Page 1

INSTALLATION AND INSTRUCTION MANUAL

REMOTE STROBE PACK

REMOTE STROBE PACK

REMOTE STROBE PACKREMOTE STROBE PACK

Model RP310

Owner's Manual & Installation Instructions

PLITSTR223 REV. B 3/3/11

Page 2

Table of Contents

Table of Contents

SAFETY WARNINGS 1

MOUNTING 2

WIRING INSTRUCTIONS 3

CONNECTING THE REMOTE HEADS 4

TROUBLESHOOTING 5-6

SERVICE & WARRANTY 7

# of Total Joules

Flash Pattern Heads Watts per Side Amps

Doubleflash 2 24 11.25 2.5

Quadflash 2 24 17.1 2.5

Table of ContentsTable of Contents

Please Note: These instructions are provided as a general guideline only. Some

vehicles may require special mounting, wiring, and/or weather-sealing. This is the

sole responsibility of the installer. Star Headlight & Lantern Co., Inc. assumes no

responsibility for the integrity of the installation for this or any of its products.

NOTICE

Due to continuous product improvements, we must reserve the right to change any specifications and

information, contained in this manual at any time without notice. Star Headlight & Lantern Co., Inc. makes no

warranty of any kind with regard to this manual, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Star Headlight & Lantern Co., Inc. shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this manual.

-i-

Page 3

• IMPORTANT: Please read all of the following instructions before installing your new

" DIA.

strobe system. This instruction sheet applies only to the models listed.

• CAUTION: All of our remote power supplies are polarity sensitive. They are polarity

protected only if the appropriate fuse is used. All wires connected to the positive

terminal of the battery should be fused at the battery for their rated load. Testing the

system before this fuse is properly installed will void the warranty on the light.

• Opening or tampering with your remote power supply will void the warranty.

The remote power supply must be mounted against a smooth metal surface in a dry

location. Water damage to the power supply will also void the warranty. Typical

mounting locations of your power supply include the interior firewall, beneath the seat

of a truck, or inside a large toolbox.

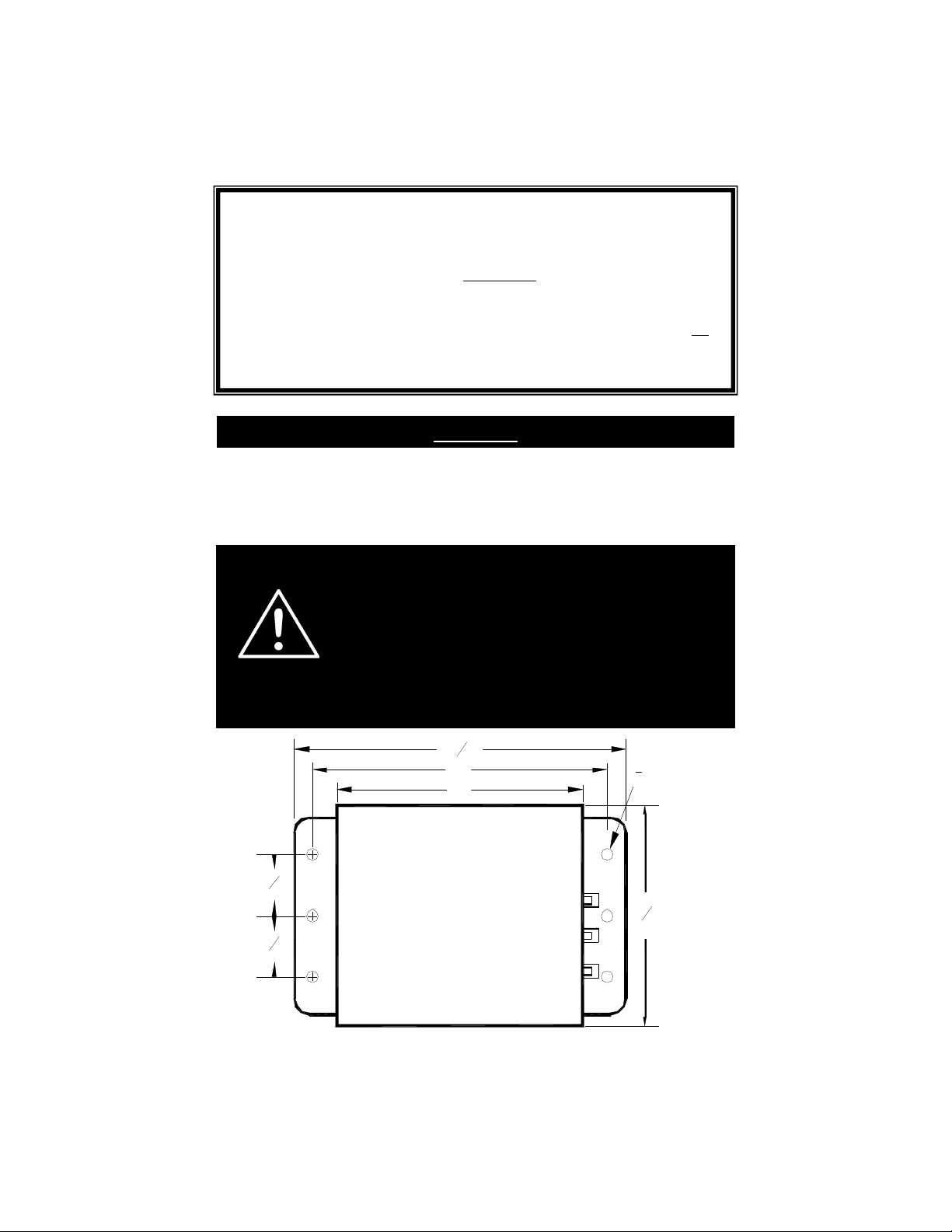

Mounting

Mount the pack on a smooth metal surface to allow for adequate heat dissipation. Do not mount

the pack near any external heat source, as this will retard its ability to dissipate heat sufficiently.

Mount the Pack using four bolts (not included). When mounting, make sure a good electrical

connection exists between the mounting plate and the vehicle chassis. This will help to eliminate

any RF interference.

When mounting the power pack and accessories, please be sure to keep

any radio frequency sensitive equipment at least 20” from the power pack,

cables, and/or wires which make up your strobe system. The pack has

been designed to limit RFI emissions, but certain very sensitive equipment

may still be affected. Symptoms may include, but are not limited to,

sporadic operation and degraded performance. Star Headlight & Lantern

Co., Inc. cannot assume any responsibility for any radio frequency induced

malfunction or damage to any radios, sirens, lightbars, or any other

equipment mounted within 20” of this strobe system. Any antennae

mounted in the proximity of the system may cause your radio to suffer the

aforementioned results.

3

6

"

4

6"

1

4

5"

RP310 SERIES

1

1

"

4

1

4

"

2

1

1

"

4

-1-

Page 4

Wiring

Power Plug

The power plug should be included with your power pack and comes complete with an 8-12”

wiring harness. This will be connected to the outlet on your pack labeled PWR. Connect

these wires as follows:

PWR

1. The black wire should be connected

to a good chassis ground.

2. The red wire from your power plug

should be connected to +12VDC

through your on/off switch (not

included).

3. If you are only operating your power

pack with an On/Off switch, you can

select the quadflash pattern by hooking

the white wire to the black wire (good

chassis ground). If you wish display the

doubleflash pattern, cut the white wire

short and tape the end.

POWER PLUG

FOR RP310

CONNECTOR

----------If you intend to utilize a Pattern Select Switch follow the instructions below----------

PATTERN SELECT WIRING: Make your connections as illustrated below, using the

optional #SP3860-2H switch available from your dealer.

1. The black wire from your power

plug on the pack should be

connected to a good chassis

ground, as should the black

wire from terminal 3 of SW1 on

the switch panel.

2. The red wire from your power

plug will connect to the red wire

extending from terminal 2 of

SW1.

3. The white wire from the power

SP 3860-2H SW ITC H P AN EL (RE AR VIEW)

w/ RP310 SE RIE S P OW ER PLU G

RED

ON

3

2

1

OF F

SW 1

FUSE

10 AMP

QU AD

3

2

1

DO UB

SW 2

PURPLE

plug allows for pattern selection.

It will be connected to the

purple wire from terminal 2 of

SW2 on the switch panel.

When the white wire is

connected to ground through

SW2 the pack will display a

quadflash pattern.

C

O

P

N

O

N

W

E

C

E

T

R

O

R

PLUGS

INT

POWER

PAK

WHITE

BL ACK

O

RE D

GO OD

CH ASSI S

GR OUN D

CONNECT TO +12 VDC

GO OD

CH ASSIS

GR OUND

4. The fused red lead from terminal 1 of SW1 should be connected to your

+12 VDC power supply.

5. When properly wired, SW1 will be on the left side (Front View) and switch the pack on

and off. SW2 will be located on the right side of the switch panel and will be used to

select between doubleflash or quadflash.

BLACK

-2-

Page 5

Connecting The Remote Heads

1. Cable is required to connect the power pack to your remote strobe heads. Cable can be

purchased from Star:

Length (ft) Shielded Cable SO Cable

w/Amp w/Weatherproof

Connector Connector

15 4415 3814-180”

20 4420 3814-240”

25 4425 3814-300”

30 4430 3814-360”

35 N/A 3814-420”

2. If you intend to use your own cable for connecting the remote heads, it must meet the

following specifications: It must be three-conductor with 600V insulation, it must be a

minimum 18 AWG for 0-30 ft. or 16 AWG for 31-60 ft., and it should be UV stabilized. Star

does not recommend the use of any cable length greater than 60 feet, as the resistance may

cause a drop in voltage resulting in inconsistent or complete loss of firing in the heads.

Please use the Table below for proper cable sizes.

Remote Power Pack Cabling Requirements

0-20 ft. 21-30 ft. 31-60 ft

Length (ft) Shielded Cable SO Cable

w/Amp w/Weatherproof

Connector Connector

40 N/A 3814-480”

45 N/A 3814-540”

50 N/A 3814-600”

55 N/A 3814-660”

60 N/A 3814-720”

Input Power and

Ground Wires

Wires to

Remote Heads

3. If you are using your own cable and need connectors to attach the cable to the power pack,

order part #CK473. The #CK473 consists of one connector (30041-20) and three male

terminals (30042-16). This is also the replacement connector for any remote heads with the

white AMP connectors (NOT weatherproof).

4. The AMP connector, found on the cables, which mates to the CK473 is a kit #CK472. The

#CK472 consists of one connector (448) and three female terminals (30042-15).

5. If you need a weatherproof connector kit for your cable to attach to our remote strobe heads,

please order part #CK702. This kit contains one connector (30185-3), three female terminals

(30042-30), and three rubber seals (30186-2).

6. If you need to order a weatherproof connector kit for your strobe head to mate with the

connector on your cable (#CK702), please order part #CK703. This kit contains one connector

(30185-4), three male pins (30042-29), and three rubber seals (30186-2).

7. For good, reliable connections between the cable system and the strobe heads in

various weather and contamination conditions, it is strongly recommended that dielectric

grease be used on the connectors. It should be applied to the rear of the connectors,

where the wires enter, as well as into each terminal area where the connectors mate,

before joining the two connectors together. We have found this procedure to be

effective even under the most extreme of conditions. Do Not Seal The Connectors

Using Silicon Or RTV.

18 AWG 18 AWG 16 AWG

18 AWG 18 AWG 16 AWG

-3-

Page 6

Troubleshooting

One Side Not Flashing

1. If a problem exists in only one head, you need to determine where the problem lies:

• The strobe tube may have burned out

• There may be an open electrical connection in the wiring harness or strobe head

• The circuit may have failed.

2. First determine whether the failure is in the strobe tube. Unplug the two strobe head

cables and flip-flop them, plugging them into the opposite connector they were just

plugged into. If the same head still doesn’t flash, you can assume the pack is probably

functioning properly and you should skip to Step 3. If the original failed head is now

flashing, and the other head has stopped working, then you can assume the problem is

in the circuit. It will have to be replaced or repaired at the factory.

3. If one of the heads will not flash when plugged into either of the outlets on the pack,

you will need to determine whether the problem is in the cabling or the head itself. This

can be done by disconnecting both heads from their respective cables and plugging

them into the opposite cables. If the same head fails to flash on both cables, and the

other head works on both cables, then you can assume the head is bad and will need

to be replaced. If both heads flash on one cable and fail on the other cable, then you

can assume the cable is faulty (as long as you followed step 2 to verify the problem

was not in the pack itself) and you will need to replace the cable or connectors.

Both Sides Not Flashing

1. Check all fuses, including those at the battery, at the switch panel, or in the dash (if

applicable). Replace any blown fuses with only fuses of identical values. Replacing

the fuse with the wrong rating may damage your pack and/or vehicle, and will void your

warranty.

2. Check the power and ground wires to your pack. With the vehicle turned off and

while the pack is running, measure the voltage across the red wire (pin 1) and the black

wire (pin 2) of the PWR connector on the power pack. Push the probes of the test

meter down into the connector at the wire entry points to contact the terminals for the

measurement. A nominal 12.5 volts should be present. Low voltage to the pack can

cause erratic flashing or even complete failure of the heads. A minimum of 9.5 volts

should be present for the pack to operate properly.

If your pack is receiving sufficient voltage then you can skip to Step 3.

If you do not have proper voltage present your power or ground is bad. Skip to the

section on Checking a Bad Power or Ground Connection.

3. Check each head. If the leads in one of the heads have shorted out, the output

voltage of the other heads may be held down as well. To test for this, unplug all of the

heads and plug them in individually. If your problem is a result of a shorted head, then

the other heads should function properly if the faulty head is no longer connected.

Note: A burned out strobe tube does not cause a short and will not affect the operation

of the remaining heads. If the problem is not with a shorted head and if proper voltage

is reaching the pack, the problem is most likely internal to the pack. Call Star to obtain

an R.M.A. number to return the pack for service.

-4-

Page 7

(Troubleshooting CONT’D)

Checking a Bad Power or Ground Connection

If sufficient voltage is not reaching the pack perform the following tests:

1. Test Power at the Battery: With the vehicle turned off and while the pack is running,

measure the battery voltage at the battery. A nominal 12.5 volts should exist. If this

voltage is below 9.5 volts the pack will not function properly and the problem is with the

battery. This reading should not be more than 1.25 volts higher than the reading in the

second step. If there is an excessive difference then continue on to the next step.

2. Test the Power Wire Between the Battery and the Switch: Move to the ON/OFF

switch in the cab and gain access to the rear of the switch panel. With the vehicle not

running and the pack on at the high power setting, measure the voltage drop in the red

wire by taking a reading with one probe on the positive side of the battery and the other

probe in pin 1 of your switch. If this reading exceeds 0.25 volts then there is a poor

connection between the switch and the battery in the red wire and it should be

checked. NOTE: Excessive voltage drop may be occurring in the connections on the

switch panel. If you have one of our switches you can increase the contact pressure by

removing the FASTON terminal from the tab on the switch. Using long nose pliers,

gently squeeze the FASTON terminal together in the area that slides on to the tab of

the switch. This will increase the pressure applied between the tabs and the connector

and reduce voltage drop.

3. Test the Power Wire Between the Strobe Pack and the Switch: This same

procedure can be used to check the wires between the switch panel and the pack.

Place one probe on the terminal at the switch and the other probe into the terminal with

the corresponding wire color in the PWR connector on the pack. Once again if any of

the readings exceed 0.25 volts then you should check those wires and their

connections.

4. Test your Ground Wire: If you still have not located the problem, troubleshoot the

connections between the good chassis ground and pin 2 (black or blue wire) of the

PWR connector on the power pack. With the vehicle not running and the pack on at

the high power setting, measure the voltage drop in the Black (Ground) wire by taking a

reading with one probe on the negative side of the battery and the other probe in pin 2

of your PWR connector. If this reading exceeds 0.25 volts then you have a bad

Ground.

-5-

Page 8

ONE YEAR LIMITED WARRANTY

The manufacturer warrants each new product against factory defects in

material and workmanship for one year after the date of purchase. The

owner will be responsible for returning to the Service Center any

defective item(s) with the transportation costs prepaid. The manufacturer

will, without charge, repair or replace at its option, products, or part(s),

which its inspection determines to be defective. Repaired or

replacement item(s) will be returned to the purchaser with transportation

costs prepaid from the service point. A copy of the purchaser's receipt

must be returned with the defective item(s) in order to qualify for the

warranty coverage. Exclusions from this warranty include, but are not

limited to, bulbs, strobe tubes, domes, and/or the finish. This warranty shall

not apply to any light, which has been altered, such that in the

manufacturer's judgment, the performance or reliability has been

affected, or if any damage has resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of

merchantability or fitness), which extend this warranty period. The loss of

use of the product, loss of time, inconvenience, commercial loss or

consequential damages, including costs of any labor, are not covered.

The manufacturer reserves the right to change the design of the product

without assuming any obligation to modify any product previously

manufactured.

This warranty gives you specific legal rights. You might also have

additional rights that may vary from state to state. Some states do not

allow limitations on how long an implied warranty lasts. Some states do

not allow the exclusion or limitation of incidental or consequential

damages. Therefore, the above limitation(s) or exclusion(s) may not

apply to you.

If you have any questions concerning this or any other product, please contact our

Customer Service Department at (585) 226-9787.

If a product must be returned for any reason, please contact our

Customer Service Department to obtain a Returned Materials Authorization

number (RMA #) before you ship the product back.

Please write the RMA # clearly on the package near the mailing label.

-6-

Loading...

Loading...