Page 1

INSTALLATION AND INSTRUCTION MANUAL

DLX3-RRK / DLX4-RRK / DLX6-RRK

LED Undercover Roof Rack Lighting Kit

The manufacturer warrants this LED light against factory defects in material and workmanship for five years

LED FIVE YEAR LIMITED WARRANTY

after the date of purchase. The owner will be responsible for returning to the Service Center any defective

item(s) with the transportation costs prepaid. The manufacturer will , without charge, repair or replace at its

option, products, or part(s), which its inspection determines to be defective. Repaired or replacement

item(s) will be returne d to the purchaser with transportation costs prepa id from the service point. A copy of

the purchaser's receipt must be returned with the defective item(s) in order to qualify for the warranty

coverage. Exclusions from this warranty include, but are not limited to, domes, and/or the finish. This

warranty shall not apply to any light, which has been altered, such that in the manufacturer's judgment, the

performance or reliability has been affected, or if any damage has resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of merchantability or fitness), which

extend this warranty period. The loss of use of the product, loss of time, inconvenience, commercial loss or

consequential damages, including costs of any labor, are not covered. The manufacturer reserves the right

to change the design of the product without assuming any obligation to modify any product previously

manufactured.

This warranty gives you specific l egal rights. You might also have additional rights that may vary from state to

state. Some states do not all ow limitations on how long an implied warranty l asts. Some states do not allow

the exclusion or l imitation of incidental or consequential damages. Therefore, the above limitation(s) or

exclusion(s) may not apply to you.

PLIT478 REV. - 8/27/12

Page 2

Due to continuous product improvements, we must reserve the right to change any specifications and

information, contained in this manual at any time without notice. Star Headlight & Lantern Co., Inc. makes no

warranty of any kind with regard to this manual, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Star Headlight & Lantern Co., Inc. shall not be liable for

errors contained herein or for incidental or consequential da mages in connection with the furnishing,

performance, or use of this manual.

Installation Notes

Proper installation of the unit is essential for years of safe, reliable operation. Please read

all instructions before installing the unit. Failure to follow these instructions can cause

serious damage to the unit or vehicle and may void warranties.

• The installer must have a firm knowledge of basic electricity, vehicle electrical systems,

and emergency equipment.

• If you need to drill any holes when installing this light, please take care to check that

BOTH SIDES of your drilling surface are clear from obstructions, to ensure that you do

not damage your vehicle and or pre-existing wiring.

• Choose a mounting location away from any air bag deployment areas.

• Controls should be placed within convenient reach of the driver.

• Use only soap and water when cleaning this product. Use of other chemicals may

discolor the lens and/or housing, thus diminishing the output of the light. Lenses that

have become discolored should be replaced immediately!

• DO NOT use a pressure washer to clean this light. Use of a pressure washer may

damage the light and WILL VOID THE WARRANTY.

Before beginning the installation:

- Determine where the light is to be mounted.

- Check to see that there are no obstructions hindering the visibility of your light from the front,

rear, or side of the vehicle (wherever applicable).

- Determine where you will mount the switch.

- Verify that you have a clear path between the light and switch for your wires to run.

NOTICE

Please Note: These instructions are provided as a general guideline only. Some

vehicles may require special mounting, wiring, and/or weather-sealing. This is the

sole responsibility of the installer. Star Headlight & Lantern Co., Inc. assumes no

responsibility for the integrity of the installation for this or any of its products.

It is the sole responsibility of the installer to ensure the warning

light is secure. The manufacturer assumes no responsibility for

the secure mounting of this light.

-1-

Page 3

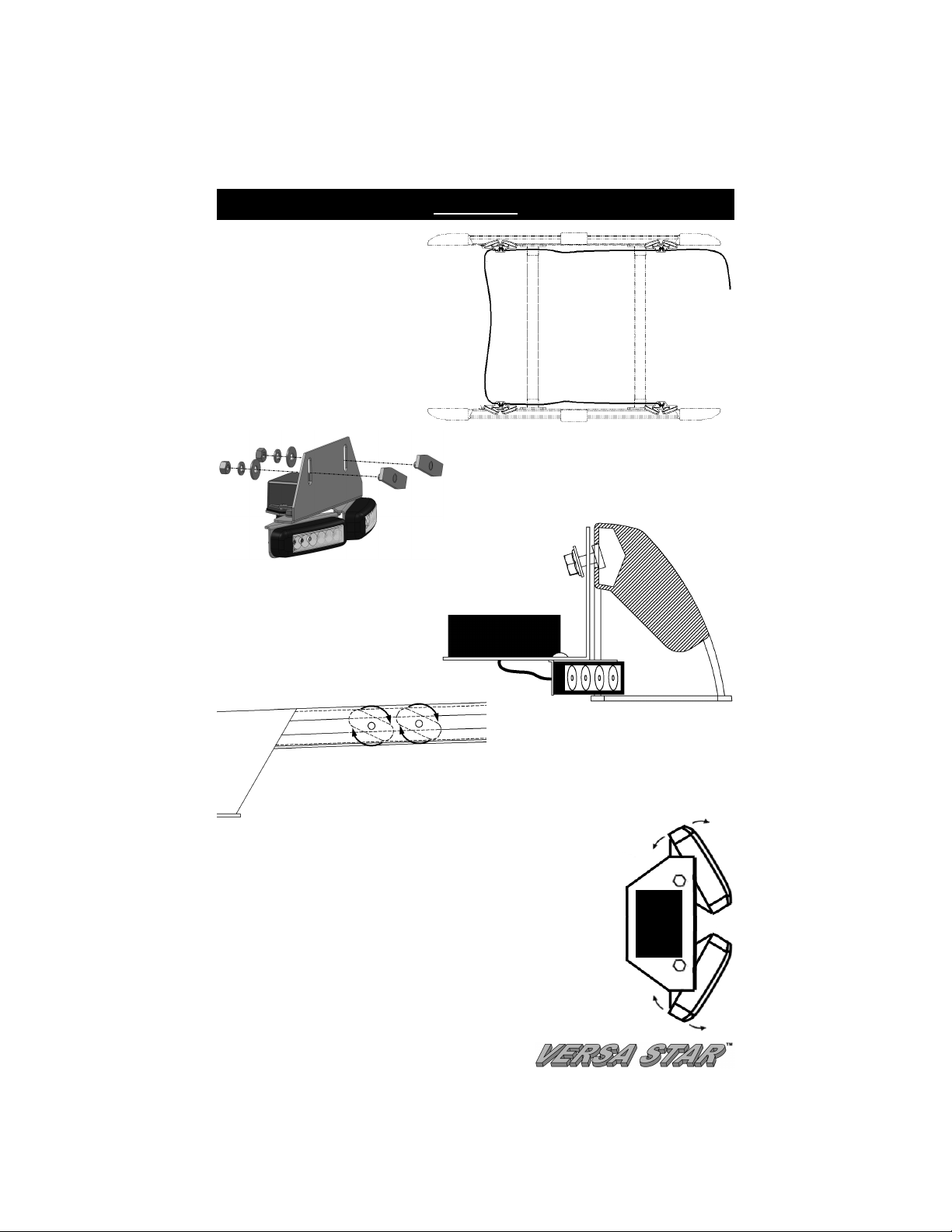

Mounting

1. Determine how you wish to mount the

lights on the roof rack paying

particular attention to where you want

to run the harness to the switch (not

included).

2. Each undercover head should come

with two T-Bolts that will be used to

attach it to the roof rack.

4. Mount one of the brackets to the

rail of the roof rack by slightly

angling the T-bolts allowing them

to slip into the slot on the rail.

3. Install one T-bolt through each slot in the Lbracket as shown to the left. Loosely secure

the T-bolt with a flat washer, lock washer, and

a nut on each bolt. Repeat this for all of the

light heads.

5. Loosely hand tighten the nuts while slightly rotating each T-bolt

clockwise until it contacts the top and bottom of the groove,

helping secure it inside the groove. You may wish to use a

screwdriver or similar tool to help you rotate the T-bolts.

6. After all of the heads have been installed, make your final

adjustments positioning each head side-to-side and up and down

where you want them. Tighten all of the nuts, ensuring the T-bolts

remain rotated against the top and bottom of the roof rack channel.

7. The angle of each individual light can be adjusted by loosening the

bolt securing it. Make your adjustments then tighten the bolt.

-2-

Page 4

External Wiring Connections

When wiring your lights, it is recommended that you take the following

• Keep LED modules and any radios as far away from each other as possible.

• Separate the radio wires and the LED wires:

precautions to reduce any Electromagnetic Interference (EMI).

• Any excess wires should be cut short.

For ease of installation, there are only two wires in the main harness of the DLX*-RRK. If

the default flash pattern and synchronization settings are acceptable, these are the

only wires you need to connect.

Black: (Ground) – Connect the black wire to the negative side of your battery.

Red: (Power) – Connect the red wire to your switch supplying power.

+10-16VDC (DLX3 heads) +10-30VDC.(DLX4/DLX6 heads)

Optional Programming

This lighting kit is designed such that there are several additional

options you can program including:

If you wish to change any of these, you will need to gain access to

the terminal block located behind each head.

To do this, remove the two screws that secure the plastic terminal

block cover (see diagram to right).

• Single or Split Flashing

• Flash Pattern

• Synchronization

Single or Split Flashing

(DLX4 and DLX6 Only)

By default, the lights in the DLX4-RRK and

DLX6-RRK assemblies are wired for “Single”

mode (the whole head flashes at once).

Optionally you can wire them for “Split

Mode” (the pattern alternates back and forth

Green/White: (Split/Single Mode) – The Green/White wire controls whether your light

Single Mode: Connect with Black to Ground — Split Mode: Connect with Red to Power

Green: (Split Mode Steady Side Swap) – If you are in Split mode and select the Steady

flashes in Single Mode or Split Mode. It is defaulted for Single Mode.

between the two halves of each light).

pattern, only one side will be steady while the other will flash. If you want to swap

the Steady side to the other half of the light, hold the green wire to ground for 15

seconds until the light flashes 5 times, then release it.

-3-

Page 5

(Optional Programming cont’d)

Pattern Programming

The capped off green

wires are used to

program the desired flash

pattern.

There are 10 different

Pattern Types you can

cycle through in two

different Phases, and an

additional “Steady Burn

Mode”.

If you have a DLX4 or DLX6 and are running in "Split Mode", the two halves will alternate

the pattern back and forth.

To change the pattern:

• Touch the green wire to ground for approximately 1 second and release it to cycle

through Patterns 1-20. After Pattern 20, the light will cycle back to Pattern 1.

PLEASE NOTE: The pattern cycle does NOT include the Steady Burn mode.

To access the Steady Burn pattern, use the programming Shortcut.

Phase 1

Phase 2

Flash

Pattern

Pattern

Type

Quadflash †

Quadflash w/Post-Pop †

Singleflash †

Doubleflash †

Pattern Description

Flash

Pattern

1 11 K Flicker †

2 12 L Fast Doubleflash

3 13 M Tripleflash †

4 14 N PSU Flicker

5 15 O PSU Random

6 16 F

7 17 G

8 18 H

9 19 I

10 20 J Variable AKA Delta-Omega

NA Steady

† - Approved patterns for SAE J845 and California Title 13

Pattern Shortcuts: Hold Green wire to ground for indicated time.

Split Mode Phases: One side flashes in Phase 1, the other

side flashes in Phase 2

Steady Burn: Not in pattern cycle. Only accessible through

shortcut. Hold Green wire to ground for 18

seconds (light will flash 6 times).

Shortcut

Pattern 1

(Phase 1)

3 sec or 1 flash

Pattern 11

(Phase 2)

9 sec or 3 flashes

Pattern 6

(Phase 1)

6 Sec or 2 flash

Pattern 16

(Phase 2)

12 sec or 3 flashes

18Sec

:

:

:

:

-4-

Page 6

(Optional Programming cont’d)

Synchronization

This harness has been pre-programmed at the factory so

that when properly mounted with the first pair of lights in the

rear of the vehicle, the next two pairs of lights at the front,

and the last pair of lights towards the rear, the four lights on

the right side of the vehicle are synchronized together and

the four lights on the left side of the vehicle are

synchronized together (see diagram to right).

We recommend using the factory default synchronization

settings. But if you wish to change the synchronization, please

review the section below and keep in mind the following:

• Only 6 lights can be synchronized. You cannot

synchronize all 8 lights.

• ALL SYNCHRONIZED LIGHTS MUST HAVE THE

SAME PATTERN TYPE !!!

• Lights that are programmed for the STEADY BURN

pattern will NOT be synchronized with any other lights.

• For lights running in Single Mode, Patterns 1-10 are in

Phase 1 and Patterns 11-20 are in Phase two.

• For lights running in Split Mode (DLX4/DLX6 only), Patterns 1-10 will flash side 1 in

Phase 1 and side 2 in Phase 2. Patterns 11-20 will flash side 1 in Phase 2, and side 2

in Phase 1.

• Lights or sides set for the SAME phase flash together (simultaneous), lights with

DIFFERENT phases flash opposite one another (alternate).

• Use the Pattern Shortcuts listed on page 4 to simplify programming.

1. If you wish to change the synchronization pattern that the lights come pre-programmed

with, remove the plastic terminal block cover as described on page 3.

2. Disconnect the white wires on

each light you will be

programming.

3. For the DLX4 and DLX6, verify

that the Green/White wire from

each light is connected correctly

so your heads are in the desired

mode (Single or Split mode), as

described on page 3.

4. Program the pattern for the first light as described on pages 4.

5. Program the second light with the same Pattern Type, selecting the Phase based upon

the desired output (alternating or simultaneous).

6. Once you have found the desired pattern on the second light, re-cap the green wire to

prevent it from coming into contact with ground again.

7. Repeat Steps 1-6 above for each additional head you wish to synchronize.

8. Reconnect the white wires in the terminal block of the synchronized lights.

9. Replace the terminal block covers.

-5-

Page 7

Troubleshooting Guide

These lights use state-of-the-art Light Emitting Diode (LED) technology. This light is

comprised of ultra-bright LEDs that are operated in a multiplexed mode to efficiently

produce light output with lifetimes up to 100,000 hours. Under normal circumstances, you

will not need to replace any LEDs in this light. If any of the LEDs in your light do fail,

please contact Star Headlight for arrangements to have them repaired.

NOTE:

Symptom Possible Cause

No Light

LED's appear dim

Erratic operation

Most failures can be traced to wiring and battery

problems. Check "quick-connects” and wiring to insure

that correct voltage/polarity is reaching the light.

Power or polarity

Inline fuse blown

Bad ground

White wire shorted

Green wire shorted

Shorts

Wiring

Low battery voltage

Power wires are too

small/long

Bad routing of wires

Check

A nominal +10-16VDC (DLX3) or 10-30VDC (DLX4 and DLX6)

should be reaching the red wire

Is power hooked up backwards?

Positive ground vehicle? (Unit designed for negative ground

vehicles)

Is an external fuse or circuit breaker used?

Are the negative leads connected to a good ground?

White wire should only be connected to other white wires.

Power applied to it will prevent the light from flashing

Green wire should remain unconnected.

If grounded, light will cease to function.

Do wires run thru bare metal holes that have damaged them?

Are the wires pinched or broken anywhere?

Measure while lights are on. Voltage below 10V will result in

Measure while lights are on. Voltage below 10V will result in

Do wires run thru bare metal holes that have damaged them?

Are the power or control wires close to:

Strobe power supplies, tubes, cables, police/two-way radios or

Try running with the car and all other accessories off

reduced LED output.

reduced LED output.

alternator?

If you have any questions concerning this or any other product, please contact our

Customer Service Department to obtain a Returned Material Authorization

Please write the RMA # clearly on the package near the mailing label.

Customer Service Department at (585) 226-9787.

If a product must be returned for any reason, please contact our

number (RMA #) before you ship the product back.

-6-

Page 8

-7-

Loading...

Loading...