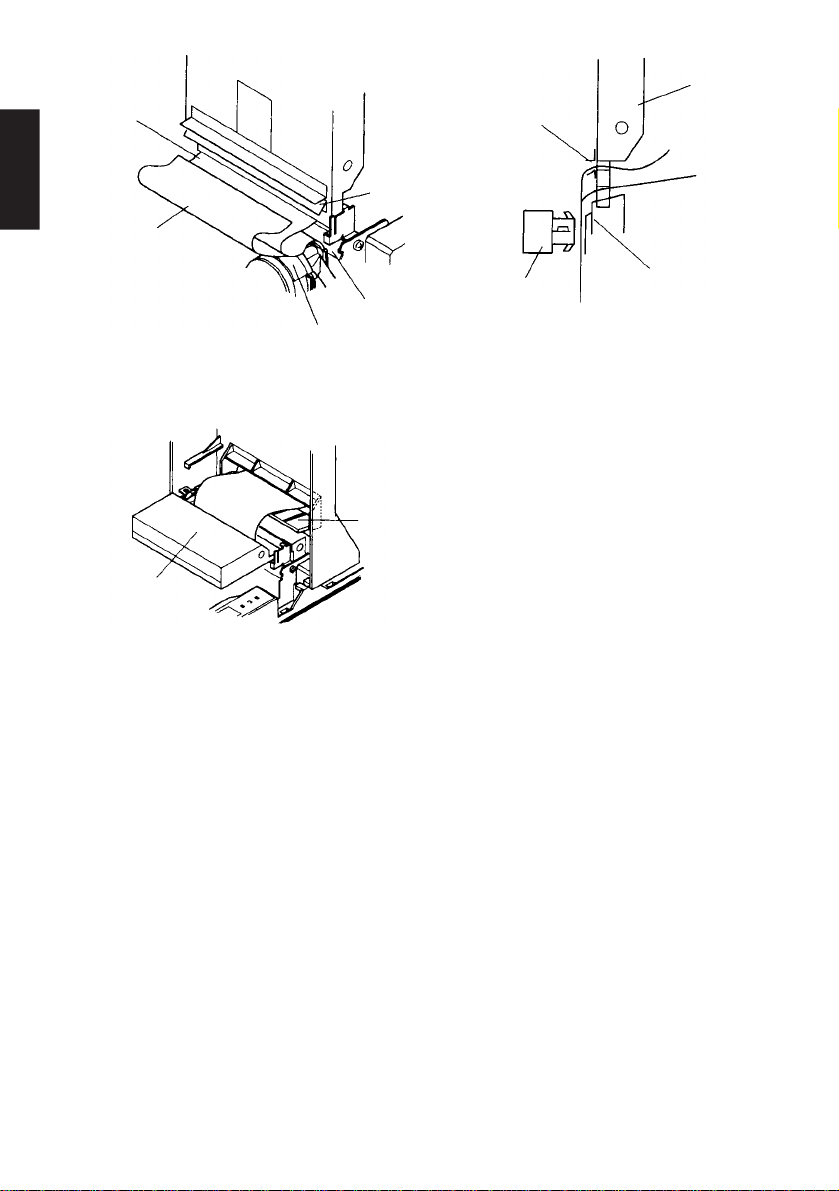

1-1. SP317

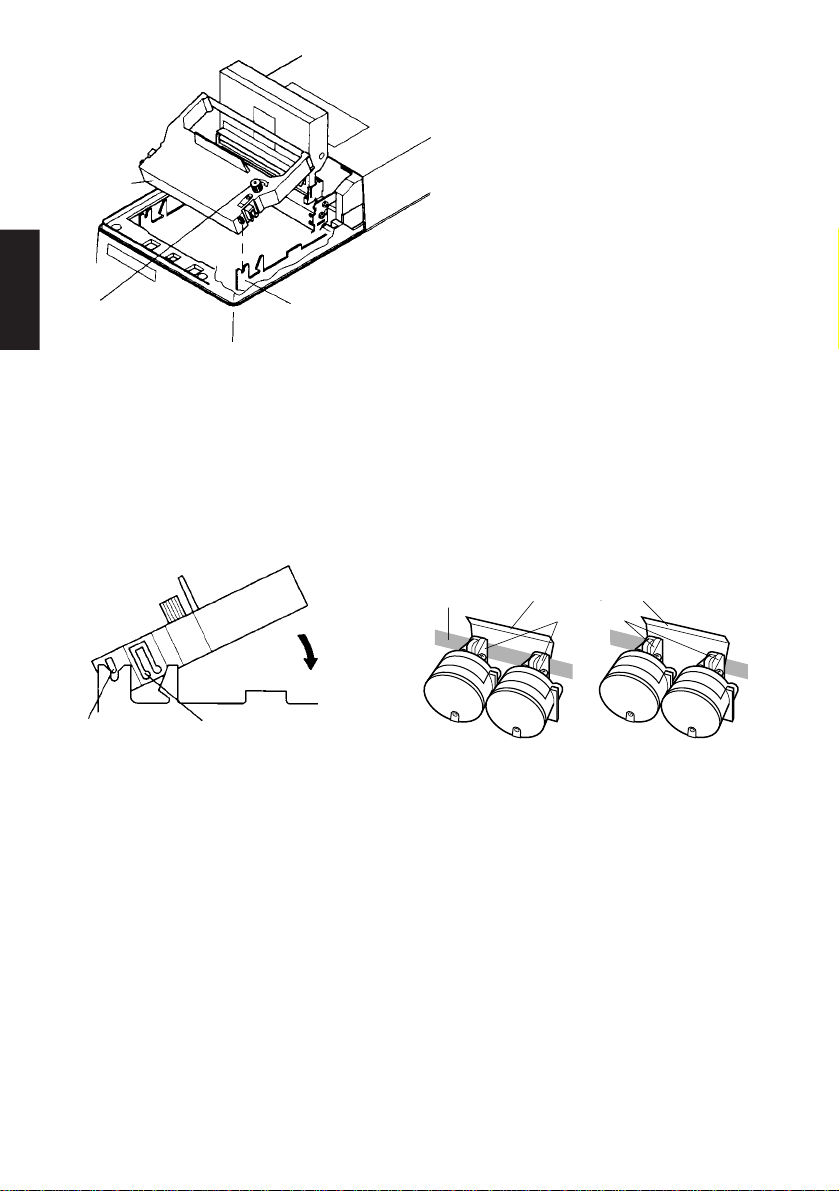

Fig. 1-1 Removing the front cover (SP317)

1 Turn the power switch on the printer

to the off position.

2 To remove the front cover lift it up

approx. 3cm. and pull it forward.

NOTE: Do not touch the print head

immediately after printing

as it can be extremely hot.

3 To remove slack in the ribbon turn

the ribbon feed knob of the ribbon

cartridge in the direction of the arrow.

4 Align the ribbon cartridge guide with

the notched part of the frame. Insert

the ribbon cartridge from that position until you hear a locking sound.

Insert the ink ribbon between the

print head and the ribbon separator.

Make sure that the ink ribbon is not

protruding beyond the ribbon separator.

5 To remove slack in the ribbon turn

the ribbon feed knob of the ribbon

cartridge in the direction of the arrow.

6 To install the front cover reverse the

removal steps.

Fig. 1-2 Loading the ribbon cartridge (SP317)

– 2 –

Page 5

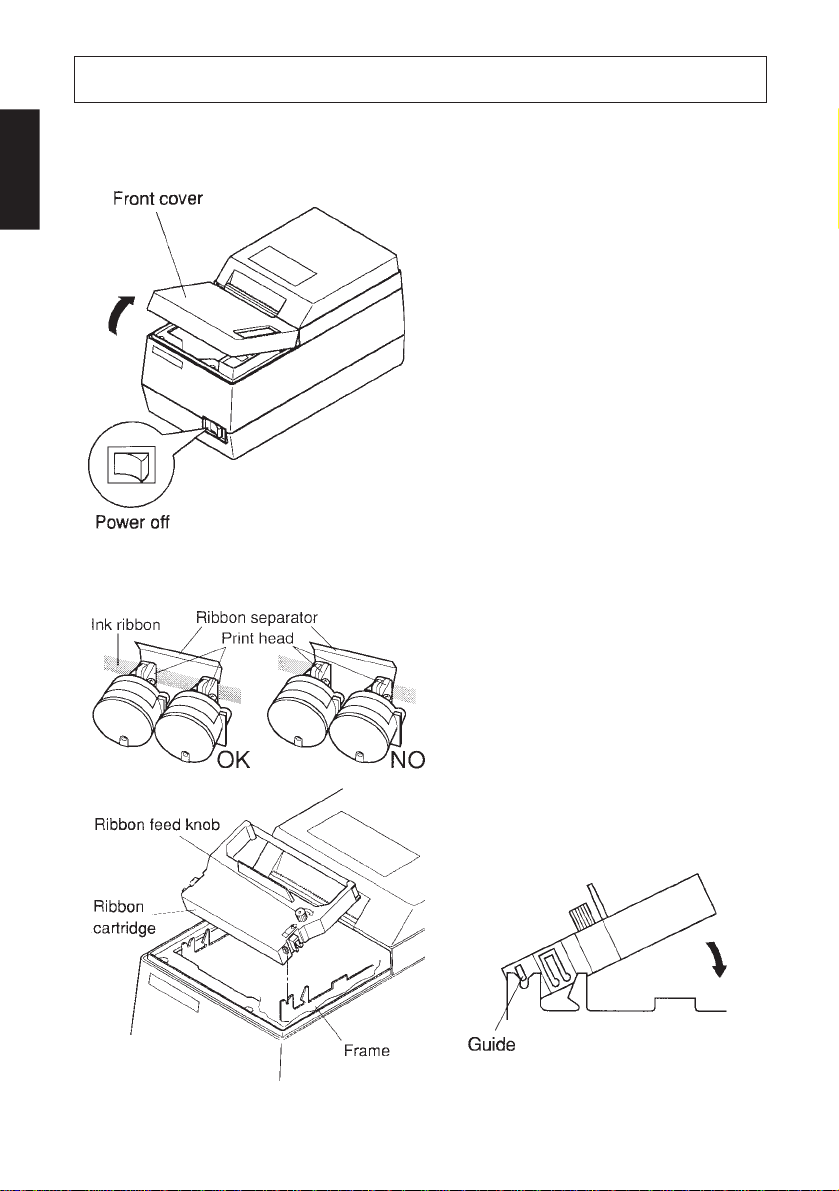

1-2. SP347

Front cover

Power off

Fig. 1-3 Removing the front cover

(SP347)

1 Turn the power switch on the printer

to the off position.

2 To remove the front cover lift it up

approx. 3cm. and pull it forward.

NOTE: Do not touch the print head

immediately after printing

as it can be extremely hot.

ENGLISH

Auto cutter

Packing material

Fig. 1-4 Raise the auto cutter and remove

the packing material (SP347)

3 Lift up the auto cutter and put it in a

vertical position, as shown in Fig. 1-

4.

4 Remove the packing material.

– 3 –

Page 6

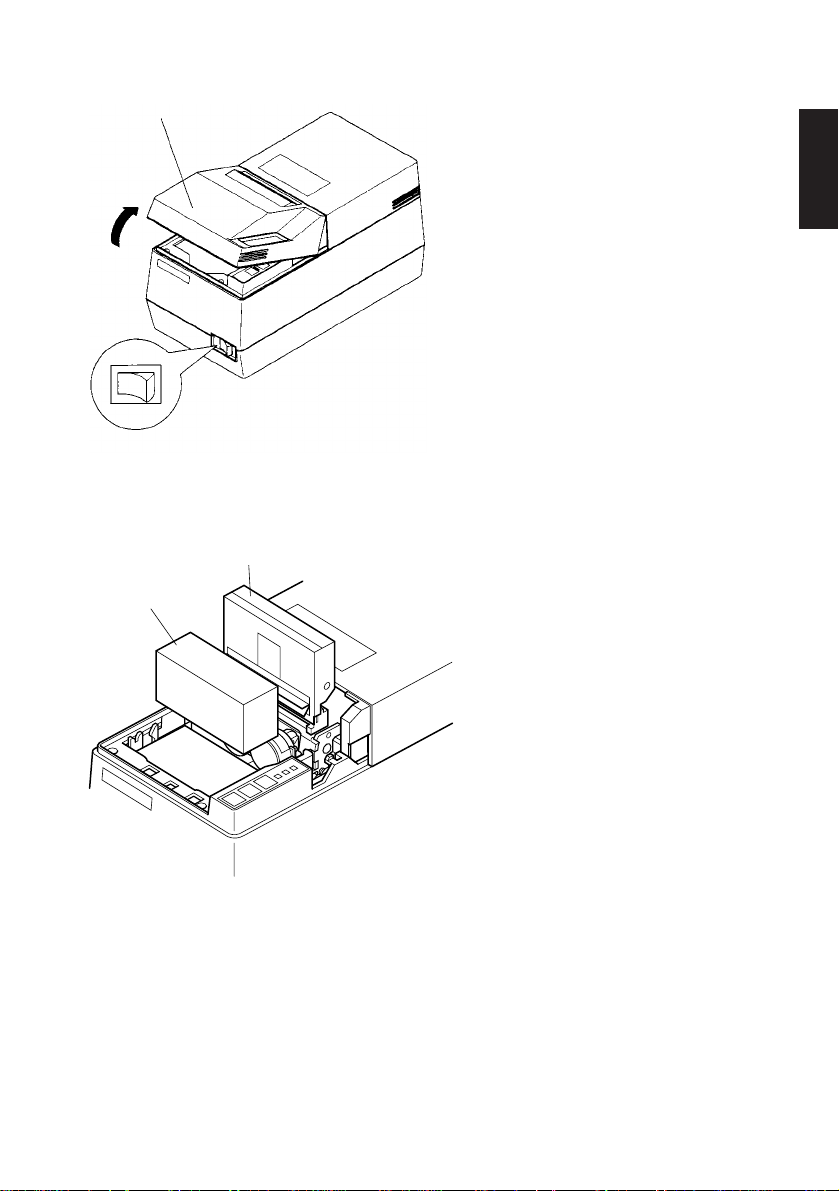

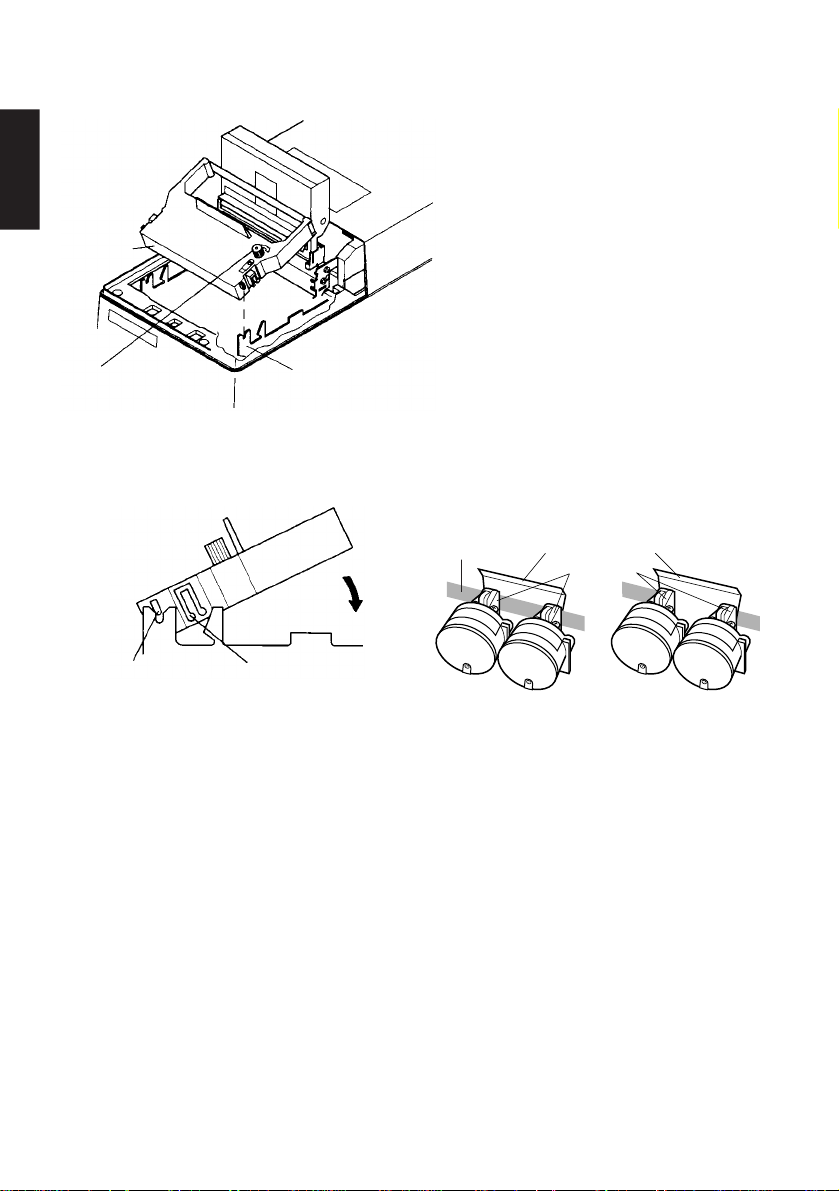

ENGLISH

Ribbon

cartridge

Ribbon feed knob

Frame

4 To remove slack in the ribbon turn

the ribbon feed knob of the ribbon

cartridge in the direction of the arrow.

5 Align the ribbon cartridge guide with

the notched part of the frame. Insert

the ribbon cartridge from that position until you hear a locking sound.

Insert the ink ribbon between the

print head and the ribbon separator.

Make sure that the ink ribbon is not

protruding beyond the ribbon separator.

6 To remove slack in the ribbon turn

the ribbon feed knob of the ribbon

cartridge in the direction of the arrow.

Ribbon separator

Print head

OK

NO

Guide

Ink ribbon

Lock part

Fig. 1-5 Loading the ribbon cartridge (SP347)

7 Lower the auto cutter and install the front cover in the reverse order of its

removal.

– 4 –

Page 7

2-1. SP317

2. LOADING THE PAPER

1 Turn the power switch on the printer

to the off position.

2 Set DIP switch 2-4 to match the

width of the paper that is being used.

(Refer to Installation Manual for

DIP switch settings.)

ENGLISH

Fig. 2-1 Removing the rear cover

(SP317)

DIP

switches

2-4

ON OFF

3.25 inches

3.0 inches

2.25 inches

(All the switches in the DIP switch

array are factory preset to the “ON”

position.)

3 To remove the rear cover lift it up

approx. 3cm and push it backwards.

4 Dependant on the width of the paper

(2.25 or 3 inches), align the roll

paper holders at the specified position .

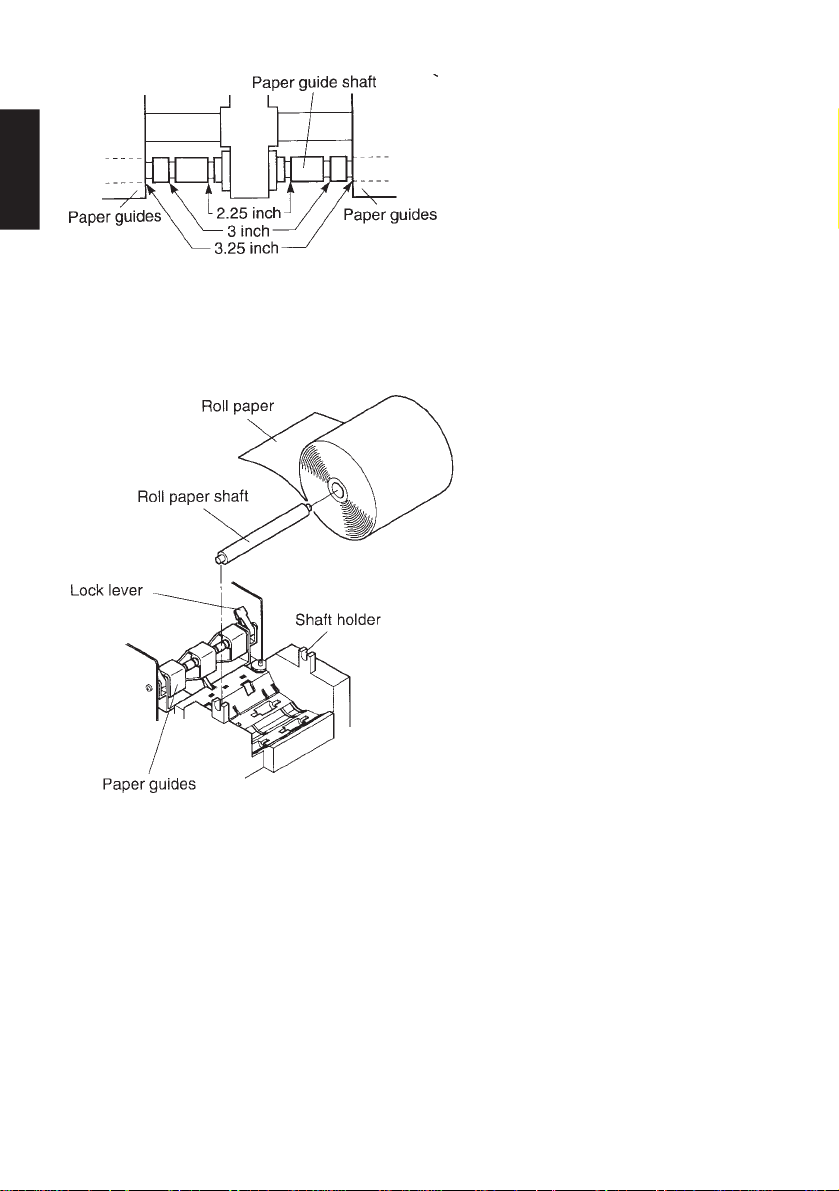

Fig. 2-2 Mounting the roll paper holders

(SP317)

– 5 –

Page 8

ENGLISH

Fig. 2-3 Setting of the paper guide

(SP317)

Fig. 2-4 Loading the paper (SP317)

5 Set the left and right paper guides.

Leave a 0.5 mm gap between the

paper guide and the edge of the

paper and fix the lock lever.

• When you insert the stop ring that

corresponds to the groove of the

paper guide shaft shown in Fig. 23, that will be the position when

you set the paper guide.

6 Turn the power switch on the printer

to the on position.

7 Cut off the front edge of the roll

paper in a straight line.

In case the front edge of the paper is

fastened with a label, etc. remove

the adhesive part of the label. If any

adhesive remains on the paper, it

will stick onto the roller of the

printer, causing the paper to misfeed.

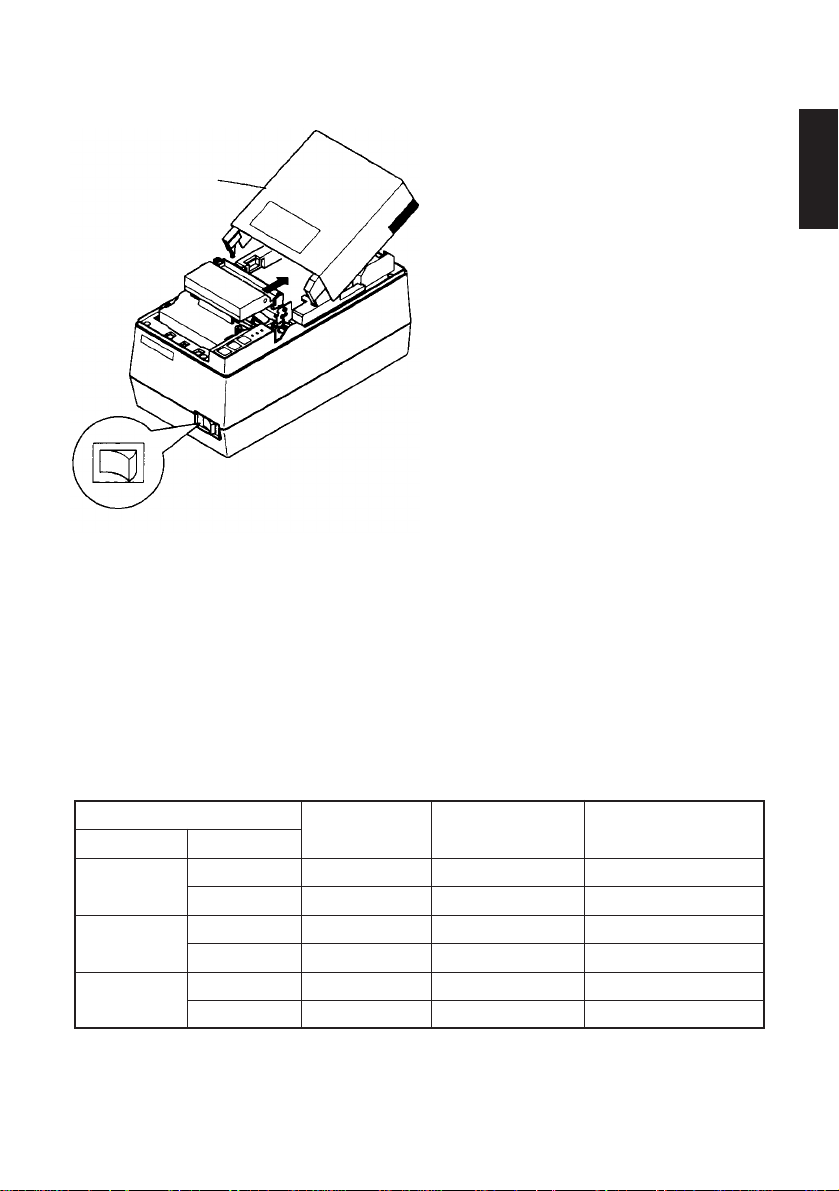

8 Hold the roll paper as shown in the

illustration, then insert the top end

of the paper beneath the paper guide

as far as it will go and press the

“FEED” switch on the control panel

to feed the paper.

9 When the front edge of the paper

feeds out of the printer, release the

“FEED” switch. Next, insert the

rollpaper into the roll paper shaft,

and set the roll paper shaft on to the

shaft holder.

0 Insert the top edge of the paper into

the tear bar slot, then mount the rear

cover by reversing the procedure

for removing the rear cover in step

3 above.

NOTE: When the paper end mark

appears on the paper, replace the roll paper before

it runs out.

– 6 –

Page 9

2-2. SP347

1 Turn the power switch on the printer

to the off position.

Rear cover

Power off

Fig. 2-5 Removing the rear cover (SP347)

4 Adjust DIP switch 2-4, the roll paper holder and the adjust lever position

according to the width and thickness of the roll paper that is being used.

• Refer to Installation Manual in regard to the position of the DIP switch.

• If you do not know the standard position of the adjust lever, lower the adjust

lever as far as it will go (on the rear cover side), and then pull it two positions.

That position is standard position A.

2 To remove the front cover lift it up

approx. 3cm. and pull it forward.

NOTE: Do not touch the print head

immediately after printing

as it can be extremely hot.

3 To remove the rear cover lift it up

approx. 3cm and push it backwards.

ENGLISH

Paper

Paper width Thickness

2.25 inches

3.0 inches

3.25 inches

1 sheet of paper

Printer paper

1 sheet of paper

Printer paper

1 sheet of paper

Printer paper

DIP switch 2-4 Adjust lever Roll paper holder

(Fig. 4-1) position (Fig. 2-6) (Fig. 2-7)

OFF A Used (Inner groove)

OFF B Used (Inner groove)

ON A Used (Outer groove)

ON B Used (Outer groove)

ON A Not used

ON B Not used

– 7 –

Page 10

ENGLISH

Paper

guide 3 inch

A: One Sheet of paper

(standard position)

B: Copy paper

Adjust lever

Fig. 2-6 Position of the adjust lever

(SP347)

Paper guide shaft

2.25 inch

3.35 inch

Paper

guide

Fig. 2-8 Roll paper guide (SP347)

Auto cutter

Roll paper

holders

Lock lever

Paper guides

For 2.25-inch

paper

Paper holder

mount notch

for 3-inch

paper

Paper holder

mount notch

for 3-inch

paper

For 2.25-inch

paper

Fig. 2-7 Mounting the roll paper

holders (SP347)

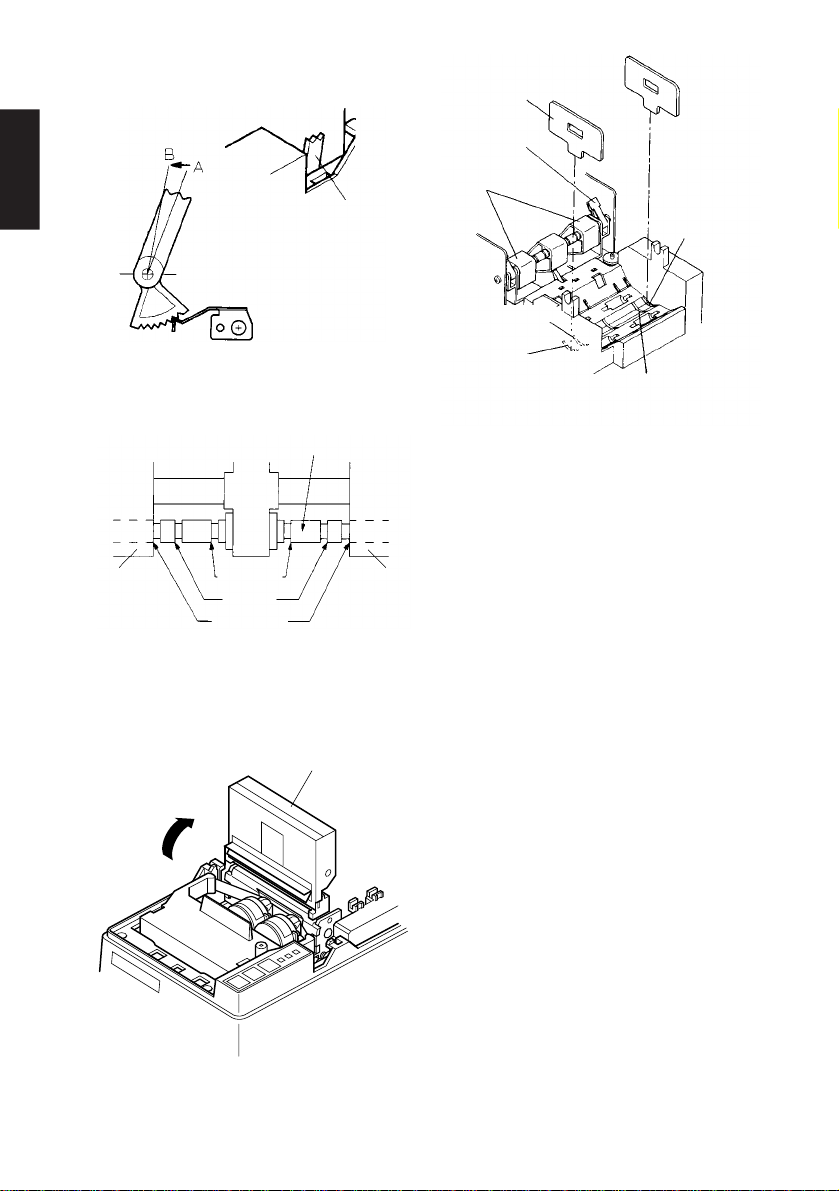

5 Set the left and right paper guides.

Leave a 0.5 mm gap between the

paper guide and the edge of the

paper and fix the lock lever.

• When you insert the stop ring that

corresponds to the groove of the

paper guide shaft shown in Fig. 28, that will be the position when

you set the paper guide.

6 Lift up the auto cutter and put it in a

vertical position, as shown in Fig. 2-

9.

Fig. 2-9 Raise the auto cutter (SP347)

– 8 –

Page 11

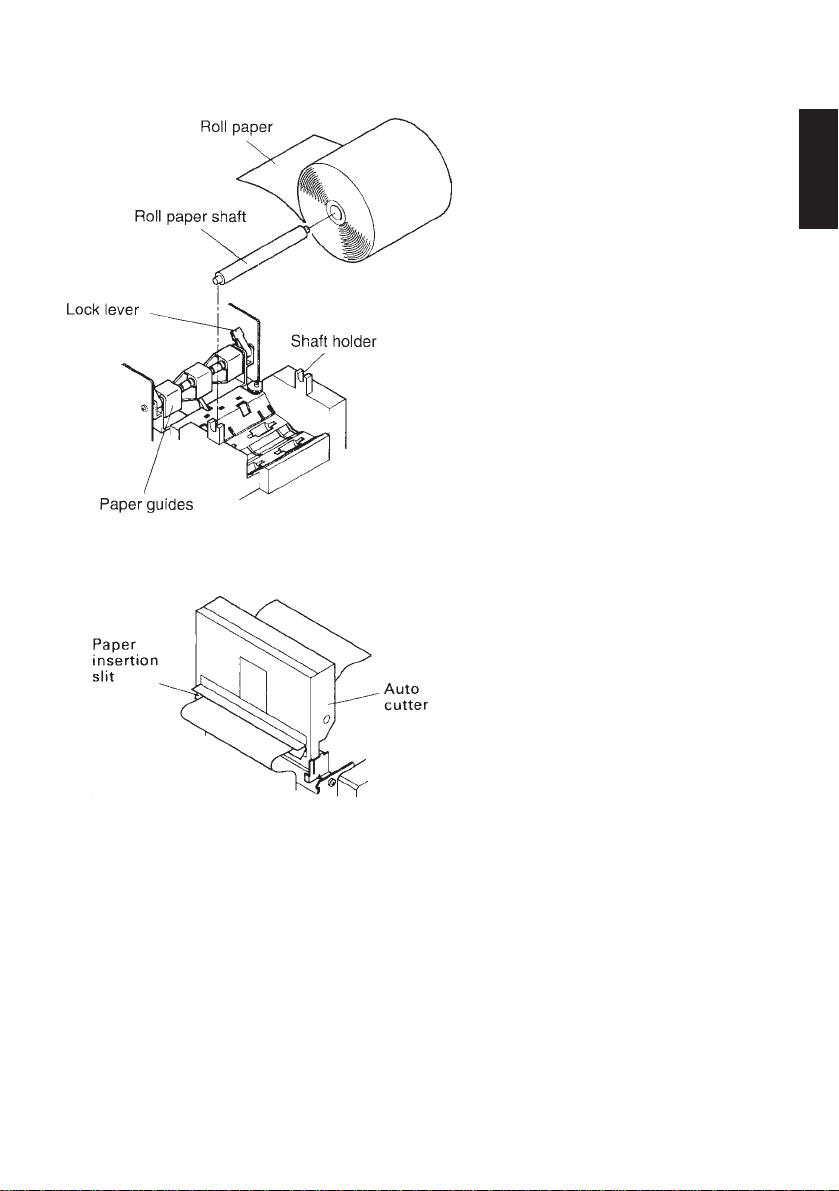

Fig. 2-10 Loading the paper (SP347)

Fig. 2-11 Insertion of the paper into the

auto cutter (SP347)

7 Turn the power switch on the printer

to the on position.

8 Cut the tip of the roll paper in a

straight line.

• In case the front edge of the paper

is fastened with a label, etc., remove the adhesive part of the label. If any adhesive remains on

the paper, it will stick onto the

roller of the printer, causing the

paper to misfeed.

9 Observe the winding direction of

the roll paper and insert the paper

until it stops under the guide.

0 Press the FEED switch (paper feed)

on the control panel

Release the switch when the roll

paper has been fed out 10 cm from

the paper outlet.

A Insert the roll paper shaft into the

paper roll and set it in the shaft

holder.

B Insert the tip of the roll paper in the

auto cutter paper slit.

• When using copying paper, insert

only the original (the upper paper)

into the slit of the auto cutter.

Insert the paper which is to be

copied (the lower paper) between

the platen and the auto cutter. In

this case, Rewinder PW300 (option) will be necessary in order to

wind the paper that is copied. Refer to the user’s manual of the

rewinder for its setting method.

ENGLISH

– 9 –

Page 12

ENGLISH

Lower

paper

Upper paper

Paper insetion

slit

Auto cutter

Paper insertion

slit Upper paper

Lower paper

Print head

Platen

Print head

Platen

Fig. 2-12 Insertion of the paper into the auto cutter

(When using copying paper) (SP347)

C Pull on the edge of the paper to

remove any slack and then lower the

Paper

outlet

auto cutter.

D Insert the paper through the front

cover paper outlet and then replace

Auto cutter

the front cover by reversing the removal steps.

E To install the rear cover reverse the

Fig. 2-13 Paper outlet of the front cover

(SP347)

removal steps.

2-3. Removing the Roll Paper

Remove the rear cover then cut off the paper near the rear of the paper guide. Then

press the “FEED” switch to feed out the rest of the paper that is remaining in the

unit.

When the paper runs out, a buzzer will sound four times per cycle for two cycles.

NOTE 1. Press the “FEED” switch to remove the rest of the paper that is in

the printer. (If you remove the paper by hand, the paper could

wrinkle or slip causing it to jam.)

NOTE 2. When the paper end mark appears on the paper, replace the roll

paper before it runs out.

– 10 –

Page 13

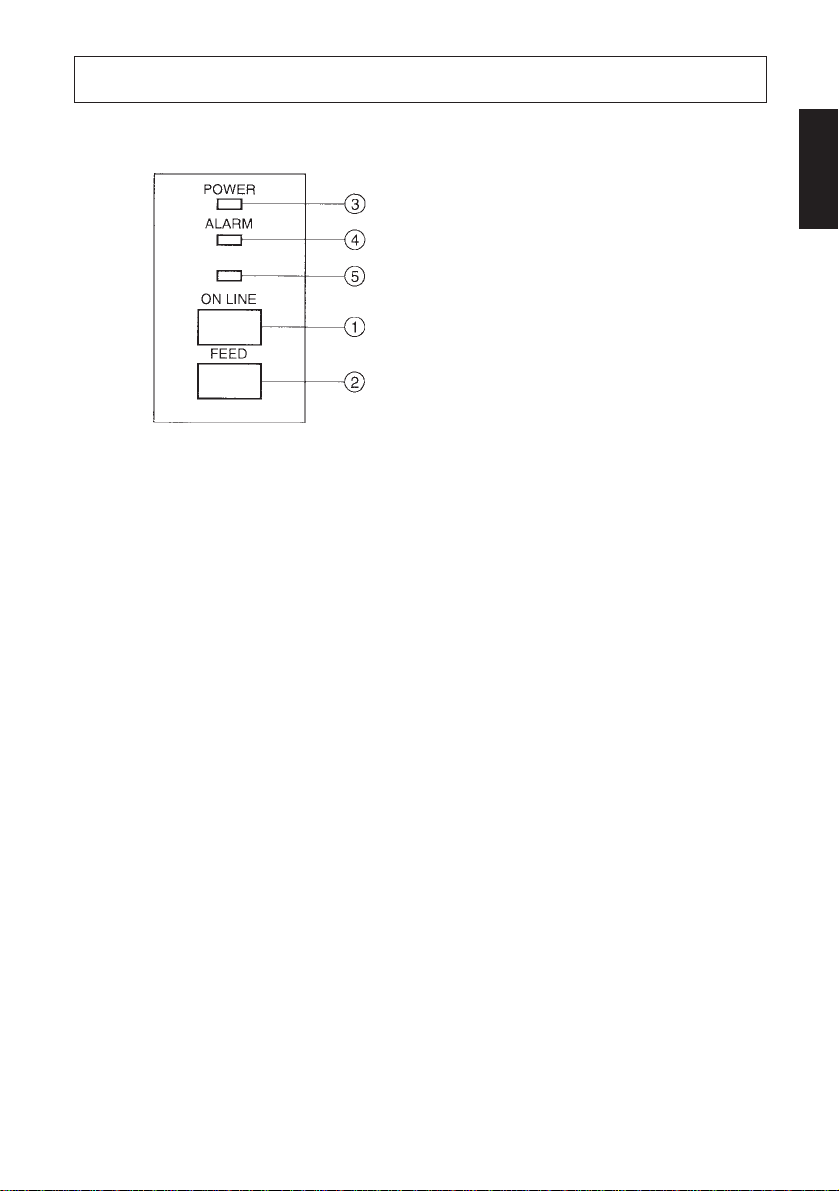

3. CONTROL PANEL

1 “ON LINE” switch

Switches the printer between “ON

LINE” and “OFF LINE”. Whenever the printer switches between

“ON LINE” and “OFF LINE”, the

buzzer gives one short beep (“ON

LINE” and “OFF LINE” switching

is possible only when the paper is

loaded in the printer.)

2 “FEED” switch

• When this switch is pressed and

then released within 0.5 sec., the

paper feeds one line.

• When this switch is depressed for

Fig. 3-1 Control panel

3 “POWER” lamp (green LED)

• Lights when the power for the printer is on.

4 “ALARM” lamp (red LED)

• Lights when the paper is out.

If the paper is out, load a new roll then press the “ON LINE” switch.

• Flashes when the front cover is open or a mechanical error (motor lock etc.)

occurs. The buzzer will give one short beep followed by a long beep.

Mount the front cover properly and press the “ON LINE” switch. If the

buzzer still sounds and the “ALARM” lamp flashes, this signifies that a

mechanical error has occurred. Locate the cause of the error and turn the

power for the printer off and back on again to reset the printer.

(In case of a mechanical error, the data will not be cleared even if the power

is turned off.)

5 “ON LINE” lamp (green LED)

LED lit: Printer is ON LINE

LED off: Printer is OFF LINE

LED flashes: Validation printing mode is set.

When all lamps 3 to 5 light simultaneously and the buzzer sounds continuously, a CPU error has occurred. In case of a CPU error, turn off the power then

turn it on again. When turning off the power, the data will be cleared.

more than 0.5 sec., the paper feeds

continuously.

(The above paper feed operation

is possible for both “ON LINE”

and “OFF LINE” modes.)

ENGLISH

– 11 –

Page 14

Page 15

TABLE DES MATIÈRES

1. INSTALLATION D’UNE CARTOUCHE DE RUBAN..................14

1-1. SP317 .........................................................................................14

1-2. SP347 .........................................................................................15

2. CHARGEMENT DU PAPIER..........................................................17

2-1. SP317 .........................................................................................17

2-2. SP347 .........................................................................................19

2-3. Enlèvement d’un rouleau de papier ...........................................22

3. PANNEAU DE COMMANDE.........................................................23

APPENDICE ...........................................................................................49

L’appendice n’est pas traduit.

– 13 –

Page 16

1-1. SP317

FRANÇAIS

Fig. 1-1 Dépose du cache avant (SP317)

1. INSTALLATION D’UNE CARTOUCHE DE RUBAN

1 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

d’arrêt.

2 Pour retirer le cache avant, soule-

vez-le d’environ 3 cm, puis tirez-le

vers l’avant.

N.B. : Ne touchez pas la tête d’im-

pression immédiatement

après une impression ; en

effet, celle-ci peut être très

chaude.

3 Pour tendre le ruban, tournez le bou-

ton d’alimentation du ruban de la

cartouche dans la direction de la

flèche.

4 Alignez le guide de la cartouche de

ruban sur l’encoche du cadre, puis

appuyez légèrement sur la cartouche de ruban afin qu’elle se mette en

place. Vous entendrez un déclic une

fois la cartouche bien en place. Insérez ensuite le ruban encreur entre la

tête d’impression et la protection du

ruban. Assurez-vous que le ruban

encreur ne dépasse pas la protection

du ruban.

5 Pour tendre le ruban, tournez le

bouton d’alimentation du ruban de

la cartouche dans la direction de la

flèche.

6 Pour remonter le cache avant, effec-

tuez les étapes de la dépose en sens

inverse.

Fig. 1-2 Installation d’une cartouche de

ruban (SP317)

– 14 –

Page 17

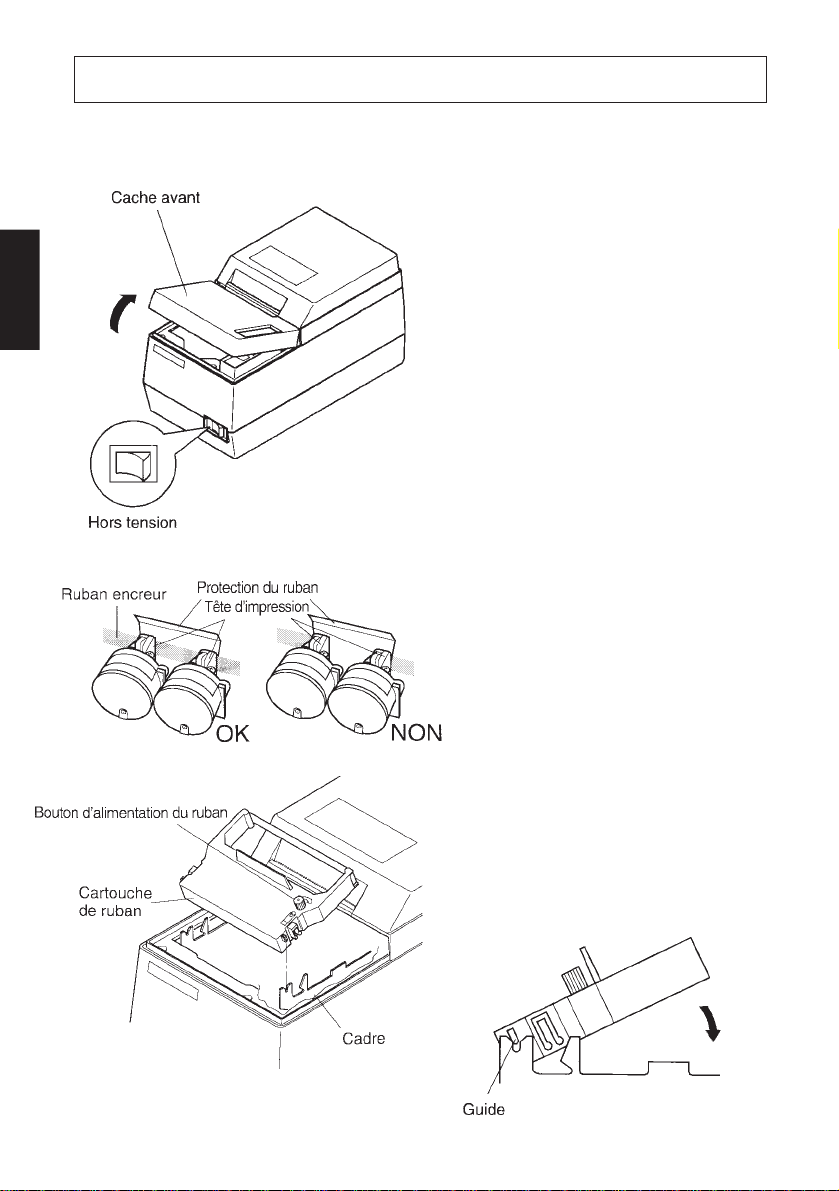

1-2. SP347

Cache avant

Hors tension

Fig. 1-3 Dépose du cache avant (SP347)

Coupoir automatique

Auto cutter

Emballage de

protection

Packing material

1 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

d’arrêt.

2 Pour retirer le cache avant, soule-

vez-le d’environ 3 cm, puis tirez-le

vers l’avant.

N.B. : Ne touchez pas la tête d’im-

pression immédiatement

après une impression ; en

effet, celle-ci peut être très

chaude.

FRANÇAIS

Fig. 1-4 Relèvement du coupoir automati-

que et enlèvement de l’emballage de

protection (SP347)

– 15 –

3 Relevez le coupoir automatique et

placez-le à la verticale, comme illustré à la figure 1-4.

4 Retirez l’emballage de protection.

Page 18

Cartouche

de ruban

FRANÇAIS

Bouton d’alimentation

du ruban

Cadre

4 Pour tendre le ruban, tournez le bou-

ton d’alimentation du ruban de la

cartouche dans la direction de la

flèche.

5 Alignez le guide de la cartouche de

ruban sur l’encoche du cadre, puis

appuyez légèrement sur la cartouche de ruban afin qu’elle se mette en

place. Vous entendrez un déclic une

fois la cartouche bien en place. Insérez ensuite le ruban encreur entre la

tête d’impression et la protection du

ruban. Assurez-vous que le ruban

encreur ne dépasse pas la protection

du ruban.

6 Pour tendre le ruban, tournez le bou-

ton d’alimentation du ruban de la

cartouche dans la direction de la

flèche.

Protection du ruban

Ruban encreur

Ribbon separator

Tête d’impression

Print head

Guide

Verrouillage

Fig. 1-5 Installation d’une cartouche de ruban (SP347)

OK

OK NON

NO

7 Rabaissez le coupoir automatique et replacez le cache avant en inversant les

étapes de sa dépose.

– 16 –

Page 19

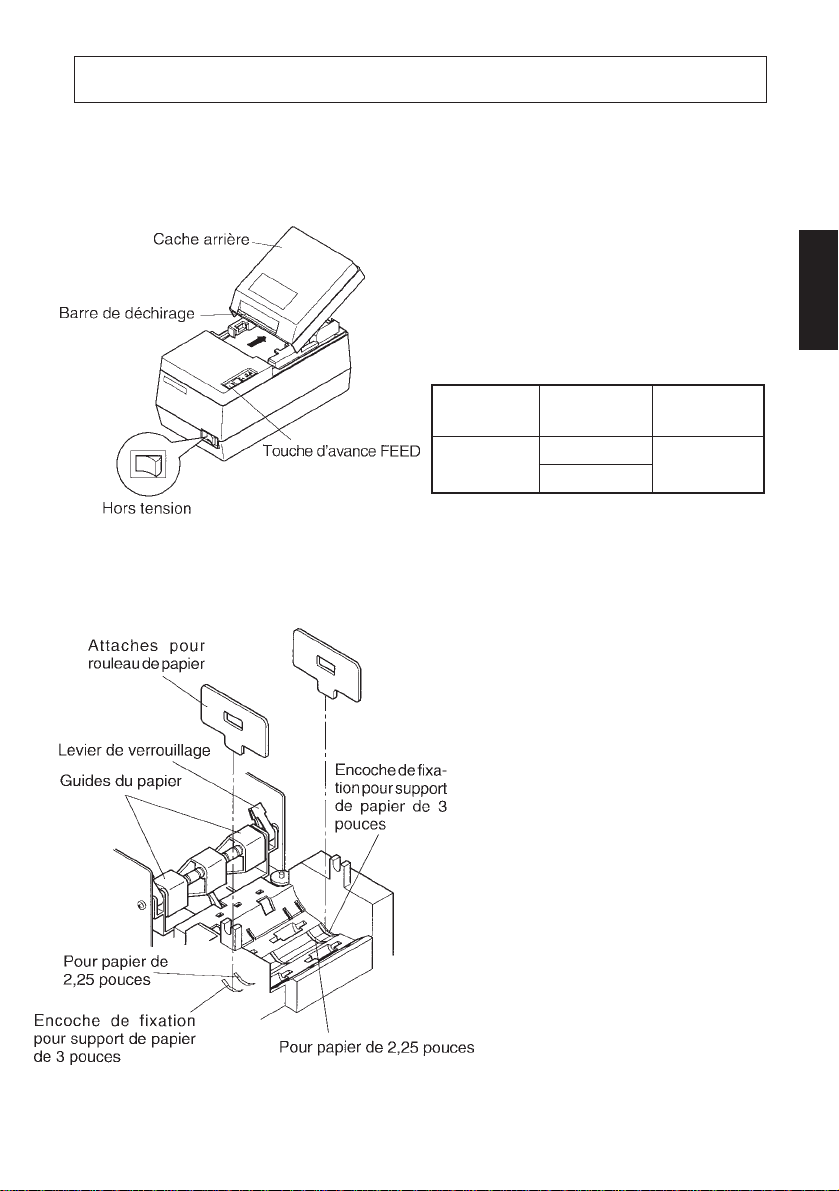

2-1. SP317

2. CHARGEMENT DU PAPIER

1 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

d’arrêt.

2 Réglez l’interrupteur DIP 2-4 en

fonction de la largeur du papier utilisé. (Se référer au Manuel d’installation pour les réglages des

microrupteurs).

FRANÇAIS

Fig. 2-1 Dépose du cache arrière (SP317)

Interrupteurs

DIP

2-4

ON OFF

3,25 pouces

3,0 pouces

2,25 pouces

(Chacun des interrupteurs DIP sont

préréglés sur la position “OUI”.)

3 Pour retirer le cache arrière, rele-

vez-le d’environ 3 cm, puis repoussez-le vers l’arrière.

4 Insérez les attaches de rouleau de

papier dans les encoches correspondant à la largeur du papier utilisé

(2,25 ou 3 pouces).

Fig. 2-2 Montage des attaches pour

rouleau de papier (SP317)

– 17 –

Page 20

FRANÇAIS

Fig. 2-3 Positionnement des guides de

Fig. 2-4 Chargement du papier (SP317)

papier (SP317)

5 Réglez la position des guides de

papier gauche et droit. Veillez à

laisser un espace de 0,5 mm entre

l’extrémité du guide et du papier,

puis bloquez le levier de

verrouillage.

• Pour régler la position des guides

de papier, placez les anneaux d’arrêt dans les espaces sur l’axe des

guides de papier qui correspondent à la largeur du papier à charger (voyez la figure 2-3).

6 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

de marche.

7 Coupez l’extrémité du papier en

veillant à couper droit.

Si l’extrémité du papier est fixée à

l’aide d’un adhésif, il convient de

l’éliminer. En effet, toute trace de

matière adhésive sur le papier que

vous insérez dans l’imprimante risque d’adhérer au rouleau d’impression et d’empêcher l’alimentation

correcte du papier.

8 Placez le rouleau de papier comme

illustré, puis insérez l’extrémité du

papier aussi loin que possible sous

le guide de papier et enfoncez ensuite la touche d’avance FEED du

panneau de commande afin de faire

avancer le papier.

9 Une fois que le papier ressort par la

fente de sortie de l’imprimante, relâchez la touche d’avance FEED.

Insérez ensuite l’axe pour rouleau

de papier dans le rouleau de papier,

puis mettez l’axe en place en le

fixant dans les encoches de maintien.

0 Insérez l’extrémité du papier dans

la fente de la barre de déchirage,

puis remettez le cache arrière en

place en inversant l’ordre de la dépose décrit au point 3 ci-avant.

N.B. : N’attendez pas que le rou-

leau soit épuisé avant de

remplacer le rouleau de papier ; remplacez-le dès que

la marque de fin de rouleau

– 18 –

est apparente.

Page 21

2-2. SP347

Cache arrière

Hors tension

1 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

d’arrêt.

2 Pour retirer le cache avant, soule-

vez-le d’environ 3 cm, puis tirez-le

vers l’avant.

N.B. : Ne touchez pas la tête d’im-

pression immédiatement

après une impression ; en

effet, celle-ci peut être très

chaude.

3 Pour retirer le cache arrière, rele-

vez-le d’environ 3 cm, puis repoussez-le vers l’arrière.

FRANÇAIS

Fig. 2-5 Dépose du cache arrière (SP347)

4 Réglez l’interrupteur DIP 2-4, les attaches pour rouleau de papier et le levier

d’ajustement en fonction de la largeur et de l’épaisseur du rouleau de papier

utilisé.

• Les réglages des interrupteurs DIP sont expliqués dans le Guide d’installation.

• Pour trouver la position standard A du levier d’ajustement, abaissez celui-

ci le plus possible (côté cache arrière), puis relevez-le de deux crans.

Papier

Largeur du papier

2,25 pouces

3,0 pouces

3,25 pouces

Épaisseur

1 feuille de papier

Papier d’imprimante

1 feuille de papier

Papier d’imprimante

1 feuille de papier

Papier d’imprimante

Interrupteur DIP 2-4 Position du levier Attaches pour rouleau

(Fig. 4-1) d’ajustement (Fig. 2-6) de papier (Fig. 2-7)

OFF A

OFF B

ON A

ON B

ON A Pas utilisés

ON B Pas utilisés

– 19 –

Utilisés (encoches intérieures)

Utilisés (encoches intérieures)

Utilisés (encoches extérieures)

Utilisés (encoches extérieures)

Page 22

A: Une feuille de papier

(position standard)

B: Papier de copie

Attaches pour

rouleau de papier

Levier de

verrouillage

FRANÇAIS

Levier d’ajustement

Fig. 2-6 Positionnement du levier d’ajus-

tement (SP347)

Axe de guides de papier

Guide de

papier

2,25 pouces

3 pouces

3,25 pouces

Fig. 2-8 Guide de rouleau de papier

(SP347)

Auto cutter

Coupoir automatique

Guide de

papier

Guides du papier

Pour papier de

2,25 pouces

Encoche de fixation

pour support de

papier de 3 pouces

Encoche de

fixation pour

support de papier

de 3 pouces

Pour papier de

2,25 pouces

Fig. 2-7 Fixation des attaches pour

rouleau de papier (SP347)

5 Réglez la position des guides de

papier gauche et droit. Veillez à

laisser un espace de 0,5 mm entre

l’extrémité du guide et du papier,

puis bloquez le levier de

verrouillage.

• Pour régler la position des guides

de papier, placez les anneaux d’arrêt dans les espaces sur l’axe des

guides de papier qui correspondent à la largeur du papier à charger (voyez la figure 2-8).

Fig. 2-9 Relèvement du coupoir automati-

que (SP347)

– 20 –

6 Relevez le coupoir automatique et

placez-le à la verticale, comme illustré à la figure 2-9.

Page 23

Fig. 2-10 Chargement du papier (SP347)

Fig. 2-11 Insertion du papier dans le

coupoir automatique (SP347)

7 Mettez le commutateur d’alimenta-

tion de l’imprimante sur la position

de marche.

8 Coupez l’extrémité du papier en

veillant à couper droit.

• Si l’extrémité du papier est fixée à

l’aide d’un adhésif, il convient de

l’éliminer. En effet, toute trace de

matière adhésive sur le papier que

vous insérez dans l’imprimante

risque d’adhérer au rouleau et

d’empêcher l’alimentation correcte du papier.

9 Placez le rouleau de papier comme

illustré, puis insérez l’extrémité du

papier aussi loin que possible sous

le guide de papier.

0 Enfoncez ensuite la touche d’avance

FEED du panneau de commande.

Faire avancer le papier, de sorte

qu’il ressorte de 10 cm par la fente

de sortie de l’imprimante, puis relâchez la touche d’avance.

A Insérez ensuite l’axe pour rouleau

de papier dans le rouleau de papier,

puis mettez l’axe en place en le

fixant dans les encoches de maintien.

B Insérez l’extrémité du papier dans

la fente de la barre de déchirage.

• Quand vous employez du papier

de copie, insérez uniquement l’original (la première feuille de papier) dans la fente du coupoir automatique. Insérez le papier de copie (la deuxième feuille de papier)

entre le cylindre et le coupoir automatique. Il est nécessaire d’installer une rebobineuse PW300 (vendue en option) afin de pouvoir

rebobiner le papier de copie. Consultez le guide de l’utilisateur de

la rebobineuse pour apprendre

comment faire rebobiner le papier

de copie.

FRANÇAIS

– 21 –

Page 24

Deuxième

feuille

FRANÇAIS

Première feuille

Fente d’insertion

du papier

Fente d’insertion

du papier

Coupoir

automatique

Première feuille

Deuxième feuille

Tête d’impression

Cylindre d’impression

Tête d’impression

Cylindre d’impression

Fig. 2-12 Insertion du papier dans le coupoir automatique

(avec papier de copie) (SP347)

C Tirez sur l’extrémité du papier afin

de tendre le papier, puis rabaisser le

Fente de

sortie du

papier

coupoir automatique.

D Insérez le papier par la fente de

papier du cache avant, puis remettez le cache avant en place en inver-

Coupoir

automatique

Fig. 2-13 Fente de sortie du cache avant

(SP347)

sant l’ordre de sa dépose.

E Replacez le cache arrière en inver-

sant l’ordre de sa dépose.

2-3. Enlèvement d’un rouleau de papier

Retirer le cache arrière, puis coupez le papier juste derrière le guide de papier.

Enfoncez la touche d’avance FEED afin de faire sortir le reste du papier qui se

trouve toujours dans l’imprimante.

Quand tout le papier est sorti, deux cycles de quatre bips sonores retentissent.

N.B. 1 : Enfoncez la touche d’avance FEED pour éliminer le reste du papier

qui se trouve dans l’imprimante.

(Si vous retirez le papier à la main, celui-ci risque de se chiffonner

ou de se mettre de travers et de causer un bourrage.)

N.B. 2 : N’attendez pas que le rouleau soit épuisé avant de remplacer le

rouleau de papier ; remplacez-le dès que la marque de fin de rouleau

est apparente.

– 22 –

Page 25

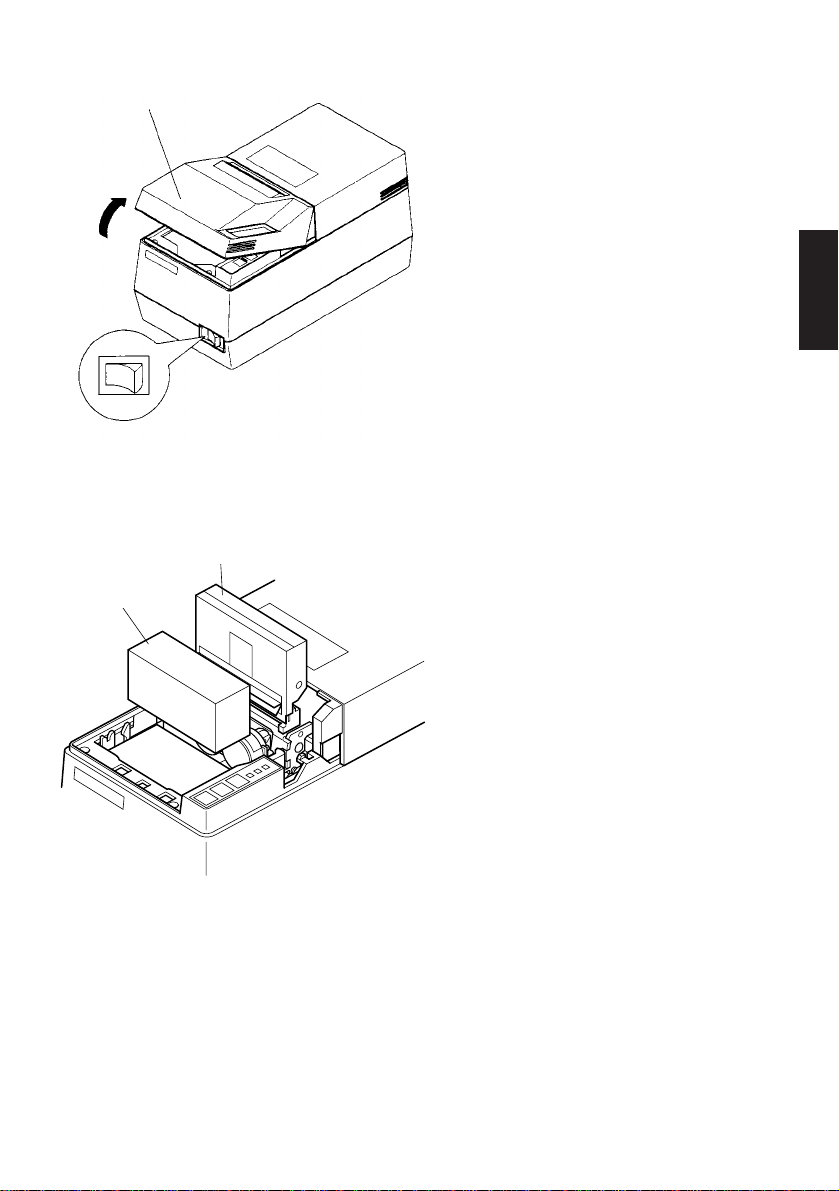

3. PANNEAU DE COMMANDE

1 Touche “en ligne” ON LINE

Cette touche permet de commuter

POWER

ALARM

ON LINE

FEED

Fig. 3-1 Panneau de commande

3

4

5

1

2

3 Voyant de marche POWER (DEL verte)

• Ce voyant s’allume quand l’imprimante est en état de marche.

4 Voyant d’alerte ALARM (DEL rouge)

• S’allume quand le papier est épuisé.

Quand le papier est épuisé, charger un nouveau rouleau, puis appuyez sur la

touche ON LINE.

• Ce voyant clignote quand le cache avant est ouvert ou une erreur mécanique

(blocage de moteur, etc.) est détectée. Un bip sonore court retentit, suivi

d’un long bip. Replacez correctement le cache avant, puis appuyez sur la

touche ON LINE. Si les bips sonores retentissent toujours et si le voyant

ALARM clignote toujours, cela signifie qu’une erreur mécanique s’est

produite. Localisez la cause de l’erreur et mettez l’imprimante hors, puis

sous tension pour réinitialiser celle-ci. (En cas d’erreur mécanique, les

données ne sont pas effacées quand vous mettez l’imprimante hors tension.)

5 Voyant “en ligne” ON LINE (DEL verte)

DEL allumée : l’imprimante est “en ligne”

DEL éteinte : l’imprimante est “hors ligne”

DEL clignote : l’imprimante est en mode d’impression “validation”

Quand tous les voyants 3 à 5 s’allument simultanément et que des bips

sonores retentissent de façon répétée signifie qu’une erreur s’est produite au

niveau du processeur central. Dans ce cas, mettez l’appareil hors, puis sous

tension. Les données sont effacées à la mise hors tension de l’appareil.

– 23 –

entre les états “en ligne” et “hors

ligne”. Un bip sonore court retentit

à chaque fois que l’imprimante passe

d’un état à l’autre. Vous ne pouvez

modifier l’état que si du papier est

chargé dans l’imprimante.

2 Touche d’avance FEED

• Si vous appuyez sur la touche,

puis la relâchez dans la demi-seconde, le papier avance d’une ligne.

• Si vous appuyez sur la touche

pendant plus d’une demi-seconde,

le papier avance de façon continue.

(Cela est valable à la fois pour le

mode “en ligne” et le mode “hors

ligne”.)

FRANÇAIS

Page 26

Page 27

INHALTSVERZEICHNIS

1. EINLEGEN DER FARBBANDKASSETTE ...................................26

1-1. SP317 .........................................................................................26

1-2. SP347 .........................................................................................27

2. EINLEGEN DES PAPIERS..............................................................29

2-1. SP317 .........................................................................................29

2-2. SP347 .........................................................................................31

2-3. Entfernen des Rollenpapiers ......................................................34

3. BEDIENFELD ..................................................................................35

ANHANG................................................................................................49

Der Anhang erscheint nur im englischen Teil dieser Bedienungsanleitung

– 25 –

Page 28

1-1. SP317

DEUTSCH

Abb. 1-1 Frontabdeckung abnehmen

1. EINLEGEN DER FARBBANDKASSETTE

1 Den Netzschalter am Drucker in

Aus-Stellung stellen.

2 Zum Abnehmen der Frontab-

deckung diese ca. 3 cm anheben,

und nach vorne ziehen.

HINWEIS: Nicht den Druckkopf

sofort nach dem Drukken berühren, da er

sehr heiß sein kann.

3 Um Schlaufen im Farbband aufzu-

wickeln, den Farbbandzuführknopf

der Farbbandkassette in Pfeilrichtung drehen.

4 Die Farbbandkassettenführung mit

dem eingekerbten Teil am Rahmen

ausrichten. Die Farbbandkassette

aus dieser Position eindrücken, bis

(SP317)

sie hörbar einrastet. Das Farbband

zwischen dem Druckkopf und dem

Farbband-Trenner einführen. Sicherstellen, daßkein Farbband über

den Farbband-Trenner herausragt.

5 Um Schlaufen im Farbband aufzu-

wickeln, den Farbbandzuführknopf

der Farbbandkassette in Pfeilrichtung drehen.

6 Zum Anbringen der Frontabdeckung

die Ausbauschritte in umgekehrter

Reihenfolge ausführen.

Abb. 1-2 Einlegen der Farbbandkassette

(SP317)

– 26 –

Page 29

1-2. SP347

Frontabdeckung

1 Den Netzschalter des Druckers in

Aus-Stellung stellen.

2 Zum Abnehmen der Frontab-

deckung diese ca. 3 cm anheben,

und nach vorne ziehen.

HINWEIS: Nicht den Druckkopf

sofort nach dem Drukken berühren, da er

sehr heißsein kann.

Netzschalter aus

Abb. 1-3 Abnehmen der Frontabdeckung

(SP347)

Automatische Abscneideinheit

Packing material

Verpackungsmaterial

Abschneideinheit anheben, und das

Verpackungsmaterial entfernen (SP347)

Auto cutter

Abb. 1-4 Die automatische

DEUTSCH

3 Die automatische Abschneideinheit

anheben und in vertikale Position

stellen, wie in der Abbildung 1-4

gezeigt.

4 Das Verpackungsmaterial entfer-

nen.

– 27 –

Page 30

Farbbandkassette

DEUTSCH

Farbbandzuführknopf

Rahmen

4 Um Schlaufen im Farbband aufzu-

wickeln, den Farbbandzuführknopf

der Farbbandkassette in Pfeilrichtung drehen.

5 Die Farbbandkassette mit dem

gekerbten Teil am Rahmen ausrichten. Die Farbbandkassette aus dieser Position bis zum hörbaren Einrasten eindrücken. Das Farbband

zwischen dem Druckkopf und dem

Farbband-Trenner einführen. Sicherstellen, daßkein Farbband über

den Farbband-Trenner herausragt.

6 Um Schlaufen im Farbband aufzu-

wickeln, den Farbbandzuführknopf

der Farbbandkassette in Pfeilrichtung drehen.

Farbband-Trenner

Farbband

Ribbon separator

Druckkopf

Print head

Führung

Verriegelungsteil

Abb. 1-5 Einlegen der Farbbandkassette (SP347)

OK

OK NEIN

NO

7 Die automatische Abschneideinheit absenken, und die Frontabdeckung an-

bringen. Zum Anbringen die Ausbauschritte in umgekehrter Reihenfolge

ausführen.

– 28 –

Page 31

2-1. SP317

2. EINLEGEN DES PAPIERS

1 Den Netzschalter des Druckers in

Aus-Stellung stellen.

2 Den DIP-Schalter 2-4 entsprechend

der Breite des verwendeten Papiers

einstellen. (Die Einstellung der DIP

Schalter finden Sie im Installationshandbuch.)

Abb. 2-1 Entfernen der Rückabdeckung

(SP317)

DIP-

Schalter

2-4

ON OFF

3,25 Zoll

3,0 Zoll

2,25 Zoll

(Alle Schalter in der DIP-Schalterleiste

sind ab Werk auf “ON” gestellt.)

3 Zum Entfernen der Rückabdeckung

diese ca. 3 cm anheben und nach

hinten drücken.

4 Je nach der Breite des Papiers (2,25

oder 3 Zoll) die Papierrollenhalter

auf die vorgeschriebene Position

ausrichten.

DEUTSCH

Abb. 2-2 Anbringen der

Papierrollenhalter (SP317)

– 29 –

Page 32

5 Stellen Sie die linke und rechte

Papierführung ein. Lassen Sie einen

0,5 mm breiten Abstand zwischen

Papierführung und Papierkante und

stellen Sie den Sperrhebel fest.

• Indem Sie den Sicherungsring ein-

setzen, der der Rille der Papierführungswelle in Abb. 2-3 entspricht, legen Sie die Position für

die Papierführung fest.

Abb. 2-3 Einstellung der Papierführung

(SP317)

DEUTSCH

Abb. 2-4 Einlegen des Papiers (SP317)

6 Den Netzschalter des Druckers in

Ein-Stellung stellen.

7 Schneiden Sie die Vorderkante des

Rollenpapiers in einer geraden Linie ab.

Wenn die Vorderkante des Papiers

mit einem Aufkleber etc. festgeklebt

ist, ziehen Sie den Aufkleber ab.

Wenn Klebstoff auf dem Papier verbleibt, kann er an der Walze anhaften und Fehleinzug bewirken.

8 Halten Sie das Rollenpapier wie in

der Abbildung gezeigt, führen Sie

das Oberende des Papiers unter der

Papierführung so weit wie möglich

ein, und drücken Sie die FEEDTaste am Bedienfeld, um das Papier

einzuziehen.

9 Wenn die Vorderkante des Papiers

aus dem Drucker ausgegeben wird,

lassen Sie die FEED-Taste los. Danach setzen Sie das Rollenpapier

auf die Rollenpapierwalze und setzen Sie die Rollenpapierwalze auf

den Wellenhalter.

0 Führen Sie die Oberkante des Pa-

piers in den Abreißkantenschlitz ein,

und bringen dann die Rückabdeckung an, indem Sie die Ausbauschritte von Schritt 3 oben in

umgekehrter Reihenfolge ausführen.

HINWEIS: Wenn die Papierend-

markierung auf dem

Papier erscheint, das

Rollenpapier austauschen, bevor es zu

Ende geht.

– 30 –

Page 33

2-2. SP347

1 Den Netzschalter des Druckers in

Aus-Stellung stellen.

Rückabdeckung

Netzschalter aus

Abb. 2-5 Abnehmen der Rückabdeckung

(SP347)

4 Den DIP-Schalter 2-4, den Rollenpapierhalter und die Einstellhebelposition

entsprechend der Breite des verwendeten Papiers einstellen.

• Die DIP-Schalterstellungen sind der Aufstellanleitung zu entnehmen.

• Wenn Sie die Normalposition des Einstellhebels nicht kennen, senken Sie

den Einstellhebel so weit wie möglich (an der Rückabdeckungsseite) ab,

und ziehen ihn dann um zwei Stellungen nach oben. Diese Stellung ist die

Normalposition A.

2 Zum Entfernen der Frontabdeckung

diese ca. 3 cm anheben und nach

vorne ziehen.

HINWEIS: Nicht den Druckkopf

sofort nach dem Drukken berühren, da er

sehr heiß sein kann.

3 Zum Entfernen der Rückabdeckung

diese ca. 3 cm anheben und nach

hinten drücken.

DEUTSCH

Papier

Papierbreite Dicke

2,25 Zoll

3,0 Zoll

3,25 Zoll

1 Blatt Papier

Druckerpapier

1 Blatt Papier

Druckerpapier

1 Blatt Papier

Druckerpapier

DIP-Schalter 2-4

(Abb. 4-1)

OFF A

OFF B

ON A

ON B

ON A Nicht verwendet

ON B Nicht verwendet

Einstellhebel- Rollenpapierhalter

position (Abb. 2-6)

Verwendet (Innenrille)

Verwendet (Innenrille)

Verwendet (Außenrille)

Verwendet (Außenrille)

– 31 –

(

Abb

. 2-7)

Page 34

A: Ein Blatt Papier

(Normalposition)

B: Kopierpapier

Rollenpapierhalter

Sperrhebel

Einstellhebel

DEUTSCH

Abb. 2-6 Position des Einstellhebels

(SP347)

Papierführungswelle

Papierführungen Papierführungen

2,25 Zoll

3 Zoll

3,25 Zoll

Abb. 2-8 Rollenpapierführung (SP347)

Automatische

Auto cutter

Abschneideinheit

Papierführungen

Für 2,25-ZollPapier

PapierhalterHaltekerbe für

3-Zoll-Papier

PapierhalterHaltekerbe für

3-Zoll-Papier

Für 2,25-Zoll-Papier

Abb. 2-7 Anbringen der

Rollenpapierhalter (SP347)

5 Stellen Sie die linke und rechte

Papierführung ein. Lassen Sie einen

0,5 mm großen Abstand zwischen

der Papierführung und der Kante

des Papiers und befestigen Sie den

Sperrhebel.

• Indem Sie den Sicherungsring ein-

setzen, der der Rille der Papierführungswelle in Abb. 2-8 entspricht, legen Sie die Position für

die Papierführung fest.

Abb. 2-9 Die automatische

Abschneideinheit anheben (SP347)

6 Heben Sie die automatische

Abschneideinheit an, und stellen Sie

sie in senkrechte Stellung wie in der

Abbildung 2-9 gezeigt.

– 32 –

Page 35

Abb. 2-10 Papier einlegen (SP347)

Abb. 2-11 Papier in die automatische

Abschneideinheit legen (SP347)

7 Den Netzschalter des Druckers in

Ein-Stellung stellen.

8 Schneiden Sie die Vorderkante des

Rollenpapiers in einer geraden Linie ab.

• Wenn die Vorderkante des Pa-

piers mit einem Aufkleber etc.

festgeklebt ist, ziehen Sie den

Aufkleber ab. Wenn Klebstoff auf

dem Papier verbleibt, kann er an

der Walze anhaften und Fehleinzug bewirken.

9 Beachten Sie die Wickelrichtung

des Rollenpapiers, und setzen Sie

das Papier ein, bis es unter der Führung stoppt.

0 Drücken Sie die FEED-Taste

(Papiervorschub) am Bedienfeld.

Lassen Sie die Taste los, wenn das

Rollenpapier 10 cm aus dem Papierauslauf ausgegeben worden ist.

A Setzen Sie die Rollenpapierwelle in

die Papierrolle ein, und setzen Sie

diese in den Wellenhalter ein.

B Führen Sie die Oberkante des

Rollenpapiers in den Schlitz der

automatischen Abschneideinheit

ein.

• Bei Verwendung von Durch-

schlagpapier setzen Sie nur das

Originalpapier (obere Papier) in

den Schlitz in der automatischen

Abschneideinheit ein. Führen Sie

das Kopierpapier (das untere Papier) zwischen Druckwalze und

automatischer Abschneideinheit

ein. In diesem Fall ist der

Rückwickler PW300 Sonderzubehör erforderlich, um das

Durchschlagpapier aufzuwickeln.

Anbringen des Rückwicklers siehe seine Bedienungsanleitung.

DEUTSCH

– 33 –

Page 36

Unteres

Papier

Automatische

Abschneideinheit

Papiereinführschlitz

Oberes Papier

Papiereinführschlitz

Oberes PapierI

Druckwalze

DEUTSCH

Abb. 2-12 Einsetzen des Papiers in den automatischen Abschneider (bei Verwen-

Druckkopf

Druckkopf

Druckwalze

dung von Durchschlagpapier) (SP347)

C Ziehen Sie die Kante des Papiers-

tau, um Schlaufen zu beseitigen,

und senken Sie dann die automatische Abschneideinheit ab.

D Führen Sie das Papier durch den

Papierauslaß

Papierauslaß in der Frontabdeckung,

und setzen Sie dann die Frontab-

Automatische

Abschneideinheit

deckung wieder auf, indem Sie die

Ausbauschritte in umgekehrter Reihenfolge ausführen.

E Zum Einbauen der Rückabdeckung

die Ausbauschritte in umgekehrter

Abb. 2-13 Papierausla· an der Frontab-

deckung (SP347)

Reihenfolge ausführen.

2-3. Entfernen des Rollenpapiers

Unteres Papier

Nehmen Sie die Rückabdeckung ab, und schneiden Sie das Papier in der Nähe der

Papierführung ab. Dann drücken Sie die FEED-Taste, um den Rest des Papiers

auszugeben, der noch in der Einheit ist.

Wenn das Papier verbraucht ist, wird ein Tonsignal bestehend aus zweimal vier

Tönen ausgegeben.

HINWEIS 1. Durch Drücken der FEED-Taste wird der Rest des noch im

Drucker befindlichen Papiers ausgegeben. (Wenn Sie das

Papier mit der Hand entnehmen, kann es knittern oder

verrutschen und einen Papierstau bewirken.)

HINWEIS 2. Wenn die Papier-Verbraucht-Markierung auf dem Papier er-

scheint, tauschen Sie die Rolle aus, bevor das Papier ganz zu

Ende ist.

– 34 –

Page 37

3. BEDIENFELD

1 Taste ON LINE

Schaltet den Drucker zwischen Online und Off-line Betrieb um. Bei

POWER

ALARM

ON LINE

FEED

Abb. 3-1 Bedienfeld

3

4

5

1

2

3 Netzlämpchen POWER (grüne LED)

• Leuchtet auf, wenn der Drucker mit Netzstrom versorgt wird.

4 Warnlämpchen ALARM (rote LED)

• Leuchtet auf, wenn das Papier verbraucht ist.

Wenn das Papier verbraucht ist, legen Sie eine neue Rolle ein und drücken

die Taste ON LINE.

• Blinkt, wenn die Frontabdeckung offen ist oder ein mechanischer Fehler

(Motorblockierung etc.) vorliegt. In diesem Fall wird ein kurzer Piepton

gefolgt von einem langen Piepton ausgegeben.

Setzen Sie die Frontabdeckung richtig auf, und drücken Sie die Taste ON

LINE. Wenn das Tonsignal weiter ertönt und die ALARM-Leuchte blinkt,

heißt dies, daß ein mechanischer Fehler aufgetreten ist. Finden Sie die

Ursache des Fehlers, und schalten Sie den Drucker aus und anschließend

wieder ein, um einen Rückstellung auszuführen.

(Bei mechanischen Störungen werden die Daten nicht gelöscht, auch wenn

der Drucker ausgeschaltet wird.)

5 Lämpchen ON LINE (grüne LED)

LED leuchtet: Drucker im On-line-Betrieb

LED erloschen: Drucker im Off-line-Betrieb

LED blinkt: Validierungsdruck ist gewählt

Wenn alle Lämpchen 3 bis 5 gleichzeitig leuchten und der Signalton

kontinuierlich erklingt, liegt ein CPU-Fehler vor. In diesem Fall das Gerät

aus- und dann wieder einschalten. Wenn das Gerät ausgeschaltet wird, werden

die Daten gelöscht.

– 35 –

jedem Umschalten zwischen Online und Off-line wird ein kurzer

Piepton ausgegeben (Umschalten ist

nur möglich, wenn Papier im Drukker eingelegt ist.)

2 FEED-Schalter

• Wenn dieser Schalter gedrückt und

dann innerhalb von 0,5 s losgelassen wird, wird das Papier um

eine Zeile vorgeschoben.

• Wenn dieser Schalter länger als

0,5 s gedrückt gehalten wird, wird

das Papier kontinuierlich vorgeschoben. (Der obige Vorschubvorgang ist sowohl im On-line als

auch im Off-line Betrieb möglich.)

DEUTSCH

Page 38

Page 39

INDICE

1. CARICAMENTO DELLA CARTUCCIA DEL NASTRO..............38

1-1. SP317 .........................................................................................38

1-2. SP347 .........................................................................................39

2. CARICAMENTO DELLA CARTA .................................................41

2-1. SP317 .........................................................................................41

2-2. SP347 .........................................................................................43

2-3. Rimozione della carta in rotolo..................................................46

3. PANNELLO DI CONTROLLO..........................................................47

APPENDICE ...........................................................................................49

L’Appendice appare solo nella sezione in inglese di questo manuale.

– 37 –

Page 40

1. CARICAMENTO DELLA CARTUCCIA DEL NASTRO

1-1. SP317

ITALIANO

Fig. 1-1 Rimozione del coperchio anteriore

(SP317)

1 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di spegnimento.

2 Per rimuovere il coperchio anterio-

re sollevarlo di circa 3 cm e tirarlo in

avanti.

NOTA: Non toccare la testina di

stampa subito dopo la

stampa perché può essere

molto calda.

3 Per eliminare allentamenti del na-

stro girare la manopola di avanzamento del nastro sulla cartuccia del

nastro in direzione della freccia.

4 Allineare la guida della cartuccia

del nastro con la parte incassata del

telaio. Inserire la cartuccia del nastro da quella posizione fino a quando si sente uno scatto. Inserire il

nastro inchiostro tra la testina di

stampa e il separatore nastro. Assicurarsi che il nastro inchiostro non

sporga oltre il separatore nastro.

5 Per eliminare allentamenti nel na-

stro girare la manopola di avanzamento del nastro sulla cartuccia del

nastro in direzione della freccia.

6 Per installare il coperchio anteriore

eseguire all’inverso il procedimento usato per la rimozione.

Fig. 1-2 Caricamento della cartuccia del

nastro (SP317)

– 38 –

Page 41

1-2. SP347

Coperchio anteriore

Spegnere

Fig. 1-3 Rimozione del coperchio anteriore

(SP347)

Taglierina automatica

Auto cutter

Materiale di

imballaggio

Packing material

1 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di spegnimento.

2 Per rimuovere il coperchio anterio-

re sollevarlo di circa 3 cm e tirarlo in

avanti.

NOTA: Non toccare la testina di

stampa subito dopo la

stampa perché può essere

molto calda.

ITALIANO

3 Sollevare la taglierina automatica e

porla in posizione verticale, come

mostrato nella Fig. 1-4.

4 Rimuovere il materiale di imballag-

gio.

Fig. 1-4 Sollevare la taglierina automatica

e rimuovere il materiale di imballaggio

(SP347)

– 39 –

Page 42

Cartuccia

del nastro

Manopola di avanzamento del nastro

ITALIANO

Telaio

4 Per eliminare allentamenti del na-

stro girare la manopola di avanzamento del nastro sulla cartuccia del

nastro in direzione della freccia.

5 Allineare la guida della cartuccia

del nastro con la parte incassata del

telaio. Inserire la cartuccia del nastro da quella posizione fino a quando si sente uno scatto. Inserire il

nastro inchiostro tra la testina di

stampa e il separatatore nastro. Assicurarsi che il nastro inchiostro non

sporga oltre il separatore nastro.

6 Per eliminare allentamenti nel na-

stro girare la manopola di avanzamento del nastro sulla cartuccia del

nastro in direzione della freccia.

Separatore nastro

Nastro inchiostro

Ribbon separator

Testina di stampa

Print head

Guida

Parte di blocco

Fig. 1-5 Caricamento della cartuccia del nastro (SP347)

OK

OK

NO

NO

7 Abbassare la taglierina automatica e installare il coperchio anteriore eseguen-

do all’inverso il procedimento usato per la rimozione.

– 40 –

Page 43

2-1. SP317

2. CARICAMENTO DELLA CARTA

1 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di spegnimento.

2 Regolare l’interruttore DIP 2-4 in

base alla larghezza della carta usata.

(Consultare il Manuale di Installazione per le impostazioni degli interruttori DIP).

Fig. 2-1 Rimozione del coperchio posteriore

(SP317)

Interruttori

DIP

2-4

ON OFF

3,25 pollici

3,0 pollici

2,25 pollici

(Tutti gli interruttori nel gruppo di interruttori DIP sono stati predisposti in

fabbrica sulla posizione “ON”.)

3 Per rimuovere il coperchio poste-

riore, sollevarlo di circa 3 cm e

spingerlo indietro.

4 A seconda della larghezza della car-

ta (2,25 o 3 pollici), allineare i supporti della carta in rotolo alle posizioni specificate.

ITALIANO

Fig. 2-2 Montaggio dei supporti per

carta in rotolo (SP317)

– 41 –

Page 44

Fig. 2-3 Regolazione delle guide della

carta (SP317)

ITALIANO

Fig. 2-4 Caricamento della carta (SP317)

5 Regolare le guide della carta sini-

stra e destra.

Lasciare uno spazio di 0,5 mm tra la

guida della carta e il bordo della

carta e fissare la leva di blocco.

• Quando si inserisce l’anello di

fermo corrispondente alla scanalatura sull’asta delle guide della

carta mostrata nella Fig. 2-3, quella

sarà la posizione quando si fissa la

guida della carta.

6 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di accensione.

7 Tagliare la parte iniziale della carta

in rotolo su una linea diritta.

Se la parte iniziale della carta è

fissata con un’etichetta, ecc., rimuovere la parte adesiva dell’etichetta.

Se rimane dell’adesivo sulla carta,

si può appiccicare al rullo della stampante, causando errori di avanzamento della carta.

8 Tenere il rotolo di carta come mo-

strato nell’illustrazione e inserire la

parte superiore della carta sotto la

guida della carta il pió possibile,

quindi premere l’interruttore

“FEED” sul pannello di controllo

per far avanzare la carta.

9 Quando la parte iniziale della carta

fuoriesce dalla stampante, rilasciare l’interruttore “FEED”. Inserire

quindi la carta sull’asta della carta

in rotolo e collocare l’asta della carta in rotolo sul supporto asta.

0 Inserire la parte iniziale della carta

nella fessura del listello di taglio,

quindi montare il coperchio posteriore eseguendo all’inverso il procedimento usato per la rimozione

del coperchio posteriore al punto 3

sopra.

NOTA: Quando appare sulla carta

il segno di fine carta, sostituire il rotolo di carta pri-

ma che si esaurisca.

– 42 –

Page 45

2-2. SP347

Coperchio posteriore

1 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di spegnimento.

2 Per rimuovere il coperchio anterio-

re sollevarlo di circa 3 cm e tirarlo in

avanti.

NOTA: Non toccare la testina di

stampa subito dopo la

stampa perché può essere

molto calda.

3 Per rimuovere il coperchio poste-

riore sollevarlo di circa 3 cm e tirarlo indietro.

Spegnere

Fig. 2-5 Rimozione del coperchio poste-

riore (SP347)

4 Regolare l’interruttore DIP 2-4, il supporto carta in rotolo e la posizione della

leva di regolazione in base alla larghezza e allo spessore del rotolo di carta

impiegato.

• Fare riferimento al manuale di installazione per la posizione dell’interruttore DIP.

• Se non si conosce la posizione standard della leva di regolazione, abbassare

la leva di regolazione il pió possibile (verso il coperchio posteriore) e quindi

tirarla in su di due scatti. Questa è la posizione standard A

Carta

Larghezza carta

2,25 pollici

3,0 pollici

3,25 pollici

Spessore

1 foglio di carta

Carta stampante

1 foglio di carta

Carta stampante

1 foglio di carta

Carta stampante

Interruttore

DIP 2-4 (Fig. 4-1) regolazione (Fig. 2-6)

OFF A

OFF B

ON A

ON B

ON A Non usato

ON B Non usato

Posizione leva di

– 43 –

Supporto carta in rotolo

(Fig. 2-7)

Usato (scanalatura interna)

Usato (scanalatura interna)

Usato (scanalatura esterna)

Usato (scanalatura esterna)

ITALIANO

Page 46

A: Un foglio di carta

(posizione standard)

B: Carta carbone

Leva di regolazione

Supporti carta

in rotolo

Leva di blocco

Guide della carta

Per carta da

2,25 pollici

Tacca di montaggio supporto

carta per carta

da 3 pollici

ITALIANO

Guide della

carta

Fig. 2-6 Posizione della leva di

regolazione (SP347)

Asta della guida della carta

2,25 pollici

3 pollici

3,25 pollici

Guide della

carta

Fig. 2-8 Guida della carta in rotolo

(SP347)

Taglierina automatica

Auto cutter

Tacca di montaggio

supporto carta per

carta da 3 pollici

Per carta da

2,25 pollici

Fig. 2-7 Montaggio dei supporti carta

in rotolo (SP347)

5 Regolare le guide della carta sini-

stra e destra.

Lasciare uno spazio di 0,5 mm tra la

guida della carta e il bordo della

carta e fissare la leva di blocco.

• Quando si inserisce l’anello di

fermo corrispondente alla scanalatura sull’asta delle guide della

carta mostrata nella Fig. 2-8, quella

sarà la posizione quando si fissa la

guida della carta.

6 Sollevare la taglierina automatica e

porla in posizione verticale, come

mostrato nella Fig. 2-9.

Fig. 2-9 Sollevare la taglierina automatica

(SP347)

– 44 –

Page 47

Fig. 2-10 Caricamento della carta

(SP347)

Fig. 2-11 Inserimento della carta nella

taglierina automatica (SP347)

7 Regolare l’interruttore di alimenta-

zione della stampante sulla posizione di accensione.

8 Tagliare la parte iniziale della carta

in rotolo su una linea diritta.

• Se la parte iniziale della carta è

fissata con un’etichetta, ecc., rimuovere la parte adesiva dell’etichetta. Se rimane dell’adesivo

sulla carta, si può appiccicare al

rullo della stampante, causando

errori di avanzamento della carta.

9 Osservare la direzione di

avvolgimento della carta in rotolo e

inserire la carta sotto la guida il pió

possibile.

0 Premere l’interruttore “FEED”

(avanzamento carta) sul pannello di

controllo.

Rilasciare l’interruttore quando la

carta è avanzata di 10 cm dall’uscita

della carta.

A Inserire la carta sull’asta della carta

in rotolo e collocare l’asta della carta in rotolo sul supporto asta.

B Inserire la parte iniziale della carta

nella fessura della taglierina automatica.

• Quando si usa carta carbone, inse-

rire solo l’originale (foglio superiore) nella fessura della taglierina automatica. Inserire la carta

della copia (foglio inferiore) tra il

rullo e la taglierina automatica. In

questo caso è necessario il

riavvolgitore PW300 (opzionale)

per riavvolgere la carta di copia.

Fare riferimento al manuale di

istruzioni del riavvolgitore per il

metodo di impostazione.

ITALIANO

– 45 –

Page 48

Carta

inferiore

Taglierina

automatica

Fessura di inserimento carta

Carta superiore

Carta superiore

Testina di stampa

Fig. 2-12 Inserimento della carta nella taglierina automatica

(quando si usa carta carbone) (SP347)

ITALIANO

Taglierina

automatica

Fig. 2-13 Uscita della carta sul coperchio

anteriore (SP347)

Fessura di

inserimento carta

Rullo

Uscita

carta

Carta inferiore

Testina di stampa

Rullo

C Tirare il bordo della carta per ri-

muovere eventuali allentamenti e

quindi abbassare la taglierina automatica.

D Inserire la carta attraverso l’uscita

carta sul coperchio anteriore e quindi rimettere il coperchio anteriore

eseguendo all’inverso il procedimento usato per la rimozione.

E Installare il coperchio posteriore

eseguendo all’inverso il procedimento usato per la rimozione.

2-3. Rimozione della carta in rotolo

Rimuovere il coperchio posteriore e quindi tagliare la carta vicino al retro della

guida della carta. Quindi premere l’interruttore “FEED” per far fuoriuscire il

resto della carta rimanente nell’unità.

Quando la carta finisce, un cicalino suona 4 volte per ciclo per 2 cicli.

NOTA 1: Premere l’interruttore “FEED” per rimuovere la carta rimanente

nella stampante. (Se si rimuove manualmente la carta, la carta può

spiegazzarsi o scivolare causando un inceppamento.)

NOTA 2: Quando appare sulla carta il segno di fine carta, sostituire il rotolo

di carta prima che si esaurisca.

– 46 –

Page 49

3. PANNELLO DI CONTROLLO

1 Interruttore “ON LINE”

Alterna lo stato dello stampante tra

“ON LINE” e “OFF LINE”. Quan-

POWER

ALARM

ON LINE

FEED

Fig. 3-1 Pannello di controllo

3

4

5

1

2

3 Spia “POWER” (LED verde)

• Si illumina quando la stampante è accesa.

4 Spia “ALARM” (LED rosso)

• Si illumina quando la carta è esaurita.

Se la carta finisce, caricare un nuovo rotolo e quindi premere l’interruttore

“ON LINE”.

• Lampeggia quando il coperchio anteriore è aperto o quando si verifica un

errore meccanico (blocco del motore, ecc.). Il cicalino emette un segnale

acustico breve seguito da uno lungo.

Montare correttamente il coperchio anteriore e premere l’interruttore “ON

LINE”. Se il cicalino suona ancora e la spia “ALARM” lampeggia, vuol dire

che si è verificato un errore meccanico. Localizzare la causa dell’errore e

spegnere e riaccendere la stampante per inizializzarla.

(Nel caso di un errore meccanico, i dati non sono cancellati anche se si

spegne l’unità.)

5 Spia “ON LINE” (LED verde)

LED illuminato: La stampante è “ON LINE”.

LED spento: La stampante è “OFF LINE”.

LED lampeggiante: È selezionato il modo di stampa a convalida.

Quando tutte le spie da 3 a 5 si illumina contemporaneamente e il cicalino

suona continuamente, si è verificato un errore CPU. Nel caso di un errore CPU

spegnere la stampante e quindi riaccenderla. Quando si spegne la stampante

i dati sono cancellati.

do la stampante alterna tra “ON

LINE” e “OFF LINE”, il cicalino

emette un breve segnale acustico.

(la commutazione “ON LINE” e

“OFF LINE” è possibile solo quando la carta è caricata nella stampante.)

2 Interruttore “FEED”

• Quando questo interruttore viene

premuto per pió di mezzo secondo, la carta avanza continuamente.

(L’operazione di avanzamento

carta sopra descritta è possibile in

entrambi i modi “ON LINE” e

“OFF LINE”.)

ITALIANO

– 47 –

Page 50

Page 51

APPENDIX

Connectors and Signals (Serial Interface)

RS-232C

Pin no. Signal name

1 F-GND — Frame ground

2 TXD OUT Transmitted data

3 RXD IN Received data

4 RTS OUT Data transmission request signal. This

5 CTS IN This signal changes to “SPACE” when

6 N/C Not connected

7 S-GND — Signal ground

8 N/C Not connected

9-10 N/C This pin is used when using the op-

11 RCH OUT This signal changes to “SPACE” when

12 N/C Not connected.

13 S-GND — Signal ground

14 FAULT OUT When a printer error occurs (such as

15 Multi-printer TXD OUT Diode coupled TXD

16 Multi-printer DTR OUT Diode coupled DTR

17 to 19 N/C This pin is used when using the op-

20 DTR OUT Data terminal ready signal. When the

21-22 N/C Not connected

23 to 25 N/C This pin is used when using the op-

I/O

direction

Function

is always “SPACE” when the printer is

turned on.

host computer is ready to transmit data.

(In this instance, the printer does not

check this signal.)

tional interface board.

the printer is ready to receive data. (The

signal line is same as pin 20.)

paper out, mechanical error, etc.), this

signal is set to “MARK”.

tional interface board.

printer is ready to receive data, this

signal changes to “SPACE”.

tional interface board.

APPENDIX

Serial interface connector

– 49 –

Page 52

20 mA current loop (option)

Pin no. Signal name

9 TTY TXDR — Indicates the ground side of the data

10 TTY TXD OUT Transmitted data of 20 mA current

17 TTY TXDR — Indicates the ground side of the data

18 TTY RXDR — Indicates the ground side of the data

19 TTY RXD IN Received data of 20 mA current loop.

23 TTY RXDR — Indicates the ground side of the data

24 TTY TXD OUT Transmission data of 20 mA current

25 TTY RXD IN Reception data of 20 mA current loop.

RS-422A (option)

APPENDIX

Pin no. Signal name

9 SD (+) OUT Transmitted data

10 SD (–) OUT Transmitted data

17 RD (+) IN Received data

18 RD (–) IN Received data

19 CS (+) IN When the host computer is set to standby

23 CS (–) IN When the host computer is set to standby

24 RS (+) OUT Data transmission request signal. When

25 RS (–) OUT Data transmission request signal. When

I/O

direction

I/O

direction

Function

signal of 20 mA loop current.

loop.

signal of 20 mA loop current.

signal of 20 mA loop current.

APPENDIX

signal at 20mA loop current.

loop.

Function

for data transmission, this signal

changes to “SPACE”.

(In this instance, the printer does not

check the signal.)

for data transmission, this signal

changes to “SPACE”.

(In this instance, the printer does not

check the signal.)

the printer is ready to receive data, this

signal changes to “SPACE”.

the printer is ready to receive data, this

signal changes to “SPACE”.

– 50 –

Page 53

Interface Connections (Serial Intefface)

The following is a basic example of interface connections. (For interface

connections, refer to the specifications for the respective interface.) An IBM PC

type serial port is shown in below.

Example of interface connections for an IBM PC

– 51 –

APPENDIX

Page 54

Connectors and Signals (Parallel Interface)

Pin No.

1 STROBE IN Signals when data is ready to be read. Signal goes

2-9 DATA1-8 IN These signals provide the information of the first

10 ACK OUT A 9 microsecond LOW pulse acknowledges re-

11 BUSY OUT When this signal goes to LOW, the printer is

12 PAPER OUT This signal is normally LOW. It will go to HIGH

13 SELECTED OUT This signal is HIGH when the printer is online.

14-15 N/C Unused

APPENDIX

16 SIGNAL Signal ground.

17 CHASSIS Chassis ground, isolated from logic ground.

18 +5VDC +5VDC (Max 50 mA)

19-30 GND Twisted pair return the signal to ground level.

31 RESET IN When this signal goes to LOW, the printer is reset

32 ERROR OUT This signal is normally HIGH. This signal goes to

33 EXT GND External ground.

34

35 N/C – Unused.

36 – – This signal is normally set to HIGH on the printer side.

Signal

Name

OUT if the printer runs out of paper.

GND

GND

COMPULSION

IN/OUT Function

OUT Compulsion signal

from HIGH to LOW (for at least 0.5 microsec.)

when the data is available.

to eighth bits of parallel data. Each signal is at

HIGH level for a logical 1 and at a LOW level for

a logical 0.

ceipt of the data.

ready to accept data. When the printer is in one of

the conditions below, “HIGH” is set.

1. Data is being entered.

2. Off line.

3. Error condition.

to its power-on condition.

LOW to signal that the printer cannot print due to

an error condition.

This connector mates with an Amphenol

57-30360 connector

Parallel interface connector (printer side)

– 52 –

Page 55

Peripheral Unit Drive Circuit

[Drive output 24V, max. 1.0 A]

Drive circuit

– 53 –

APPENDIX

Page 56

Dot Alignment Adjust Mode

When the dot alignment adjust mode is entered, seven types of ruled lines are

printed with the print timing being shifted by half each time, and an asterisk (*)

is added at the currently specified position. To specify printing of a ruled line at

a position different from that marked with the asterisk, press the ONLINE or the

FEED button.

ONLINE: Select the printing status one line above when pressed once.

FEED: Select the printing status one line down when pressed once.

APPENDIX

– 54 –

Page 57

To reset the printing status, meaning to return the specified position to the default

position (the fourth printing status from the top), press the FEED button while

holding down the ONLINE button.

To exit the dot alignment adjust mode, press the ONLINE button, while holding

down the FEED button. The dot alignment adjust mode setting is stored in the

memory, a pattern using the selected setting, followed by “Adjust Completed” is

printed, and the mode returns to the online mode.

– 55 –

APPENDIX

Page 58

General Specifications

Printing method: Serial impact dot matrix

Print direction: Bi-directional

Number of head pins: 9 × 2 (Twin head)

Number of print columns: 40 columns, 14.9 CPI

33 columns, 12.5 CPI

22 columns, 8.3 CPI

Character set: ASCII 96 (characters)

Special characters 64

Block graphics 64

IBM special characters 64

IBM block graphics 50

KATAKANA 64

International characters 12

Download characters 10

Font configuration 5 × 9 or 7 × 9

Paper width 3.25 inch (82.5 mm) 3.0 inch (76 mm) 2.25 inch (57.5 mm)

CPI 14.9 12.5 8.3 14.9 12.5 8.3 14.9 12.5 8.3

Number of columns

APPENDIX

Dot space

(H × V mm)

Column spacing (mm)

Character size

(mm)

Total no. of dots 200 198 132 200 198 132 140 138 90

Print area (mm) 67.7 67.0 66.8 67.7 67.0 66.8 47.3 46.6 45.4

Left/Right margins

40 33 22 40 33 22 28 23 15

0.340 0.340 0.510 0.340 0.340 0.510 0.340 0.340 0.510

ЧЧЧЧЧЧЧЧЧ

0.353 0.353 0.353 0.353 0.353 0.353 0.353 0.353 0.353

1.70 2.04 3.06 1.70 2.04 3.06 1.70 2.04 3.06

1.32 1.66 2.34 1.32 1.66 2.34 1.32 1.66 2.34

ЧЧЧЧЧЧЧЧЧ

2.42 2.42 2.42 2.42 2.42 2.42 2.42 2.42 2.42

7.4/7.4 7.4/8.1 7.4/8.3 4.2/4.2 4.2/4.8 4.2/5.0 5.1/5.1 5.1/5.8 5.1/7.0

– 56 –

Page 59

Print speed: Approx. 5.53 lines per sec.

Line spacing: 1/6-inch (initial setting), 1/8-inch, 1/12-inch,

n/72-inch, n/144-inch

Paper feed method: Friction feed

Paper feed speed: Approx. 3 inches/sec.

Paper specifications

Paper type: Ordinary bond and carbonless copy paper

Paper width: 82.5 ±0.5 mm (3.25 inches)

76 ±0.5 mm (3.0 inches)

57.2 ±0.5 mm (2.25 inches)

Roll diameter: 85 mm (3.35 inches) max.

Thickness (single) 0.07 mm to 0.10 mm

(copies) Original + 1 copy (Max. 0.14 mm)

Original + 2 copies (Max. 0.2 mm)

However, paper that can be cut with the auto

cutter is one sheet of 0.06 – 0.085 mm

thickness.

Internal diameter of roll: 12 ±1 mm

Note: The paper must not be glued to the core.

Ink ribbon specifications

Ribbon type: Cartridge cassette

Color: Standard purple or optional black

Ribbon material: Nylon (#40 denier)

Ribbon life: Purple (standard) 6,000,000 characters

Black (option) 1,600,000 characters

Interface:

Serial interface: RS-232C serial interface (standard)

20 mA current loop (option)

RS-422A (option)

Parallel interface: Centronics compatible

Data buffer: Selectable between 1 K and 256 bytes

Peripheral unit drive circuit: 2 circuits (24 V, max. 1 A with a 1 circuit

compulsion switch)

Power Supply: AC120 V ±10 % 60 Hz (for US)

AC230 V –10 % ~ 240 V + 6 % 50/60 Hz

(for EU)

AC220 V ±10 % 50/60 Hz (for Hong Kong,

Korea)

APPENDIX

– 57 –

Page 60

AC power cable: Approx. 155 cm long

Power consumption: Max. 70 W Avg. 30 W (During continuous

printing of ASCII characters)

Ambient temperature/humidity

Operating temperature: 0°C to +50°C

Operating humidity: 10 % to 90 % RH (without condensation)

Storage temperature: –20°C to +70°C

Storage humidity: 5 % to 95 % RH (at 40°C) without condensa-

tion.

Mechanism reliability: 5,000,000 lines MCBF (except head life and

auto cutter)

Print head life: One hundred million characters

Auto-cutter reliability: 600,000 cut (MCBF) (SP347)

APPENDIX

Overall dimensions (mm) (SP317)

169 W × 330 D × 170 H (m)

Approx. 4.3 kg

– 58 –

Page 61

Overall dimensions (mm) (SP347)

169 W × 330 D × 176 H (mm)

Approx 4.6 kg

APPENDIX

– 59 –

Page 62

MEMO

P 1996.01

P 1996.03

Page 63

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

70-D Ethel Road West, Piscataway, NJ 08854 U.S.A

Tel: (908) 572-9512, Telefax: (908) 572-5095,

Telex: 299766 STAR UR

STAR MICRONICS DEUTSCHLAND GMBH

Westerbachstraße 59, D-60489 Frankfurt/Main 90, Germany

Tel: 0697-89990, Telefax: 0697-81006, Telex: 417 5825 STAR D

HEAD OFFICE

STAR MICRONICS CO., LTD.

20-10 Nakayoshida, Shizuoka, 422 Japan

Tel: (054) 263-1115, Telefax: (054) 263-8714

STAR MICRONICS U.K. LTD.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks, HP13 7DL, UK

Tel: 01494-471111, Telefax: 0494-473333

Printed in Japan, 80870006

Loading...

Loading...