Page 1

Star Phantom

Star Phantom

®

Rear Window Undercover Interior

LED Traffic Director

Models

ULB42-TD ULB44-TD

(Discrete LEDs) (Gen 4 Starburst LEDs)

The manufacturer warrants this LED light against factory defects in mater ial and workmanship for five years

after the date of purchase. The owner will be responsible for returning to the Service Center any defective

item(s) with the transportation costs prepaid. The manufacturer will, without charge, repair or replace at its

option, products, or part(s), which its inspection determines to be defective. Repaired or replacement

item(s) will be returned to the purchaser with transportation costs prepaid from the service point. A copy of

the purchaser's receipt must be returned with the defective item(s) in order to qualify for the warranty

coverage. Exclusions from this warranty include, but are not limited to, domes, and/or the finish. This

warranty shall not apply to any light, which has been altered, such that in the manufacturer's judgment, the

performance or reliability has been affected, or if any damage has resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of merchantability or fitness), which

extend this warranty period. The loss of use of the product, loss of time, inconvenience, commercial loss or

consequential damages, including costs of any labor, are not covered . The manufacturer reserves the right

to change the design of the product without assuming any obligation to modify any product previously

manufactured.

This warranty gives you specific l egal rights. You might also have additional rights that may vary from state to

state. Some states do not allow limitations on how long an implied warranty lasts. Some states do not allow

the exclusion or l imitation of incidental or consequential damages. Therefore, the above limitation(s) or

exclusion(s) may not apply to you.

If you have any questions concerning this or any other product, please contact our

If a product must be returned for any reason, please contact our

Customer Service Department to obtain a Returned Materials Authorization

Please write the RMA # clearly on the package near the mailing label.

LED FIVE YEAR LIMITED WARRANTY

Customer Service Department at (585) 226-9787.

number (RMA #) before you ship the product back.

PLITSTR344 REV. E 5/20/14

Page 2

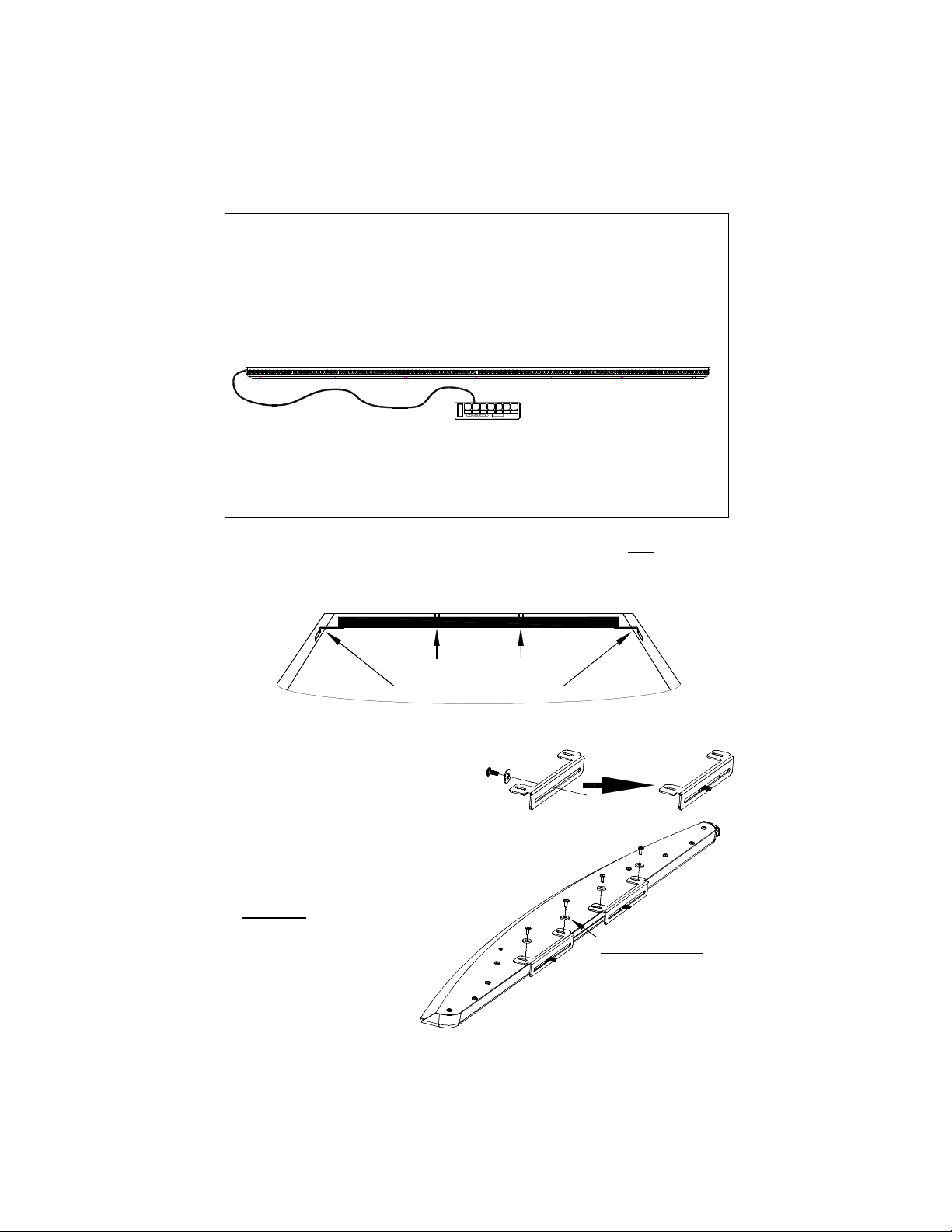

Mounting

IMPORTANT: Please read all of the following instructions before installing your new warning light.

The

Star Phantom

®

line of lights is designed to be

mounted on the inside of your vehicle. They are not intended for

exterior applications and are not warranted against water damage.

It is the sole responsibility of the owner to ensure the warning light is

secure. Check your light every time you enter the vehicle to ensure that

it is mounted securely. The manufacturer assumes no responsibility for

the secure mounting of this light.

The following mounting instructions describe the standard, most common way to

mount this light. This method may or may not apply to your vehicle. Because

vehicles can vary widely in their design, it may be necessary to configure the brackets

differently than described. Some applications may require you to design your own

custom brackets. The installer assumes all responsibility for the integrity of the

installation. It is the sole responsibility of the owner to ensure the light is secure.

P30073-4

(QTY=12)

#8 FLAT WASHERS

P30150-220P

P30054-27

(QTY=2)

#10-32 x 1/2" CARRI AGE BOLT

P30076-8

(QTY=2)

1/4" FLAT WASHER

(USE AS SPACER)

(QTY=2)

ATTACHING BRACKET

P30150-97P

(QTY=2)

DOUBLE SLOTTED "L" BRACKET

P30073-3

(QTY=2)

#8 TOOTH WASHER

P30093-5

(QTY=2)

#8 NUT

P30150-79P

FORKED "L" BRACKE T (Style 1)

P30150-189P

FORKED "L" BRACKE T (Style 2)

P30073-4

#8 FLAT WASHER

P30053-24

3

#8 x

" SELF-TAPPING P HILIPS HEAD SCREW

8

(QTY=2)

P30053-29

3

#8-32 x

" PHILIPS HEAD SCR EW

8

(QTY=6)

P30053-24

3

#8 x

" SELF-TAPPING PHILIPS HEAD SCREWS

8

P30073-4

#8 FLAT WASHERS

P30150-97-2P

SLOTTED STRIAGH T BRACKET

(QTY=2)

-1-

(QTY=2)

(QTY=2)

P30094-10

(QTY=2)

#10-32 SERRATED FLANGE NUT

Page 3

Mounting (CONT'D)

Before beginning the installation:

• Determine where the Traffic Director is to be mounted.

• Ensure there are no obstructions hindering the visibility of your traffic director.

• Select a location to mount your controller that is dry, out of direct sunlight, and free of

dirt and dust. Under the vehicle's instrument panel is usually the best choice.

• Determine the path your cable, which connects the controller to the Traffic Director,

will take. The cable should exit the left side of the Traffic Director when you are

facing both the lightbar and the controller.

Be sure the cable attached to your Traffic Director is long enough for proper installation.

If it is too short, you will need to order a Traffic Director with the correct length cable pre-

installed. The standard length for the cables is 15'. Star does not recommend

“splicing in” additional cable when the supplied cable is too short. Traffic Directors

with 30', 45' and 60' cables are available upon request.

This light is designed to be mounted in the rear window of a vehicle using both the forked

brackets and the corner post brackets. Failure to use both brackets could result in a

faulty mount and will void the warranty. If your vehicle is not compatible with these

brackets you must custom design mounting brackets

.

Forked Brackets

Corner Post Brackets

FORKED BRACKET INSTALLATION

1. Insert a carriage bolt through one of the

1/4” washers and slide it through the back

of each of the long L-brackets. Please

note that washer is used as a spacer on

the square neck of the carriage bolt.

2. Remove the four of the #8 Phillips head screws shown to the

right from the light and add the # 8 washers. Use them to

install the long L-brackets.

CAUTION: Take extreme caution not to over

tighten the screws!!!

-2-

P30073-4 (QTY=4)

#8 FLAT WASHERS

Page 4

Forked Bracket Installation (CONT'D)

3. Attach a forked bracket to each L-bracket

using one of the nuts.

Note: There are two different style forked

brackets included. Use the one that suits

your application best.

Leave the nut slightly loose to

allow for minor adjustments during

the remainder of the installation.

4. Determine an appropriate user-supplied screw to penetrate the

headliner and securely mount the bracket to the roof brace (or other

mounting location) through the mounting hole in each forked bracket.

CAUTION: Take care to ensure when selecting a screw and drilling the hole that it

Mounting

Hole

is capable of supporting the weight of the light and that it does not penetrate the

roof of the vehicle.

Press light tightly

against window

5. Using the slots in the brackets, adjust the

light so that it fits tightly against the window,

carefully bending the forked brackets, if

necessary, and tighten the screws.

Tighten the nuts securing

the mounting brackets

CAUTION: Take extreme caution not to over tighten the screws!!! Over tightening

of the screws can strip the holes.

CORNER POST BRACKET INSTALLATION

1. Connect one of the double-slotted "L" brackets to each of the

slotted straight brackets using one of the screws, a flat washer,

a tooth washer, and a nut.

2.

Connect one bracket to each end of your

Star Phantom

®

using the

screws provided. Loosen both screws slightly to allow for adjustability

when installing the lightbar.

-3-

Page 5

Corner Post Bracket Installation (CONT'D)

3. Adjust the mounting brackets so that they rest flat against the corner post on each side

of the vehicle., then tighten all the screws.

4. Mark the two spots where you will be attaching your screws to the corner post and drill a

1/8" hole in each of the marked locations.

Caution: Be sure to check that there are no airbags, wires, or anything else behind the

molding that may be damaged by the screw holes.

5. Use two of the self-tapping screws in each side to secure each bracket to the corner

posts.

6. Once the brackets are securely tightened, check your mount to ensure the desired angle

is achieved. Stand behind the vehicle and inspect the light through the rear window.

Make any final adjustments necessary.

CAUTION: Take extreme caution not to over tighten the screws!!! Over tightening of

the screws can strip the holes and result in a faulty mount.

Because of the wide variety of mounting applications, Star Headlight

& Lantern Co., Inc. assumes no responsibility for the secure mounting

of this light. It is the responsibility of the installer and/or owner to

ensure the lightbar is mounted securely. Check your light every time

you enter the vehicle to ensure that it is mounted securely.

-4-

Page 6

Electrical Connections

1. The cable attached to your Traffic Director should have a green connector (part #CPSS-

153) attached to it. Eight colored 18 AWG wires, one bare drain wire, and a large red

12AWG wire should already be connected from the cable to the connector.

2. Connect a ground wire to the interior empty terminal on the green connector. (See

diagram above) The corresponding terminal plugs into the outlet on the back of the

controller and is marked BAT-.

3. Supply power for the unit from a fused, +12 VDC source capable of delivering at least 15

amps of current (use a 20 amp fuse). Star recommends the use of an ignition switched

supply to avoid the possibility of draining the vehicle's battery should the unit be

accidentally left on.

4. Connect your power supply to the terminal on the green connector that corresponds to

the outlet on the back of the controller marked BAT+.

5. The lamp brightness will be somewhat diminished if a large voltage drop exists between

the vehicle's battery and the controller. If voltage drop is a problem, use a relay to

control a direct battery feed. A generic relay designed for automotive lamp service

should be available from most automotive stores for this purpose. If using a relay, don't

forget to fuse the feed and signal wires at their source, with appropriate values.

6. Your Traffic Director should now be ready to operate.

It is imperative that you supply a ground wire to the terminal marked

"BAT -" on the controller. You must not let the controller's case

supply ground. Use 12 AWG wire for all power and ground

connections

-5-

Page 7

(Wiring CONT’D)

Wiring for Optional Automatic Activation

1. The Traffic Director may also be wired to automatically bypass the ULB42-TD--2 controller On/

Off switch and turn on through the use of an alternate power source (i.e. lightbar switch, siren

switch, reverse switch, etc.).

2. When you apply +12VDC

to the 12AWG wire

supplying the stick with

power, you will bypass the

On/Off switch and activate

the Traffic Director. When

activated, the Traffic

Director will automatically

enter the "Warn" pattern.

Operation

Important: This product is used to direct traffic. Improper use may

result in vehicular collision, personal injury and/or death. Star

Headlight & Lantern Co., Inc., and its subsidiaries shall not be held

responsible for damages directly or indirectly caused by improper

use of this product. Always carefully consider the effect on traffic

that the selected light pattern will have before engaging the lights.

1. Operation of your Traffic Director is straightforward. The controls include an On/Off

switch, four Pattern Select buttons, and three additional "option" buttons.

ULB42-TD-2 Controller

2. When the On/Off switch is activated, the traffic director will automatically go into the

WARN pattern. The LED display should show the "WARN” pattern and the WARN label

should glow red.

3. Select the desired pattern (if different from

the current pattern) by using any of the

Pattern Select buttons. The Pattern Select

buttons include Left, Center, Right, and

Warn. The selected pattern label should

change to red and the roof display should

mimic exactly the display on the controller.

-6-

Page 8

Operation (CONT'D)

4. The ULB42-TD-2 controller also has three "option" buttons: Fast, Dim, and Alt.

Fast

This button allows the user the option to display any of the patterns in a "faster" mode.

This button will also change the two end lights to flash in a fast random pattern (if they

have been enabled by the Alt button). Pressing the "Fast" button once should change

the "Fast" label to red and speed up the pattern. Pressing the button again will change

the "Fast" label back to green and revert the pattern to the standard speed.

Dim

When the "Dim" button is pressed the "Dim" label

will change to red and the Traffic Director will dim

slightly (Night Mode). Pressing it again will return

the Traffic Director to full brightness.

Alt

The two arrays on each end are not part of the “traffic

directing” patterns. The "Alt" button will enable and

disable the end flashing LED arrays.

Only the center 6 arrays will be utilized during the Left, Center Out, and Right patter ns.

The last two segments on each end will alternate ba ck and forth producing an In -Out warning pattern.

5. When using the Traffic Director, always be sure that the pattern selected is appropriate

for the present hazard condition. The potential danger in displaying an inappropriate

pattern cannot be overstated.

6. To avoid possible damage, the controller should be turned off prior to engine starting. It

is possible, though not likely, to confuse the controller if the vehicle's battery is low and

the engine is started with the controller running. If you notice that the controller's display

shows something out of the ordinary, simply push the power switch to the off position

and back on again. This should clear any fault caused by improper voltage being

supplied to the unit.

Once your Traffic Director is installed, please test all the patterns, options, and alternate

versions to familiarize yourself with the various patterns and the operation of the controller.

Troubleshooting

The ULB42-TD and ULB44-TD contain no user serviceable parts. The ULB42-TD-2

controller contains two ATO "blade-type" fuses located in the back of the controller. The

fuses are accessible from the rear of the controller. The 20 amp fuse controls power to the

bar light assembly, while the 2 amp fuse powers the controller. If the 20 amp fuse blows the

controller will continue to function normally, however, the lightstick will not. It is important to

note that under normal circumstances the only reason a fuse will blow is because there is a

fault in the system. If a fuse blows repeatedly it is a signal that something is wrong.

Do not replace a blown fuse with anything other than the same amperage rating as marked

on the rear panel of the controller; doing so may damage the unit, or worse yet start a fire.

Likely causes of blown fuses are improper wiring or harness damage.

-7-

Loading...

Loading...