MANU-1072-HIN Rev. E

REBOKE 6000 TSI

Farming Wagon

Instruction Manual

STARA S/A - INDÚSTRIA DE IMPLEMENTOS AGRÍCOLAS

CNPJ: 91.495.499/0001-00

Av. Stara, 519 - Caixa Postal 53

Não-Me-Toque - RS - Brazil - CEP: 99470-000

Telephone/Fax: (0xx54) 3332-2800

e-mail: stara@stara.com.br

Home page: www.stara.com.br

MANU-1072-HIN

February/2016 - Revision E

REBOKE 6000 TSI

FARMING WAGON

INSTRUCTION MANUAL

CONTENT

FOREWORD .......................................................................................................................................7

INTRODUCTION ................................................................................................................................9

1 - MAIN COMPONENTS ................................................................................................................. 11

2 - IDENTIFICATION ........................................................................................................................12

3 - TECHNICAL SPECIFICATIONS .................................................................................................12

4 - DIMENSIONS ..............................................................................................................................14

5 - SAFETY PROCEDURE ...............................................................................................................15

5.1 - General safety procedures .................................................................................................. 15

5.2 - Understanding safety information ....................................................................................... 15

5.3 - Decal care............................................................................................................................16

5.4 - Intended use ........................................................................................................................ 16

5.5 - Improper operation ..............................................................................................................16

5.6 - Preventing unexpected machine start-up ........................................................................... 17

5.7 - Precautions to work with safety ...........................................................................................17

5.8 - Operating the implement with safety ...................................................................................18

5.9 - Safety measures transporting the implement .....................................................................20

5.9.1 - Transporting on public roadways ......................................................................................20

5.9.2 - Transporting the implement on trucks or shipping pallets ............................................... 20

5.9.3 - Lights and safety devices ................................................................................................. 20

5.10 - Avoid heating parts near uid lines ...................................................................................21

5.11 - Emergency procedures ......................................................................................................21

5.12 - Avoid uids under high pressure .......................................................................................21

5.13 - Clean water reservoir .........................................................................................................22

5.14 - Cautions while on hilly terrain ............................................................................................ 22

5.15 - Safety procedures for tires ................................................................................................22

5.16 - Safety measures during implement maintenance .............................................................23

5.17 - Protecting the environment ............................................................................................... 24

5.18 - Operator cautions when handling toxic products ..............................................................24

6 - MAINTENANCE ..........................................................................................................................25

6.1 - Retightening and lubrication ................................................................................................25

6.2 - Treatment system clean-up procedure ...............................................................................25

6.3 - Safety shields ......................................................................................................................26

6.4 - Main tank cares ...................................................................................................................27

6.5 - Paint care and cleaning ....................................................................................................... 27

7 - ASSEMBLY ..................................................................................................................................27

7.1 - Wheel assembly to axle installation ..................................................................................... 28

7.2 - Wheel axle to chassis installation .......................................................................................28

7.3 - Trailer hitch installation ........................................................................................................28

7.4 - Mounting the chassis, the main tank, support plate and chassis supports ........................29

7.5 - Mounting the cap, grating, the ladder and the canvas support arches ............................... 29

7.6 - Funnel installation ................................................................................................................29

7.7 - Support and the rest installation ..........................................................................................30

7.8 - Installing the 1

st

stage auger to the chassis.........................................................................30

7.9 - Mounting the output chute ...................................................................................................30

7.10 - Installing 2

nd

stage auger screw .........................................................................................31

7.11 - Mounting the clean water reservoir, treatment pumps, personal hygiene reservoir and

pump supports. ............................................................................................................................31

7.12 - Treatment control center installation .................................................................................. 31

7.13 - Hydraulic system installation .............................................................................................. 32

7.14 - Installing the treatment system ..........................................................................................32

7.15 - Independent hydraulic system installation .........................................................................32

7.16 - Tractor hook-up ..................................................................................................................33

7.17 - Convoy hook-up with the 14000 Plus/16000 Plus/11000 and 24000 ................................ 34

8 - OPERATION AND CALIBRATIONS ...........................................................................................34

8.1 - Procedures while maneuvering during the job ....................................................................34

8.2 - Independent hydraulic system operation ............................................................................35

8.3 - Seed treatments procedures ............................................................................................... 35

8.4 - Calibration procedures ........................................................................................................35

8.5 - Procedure to initiate the treatment ...................................................................................... 36

8.6 - Basic calibration tips for the treatment and graphite systems ............................................ 36

8.7 - Circuit cleaning procedure...................................................................................................37

9 - INTELLIGENT ELECTRONIC METERING SYSTEM ................................................................. 37

9.1 - Electronic metering system panel ........................................................................................ 37

9.2 - Functions .............................................................................................................................38

10 - METERING TROUBLESHOOTING ..........................................................................................40

11 - MULTIPLEX DL-128 MODULE PANEL ..................................................................................... 41

12 - INSTANT ELECTRONIC METERING SEED TREATMENT SYSTEM ..................................... 42

13 - SYSTEM TROUBLESHOOTING ...............................................................................................43

WARRANTY CLAIMS ......................................................................................................................45

WARRANTY REGISTRATION .........................................................................................................53

TECHNICAL DELIVERY TERMS .....................................................................................................57

TECHNICAL CHECK-UP TERMS .................................................................................................... 61

FOREWORD

This user manual was designed to guide you in the operation of your implement, its components,

and to instruct you on operation procedures and maintenance.

Read this manual thoroughly before using this product for the rst time, and make sure to take all

the necessary safety precautions.

This manual should be considered as a fundamental part and should be well cared for so that it is

always available for review since it contains instructions starting with the purchase of the implement

or machine to maintenance and long term care. At the end, there are also instructions on Warranty

Terms, Warranty Registration, Technical Delivery and Technical Check-up.

Due to the constant evolution of our products, Stara reserves the right to make changes to the

contents of this manual without prior notice.

This manual is available on our site www.stara.com.br, along with information on our entire product

line.

INTRODUCTION

Dear client, you have just become the proud owner of an implement made with the highest

technology, and which had the direct involvement of farming professionals who furnished their

inputs in its development.

The Reboke 6000 TSI has as its main feature, the ability to treat the seed in the eld, during the

re-lling process, thus reducing unnecessary seed handling. Also, the seed inoculation treatment

process has great benets in that the seed microorganisms have a longer life span, an additional

benet as it is placed in the soil shortly after the inoculation. Additionally, the Reboke 6000 TSI eld

treatment limits the waste of treated seed.

With proper use and a timely maintenance program, the Reboke 6000 TSI will further extend the

implement’s life expectancy, thus making it a highly protable investment. With that, we recommend

that you read this instruction manual carefully, and refer to it whenever there are questions and

doubts.

Stara makes available its technical assistance to help you and the dealership, in an effort to

maximize your implement’s protability.

Reboke 6000 TSI Instruction Manual

11

1 - MAIN COMPONENTS

The Reboke 6000 TSI farming wagon is made up of some basic components:

A - Chassis

B - Hitch

C - Drive-train

D - Grating

E - Canvas support arch

F - Main tank

G - Support

H - Ladder

I - Auger 1

st

stage

J - Auger 2

nd

stage

K - Treatment circuit

L - Clean water reservoir

M - Personal hygiene reservoir

Figure 1

I

J

A

D

E

F

M

C

G

K

L

K

H

B

Reboke 6000 TSI Instruction Manual

12

2 - IDENTIFICATION

All of Stara’s implements have and identication plate, which

lists the weight, capacity, model, manufactured date and serial

number.

When requesting parts or any information at your dealership,

mention the information which identies your implement.

The identication plate (Figure 2) is xed to the chassis of the

implement.

3 - TECHNICAL SPECIFICATIONS

Length with an auger 5.2 m

Length without an auger 3.4 m

Overall width of drive-train with an auger 5 m

Overall width of drive-train 2.7 m

Height with a closed auger 3.3 m

Height with an open auger 4.3 m

Auger output work height 3.7 m

Base raw material

Main tank Polyethylene

Chassis, output

chute and slidegate

Carbon steel

Seed treatment capacity 150 kg/min

Treatment pumping capacity 35 l

Minimum tractor pump ow-rate 50 l/min

Inoculant dosage range 80 to 700 ml

Pesticide dosage range 200 to 2000 ml

Treatment types Liquid inoculates, pesticides and graphite

Figure 2

Reboke 6000 TSI Instruction Manual

13

Minimum tractor power requirement 75 hp

Auger and feeder belt drive system TE 65 motor with electro-hydraulic controls.

Treatment system Remote controlled, electronic RPM sensor control

Hydraulic system

Electric system

Two helical pumps with reduction motors; Directional valves controller;

Inoculant and pesticide agitators; Graphite applicator with mixer.

Tires 7.50 x 16” - 10 Ply

Optional

Independent hydraulic system:

Oil reservoir with 110 liter capacity and a pump with output rate of 50 l/

min, PTO driven shaft at 540 rpm.

Convoy hitch

SHS oil system

(optional)

ST OIL ISO 68

Table 1

Reboke 6000 TSI Instruction Manual

14

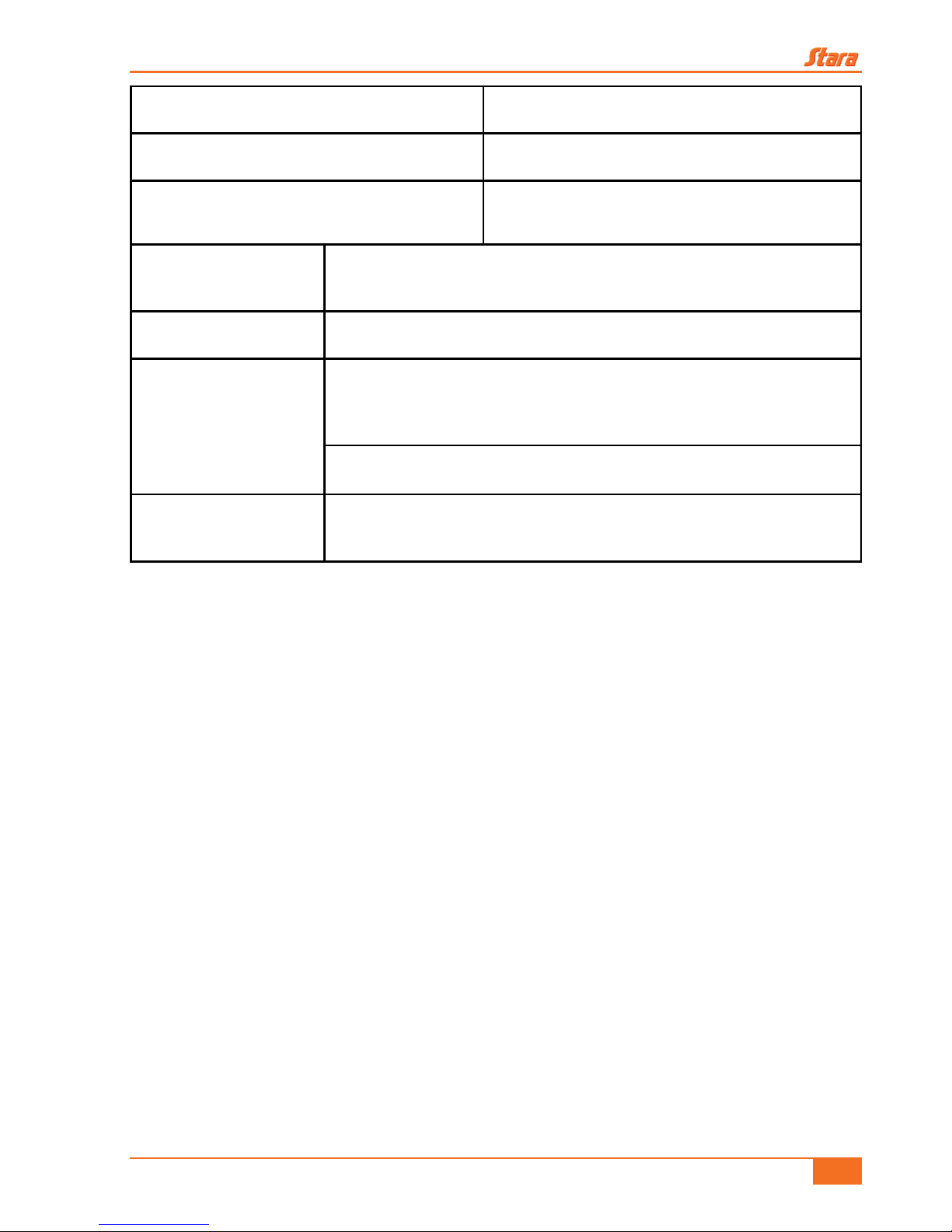

4 - DIMENSIONS

Figure 3

2.7 m

5 m

4.3 m

3.7 m

3.3 m

3.4 m

5.2 m

Figure 4

Reboke 6000 TSI Instruction Manual

15

5 - SAFETY PROCEDURE

The following items will describe the importance of operator

safety, also clarifying common risk situations during normal use

and implement maintenance, suggesting possible actions during

these situations.

Precautions are necessary in light of the equipment being used and working conditions found in the

eld, or in maintenance areas. The manufacturer has no direct control regarding these precautions

thus it becomes the responsibility of the owner to enforce these safety procedures while working

with the implement.

This implement follows design and work related SAFETY POLICIES FOR MACHINERY

EQUIPMENT CONSTRUCTION per NR-12.

Changing the original design of the implement is not allowed, since any alterations could affect the

operation of the implement, its safety and could reduce its lifespan.

Should you not fully understand any part of this manual and need the assistance of a technician,

please contact your local Stara dealership.

Carefully read all safety related messages and warnings in your manual (Figure 5).

IMPORTANT!

Maintain this instruction manual in good condition and do not forget to consult

it on a regular basis.

5.1 - General safety procedures

• When inspecting and refueling or relling other materials, all should be done with the implement

turned off and parked, using all safe means of accessibility.

• It is forbidden to carry passengers on self-propelled machines and implements.

• When servicing or inspecting the implement in high risk areas, these should only be done by

trained or skilled workers, when dealing with security issues

5.2 - Understanding safety information

This symbol is used as a warning sign (danger, warning and

caution). When you see this sign on your implement, be aware of

possible hazards (Figure 6).

Follow all recommended safety precautions and operational

safety practices, understand the importance of your safety.

• Accidents can cripple you, even cause death.

• Accidents can be prevented.

9100-6207

Figure 5

Figure 6

Reboke 6000 TSI Instruction Manual

16

5.3 - Decal care

• Do not remove or disgure safety or job instruction decals.

• Maintain safety decals in good condition.

• Replace any damaged or missing decals.

• Replacement safety decals can be found at your local Stara dealership.

5.4 - Intended use

• This implement was specically designed to be used with grains, seeds, fertilizers or in seed

treatments.

• This implement should be driven and operated by a trained operator.

5.5 - Improper operation

• To avoid the risk of injuries or death, do not transport

passengers or objects on the catwalk or on any part of the

implement (Figure 7).

• Do not use the tank or the output system of the implement

with other then specied products.

• Hitching-up, hooking-up or pushing other implements or accessories is not allowed.

• The implement should only be used by qualied operators who knows all controls and operation

techniques.

WARNING!

Any improper use of the implement, specially

on irregular terrain or hilly terrain could cause

overturning of the implement. Be extremely

cautious during rain, snow, icing or any slippery

terrain. If necessary get off the machine and

check the consistency of the soil.

WARNING!

Never leave the machine while it is in motion,

even if it is overturning, or suffer the possibility

of being crushed.

9100-6208

Figure 7

9100-5905

Figure 8

Reboke 6000 TSI Instruction Manual

17

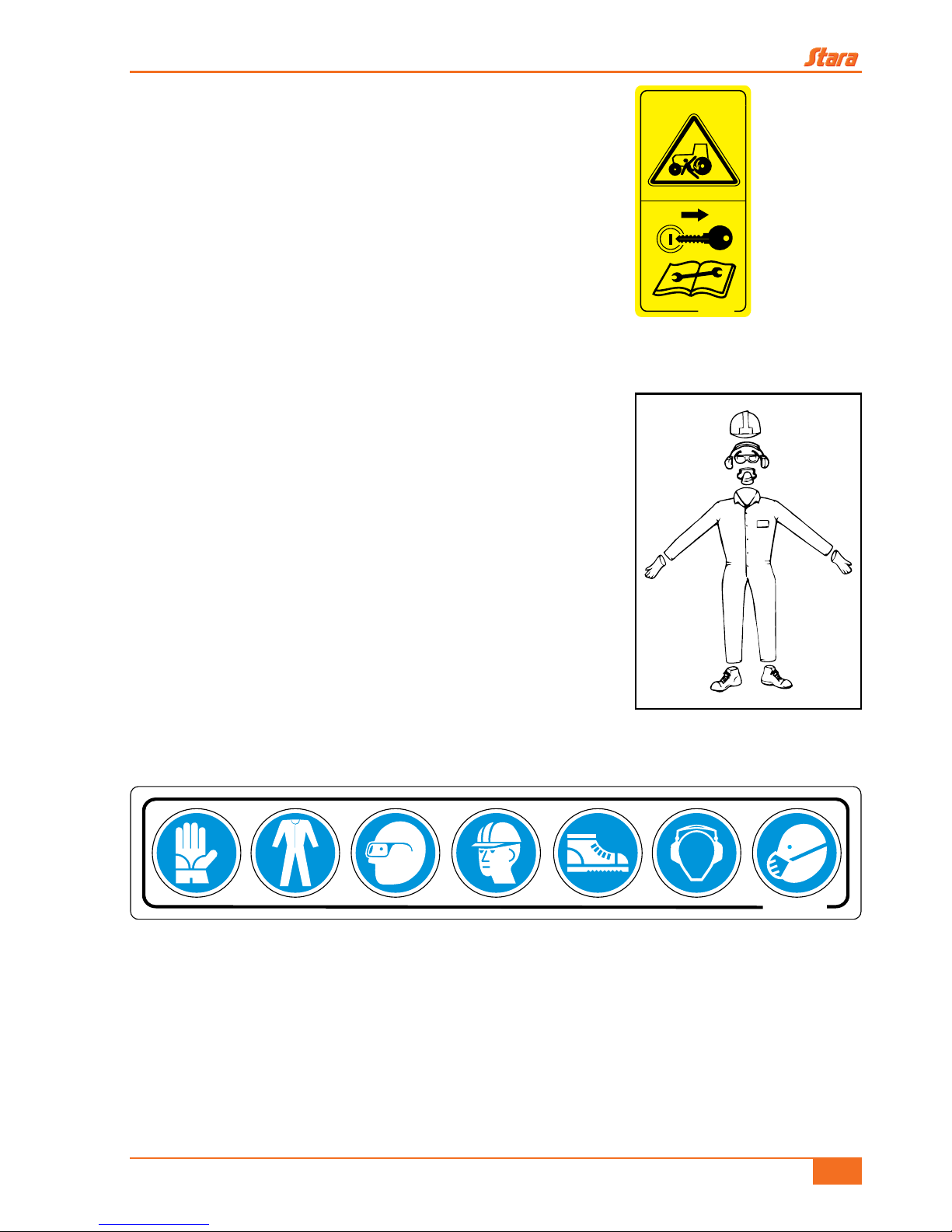

5.6 - Preventing unexpected machine start-up

• Protect yourself against possible injuries and even death, due

to an unexpected machine start-up.

• Do not start the tractor if the implement is not properly hitched

(Figure 9).

5.7 - Precautions to work with safety

When performing certain procedures with the implement, use the

required safety equipment as listed below (Figure 10 and Figure

11).

• Waterproof gloves;

• Waterproof long sleeve overalls;

• Safety glasses;

• Hard hat;

• Waterproof steel toe safety shoes;

• Hearing protection;

• Safety breathing mask with appropriate lter.

9100-5911

Figure 9

Figure 10

9100-6958

Figure 11

Reboke 6000 TSI Instruction Manual

18

5.8 - Operating the implement with safety

• Learn how to properly operate the implement.

• Do not allow untrained persons to operate the implement.

• Maintain the area of movement free while the implement is in operation (Figure 12).

• Before operating the implement, check for any persons or obstructions nearby (Figure 13).

• When using the jack or support stand, take care of possible accident hazards (Figure 14).

• Stay clear of mechanical moving parts like augers, gears and belts (Figure 15 and Figure 16).

• Periodically inspect all safety equipment on the implement before using it.

• Operate the implement only when all safety shields are properly installed and in their proper

positions.

• Do not operate near obstacles, rivers or streams.

• Before unhitching the wagon from the tractor, be sure to place stop blocks under the tires.

• Drive with caution and slowly while on rugged and hilly terrain.

• When going down-hill with the implement, use the same gears used while climbing (braking

motor).

• Restricted access for maintenance only, which should be done by specialized personnel who

will be accessing this area, and it is mandatory that all drive systems be disconnected.

• For greater implement safety and useful life, avoid heavy loads greater then the nominal

capacity specied for each implement.

• Use a tractor properly sized for the power requirements and, counterweights compatible with

the load and topography of the terrain, so that the tractor can safely control the implement.

Verify the minimum power requirements recommended for each implement model.

9100-5781

Figure 12

9100-5783

Figure 13

9100-5784

Figure 14

9100-5900

Figure 15

9100-5882

Figure 16

Reboke 6000 TSI Instruction Manual

19

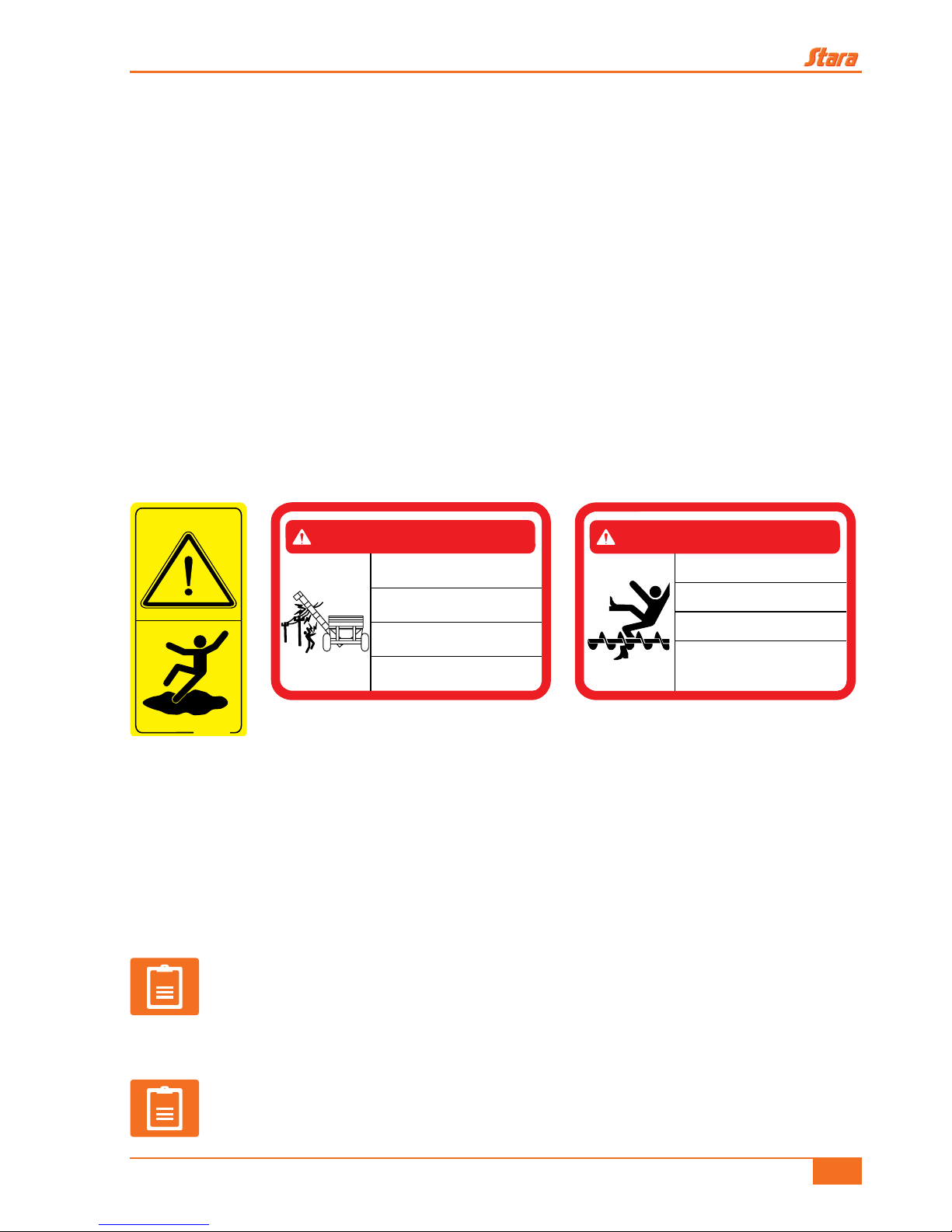

• Reduce speed on curves.

• When climbing on the implement, use the anti-skid steps on the ladder. Keep all steps, hand-

rails and catwalks free of residues like oil or grease, which could cause accidents (Figure 17).

• When covering the wagon with its canvas covering, avoid walking on the edges of the tank and

make use of the ladder, thus you will limit any accidental falling hazards.

• In case there is a need to enter the implement’s tank, use the ladder.

• Check the implement for proper working conditions. In case of any irregularities which may

hamper the operations, order the proper maintenance corrections prior to the operating or

transporting.

• Before operating the implement check the surrounding job area. Check for any nearby

obstructions like, trees, fences and high power electrical lines which are sources to serious

injury or even fatal hazards (Figure 18).

• Entering the tank area during use is prohibited. Access is allowed only for maintenance

servicing, while using safety rigging attached to the platform (Figure 19).

• When driving, drive at speeds compatible with the terrain and never above 16 km/h, thus you will

protect the implement by reducing maintenance costs and increasing its useful life.

• Reduce speed on wet or frozen surfaces or surfaces covered with gravel.

• Do not operate under the inuence of alcohol, tranquilizers or stimulants.

• Do not pick-up hitchhikers.

NOTE!

The optional rear hydraulic braking system has been sized only to assist the

tractor in the eld when controlling the tractor/wagon package on rough and

hilly terrain. It should not be used as the only braking device when the wagon

is loaded.

NOTE!

Before transporting the wagon, check that the output-chute is secure on its rest,

thus keeping the auger screw from dislodging and possibly cause and accident.

9100-6957

Figure 17

NÃO SE APROXIME DE LINHAS DE TRANSMISSÃO

OU CABOS ENERGIZADOS. O CHOQUE ELÉTRICO

PODE OCORRER COM OU SEM CONTATO DIRETO.

NO SE ACERQUE DE LÍNEAS DE TRANSMISIÓN O

CABLES ENERGIZADOS, EL CHOQUE ELÉCTRICO

PUEDE OCURRIR CON O SIN CONTACTO DIRECTO.

STAY CLEAR OF TRANMISSION LINES OR POWER

LINES, ELECTRIC SHOCK MAY OCCUR WITH OR

WITHOUT DIRECT CONTACT.

НЕ ПРИБЛИЖАЙТЕСЬ КЛИНИИ ПЕРЕДАЧ ИЛИ

ЭЛЕКТРИЧЕСКИМПРОВОДАМ, ПОРАЖЕНИЕ

ЭЛЕКТРИЧЕСКИМТОКОМ МОЖЕТПРОИЗОЙТИ

ПРИ НЕПОСРЕДСТВЕННОМ КОНТАКТЕ ИЛИ БЕЗ НЕГО.

9100-6963

PERIGO / PELIGRO / DANGER / ОПАСНОСТЬ

Figure 18

PROIBIDO O ACESSO AO RESERVATÓRIO

DURANTE O USO!

ACESSO SOMENTE PARAMANUTENÇÃO!

9100-8660

RESERVOIR ENTRY PROHIBITED

DURING OPERATION!

ENTRY ALLOWED DURING MAINTENANCE ONLY!

¡PROHIBIDO EL ACCESOAL ESTANQUE

DURANTE EL USO!

¡ACCESO SOLAMENTE PARAMANUTENCIÓN

ЗАПРЕЩЕНОНАХОДИТСЯ ВНУТРИ

БУНКЕРА-НАКОПИТЕЛЯ ПРИ РАБОТЕ ОБОРУДОВАНИЯ

НАХОДИТСЯ ВНУТРИБУНКЕРА-НАКОПИТЕЛЯ

РАЗРЕШЕНО ТОЛЬКОПРИ ВЫКЛЮЧЕННОМ

ОБОРУДОВАНИИСЦЕЛЬЮ ТЕХОБСЛУЖИВАНИЯ

PERIGO / PELIGRO / DANGER /ОПАСНОСТЬ

Figure 19

Reboke 6000 TSI Instruction Manual

20

5.9 - Safety measures transporting the implement

5.9.1 - Transporting on public roadways

• Traveling with the implement on public roads is prohibited.

• Know and respect all trafc signs.

• When transporting the implement use great caution.

• Do not obstruct trafc lanes.

5.9.2 - Transporting the implement on trucks or shipping pallets

• The implement should be partially disassembled.

• Properly position the implement so that none of its parts stick outside the atbed area.

• Use chains to tie-down the implement to the atbed by its tires with blocks, applying the

implement’s own brakes.

• The implement’s chassis should be tied-down the truck body frame, using heavy-duty straps.

• Maintain the parking brake applied.

• Be aware of the implement’s height limitations. Be careful when driving near trees, power lines

and overpasses.

5.9.3 - Lights and safety devices

When transporting implement on public highways, use extreme caution and safety, follow all transit

and local laws.

• Frequently check rear view mirrors.

• Always use your turn-signals to indicate your turning direction.

• The safety beacon should be located on top of the cabin and turned-on.

• Use driving lights, warning signals and turn-signals when driving, day or night.

• Respect all trafc signs.

• Always maintain warning signals, headlights and reectors clean, so that they may always be

visible. Also, check that headlights, turn-signals and warning signals are all working properly

should they not be functioning properly, call a repair technician to x them.

• Use anti-skid steps and hand-rails, thus avoiding slipping on catwalks or ladders.

• Besides all these safety features, plus having a skilled and capable operator, these will increase

the safety factor of personnel in surrounding area.

Reboke 6000 TSI Instruction Manual

21

5.10 - Avoid heating parts near uid lines

The heat on the lines may cause the material to become brittle

and to rupture, releasing pressurized uid. This may cause

severe burns or injuries.

5.11 - Emergency procedures

• Always be prepared for any type of res.

• In case of a re, or any other hazardous situation detrimental to the operator, he should seek

shelter in a secure place as quickly as possible.

• Keep all emergency phone numbers like doctors, ambulance services, hospitals and re

department near your phone.

5.12 - Avoid uids under high pressure

• High pressure uid leaks can penetrate the skin, which could

cause severe injuries.

• Avoid such hazards by relieving the pressure prior to

disconnecting the hydraulic lines or other lines. Tighten all

connections prior to pressuring-up the system.

• Protect yourself against high pressure uids.

• In case of an accident, seek immediate medical attention. Any

uid that penetrates the skin needs to be surgically removed

within a few hours so that gangrene will not set in.

• Do not loosen hydraulic hoses while under pressure. Take great care when servicing the

hydraulic system and use your personal safety equipment like, gloves and safety glasses.

• Only the qualied technicians can x this type of system. Consult with your local Stara dealership.

Figure 20

9100-5785

Figure 21

Reboke 6000 TSI Instruction Manual

22

5.13 - Clean water reservoir

Supplies a clean water source for eld wash-down in case of

an emergency when dealing with chemical products. Should

you come into contact with these chemicals, wash-up and seek

immediate medical assistance.

WARNING!

This water is not safe for human consumption.

5.14 - Cautions while on hilly terrain

• Avoid holes, ditches and obstacles which could overturn the implement, specially on steep hills.

• Avoid tight curves on sloppy or hilly terrain.

• Never operate the implement near ditches or rivers, which could be prone to overturning.

• Stay away for steep hills which could increase uneven cutting, along with hampering the safe

operation of the implement, even causing overturning.

5.15 - Safety procedures for tires

• Never try to rell a tire which is completely at. If the tire has

lost complete pressure, contact the nearest tire specialist.

• Always try to use a protective cage or safety shield when

trying to ll a tire (Figure 25).

• In case of a punctured tire, deate it to remove the object responsible for the puncture. The work

9100-5763

Figure 22

PAREA MÁQUINA EM LOCAL SEGURO. NÃO ESTACIONE A

MÁQUINA EM ACLIVE OU DECLIVE.

9100-6959

PARK THE MACHINE INA SECURE PLACE.

DO NOT PARK ONASLOPE OR GRADE.

PARALA MÁQUINA EN LOCAL SEGURO.

NO APARQUE LAMÁQUINA EN ACLIVE O DECLIVE.

УСТАНАВЛИВАЙТЕ МАШИНУВБЕЗОПАСНОМ МЕСТЕ.

НЕ ПАРКУЙТЕ ЕЕ НА СКЛОНЕ ИЛИ ПОДУГЛОМ.

PERIGO / PELIGRO / DANGER /ОПАСНОСТЬ

Figure 23

AO EFETUAR A DESCARGADA REBOKE,VERIFIQUE SE A

MESMA ESTÁ ESTACIONADAEM TERRENO NIVELADO.

CASO O MESMO POSSUA ALGUMAINCLINAÇÃO, O TUBO DE

DESCARGA DEVE ESTAR VOLTADO PARA O LADO DO ACLIVE.

AO EFETUAR A DESCARGADA REBOKE,VERIFIQUE SE A

MESMA ESTÁ ESTACIONADAEM TERRENO NIVELADO.

CASO O MESMO POSSUA ALGUMAINCLINAÇÃO, O TUBO DE

DESCARGA DEVE ESTAR VOLTADO PARA O LADO DO ACLIVE.

9100-6962

WHEN UNLOADING THE TRAILER WAGON,VERIFY THATIT

IS PARKED ON LEVELTERRAIN. IF IT IS ON A SLOPE, THE

DISCHARGE CHUTE TUBE SHOULD BE TURNED TOWARD

THE SLOPE.

AL EFECTÚAR LA DESCARGADE LA REBOKE, VERIFIQUE SI

LA MISMA ESTÁAPARCADA EN TERRENO NIVELADO.

SI EL MISMO TENGAALGUNAINCLINACIÓN, ELTUBO DE

DESCARGA DEBE DE ESTAR VUELTO PARAEL LADO DELACLIVE.

ПРИ РАЗГРУЗКЕ БУНКЕРА-НАКОПИТЕЛЯ, УБЕДИТЕСЬ,

ЧТООНСТОИТ НА РОВНОЙ МЕСТНОСТИ.ЕСЛ ИОН

НАХОДИТСЯ НА СКЛОНЕ,РАЗГРУЗОЧНЫЙ ЖЕЛОБ

ДОЛЖЕН БЫТЬ ПОВЕРНУТКСКЛОНУ.

PERIGO / PELIGRO / DANGER / ОПАСНОСТЬ

Figure 24

Figure 25

Reboke 6000 TSI Instruction Manual

23

to dismount and remount the tire should be done solely by a qualied professional.

• Any changes to the rim balancing can cause the tire to explode. For that reason, dismount the

tire before making any repairs to the rim.

Instructions when inating a tire:

• Use an appropriate air hose, long enough to reach work area, having an air gun with a dual

valve and an incremental metering scale with which to measure and see the pressure reading.

• Place yourself behind the specied safety line, along with any other personnel before beginning

to inate the tire.

• Never inate the tire to pressures higher then specied.

5.16 - Safety measures during implement maintenance

• Before using or servicing the implement (Figure 26), review

the manual instructions of section 6 on page 25.

• In order for someone to operate your implement and

equipment, the operator should be capable, properly trained

and must have read the instructions contained in this manual.

• Always maintain the implement in good working conditions,

performing all required maintenances as dened by the type

and frequency of implement operation, and also the types of

products involved.

• Check for any signs of ware and tare, noises and any places where there is a lack of lubrication.

In case of a break-down or component failure, seek your dealership in order to replace the part

with an original one.

• After any servicing, re-install all safety shields and tighten all hardware.

• It is recommended that all maintenance services be performed by trained and capable

professionals, having all implement mechanical devices turned-off.

• Maintain all components like, hoses, connections and clamps in good working conditions, in

order to prevent leaks.

• While performing any maintenance on the implement, immediately clean-up any oil spills.

• Do not smoke, nor install any electrical equipment near ammable products, be it on the

implement or storage areas.

• Failure to perform proper maintenance and or the improper operation of the implement

by untrained personnel, can cause serious accidents and injuries, besides damaging the

implement.

• Maintain the work area clean and dry.

9100-5897

Figure 26

Reboke 6000 TSI Instruction Manual

24

• Before doing any maintenance or adjustments, turn-off all power sources (electric, hydraulic),

turn-off the equipment’s main engine and operate controls to relieve any built-up hydraulic

system pressures.

• After using the implement wash-it, thus extending its useful life.

• Whenever you perform maintenance, be sure to use all personal safety equipment (PPEs), as

mentioned in the manual (Figure 11).

5.17 - Protecting the environment

It is illegal to pollute channels, rivers or the soil. Improper waste

disposal is a threat to the environment and the ecology.

• Use containers to dispose used oils.

• Use leak and spill proof containers, when draining used uids.

• Do not dump waste on the soil, sewer systems and waterways.

In order to know the proper manner to recycle or to dispose of waste, which are the correct methods

to discard oils, lters, tires and electronic equipment, seek your local waste recycling center or your

local Stara dealership.

5.18 - Operator cautions when handling toxic

products

The Health Department Agency of Brazil, has subdivided

toxic products into four groups. These classications are

fundamental in understanding the toxicity of a product,

and their acute side effects. See below the toxicological

classes and their respective identifying colors which are

placed on their containers.

CLASS I Extremely toxic Red band

CLASS II Highly toxic Yellow band

CLASS III Moderately toxic Blue band

CLASS IV Low toxicity Green band

Figure 27

PRODUTOS TÓXICOS

TOXIC PRODUCTS

PRODUCTOS TÓXICOS

ТОКСИЧНЫЕ ВЕЩЕСТВА

UTILIZE EQUIPAMENTOS DE SEGURANÇA

ADEQUADOS PARA O MANUSEIO.

UTILICE EQUIPOS DE SEGURIDAD

ADECUADOS PARA ELMANOSEO.

DURING HANDLING, USE APPROPRIATE

SAFETY EQUIPAMENT.

ВО ВРЕМЯ РАБОТЫ, ИСПОЛЬЗОВАТЬ

СООТВЕТСТВУЮЩЕЕ ОБОРУДОВАНИЕ

ДЛЯ БЕЗОПАСНОСТИ.

9100-4725

Figure 28

Table 2

Reboke 6000 TSI Instruction Manual

25

6 - MAINTENANCE

6.1 - Retightening and lubrication

When you start to use the wagon, be sure to do a general inspection of all hardware, especially

paying attention to the wheel screws, hitch bar and the auger screw support.

After the rst two working hours, check all hardware tightness and retighten if necessary. In the

future adopt a procedure to periodically inspect (daily) the hardware while in use, always paying

attention to the wheels and hitching bar hardware.

While in use, daily inspect all hardware (wheel assemblies, axles, brackets, chassis/hitch

assemblies, bearing xtures) and, tighten as needed.

Grease daily all points where there is some form of friction between components. All grease joints

are dened by decals found on the implement. Grease the bearing xtures of the auger screw every

eight working hours. Use blue grease, specic to bearings.

Do not remove excess grease which forms during lubrication, since it is an excellent barrier against

dirt and water.

Maintain tires calibrated, periodically inspecting them, knowing that the maximum indicated

implement load is of 102 psi.

After nishing the work day, washout the treatment system using the water in the clean water tank.

When washing down the Reboke, do not allow for direct water contact with boxes which house the

electronic systems, doing so could damage components.

6.2 - Treatment system clean-up procedure

NOTE!

Clean-out the insides of the tube after use, any product built-up can lock-up the

springs.

The treatment system should be cleaned-out after the last treatment of the day, doing so will avoid

plugging up the system, just follow these steps:

• 1

st

- Drain the pesticide and inoculant reservoirs so that you can use them later on again.

• 2nd - Open the clean water valves and using their own pumps perform the rst system wash-

down, leaving extra water for a second wash-down.

NOTE!

The wash-down water can be recycled on the next solution batch mixture.

Reboke 6000 TSI Instruction Manual

26

6.3 - Safety shields

Do not operate the implement if any safety shields

are not in their proper places. The absence of

any safety shields can lead to serious hazards to

the implement’s operator.

The safety shields which are illustrated on

gures should always be removed with the

implement turned-off and only when performing

maintenance, during partial or full hook-up

assembly replacements, or during the cleaning

of the auger screw (C) (Figure 33).

To remove the shields, rst remove the screws (B) that hold the shields (A) (Figure 32) in place,

and after completing the maintenance, replace the shields to their proper places and reinstall the

screws.

Figure 29

SAFETY SHIELD

INSIDE FUNNEL

Figure 30

PROTECTIVE

GRATING

Figure 32

Figure 31

PROTECTIVE

BOX

Figure 33

A

B

C

Reboke 6000 TSI Instruction Manual

27

6.4 - Main tank cares

The main tank is made of medium-high density polyethylene and has characteristics for high

durability even while being exposed to sun, rain and temperature variations. Applying certain cares

will further extend the usable life of the tank, like:

• Maintain the wagon under cover when not in use.

• Avoid heavy jolts, which can cause fractures and cracking.

• Do not drag sharp objects on the surfaces of the tank.

• Do not drop heavy or hot objects inside the tank.

• Take great cares when moving the tank during its mounting or dismounting.

Should there occur some form of cracking on the polyethylene tank, it is possible to repair it by using

a polyethylene solder string and a hot air blower process.

6.5 - Paint care and cleaning

The Reboke 6000 TSI does not need lots of maintenance cares, but, certain items do demand

careful servicing so that their life expectancy will be assured by doing so:

• After use high-pressure wash to wash-down all residues, next bathe all metallic surfaces and

parts with oil. This wash-down procedure must be done immediately after implement usage.

• Bathe metallic parts with oil immediately after using the implement.

• Touch-up paint on metal parts as needed, in order to keep rust from forming on parts.

NOTE!

The 6000 TSI Reboke was designed in such a way the its components will not be

impregnated with product residue, since all its parameters are bent outward or

downward.

7 - ASSEMBLY

The 6000 TSI farming wagon leaves the factory with some of its sub-assemblies already assembled,

but, to facilitate transporting, the larger sub-assemblies are assembled at the dealership or directly

at the nal client.

Reboke 6000 TSI Instruction Manual

28

7.1 - Wheel assembly to axle installation

After mounting the tires to the rims (this should

be done by qualied persons), continue by

mounting the wheel assemblies to the axle,

being careful to tighten the bolts in a staggered

pattern, so that the rims are well centered on the

hub.

Tighten all wheel bolts before using the wagon

for the rst time, and retighten all wheel bolts

after the rst job hour.

7.2 - Wheel axle to chassis installation

To install the axle assembly, place the mounting

holes facing upwards, block-in the tires, and with

the help of a winch or hoist position the chassis

support beams so that their mounting holes

lines-up with the chassis.

7.3 - Trailer hitch installation

When mounting the hitch to the chassis of the

6000 TSI Reboke, line-up the hitch mounting

holes to the front of the chassis. Insert the

locking-pin and secure it with bolts.

Figure 34

CHASSIS

WHEEL AXLE

SUPPORTS

Figure 35

Figure 36

Reboke 6000 TSI Instruction Manual

29

7.4 - Mounting the chassis, the main tank,

support plate and chassis supports

Before mounting the main tank, mount the

chassis and the chassis supports. Install the

polyethylene main tank as shown.

WARNING!

The main tank should be carefully

placed onto the chassis, thus

avoiding scratches and cracking,

since it cannot handle violent

shocks.

7.5 - Mounting the cap, grating, the ladder

and the canvas support arches

Proceed in mounting the ladder. Next, install the

cap at the bottom of the main tank. Then mount

the grating support and next mount them on the

upper borders of the tank, in a way that support

side tubings will rest on the tank bends, with the

screen slightly raised to the side. Place both

gratings in the same manner, securing them

downward to the center piece, so that both are

supported by the tank bends. Next, secure them

between each other with nuts and bolts. Then,

install the canvas support arches.

7.6 - Funnel installation

Mount the funnel, but leave the screws loose.

TANK SUPPORT

Figure 37

ARCHES

CAP

LADDER

GRATING

Figure 38

Figure 39

Reboke 6000 TSI Instruction Manual

30

7.7 - Support and the rest installation

Mount the support and the rest, leaving the

mounting screws loose.

7.8 - Installing the 1

st

stage auger to the

chassis

The auger screw assembly leaves the factory

pre-assembled, thus leaving only to mount it

onto the chassis. Secure the lower part of the

auger screw assembly to the funnel, and then

install the upper portion to the auger screw

support. To nish, tighten all hardware, even

those on the funnel.

7.9 - Mounting the output chute

Mount the output chute according to the image

to the side.

SUPPORT

REST

Figure 40

1st STAGE

AUGER

Figure 41

Figure 42

Reboke 6000 TSI Instruction Manual

31

7.10 - Installing 2

nd

stage auger screw

With the 1

st

stage auger screw mounted on the

chassis, proceed with mounting the 2nd stage

auger.

With the auger screw being held by the rest,

install the opening hydraulic cylinder and adjust

it so that it will hold the auger securely in-place,

when it is fully retracted.

7.11 - Mounting the clean water reservoir,

treatment pumps, personal hygiene reservoir

and pump supports.

Mount these items accordingly.

7.12 - Treatment control center installation

Install the control center accordingly.

2nd STAGE

AUGER

Figure 43

CLEAN WATER

RESERVOIR

PERSONAL HYGIENIC

RESERVOIR

PUMP

PUMP

Figure 44

Figure 45

Reboke 6000 TSI Instruction Manual

32

7.13 - Hydraulic system installation

The hydraulic system installation begins with the electro-hydraulic controls, which are mounted over

the hitch assembly. Next, mount the remaining components (hoses, connections, etc.).

7.14 - Installing the treatment system

Install the treatment system starting with the

pumps, next to the pumps and to the control

center, then on to the spray nozzles and returning

back to the pumps.

Hook-up the electrical system to the electronics

control panel, hooking-up the pumps, solenoids,

agitator motors, the graphite mixer, and the work

lights.

7.15 - Independent hydraulic system

installation

The independent hydraulic system is an optional

package, and its mounting is done on the front

side of the chassis, above the hitch.

Figure 46

CONTROL

PANEL

PUMPS

Figure 47

Reboke 6000 TSI Instruction Manual

33

7.16 - Tractor hook-up

The Reboke 6000 TSI is hooked-up to the tractor’s traction bar using a hitch pin.

WARNING!

When hooking-up the wagon to the tractor’s traction bar, remember to install the

locking-pin on the hitch pin (Figure 48).

WARNING!

Removing the hold-down bolt or not using the safety chain can lead to the

forfeiture of the implement’s warranty (Figure 49).

To nalize the hook-up, connect the hydraulic system hoses to the tractor’s hydraulic system.

Before connecting the lines, clean all the hose connectors(male) with a clean cloth, next retract the

receptacle(female) lock-ring toward the connection plate using one hand, and with the other, install

the hose terminal, and release the quick-disconnect (Figure 50).

If you cannot mate the hose to its mating connection, relieve the line pressure by pressing the

needle valve on the hose terminal (male) against a clean solid surface. Next return to the connection

procedure again (Figure 51).

PIN

LOCK-PIN

Figure 48

CHAIN

BOLT

Figure 49

Figure 50 Figure 51

Reboke 6000 TSI Instruction Manual

34

7.17 - Convoy hook-up with the 14000 Plus/16000 Plus/11000 and 24000

The Reboke 6000 TSI can be optionally hooked-up to other farming wagons such as the 14000

Plus, 16000 Plus, 11000 and 24000. If you opt for this option, it is necessary to use the convoy

hookup kit, which will match the hitch and supply the hydraulic extension hoses, which will mate-up

to the trailer itself or the hydraulic controls of the tractor, or the forward wagon’s SHS. The convoy

layout for the Reboke 6000 TSI in a convoy with the 14000 Plus wagon, is shown below.

8 - OPERATION AND CALIBRATIONS

8.1 - Procedures while maneuvering during the job

Whenever you need to move the Reboke 6000 TSI from a barn to the eld, or from the eld back

to the barn, or even from one eld to another, completely empty out the auger and place the feeder

chute in its resting position while transporting.

WARNING!

Before transporting the wagon, verify that the auger screw is secure in its rest,

thus you will avoid that it dislodge from its rest, and cause accidents.

While maneuvering drive at speeds relative to the terrain and never above 16 km/h, this way you will

be protecting your implement, reducing maintenance costs and increasing its life span.

NOTE!

The Reboke 6000 TSI chassis was designed to handle loads up to six tons,

depending of the type of tires being used. Staying within these limits will

guaranty your safety along with a longer life expectancy of your implement.

IMPORTANT!

When transporting the implement, the auger should be retracted to the rest

position. Never transport it while the auger is on output position.

Figure 52

Reboke 6000 TSI Instruction Manual

35

8.2 - Independent hydraulic system operation

The independent hydraulic system was designed to work within the following specications and

characteristics:

• System output: 50 l/min.

• Working pressure: 130 - 150 kg/cm².

• Avoid working the drive-shaft at speeds above 540 rpm (tractor PTO output), or cavitation may

occur (loud noise and premature ware and tare of components) on the hydraulic pump.

• Always operate the drive-shaft in a straight line of sight (tractor lined-up with the wagon), to

increase the life span of the drive-shaft components, and avoid excessive vibration.

• Do not leave the system running while not in use. Doing so will keep the hydraulic oil from

overheating. If at all possible, turn-off the whole system during the intervals between loading

and unloading operations.

8.3 - Seed treatments procedures

Seed treatment is done by following these steps:

• 1

st

- With the main tank full, open the slide-gate so that the seeds will ow out the base of the

auger screw.

• 2

nd

- The seed will be carried upwards by the auger screw, and at the beginning of this process

chemical products will be delivered for the treatment using the spray nozzles.

• 3

rd

- The seed is mixed with the chemical additives, inoculate and graphite while running the job,

by means of the auger screw on the treatment unit and the output chute.

8.4 - Calibration procedures

To adjust the seed treatment unit, proceed in the following order:

• 1

st

- Run the tractor up to the desire operating speeds.

• 2

nd

- Totally open the ow valve and partially open the seed control slide-gate.

• 3rd - Activate only the seeding function “SEM” on the electronic keypad.

• 4

th

- Operate the system until the seed ow rate at the output chute, next take a sampling at the

output chute for the span of one minute, weigh and note the collected weight.

NOTE!

If the collected rate was insufcient or excessive, make needed adjustments on

the slide-gate, and redo the sampling process until reaching the desired rates

(suggested working rates up to 150 kg/min).

Reboke 6000 TSI Instruction Manual

36

To work with the agricultural engineer’s recommended dosages use the following calculations:

Recommended dosage = ml of solution/kg of seeds

Job output rate= collection in kg/min

ml of solution x job output rate = solution volume (ml/min)

kg if seeds

Resulting example:

Thus the recommended dose will be, 200 ml of solution per 50 kg of seeds and the job output rates

suggested in this manual is = 100 kg/min. The ending result will be:

200 ml x 100 kg/min = 400 ml/min

50 kg

• 5

th

- To calibrate the treatment system, use the function keypad and press the pesticide function

“DEF” or inoculate “INOC”, depending on your requirements, after pressing the desired key for

three seconds, enter the desired dose and then conrm it by pressing the number two key, thus

the system will record the information, otherwise the information will be lost.

• 6

th

- In case a desired dose is not achieved, follow the steps on the Functions section, on page

38 keep in mind that the calibration can be done more then once to reach the desired dose.

• 7th - When using the graphite system, press the function key “GRA” on the electronic keypad and

then press the same key for three seconds to calibrate the graphite rate, which is available in a

scale of 0% to 100%. To nalize, press the number two key to record the information. In case

the desired rate is not achieved, use the 14 toothed gear for higher rates, and for lower rates

use the 23 toothed gear.

8.5 - Procedure to initiate the treatment

After concluding the calibrations, press the desired treatment operation on the function keypad, and

open the control valve. From this point on, use only the remote controls for the job.

WARNING!

Do not operate the panel with the control valves closed, otherwise the system

will not tolerate the pressure. Do not use the main tank when empty, otherwise

the pump can be damaged, resulting in the forfeiture of the warranty.

8.6 - Basic calibration tips for the treatment and graphite systems

Maintain the tractor rpm so that the treatment system screws remain around 530 to 550 rpm.

Always leave the pesticide tank mixer turned on while using it for seed treatment, thus avoiding any

settling of the solution.

Reboke 6000 TSI Instruction Manual

37

8.7 - Circuit cleaning procedure

The treatment circuit should be cleaned after each last job of the day, thus avoiding that the lines

clog-up, to do so follow these steps:

• 1

st

- Drain the reservoirs containing pesticides and inoculates, for future use.

• 2nd- Open the clean water valves and using the electric pumps, make the 1

st

system ush,

keeping part of the clean water for the 2nd and nal system ushing.

NOTE!

The wash-down water can be reused on the next treatment. To do so, close the

pump output ow valves, thus retaining the water in the pumps. Next, drain them

or open the drain during the cleaning process, saving the water in other vessels.

9 - INTELLIGENT ELECTRONIC METERING SYSTEM

9.1 - Electronic metering system panel

1

Graphite function key

11

Browser down-page select key

2

Browser menu key

12

Seed function key

3

Browser up-page select key

13

Main on/off key

4

Pesticide function key

14

Communication error alarm

5

Agitator on/off key

15

Not used

6

Light on/off key

16

Not used

7

Treatment start/cancel key

17

Not used

Figure 53

15 16 17

18

6

19

7

10

12

13

4

1

2

3

9

5 8

11

20

14

Reboke 6000 TSI Instruction Manual

38

8

Calibration function key

18

Message display

9

Browser increase key

19

Inclination indicator

10

Inoculation function key

20

Browser decrease key

9.2 - Functions

1 - On/Off function (13): the objective of the On/Off function key is to reduce power drainage while

the equipment is still connected to the tractor when it is stopped (note that the LED on the key

remains lit while the function is on).

2 - Treatment function (7): the Pesticide, Inoculation, Seed and Graphite motors will be activated

only after the treatment process has begun (note that the LED on the key remains lit while the

function is on).

3 - Agitator Function (5): the agitator motor can be started or turned-off regardless of treatment

process (note that the LED on the key remains lit while the function is on).

4 - Programming ml/min (Pesticide or Inoculant): press key number 4 or number 10 for three

seconds, and using keys 3, 9, 11 and 20, select the desired volume, next press key no. 2 to conclude

programming function.

5 - Calibration function: after programming the volume and obtaining a sampling of the product

volume within the time frame of 1 minute, follow the steps listed below: in case that the programmed

volume does not match the collected volume, use this function as listed below:

• Step 1: press key 8, and using keys 3, 9, 11 and 20, insert the values obtained in the sampling of

the PESTICIDE (Note that the LED on key 4- PESTICIDE will remain blinking).

• Step 2: press key 2 to conrm the selected value. (Note that the LED on key 10- INOCULANT

will remain blinking).

• Step 3: using keys 3, 9, 11 and 20, insert the value obtained in the sampling of the INOCULANT.

• Step 4: press key 2 to conrm the selected value.

• Step 5: Done! The system calibration is nished.

• Step 6: to conrm the calibration, repeat the sampling process and compare the volume of the

collected product values as programmed on item “4”.

6 - Verifying the PESTICIDE and INOCULANT pump ow rates: after concluding the calibration

process, we can now verify the ow-rates of each pump as calculated by the system, according to

the sampling data inserted on “Items 4 and 10”.

Follow the steps listed below to program the ow rates for each pump:

• Step 1: press key 2, and using keys 9 and 20, select the option: ” PUMP FLOW RATES ”, next

press key 2.

Table 3

Reboke 6000 TSI Instruction Manual

39

• Step 2: using keys 3 and 11, select a desired pump.

• Step 3: using keys 9 and 20, it is possible to manually adjust the ow rate of each pump, according

to manufacturer’s data (When modifying this value, it is mandatory that the a sampling process

be re-done, to verify “PROGRAMMED VOLUME x COLLECTED VOLUME ”).

7 - Adjusting the graphite speed: press key 1 for three seconds and using keys 3, 9, 11 and 20,

select the desired strength percentage, and then press key 2 to conclude the programing.

8 - Manual operation mode (pesticide and inoculant): should a pesticide or inoculant pump

speed sensors fail, the system will indicate a short-circuit at the specic output, and the manual

operation will be activated. In this mode, the system will apply the programmed values, ignoring

sensor readings.

Follow the steps listed below to start/stop the manual operation mode:

• Step 1: press key 2, and using keys 9 and 20, select an option: “Manual Mode Start/Stop ”, next

press key (2).

• Step 2: using keys 9 and 20, select option “Start”, next press key 2.

• Step 3: now, when selecting the programming function of “Item 4”, you will note that the units of

“ ml/min ” were changed to the unit of “ % ”, which refers to the strength level being applied by

each pump. The same situation will be repeated on “ item 10 ”.

9 - Driver Control: the system has an inclination sensor, which informs the operator of the

implement’s inclination positioning.

Follow the steps listed below to gauge the Control Drive system:

• Step 1: place the Reboke on a leveled surface.

• Step 2: press key 2, and using keys 9 and 20, select the option “ZERO- OUT THE

INCLINEOMETER”), then press key 2.

• Step 3: the procedure to verify the inclinometer has now been concluded. Note that only the rst

green LED on the light bar indicator of the inclinometer should remain lit.

10 - Communication Error Indicator: the blinking indicator (14), indicates that there is a CAN

communication fault between the Keypad and Power Module.

11- System Parameters: the system parameters (for example, pump ow rate values) are saved in

2 places, one in the keypad and the other in the module. In case these values are changed and are

different, a message will appear ”parameter are different”, and the next option will be to select which

parameter to be used,on the keypad or the module.

NOTE!

If the keypad is removed, the module parameters will be used, and if the module

is removed, then the “keypad parameters” will be used.

12- Remote control use/non-use: in case the remote control is lost or damaged, to add a new

remote control press key 2, and using keys 9 and 20, select the option Remote control, toggle key

2 and then add the remote control, and press 2 again, next keep pressing the remote control until

Reboke 6000 TSI Instruction Manual

40

Table 4

the system recognizes it. In case of not using the remote control, follow the same process stated

above, except select delete for the remote control and then press the no. 2 key, thus following the

procedure and the process will be completed.

10 - METERING TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Nothing works.

On/Off key was not pressed. Press on/off key.

Reboke not connected to

tractor.

Connect the power cable to the

tractor.

Polarities inverted.

Check the battery polarity

connections between the

tractor and the Reboke.

Communication error. CAN cable damaged.

Replace the cable.

Invert the CAN H and CAN L

wires.

Output 1 or 2

short-circuited.

Pump seized-up due to lack of

circuit cleaning after last use.

Apply 12 V directly to the

motor to dislodge the pump,

and proceed with the circuit

cleaning.

Pump motor has a short-circuit. Replace the motor.

Hydraulic motor

not working.

Pressure below 180 kg/cm².

Adjust hydraulic control

pressure to 180 kg/cm².

Motor will not reduce speed. Pump speed sensor defective.

Adjust the sensor, or if

damaged, operate manually.

Output 3 short-circuited.

Motor has a short-circuit or

brushes are damaged.

Replace the motor.

Output 5 short-circuited.

Inspect the harness or replace

the solenoid valve.

Inspect the harness or replace

the solenoid valve.

Output 6 short-circuited.

Light harness has a shortcircuit.

Inspect the harness.

Output 7 short-circuited.

Agitator motor has seized-up,

or has a short.

Inspect the harness or replace

the agitator motor.

Will not calibrate. Improper sensor calibration.

Calibrate sensors (run motor

at low speeds and verify if the

sensors LEDs blink according

to the pump’s rpms).

Remote control will not

work.

Weak battery. Replace remote control battery.

Reboke 6000 TSI Instruction Manual

41

11 - MULTIPLEX DL-128 MODULE PANEL

S5 TO S12

OUTPUT

CONNECTIONS

MULTIPLEX

PANEL

CONNECTION

INPUT

CONNECTOR

FROM E1 TO E14

GND

S1 S2 S3

(+) 12VCC

MULTIPLEX PANEL

CONNECTION

FUNCTION INDICATORS:

28 red: Output functions (loads)

18 green: Input functions (sensors)

1 yellow: Active

1 blue: Function status

Figure 54

Reboke 6000 TSI Instruction Manual

42

12 - INSTANT ELECTRONIC METERING SEED TREATMENT SYSTEM

POWER CABLE

POWER CABLE

RETURN

RETURN

TRACTOR

PESTICIDE

INOCULANT

PRESSURE

OUTPUT

PRESSURE

OUTPUT

DOSAGE

OUTPUT

TREATMENT

OUTPUT

TREATMENT

OUTPUT

SYSTEM POWER

CABLE

1 PESTICIDE RESERVOIR

2 INOCULANT RESERVOIR

3 PESTICIDE METERING PUMP

4 INOCULANT METERING PUMP

5 INDUCTIVE SENSOR

6 REDUCTION MOTOR

7 ELECTRIC MOTOR

8 2 WAY VA LV E

9 “T” CONNECTION

10 3 WAY VALVE

11 ELECTRONIC CONTROLLER

Figure 55

Reboke 6000 TSI Instruction Manual

43

13 - SYSTEM TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Hoses with xed

connectors leaking.

Improper tightening. Carefully retighten.

Insufcient thread sealant.

Use thread sealant tape and

carefully retighten.

Quick-disconnects

leaking.

Improper tightening. Carefully retighten.

Insufcient thread sealant.

Use thread sealant tape and

carefully retighten.

Damaged repairs. Replace damaged repairs.

Hydraulic motor leaking.

Defective o-ring seals. Replace o-rings.

Oil temperature above 80°C.

Stop the job until the temperature

cools down, then change tractors

or add an independent hydraulic

system on the tractor.

Hydraulic motor does

not work.

Pressure below 180 kg/cm².

Adjust the hydraulic control

pressure to 180 kg/cm².

Low oil level. Top-off the hydraulic oil level.

Low oil ow rate (under 40 l/min

for the TE-50 motor or under

60 l/min for the TE-80 motor).

Repair the pump if that is the

case, or replace the tractor with

one which has a pump that is

compatible with the motor being

used.

Dirty oil.

Clean or replace the hydraulic oil

lter if it is found to be dirty.

Hoses inverted.

Operate the controls according to

the indication of the arrow (left).

Plug pressure unequal. Adjust or replace, if necessary.

Quick-disconnects do

not mate.

Mismatched Quick-disconnects.

Replace quick-disconnects with

the proper mating parts.

Manometer pressure

changes.

Dirty nozzles or lters. Clean them as needed.

Table 5

WARRANTY CLAIMS

MUST BE KEPT ON FILE

The information contained in this warranty claim has been written, in a generalized way, thus

covering your new Stara implement. Should there be the need for additional information regarding

the use of your implement, we suggest reading the instruction manual.

All the information contained in this warranty claims are based on the last available data at the time

of its publication, being subject to changes without any previous warnings.

Please be aware that, any modications made to your Stara implement could affect your productivity,

safety and operation.

With these modications, you could jeopardize loosing your contractual warranty agreement issued

by Stara S/A Indústria de Implementos Agrícolas.

When purchasing your new Stara implement, demand that your authorized dealership chain

completely ll-out this warranty claim, along with explanations regarding the warranty issued by

Stara S/A Indústria de Implementos Agrícolas.

STARA’S IMPLEMENTS WARRANTY

1 - BASIC COVERAGE PERIOD

Stara S/A Indústria de Implementos Agrícolas, through its authorized dealership chain, guarantees

its implements under normal usage conditions, against parts manufacturing defects or installation,

for a total period as dened in the chart below:

IMPLEMENTS WARRANTY PERIOD

Self-propelled 12 months or 1,000 hours

Tractors 12 months or 1,000 hours

Technology equipment 12 months

Spreaders 6 months

Headers 6 months

Sprayers - Drawn/Hitched 6 months

Planters and Seeders 6 months

Other products 6 months

Original Stara parts and accessories 6 months

The rst 90 (ninety) days refer to a legal warranty as dened by the Brazilian courts and, an additional

contractual period issued freely by Stara S/A Indústria de Implementos Agrícolas.

The warranty begins at the date of issue of the implement’s sales invoice, having as its end user,

the rst owner.

• NOTE

The warranty time-frame for parts and components replaced during the basic warranty

period, expire on the end date of the contractual warranty as issued by Stara S/A Indústria de

Implementos Agrícolas.

1.1 - Accessories

Some implements can be purchased, through the authorized dealerships with pre-installed

accessories.

When dealing with accessories, even though genuine Stara parts, its warranty period has no

relationship with the implement’s warranty time-frame.

Thus, when purchasing your implement, demand all sales receipts for the accessories which were

installed on the implement, which will allow you to partake in the said warranties of these items.

For detailed information regarding warranty coverage of genuine Stara accessories, consult item 7

of this document.

1.2 - Transferable warranty

This warranty is totally transferable to the subsequent owners of the implement, as long as the

new owner has possession of the original warranty claims document, where all required periodic

maintenance are logged, and the starting date of the warranty.

2 - LIMITED WARRANTY COVERAGE

Tires, inner tubes and injection pumps are only directly guaranteed by their manufactures, of the

referred components. Stara, through its authorized dealerships, limits itself to only forwarding the

respective guarantees to the manufactures (or their authorized distributors) of said components.

Stara does not hold itself responsible for a positive or negative solution to a complaint which is

presented by the owner. Substituting complete assemblies like an engine, transmission or axles, will

only be done if there is no possibility of a partial repair by a technician.

3 - NATURAL WEAR AND TARE PARTS

Substituting parts and components during their normal usage on the implement and, due to natural

wear which is common to all parts and components, is not covered by the warranty, as long as it is

not related to a manufacturing defect.

Examples of natural wear and tare parts: electrical items; lters; belts; bearings; quick-disconnects;

cutting bars; wear shield plates; slide plates; chains; grain tank canvas cover; wind-shield wipers;

brake pads, disc brakes and brake shoes; tires; clutch plate, clutch discs and bearings.

4 - ITEMS AND SERVICES NOT COVERED BY THE WARRANTY

Factors out of the control of Stara S/A Indústria de Implementos Agrícolas.

(I) Repairs and adjustments resulting from improper use of the implement (examples: over-speeding

the engine, overloading, improper operations), negligence, modications, alterations, abuses,

accidents, improper adjustments and repairs, using non-genuine parts and any other usage

contrary to specications listed on the instruction manual.

(II) Damages to the implement of any sort due to adverse environmental conditions, such as acid

rain, reaction to chemical substances, tree sap, salinity, hail, strong winds, lightning, ooding,

impact damage by any objects and any other acts of nature.

(III) Failure to perform maintenance on the implement, necessary repairs and adjustments due to

improper maintenance (done by a third party or any other non-authorized dealerships), failure to

use the implement, the use of uids (and lubricants) not recommended by Stara S/A Indústria de

Implementos Agrícolas.

(IV) Repairs and adjustments resulting from the use of fuel with poor quality and/or that has been

adulterated.

4.1 - Additional expenditures

The warranty does not cover any expenditures for transporting the implement and loss of prots.

4.2 - Adulterated hourmeter

Any factors or evidence which proves that an hourmeter has been changed and tampered with, will

give just cause for the cancellation and termination of the warranty.

4.3 - Owner is responsible for maintenances

Engine adjustments, lubrication, cleaning, lter replacements, uids, natural wearing parts, are

some of the items used by the implement on their scheduled maintenances. Thus, these are charges

incurred by the owner of the implement.

5 - OWNER’S RESPONSIBILITIES

5.1 - Getting warranty service

The owner has the responsibility to deliver his implement for repairs at any Stara authorized

dealership, in order to maintain his warranty.

Fundamental conditions when honoring the warranty:

(I) The claim must be directed to a Stara authorized dealership, after it has been established that

there is evidence of a nonconformity.

(II) The warranty document for the implement must be presented and, that it be properly lled-out,

along with it all maintenance records as required by the scheduled maintenances.

5.2 - Maintenance

It is the owner’s responsibility for the proper operation, required operator training of those who will

operate the implement, not limiting it to those required by law, like maintenance and care, according

to the instructions listed in the instruction manual.

6 - HOW TO OBTAIN TECHNICAL ASSISTANCE

6.1 - Client satisfaction

Stara S/A The Agricultural Implements Company, is constantly looking for ways to improve its

implements and to client satisfaction.

All Stara authorized dealerships maintain a full arsenal of tools, equipment and technicians highly

trained by Stara S/A The Agricultural Implements Company, so that your implement has the best

repairs and services, all with a high standard of quality. Thus, when needed seek your nearest Stara

authorized dealership.

6.2 - Required information

In case there is the need to repair your Stara implement, keep on-hand the following information

and documents:

(I) A clear description of the nonconformity, including the conditions under which it occurred.

(II) Warranty claim document, instruction manual and all receipts which need to be legible, as proof

for oil changes not done by Stara authorized dealerships.

• IMPORTANT

The warranty claim document is required to have, a logged registry (stamps) of all check-ups

performed, according to the scheduled hours and time-frames.

All receipts needed as proof of oil changes not done by Stara approved dealerships.

It is the implement’s owner’s responsibility to retain all receipts in a legible manner, as proof for

an oil substitution which was done by a third party, and that it is recommended by Stara S/A The

Agricultural Implements Company, according to guidelines written in the instruction manual.

The receipts mentioned above will be required in situations where proof of oil changes are

necessary. Thus, when selling the implement, do not forget to supply these receipts to the

new owner. If you are purchasing the implement, request this documentation from the previous

ow ner.

• IMPORTANT

In the event that you need to repair the implement’s engine, the above mentioned documents

will be required for the warranty claim.

6.3 - Scheduled maintenance program

The scheduled maintenance program for the implement is written in the instruction manual.

In this plan you will nd all the required and necessary information for the best operation of your

Stara implement.

• IMPORTANT

All and any costs with reference to labor costs and parts and components replacement foreseen

in the maintenance program will be the responsibility of the implement’s owner, except for

changes paid for by the manufacturer.

6.4 - Implement’s scheduled maintenance plan

All scheduled maintenances listed in the instruction manual, will be done exclusively by a Stara

authorized dealership, also it shall be logged-in on the scheduled maintenance pages, which are

found at the end of this warranty claim.

The simple changing of oil and lters, as shown on the scheduled maintenance guidelines, does not

omit the mandatory requirements for regular scheduled maintenances.

Not complying with the regular scheduled maintenance program can compromise the proper

operation of your Stara implement, leading to possible nonconformities, which can be prevented by

implementing a regular scheduled maintenance program.

Stara S/A The Agricultural Implements Company reserves the right to make that judgment.

Therefore, we recommend that the whole scheduled maintenance program be fullled, so that such

situations can be avoided.

7 - WARRANTY OF GENUINE STARA REPLACEMENT PARTS

7.1 - Purchased and installed at an authorized Stara dealerships

In order to maintain the warranty of the genuine Stara replacement parts, they are required to be

purchased and installed by authorized Stara dealerships.

So that the warranty can be honored, the original receipt for the genuine Stara replacement part,

along with the Service Order for the installation of the replacement part on the implement will be

required as proof for the warranty period.

7.2 - Third party installation of purchased Stara authorized replacement parts

Third party installation of purchased Stara authorized replacement parts, are covered exclusively

under the legal warranty of 90 (ninety) days, against defects when proven to be due to the

manufacturing defects.

So that the warranty can be honored, the original authorized dealer receipt of purchase will be

required, to prove its validity for the warranty period.

• IMPORTANT

The warranty of the Stara genuine replacement parts, like the implement’s warranty, do not

cover the natural wear of the parts, as long as it does not deal with manufacturing defects.

Stara will only honor warranties of genuine parts purchased at authorized dealerships.

8 - WARRANTY OF GENUINE STARA ACCESSORIES

8.1 - Purchased and installed at Stara authorized dealerships

In order to honor the warranty of the Stara accessories, they must be purchased and installed by

authorized Stara dealerships. So that the warranty can be honored, the original receipt for the Stara

genuine accessory, along with the Service Order for its installation on the implement will be required

as proof for the warranty period

8.2 - Third party installation of purchased Stara authorized accessories

Third party installation of purchased Stara authorized genuine accessories, are covered exclusively

under the legal warranty of 90 (ninety) days, against defects when proven to be due to the

manufacturing defects.

So that the warranty can be honored, the original authorized dealer receipt of purchase will be

required, to prove its validity for the warranty period.

• IMPORTANT

The warranty period for genuine Stara accessories is exclusive and has nothing to do with the

warranty period of the implement.