Page 1

ROS

Operator Manual

Page 2

2 ROS - Operator Manual 170719

We have checked that the contents of this document correspond to the model described. There

may be discrepancies nevertheless, and no guarantee can be given that they are completely

identical. The information contained in this document is reviewed regularly and any necessary

changes will be included in the next edition. We welcome suggestions for improvement.

Specifications and document subject to change without prior notice.

Information supplied in this manual is copyright. No part of this work may be reproduced or

copied in any form or by any means, electronic or mechanical without the express permission of

the author / publisher.

Service 0800 782 754

Parts 09 829 0930

Manufactured in New Zealand by Washtech Ltd.

414 Rosebank Road, Avondale, Auckland 1026.

PO BOX 90548, Auckland

CONTENTS

Safety Instructions.......................................................................................................................................................3

Installation Checklist.................................................................................................................................................. 4

Installation Diagram.................................................................................................................................................... 4

Installation Instructions............................................................................................................................................. 5

Polish Free Chemical................................................................................................................................................... 6

Polish Free Calibration.................................................................................................................................................7

RO Operation................................................................................................................................................................. 8

Optimizing Polish Free Results................................................................................................................................ 8

Maintenance.................................................................................................................................................................. 9

RO Layout Diagram.....................................................................................................................................................10

RO Schematic................................................................................................................................................................11

WARNING

Before installation and commissioning, you must read the safety instructions and warnings

carefully and all the warning labels attached to the equipment.

IMPORTANT

Polish free results are achieved through a combination of the equipment, chemicals and

processes. Failure to implement all the recommended steps might lead to inferior results.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual will invalidate

the product warranty and relieves the manufacturer of any responsibility

IMPORTANT

The alteration of machine operation, design or the replacement of parts not approved by

the manufacturer may void warranties and approvals.

IMPORTANT

This machine is intended for commercial use only.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

!

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

Page 3

3 ROS - Operator Manual 170719

Safety Instructions

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

!

WARNING

Equipment contains dangerous voltages and can be hazardous if installed or operated

incorrectly. Non-compliance with warnings or failure to follow the instructions

contained in this manual can result in loss of life, severe personal injury or serious

damage to property.

Installation

• Use qualified, skilled personnel

• Follow installation instructions

• Connect to correct voltage and supply current

• Provide fully accessible electrical Isolation Switch & water supply valves

Training and Supervision

• Read and understand the Operating instructions and train all staff

• This appliance must not be operated by children or infirm persons

• Machine panels must only be removed by suitably qualified and trained personnel

– internal hazards include live electrics and very hot surfaces

• This appliance is not intended for use as a stepladder

Cartridge Replacement

• Turn off power and unplug machine from mains before replacing water filtration

cartridge

Chemicals

• Commercial dishwashing detergents are hazardous – handle with care

• Read and follow the safety information found on the labels of detergent

containers and Material Safety Data Sheets

• Use protective eye-wear and clothing if decanting containers

Cleaning

• Do not hose down the machine or splash water over the exterior

Improper Use

• This unit is only intended to supply treated water to a commercial glasswashing

machine and should not be used for any other purpose

Water Leaks

• If the unit develops a leak disconnect the power by pulling the plug out of the wall

socket, then turn off the water supply and contact your service agent

Service/repair

• Under no circumstances the user should attempt to carry out repairs

• All service/repair work must be carried out by qualified personnel only

Power Cord Replacement

• If the supply cord is damaged, it must be replaced by the manufacturer or its

service agent or a similar qualified person in order to avoid a hazard

Page 4

4 ROS - Operator Manual 170719

Unpack

• Unpack the machine, check for damage and complete delivery.

Positioning

• Place machine on sound waterproof self draining floor, fit feet and adjust feet to level

Water

• Flush supply lines before connection

• Connect hose supplied to adjacent accessible isolator valve - 20 mm 3/4 female

• Flow rate required - 1 litres per minute

• Pressure required - 200-350 kPa - fit limiter above this pressure

• Back Flow - Combination Dual Check Valve and Pressure Limiting Valve

Power

• 0.3A 240V 50Hz via switched outlet adjacent to the unit, which is supplied with cord set

including 10A plug.

Waste

• Connect drain pump hose supplied to upstand or sink waste connection

Troubleshooting Installation

• If machine doesn’t fill after switching on power, check & ensure that hot water supply tap is

open, water supply pressure is not below specification

Installation Checklist

WARNING

Installer must be suitably qualified and ensure compliance with all codes and standards

including AS/NZS3500.1.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

!

A Cold (only) connection Quick fit connect

water pressure 350Kpa

flow 20L/min

B Waste connection Quick fit connect

C Electrical Single phase 240V 50HZ 0.3amp

10amp plugset supplied

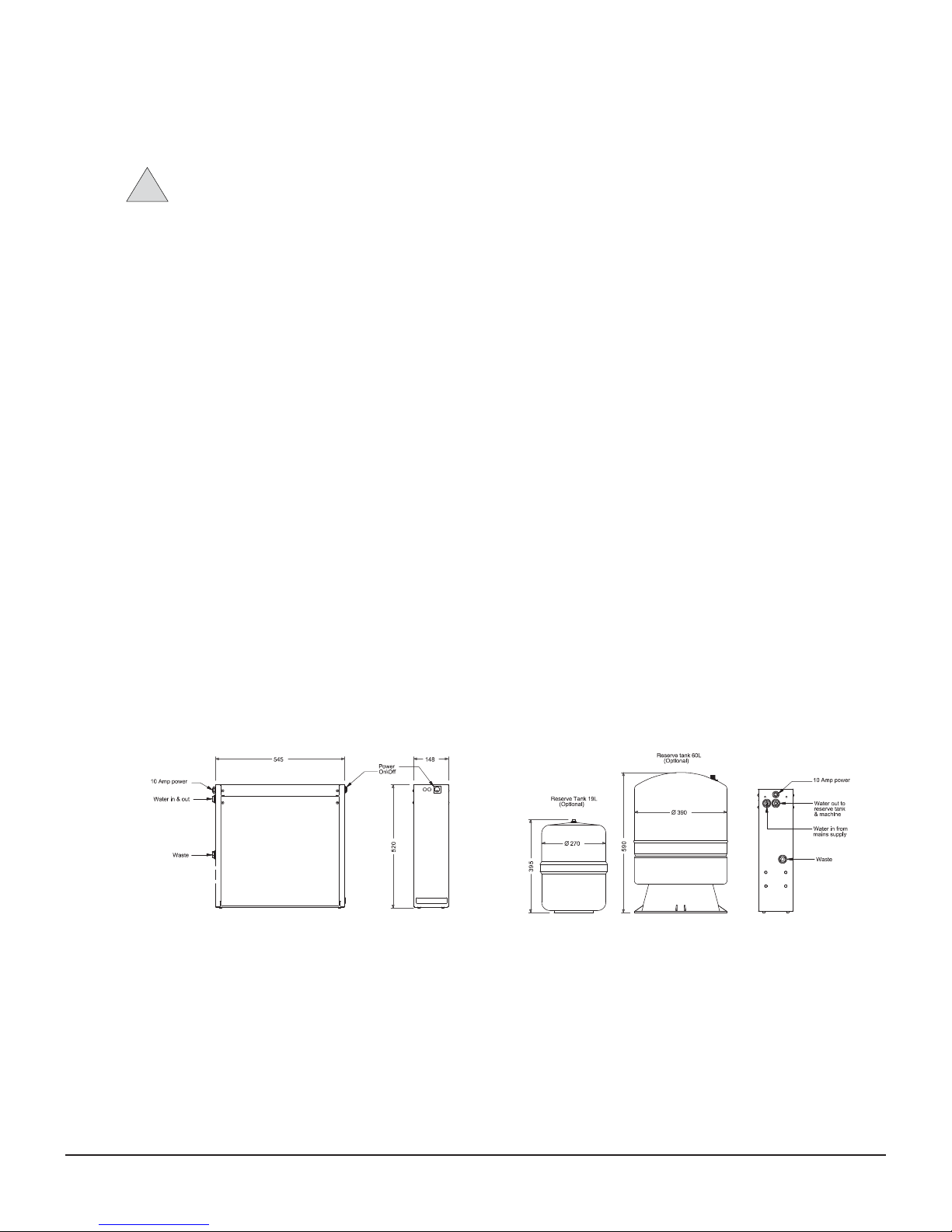

Installation Diagram

RO INST 12-014-17 3 B

Page 5

5 ROS - Operator Manual 170719

Fit the tubes supplied, to the solenoid valve of the glasswasher, an isolating valve on the

water main and an appropriate drain point.

Remove the shipping tubes from the tube fittings at the rear of the filtration unit.

Cut the tubes supplied to length and insert them into their labelled points at the rear of

the unit, and open the isolating valve.

Installation Instructions

IMPORTANT

The hoses supplied with this unit must be used for the purposes indicated on the label.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

THE HOSES SUPPLIED WITH THIS UNIT MUST BE USED FOR THE

PURPOSES INDICATED ON THE LABELS.

Fit the tubes supplied to the solenoid valve of the glasswasher, an isolating valve on the

water main and an appropriate drain point.

Remove the shipping tubes from the tube fittings at the rear of the filtration unit.

Cut the tubes supplied to length and insert them into their labelled points at the rear of

the unit, and open the isolating valve.

See below for a guide to fitting and removing tubes.

Plug the power lead for the unit into a power point and switch on.

The pump in the unit will now run to build up pressure in the storage tank. By placing a

hand on the unit vibrations will be detected indicating the operation of the pump.

When the pressure builds up to 350Kpa the pump will cut out and the unit is now ready

for the

dishwasher to be switched on and filled.

The pump in the unit will now cycle on and off to keep up the pressure in the storage

tank.

The high pressure switch controls the pump so that the pressure in the tank can not

exceed 350Kpa.

The low pressure switch will cut the pump off in the event of loss of water at the inlet to

the unit..

Cut the tube

square and remove burrs and

sharp edges

Push the tube into the

fitting to the tube stop

Pull on the tube to

check that is secured.

To disconnect, push the

collet square against the

fitting. With the collet

held in this position the

tube can be removed.

MACHINE

RO Operation

To operate an ROS unit

• Plug the power lead for the unit into a power point and switch on the machine.

• The POWER light will glow red. The pump in the unit will now run to build up pressure in

the storage tank. By placing a hand on the unit vibrations will be detected indicating the

operation of the pump.

• When the pressure builds up to 350Kpa the pump will cut out and the unit is now ready

for the dishwasher to be switched on and filled.

• The OPERATION light will glow green. The pump in the unit will now cycle on and off to

keep up the pressure in the storage tank.

• The high pressure switch controls the pump so that the pressure in the tank can not

exceed 350Kpa.

• The low pressure switch will cut the pump off in the event of loss of water at the inlet

to the unit..

NOTE: The Operating light will not turn on if:

• The water supply to the ROS unit has been turned off

• If there is any obstruction to the water supply to the ROS unit

• The external tank is full

POWER

POWER

OPERATION

Page 6

6 ROS - Operator Manual 170719

Polish Free Chemicals

WARNING

If you use different chemicals, you will have to carefully recalibrate the chemical

injection levels to compensate for the different formulations and concentrations.

Without recalibration polish free results will be negatively impacted.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

NOTE

Polish free results are dependant on using the right concentrations of the right

chemicals. An RO system is inclusive of your glasswasher, RO unit, chemicals,

operating procedures and drying area. If one of these components is altered without

recalibration of the system, inferior polish free results can be expected.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

Starline has worked with Kemsol to develop the following chemicals to be used with a Starline

Glasswasher and Starline Reverse Osmosis system.

Ultimate

Automatic liquid detergent for commercial dish

and glasswash machines, designed for reverse

osmosis automatic glass and ware machine

units. Safe when used as directed on all

commercially automatically washed items.

Not recommended for aluminum or sensitive

metal-constructed kitchen items.

Features & Benefits

• Delivers exceptional results

• Ideal for use with any machine type

• Fitted with the Kemlock closed loop system

• Septic tank safe, when used as directed

Optimum

A drying aid concentrate specifically designed

for reverse osmosis automatic glass and ware

machine units. Significantly reduces or eliminates the requirement for post-clean

drying and polishing of glass and dishware,

leaving rinsed surfaces dry and spotlessly

streak-free.

Features & Benefits

• Leaves surfaces dry and spotlessly

streak-free

• Ideal for use with any machine type

• Fitted with the Kemlock closed loop system

• Septic tank safe, when used as directed

Automatic liquid detergent for commercial dish and

glasswash machines, designed for reverse osmosis

automatic glass and ware machine units. May also be

used with other machine types where operators

demand high performance detergent delivering

exceptional results. Safe when used as directed on all

commercially automatically washed items.

Not recommended for aluminium or sensitive

metal-constructed kitchen items. Septic tank safe,

when used as directed.

MPI APPROVED C31 (All Animal Product Except Dairy)

Engineered for Reverse Osmosis Systems

Features & Benefits

• Delivers exceptional results

• Ideal for use with any machine type

• Fitted with the Kemlock closed loop system

• Septic tank safe, when used as directed

AUTO DISHWASH DETERGENT

ultimate

®

A drying aid concentrate specifically designed for

reverse osmosis automatic glass and ware machine

units. May also be used with other machine types where

operators demand high-performance rinse aid delivering

exceptional results. Significantly reduces or eliminates

the requirement for post-clean drying and polishing of

glass and dishware, leaving rinsed surfaces dry and

spotlessly streak-free.

Septic tank safe, when used as directed.

®

Features & Benefits

• Leaves surfaces dry and spotlessly streak-free

• Ideal for use with any machine type

• Fitted with the Kemlock closed loop system

• Septic tank safe, when used as directed

SPOT-FREE RINSE ADDITIVE

optimum

MPI APPROVED C31 (All Animal Product Except Dairy)

Engineered for Reverse Osmosis Systems

CHEMICAL

Page 7

7 ROS - Operator Manual 170719

NOTE

To ensure best product performance it is strongly recommended that you use a

professional machine servicing agent, to set chemical dosage rates. Settings will

depend on machine type and operation. Product should be dosed specific to machine

manufacturer or distributor recommendations.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

Polish Free Calibration

NOTE

To achieve optimal polish free results, Washtech have designed Starline glasswashers

to be run on Kemsol Ultimate and Optimum detergent and rinse fluid.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

START

UP

POWER

DOWN

User Settings on your Starline Glasswasher

• Press the UP and DOWN key simultaneously for a few seconds

• Navigate through settings by pressing the POWER key

• Parameter values can be changed using the UP or DOWN keys

• Press START key to save changes and exit menu.

Choose your machine from the list below & adjust the following settings accordingly:

Machine Model F-Detergent Time W-Detergent Time Rinse Aid

GM 23 6 30

GL 10 14 30

UD 15 10 30

UL 13 10 30

Technical Settings on your Starline Glasswasher

• Press the UP, DOWN and START key simultaneously for a few seconds

• Navigate through settings by pressing the POWER key

• Parameter values can be changed using the UP or DOWN keys

• Press START key to save changes and exit menu.

For all machines adjust: FILL TIMEOUT to 20 minutes.

CALIBRATION

NOTE

If you are washing plates and cutlery in the same machine speak to Washtech as the

settings may need to be increased to accommodate the extra soiling.

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

To calibrate your Starline Glasswasher for polish free washing with Kemsol Ultimate and

Optimum, the following steps are to be followed.

Page 8

8 ROS - Operator Manual 170719

Optimizing Polish Free Results

APPROPRIATE RACKS

ADEQUATE DRYING TIME

Owner’s Manual

Glasses must be given the appropriate space

and time to dry. If space and time is an issue we

recommend using a drying table.

Drying tables facilitate fast drying and cooling of

glasses following the washing process.

Features & Benefits

• Drying tables reduce the drying time

• Drying tables speed up the turnaround time

of glasses whilst delivering them in perfect

condition for dispense

• The use of wet, warm glasses will impair the

presentation of the glass.

ATE LI ER R AOS

The rack design ensures water circulates efficiently over and

around the items in the rack, significantly improving washing

results. The sides are high enough to keep all items safely inside

the rack during the wash cycle.

External dimensions: 500 x 500 x 174 mm

Internal dimensions: 460 x 460 x 150 mm

Stacked height of 2 R500s: 305 mm

3

1

2

Base rack R500

1

3

2

4

5

Thanks to a range of optional and movable inserts, you can

rearrange the internal configuration of the rack as often as you

wish to meet your various warewashing needs, making this the

ideal unit for pubs, bars, cafes and restaurants.

Glasrelax GR500

The Glasrelax insert is designed to safely hold glasses in an inclined

position. This helps to reduce breakages, and also improves water

flow. Up to 5 Glasr

elax inserts can be placed in the rack.

Cutlery holder CBS

With pyramid-shaped base to improve water flow.

External dimensions: 105 x 105 x 140 mm

Plate insert PI 400

This insert for washing plates can hold 9 plates, each measuring up

to 240 mm.

Plate rack P 18 – 12

The plate rack P 18 – 12, external dimensions 500 x 500 x 100 mm

is the ideal addition if plates are to be washed. It holds 18 flat or

12 deep

plates.

Drip tray AWAT 500

The perfect drip tray for use on the counter.

2

3

4

5

Accessory

You can use up to 4 Glasrelax inserts for larger glasses

and up to 5 Glasrelax inserts for smaller glasses.

With four inserts (advised for larger glasses):

Row 1 can be used to hold tulip-shaped glasses up to 111 mm diameter.

Rows 2 – 4 can be positioned to allow for glasses measuring up

to 95 mm diameter.

With five inserts:

Row 1 can be used to hold tulip-shaped glasses up to 97 mm

diameter.

Rows 2 – 5 can

be positioned to allow for glasses measuring up

to 75 mm diameter.

6

7

Glasrelax GR500 suggestions for positioning the inserts

1

4 x GR500

6

5 x GR500

7

for 9 glasses

compartment

size

150 x 150 mm

for 16 glasses

compartment

size

113 x 113 mm

for 20 glasses

compartment

size

99 x 99 mm

20

for 25 glasses

compartment

size

90 x 90 mm

for 36 glasses

compartment

size

74 x 74 mm

for 44 glasses

compartment

size

67 x 67 mm

44

for 49 glasses

compartment

size

63 x 63 mm

for 20 glasses

compartment

size

113 x 90 mm

for 35 glasses

compartment

size

90 x 63 mm

5 x 7

Rack System 500

NEW

NEW

Concaved bases of glassware allow chemical saturated water to pool and not drain off of the

glasses while in the machine. Once removed from the machine, if the water is allowed to run

down the side of the glassware and dry, this can stain the glasses.

We recommend using Tilt racks with our RO systems. Tilt racks enhance the cleaning result by

allowing all water to drain off the glassware.

CLEAN MACHINE

Carry out proper shut down and cleaning procedures

every night to ensure optimum performance of your

Starline glasswasher.

If arm (6) jets and filters (1, 2 & 3) are not adequately

cleaned blockages can form, impeding water flow. This

will result in a reduction in spray area, which will effect the

amount of water and chemical dispersed over each glass.

Cleaning instructions are provided with each Starline

glasswasher. If you however require copies of these

instructions please contact your local Starline dealer.

Talk to a Starline dealer about tilt rack and drying tables.

2

1

3

4

6

6

5

Page 9

9 ROS - Operator Manual 170719

This filtration unit uses one sediment filter cartridge, one carbon filter cartridge, and two

reverse osmosis membrane cartridges.

It is recommended that the sediment cartridge be checked every 3 months and that spare

cartridges are kept available for prompt replacement when showing signs of wear. The lifetime

of the cartridge will vary according to the quality of the water source and the number of cycles

performed per day. Replacing the cheaper sediment and carbon filters more frequently will

help protect and extend the life of the more expensive RO membranes.

If the cartridges are not regularly replaced they will become blocked and the water flow will

diminish to the extant that it will effect the efficient operation of the glasswasher.

If the cartridges become blocked up and there are no spare cartridges available, the bypass

valves on the unit may be operated and the glasswasher will run on untreated water until new

cartridges are fitted.

Maintenance

WARNING

Turn off power and unplug machine from mains power supply before replacing water

filtration carridges

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

!

WARNING

To prevent flooding turn the valve of the storage tank off before removing/replacing

the cartridges

WARNING

Before installation and commissioning, you must read the safety instructions

and warnings carefully and all the warning labels attached to the equipment.

IMPORTANT

Failure to comply (even partially) with the instructions given in this manual

will invalidate the product warranty and relieves the manufacturer of any

responsibility.

IMPORTANT

The alteration of machine operation, design or the replacement of parts not

!

!

!

CARTRIDGE REPLACEMENT

Page 10

10 ROS - Operator Manual 170719

RO Layout Diagram

RO 0002 12/01/16 3 D

Page 11

11 ROS - Operator Manual 170719

RO Schematic

180100 07/02/13 1 A

Page 12

Information supplied in this manual is copyright.

No part of this work may be reproduced or copied

in any form or by any means, electronic or

mechanical without the express permission of the

author/publisher

Manufactured in New Zealand by Washtech Ltd.

414 Rosebank Road

Avondale

Auckland 1026

New Zealand

PO Box 90548, Auckland

24HR Service 0800 Starline

Tel 09 829 0930

Fax 09 829 0935

E-mail info@washtech.co.nz

web www.starline.co.nz

ISO9001

All Washtech products are designed and

manufactured by Washtech using the

internationally recognised ISO9001 quality

management system, covering design,

manufacture and final inspection, ensuring

consistent high quality at all times.

In line with policy to continually develop and

improve its products, Washtech Ltd reserves the

right to change specifications and design without

prior notice.

The Spirit of Excellence

an Ali Group Company

Loading...

Loading...