Sta-Rite LDF 400 Installation Manual

Flowmeter Installation Instructions

(for LDF 400 Series)

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use

of

this product. This information should be given to the owner/operator of this equipment.

Call

(800) 831-7133 for additional free copies of this manual.

General

1. Pentair Flow meters should not be exposed to more than 240° F. and 150 PSI.

2. Only hand tightening is required on threaded nuts. No pliers or other tools should be used for any reason.

3. To obtain best possible reading, Flowmeter should be installed in an exact vertical plane with a

minimum

4. Proper pipe alignment is essential. Misalignment will put excessive stress on the Flowmeter.

of one foot of straight uninterrupted pipe on the upstream and downstream ends.

WARNING! Improper installation of the Flowmeter can result in

damage to the Flowmeter and/or property damage

5. Flowmeter models with threaded brass ends should not be connected to fittings with plastic female

threads as overtightening may crack the plastic fitting.

6. For solar applications, install Flowmeter on cool side of line.

CAUTION

The Polysulfone Flowmeter body is adversely affected by ultraviolet light. Therefore, complete care should be

taken

to protect it from direct sunlight situations. Failure to follow these instructions can result in damage

to the Flowmeter and/or property damage.

Installation

1. Remove brass or plastic Flowmeter ends and solder or thread them to pipe. Assemble body to ends

making sure both o-ring seals are in place and free of debris.

2. If installation is being made in an existing system, models with threaded ends should be engaged in

mating system fittings at both ends to determine length of pipe to be removed. Flowmeters with

solder connection ends will require removal of system tubing for a length equal to the total length of

the Flowmeter assembly MINUS 2 in. This will allow 1 in. at each end for insertion of the copper

into the Flowmeter ends.

tubing

CAUTION

If installation requires cemented plastic slip connectors on one side of the coupling, be sure to allow enough

time for the cement (or solvent) to dry and for the fumes to dissipate before the meter is installed. Crazing or

cracking

may occur in the Flowmeter assembly if it comes in contact with incompatible materials or fumes.

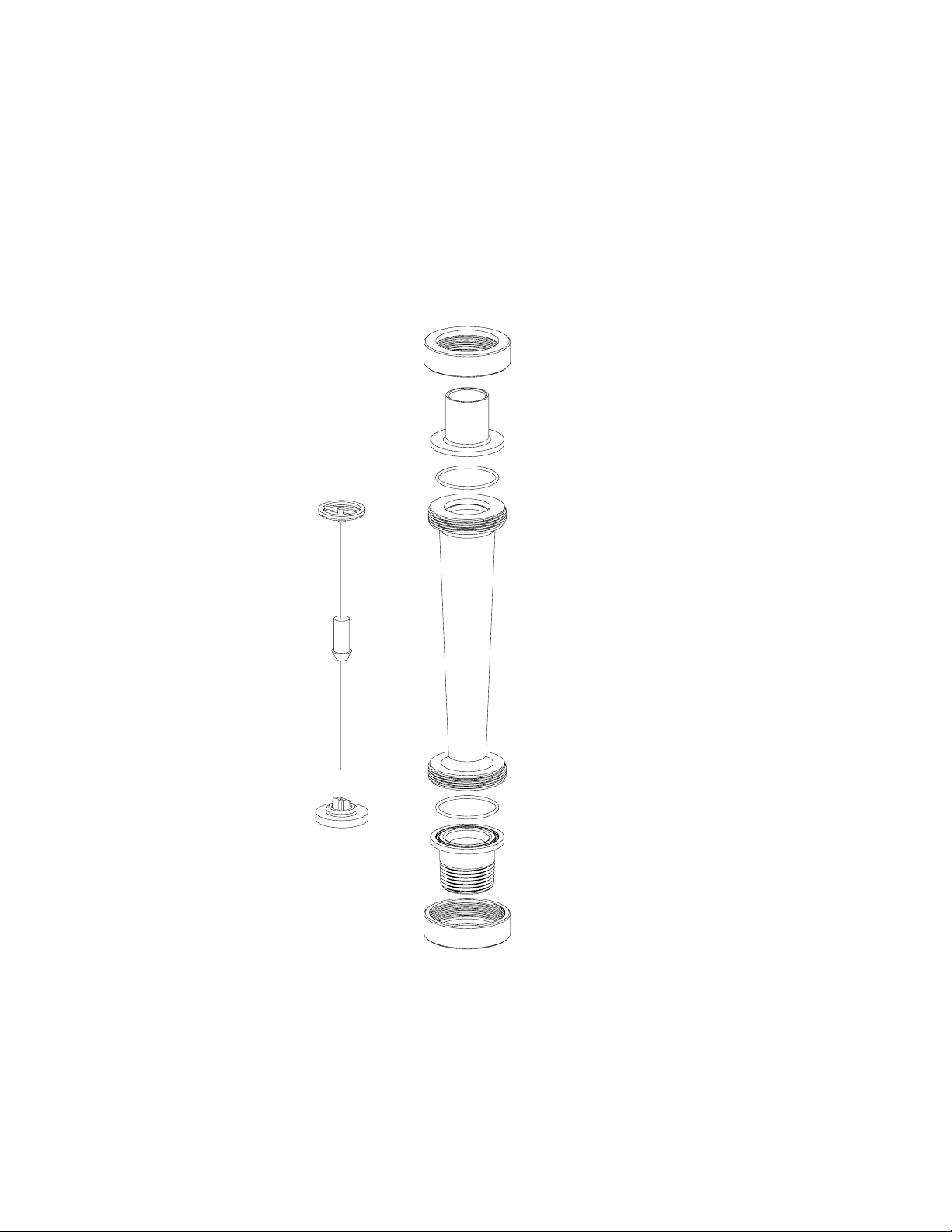

See Flowmeter assembly illustration on page 2.

www.pentairpool.com or www.staritepool.com

Rev. B 7-30-10 1 P/N 370019

Maintenance

*370019*

1. Pentair Flowmeters are designed for easy cleaning and maintenance.

2. Unscrew knurled nuts on top and bottom of Flowmeter and slide body away from plumbing. Invert

and shake the Flowmeter so the float gently taps the top guide support out of its seat. The top guide

support, float and guide wire can then be removed to clean body with a mild soap solution.

3. To reassemble, make certain the float is replaced with the pointed end facing down. Insert guide wire

through the float and into the center hole in the bottom guide support. Then push in top guide support

onto the guide wire and into the recess in the top of the body until flush with the body end. Make

sure both o-ring seals are installed and free of debris prior to reconnecting the body to the ends.

4. Hand tighten the nuts on both ends.

NUT

END

(SOLDER TYPE)

O-RING

TOP GUIDE

SUPPORT

GUIDE

BOTTOM GUIDE

SUPPO

RT

WIRE

FLOAT

BODY

O-RING

END

(THREADED TYPE)

NUT

SAVE THESE INSTRUCTIONS.

© 2010 Pentair Water Pool and Spa, Inc. All rights reserved

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000 - 10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Pentair Water Pool and Spa® is a trademark and/or a registered trademark of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the

United States and/or other countries. Unless noted, names and brands of others that may be used in this document are not used to indicate an

affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may

be the trademarks or registered trademarks of those parties or others.

P/N 370019 Rev B 7-30-10

2

Technical Support: (800) 831-7133

Loading...

Loading...