Page 1

INSTALLATION AND INSTRUCTION MANUAL

SABRE

SABRE

SABRESABRE

LIGHTBARS

LIGHTBARS

LIGHTBARSLIGHTBARS

Owner's Manual & Installation Instructions

Owner's Manual & Installation Instructions

Owner's Manual & Installation InstructionsOwner's Manual & Installation Instructions

PLITSTR325 REV F 8/4/11

Page 2

!

When mounting your lightbar, please be sure to keep any radio frequency

sensitive equipment at least 20” from the bar and power cable(s). This is

especially critical in lightbars utilizing strobes. Our strobe power supplies

have been designed to limit RFI emissions, but certain very sensitive

equipment may still be affected. Symptoms may include, but are not

limited to, sporadic operation and degraded performance. Star Headlight

& Lantern Co., Inc. cannot assume any responsibility for any radio

frequency induced malfunction or damage to any radios, sirens, lightbars,

or any other equipment mounted within 20” of a strobe lightbar. Any

antennae mounted in the proximity of the lightbar may cause your radio to

suffer the aforementioned results.

PLEASE NOTE: THE DIRECT MOUNT IS THE

STANDARD MOUNT INCLUDED WITH THE LIGHTBAR.

THE HOOK MOUNTS MUST BE USED ON ALL POLICE

AND/OR OTHER EMERGENCY VEHICLES!!!

THE HOOK MOUNTS ARE SOLD SEPARATELY. THEY

ARE NOT INCLUDED WITH EACH LIGHTBAR. THEY

MUST BE ORDERED SEPARATELY. SEE THE

ACCOMPANYING HOOK MOUNT MANUAL FOR A

COMPLETE LIST OF AVAILABLE MOUNTS AND

KNOWN VEHICLE APPLICATIONS.

I

t is the sole responsibility of the owner to ensure the lightbar is

mounted securely. Check your light every time you enter the

vehicle to ensure that it is mounted securely. The manufacturer

assumes no responsibility for the secure mounting of this light.

-i-

Page 3

Please Note: These instructions are provided as a general guideline only. Specific

mounting, wiring, and/or weather-sealing may be necessary and are the sole

responsibility of the installer. Star Headlight & Lantern Co., Inc. assumes no

responsibility for the integrity of the installation for this or any of its products.

WARNINGS i

QUICK-INSTALL WIRING GUIDE 1-2

Table of Contents

MOUNTING INSTRUCTIONS 3

(For Mounting see Mounting Bracket Manual)

WIRING INSTRUCTIONS 3-10

Direct Wiring Guide 3-4

Electrical Connections 5

Wire Functions 6

Strobe Power Supply Connections 7-10

PATTERN PROGRAMMING 11-14

Strobe Pack Flash Patterns 11

LED Flash Patterns 12-14

PARTS 15-17

SWITCHES 17

TROUBLESHOOTING 18-20

WARRANTY 21

SERVICE 21

Due to continuous product improvements, we must reserve the right to change any specifications and information,

contained in this manual at any time without notice. Star Headlight & Lantern Co., Inc. makes no warranty of any

kind with regard to this manual, including, but not limited to, the implied warranties of merchantability and fitness

for a particular purpose. Star Headlight & Lantern Co., Inc. shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this manual.

-ii-

NOTICE

Page 4

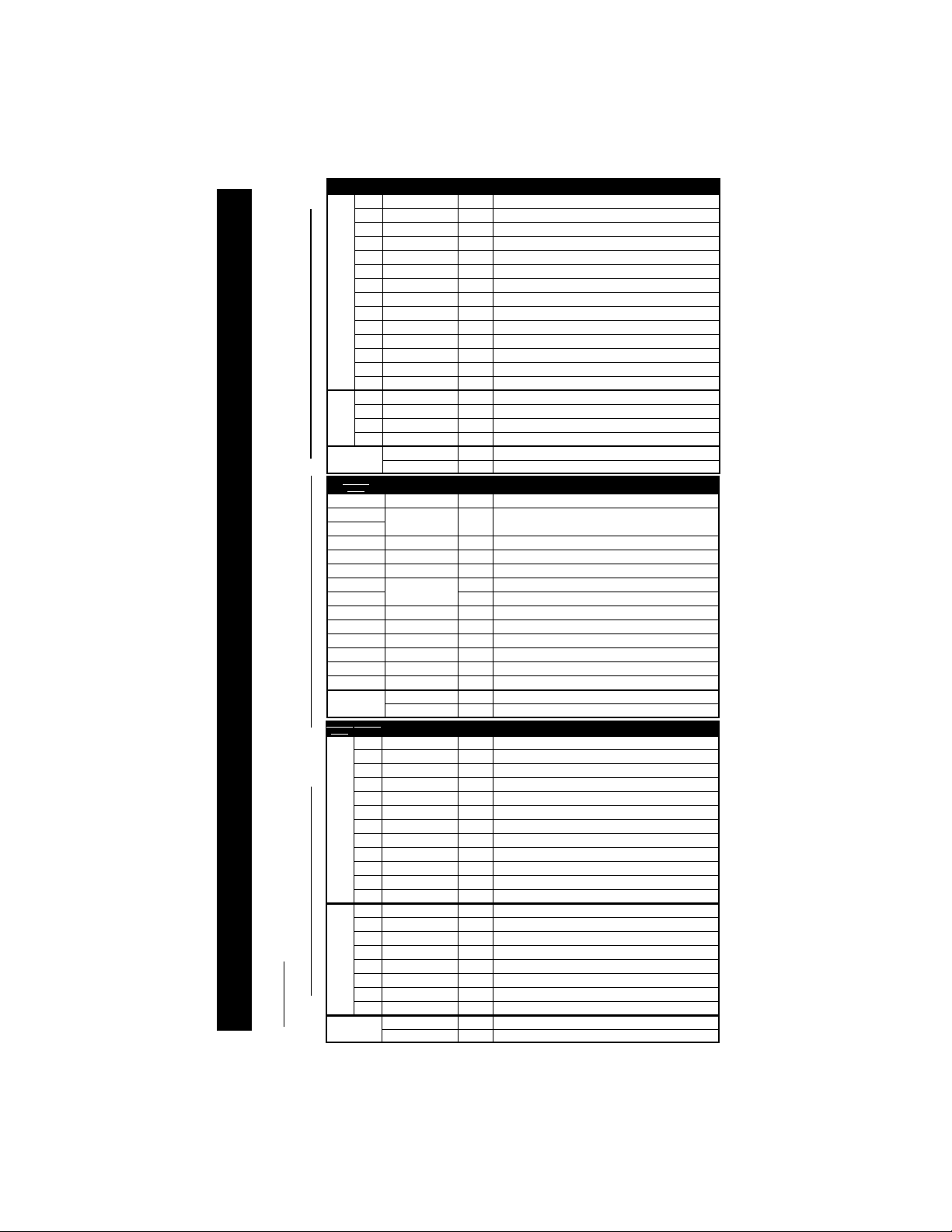

Terminal

Terminal

Terminal

Terminal

Terminal Terminal

Block

Block

BlockB lock

A

P271-RAZOR

B

CONNECTED

Wire Harness for Bars Without Stop/Tail/Turn Lights

P271-TOWBAR Layout 1

CONNECTED

Terminal

Terminal

Terminal Terminal

Wire Harness for Bars with Incandescent STT Lights

Block

Block

BlockBlock

QUICK-INSTALL WIRING GUIDE

P271-TOWBAR Layout 2

Wire Harness for Bars With LED STT Lights

Please Note: If your lightbar has an LED or incandescent traffic director in it, there will also be a separate bundled 9-conductor cable specifically for that function.

CONNECTED

TerminalTerminal

TO BASE

Terminal

Terminal

TerminalTerminal

Block

Block

BlockB lock

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TO BASE

Terminal

Terminal

TerminalTerminal

A

B

TO BASE

Color AWG Function

1

Blue 18 Driver side Alley

2

White w/Blue 18 Intersection Clearing Lights

3

White w/Yellow 18 Front Corner

4

Orange w/Yellow 18 Front Outboard

5

Brown w/Yellow 22 Front Inboard and Ends

6

Red 14 Power

7

Red w/Green 22 Pattern Select

8

Purple 22 High/Low Power (Ground for Low)

9

Green w/Yellow 18 Lower Level Takedowns

10

Red w/Black 18 Upper Level Takedowns or AUX

11

White w/Brown 18 Front Pursuit

12

Green w/Red 18 Rear Center or TD Warn

13

Brown w/Red 22 Rear Inboard or TD Left

12

Orange w/Red 22 Rear Outboard or TD Right

1

White w/Red 18 Rear Corner (rear ICL)

2

Yellow w/Black 18 Cruise

3

White w/Black 18 Alley w/Flash

4

Gray 18 Passenger Alley

Black 10 Ground (Battery Negative)

Bare 18 Shield/Drain (Battery Negative)

Color AWG Function

Light Blue 16 Driver Side Alley Light

Orange 14 Rotators

Yellow 16 Left Stop Light

Green 16 Right Stop Light

White/Orange 14 Work Lights

Brown

Red 14 Strobe Power

Red/White 14 Power for Optional Components

Red/Green 22 Strobe Pattern Select

Black/Green 22 Strobe Head Select 1

White/Green 22 Strobe Head Select 2

Gray 16 Passenger Side Alley Light

Black 10

Bare 18

Color AWG Function

1 OPEN OPEN

2 OPEN OPEN

3 OPEN OPEN

4 Blue OPEN or Driver Alley or Steady Burn Alley

5 Orange 16 Front LEDs

6 W hite w/Orange 14 Rear Work Lights

7 Red 14 Power

8 Red w/White 14 Rear LEDs

9 Red w/Green 22 Pattern Select

10 Black w/Green 22 Strobe Control 1 or OPEN

11 W hite w/Green 22 Strobe Control 2 or OPEN

12 Gray 16 OPEN or Passenger Alley

1 Yellow 16 Left ( Driver) Turn Signal

2 Di ode Red 6” Wire

3 OPEN OPEN

4 Green 16 Right (Passenger) Turn Signal

5 Di ode Red 6” Wire

6 OPEN OPEN

7 Brown 18 Tail Lights

8 Diode Red 6” Wire/Power

BLACK 10 Ground (Battery Negative)

BARE 18 Shield/Drain (Battery Negative)

18 Tail Lights/I.D. Lights

OPEN

Ground (Battery Negative)

Shield/Drain (Battery Negative)

-1-

Page 5

Wire Harness for Bars With Rotators

Wire Harness for Bars with Strobe Lights

P271-ROTATOR

CONNECTED

P271-STROBE

CONNECTED

Terminal

Terminal

TerminalTerminal

1

2

3

4

5

6

7

8

9

10

11

12

TO BASE

Terminal

Terminal

TerminalTerminal

Block

Block

BlockBlock

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TO BASE

COLOR

COLOR AWG

COLORCOLOR

Blue 16 Driver Side Alley

White w/Brown 16 Front Flashers

White w/Blue 18 Intersection Clearing Lights

Green w/Yellow 14 Front Takedown/Worklights

Red w/Green 22 Pattern Select or OPEN

Orange 14 Rotators

Red w/White 14 Alternate Power

Orange w/Black 14 Alternate Rotators

White 16 Rear Flashers

Orange w/Red 16 Alternate Rear Flasher

Gray 16 Passenger Side Alley

Black 10 Ground (Battery Negative)

Bare 18 Shield/Drain (Battery Negative)

Color AWG Function

Light Blue 16 Driver Side Alley Light

White w/Brown 16 Pursuit

White w/Blue 18 Intersection Clearing

Green w/Yellow 14 Takedowns

Red 14 LED Power

Red w/Black 14 Driver Side or Lower Front Pattern

Red/White 14 Synchronization

Red/Green 22 Passenger Side or Lower Front Pattern

Black/Green 22 Rear Enable

White/Green 22 F ront Enable

Orange 14 OPEN

White 16 Rear Flasher

Orange w/Red 16 High/Low Power

Gray 16 Passenger Side Alley Light

Black 10

Bare 18

AWG

AWGAWG

FUNCTION

FUNCTION

FUNCTIONFUNCTION

Ground (Battery Negative)

Shield/Drain (Battery Negative)

QUICK-INSTALL WIRING GUIDE

Please Note: If your lightbar has an LED or incandescent traffic director in it, there will also be a separate bundled 9-conductor cable specifically for that function.

-2-

Page 6

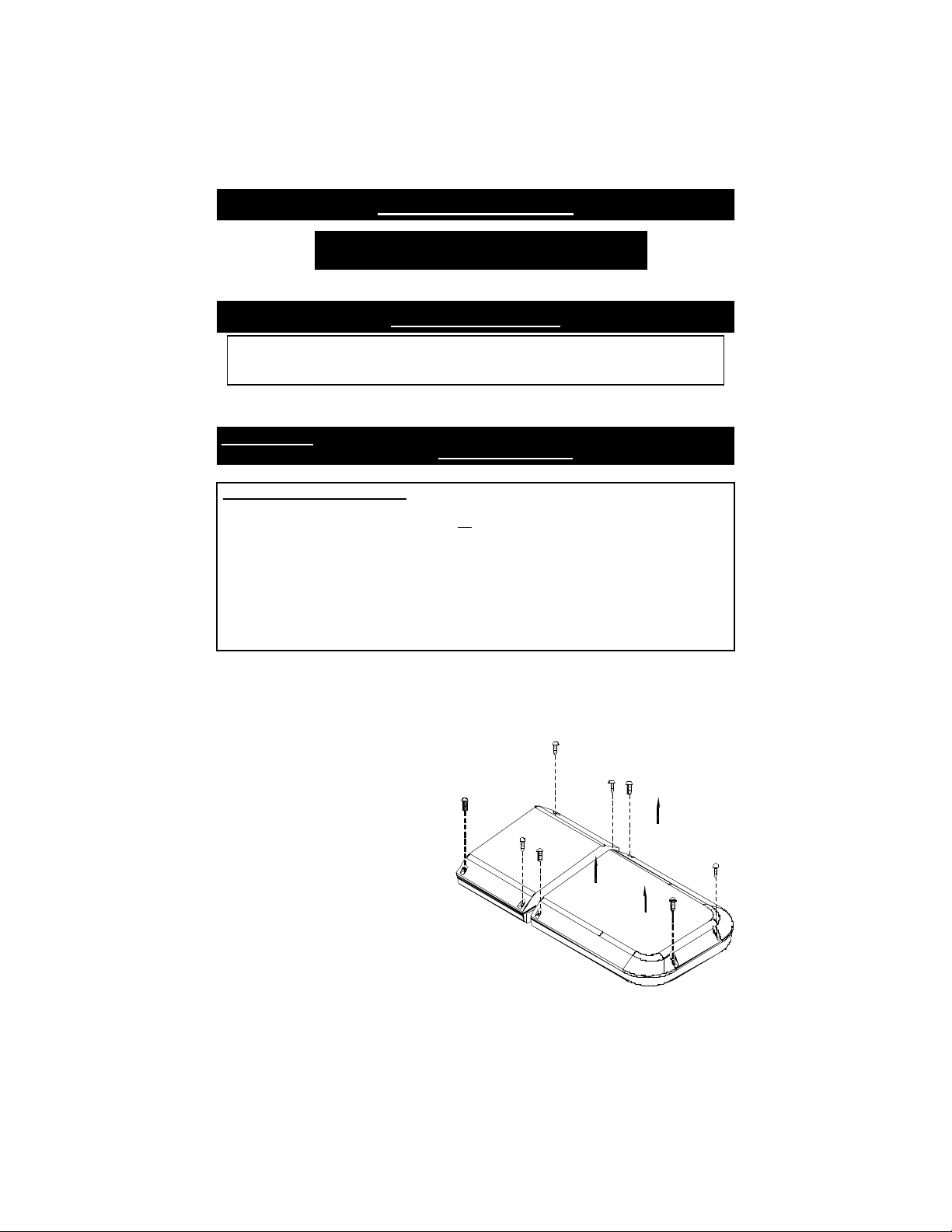

Mounting Instructions

Please review the separate Mounting Bracket manual that

is also enclosed with your bar for mounting instructions.

Wiring Instructions

All standard lightbar models are designed for 12VDC negative ground vehicles

only. Reverse polarity will cause serious damage to the lightbar and/or vehicle.

Contact the automotive dealer if there are any doubts about the polarity of your vehicle.

Direct Wiring Guide

PLEASE NOTE: If you are using the existing 15-foot cable supplied with the lightbar,

If the wire supplied is too short, Star recommends direct wiring to the terminal block on

the inside of the lightbar, rather than making connections to the end of the wire that is

supplied. This lightbar is designed so that no wire connectors are needed and only a few

common tools are necessary in order to do this. Direct wiring allows the wire connections

to the lightbar to be made in a clean and dry environment, avoiding any problems that may

arise due to weathering on external connections. There is also an increase in voltage loss

with the addition of each connection. Wiring directly inside the lightbar reduces the number

of connections. However, making connections to the wires already provided is an

acceptable alternative, as long as these connections are good electrical connections and

are resistant from weathering effects. For direct wiring into the lightbar, follow the

instructions listed below.

you may skip to the Electrical Connections section on page 4.

1. Determine the number of wires that you will need to run. This can be done by counting

the number of wires coming out of your lightbar.

2. Using the Wire Usage Table on page 10, identify your wires and select appropriate wire

sizes and colors.

3. Locate the end of the lightbar that has

the external wires entering the base of

the lightbar. The black terminal block

(s), which you will be making your

wire terminations to, should also be

located at this same end.

4. Remove the dome lens at this

end of the lightbar:

Step 1 : Loosen the four screws

holding each dome on.

Step 1

Step

2

Step 2 : Lift the dome off of the base,

exposing the interior

components.

Step 3 : When all work is completed,

reverse the steps to reinstall

the dome, taking care that

the gasket is properly

aligned.

-3-

Page 7

(Direct Wiring Guide CONT’D)

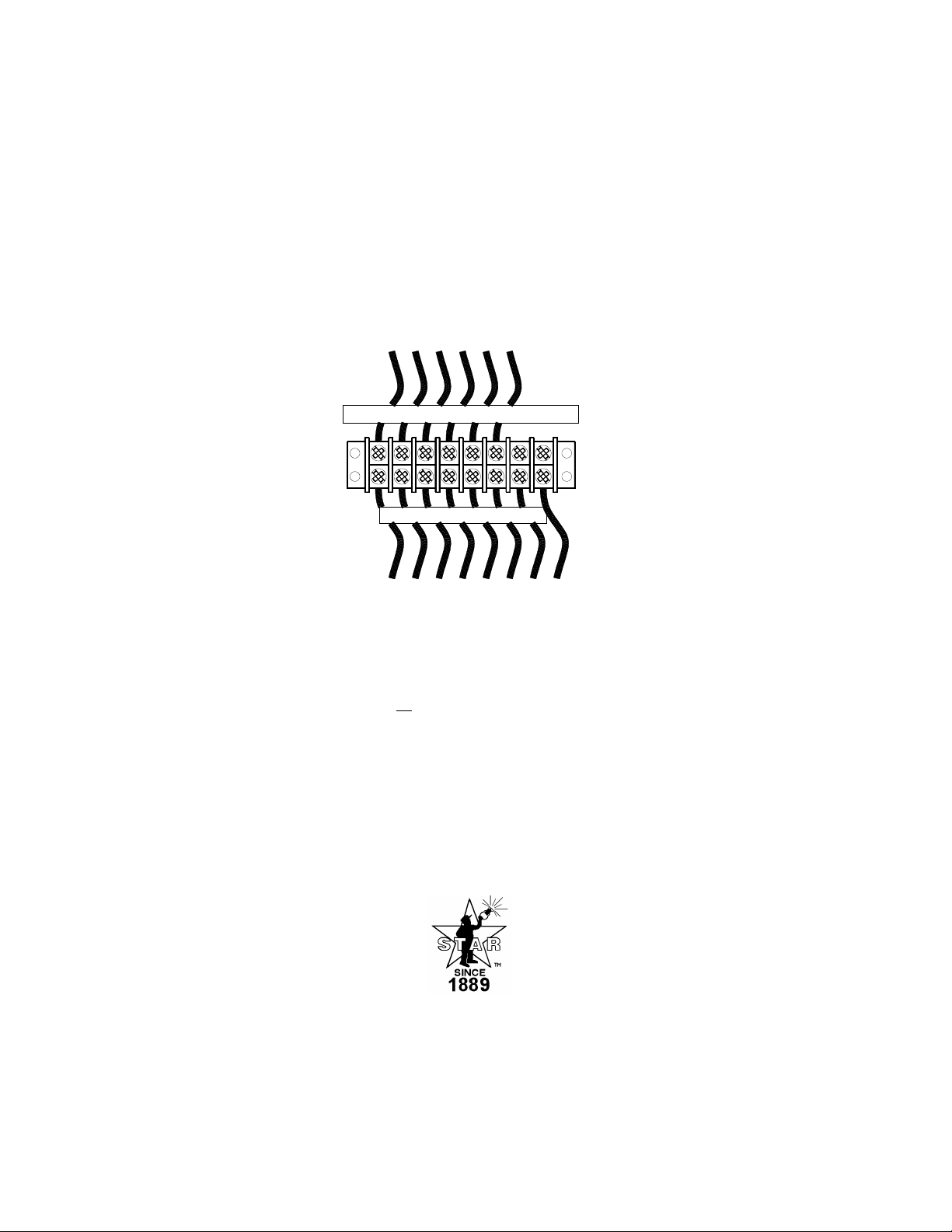

5. All of the wires coming from outside of the lightbar are terminated on the same side of

the terminal block and the wires leading to the internal components terminate on the

opposite side of the terminal block. Loosen the screws on the terminal block and

remove only those wires that exit the lightbar through the hole in the base. There

may be “dead” wires from the harness connected to the terminal block inside your

lightbar, but there will be no wires connected to the terminal across from them. These

are extra wires in the harness that are not used. Replacing these wires in your new

harness is not necessary.

From Lightbar Components

From Wire Harness

These

Remove

6. Run the new external wires up through the wire bushing into the base and into the

terminal block(s). The function of each of the colored wires in the original wiring harness

is listed in the Wire Harness Usage Table on page 1. There should also be a label next

to the terminal block indicating which color wire should be connected to each terminal.

7. Strip each wire 1/4". Connect the external wires to the proper poles of the terminal

block by inserting the stripped portion of the wire under the rising clamp screw and

tightening down the screw. No wire terminals are needed for connecting wires to this

terminal block.

Be sure to check that no strands of wire are loose and shorting to the

adjacent terminal or to the base of the lightbar.

The correct wire size and color listed in the table on page 1 corresponds directly with the

wiring of the lightbar. All switches used should be rated for at least 125% of their rated load.

8. Once your new wire harness has been connected to the lightbar, you may continue to

the Electrical Connections section.

-4-

Page 8

Electrical Connections

All standard lightbar models are designed for 12VDC negative ground vehicles

only. Reverse polarity will cause serious damage to the lightbar and/or vehicle.

Contact the automotive dealer if there are any doubts about the polarity of your vehicle.

RF INTERFERENCE

Please take the following steps to help eliminate any Radio Frequency Interference (RFI)

with your two-way radio.

• DO NOT run the power wire for the lightbar along same path as any antenna wires.

• DO NOT run the power wire for the lightbar along same path as any radio power wires.

• DO NOT tap power for the lightbar off of the radio power wires.

• DO NOT mount the lightbar within 20” of any antennae. Sometimes mounting the

lightbar or antenna over by just one foot can make a large difference in the interference.

• Ensure the black wire from the lightbar has a good connection to the negative side of

the battery.

• For all standard lightbars, 15 feet of cable (usually including a drain wire and a foil shield)

is supplied with the bar. All wires are color coded and sized at the correct gauge. If this

length is not sufficient, it is recommended that the wire harness be completely replaced

with the only connections to be made directly at the terminal block inside the lightbar.

This will reduce the number of wire connections and help prevent any weathering

problems on these connections. Refer to the Direct Wiring Guide on pages 3-4 for further

instructions on this.

• CAUTION: All wires and switches should be rated for at least 125% of their

maximum current load. In addition, all wires connected to the positive terminal of the

battery should be fused at the battery for 125% of their rated load. The load can be

calculated by adding all lamp wattages and dividing by 13. (Load <Amps> = Total

Watts / 13 volts) Do not use 1/4" diameter glass fuses, as they are not suitable for

continuous duty above 20 amps. A table of recommended wire colors and wire sizes is

provided on page 1. If you are unsure of the current draw, please contact our Customer

Service Department.

• TESTING THE LIGHTBAR BEFORE IT IS PROPERLY FUSED & INSTALLED WILL

VOID THE WARRANTY!!

• The black ground wire should be connected to the negative terminal of your vehicle’s

battery. This wire should be at least #10 AWG wire and be as short as possible in order

to minimize the voltage loss in this wire and reduce any chance of overheating.

• Since many of the lightbars we build have custom components, occasionally wire colors

may slightly vary. If you are unsure of the function of a particular wire, you may test the

function by grounding the black wire and applying +12VDC to the wire in question. Be

sure to use a 20-amp fuse when testing.

-5-

Page 9

Wire Functions

PLEASE NOTE: There are three different harnesses that could be installed on your lightbar.

Please review the Quick-Install Wiring Guide on page 1 for proper connection of your wires.

Your harness will contain all of the colored wires, the drain wire, and the foil shield, but

most applications will not use every wire. The “dead” wires in the harness will be

connected to the terminal block inside your lightbar, but there will be no wires connected

to the terminal across from them. These “dead” wires can be used for additional

components that may be added at some point in the future, or they may be used to

separately switch components that are currently wired together.

Black: (GROUND) - The black wire is the ground wire and MUST be connected

on EVERY lightbar.

Red: (Power/+12VDC) - The red wire provides the main power to the LED

flashers and/or strobe packs. Connect the red wire directly to continuous

+12VDC through a high-current fuse.

Please Note: When the red wire is connected to +12VDC the pack

will draw a small current (50 mA). If your vehicle will be

sitting for extended periods of time (i.e. more than a

few days), it is recommended the red wire be routed

through a switch or ignition switched relay.

Bare Wire: (Drain/GROUND) - This wire will help eliminate RFI. We recommend that it

be connected to ground.

Purple: (High/Low Power) - The purple wire is optional and can be used to switch

LED applications to low power. Connect the purple wire to ground to

operate the bar under low power.

Red w/Green: (Pattern Select/Touch and Release to +12VDC) - The red w/green stripe

wire is used to select the flash pattern of your LEDs or strobes. It will

normally be left unconnected. (For more detailed instructions, see

Pattern Programming on pages 8-10).

Please note: If you have a lightbar with a strobe pack or LED

flasher, the Red w/Green Stripe wire is only used when

programming the flash pattern. This wire MUST NOT be connected

to continuous +12VDC!!! Once the pattern has been selected, tape

the end of this wire off. (See pages 8-10)

All Other Colors: The remaining wires are typically On/Off controls for the lights shown in the

corresponding Quick-Install Wiring Guide on the page 1. Most applications

will not use every color wire.

Connect the wires that your lightbar utilizes to +12VDC through your switches

(not included). The “dead” wires (not needed) will be connected to the terminal

block inside your lightbar, but there will be no wires connected to the terminal

across from them. These wires do not need to be connected at the other end

of the harness.

-6-

Page 10

Remote Strobe Power Supply Connections For Linear Strobe Heads

If your lightbar contains linear strobe heads, follow the instructions below for proper wiring

of the strobe power supply. Please note that any additional lights in your lightbar must

also be connected to +12VDC through a switch. This section only discusses the proper

wiring of the strobe power supplies. For each strobe head configuration, you will be shown

two ways to wire the lightbar:

1. All strobe heads turn On and Off together

2. Separate activation of Front and Rear facing strobe heads

Lightbars with Two or Four Linear Strobe Heads

4 2

RP249-L

3

1

Four wires in your cable harness control the strobe power supply and the strobe heads

connected to it: The functions of those wires are as follows:

Red - Power to the strobe power supply

White w/Green Stripe - On/Off control for Front Linear Strobe Heads

Black w/Green Stripe - On/Off control for Rear Linear Strobe Heads

Red w/Green Stripe - Pattern Select

Activating All Strobe Heads Together

(MOST APPLICATIONS)

To turn on all four heads connected to the power supply together, connect the Red, White

w/Green Stripe, and Black w/Green Stripe together through your switch. When the switch

is thrown, all of your strobes will flash. (#1 & #4 will alternate with #2 & #3)

Harness from

Lightbar

Red

White w/Green

On/Off

SWITCH

CONNECT

TO +12 VDC

Black w/Green

Touch and Release To

Red w/Green

+12VDC to Change Pattern

DO NOT PERMANANENTLY

CONNECT Red w/Green

!

Stripe TO +12VDC!!!

Proceed to the Pattern Programming section on page 11 to program the flash pattern of your

strobe pack.

-7-

Page 11

(Strobe Pack Connections For Lightbars With 4 Linear Heads CONT’D)

Activating the Front and Rear Strobes Separately

If you would like the ability to switch the Front Strobes On and Off separate from the Rear

Strobes, connect the White w/Green Stripe wire to the switch that will activate your Front

Strobes, and connect the Black w/Green Stripe wire to the switch that will activate your

Rear Strobes.

The Red wire must be connected to constant +12VDC.

Please Note: When the red wire is connected to +12VDC the pack will draw a small

current (50 mA). If your vehicle will be sitting for extended periods of time

(i.e. more than a few days), it is recommended this wire be routed through

a switch or a high-current ignition switched relay.

Harness from

Lightbar

Front Strobes

On/Off Switch

White w/Green

Rear Strobes

On/Off Switch

Black w/Green

Red

Please Note: When the Red wire is connected to +12VDC the pack will

draw a small current (50 mA). If your vehicle will be sitting for extended

periods of time (i.e. more than a few days), it is recommended the Red wire

be routed through a switch or a high-current ignition switched relay.

CONNECT TO CONSTANT +12 VDC

CONNECT

TO +12 VDC

CONNECT

TO +12 VDC

Touch and Release To

Red w/Green

+12VDC to Change Pattern

DO NOT PERMANANENTLY CONNECT

!

Red w/Green Stripe TO +12VDC!!!

Note: If you have power to both White w/Green and Black w/Green #1 & #4 will flash together

alternating with #2 & #3. For two outlet packs, the two heads will alternate.

Proceed to the Pattern Programming section on page 11 to program the flash pattern of your

strobe pack.

-8-

Page 12

(Strobe Pack Connections For Lightbars With Linear Heads CONT’D)

Lightbars with Eight Linear Strobe Heads

4A

RP249-L

Front

(Pack A)

4B

3B 2B

2A3A

RP249-L

Rear

(Pack B)

1A

1B

Three wires in your cable harness control the strobe power supplies and the strobe heads

connected to them: The functions of those wires are as follows:

Red - Front Linear Strobe Heads On/Off

Red w/Black Stripe - Rear Linear Strobe Heads On/Off

Red w/Green Stripe - Pattern Select

Note: Heads #1 & #4 will flash together alternating with #2 & #3.

Activating All Strobe Heads Together

(MOST APPLICATIONS)

Harness from

Lightbar

To turn on all eight heads

connected to the power supply

together, connect the Red and

Red w/Black Stripe wires together

through your On/Off switch.

When the switch is thrown, all of

your strobes will flash. (#1 & #4

will alternate with #2 & #3)

Proceed to the Pattern

Programming section on page 11

Red

Red w/Black

Red w/Green

On/Off

SWITCH

CONNECT

TO +12 VDC

Touch and Release To

+12VDC to Change Pattern

DO NOT PERMANANENTLY

CONNECT Red w/Green

!!!!

Stripe TO +12VDC!!!

to program the flash pattern of your

strobe packs.

Activating Front and Rear Strobes Separately

To turn on your front strobe

Harness from

Lightbar

separately from your rear

strobes, connect the Red and

Red w/Black Stripe wires

through two separate switches.

Red

When one switch is thrown, only

the front strobes will flash. (#1 &

#4 will alternate with #2 & #3).

When the other switch is thrown

the rear strobes will flash.

Proceed to the Pattern

Programming section on page 11

Red w/Black

Red w/Green

to program the flash pattern of your

strobe pack.

-9-

Front Strobes

On/Off Switch

Rear Strobes

On/Off Switch

+12VDC to Change Pattern

DO NOT PERMANANENTLY

CONNECT Red w/Green

!

Stripe TO +12VDC!!!

CONNECT

TO +12 VDC

CONNECT

TO +12 VDC

Touch and Release To

Page 13

(Strobe Pack Connections For Lightbars With Linear Heads CONT’D)

Lightbars with Ten or Twelve Linear Strobe Heads

4A 3A

RP249-L

Front

(Pack A)

3B4B

(Pictured above is one example of a bar with 12 linear strobe heads)

RP249-L

Center

(Pack C)

4C

3C

RP249-L

Rear

(Pack B)

2C

1C

2A 1A

1B2B

Four wires in your cable harness control the strobe power supplies and the strobe heads connected

to them: The functions of those wires are as follows:

Red w/Black Stripe

Activating Front and Rear Strobes Separately

(RECOMMENDED FOR MOST APPLICATIONS)

Red w/White Stripe

Red w/Green Stripe

To turn on your front strobe heads

Red

- Front Linear Strobe Heads On/Off

- Rear Linear Strobe Heads On/Off

- Constant Power (+12 VDC) for Center Strobe Pack

- Pattern Select

Harness from

Lightbar

separately from your rear strobes,

connect the Red w/White Stripe wire to

constant +12VDC.

Please Note: When the Red w/White

Stripe wire is connected to +12VDC the

pack will draw a small current (50 mA). If

your vehicle will be sitting for extended

Red

Red w/Black

Front Strobes

On/Off Switch

Rear Strobes

On/Off Switch

CONNECT

TO +12 VDC

CONNECT

TO +12 VDC

periods of time (i.e. more than a few days),

it is recommended the Red w/White Stripe

wire be routed through a switch or a highcurrent ignition switched relay.

Then connect the Red and Red w/Black

Stripe wires through two separate

switches. When one switch is thrown,

only the front strobes will flash. (#1 & #4

will alternate with #2 & #3). When the

Red w/White

Please Note: When the Red w/White Stripe wire is connected to +12VDC

the pack will draw a small current (50 mA). If your vehicle will be sitting for

extended periods of time (i.e. more than a few days), it is recommended the

Red w/White Stripe wire be routed through a switch or a high-current

ignition switched relay.

Red w/Green

CONNECT TO CONSTANT +12 VDC

Touch and Release To

+12VDC to Change Pattern

DO NOT PERMANANENTLY CONNECT

!

Red w/Green Stripe TO +12VDC!!!

other switch is thrown the rear strobes will flash.

Proceed to the

Pattern Programming

section on page 11 to program the flash pattern of your

strobe pack.

Activating All Strobe Heads Together

To turn on all of the strobe heads in your

lightbar together, connect the Red, Red

w/Black Stripe, and Red w/White Stripe

wires together through your switch.

When the switch is thrown, all of your

strobes will flash. (#1 & #4 will alternate

with #2 & #3).

Please note: For this application,

your switch MUST be able to handle

30 amps. This configuration is

usually not recommended, since

most switches are not capable of

handling such a heavy load.

Proceed to the

Pattern Programming

section on page 11 to program the flash pattern of your

strobe pack.

Harness from

Lightbar

Red

Red w/Black

Red w/White

Red w/Green

On/Off

SWITCH

DO NOT PERMANANENTLY

CONNECT Red w/Green

!!!!

Stripe TO +12VDC!!!

CONNECT

TO +12 VDC

Touch and Release To

+12VDC to Change Pattern

-10-

Page 14

Pattern Programming

● Lightbars with LEDs or strobes can be programmed with the user’s choice of flash

pattern.

● If you have both strobes and LEDs in your lightbar,

pack(s) and LED flasher(s) must be done separately

● If you have multiple strobe packs or multiple LED flashers, all of the strobe packs can be

programmed together and all of the LED flashers can be programmed together or each

strobe pack or LED flasher can also be programmed separately, if you desire different

patterns for each.

1. To program the flash pattern turn

wish to program.

only

the strobe pack(s) or LED flasher on that you

2. Briefly touch the red w/green stripe wire to +12VDC and release it. Continue to briefly

touch and release this wire to +12VDC until you find the pattern desired. The pattern

lists for the strobe packs or various LED flashers can be found below and on the

following three pages.

3. Once you have the pattern you like, turn the pack or flasher off. The pack or flasher will

remember the pattern next time it is activated.

4. Repeat steps 1-3 for each additional strobe pack or LED flasher you wish to program.

5. Once your programming is complete, tape the end of the red w/green stripe wire so that

it does not come into contact with +12VDC.

Strobe Pack Flash Patterns

Pattern Warning Pattern Style

1 Alternating Five-Flash

2 Pseudo-Random

3 Alternating Singleflas h

4 Alternating Doubleflash

5 Alternating Quadflash

The strobe packs are defaulted for Five-Flash mode. You can scroll through pseudorandom, singleflash, doubleflash, quadflash, and back to five-flash by touching and

releasing the red w/green stripe wire to +12VDC.

Please note:

If you have only the corner strobes activated (white w/yellow wire or white w/

red wire), heads 1 and 4 will alternate (see the center lightbar layout diagram on page

2). If you have only the front or rear strobes activated (brown w/yellow or brown w/

red) then heads 2 and 3 will alternate. If you activate the corners AND the fronts or

rears at the same time, heads 1 and 4 will flash together, opposite of 2 and 3.

Automatic Power Up Head Check

Each 4-outlet power pack comes with a safety feature which checks for proper operation of each

individual strobe head each time you turn on the strobe pack. This feature works by quickly

flashing each head once separately and determining if any of the heads did not flash. If two heads

normally flash together, and one fails and does not flash during the start up test, the strobe pack

will automatically reduce the output power to that particular side so that the “other” remaining

head(s) isn’t over powered. The power to that side will be reduced until the strobe pack is turned

off and on again and the faulty head tests good.

The 4-outlet strobe pack will check all four heads each time the pack is turned on EVEN if the head

select feature is being used and only two heads are to be activated. After checking all four heads,

the pack will begin flashing normally. It takes approximately 0.250 sec. to check all four heads.

Note: If you replace the non-working head, it is necessary to cycle power to the pack

before that head and the one that flashes with it will start flashing again at full

power. (You should never replace a defective head with the pack activated!!)

programming of the strobe

.

(default)

-11-

Page 15

LED Flash Patterns

Front and Rear DLX6 and Batwing LED Patterns

(LDF375-1 Flasher)

Pattern Warning Pattern Style

2 Alternating Slow Single (1-5 vs 6-10)

3 Alternate Pursuit Mode

4 Alternating Quad Flash (1-5 vs 6-10)

5 Alternating Triple (1,2,6,7,8 vs 3,4,5,9,10)

6 Alternating Quint (1,2,6,7,8 vs 3,4,5,9,10)

7 Simultaneous Slow Single (All Modules)

8 Simultaneous Fast Single (All Modules)

9 Simultaneous Triple Flash (All Modules)

10 Simultaneous Quad Flash (All Modules)

11 Simultaneous Q uint Flash (All Modules)

12 Simultaneous Fast Triple Flash (All Modules)

13 Simultaneous Fast Quint Flash (All Modules)

14 In/Out Single (1,2,9,10 vs 3-8)

15 In/Out Triple (1,2,9,10 vs 3-8)

16 In/Out Quint (1,2,9,10 vs 3-8)

17 In/Out Single (1,2,3,8,9,10 vs 4-7)

18 In/Out Triple (1,2,3,8,9,10 vs 4-7)

19 In/Out Quint (1,2,3,8,9,10 vs 4-7)

20 1-5 Steady; 6-10 Single Flash

21 1-5 Steady; 6-10 Slow Single Flash

22 6-10 Steady; 1-5 Single Flash

23 6-10 Steady; 1-5 Slow Single Flash

24 Sequential Back And Forth

25 Sequential In/Out

26 Burst All w/ Alternating Burst

27 Alternating Burst w/ Simultaneous Double Then Quint

28 Simultaneous Burst w/ Alte rnating Double Then Quint

29 Hyper-Random

30 Pre-P op Triple Flash

31 Alternating Pre-P op Triple Flash

32 Demo (Cycle Through Patterns 1-4,6-9,13-20,25-29)

1 Pursuit Mode

(1 flash/3 sec default)

(3 flashes/9 sec default)

(Title 13 Approved)

(Title 13 Approved)

(2 flashes/6 sec default)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

Please Note: At any time during the programming sequence, you can reset the flash

pattern back to any of the default patterns (Pattern 1, 18, or 24) by holding

the red w/green Pattern Select wire to +12VDC until the heads flash the

specified number of times, then releasing it.

Each LED flasher has 20 output terminals (10 pairs). The two terminals in each pair are

electrically connected and will flash at the same time. The numbers in parenthesis in the

list above indicate which output pairs flash together vs. the pairs they flash opposite of.

Front and Rear DLX6 and Batwing LED Flasher Units

(LDF375-1 / 8070-375-1)

White

Orange

Brown

Yellow

Red/Green

Black

Purple

White = Corner Enable

Orange = Outboard Enable

Brown = Inboard & Ends

Yellow = Cruise

Please Note: The 20 output

terminals are enabled by 3

different inputs:

White - 1,2,9,10 (Corners)

Orange - 3,8 (Outboard)

Brown - 4,5,6,7 (Inboard & Ends)

d

e

R

e

g

r

a

L

Output Pair

Red/Green = Pattern Select

Black = Ground

Purple = High/Low Power

Large Red = Power

-12-

1

2

3

4

5

6

7

8

9

10

Page 16

(LED Pattern Programming CONT’D)

Takedown or Alley Light DLX6 and Batwing LED Patterns

(LDF375-2 Flasher)

Pattern Warning Pattern Style

2 Alternating Slow Single (1,3 vs 2,4)

3 Alternate Pursuit Mode

4 Alternating Quad Flash (1,3 vs 2,4)

5 Alternating Triple (1,3 vs 2,4)

6 Alternating Quint (1,3 vs 2,4)

7 Simultaneous Slow Single (All Modules)

8 Simultaneous Fast Single (All Modules)

9 Simultaneous Triple Flash (All Modules)

10 Simultaneous Quad Flash (All Modules)

11 Simultaneous Q uint Flash (All Modules)

12 Simultaneous Fast Triple Flash (All Modules)

13 Simultaneous Fast Quint Flash (All Modules)

14 In/Out Single (1,3 vs 2,4)

15 In/Out Triple (1,3 vs 2,4)

16 In/Out Quint (1,3 vs 2,4)

17 Simultaneous Double Flash, Post-Pop

18 Simultaneous Triple Flash, Post-Pop

19 Simultaneous Q uint Flash, P ost-Pop

20 Alternating Double Flash, P ost-Pop (1,3 vs 2,4)

21 Alternating Triple Flash, Post-Pop (1,3 vs 2,4)

22 Alternating Quint Flash, Post-Pop (1,3 vs 2,4)

23 Alternating Pre-P op Quint Flash (1,3 vs 2,4)

24 Sequential Back And Forth

25 Sequential In/Out

26 Burst All w/ Alternating Burst

27 Alternating Burst w/ Simultaneous Double Then Quint

28 Simultaneous Burst w/ Alte rnating Double Then Quint

29 Hyper-Random

30 Demo (Cycle Through Patterns 1-4,6-9,13-20,25-29)

1 Pursuit Mode

(1 flash/3 sec default)

(Title 13 Approved)

(Title 13 Approved)

(2 flashes/6 sec default)

(3 flashes/9 sec default)

The numbers in parenthesis in the list above indicate which output pairs flash

together vs. the pairs they flash opposite from.

Please Note: Please Note: At any time during the programming sequence, you can reset

the flash pattern back to any of the default patterns (Pattern 1, 18, or 24) by

holding the red w/green Pattern Select wire to +12VDC until the heads flash

the specified number of times, then release it.

Takedown (Pursuit) and Alley LED Flasher Units

White

Orange

Brown

Yellow

Black

Red/Green

Purple

White = Steady 1 & 2 (Takedowns)

Orange = Steady 4 & 5 (Driver Alley)

Brown = Steady 3 (Passenger Alley)

Yellow = Flash 1 & 2 (Pursuits)

(LDF375-2 / 8070-375-2)

Function Connect to Pairs

Takedown/Pursuit Lights 1 & 2

Passenger Alley 3

Driver Alley 4 or 5

Output Pair

1

2

3

4

Black = Ground

n

e

e

d

Red/Green = Pattern Select

r

e

G

R

/

Purple = High/Low Power

e

e

u

g

l

r

B

a

L

Large Red = Power

5

-13-

Page 17

(LED Pattern Programming CONT’D)

Patterns for All LEDs Excluding DLX6 and Batwing

(LDF398 Flasher)

Pattern Warning Pattern Style

1 Pursuit Mode

2 Alternating Slow Single (1-5 vs 6-10)

3 Alternate Pursuit Mode

4 Alternating Quad Flash (1-5 vs 6-10)

5 Alternating Triple (1,2,6,7,8 vs 3,4,5,9,10)

6 Alternating Quint (1,2,6,7,8 vs 3,4,5,9,10)

7 Simultaneous Slow Single (All Modules)

8 Simultaneous Fast Single (All Modules)

9 Simultaneous Triple Flash (All Modules)

10 Simultaneous Quad Flash (All Modules)

11 Simultaneous Q uint Flash (All Modules)

12 Simultaneous Fast Triple Flash (All Modules)

13 Simultaneous Fast Quint Flash (All Modules)

14 In/Out Single (1,2,9,10 vs 3-8)

15 In/Out Triple (1,2,9,10 vs 3-8)

16 In/Out Quint (1,2,9,10 vs 3-8)

17 In/Out Single (1,2,3,8,9,10 vs 4-7)

18 In/Out Triple (1,2,3,8,9,10 vs 4-7)

19 In/Out Quint (1,2,3,8,9,10 vs 4-7)

20 1-5 Steady; 6-10 Single Flash

21 1-5 Steady; 6-10 Slow Single Flash

22 6-10 Steady; 1-5 Single Flash

23 6-10 Steady; 1-5 Slow Single Flash

24 Sequential Back And Forth

25 Sequential In/Out

26 Burst All w/ Alternating Burst

27 Alternating Burst w/ Simultaneous Double Then Quint

28 Simultaneous Burst w/ Alte rnating Double Then Quint

29 Hyper-Random

30 Demo (Cycle Through Patterns 1-4,6-9,13-20,25-29)

(Default)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

(Title 13 Approved)

Each LED flasher has 20 output terminals (10 pairs). The two terminals in each pair are

electrically connected and will flash at the same time. The numbers in the list above, in

the parenthesis, indicate which output pairs flash together vs. the pairs they flash

opposite of.

Please Note: At any time during the programming sequence, you can reset the flash

pattern back to the default mode (Pattern 1 – Pursuit) by holding the red

w/green Pattern Select wire to +12VDC for 5 seconds, then releasing it.

Flasher Unit for All LEDs Excluding DLX6 and Batwing

(LDF398 / 8070-285-1)

White

Orange

Brown

Purple

Black

Red/Green

White = Corner Enable

Orange = Outboard Enable

Brown = Inboard & Ends

Purple = High/Low Power

Please Note: The 20

output terminals are

enabled by 3 different

inputs:

White - 1,2,9,10 (Corners)

Orange - 3,8 (Outboard)

Brown - 4,5,6,7 (Inboard

& Ends)

d

e

Black = Ground

R

e

Red/Green = Pattern Select

g

r

Large Red = Power

a

L

-14-

Output Pair

1

2

3

4

5

6

7

8

9

10

Page 18

SABRE

Parts

Bulbs and Tubes

LST129-4

4.5" LINEAR STROBE TUBE

LST129-7

7" LINEAR STROBE TUBE

ST3901-7

360° STROBE HEAD

2073-H50S

(4 amps)

50-WATT SHORT HALOGEN BULB

(FOR ROTATORS AND TAKEDOWNS)

2073-1157

(2.1 amps)

STOP-TURN-TAIL BULB

2073-H27

(2.1 amps)

27-WATT HALOGEN BULB

(LOWER LEVEL)

2073-94

(1 amp)

INCANDESCENT DIRECTIONAL

ARROW BULB

ST3901-12

STROBE TUBE FOR STROBE

INTERSECTION CLEARING LIGHT

Power Supplies/Flashers

RP249-L

(9 amps)

4-HEAD REMOTE STROBE PAK

RP249A-L

(7 amps)

2-HEAD REMOTE STROBE PAK

520-181-SBQ

2-HEAD REMOTE STROBE PAK and

REPLACEMENT 520-29 V-Mirror

520-181-SBQ2

2-HEAD REMOTE STROBE PAK and

REPLACEMENT 520-29-2 LARGE V-Mirror

TD77-2

TRAFFIC DIRECTOR CONTROL BOX

LDC-TD

LED CONVERTER CIRCUIT FOR TD77-2

WHEN USED w/M-Tech HEADS

FM3661-S

1.9 FPS HALOGEN FLASHER

FM3662-S

2.9 FPS HALOGEN FLASHER

LDF398

8-OUTPUT LED FLASHER FOR M-TECH HEADS

(20 OUTPUT TERMINALS)

LDF375-1

8-OUTPUT LED FLASHER w/CRUISE

FOR VERSASTAR HEADS

(20 OUTPUT TERMINALS)

LDF375-2

8-OUTPUT LED FLASHER FOR

ALLEYS & TDP VERSASTAR HEADS

(20 OUTPUT TERMINALS)

LDF288-ICL

8-OUTPUT LED FLASHER FOR

ALLEYS & TDP VERSASTAR HEADS

(20 OUTPUT TERMINALS)

LDF369

2-OUTPUT LED FLASHER FOR ALL LED HEADS

EXCEPT M-TECH & VERSASTAR (8 OUTPUT TERMINALS)

LDF389

STT Controller for Lower Level Linear

LED Heads (820-14D1-R)

(2 amps)

(2 amps)

Domes, Filters, and Lenses

520-21-*

UPPER END DOME

(*= A, B, C, G, or R)

520-22-*

UPPER CENTER DOME

(*= A, B, C, G, or R)

820-21L-*

LOWER INTERCEPTOR/SABRE

END DOME (*= A, B, C, G, or R)

520-22L-*

LOWER INTERCEPTOR/SABRE

CENTER DOME (*= A, B, C, G, or R)

520-100-*

COLOR FILTER FOR LOW

PROFILE ROTATORS

(*=A,B,G,R)

LSF4.5-*

COLOR FILTER FOR 4.5" SH3964

STROBE HEAD (*=A,B,G,R)

LSF7-*

COLOR FILTER FOR 7" SH3967

STROBE HEAD (*=A,B,G,R)

820-100LL-*

COLOR FILTER FOR LOWER

LEVEL LIGHTS (*=A,B,G,R)

333-5-*

DOME FOR 360° STROBE HEAD

(*= A, B, C, G, or R)

Mirrors

520-29-1

SMALL V-MIRROR FOR

SABRE AND RAZOR LIGHTBARS

520-29

MEDIUM V-MIRROR FOR

SABRE AND RAZOR LIGHTBARS

520-292

MEDIUM DOUBLE V-MIRROR

FOR SABRE AND RAZOR LIGHTBARS

520-29-2

LARGE V-MIRROR

FOR SABRE AND RAZOR LIGHTBARS

520-2*

Z-MIRROR FOR SABRE

(*=L or R)

Miscellaneous

820-39-PB

DIRECT MOUNT KIT

HOOK MOUNTS

THESE ARE PICTURED IN THE HOOK MOUNT MANUAL

AND WORK IN CONJUNCTION WITH THE 820-39P*

* = COLOR (White, Black, Clear, or Gray)

30047-61

DOME GASKETING (1 FOOT)

30053-33

TOP DOME SCREWS

920-37

(0.33 amps)

SINGLE ID/MARKER LIGHT FOR 820-38-1

820-36

(1 amp)

TRIPLE I.D./MARKER LIGHT BRACKET ONLY

TRIPLE I.D./MARKER LIGHT BRACKET

WITH THREE 920-27 ID LIGHTS

820-38-1

(1 amp)

-15-

Page 19

(Parts CONT’D)

FHR

HR

RSH

RSH

RSH

RP249A-L

RP249-L

DH

DHF

DHF

DHF

DHP

Upper Level Lighting

520-99 OR 520-99F

95FPM OR 150FPM HALOGEN

ROTATOR

ST3901-7

360° REMOTE STROBE HEAD

RSK520-SBQ

2-HEAD 360° STROBE KIT W/181SBQK POWER

SUPPLY/MIRROR ASSEMBLY AND TWO

ST3901-7 HEADS

SH3954 (SH3954-1 when angled)

4" LINEAR STROBE HEAD FOR

SABRE AND RAZOR LIGHTBARS

RSK249A-L4K

4.5" 2-HEAD LINEAR STROBE KIT

W/RP249A-L POWER SUPPLY

RSK249-L4K

4.5" 4-HEAD LINEAR STROBE KIT

W/RP249-L POWER SUPPLY

SH3957

7" LINEAR STROBE HEAD FOR

SABRE AND RAZOR LIGHTBARS

7" 2-HEAD LINEAR STROBE KIT

W/RP249A-L POWER SUPPLY

RSK249-L7K

7" 4-HEAD LINEAR STROBE KIT

W/RP249-L POWER SUPPLY

LSF-EC-*

LINEAR STROBE ENDCAP

520-51

(2.1 amps)

LOW PROFILE UPPER LEVEL

TAKEDOWN / WORKLIGHT

520-51F

LOW PROFILE UPPER LEVEL

FLASHING LIGHT

520-51FK*

2-LIGHT LOW PROFILE HALOGEN

FLASHER KIT w/FM3662 FLASHER

FRONT or REAR (*=F or R)

520-51HP

LOW PROFILE UPPER LEVEL

TAKEDOWN/PURSUIT LIGHT

S520-DLX6-3*

DLX6 END OR CORNER LED

S520-DLX6-4*

DLX6 OUTER LED

S520-DLX6-1*

DLX6 INNER LED

520-DLXLL6-1*

DLX6 INNER LED WITH BRACKET

(4 amps)

(2 amps)

(7 amps)

(9 amps)

(9 amps)

(2.1 amps)

(2.1 amps)

(2.1 amps max)

Traffic Directors

M-TECH HEADS (Standard or Value Versions)

820-14TDAK

LDALDALDALDALDALDALDA LDA

LOWER LEVEL INCADESCENT ARROWSTICK FOR

INTERCEPTOR w/TD77-2 CONTROLLER & CABLE

820-14TDK46

LOWER LEVEL LED ARROWSTICK FOR 46"

BARS w/TD77-2 CONTROLLER & CABLE

820-14TDK56

LOWER LEVEL LED ARROWSTICK FOR 56"

BARS w/TD77-2 CONTROLLER & CABLE

820-14TDK6*

LOWER LEVEL 6 ARRAY LED ARROWSTICK

w/TD77-2 CONTROLLER & CABLE (*=A,R)

S520-DLX6TDK6A

DLX6 TRAFFIC DIRECTOR KIT

S520-BWTDK6A

BATWING TRAFFIC DIRECTOR KIT

520-D1 or 520-D1V

M-Tech LED Lighthead

520-D1AL or 520-D1ALV

M-Tech LED Lighthead

w/Left Angle Reflector

520-D1AR or 520-D1ARV

M-Tech LED Lighthead

w/Right Angle Reflector

520-D1LEC or 520-D1LECV

M-Tech LED Lighthead w/Left Endcap

520-D1REC or 520-D1RECV

M-Tech LED Lighthead w/Right Endcap

520-D1EC or 520-D1ECV

M-Tech LED Lighthead w/Endcaps

520-D3 or 520-D3V

M-Tech LED 3-Lighthead End Assembly

520-D2 or 520-D2V

M-Tech LED 2-Lighthead End Assembly

220-ECL

M-TECH LEFT ENDCAP W/LENS

220-ECR

M-Tech Right Endcap w/Lens

LDH3903-*

LOW PROILE 3-ARRAY

LINEAR LED HEAD

(*=COLOR)

LDH3903K2-*

2-HEAD LINEAR 3-LED KIT W/

LDF369 FLASHER

(*=A,B,C,R,BR)

LDH3903K4-*

4-HEAD LINEAR 3-LED KIT W/

LDF369 FLASHER

(*=A,B,C,R,BR)

LDH3906-1-*

LOW PROILE 6-ARRAY

LINEAR LED HEAD

(*=COLOR)

LDH6K2-1**

2-HEAD LINEAR 6-LED KIT W/

LDF369 FLASHER (*=A,B,C,R,BR)

LDH6K4-*

4-HEAD LINEAR 6-LED KIT W/

LDF369 FLASHER (*=A,B,C,R,BR)

S520-308-4*

BATWING LED

S520-308-6*

BATWING T.D. LED

(8 amps max)

(2 amps max)

(2 amps max)

(1.5 amps max)

(0.8 amps max)

(0.8 amps max)

(0.8 amps max)

(0.8 amps max)

(0.8 amps max)

(0.8 amps max)

(1.6 amps max)

(1.6 amps max)

(0.4 amps max)

(0.8 amps max)

(1.6 amps max)

(0.8 amps max)

(1.6 amps max)

(3.2 amps max)

Please note that these items are not drawn to scale. Many have been enlarged to show more detail

-16-

Page 20

(Parts CONT’D)

820-14D1-*

1 LOWER LEVEL LED ARRAY

For Flashers or STT (*=A,B,R,BR)

820-1LDF*

1 LOWER LEVEL LED ARRAY (820-14D1*)

w/LDF369 FLASHER (*=A,B,R,BR)

820-2LDFK-**

2 LOWER LEVEL LED ARRAYS

w/LDF369 FLASHER (*=A,B,R,BR)

820-14LDSTTK

2 LOWER LEVEL RED LED ARRAYS

w/LDF389 STT FLASHER

820-4LDFK-****

4 LOWER LEVEL LED ARRAYS

w/LDF369 FLASHER (*=A,B,R,BR)

820-14D2-*

LOWER LEVEL DOUBLE LED ARRAY (*=A,R)

820-14D3-*

LOWER LEVEL TRIPLE LED ARRAY (*=A or R)

S520-DLX6LL-1*

DLX6 LOWER LEVEL LED

S520-308LL-4*

BATWING LED

S520-DLX6ICLK

DLX6 LED INTERSECTION CLEARING LIGHT KIT

520-DLX6ICLK

LOWER LEVEL LED INTERSECTION CLEARING LIGHT

KIT w/LDF288-ICL FLASHER AND BRACKETS

820-14ICL

L

C

I

I

C

L

LOWER LEVEL INTERSECTION CLEARING LIGHT

820-14ICLK

L

C

I

LOWER LEVEL INTERSECTION CLEARING

LIGHT KIT w/FM3662 FLASHER

(0.65 amps)

(0.65 amps)

(1.3 amps max)

(1.3 amps max)

(2.6 amps max)

(0.5 amps max)

(0.75 amps max)

(2.1 amps max)

(2.1 amps max)

LTP LTP LTP

LDH

LDHLDH LDH

LDF

LDFLDF LDF LDF

LTP

820-14 or 820-14LDH

LDH

LOWER LEVEL DIRECTIONAL HALOGEN LIGHT

LDH

820-14LAL

LOWER LEVEL ALLEY LIGHT

820-14ALK

LDH

LOWER LEVEL ALLEY LIGHT KIT

820-14DHK*

LDHLDH

LOWER LEVEL DIRECTIONAL HALOGEN

2-LIGHT KIT (TAKEDOWNS/WORKLIGHTS)

820-14DHK4*

LDH

LOWER LEVEL DIRECTIONAL HALOGEN

4-LIGHT KIT (TAKEDOWNS/WORKLIGHTS)

820-14STT

LSTT

LOWER LEVEL STOP/TAIL/TURN LIGHT

820-14LDF

LDF

LOWER LEVEL FLASHING LIGHT

520-14DHFK*

LOWER LEVEL 2-LIGHT FLASHER KIT w/FM3662-S

LDF

FLASHER FRONT or REAR (*=F OR R)

520-14DHFK4*

LOWER LEVEL 4-LIGHT FLASHER KIT w/FM3662-S

FLASHER FRONT or REAR (*=F OR R)

820-14LTP

LTP

LOWER LEVEL TAKEDOWN/PURSUIT LIGHT

520-14DHPK*

LOWER LEVEL 2-LIGHT TAKEDOWN/PURSUIT KIT

LTP

w/FM3662-S FLASHER FRONT or REAR (*=F OR R)

520-14DHPK4*

LOWER LEVEL 4-LIGHT TAKEDOWN/PURSUIT KIT

LTP

w/FM3662-S FLASHER FRONT or REAR (*=F OR R)

(2.1 amps)

(2.1 amps)

(4.2 amps max)

(*=F or R)

(*=F or R)

(2.1 amps)

(1.05 amps)

(*=F or R)

(*=F or R)

(2.1 amps max)

(*=F or R)

(*=F or R)

(4.2 amps max)

(2.1 amps max)

(4.2 amps max)

(8.4 amps max)

(4.2 amps max)

(8.4 amps max)

Please note that these items are not drawn to scale. Many have been enlarged to show more detail

Switches and Switchboxes

SP3860-1 SP3860-2 SP3860-3 SP3860-4

SP1515

SB1515

SP3015

SB3015

-17-

ROTATORS

STROBES

MODE

1 2 3

RIGHT

LEFT

ALLEY

ALLEY

SB4020

HEADLIGHT

GRILL

FLASHER

LIGHTS

SB4040

CORNER

WORK

FLASHERS

LIGHTS

TAKE

LIGHTS

DOWN

Page 21

Troubleshooting

If a light on your bar fails to work, please refer to this section to help solve your problem.

If you still cannot resolve your problem, please contact our Customer Service

Department at 585-226-9787.

The chart below contains some basic guidelines for troubleshooting any problems you may

experience with your bar. The section following the chart will explain in further detail how to

perform some of the troubleshooting tasks.

Symptom:

One single LED light is Out LED Head needs to be replaced

One LED head does not flash Check wiring between LED head and flasher unit

Multiple LED heads not

flashing

One flashing light out

Multiple flashing lights out Check power to terminal block

One remote strobe head out Check the strobe head

Multiple strobe heads out

Possible Solutions

Check LED head

Check that + 12VDC is applied to control line for that head

Check power to terminal block

Check that the bar is properly grounded

Check power from terminal block to LED flasher unit

Check that the LED flasher unit is grounded properly

Check that + 12VDC is applied to control line for those heads

Check that the red w/green stripe pattern select wire is not connected to

+12VDC

Check bulb

Check power wire from flasher unit to bulb

Check that the bulb is grounded

Check that the bar is properly grounded

Check power from terminal block to flasher unit

Check that the flasher unit is grounded properly

Check the cable from the remote pack to the strobe head

Check power to terminal block

Check power to strobe pack Power Outlet (PWR)

Check power to strobe pack Control Outlets (CTRL)

Check that the pack is properly grounded

Check that the red w/green stripe pattern select wire is not connected to

+12VDC

-18-

Page 22

Determining if the bar is properly grounded:

1. While the bar is turned on, using a test meter, measure the voltage from the base of the bar

itself to the negative post of the battery or a good chassis ground if the battery can’t be easily

reached. You may need to scrape away a bit of anodizing or paint in order to ensure a good

connection with the probe of your test meter.

2. If the difference shown is greater than .25 volts, then your ground is not sufficient.

3. If the ground is insufficient, locate the ground wire connection in your lightbar by removing the

dome over the section where the wires enter the bar. Please follow the appropriate dome

removal instructions listed earlier in this manual when removing this dome. The ground wire is

the large (10AWG) black wire attached to the inside of the lightbar base with a ring terminal.

Check the integrity of the connection of the ground wire to both the lightbar base and at the

other end to a good chassis ground.

4. While inspecting the ground wire connections you should also check that the wire itself is not

damaged. Carefully inspect the wire along its entire length, paying special attention to those

areas where the wire passes through any holes that may have sharp edges, which can

damage the wire, and the areas where the wire makes any sharp bends.

Checking the power to the terminal block

(Determining if the proper voltage is reaching your bar):

1. Locate the terminal block in your lightbar by removing the dome over the section where the

wires enter the bar. Please follow the appropriate dome removal instructions listed earlier in

this manual when removing this dome. After entering the bar, the wires will be connected to

the terminal block with a number of small Phillips head screws.

2. With the bar turned on, use a test meter to test the voltage at the terminal block. A nominal

12.5 volts should be present. Low voltage can cause erratic flashing in strobe heads or even

complete failure of the heads. A minimum of 10.5 volts should be present for the pack to

operate properly. Low voltage in strobe lights, flashing lights, or LEDs can result in lowered

intensity or even complete failure.

3. Be sure to test each wire that comes into the terminal block for proper voltage.

4. Carefully inspect each wire in the terminal block. Check that the ends of the wires have not

frayed and shorted against one another or against the base. This may cause lights to operate

inadvertently or may result in the failure of lights.

Checking one non-working strobe or LED head:

If a problem exists in only one head

there may be an open electrical connection in the wiring harness or strobe head.

, a strobe tube or LED head may have burned out, or

1. Check connections at and between the strobe pack and the faulty strobe head or between the

flasher unit and LED head, including all wiring.

2. Disconnect both the faulty head and a working head.

3. Check the faulty head by connecting it into the side you just unplugged the working head from.

If the faulty head still does not work, then the head is bad and will need to be replaced.

4. If the head that was not flashing works when connected to the other side, the problem

probably lies in the power pack or flasher unit. Verify this by plugging the other head

(the original working head you just unplugged) into the side that previously had the nonworking head.

-19-

Page 23

Checking multiple non-working strobe or LED heads:

If two or more of the heads connected to one of the packs are not flashing, follow these

steps to determine the problem:

1. Check the power to the terminal block as explained on the previous page.

2. Check that the bar is grounded properly as explained on the previous page.

3. Check all fuses, including those at the battery, at the switch panel, in the dash, and on

the pack (if applicable). Remove these fuses, and check them to confirm they have not

blown. Replace any blown fuses with only fuses of identical values. Replacing the fuse

with the wrong rating may damage your pack and/or vehicle, and will void your warranty.

4. Check that the proper voltage is reaching the pack or flasher unit with the vehicle turned

off and while the bar is running. For strobe packs, measure the voltage across the red

wire (pin 1) and the black or blue wire (pin 2) of the

PWR

connector on the power pack.

Push the probes of the test meter down into the connector at the wire entry points to

contact the terminals for the measurement. Note this reading. A nominal 12.5 volts

should be present. Low voltage to the pack can cause erratic flashing in the heads or

even complete failure of the heads. A minimum of 10.5 volts should be present for the

pack to operate properly. If you do not have proper voltage present skip to step 8. If

your pack is receiving sufficient voltage then continue to step 5.

5. Check that the proper voltage is reaching the Black wire and White wire of the

CTRL

plug on your strobe pack with the vehicle turned off and while the bar is running.

Measure the voltage across the Black wire (pin 2) and a good chassis ground. Push the

probes of the test meter down into the connector at the wire entry points to contact the

terminals for the measurement. Note this reading. Also check the voltage on the White

wire. A nominal 12.5 volts should be present. A minimum of 10.5 volts should be

present for the pack to operate properly. If you do not have proper voltage present, skip

to step 8. If your pack is receiving sufficient voltage then continue to step 6.

6. Check that there is NO VOLTAGE on the Red w/Green Stripe wire (Pattern Select wire)

of the

CTRL

plug on your strobe pack. Measure the voltage across the Red w/Green

stripe wire (pin 1) and a good chassis ground. Push the probes of the test meter down

into the connector at the wire entry points to contact the terminals for the measurement.

If there is voltage being applied to this wire, it will prevent the strobe pack from flashing.

7. If the leads in one of the heads have shorted out, the output voltage of the other heads

may be held down as well. To test for this, unplug all of the heads and plug them in

individually, one at a time. If your problem is a result of a shorted head, then the other

heads should function properly if the faulty head is no longer connected. Note: A

burned out strobe tube does not cause a short and will not affect the operation of the

remaining heads. If the problem is not with a shorted head and if proper voltage is

reaching the pack, the problem is most likely internal to the pack. Call Star to obtain an

R.G.A. number to return the pack for service.

8. If sufficient voltage is not reaching the pack perform the following tests: With the vehicle

turned off and while the pack is running, measure the battery voltage

at the battery

. A

nominal 12.5 volts should exist. Note this voltage. If this voltage is below 10.0 volts the

pack will not function properly and the problem is with the battery. This reading should

not be more than 1-1.25 volts higher than the reading in the 4th step. If there is an

excessive difference then continue on to the next step.

9. With the vehicle not running and the lightbar on, measure the voltage in the red wire by

taking a reading from the positive side of the battery to pin 1 of your switch. If this

reading exceeds 0.25 volts then there is a poor connection between the switch and the

battery in the red wire and it should be checked.

10. If you still have not located the problem, troubleshoot the connections between the good

chassis ground and pin 2 (black wire) of the

PWR

connector on the power pack, while

the lightbar is running. If this reading exceeds 0.25 volts then there is a poor connection

between the switch and the ground in the black wire and it should be checked.

11. This same procedure can be used to check the wires between the terminal block and the pack.

Place one probe on the terminal at the terminal block and the other probe into the terminal with

the corresponding wire color in the connector on the pack. Once again if any of the readings

exceed 0.25 volts then you should check those wires and their connections.

-20-

Page 24

ONE YEAR LIMITED WARRANTY

LED FIVE YEAR LIMITED WARRANTY

The manufacturer warrants each new product, under normal use, against factory defects in

material and workmanship for one year after the date of purchase. The manufacturer

warrants the LED components in this light against factory defects in material and workmanship

for five years after the date of purchase. The owner will be responsible for returning to the

Service Center any defective item(s) with the transportation costs prepaid. The manufacturer

will, without charge, repair or replace at its option, products, or part(s), which its inspection

determines to be defective. Repaired or replacement item(s) will be returned to the

purchaser with transportation costs prepaid from the service point. A copy of the purchaser's

receipt must be returned with the defective item(s) in order to qualify for the warranty

coverage. If a copy of the receipt is not provided, the warranty period shall cover five years

from the date of manufacture.

Exclusions from this warranty include, but are not limited to, bulbs, strobe tubes, domes, and/

or the finish. This warranty shall not apply to any light, which has been altered, such that in the

manufacturer's judgment, the performance or reliability has been affected, or if any damage

has resulted from abnormal use or service. This warranty does not apply to defect or damage

occurring as a result of disaster, accident, abuse, misuse, lightning, power surges, or failure to

follow instructions in any enclosed manuals. Any damage or defects occurring as a result of

any unauthorized service or repairs by unauthorized persons shall be excluded from this

warranty.

There are no warranties expressed or implied (including any warranty of merchantability or

fitness), which extend these warranty period. The loss of use of the product, loss of time,

inconvenience, commercial loss or consequential damages, including costs of any labor, are

not covered. The manufacturer reserves the right to change the design of the product

without assuming any obligation to modify any product previously manufactured.

This warranty gives you specific legal rights. You might also have additional rights that may

vary from state to state. Some states do not allow limitations on how long an implied warranty

lasts. Some states do not allow the exclusion or limitation of incidental or consequential

damages. Therefore, the above limitation(s) or exclusion(s) may not apply to you.

If you have any questions concerning this or any other Star product,

please contact our

Customer Service Department

at (585) 226-9787.

If a product must be returned for any reason, please contact

our Customer Service Department to obtain a

Returned Materials Authorization number (RMA #) before you ship the product to Star.

Please write the RMA # clearly on the package near the mailing label.

-21-

Loading...

Loading...