Star Headlight & Lantern SS651-013, SS651MT-013, LCS653-013, LCS653-1-013 Installation Notes

Page 1

SS651

SS651----013, SS651MT

SS651SS651

LCS653

LCS653----013, and LCS653

LCS653LCS653

Contents SS651 LCS653 LCS653-1 SS651MT

Amplifier box 1 1 1 1

Wiring Connector 1 1 1 1

Control head (switch panel) 1 1 1 1

Blue ¼" quick connect terminals 0 6 3 0

Pink ¼" quick connect terminals 6 6 6 0

013, SS651MT----013

013, SS651MT013, SS651MT

013, and LCS653----1111----013

013, and LCS653013, and LCS653

Siren Amplifiers

Siren Amplifiers

Siren AmplifiersSiren Amplifiers

013

013013

013

013013

Input Voltage

Audio Input Current

Standby Current

Output Power

Siren Frequency

High Voltage Protection

Short Circuit Current

Operating Temperature

Size

Boxed Weight

10 - 16 VDC (negative ground)

8 Amps @ 13.6 VDC (100W speaker)

Enable wire off 0mA

Backlighting off: 8 mA

105 WATTS RMS MAX. (15.0 VDC - single 100W speaker)

675Hz - 5kHz

> 16 VDC will cause siren output to cease, resume at normal

< 10 VDC will cause siren output to cease, resume at normal

50 AMPS (supply circuit must be capable of supplying this)

-15° F to +140°F

Amplifier: 2” High, 6” Wide, 5-3/4” Deep

(plus 3/4" flange on each side)

SS651-CH / SSS651-CH4 Control Head (Switch Panel):

3" High x 3" Wide, x 1-1/2" Deep

SS651-CH3 Control Head (Switch Panel)

3" High x 2-3/8" Wide, x 1-1/2" Deep

SS651MT-CH - Weatherproof Control Head:

2.5" High x 4.5" Wide x 2-1/8" Deep (3" Deep

SS651, LCS653, and LCS653-1 - 3.4 lbs.

SS651MT - 4.3 lbs.

with switches)

PLITSTR248 REV. J 1/14/15

Page 2

TABLE OF CONTENTS

SPECIFICATIONS Cover

INSTALLATION INFORMATION 1

GENERAL DESCRIPTION 1

INSTALLATION NOTES 2

MOUNTING 2-3

ELECTRICAL CONNECTIONS 4-6

WIRING DIAGRAMS 5-6

DIP SWITCH SETTINGS 7

OPTIONAL TONE PROGRAMMING 8

OPERATION 9

TROUBLESHOOTING 10

WARRANTY/SERVICE 11

Installation Information

MODELS: SS651-013 SS651MT-013 LCS653 LCS653-1

SERIAL NO: DIP SWITCH OPTIONS

PURCHASE DATE: _____ Negative Aux. Polarity

DEALER: _____ Hands Free Enabled

INSTALLATION DATE:

INSTALLER:

Model and serial number located on the bottom of the amplifier unit

General Description

The SS651, SS651MT, LCS653, and LCS653-1 Sirens are designed for single 100W

speaker use. They come standard with the amplifier unit as well as a remote control

head (switch panel). The primary operating modes are Wail, Yelp, Standby, Manual,

and Horn. Both the Manual Control and the Horn function will override all other

functions, and can be utilized at any time via a rocker switch. The Phaser function

can be optionally disabled (reprogrammed) for any necessary applications.

These units are designed to allow maximum versatility in mounting. The control head

is remote from the siren amplifier box creating a compact user interface panel that

can be easily mounted under the dashboard. The amplifier box can then be

mounted remotely in the trunk, under the dashboard, under the seat, or wherever

convenient. The SS651MT offers a waterproof switch assembly for motorcycle and

marine applications.

The siren amplifier has been designed with several protection features to provide

exceptional field service. Excessively high voltage detection will disable the siren

output to protect both the amplifier and the speaker. Fused inputs provide safety

against reverse polarity. Speaker protection shuts down the output if the speaker

output becomes electrically shorted. CAUTION: These protection features will not

guard against overloading the outputs.

-1-

Page 3

Installation Notes

Proper installation of the unit is essential for years of safe, reliable operation. Please

read all instructions before installing the unit. Failure to follow these instructions can

cause serious damage to the unit or vehicle and may void warranties.

Qualifications

The installer must have a firm knowledge of basic electricity, vehicle electrical

systems and emergency equipment.

Keep These Instructions

Keep these instructions in the vehicle or other safe place for future reference.

Advise the vehicle operator of the location.

Unpacking

Inspect contents for shipping damage. If any damage is found, alert the carrier

immediately.

Mounting

AMPLIFIER BOX

The amplifier box should be mounted through its flanges using four #8 screws (not included)

or other suitable fastener.

• Using the amplifier as a template, mark the

location of the four mounting holes to be

drilled. Be sure to check for obstructions

behind the mounting hole locations.

• Drill the four mounting holes and secure

the amplifier box using appropriate

hardware (not supplied).

CONTROL HEAD

The control head is designed to be mounted in an easily accessible

location such as under the dash, in the overhead console, or in a

center console. Choose a mounting location convenient to the

operator and away from any air bag deployment areas. Be sure to

choose a location that has at least two inches of depth to

accommodate the control head and cables. Consider wire routing

and access to connections when selecting location as well.

• Using the switch panel unit itself as a template, mark the location of the two mounting

holes to be drilled. Be sure to check for obstructions behind the mounting hole locations.

• Drill the two mounting holes and install the control using two screws or other suitable

fastener (not provided).

• Mount in a location with adequate ventilation to prevent overheating.

• Devices should be mounted only in locations listed in SAE standard J1849.

• Controls should be placed within convenient reach of the driver.

• Assure clearances before drilling in vehicle.

• Sound levels produced by attached speakers can cause permanent hearing loss.

• Never operate this unit without adequate hearing protection for you and others in the

area. (OSHA 1910.95)

!!! CAUTION !!!

-2-

Page 4

(Mounting CONT’D)

MOTORCYCLE/MARINE AMP INSTALLATIONS (SS651MT ONLY!)

This SS651-AMP can be used on a motorcycle or for marine applications by sealing

the case with silicone sealant along the mating edges and around the wire

connector. In order to reduce water entry, the amplifier should be oriented with the

wire connector faced down. Only the waterproof switch assembly found in the

SS651MT (SS651MT-CH) should be used for wet location operation.

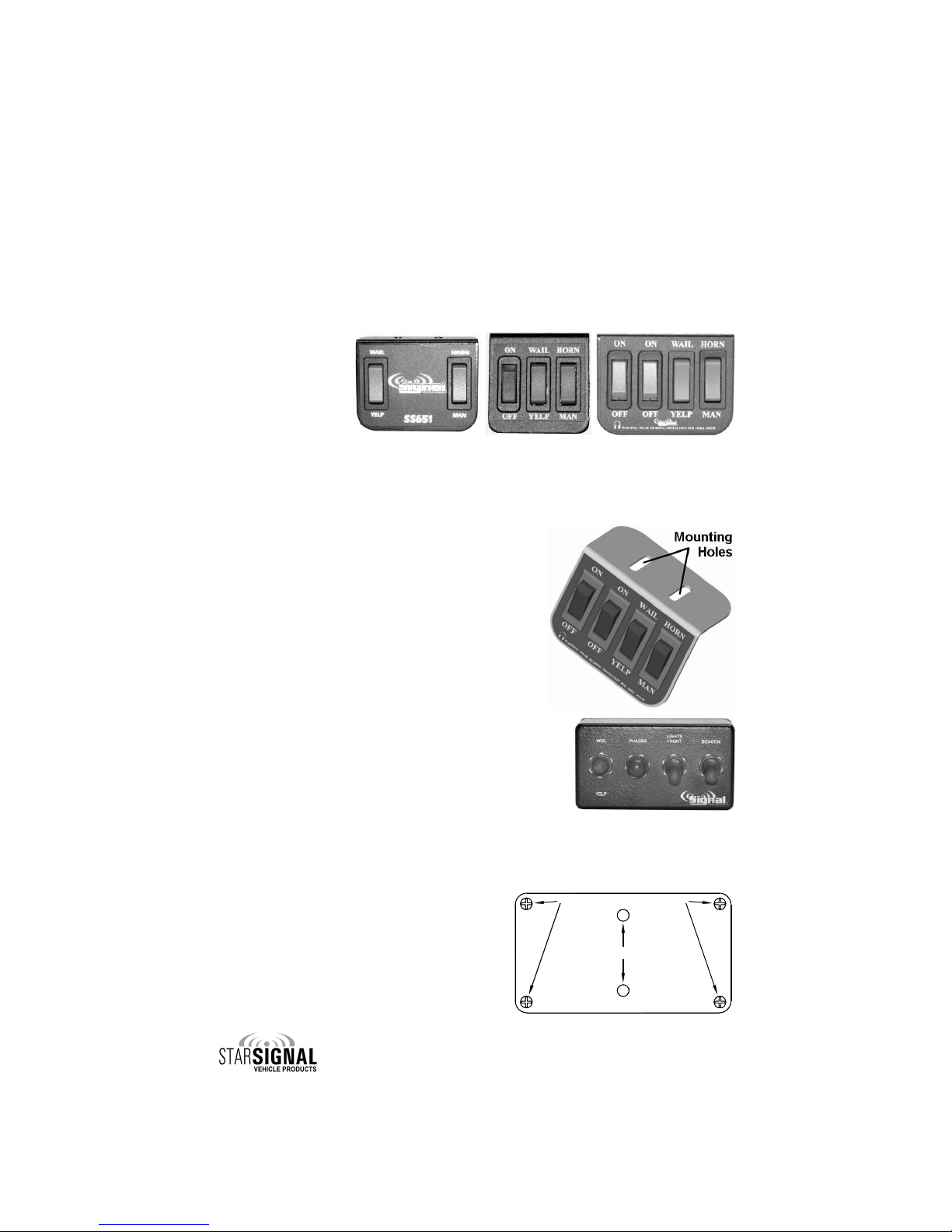

CONTROL HEADS

The control head is

designed to be

mounted in an

easily accessible

location such as

under the dash, in

the overhead

SS651-CH

SS651-CH4 SS651-CH3

console, or in a center console. Choose a mounting location convenient to the

operator and away from any air bag deployment areas. Be sure to choose a

location that has at least two inches of depth to accommodate the control head

and cables. Consider wire routing and access to connections when selecting

location as well.

• Using the switch panel unit itself as a template, mark

the location of the two mounting holes to be drilled.

Be sure to check for obstructions behind the

mounting hole locations.

• Drill the two mounting holes and secure the switch

panel using appropriate hardware (not supplied).

• Permanently mount the control using two screws

(not provided).

SS651MT-CH CONTROL HEADS

The SS651MT-CH weatherproof control head is designed

for use in locations that may be exposed to water.

• Choose a mounting location convenient to the

operator and away from any air bag deployment

areas.

SS651MT-CH

• Be sure to choose a location that has at least two inches of space on the right

side to accommodate the cable exiting the side of the control head.

• Consider wire routing when selecting location as well.

• The SS651MT-CH can be mounted through

Remove these four screws

the two holes in the rear cover. To gain

access to the mounting holes, detach the

rear cover by removing the four screws

affixing it to the control head.

Mounting Holes

• Secure the switch panel using appropriate

hardware (not supplied).

Rear of SS651MT-CH

-3-

Page 5

Electrical Connections

Wire Size and Termination

Electrical connections to this unit are made through the green 10-terminal

connector located in the rear of the unit (P/N P30041-177).

Examine the charts below to determine the proper gauge of the wire you should

use. Please review the following recommendations to follow when making your

installation:

• Use only high quality crimp connectors. Make sure all connections are tight.

• Minimize the number of splices to reduce voltage drop.

• Route wiring to prevent wear, overheating, and interference with air bag

deployment.

• Use grommets and sealant when passing through compartment walls.

• Ground connections should only be made to substantial chassis components,

preferably directly to the negative of the vehicle battery.

• Install and check all wiring before connection to vehicle battery.

• CAUTION: All wires should be rated for at least 125% of their maximum current

load. All wires connected to the positive terminal of the battery should be fused

at the battery for their rated load.

• Review the charts below that indicate the recommended wire gauge, based

upon the length of the wire run and the current that will pass through the wire.

• Wiring packages are available from your distributor (Star P/N SWH-151).

RECOMMENDED WIRE GAUGE

Current

10'

< 2.0A 22 AWG 18 AWG 18 AWG

4.0A 18 AWG 16 AWG 16 AWG

5.5A 18 AWG 16 AWG 14 AWG

8.0A 16 AWG 14 AWG 14 AWG

12.0A 16 AWG 12 AWG 12 AWG

20'

25'

AMPLIFIER WIRING GUIDE

Input/

Output

A

B

C

D

1

2

3

4

5

6

Description

Manual Switch Blue 0.001 AMPS

Horn Gray 0.001 AMPS

Yelp Violet 0.001 AMPS

Wail White 0.001 AMPS

AUX Green 0.002 AMPS

Ignition Switched Power Yellow 0.14 AMPS

Speaker 1 Brown 4 AMPS

Speaker 2 Brown 4 AMPS

Battery Negative/Ground Black 11 AMPS

Audio/Siren Power Red 10 AMPS

-4-

Typical

Color

P30144-177

Typical

Current

Page 6

(Electrical Connections CONT’D)

Program Button DIP Switches 10-Terminal Connector Micro Feedback LED

+12 VDC

Positive Side

Horn Switch

VEHICLE HORN

Positive AUX Horn Jumper

+12 VDC

Negative Side

Horn Switch

VEHICLE HORN

OR

A CB D

Manual

Horn

Yelp

SWITCH PANEL

21 3 4 5 6

AUX Input (Steering Wheel)

Wail

Ignition Switched Power (+12VDC)

SPEAKER

11 OHMS

Ground (#14 AWG)

Speaker -

Speaker +

Audio Power (#14 AWG)

15 AMP

FUSE

Negative AUX Horn Jumper

-

BATTERY

MANDATORY ELECTRICAL CONNECTIONS

Ground - Connect terminal 5 to the negative terminal of the battery.

Enable - Connect terminal 2 to a 10-16VDC ignition switched power source.

Audio Power - Connect terminal 6 to 10-16VDC through a 15A fuse.

(You MUST connect this wire!!)

Speaker - Connect terminals 3 and 4 to your speaker.

(You MUST connect this wire!!)

(You MUST connect this wire!!)

OPTIONAL ELECTRICAL CONNECTIONS

AUX Input - If you will be using the Hands Free option (see page 7) to activate

and change siren tones with the vehicle horn, connect terminal 1

to the horn switch. Be sure that you have set DIP switch #1 for the

correct polarity (see page 7).

-5-

Page 7

(Electrical Connections CONT’D)

CONNECTION OF CONTROL HEADS

SS651-CH (for SS651), SS651-CH3 (for LCS653-1), and SS651-CH4 (for LCS653)

A

B C D 1 2 3 54 6

Wail

Horn

Manual

SS651-CH

Please note th at pressing the switch up activates the bottom

terminal and p ressing the switch down a ctivates the top terminal.

Manual

Wail

Chassis

Ground

1

2

3

Good

Yelp

SW1

Horn

1

2

3

Chassis

Ground

SW2

Good

Yelp

• Electrical power

connections to the

control head are made

using the 1/4" quick

connect terminals

provided.

• After your wires are run

from the location of the

siren amp to the location

of the control head,

crimp the enclosed

terminals on to the ends

of the wires and plug

them into the

appropriate terminals on

the back of the control

head.

SS651MT-CH

A

Manual

1 2 4CB D

Wail

Horn

Yelp

SS651-CH3

HORN

(SWITCH

REAR VIE W)

Please not e that pressing the switc h up activates the bottom

terminal and pressing the switch dow n activates the top term inal.

1b

1

1a

MAN

SW3

Manual

Wail

Horn

Yelp

YELP

ONWAIL

3

1b

2

1

1

1a

OFF

SW1SW2

SS651-CH4

ON

WAIL

HORN

1b

MAN

SW4

1b

1

1

1a

1a

YELP

SW3

(SWITCH

REAR V IEW)

Please note that pressing the switc h up activates the bottom

terminal an d pressing the switch down activates the top ter minal.

OFF

SW2

ON

3

3

2

2

1

1

OFF

SW1

Power To Lig hts

Controlled b y SW1

653

20 AMP

FUSE

+

BATTERY

6531 2 4CBA D

Power To L ights

Controlled by SW2

Power To L ights

Controlled by SW1

20 AMP

FUSE

+

20 AMP

FUSE

BATTERY

The SS651MT-CH control head comes with 8’ leads. They will be connected to the

appropriate wires from the SWH-36 or lights by soldering or using appropriate

connectors (user supplied) and/or additional wire when necessary. Refer to the

diagram below.

A B

Manual

DC 1 2 3 4 5 6

Wail

Yelp

WAIL

YELP

FRONT

LIGHTS

PHASER

BEACON

Yellow (#1 8 AWG)

Blue (#18 A WG)

Gray (#18 A WG)

Red (#18 A WG)

Orange (#1 8 AWG)

Brown (#18A WG)

Red (#12 A WG)

MANUAL: T erminal A

YELP: Termin al C

WAIL: Term inal D

Power to Be acon

Power to Fr ont Lights

Ground

Input Power : +12VDC Battery

-6-

15 AMP

FUSE

BATTERY

+

Page 8

DIP Switch Settings

These sirens have two optional settings that can be

selected during installation using the DIP switches

located on the back of the amplifier case:

• Auxiliary Input Polarity

• Hands Free Cycler Mode Enable

DIP Switches

DIP

SWITCH

1

2

DIP Switch 1 - Auxiliary Input Polarity (AUX Function)

FUNCTION

AUX terminal Polarity Posi tive switching Negative switching

Hands Free Cycler

mode

UP (Off)

(default)

Hands Free Cycler

mode disabled

DOWN (On)

Hands Free Cycler

mode enabled

Applying a positive voltage to the AUX input

(Terminal 1 of the green connector) normally

activates the auxiliary function (Air Horn standard,

or Hands Free Cycler function optional). To have

the AUX function instead activate when Terminal

1 is connected to ground (negative), flip DIP

switch #1 into the DOWN (On) position (as

pictured to the right).

DIP Switch 2 - Hands Free Cycler Mode Enable

This siren is shipped with the Hands Free Cycler mode DISABLED. To

enable Hands Free Cycler mode, set DIP switch #2 into the DOWN

(On) position (as shown to the right).

See page 9 for additional details on Hands Free Cycler mode.

-7-

Page 9

Optional Tone Programming

These sirens can be programmed to produce 6 different tones/sounds by activating

its various functions:

Function Default Tone

Wail Wail

Yelp Yelp

Yelp Step Up Phaser

Manual Ramp Up

Horn Air Horn

Auxiliary Air Horn

Each Function listed above can be programmed for a different tone. If you would

like to change the tone for any of the six functions, follow the instructions below.

1. Power the unit up.

2. Activate the function you wish to change.

3. Press and release the Program button on the

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Wind Down or Hard Stop Option

By default, the Wail and Manual tones indicated by the “†” above will “wind down”

when they are de-activated. If you prefer to have them immediately stop (i.e. hard

stop), hold the Program Button for 3 seconds (until the LED flashes once). This will

change them to a hard stop. Repeat to change back to the wind down option.

• For Wail and Yelp functions, flip the Wail/Yelp switch into the

corresponding position.

• For the Manual, Horn, or AUX functions, press and hold the Manual

button, Horn button, or steering wheel horn, respectively.

• For the Yelp Step Up function, flip the Wail/Yelp switch into the Yelp

position, then press and release the Manual button.

The tone that is currently programmed for that function will sound.

Program Button

rear of the siren to cycle through the list of

optional tones. Review the chart below for a list

of optional tones.

Tones For Wail, Yelp, and

Yelp Step-Up Function

WAIL (Wail default) §, *, †

YELP (Yelp default) §, *

PHASER (Yelp Step Up default)

TWO TONE

MECHANICAL WAIL

MAX YELP §, *

HOOT

RAPID HOOT

AIR HORN & YELP

GHOST

RAPID GHOST

SINGLE AIR HORN

SINGLE QUICK

DOUBLE POST POP AIR HORN

TWO TONE AIR HORN

STANDARD AIR HORN

§ = SAE approved

* = California Title 13 approved

† = See below

(FIRE ENGINE)

†

Tones For Manual Button

1

2

3

4

5

6

7

8

9 MANUAL (MN default) *, †

10 MECHANICAL MANUAL

and AUX terminal

STANDARD AIR HORN (AUX default)

LOW FREQUENCY AIR HORN

RAPID AIR HORN

AIR HORN II

DOUBLE POST POP AIR HORN

SINGLE AIR HORN

SINGLE QUICK AIR HORN

TWO TONE AIR HORN

(FIRE ENGINE)

►►►►

System Reset

†

Tones for Horn Button

1

STANDARD AIR HORN (default)

2

LOW FREQUENCY AIR HORN

3

RAPID AIR HORN

4

AIR HORN II

5

DOUBLE POST POP AIR HORN

6

SINGLE AIR HORN

7

SINGLE QUICK AIR HORN

8

TWO TONE AIR HORN

◄◄◄◄

If you would like to reset all of the siren programming

options to their defaults, activate any tone and press the

Program button for six (6) seconds. The LED will flash

once, then twice, then all siren tones will stop.

-8-

Page 10

Operation

Wail/Off/Yelp Button

This is the 3-position button used for

basic operation of the siren. While in

the Wail or Yelp positions the siren will

produce the tone programmed for

that function (see previous page). The

Wail and Yelp functions are defaulted

for the Wail and Yelp tones.

Wail Tone: A normal rise-fall tone used

Yelp Tone: A rapid warble tone used in

Center Off Position: (Manual/Standby) - A silent mode that allows momentary

Manual Button

When the unit is powered up with the Wail/Off/Yelp button in the Off position (not

producing any siren tones), by default this momentary push button switch provides

a manually rising and falling siren tone while being pressed. The siren output winds

down when the Manual momentary switch is released.

With the Wail or Yelp mode selected, pressing the Manual button will “step” the

siren up to the next button’s programmed tone:

These quicker tones are used to momentarily alert motorists at intersections and

very highly congested areas. Pressing the button once changes to the next faster

tone. Pressing the Manual button again, reverts the siren back to the original tone.

(See previous page to program optional tones.)

Horn Button (SS651MT excluded)

This momentary push button switch provides a simulated air-horn tone while

pressed. It is useful at intersections or in high noise areas. This tone will override all

other siren tones. (See previous page to program optional tones.)

Auxiliary Function (AUX Terminal) and Hands Free Cycler Mode

Note: Requires connection of the AUX terminal (see page 5).

The AUX terminal is typically connected to the vehicle horn switch. See page 7 to

select positive (+12VDC) or negative (ground) activation.

Normally when the unit is on and in any mode, activating the AUX terminal (i.e.

pressing the vehicle’s horn) will produce the programmed Air Horn tone (see

previous page to program optional Air Horn tones).

If you enable Hands Free Cycler mode using DIP switch #2 as shown on page 7,

pressing the vehicle’s horn continuously for 3 seconds will activate the Hands Free

Cycler mode. This mode allows you to use the vehicle’s horn to cycle through the

siren tones associated with the following functions:

on highways and areas with

low traffic or constant traffic

flow.

light to moderately

congested areas.

push-button activation of the Manual and Horn functions.

(WailYelpYelp Step Up)

(WailYelpYelp Step UpSilent)

-9-

Page 11

Troubleshooting

Auto Shutdown

This unit is designed to automatically shut down when certain undesirable conditions

exist, to prevent internal damage. All audio functions are disabled until the issue is

corrected.

Micro Feedback LED

This unit is designed with an LED that not

only provides feedback when

programming, but also helps troubleshoot

audio issues.

LED Pattern Diagnosis

Steady On Speaker functioning properly

Off No Siren Tone Active or Speaker open (faulty connection)

Single Flash Over Voltage/Under Voltage

Double Flash Over Current

Symptom Possible Cause Check

No power Check power Wires

No siren tone Bad speaker or speaker wiring

Distorted siren sound Speaker assembly loose

Intermittent siren tone Low voltage protection

Horn function or

Manual function

stuck on

Wrong siren tone Option accidentally changed See programming and setting to defaults section

• Over Voltage/Under Voltage

• Over Current

Fuse or circuit breaker blown

High voltage or low voltage

protection

Blown Fuse

Intermittent AUX input

connection

Low or high vehicle voltage

Circuit breaker in supply

connection

Shorted speaker or speaker wire

Aux. Input improperly connected

or Aux. Input Polarity Option

set wrong

Micro Feedback LED

When activated, power to both Ter minals 2 and 6?

Is power hooked up backwards? Positive ground vehicle?

Are the negative leads connected to a good ground?

Measure voltage between ground & +12v terminal

Measure voltage between ground & ignition switched

terminal.

Check Fuse under amplifier cover.

Check external fuses or circuit breakers

Does LED remain off when siren tone is selected?

Disconnect the speaker at the amplifier, and turn a tone on.

If you hear sound, the siren is working correctly and

you have a failed speaker or faulty speaker wiring .

Is LED single flashing?

Measure voltage between ground & ignition switched

terminal. The input voltage must be between 10 & 16V

Check fuse inside amp housing

Is the speaker loose?

Is the Aux. Input used and wired properly?

Is LED single flashing?

Input voltage must be between 10 & 16 volts while siren is

on.

Wires connected tightly to the back of the unit?

Loose connection on a power lead?

Input greater than 10V with the siren turned on?

Is a circuit breaker used with at least a 30A rating?

Does the speaker have water damage, or is a wire pinched?

Remove the Aux input wire at the amp. Does the problem

stop? If so the aux polarity DIP switch may be set wrong

or the AUX terminal may be wired incorrectly

-10-

Page 12

PARTS

Service

Part Description

P30235-18-1P Amplifier Top Cover

S30234-18-1 Amplifier Bottom Mounting Plate

SWH-151 Optional Wiring Harness (not included)

P30050-28 Rear Amplifier Case Screws

P30028-27 15 Amp Mini Automotive Blade Fuse for Amplifier

30032-8 TIP36C Power Transistor

30007-41 3-Position Rocker Selector Switch (WAIL/YELP)

30007-42 Momentary Rocker Switch (HORN/MAN)

SW-40 Lighted ON/OFF Rocker Switch (LCS653)

The manufacturer warrants each new product against factory defects in material and

ONE YEAR LIMITED WARRANTY

workmanship for one year after the date of purchase. The owner will be responsible for returning

to the Service Center any defective item(s) with the transportation costs prepaid. The

manufacturer will, without charge, repair or repl ace at its option, products, or part(s), which its

inspection determines to be defective. Repaired or replacement item(s) will be returned to the

purchaser with transportat ion costs prepaid from the service point. A copy of the purchaser's

receipt must be returned with the defective item(s) in order to qualify for the warranty coverage.

Exclusions from this warranty include, but are not limited to, bulbs, strobe tubes, domes, and/or the

finish. This warranty shall not apply to any light, which has been altered, such that in the

manufacturer's judgment, the performance or reliability has been affected, or if any damage has

resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of merchantability or fitness),

which extend this warranty period. The loss of use of the product, loss of time, inconvenience,

commercial loss or consequential damages, including costs of any labor, are not covered. The

manufacturer reserves the right to change the design of the product without assuming any

obligation to modify any product previously manufactured.

This warranty gives you specific legal rights. You might also have additional rights that may vary

from state to state. Some states do not allow limitations on how long an implied warranty lasts.

Some states do not allow the exclusion or limitation of incidental or consequential damages.

Therefore, the above limitation(s) or exclusion(s) may not apply to you.

If you have any questions concerning this or any other product, please contact

our Customer Service Department at (585) 226-9787.

If a product must be returned for any reason, please contact our Customer Service

Department to obtain a Returned Materials Authorization number (RMA #) before you ship

the product back. Please write the RMA # clearly on the package near the mailing label.

NOTICE

Due to continuous product improvements, we must reserve the right to change any

specifications and information, contained in this manual at any time without notice. Signal

Vehicle Products and/or the manufacturer make no warranty of any kind with regard to this

manual, including, but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Signal Vehicle Products and/or the manufacturer shall not be liable for errors

contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this manual.

-11-

Loading...

Loading...