Page 1

INSTALLATION AND INSTRUCTION MANUAL

200A SERIES

200C SERIES

200E SERIES

400A

450A SERIES

CAUTION: All of our DC powered warning lights are polarity sensitive.

These lights are polarity protected only if the appropriate fuse is used.

All wires connected to the positive terminal of the battery should be

fused at the battery for their rated load. Testing the light before this

fuse is properly installed will void the warranty on the light.

These lights are standard negative ground. Isolated or floating units for

positive ground vehicles are clearly labeled and are available upon request. In

this case connect the power to the proper polarity as marked on the wires.

ONE YEAR LIMITED WARRANTY

The manufacturer warrants each new product against factory defects in material and

workmanship for one year after the date of purchase. The owner will be responsible for returning

to the Service Center any defective item(s) with the transportation costs prepaid. The

manufacturer will, without charge, repair or replace at its option, products, or part(s), which its

inspection determines to be defective. Repaired or replacement item(s) will be returned to the

purchaser with transportat ion costs prepaid from the service po int. A copy of the purchaser's

receipt must be returned with th e defective item(s) in order to qualify for the warranty coverage.

Exclusions from this warranty include, but are not limited to, bulbs, strobe tubes, domes, and/or the

finish. This warranty shall not apply to any light, which has been altered, such that in the

manufacturer's judgment, the performance or reliability has be en affected, or if any damage has

resulted from abnormal use or service.

There are no warranties expressed or implied (including any warranty of merchantability or fitness),

which extend this warranty period. The loss of use of the product, loss of time, inconvenience,

commercial loss or consequential damages, including costs of any labor, are not covered. The

manufacturer reserves the right to change the design of the product without assuming any

obligation to modify any product previously manufactured.

This warranty gives you specific le gal rights. You might also h ave additional rights that may vary

from state to state. Some states do not allow limitations on how long an implied warranty lasts.

Some states do not allow the exclusion or limitation of incidental or consequential damages.

Therefore, the above limitation(s) or exclusion(s) may not apply to you.

If you have any questions concerning this or any other product,

please contact our Customer Service Department at (585) 226-9787.

If a product must be returned for any reason, please contact our Customer Service Department

to obtain a Returned Materials Authorization number (RMA #) before you ship the product back.

Please write the RMA # clearly on the package near the mailing label.

PLITSTR101 REV. E 9/16/11

Page 2

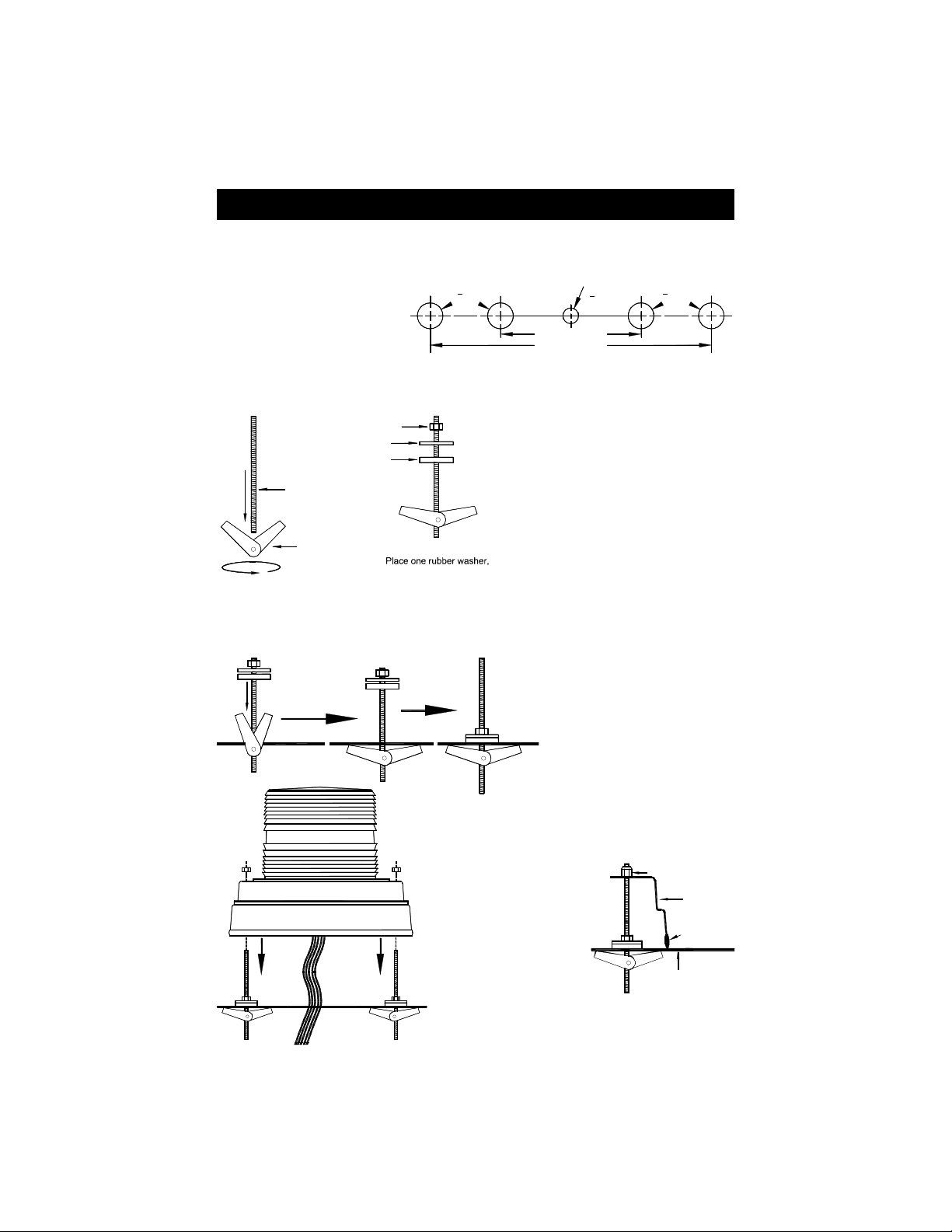

Mounting Toggle Wing Models

1. Your new warning light comes complete with a rubber mounting gasket, 2 toggle wings,

2 threaded rods, 2 neoprene washers, 2 steel washers, 2 nuts, and 2 self-locking nuts.

2. Mark two mounting holes on

7” centers for the 400A, and

450A Series or 3½” centers

5

" DIA.

8

for the 200C or 200E series

and mark a spot for the wire

hole centered directly

between them.

3. Drill a 5/8" hole in the outer two marked locations. Then drill a 3/8" hole in the center

marked location for your wires to run through. CAUTION: Take care not to drill through

the headliner of the vehicle.

NUT

STEEL WASHER

RUBBER WASHER

THREADED ROD

4. Attach the rubber mounting gasket

around the base of the light.

5. Carefully remove the lens by

removing the three screws at the base

of the lens. Lift off the lens and

remove it taking care to ensure you do

not lose or destroy the lens gasket.

6. Attach a toggle wing to one end of one

of each of the threaded rods.

7. Place the rubber and steel washers

around each of the threaded rods

according to the diagram to the left.

Screw toggle wing

and threaded rod

together

TOGGLE WING

one steel washer, and

one nut on each rod

8. Then push the toggle wing through the top of one of the outer holes in the mounting

surface until it opens under the mounting surface.

WIRE HOLE

3

8

3½" CENTERS

7" CENTERS

" DIA.

5

" DIA.

8

Insert the threaded rod

and toggle wing

through the mounting

surface

MOUNTING SURFACE

Route wires through center hole, slide

light over rods, and secure with nuts

Tighten the nut,

securing the rod in

place

9. Tighten the nut down such

that it seats the steel washer

firmly against the rubber

washer, and the mounting

surface, holding the rod in

place. Repeat this for each

threaded rod.

10. Route the wires through the center hole, align

the outer holes in the base with the threaded

rods and slide the base onto the rods.

11. Fasten one of the

self-locking nuts to

each of the threaded

rods and tighten

until snug.

12. Once all of the nuts are tight and the base is

secure, reattach the outer lens(es).

-1-

SELF -LO CKI NG NUT

BASE

MOUNT ING

GAS KET

MOUN TING

SURF ACE

Page 3

Mounting Plastic Base Models

Remove the 4 screws in the

side of the Aluminum housing

and slide the plastic base out

Gasket

Plastic Mounting Base

3 Locate the various knockouts on the bottom

of the base and determine which mounting

holes will work best for your application.

Clear the knockouts using a punch or other

appropriate tool.

4. Using the plastic mounting base as a

template, mark the appropriate holes on the

mounting surface. Take care to ensure that

the base does not move while you are

marking each of the holes.

1. Remove the four screws in the side

of the aluminum housing.

2. Slide the plastic base out of the

aluminum case. Take care not to

damage the gasket when separating

the plastic base from the aluminum

case.

0.196" Diameter

on 2.975" Radius

3 @ 120°

0.264" Diameter

on 2.5" Radius

2 @ 180°

101-AP

0.261" Diameter

on 3.125" Radius

3 @ 120°

1" NPT THREADED

PIPE MOUNT

0.189" Diameter

on 1.75" Radius

2 @ 180°

5. Remove the plastic mounting base and drill a 3/8" hole in the marked locations. Then, if

applicable, drill a 3/8" hole for the wires in the center of the outer holes.

CAUTION: Take care not to drill through the headliner of the vehicle below.

6. Push the enclosed rubber well nuts through the outer holes until the

bottom side of the wider lip rests on the surface of the vehicle.

7. Route the wires through the center hole, if applicable and align the holes with the well

nuts. Install the screws through the base, into the well nuts, and tighten until snug.

8. Once the plastic mounting base is installed on the vehicle, you may replace the light on

the base and reinstall the four screws that affix the light to the plastic mounting base.

-2-

Page 4

Wiring

1. For 110/120VAC models, the black and white wires may be connected either way

(polarity is not important).

2. For all other models, the black or white wire on your light is the ground lead and should

be connected to a good chassis ground.

3. The red wire on your light should be connected to the positive side of the power through

a fused switch, checking your warning light for proper voltage and amperage.

4. If you are installing a single-flash, 12-48 VDC, or rotating model, you are now finished

and may skip the remaining steps.

5. For strobe models with a purple wire:

If your light comes with a purple wire, it has the ability to switch between Low and High

power (if desired).

To run on High Power Only:

Connect the Purple wire with the

Black wire to Ground.

To run on Low Power Only:

Disconnect the Purple wire (or

cut it short and tape it off).

If you intend to make use of the

High/Low option through a switch,

refer to the wiring diagram to the

right for proper connections using

a two-switch switch panel

available from Star. When the

purple wire is grounded through

your switch, the light will operate

under High Power.

LED Indicator

These lights also have an LED Diagnostic Indicator.

The LED indicator is designed to flash when the strobe

tube should be flashing. If a strobe light is not working,

troubleshooting becomes easy with this new LED.

Simply examine the circuit when power is applied to it.

If the strobe tube is not

flashing, but the LED is flashing, you have a bad strobe

tube. If the LED is not flashing, the circuit is either not

receiving the proper voltage, or the circuit has failed.

Pattern Select Jumper

The circuits now found in these lights have a jumper on them allowing the end user to select

the desired flash pattern (singleflash, doubleflash, or quadflash). If you wish to change the

pattern, activate the light and follow the instructions below.

1. The Pattern Select Jumper is stored on pins 1 & 2.

2. To change the pattern, remove the jumper from pins 1 & 2,

momentarily place it over pins 2 & 3, then remove it. The

pattern should advance to the next.

3. Continue to touch and release the jumper to pins 2 & 3 to

cycle through the patterns:

4. Once you have selected a pattern, replace the jumper on

Singleflash Doubleflash Quadflash

pins 1 & 2.

SP3860-2H SWITCH PANEL (REAR VIEW)

WARNING

BLACK

GOOD

CHASSIS

GROUND

LIGHT

HIGH

LOW

RED

PURPLE

PURPLE

MALE TERMINAL

3

2

1

RED

(FOR BLACK WIRE)

3 2 1

MALE TERMINAL

(FOR BLACK WIRE)

3 2 1

ON

3

2

1

OFF

SW1SW2

S8070-159-14

RED LEAD w/FEMALE TERMINAL

PATTERN SELECT

JUMPERS

MALE TERMINAL

(FOR PURPLE WIRE)

PATTERN SELECT

BLACK

10 AMP

FUSE

CONNECT RED

FUSED LEA D TO

+12 VDC

(FOR RED WIRE)

3 2 1

S8070-159-14

RED LEAD w/FEMALE TERMINAL

JUMPERS

3 2 1

MALE TERMINAL

(FOR PURPLE WIRE)

(FOR RED WIRE)

GOOD

CHASSIS

GROUND

DIAGNOSTIC

LED

DIAGNOSTIC

LED

-3-

Loading...

Loading...