Page 1

274

274----RCK

274274

RCK

RCKRCK

Universal Rooftop Mounting Rack

NOTICE

Due to continuous product improvements, we must reserve the right to change any specifications

and information, contained in this manual at any time without notice. Star Headlight & Lantern

Co., Inc. makes no warranty of any kind with regard to this manual, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Star Headlight &

Lantern Co., Inc. shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual.

Please Note: These instructions are provided as a general guideline only. Some

vehicles may require special mounting, wiring, and/or weather-sealing. This is the

sole responsibility of the installer. Star Headlight & Lantern Co., Inc. assumes no

responsibility for the integrity of the installation for this or any of its products.

It is the sole responsibility of the owner to ensure the lightbar is

mounted securely. Check your light every time you enter the

vehicle to ensure that it is mounted securely. The manufacturer

assumes no responsibility for the secure mounting of this light.

When mounting your lightbar, please be sure to keep any radio frequency

sensitive equipment at least 20” from the bar and power cable(s). This is

especially critical in lightbars utilizing strobes. Our strobe power supplies have

been designed to limit RFI emissions, but certain very sensitive equipment

may still be affected. Symptoms may include, but are not limited to, sporadic

operation and degraded performance. Star Headlight & Lantern Co., Inc.

cannot assume any responsibility for any radio frequency induced malfunction

or damage to any radios, sirens, lightbars, or any other equipment mounted

within 20” a strobe lightbar. Any antennae mounted in the proximity of the

lightbar may cause your radio to suffer the aforementioned results.

PLITSTR184 REV. D 12/20/12

Page 2

Prior to starting your installation, please read through all of the instructions to

familiarize yourself with the installation of the bar AND any components that you may

be mounting to the bar. Based upon your application, determine whether you wish to

install the bar on the vehicle first, then add your components, or whether you wish to

install any or all of your components onto the bar first.

Tow Mounts

If your bar came equipped with the tow mounts, simply loosen

the 4 nuts securing each mount, slide it to the desired position,

and re-tighten them.

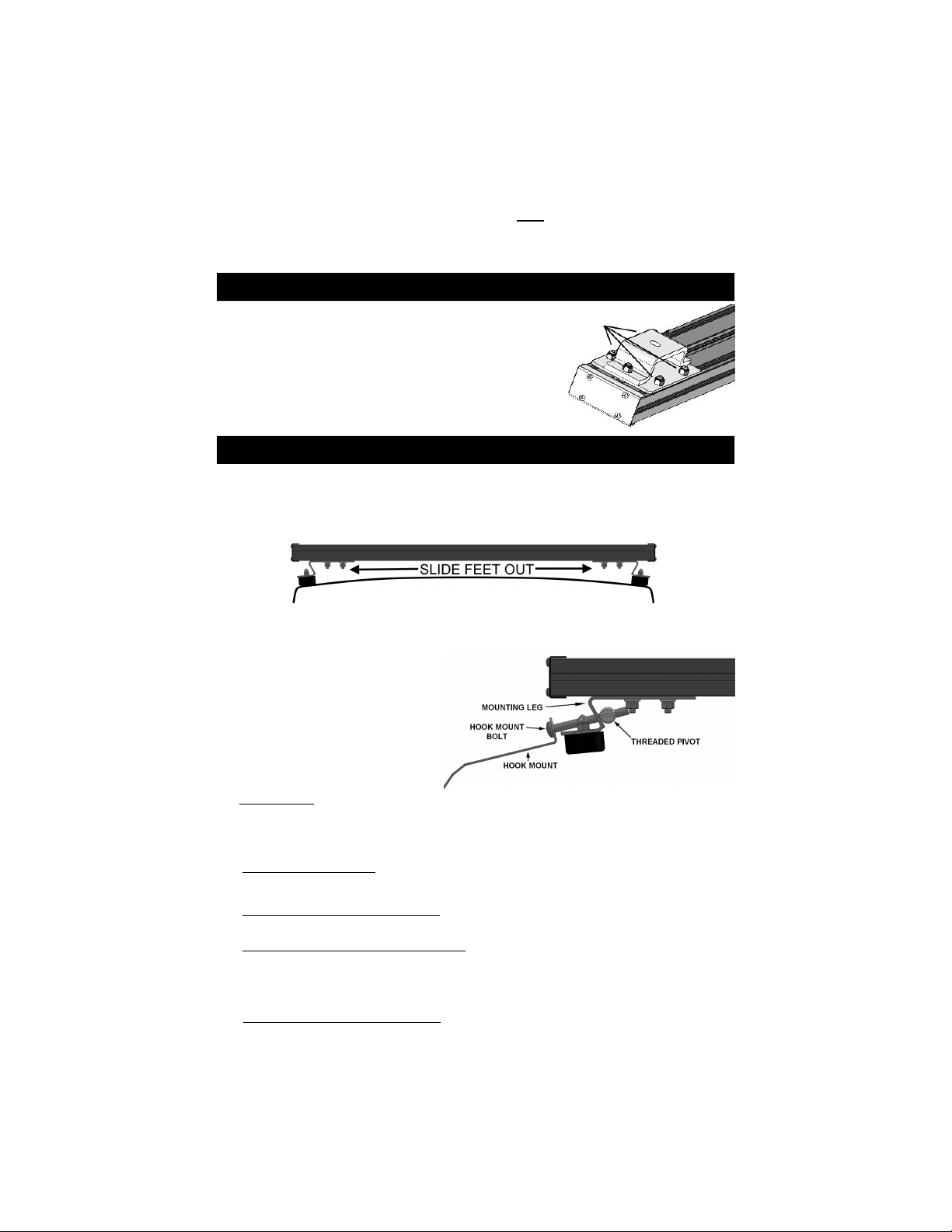

Hook Mounts

1. Carefully place your lightbar in position onto the roof of the vehicle and slightly loosen

the nuts that hold the mounting legs to the extrusion. The tabs on the mounting feet can

be bent slightly to an angle that matches the curvature of the roof, if necessary.

2. Slide the mounting brackets (legs) as close to the edge of the roof as possible.

3. Once the lightbar is in the correct position, level front to back and centered side-to-side,

tighten hex nuts securing the mounting brackets to the extrusions.

4. Attach the optional hook mounts to

each bracket using the bolt

provided with the mounts. Slip the

bolt through the hole in the hook

mount bracket and through the

hole in the mounting leg, then

screw it into the threaded pivot in

the mounting leg.

Please Note: For some applications, the bolt we provide may not be long

5. If using a Gutter Hook, tighten the bolt on one mounting bracket until the hook is just

under the gutter. Repeat this on the other side. Then alternate sides, tightening each

bolt approximately 1/2 turn until the mount is secure.

Do not over-tighten either mount! It is not necessary to dimple the roof in order to

achieve a secure, stable mount.

6. If you are installing a gutterless hook, tighten the bolt until the gutterless hook lip just

touches the inside lip of door jamb. Drill two or three holes and install the two sheet

metal screws through the enclosed rubber washers to secure the gutterless hook on the

inside lip of the door jamb. Repeat this for the other side of the bar. Then alternate

sides, tightening each bolt approximately 1/2 turn until the mount is secure.

Do not over-tighten either mount! It is not necessary to dimple the roof in order to

achieve a secure, stable mount.

enough. If the mounting brackets are fully extended and the hook

mounts still will not reach the edge of the vehicle, you may use a

longer 5/16"-18 bolt obtained locally.

-2-

Page 3

Component Installation

Installation of most optional components will require temporary removal of the end caps to

slide bolts onto the extrusion and/or to run wiring inside the extrusions. Proceed as follows:

1. Remove the four screws

securing one of the endcaps on

the 274-RCK and slide the

endcap off.

If you have a traffic director

version, remove the endcap

from the end OPPOSITE the

cable.

When reinstalling, ensure the

gasket is seated properly so

that it will not leak.

2. If you wish to route any wires from your components

around the bottom of the extrusion and inside of it,

it is recommended that you remove the front

extrusion to allow for easy access to the

inside of the rear extrusion.

A. Loosen any nuts that secure any mounting plates/brackets to the front extrusion.

(shown with optional traffic director)

B. Loosen the two nuts on each mounting bracket that secures the

mounting brackets to the front extrusion.

C. Remove the four screws securing

both endcaps to the extrusion and

slide the endcaps off.

D. Slide the front extrusion off the bolts attaching

the mounting legs and strobe light plate.

3. If necessary, slide the plastic “window” out of the rear

extrusion exposing the inside of the rear extrusion. (Your

rack may come with the window separate.)

-3-

Page 4

(Component Installation CONT’D)

4. Determine where you wires from your

components will wrap under the bar and enter

the extrusion and cut the plastic window to the

desired length.

• Using a sharp utility knife, heavily score a

“snap” line on the plastic.

• Bend the plastic back and forth about the

scored line until it breaks.

5. Route the wires from the first light under the extrusions (or over the top of the extrusion,

if applicable), connect them to the appropriate wires from the harness, and tuck the

connectors into the extrusion.

6. Measure the distance to the

wires from the next light and cut

another length of the plastic

window. Slide it into the

designated slot in the extrusion

as close as possible to the wires

from the first light.

7. Repeat steps 4-6 for each light you need to connect, cutting the last plastic window

piece to extend to the end of the extrusion.

8. Once all plastic window pieces are in place, slide the front extrusion over the bolts and

back onto the assembly.

9. If you are adding mounting plates/brackets, slide any

appropriate bolts into each slot based upon your application(s).

10 Replace the end cap and re-install the screws.

DO NOT OVER-TIGHTEN THE SCREWS. IF THE

SCREW HOLES ARE STRIPPED, THE SECURE

MOUNTING OF YOUR COMPONENTS MAY BE

COMPROMISED.

-4-

Loading...

Loading...