Page 1

INSTALLATION AND INSTRUCTION MANUAL

DL15

DL15-

DL15DL15

LED TRAFFIC DIRECTOR

WARNING STICK

-30W

30W

--

30W30W

and

PLITSTR77 REV. C 9/12/11

Page 2

IMPORTANT: Please read all of the following instructions before installing your new LED

Traffic Director and Warning Stick.

CAUTION: Please be sure to check that your light is properly fused. Testing the light

before this fuse is properly installed will void the warranty on the light.

WARNING!!!! Care should be taken when positioning this warning light so that the light

and/or cord does not interfere with the proper operation of any of the

airbags! Failure to heed this warning may result in serious or fatal injury.

It is the sole responsibility of the owner to ensure the warning light is

secure. Check your light every time you enter the vehicle to ensure that

it is mounted securely. Star Headlight and Lantern Co. assumes no

responsibility for the secure mounting of this light.

These lights use state-of-the-art Light Emitting Diode (LED) technology. This warning

light is comprised of ultra-high intensity LEDs that are operated by a micro-controller to

efficiently produce light output with lifetimes up to 100,000 hours.

Please Note: These instructions are provided as a general guideline only. Some

vehicles may require special mounting, wiring, and/or weather-sealing. This is the

sole responsibility of the installer. Star Headlight & Lantern Co., Inc. assumes no

responsibility for the integrity of the installation for this or any of its products.

-i-

Page 3

Important

: This product is used to direct traffic. Improper use

may result in vehicular collision, personal injury and/or death. Star

Headlight & Lantern Co., Inc., and its subsidiaries shall not be held

responsible for damages directly or indirectly caused by improper

use of this product. Always carefully consider the effect on traffic

that the selected light pattern will have before engaging the lights.

Table of Contents

Safety Warnings i

Preparation 1

Stick Mounting 2-3

Electrical Connections 4

SP1515-TDC and

User Supplied Switches 4

Pattern Selection 5-6

Operation 7

TD77-2 8-12

Cover Removal

Jumper Setting

Connections

Operation

Pattern Display LEDs

TDC850 12-15

Cover Removal

Jumper Setting

Connections

Operation

Stick Adjustment 16

Parts 16

Troubleshooting 16

Warranty 17

8

9

10

11

12

12

13-14

14

15

Due to continuous product improvements, we must reserve the right to change any specifications and

information, contained in this manual at any time without notice. Star Headlight & Lantern Co., Inc. makes no

warranty of any kind with regard to this manual, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Star Headlight & Lantern Co., Inc. shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this manual.

-ii-

NOTICE

Page 4

Preparation

Before beginning the installation:

• Determine where the Traffic Director is to be mounted.

• Check to see that there are no obstructions hindering the visibility of

your traffic director.

• Select a location to mount your controller (purchased separately or

user supplied). The controller must be located in a dry location out of

direct sunlight, free of dirt and dust. Under the vehicle's instrument

panel is usually the best choice.

• Once you have selected these locations, determine the path that

your cable connecting the controller to the Traffic Director will take.

The cable should exit the driver’s side of the rear facing Traffic

Director.

Be sure the cable attached to your Traffic Director is long enough for

proper installation. If it is too short, you will need to order a Traffic

Director with the correct length cable pre-installed. The standard length

for the cables is 15'. Star does not recommend “splicing in”

additional cable when the supplied cable is too short. Traffic

Directors with longer cables are available upon request.

-1-

Page 5

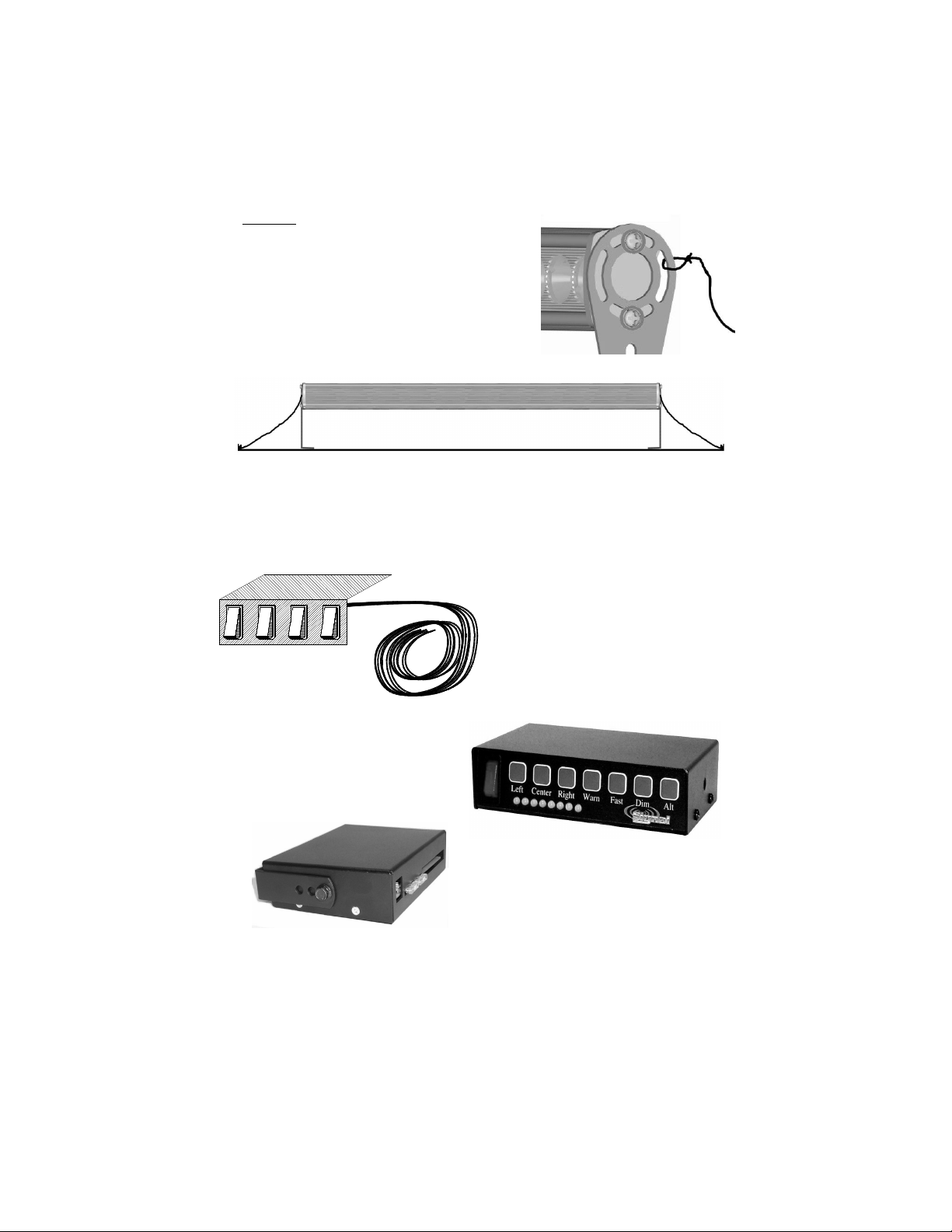

Mounting

It is the owners sole responsibility to ensure that the mount is

secure and will not come loose while the vehicle is in motion.

1. Select a location for the light to be mounted. Take into consideration viewing angles,

mounting holes, and where the cable will run when selecting a location. The cable

should exit the driver’s side of the rear-facing stick.

2. Once you have selected the location to mount your light(s), determine which leg size

suits your application best. There are three different size legs included with the

DL15-30W Series lights: Short Leg Brackets (DL15-BKT-S), Medium Leg Brackets

(DL15-BKT-M), and Tall Leg Brackets (DL15-BKT-T).

DL15-BKT-M

DL15-BKT-S

3. Remove the two screws in one end of the light and use

them, with two of the enclosed washers, to attach one of

the mounting legs, routing the cord through the center

of the leg (shown to the right). When

installing the legs, take into account

which direction the light will face, where

the legs will mount, and which end the

cord will exit from. Select the appropriate

slots in the leg to fasten the screws

through. Repeat this step for the other

side with the other leg.

Please note: The cable needs to run through the center of the mounting bracket

as pictured above and exit the driver’s side of the rear facing DL15-30W.

DL15-BKT-T

CAUTION!!:

you are installing the legs, please take extreme care to ensure that the endcap is

replaced in the exact same orientation it was originally in. If it is not replaced

properly the weatherproof seal may be broken and the warranty will be voided.

4. Mount your light in the desired location. Use appropriate fasteners (not supplied) to secure

the legs to your mounting surface.

In the event the endcap should become detached from the lightstick as

It is the owners sole responsibility to ensure that the mount is

secure and will not come loose while the vehicle is in motion.

-2-

Page 6

(Mounting CONT’D)

5. You must then install the enclosed tether cords, which

will help secure the light in case of impact. Attach one

tether to each leg as pictured to the right. Attach the

other end of each tether to a secure mounting point.

6. Each tether should be secured in separate locations

within 10" outside the legs of the light. Make sure there

is virtually no slack in the tethers. (See diagram below.)

CAUTION: Be sure the mount and/or fasteners used

are sufficient to support the weight of your light in

case of an accident.

7. Once the DL15-30W is mounted, you should select a location for your switch panel that is

easily accessible to the driver. The switches must be located in a dry location out of direct

sunlight, free from dirt and dust. Under the vehicle's instrument panel is usually the best

choice. You may use your own switches, or you may order the SP1515-TDC, TD77-2, or the

TDC850 (for use with SVP sirens that have built-in traffic director controls). If you are using

your own switches, you will need a 4-switch switch panel, with 4 SPST On/Off switches.

SP1515-TDC

(Optional Switch Panel)

(Optional Controller w/LED Display)

TD77-2

TDC850

(Optional Controller for use w/SVP sirens)

8. Mount your switch panel using appropriate fasteners (not supplied).

9. Once the light and switch panel are secured, route your cable to your switch such that it does

not interfere with the vision of the driver or the operation of the steering wheel, gear shifter,

and/or any airbags.

-3-

Page 7

Electrical Connections

The DL15-30W comes with a 15' six-conductor cable. The six wires perform the following

functions:

You can control your light using your own switches, with the optional SP1515-TDC (see

below), or with the optional TD77-2 (see pages 8-12).

If you will be using the OPTIONAL TD77-2 to control your light, please skip to the

corresponding section on page 8.

If you are using your own switches, you will need a 4-switch switch panel, with 4 SPST On/Off

switches.

1. Connect the black wire to a good chassis ground.

2. The red, yellow, purple, and green wires will be connected to your switch panel. Please

3. After the black wire is grounded, and the red, yellow, purple, and green wires are

Black Wire (18AWG) - Ground

Red Wire (18AWG) - Power (operating voltage 10-16VDC)

Yellow Wire (22AWG) - Left Arrow (+12VDC)

Purple Wire (22AWG) - Center Out(+12VDC)

Green Wire (22AWG) - Right Arrow(+12VDC)

White Wire (22AWG) - Pattern Change (Touch and release to ground)

Connecting the Optional SP1515-TDC

(you may also use your own standard On/Off switches)

review the diagram below for proper wiring, using four SPST switches. The SP1515TDC (available from Star) utilizes four lighted switches. If you are using your own “non-

lighted” switches, there will be no #3 terminal on each switch, and the switch panel itself

will not need to be grounded.

connected to your switch panel, the light is ready for operation and pattern selection.

STAR MODEL #SP1515-TDC

OPTIONAL LIGHTED SWITCH PANEL

(REAR VIEW)

R

SW4

GREEN

GREEN

C-O

3

2

1

3

2

1

SW3 SW2

PURPLE

P

U

R

L

3

2

1

RED

YELLOW

Y

E

L

L

O

P

L

E

W

PWR

3

2

1

SW1

R

E

D

BLACK

FUSED RED LEAD

10 AMP

FUSE

(Not used for non-lighted switches)

GOOD

CHASSIS

+12 VDC

GROUND

W

CONNECT TO

BLACK

H

I

T

E

Touch And Release to Ground

to Select Pattern, Then Cap Off

Please note: For non-lighted switches, there will be no Terminal #3 on each switch

and there is no ground wire (black wire) on the switch panel.

-4-

Page 8

Optional Pattern Selection

Pattern Selection for the DL15-30W when Using the SP1515-TDC

After your light and switch panel have been installed, you have the option of changing either

or both of the following:

When the light is initially activated by turning the PWR switch on, it will display a “Warn

Pattern”. The light has been pre-programmed at the factory to display Pattern 1 (Alternating

Slow Singleflash). Review the list below and decide if you wish to change the default

Warning Pattern.

Pattern Description

1 Alternating Slow Single (1-5 vs. 6-10) (default) †

2 Alternating Fast Single (1-5 vs. 6-10)

3 Alternating Triple (1-5 vs. 6-10)

4 Alternating Quad (1-5 vs. 6-10)

5 Alternating Quint (1-5 vs. 6-10)

6 Alternating Triple (1,26,7,8 vs. 3,4,5,9,10)

7 Alternating Quint (1,26,7,8 vs. 3,4,5,9,10)

8 Simultaneous Slow Single (All modules) †

9 Simultaneous Fast Single (All modules)

10 Simultaneous Triple (All modules)

11 Simultaneous Quad (All modules)

12 Simultaneous Quint (All modules)

13 Simultaneous Triple (All modules)

14 Simultaneous Quint (All modules)

15 In/Out Single (1,2,9,10 vs. 3-8)

16 In/Out Triple (1,2,9,10 vs. 3-8)

17 In/Out Quint (1,2,9,10 vs. 3-8)

18 In/Out Single (1,2,3,8,9,10 vs. 4-7)

19 In/Out Triple (1,2,3,8,9,10 vs. 4-7)

20 In/Out Quint (1,2,3,8,9,10 vs. 4-7)

21 1-5 Steady; 6-10 Single Flash †

22 1-5 Steady; 6-10 Slow Single Flash †

23 6-10 Steady; 1-5 Single Flash †

24 6-10 Steady; 1-5 Slow Single Flash †

25 Sequential Back and Forth

26 Sequential In/Out

27 Burst All w/ Alternating Burst

28 Alternating Burst w/ Double then Quint

29 Simultaneous Burst /w Double then Quint

30 Hyper Random

31 Demo Mode (two sequences of each pattern, except 20-23)

x OFF

† = California Title 13, SAEJ595, and SAEJ1318 Approved)

A. The default Warning Pattern

B. The style of your Traffic Directing Patterns

(or User Supplied Switches)

Optional Warning Patterns

Arrays for the DL15-30W

Array #1 Array #2 Array #3 Array #4 Array #5 Array # 6 Array #7 Ar ray #8 Array #9 Array # 10

{

{

{

{

{

{

{

{{{

-5-

Page 9

B

L

A

C

K

=

G

r

o

u

n

d

(Optional Pattern Selection CONT’D)

If you do not wish to change the Warning Pattern, skip to the Optional Traffic Directing

Pattern Styles section below. To change the default Warning Pattern, proceed below.

PWR C-OL R

1. To select the Warning Pattern,

activate your light by turning on the

PWR switch. When activated the

stick should be in Pattern 1

(Alternating Slow Single (1-5 vs. 6-10))

.

(Switch panel shown with PWR switch in “ON”

position and other switches in “OFF” position.)

2. Touch and release the white wire to ground to scroll

through the patterns listed on the previous page.

3. Once you have found

the desired Warning

P

GREEN = Right

U

Y

R

E

P

L

E

=

C

-

O

Pattern, you can turn

the light off. The light will “remember” the last selected pattern

R

E

D

=

P

L

L

O

W

W

=

R

L

e

f

t

W

H

I

T

E

=

P

a

t

t

e

r

n

S

e

l

e

when switched off and that pattern will be displayed the next time the

light is switched on.

Optional Traffic Directing Pattern Styles

After the PWR switch is activated and any of the Traffic Directing Patterns (L, C-O, R) are

activated, the light will display the corresponding pattern (Left, Center-Out, or Right).. There

are several different “styles” is which these patterns can be displayed. The light has been

pre-programmed at the factory to display Style 1 (10 Head Normal) when any of the Traffic

Directing Patterns are activated. Review the list below and decide if you wish to change the

default Traffic Directing Pattern Style.

Style Description

1 10 Head Normal (default)

2 10 Head Dual Light

3 10 Head Normal with End Blink

4 10 Head Dual Light with End Blink

5 6 Head Normal w/Warn

6 6 Head Dual Light w/Warn

Normal - Starts with one light and consecutively adds lights to the pattern until they are all

Dual Light - Only two lights will be illuminated the same time. The two lights will "roll" or “travel”

End Blink - Same as the Normal or Dual Light pattern with the exception that the last light will double

Warn - This option only uses the center 6 arrays (3 LED’s in each array) for traffic directing. The

illuminated

in the direction of the selected pattern

blink.

two arrays on each end will flash back and forth in a warning pattern.

1. If you wish to change the Traffic Directing Pattern Style, turn the PWR switch on and

activate any one of the other switches (L, C-O, or R). This will place the bar into Traffic

Directing Mode.

2. Touch and release the white wire to ground to scroll through the six different display

styles listed above.

3. Once you have found the desired style, switch the light off and tape or place a wirenut

over the end of the white wire to prevent it from coming into contact with the ground again.

4. OPTIONAL: If you wish to utilize your own remote pattern select switch, you may

connect the white wire to ground through a momentary on/off switch (user supplied).

NOTE: Adding this switch will void the California Title 13 approval.

c

t

-6-

Page 10

Operation

SP1515-TDC or Standard Switch Operation

Important

vehicular collision, personal injury and/or death. Star Headlight & Lantern Co.,

Inc., and its subsidiaries shall not be held responsible for damages directly or

indirectly caused by improper use of this product. Always carefully consider the

effect on traffic that the selected light pattern will have before engaging the lights.

1. Operation of the DL15-30W is straightforward. Four switches are used to control the

various functions : Warn, Left, Center Out, and Right Patterns.

2. The unit is activated by switching the PWR switch ON (attached to red wire). The

light will go into Warning mode with the pattern you have pre-selected (see the

Pattern Selection section on the following page).

3. Select a Traffic Directing pattern by switching the appropriate switch ON.

L - Left Pattern

C-O - Center Out Pattern

R - Right Pattern

Please note: The PWR switch must also be on for the Traffic Directing

4. If more than one of the Traffic Directing switches (R, C-O, L) is activated, the stick

will default to the Center-Out mode for safety reasons.

5. When using the Traffic Director, always be sure that the pattern selected is

appropriate for the present hazard condition. The potential danger in displaying

an inappropriate pattern cannot be overstated.

: This product is used to direct traffic. Improper use may result in

PWR L

Patterns to activate.

C-O R

Once your Traffic Director is installed, please test all the patterns, options, and

alternate versions to familiarize yourself with the various patterns and the

operation of the controller.

-7-

Page 11

Optional TD77-2 Controller

TD77-2

(Optional Controller w/LED Display)

You may choose to control your DL15-30W with the optional TD77-2 controller (ordered

separately). This controller has a number of benefits over the SP1515-TDC or any other

standard switches:

TD77-2 Control Box Cover Removal

• The TD77-2 provides an LED display that shows which mode

the light stick is operating in (Off, Left, Center, Right, or Warn).

• The TD77-2 allows you to change your Warning Pattern and

the style of your Traffic Directing Patterns. (Please note that

this feature must be disabled if you need to meet

California Title 13 specifications.)

• The Pattern Control Switches on the TD77-2 are all backlit

anytime the unit is powered on.

Prior to connecting the TD77-2 to your DL15-30W, you must set an internal

jumper. YOUR TD77-2 WILL NOT CONTROL THE DL15-30W

LIGHTSTICK PROPERLY WITHOUT FIRST SETTING THIS JUMPER.

1. Remove the four recessed

Philip head screws (two on

each side of the control box).

2. Remove the top cover by

sliding it towards the back of

the unit.

-8-

Page 12

(Optional TD77-2 Controller CONT’D)

TD77-2 Jumper Setting for use with the DL15-30W

1. Locate the “Option” jumper location near the center of the board. (See diagram below).

TD77-2 Controller (DL15-30W Mode)

Move Jumper

from 1st pair

To use the TD77-2 with the DL15-30W, YOU

MUST remove the jumper on the 1st pair of pins

!

and turn it sideways over the bottom row of the

1st and 2nd pair of pins.

2. The first set of pins (see above) will have a jumper on them. Remove this jumper from

the first pair of pins and place it over the bottom pins of the first and second pair of pins

as pictured above.

3. Replace the cover of the TD77-2, taking care not to over tighten the screws.

-9-

Page 13

(Optional TD77-2 Controller CONT’D)

Connection of the DL15-30W wires to the TD77-2

+12 VDC

EMPTY

EMPTY

EMPTY

EMPTY

YELLOW

GREEN

VIOLET

WHITE

BLACK

GROUND

RED

1 2 3 4 5 6 7 8 9 10 11 12

CONTROL WIRES

GROUND TO

LIGHTSTICK

OUTPUT POWER

BATTERY +

BATTERY -

TO LIGHTSTICK (+12VDC)

1. The TD77-2 control box comes with a removable green terminal block connector on the back

(part #CPSS-153). Remove the terminal block from control box and loosen all 12 terminal

screws. This will open the wire entries.

2. Make the wire connections as shown above, taking care to tighten down each screw once the

appropriate wire is inserted.

Wires From DL15-30W

Yellow: Connect the yellow wire from the lightstick to Terminal 1 of the green

Violet: Connect the violet wire from the lightstick to Terminal 2 of the green

Green: Connect the green wire from the lightstick to Terminal 3 of the green

White: Connect the white wire from the lightstick to Terminal 4 of the green

Black: Connect the black wire from the lightstick to Terminal 9 of the green

Red: Connect the red wire from the lightstick to Terminal 10 of the green connector.

Additional Connections

Ground: Using a minimum 18 AWG wire, connect this terminal to the negative of the vehicle

+12 VDC: Using a minimum 18 AWG wire, connect this terminal to a +12 VDC source, fused

3. After all of the connections are complete, insert the terminal block into the mating receptacle in

the back of the control box and tighten the two terminal block locking screws on either end of

the block to prevent it from vibrating loose.

connector. This wire activates the Left Arrow pattern on the arrow stick.

connector. This wire activates the Center Out pattern on the arrow stick.

connector. This wire activates the Right Arrow pattern on the arrow stick.

connector. This is the Pattern Select wire for the arrow stick. This wire is

optional and may be left unconnected if you do not want the user to change

your pattern options.

connector. This is the Ground wire to the arrow stick.

This wire supplies +12VDC to the arrow stick.

battery (recommended) or a good chassis ground.

with a 15A fuse at the source (battery). Star recommends the use of an ignition

switched source to avoid the possibility of draining the vehicle's battery should the

unit be accidentally left on. The lamp brightness will be somewhat diminished if a

large voltage drop exists between the vehicle's battery and the controller. It is

imperative that you supply a ground wire to the terminal marked “GROUND” ("bat -"

on the controller). You must not let the controller's case supply ground.

-10-

Page 14

(Optional TD77-2 Controller CONT’D)

TD77-2 Operation

TD77-2

(Optional Controller w/LED Display)

On/Off

Use the red rocker switch (located on the left side of the front panel of the controller) to

activate both the traffic director and the control box. When you switch it on, the stick will

automatically display the Warning Pattern (the WARN button will be illuminated in red – the

color indicating it has been activated). The LED display on the front of the controller will

mimic the output of the stick.

Changing the Traffic Directing Direction

Press the Left, Center, Right, and Warn buttons to toggle the different directional functions

of your stick. The text back light will go from green to red when the stick is operating in the

selected function. Pressing the same directional function a second time will default the stick

back to the Warn pattern.

Changing the Pattern Style

1. The ALT button on the controller will allow you to set two pattern options:

2. To select the Warning Pattern, activate your light by turning on the power switch. When

first activated, the stick should be in Pattern 1 (Alternating Slow Single (1-5 vs. 6-10)).

3. You may cycle through the different patterns, shown on the page 7, by briefly pressing

the ALT button until the lights de-activate, then releasing it. Touch and release the ALT

button until you find the desired pattern.

4. Once you have found the desired Warning Pattern, you can turn the light off. The light

will “remember” the last selected pattern when switched off and that pattern will be displayed

the next time the light is switched on.

5. After the Warning Pattern is selected, you can also select the style of the Traffic

Directing Pattern you wish to use (see list on page 7).

6. With the power switch turned back ON, activate one of the other switches (LEFT, C-O,

or RIGHT) to place the bar into Traffic Directing Mode. Once again, touch and release

the ALT button and it will scroll through the six different display styles listed in the chart

on page 7. Once you have found the desired style, switch the light off.

PLEASE NOTE: The LED display only indicates what MODE you are in (i.e. Off, Left, Center,

Right, or Warn). It will not mimic the exact pattern STYLE. Changing (scrolling through) the

STYLES will not affect the LED display.

1. The Warning Pattern

2. The style of your Traffic Directing Patterns

(See the list on page 7)

-11-

Page 15

(Optional TD77-2 Controller CONT’D)

TD77-2 Pattern Display LEDs

The four left most LEDs of the LED display on the front of the controller will mimic the

output of the stick (LEFT, RIGHT, CENTER, WARN).

• The four right amber LEDs are tied into the

outputs controlling your light bar, they will

always be lit, it is recommended you cover

these LEDs with the provided sticker. Place

the top of the sticker over the LEDs and wrap

it around the bottom of the controller, as

pictured to the right.

• For these LEDs to be accurate, you MUST have the bar wired properly with the wires

exiting on the drivers side and have a correctly functioning light stick.

• These LEDs simply show the basic pattern selected, the operation of the stick will

vary depending on the pattern selected by the user for each of the directional

functions.

Optional TD850 Controller

TDC850

(Optional Controller for use w/SVP sirens)

If you are installing the DL15-30W in a vehicle that has an SVP siren with Traffic Director

controls (i.e. LCS850, or LCS881), you may choose to control your DL15-30W with the

optional TDC850 controller (ordered separately) and the switches built into the siren.

-12-

Page 16

(Optional TDC850 Controller CONT’D)

TDC850 Option Jumpers

TDC850 Control Box Cover Removal

1. Remove the four recessed Philip head screws

(two on each side of the arrow stick control box).

2. Remove the top cover by sliding it towards the

front of the unit.

3. Locate the extra jumper location near the fuses. Also find the “Option” jumper location

near the center of the board. (See diagram below).

4. There are seven jumpers located inside the TDC850 that can control different options.

By default six of the jumpers are located on the Extra Jumper pins.

5. The 7th jumper will be in the “Phantom Mode” position over the 1st pair of jumpers.

Remove this jumper from the 1st pair of pins and place it over the bottom pins of the 2nd

and 3rd pair of pins as pictured below.

TDC850 Controller (DL15-30W Mode)

!

Phantom Mode (REMOVE

THE JUMPER FROM

THIS PAIR!!!)

Pattern Select wires

controlled by +12VDC

Extra Jumper Locations

Control Wires

switched by Ground

Remove the jumper on the 1st pair of pins

and turn it sideways over the bottom row of

!

the 2nd and 3rd pair of pins (as pictured

here) for DL15-30W Traffic Directing Mode

Move Jumper from 1st

pair across bottom pin

of 2nd and

3rd pair

-13-

Page 17

(Optional TDC850 Controller CONT’D)

6. OPTIONAL: There are two other jumpers that can be used when connecting other brand

lightsticks that have either a +12VDC activated pattern select wire or control wires that

are activated by connection to Ground. Please call our Customer Service Department at

585-226-9787 for details on this.

Arrow Stick Wiring Connections

The arrow stick control box (TDC850) comes with a removable green terminal block connector

(Power Connector). Remove the terminal block from control box.

Loosen all 12 terminal screws. This

will open the wire entries. Make the

power wire connections as shown

below, taking care to tighten down

TDC850 Arrowstick Controller

each screw once the appropriate wire

is inserted into the proper terminal.

After all the power connections are

complete, insert the terminal block

into the mating receptacle in the back

of the control box. Tighten the two

terminal block locking screws on

either end of the block to prevent it

from vibrating loose.

YELLOW

EMPTY

1 2

Black: Ground wire to the arrow stick.

Green: Activates Right Arrow on the arrow stick.

Yellow: Activates Left Arrow on the arrow stick.

Violet: Activates Center Out pattern on the arrow stick.

White: This is the Pattern Select wire for the arrow stick. It is optional and only

GREEN

BLACK

EMPTY

3

4

CONTROL WIRES

5 6

WHITE

VIOLET

(OPTIONAL)

EMPTY

7

EMPTY

8 9 10

OUTPUT POWER TO LIGHTSTICK (+12VDC)

RED

GROUND

11 12

+12 VDC

BATTERY +

BATTERY -

needs to be wired into the connector if you desire to change your

Red: This is the +12Voutput to supply power to the arrow stick.

Ground: Connect to good chassis ground, or the negative of the vehicle battery. It is

pattern options.

imperative that you supply a ground wire to the terminal marked "bat -"

+12 VDC: Connect to a fused, 12 VDC source.

on the controller; you must not let the controller's case supply ground.

Star recommends the use of an ignition switched supply to avoid the

possibility of draining the vehicle's battery should the unit be

accidentally left on. The lamp brightness will be somewhat diminished if

a large voltage drop exists between the vehicle's battery and the

controller. If voltage drop is a problem, use a relay to control a direct

battery feed. A generic relay designed for automotive lamp service

should be available from most automotive stores for this purpose. If

using a relay, don't forget to fuse the feed and signal wires at their

source, with appropriate values. For non-LED arrow sticks, use 12

AWG wire for all power and ground connections.

-14-

Page 18

(Optional TDC850 Controller CONT’D)

A telephone style cable splitter is provided with the siren. Follow the instructions

included with your siren for proper connection of the siren amp, siren/light controller,

and TDC850.

Arrow Stick Pushbutton Switches

The S1 Light Control Switch will be used to change the pattern of the lightstick. Press and

release the S1 button to change the pattern. The Warning Pattern has thirty (30) different

options/patterns you can select. The Traffic Directing Patterns (R,L,C,O) have six (6)

different options. For the complete pattern/option listing, please see page 7.

The WLRCO push button toggles the arrow output through a different pattern with each

push. (Warning, Left arrow, Right arrow, Center out arrow, and Off). The four LED arrows

to the left of the WLRCO button provide feedback as to the output of the arrow stick.

LCS880 Control Head

OFF L1 L2 L3

S1 S2 S3

HFHORNMAN YELPWAIL

LRCO

Light control button S1 will be

used to change lightstick pattern

-15-

S4 S5

RADIOPHSR

WARN

Page 19

Stick Adjustment

After the light is securely installed, loosen the adjusting

screws located on each end of your light. Tilt the light to

the desired angle and tighten the screws. Turn the light

on and check the light from the front or rear of the

vehicle, through the window (if applicable), to ensure that

it is at the most desirable angle, and that the light is not

impeded by any obstacles and/or window tinting

Parts

Adjusting Screw Washers P30072-3

Short (1-¾") Mounting Legs DL15-BKT-S

Medium (2-7/8") Mounting Legs DL15-BKT-M

Tall (5") Mounting Legs DL15-BKT-T

Kit w/1 pair each: Short, Medium, & Tall Legs DL15-SMTK

Optional 4-Switch Switch Panel SP1515-TDC

Optional Controller w/ LED Display TD77-2

Troubleshooting

The DL15 uses state-of-the-art Light Emitting Diode (LED) technology. This warning

light is comprised of ultra-high intensity LEDs that are operated by a micro-controller

to efficiently produce light output with lifetimes up to 100,000 hours. Under normal

circumstances, you will not need to replace any lights in this warning light.

Symptom

No power Power source not turned on

Odd flash

pattern

Directional

buttons

reversed

Possible Cause

Power hooked up backwards

Positive ground vehicle

Connector loose

Fuse blown

Loose connection at power source

Programmed for a random flash

pattern

Jumper not set properly

Mis-wired controller

Traffic director mounted upside

down

Is ignition switch an EXTERNAL SWITCH?

Check that Power and Ground wires are correct

Check vehicle’s owner’s manual to be sure

vehicle is NOT positive ground.

Check connector

Is an external fuse or circuit breaker used?

Check wires connected to +12VDC

Are the negative leads connected to a good

ground?

Try cycling the patterns.

See jumper setting instructions.

Swap left and right control wires.

Turn Traffic Director over or swap left and right

control wires.

Check

-16-

Page 20

LED FIVE YEAR LIMITED WARRANTY

The manufacturer warrants this LED light against factory defects in material and workmanship for

five years after the date of purchase. The owner will be responsible for returning to the Service

Center any defective item (s) with the transportation costs prepaid. The manufacturer will, without

charge, repair or replace at its option, products, or part(s), which its inspection determines to be

defective. Repaired or replacement item(s) will be returned to the purchaser with transportation

costs prepaid from the service point. A copy of the purchaser's receipt must be returned with the

defective item(s) in order to qualify for the warranty coverage. Exclusions from this warranty

include, but are not limited to, domes, and/or the finish. This warranty shall not apply to any light,

which has been altered, such that in the manufacturer's judgment, the performance or reliability

has been affected, or if any damage has resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of merchantability or fitness),

which extend this warranty period. The loss of use of the product, loss of time, inconvenience,

commercial loss or consequential damages, including costs of any labor, are not covered. The

manufacturer reserves the right to change the design of the product without assuming any

obligation to modify any product previously manufactured.

This warranty gives you specific legal rights. You might also have additional rights that may vary

from state to state. Some states do not allow limitations on how long an implied warranty lasts.

Some states do not allow the exclusion or limitation of incidental or consequential damages.

Therefore, the above limitation(s) or exclusion(s) may not apply to you.

If you have any questions concerning this or any other product,

please contact our Customer Service Department at (585) 226-9787.

If a product must be returned for any reason, please contact our Customer Service Department to

obtain a Returned Materials Authorization number (RMA #) before you ship the product back.

Please write the RMA # clearly on the package near the mailing label.

-17-

Loading...

Loading...