Page 1

LINE THERMAL PRINTER

W inT pe 800C

TECHNICAL MANUAL

y

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

© Copyright 1996 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

This manual describes the WinType 800C line thermal printer.

It is intended for use as a reference for periodic inspections and maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

• This manual is divided into the following sections:

Chapter 1 General Specifications

Chapter 2 Adjustments

Chapter 3 Parts Replacement

Chapter 4 Maintenance and Lubrication

Chapter 5 Troubleshooting

Chapter 6 Parts List

1

2

3

4

5

6

7

Page 4

– 1 –

GENERAL SPECIFICATIONS

CHAPTER 1

GENERAL SPECIFICATIONS

1. General Specifications..........................................................................................3

2. External Dimensions.............................................................................................4

3. Control Panel .........................................................................................................6

4. Interface .................................................................................................................7

4-1. Connector Signals .................................................................................................. 7

5. DIP-SW Settings (Tentative) .................................................................................8

1

Page 5

– 3 –

GENERAL SPECIFICATIONS

1. General Specifications

Engine

Printing process Thermal wax transfer

Resolution 300 X 300 dpi

Printing speed

Letter size paper Monochrome 31 seconds/page

3 color (YMC) 64 seconds/page

4 color (YMCB) 80 seconds/page

A4 size paper Monochrome 32 seconds/page

3 color (YMC) 67 seconds/page

4 color (YMCB) 85 seconds/page

Legal size paper Monochrome 37 seconds/page

3 color (YMC) 87 seconds/page

4 color (YMCB) 107 seconds/page

Special A4 size paper Monochrome 37 seconds/page

3 color (YMC) 87 seconds/page

4 color (YMCB) 107 seconds/page

Paper feed

Speed Paper: 4, 6, 8 or 10 ms/line (depending on data transfer speed)

OHP film: 6, 8 or 10 ms/line (depending on data transfer speed)

Paper handling Paper tray Capacity: 50 sheets of coated/presentation grade paper

Paper stacker: 10 sheets

Manual insertion:Available

Interface Centronics parallel

Power supply 120VAC, 220VAC, 230VAC, 240VAC, 50/60Hz

(varies according to the country of purchase)

Power consumption At standby: 17W

At printing: 120W

Dimensions 14.13" (W) x 10.08" (D) x 5.04" (H)

(359mm (W) x 256mm (D) x 128mm (H))

Weight 16.5 lbs. (7.5 kg.)

Reliability information Printer life 25,000 pages or 5 years

Printer head life 5,000 pages (A4 size, 3 color, 20% duty)

Noise level ISO-7779

53.0 dB

Environment

Temperature Operating: +10° to +35°C (50° to 95°F)

Non-operating: -20° to +55°C (- 4° to 131°F)

Humidity Operating: 30 to 70% RH (no condensation)

Non-operating: 30 to 90% RH (no condensation)

Page 6

– 4 –

GENERAL SPECIFICATIONS

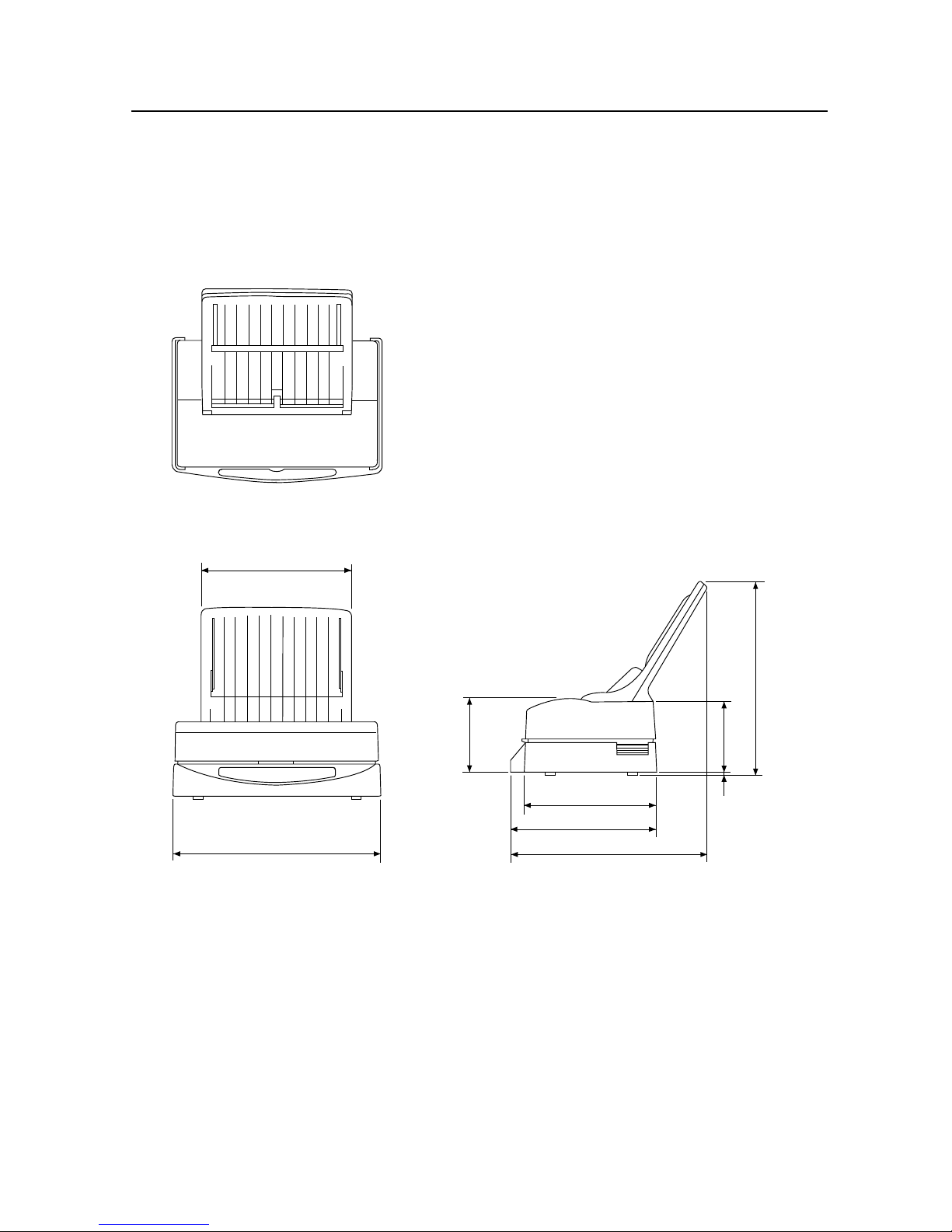

2. External Dimensions

Fig. 1 - 1 External Dimensions

260

359

5

234

122

335

256

341

128

Page 7

– 5 –

GENERAL SPECIFICATIONS

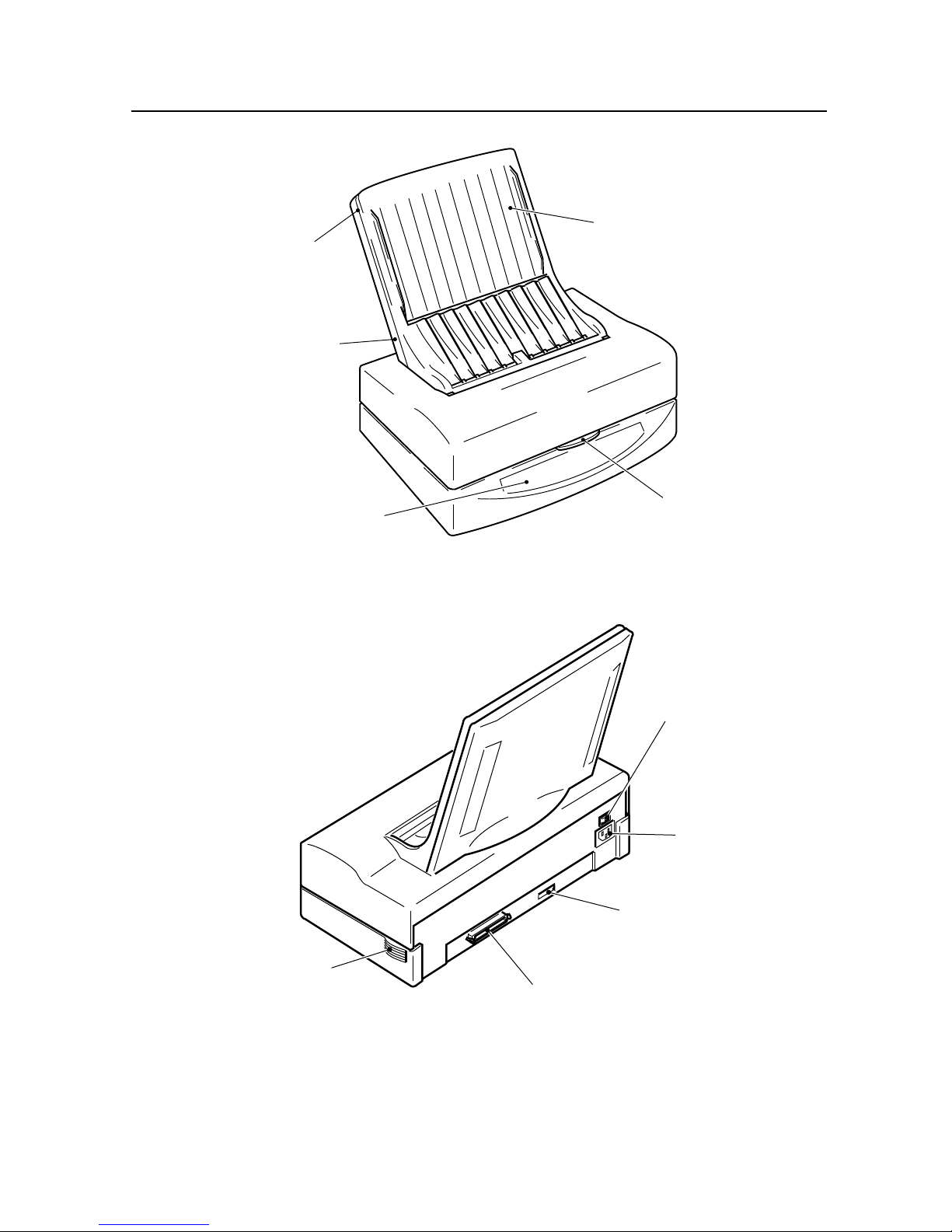

Fig. 1 - 2 Front View of the Printer

Fig. 1 - 3 Rear View of the Printer

Paper Tray

(Abbreviation of Paper

Tray Base and Paper

Tray Cover)

Paper Tray Cover

Paper Tray Base

Control Panel

Top Cover

Release

Power Supply

Switch

Power Supply

Connector

DIP Switches

Parallel Interface

Cooling Fan

Vents

Page 8

– 6 –

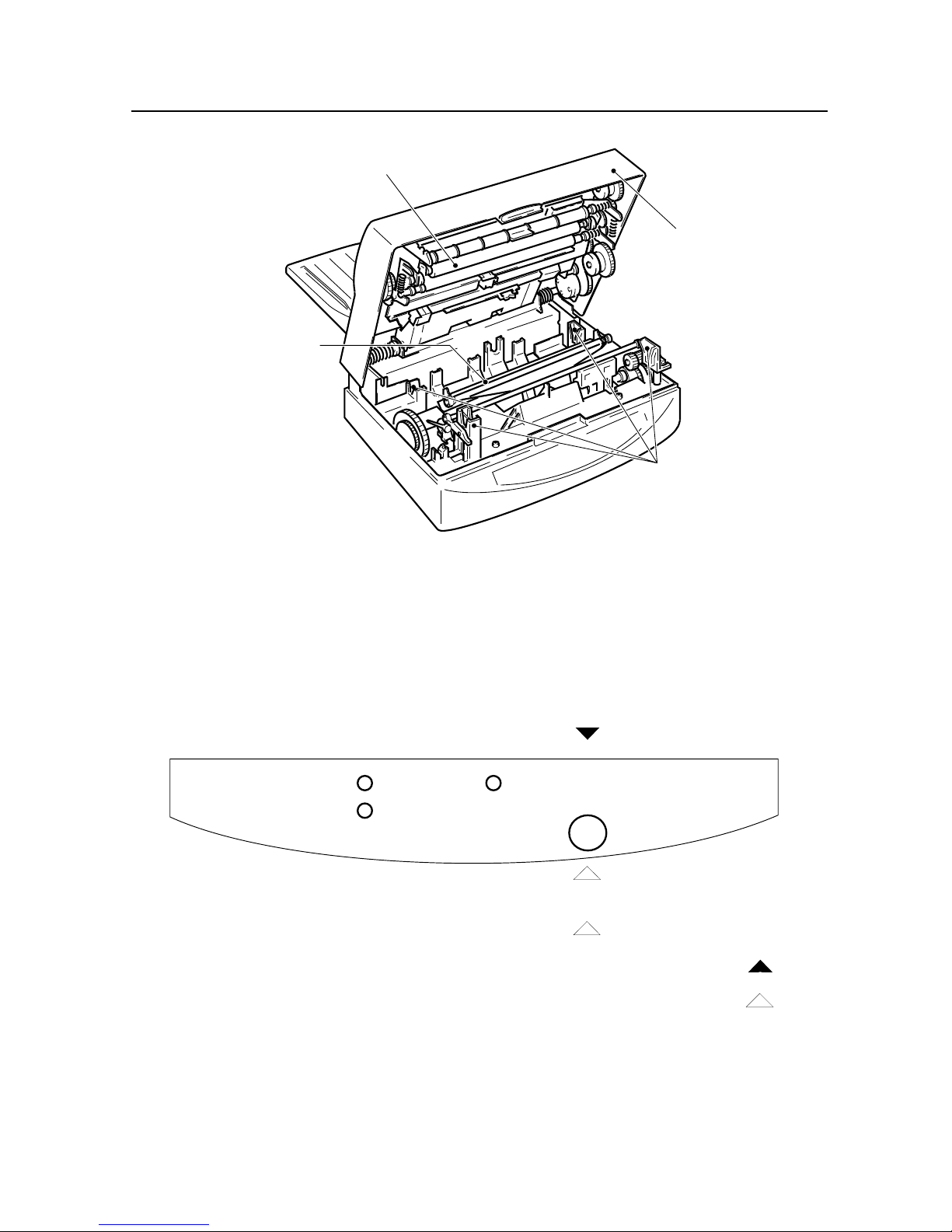

GENERAL SPECIFICATIONS

Paper

Film Roll

Ready

3. Control Panel

Fig. 1 - 4 View of the Inside of the Printer

Platen Roller

Top Cover

Thermal Head

Bobbin Sockets

Power ON

ONLINE/READY

OFFLINE/NOT READY

OFFLINE (Not Ready)

ONLINE (READY)

Test Print

Hold

Push

Fig. 1-5 Control Panel

Page 9

– 7 –

GENERAL SPECIFICATIONS

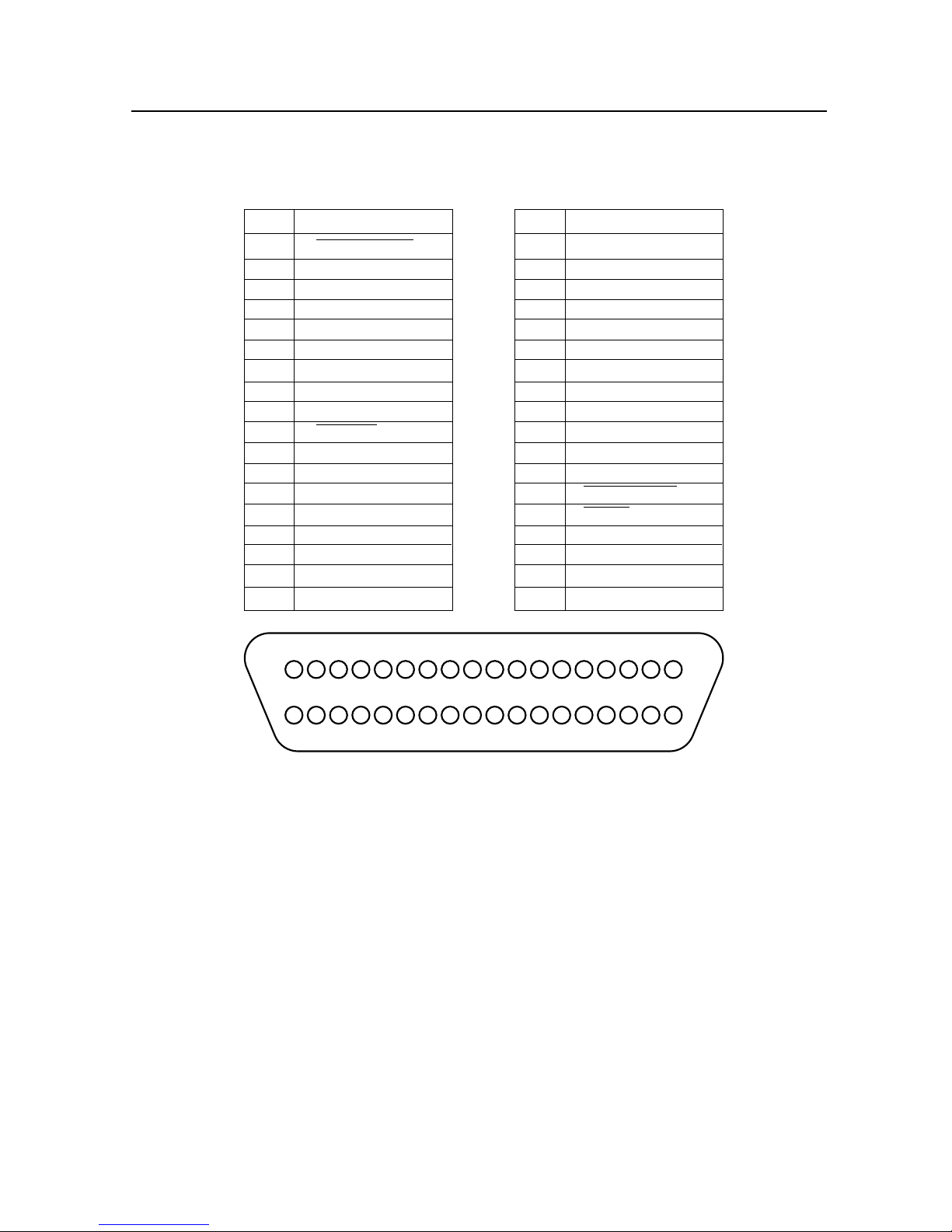

4. Interface

4-1. Connector Signals

Pin Signal Pin Signal

1 DATA STROBE 19 GND

2 DATA 1 20 GND

3 DATA 2 21 GND

4 DATA 3 22 GND

5 DATA 4 23 GND

6 DATA 5 24 GND

7 DATA 6 25 GND

8 DATA 7 26 GND

9 DATA 8 27 GND

10 ACKNLG 28 GND

11 BUSY 29 GND

12 EOP 30 GND

13 ON LINE 31 INPUT PRIME

14 GND 32 FAULT

15 33 GND

16 GND 34 EOI

17 CHASSIS GND 35

18 +5V (Max. 160mA) 36

118

19

36

Fig. 1-6 Pin Assignment

Page 10

– 8 –

GENERAL SPECIFICATIONS

5. DIP-SW SETTINGS (Tentative)

SW No. Function

1, 2 MEDIA mode

SW1 SW2

ON ON Coated paper mode

(A-PWC, A4-PWC, SA-PWC, SA4-PWC)

ON OFF Normal paper mode (Hammermill 10468-7, Xerox L-A4)

OFF ON OHP film mode (A-TFC, A4-TFC, SA-TFC, SA4-TFC)

OFF OFF Not Used (Coated paper mode)

3, 4, 5 Film roll type

SW3 SW4 SW5

ON ON ON TL1-11C3H 3 color film roll for Letter and A4

ON ON OFF TL1-14C3H 3 color film roll for Legal and SA4*

ON OFF ON TL1-11C4H 4 color film roll for Letter and A4

ON OFF OFF TL1-14C4H 4 color film roll for Legal and SA4*

OFF ON ON TL1-CBH monochrome film roll

OFF ON OFF Not used (monochrome film roll)

OFF OFF ON Not used (monochrome film roll)

OFF OFF OFF Not used (monochrome film roll)

6 Print Media Size

SW6

ON Letter or A4

OFF Legal or Special A4

7, 8, 9 Density

SW7 SW8 SW9 Density

ON ON ON 0 (Default)

ON ON OFF +1

ON OFF ON +2

ON OFF OFF +3 (Darkest)

OFF ON ON –1

OFF ON OFF –2

OFF OFF ON –3 (Lightest)

OFF OFF OFF Not used (Default)

10 Reserved

SW10

ON Normal

OFF TEST 2 (Factory test mode)

Notes:

Factory setting: 1234567890

OFF

ON **********

*SA4 means 'Special A4' which size is 210 X 335.6 mm.

Page 11

– 9 –

CHECK AND ADJUSTMENT

CHAPTER 2

ADJUSTMENTS

1. Adjusting power output voltage ........................................................................11

1-1. Adjusting thermal head voltage .......................................................................... 11

1-2. Checking that there is 5V......................................................................................11

2. Circuit Diagram....................................................................................................12

3. Off-register...........................................................................................................13

3-1. Preparations.......................................................................................................... 13

3-2. Checking off-register............................................................................................ 13

3-3. X direction only..................................................................................................... 14

3-4. X and Y directions ................................................................................................ 14

2

Page 12

– 11 –

CHECK AND ADJUSTMENT

1. Adjusting power output voltage

1-1. Adjusting thermal head voltage

(1) Turn OFF the power to the printer.

(2) Take the Harness Head Power Connector off of the Thermal Head.

(Refer to "1. Thermal Head" in Chapter 3.)

(3) Turn ON the power to the printer.

(4) Measure the voltage of pins 1 – 6 (VTM) and 7 – 12 (GND) of the Harness Head Power Connector. The

left edge pin of the Power Supply is pin 1.

(5) Adjust so that there is 24.5V (±0.1V) in the Thermal Head. (You can adjust by using a regular (+) screw

driver to rotate the VTH adjustment screw.)

(6) After adjusting, turn ON the power to the printer.

(7) Connect the Harness Head Power and attach the Thermal Head.

1-2 Checking that there is 5V

(1) Turn OFF the power to the printer.

(2) Take the Harness Head Power Connector off of the Thermal Head.

(3) Turn ON the power to the printer.

(4) Measure the voltage of pins 13 (5V) and 7 – 12 (GND) of the Harness Head Power Connector.

(You cannot adjust the voltage here.)

5V Vth

Power Supply

Adjust using a (+) screwdriver.

Page 13

– 12 –

CHECK AND ADJUSTMENT

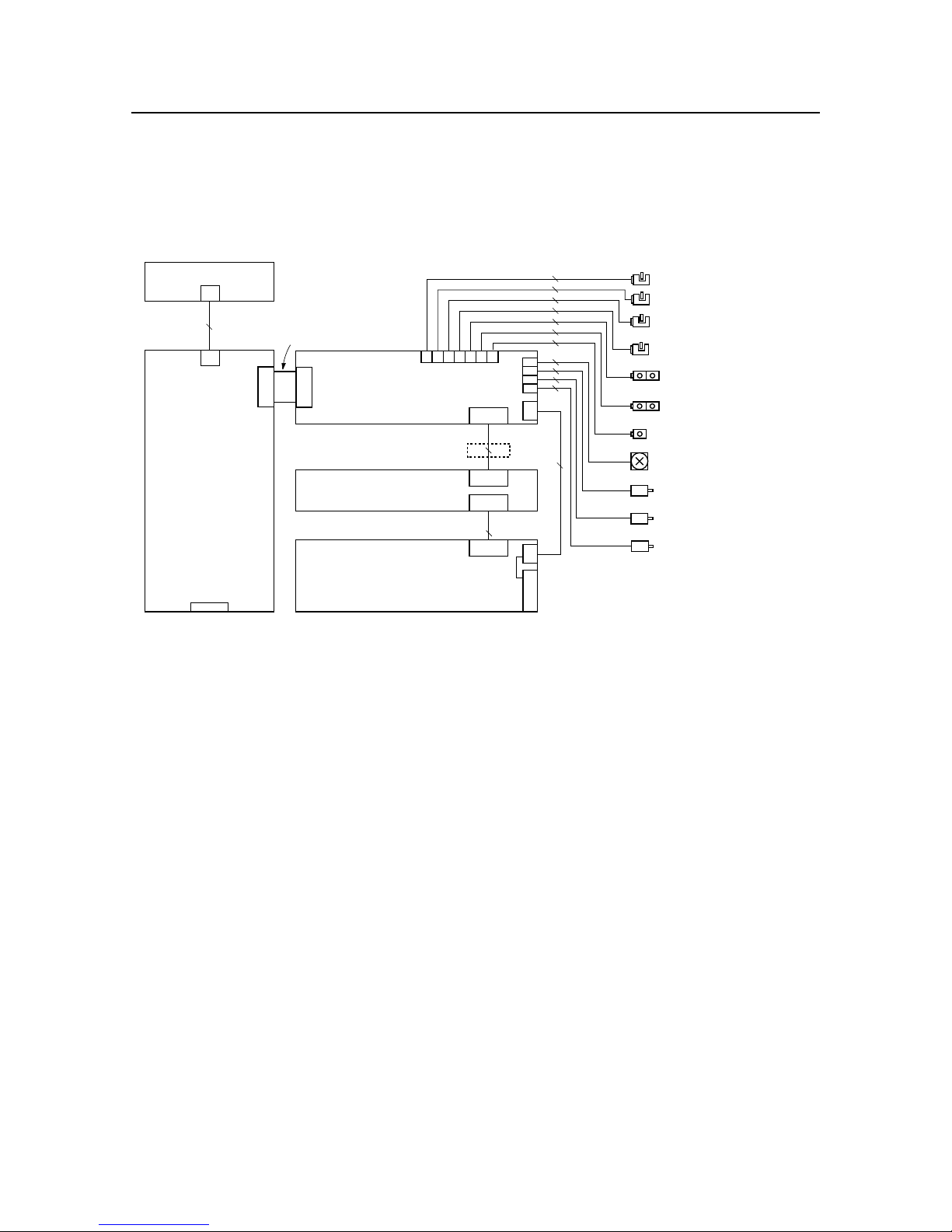

2. Circuit Diagram

Control PCB

Centronics

I/F PC Board

Harness I/F J11

Harness Head J12

Thermal Head

Power Supply

J18 J20 J22 J24

J19 J21 J23

YELLOW

GREEN

RED

VIOLET

PINK

BLUE

BROWN 2

2

2

3

3

3

3

2

6

4

4

9

BLK

Harness Head Power

BLK

13

9

13

13

16

J14 2

J17 6

J16 5

J15 4

Engine PCB

Ferrite Core

Harness Engine J30

3030 30

J11

Film Roll DOWN Sensor (includ.

Base)

Film Roll UP Sensor

(includ. Roller Base Unit)

Paper Start Sensor

(includ. Roller Base Unit)

Head Fan (includ. Base)

Paper Motor

Film Roll Motor

Head U/D Motor

FAN

J12

J30

9

Cam Sensor (includ. Roller Base Unit)

EOP Sensor (includ. Paper Plate Unit)

Cover Open Sensor (includ. Paper Motor)

Paper Edge Sensor

(includ. Roller Base Unit)

Page 14

– 13 –

CHECK AND ADJUSTMENT

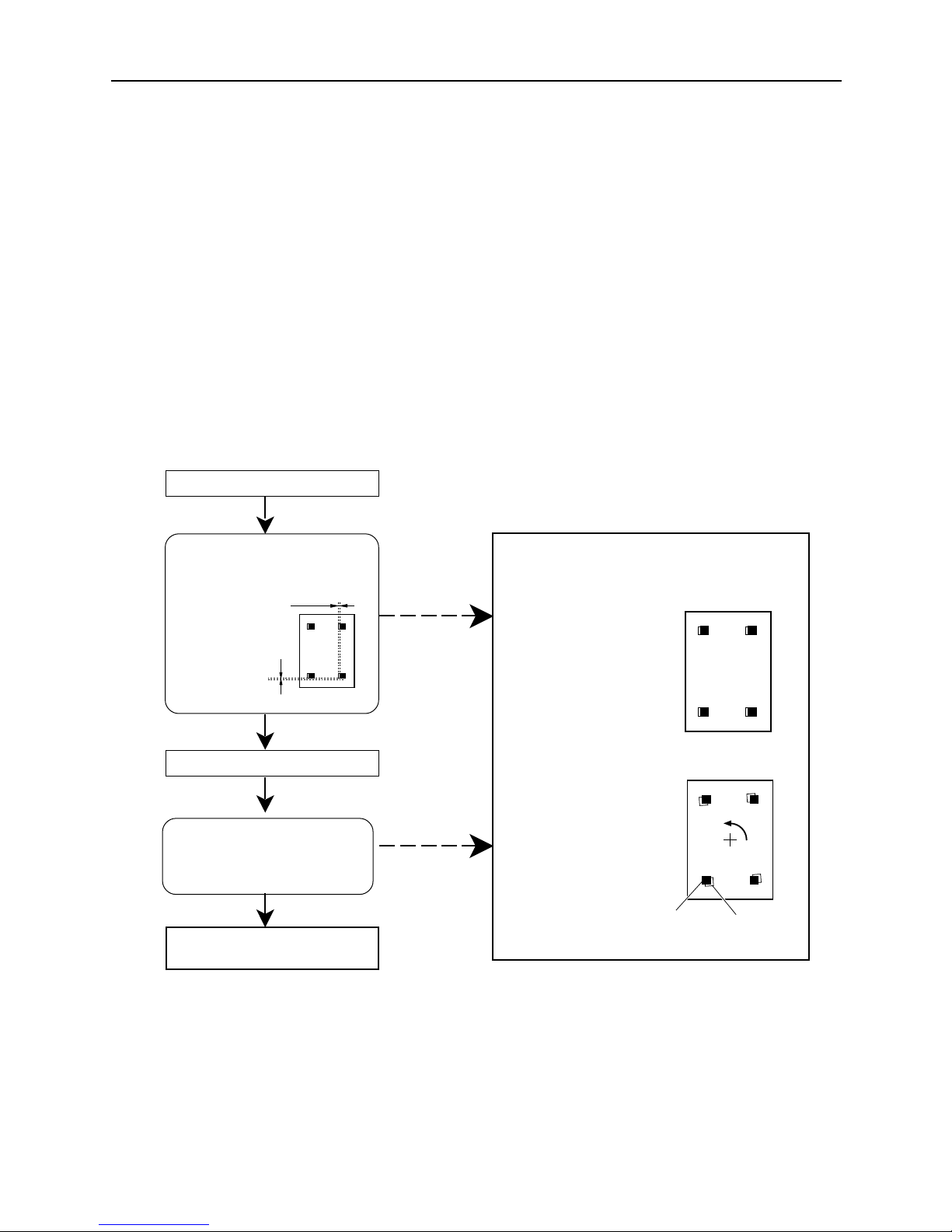

3. Colour off-register

This printer is shipped from the factory after it has undergone thorough colour off-register adjustments. However,

colour off-register may occur as a result of any of the following causes.

• Use of the printer over a long period of time.

• Replacement of the Thermal Head Unit, Upper Mechanical Unit or the Lower Mechanical Unit.

If this should occur, adjust using the following procedures.

3-1. Preparations

(1) Set the left side Pinch Roller Spring positions to F2 and B2. (Refer to section 3-4)

(2) Set the right side Pinch Roller Spring positions to F2 and B2. (Refer to section 3-4)

(3) If you have just finished cleaning the Platen Rollers and Pinch Rollers, print more than 10 sheets.

3-2. Checking colour off-register

Print 1 self test.

Print 4 more self tests.

Are points 1 – 4 colour offregister less than 0.25mm in the

X or Y directions for all five

tests?

yes

no

no

Are points 1 – 4 colour offregister less than 0.2mm in the X

orY directions?

Adjustment is needed. Adjust according to the

type of colour off-register.

Magenta Yellow

or Cyan

The colour off-register

occurred to parallelism.

(Refer to section 3-3)

The colour off-register

occurred to turn.

(Refer to section 3-4)

Y Direction

It is within the tolerance range.

Further adjustment is not needed.

yes

X Direction

Page 15

– 14 –

CHECK AND ADJUSTMENT

Standard

112321314233524345545

Left Side Hook Position

Right Side Hook Position

3-3. The colour off-register occurred to parallelism

3-4. The colour off-register occurred to turn

(2) If colour off-register occurs even though item (1) is correct, replace the Roller Base

Unit.

(2) If colour off-register are not correct, refer to the following table and change the left

and right Pinch Roller Springs' hook positions.

(1) Check that the fitting of the Head Spring of the Thermal Head Unit is correct.

(It should be standing vertically .)

Incorrect

After adjusting, refer to the previous page and check that colour off-register is correct.

545543425332413123211

Thermal head

Head bracket

(1) Change the Pinch Roller Springs' hook positions on the left-side of the Roller Base

Unit. (The right-side of the Roller Base Unit position of 3 )

Example of yellow is in the

case of left-turn.

Magenta Yellow

or Cyan

Springs get tighter as

numbers get larger.

(F)

(B)

F2

F1

F3

B1

B2

B3

1

2

3

4

5

• If YELLOW is in

the case of left-turn

, loosen the spring.

• If YELLOW is in

the case of right-turn

, tighten the spring.

YELLOW

right-turn

YELLOW

left-turn

After adjusting, refer to the previous page and check that colour off-registe is correct.

Page 16

– 15 –

PARTS REPLACEMENT

CHAPTER 3

PARTS REPLACEMENT

1. Thermal Head ......................................................................................................17

2. Paper Motor .........................................................................................................19

3. Centronics I/F PC Board.....................................................................................21

4. Engine PC Board.................................................................................................23

5. Control PC Board ................................................................................................24

6. Power Supply (First Half) ...................................................................................25

7. Power Supply (Second Half) ..............................................................................27

8. Film Roll Motor ....................................................................................................28

9. Base......................................................................................................................29

10. Cover Shaft Unit ..................................................................................................30

11. Paper Plate Unit ...................................................................................................31

12. Head U/D Motor ...................................................................................................32

13. Top Cover.............................................................................................................33

14. Torque Limit and Roller Base Unit ....................................................................34

1

2

3

Page 17

– 17 –

PARTS REPLACEMENT

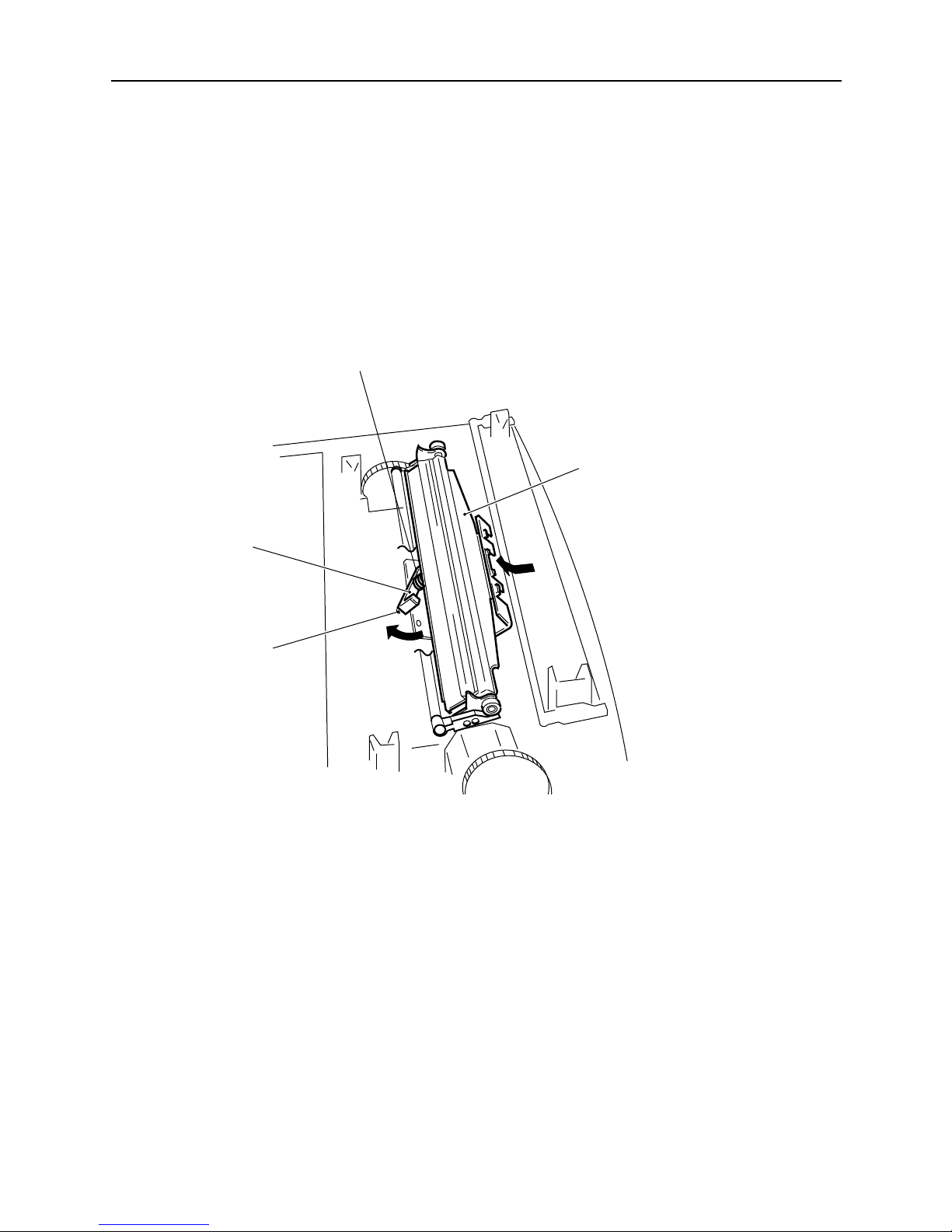

1. Thermal Head

[Remove]

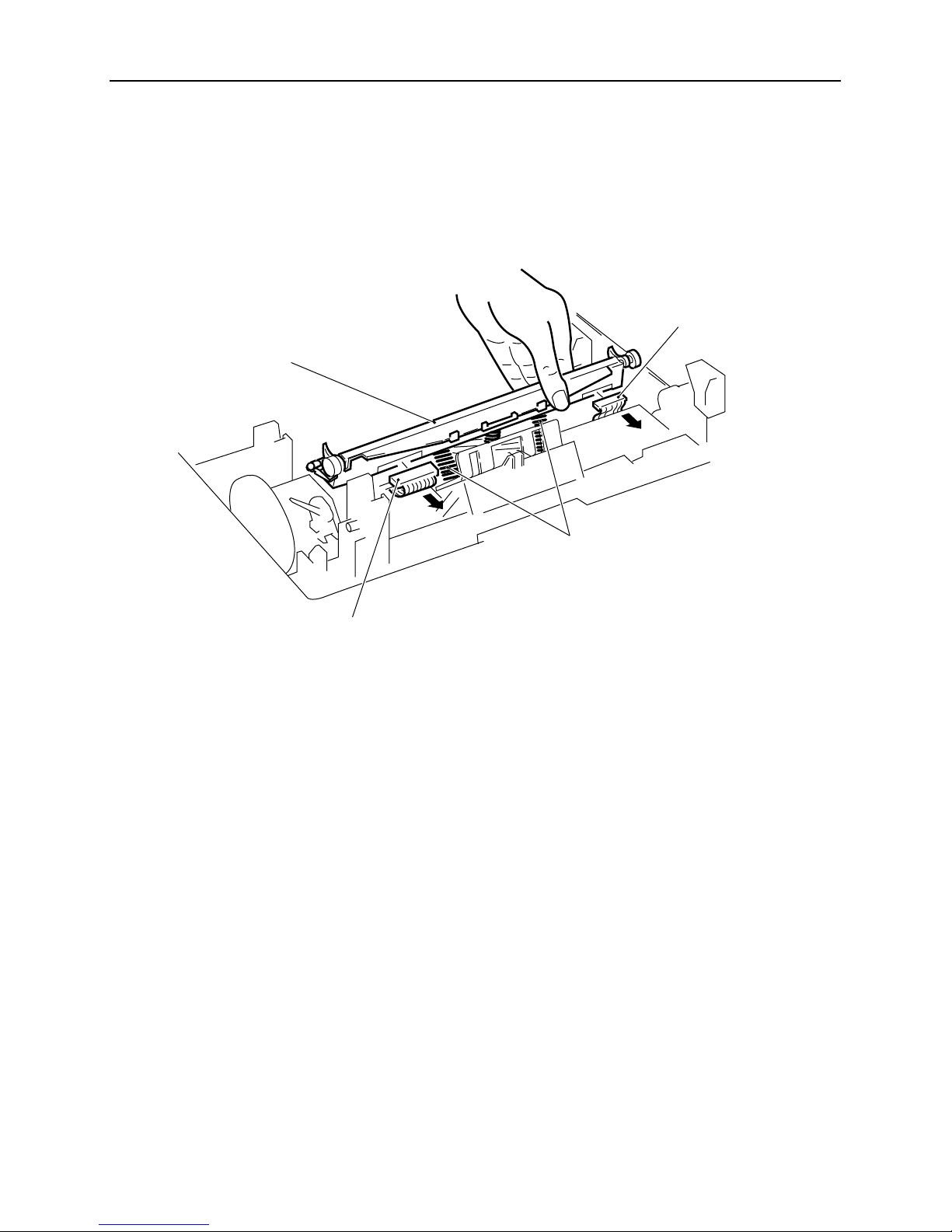

(1) Lift up the left side of the Stopper Head and remove the protruding piece.

Rotate in the direction of arrow (a).

(2) Push the Thermal Head in the direction of arrow (b) and remove the Thermal Head Hook. Be careful

because the pressure of the Spring pushes the Thermal Head upward.

Stopper Head

Protruding

Piece

Thermal Head

Spring Head Pin

(b)

(a)

Page 18

– 18 –

PARTS REPLACEMENT

(3) Remove Harness Head J12 and the Harness Head Power Connector.

When doing this, the Spring Heads (2 pcs.) and Spring Head Pins will come loose. Take special care not to

loose them.

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Harness Head Power

Spring Head

Thermal Head

Harness Head J12

Page 19

– 19 –

PARTS REPLACEMENT

2. Paper Motor

[Remove]

(1) Remove the Self-tap Screws fastening (M3 X 10) the Paper Motor.

Paper Motor

Self-tap screws

(M3 X 10)

1 Thermal Head

2 Paper Motor

Page 20

– 20 –

PARTS REPLACEMENT

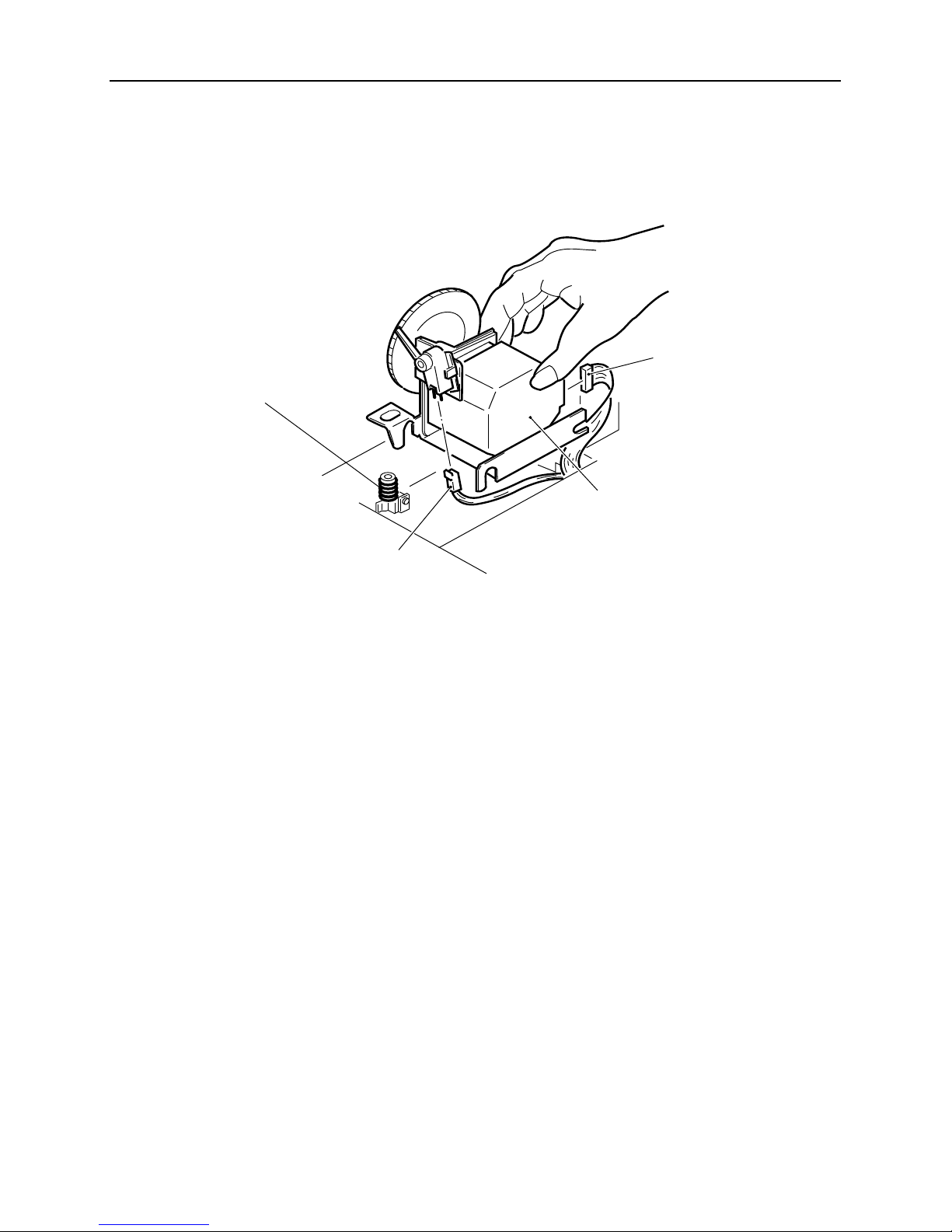

(2) Lift up the Paper Motor and remove the Connector. (Two places in the motor and sensor.)

When doing this, the Spring Paper Motor will come loose. Be careful not to lose it.

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Insert the Base Pin into the rear groove of the Paper Motor from the front and insert the Base Pin into the front

groove of the Paper motor coming down from above.

After attaching, check to make sure that springs for the Spring Paper Motor are securely fastened. When pushing

down on the Paper Motor from above, the Paper Motor should move smoothly back to its original position with the

force of the Springs.

Connector

Paper Motor

Spring Paper Motor

Connector

Page 21

– 21 –

PARTS REPLACEMENT

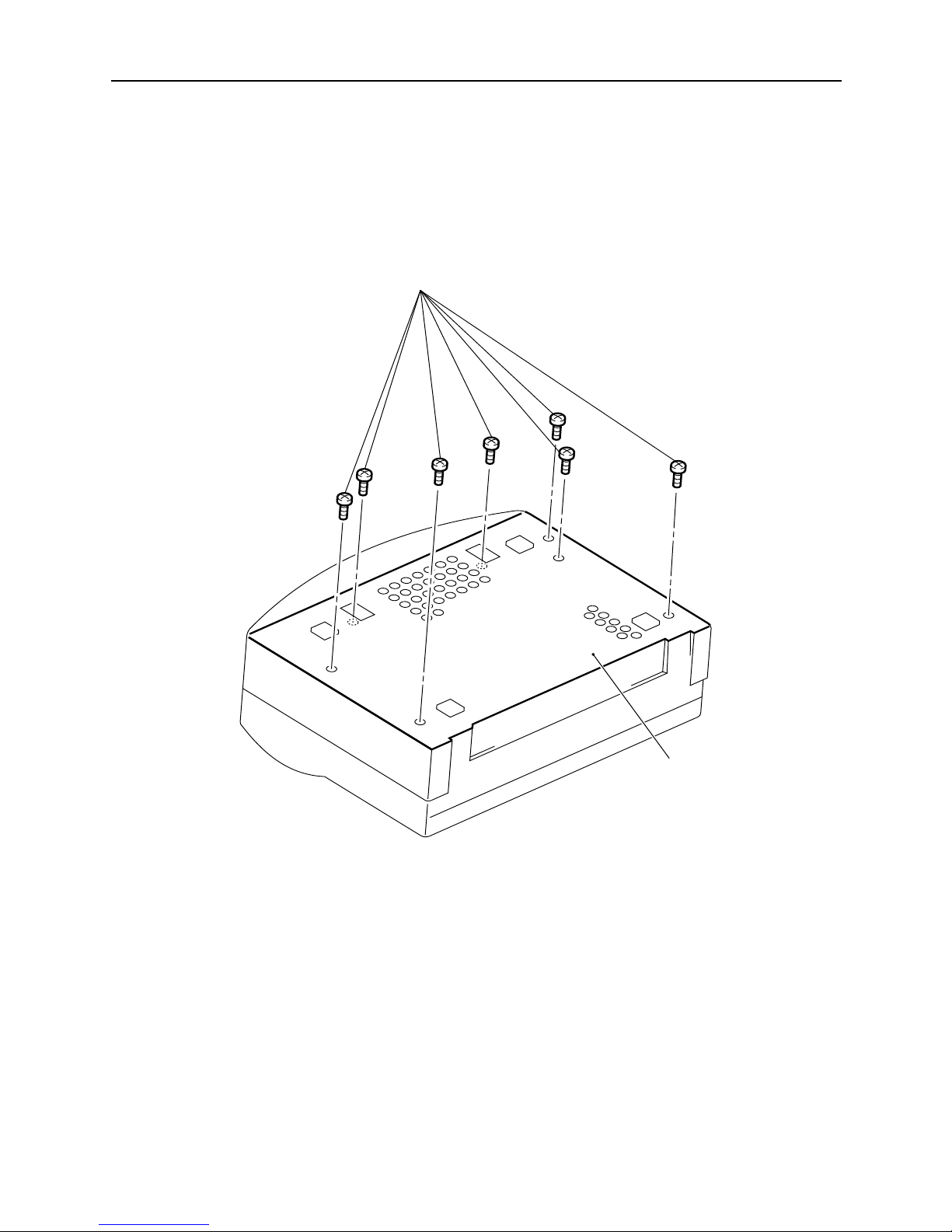

3. Centronics I/F PC Board

[Remove]

(1) Turn the printer upside down.

(2) Remove the Self-tap Screws (7 places/M3 X 10) from the ASSY Plate Bottom.

ASSY Plate Bottom

Self-tap Screws (M3 X 10)

Page 22

– 22 –

PARTS REPLACEMENT

(3) Remove the SW-PW-P Pan Head Screws (5 places/M3 X 10) fastening the I/F Cover.

(4) Remove the Self-tap Screws (4 places/M3 X 10) fastening the Centronics I/F PC Board.

(5) Remove Harness I/F J11 Connector and Control PC Board Harness Connector from the Centronics I/F PC

Board.

Self-tap Screws (M3 X 10)

Control PC Board Harness

Centronics I/F PC Board

SW-PW-P Pan Head Screws

(M3 X 8)

Harness I/F J11

I/F Cover

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

The Harness Connector for the Control PC Board should be attached so that the blue mark can be seen.

Page 23

– 23 –

PARTS REPLACEMENT

4. Engine PC Board

3 Centronics I/F PC Board

4 Engine PC Board

[Remove]

(1) Remove the Connectors (14 places) from the Engine PC Board.

(2) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Engine PC Board.

Self-tap Screws

(M3 X 10)

Engine PC Board

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Page 24

– 24 –

PARTS REPLACEMENT

5. Control PC Board

[Remove]

If you have already removed 3 Centronics I/F PC Board , perform only step (4).

(1) Turn the printer upside down.

(2) Remove the Self-tap Screws (7 places/M3 X 10) fastening the ASSY Plate Bottom.

(3) Remove the Harness Connector of the Control PC Board from the Centronics I/F PC Board.

(4) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Control PC Board.

Self-tap Screws

(M3 X 10)

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Tighten the screws while pressing the Control PC Board to the Base so that the gap between the Control PC Board

and the Base will be small.

The Harness Connector for the Control PC Board should be attached so that the blue mark can be seen.

Control

PC Board

Page 25

– 25 –

PARTS REPLACEMENT

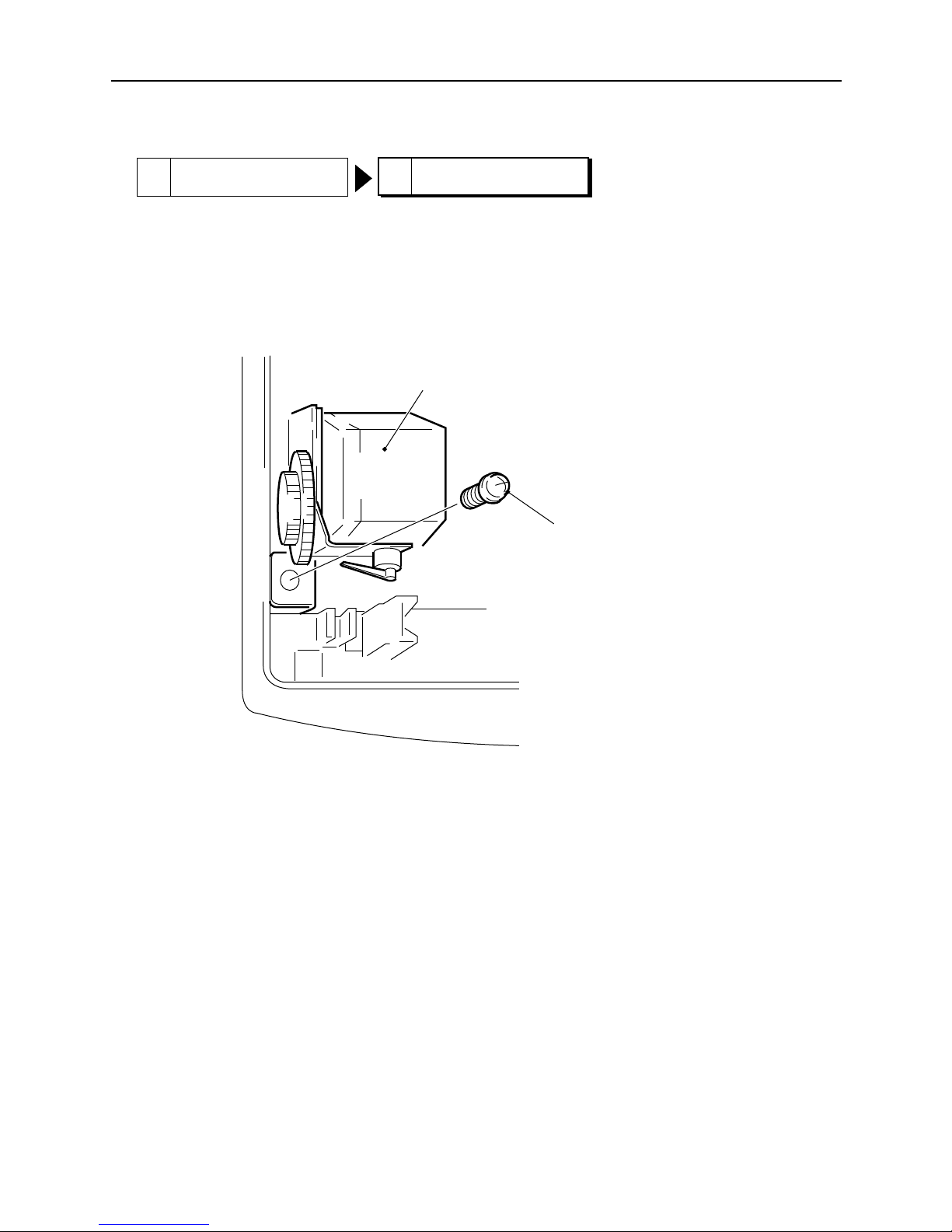

6. Power Supply (First Half)

[Remove]

(1) Remove the Self-tap Screw (M3 X 10) fastening the Plate Earth E.

Plate Earth E

Self-tap Screw

(M3 X 10)

P-Truss Screws

(2) Remove the Cable from the Hook.

(3) Turn the printer right-side up.

(4) Use a small (+) screw driver to remove the P-Truss Screws (4 places/M3 X 8).

1 Thermal Head

3 Centronics I/F PC Board 4 Engine PC Board

6 Power Supply (First Half)

Page 26

– 26 –

PARTS REPLACEMENT

(5) Gently lift the Upper Mechanism to remove it. Be careful because this is affected by the springs. It is easier

to remove while pressing down on the Springs.

(6) Remove the Cable from the Lower Mechanism.

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Assemble so that the tips of the Spring fit into the Plate Power grooves.

Page 27

– 27 –

PARTS REPLACEMENT

7. Power Supply (Second Half)

1 Thermal Head

3 Centronics I/F PC Board 4 Engine PC Board

6 Power Supply (First Half)

7

Power Supply (Second Half)

[Remove]

(1) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Plate Earth Head.

(2) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Power Supply.

(3) Remove the Power Supply by lifting it up. Be careful because the Plate Power will come loose.

(4) Remove the Harness Head Power and the Harness Engine J30 from the Power Supply.

Self-tap Screws (M3 X 10)

Power Supply

Plate Earth Head

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Power Supply

Harness Head Power

Harness Engine J30

Plate Power

Page 28

– 28 –

PARTS REPLACEMENT

8. Film Roll Motor

3 Centronics I/F PC Board

4 Engine PC Board 8 Film Roll Motor

[Remove]

(1) Turn the printer right-side up.

(2) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Film Roll Motor.

(3) Remove the Film Roll Motor. Be careful of the Cable.

Self-tap Screws (M3 X 10)

Film Roll Motor

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Page 29

– 29 –

PARTS REPLACEMENT

9. Base

1 Thermal Head

2 Paper Motor 3 Centronics I/F PC Board

4 Engine PC Board 5 Control PC Board 6 Power Supply (First Half)

7

Power Supply (Second Half)

8 Film Roll Motor

9 Base

[Remove]

(1) Remove all components of '1' through '8.' The item remaining is the Base.

Base

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Page 30

– 30 –

PARTS REPLACEMENT

1 Thermal Head

6 Power Supply (First Half)

10 Cover Shaft Unit

3 Centronics I/F PC Board

4 Engine PC Board

[Remove]

(1) Remove the Self-tap Screws (6 places/M3 X 20) fastening the Shaft of the Cover shaft unit in the Upper

Mechanism and the Self-tap Screws fastening the Metal Plate (2 places/M3 X 10).

Be careful because the Spring Cover L and R will come loose when doing this.

Self-tap Screws (M3 X 10)

Self-tap Screws (M3 X 10)

Cover Shaft Unit

Self-tap Screws (M3 X 20) Self-tap Screws (M3 X 20)

Spring Cover R

Spring Cover L

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Be careful of the direction of the L and R Spring Covers.

10. Cover Shaft Unit

Page 31

– 31 –

PARTS REPLACEMENT

1 Thermal Head

6 Power Supply (First Half)

11. Paper Plate Unit

3 Centronics I/F PC Board

4 Engine PC Board

[Remove]

(1) Remove the Cable coming from the Roller Base Unit.

(2) Remove the Self-tap Screws (2 places/M3 X 10) fastening the Paper Plate Unit.

10 Cover Shaft Unit

11 Paper Plate Unit

Self-tap Screws (M3 X 10)

Self-tap Screws (M3 X 10)

Cable

Paper Plate Unit Roller Base Unit Cable

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Page 32

– 32 –

PARTS REPLACEMENT

1 Thermal Head

12. Head U/D Motor

3 Centronics I/F PC Board

4 Engine PC Board

[Remove]

(1) Remove the Self-tap Screws (M3 X 10) fastening the Head U/D Motor.

6 Power Supply (First Half) 10 Cover Shaft Unit

12 Head U/D Motor

Self-tap Screws (M3 X 10)

Top Cover Rib

Roller Base Unit Cable

Head U/D Motor

[Caution in assembly]

Attachment is done by reversing the procedures used for removal. Be sure that the Hook and groove are correctly

aligned.

Set the wiring so that the Roller Base Cable passes between the Head U/D Motor left side and the Top Cover Rib.

Page 33

– 33 –

PARTS REPLACEMENT

13. Top Cover

1 Thermal Head

3 Centronics I/F PC Board 4 Engine PC Board

6 Power Supply (First Half) 10 Cover Shaft Unit 11 Paper Plate Unit

12 Head U/D Motor

[Remove]

(1) Remove the Self-tap Screws (5 places/M3 X 10) fastening the Roller Base Unit.

(2) Remove the Roller Base Unit. The item remaining is the Top Cover.

13 Top Cover

Self-tap Screw (M3 X 10) Self-tap Screw (M3 X 10)

Top Cover

Roller Base Unit

Self-tap Screw (M3 X 10)

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Page 34

– 34 –

PARTS REPLACEMENT

14. Torque Limit and Roller Base Unit

1 Thermal Head

3 Centronics I/F PC Board 4 Engine PC Board

6 Power Supply (First Half) 10 Cover Shaft Unit 11 Paper Plate Unit

12 Head U/D Motor 13 Top Cover

14

[Caution in assembly]

Attachment is done by reversing the procedures used for removal.

Roller Base Unit

Page 35

– 35 –

MAINTENANCE AND LUBRICATION

CHAPTER 4

MAINTENANCE AND LUBRICATION

1. Maintenance.........................................................................................................37

1-1. Precautions for Maintenance............................................................................... 37

1-2. Checking Operation.............................................................................................. 38

1-3. Tools for Maintenance and Adjustment.............................................................. 39

2. Lubrication...........................................................................................................39

4

Page 36

– 37 –

MAINTENANCE AND LUBRICATION

1. Maintenance

1-1. Precautions for Maintenance

In order to prevent any damage from occuring when performing maintenance, please observe the following points.

(1) Never print when there is no paper in the printer.

(2) Always turn OFF the electricity when replacing components. Be especially careful when working with

electrical components by removing the power cord and making certain that the power to the printer is OFF.

(3) Be careful not loose any components that can be re-used when replacing components.

(4) After replacing components, use the following table to tighten screws to their appropriate torque.

Screw Types Tightening Torque (kgcm)

Pan Head Screw (M3 - Steel) 7.3±0.5

Self-tap Screw (M3 - Steel) Resin 5±0.5

Press 7.3±0.5

P-Truss Screws 7.3±0.5

Pan Head Screws = (+) hole small screws; self-tap screws = (+) hole tapping screws.

(5) Be careful around plastic or resin made materials and components (wiring, PC Boards Covers, etc.) when

working with tools which generate heat.

(6) When replacing PC Boards, ground your body. Static electricity will damage electrical components.

(7) If you must transfer the PC Board to another area, wrap it in a static electricity conductive sheet.

(8) After finishing repair work on the printer, check that all screws and connectors are securely fitted. Always

check the printer's operation after checking connections.

(9) When replacing components, wrap paper or some other protective material around the rubber rollers to

prevent them from being damaged.

(10) Before replacing components, always remove the interface cable.

(11) When replacing components, always use new screws.

(12) Use "LockTite R" when tightening screws to prevent slippage.

Page 37

– 38 –

MAINTENANCE AND LUBRICATION

Fig. 4-1 Test Print Sample

1-2. Checking Operation

This printer has a built-in test print function. Using this self test print you can check the following points.

• Functioning of control circuits.

• Functioning of printer mechanism.

• Printing quality

The following describes how to test print.

(1) Turn ON the power to the printer while pressing the Ready button on the control panel on the front of the

printer.

(2) Hold the Ready button for approximately 3 seconds after turning ON the power.

(3) Release the Ready button when printing starts.

Page 38

– 39 –

MAINTENANCE AND LUBRICATION

1-3. Tools for Maintenance and Adjustment

• General Tools

(Note) Use "LockTite R" when tightening screws to prevent slippage.

Name No. of Pcs. Needed Purpose

+ Screw driver 1 Screw attachment/removal

+ Screw driver 1 Screw attachment/removal

+ Screw driver 1 Voltage adjustment

Digital multimeter 1 DC voltage measurement

2. Lubrication

In order to maintain the printer's functions and performance, it is suggested that the following items be inspected and

performed at least annually.

(1) Remove the paper and film roll and vacuum out paper scraps and dirt from inside the of the printer using a

vacuum cleaner.

(2) Wipe away any dirt from the Thermal Head, Platen Rollers, Paper Feed Rollers, Pinch Rollers, etc. using a

soft cloth applied with alcohol. (See the Users Manual for details.)

Page 39

– 41 –

TROUBLESHOOTING

5

CHAPTER 5

TROUBLESHOOTING

1. Troubleshooting Guide..........................................................................................43

1-1. General Information.............................................................................................. 43

1-2. Troubleshooting using the Control Panel .......................................................... 46

1-3. Error Messages Displayed with Windows.......................................................... 47

2. Troubleshooting Charts.........................................................................................48

2-1. General Information.............................................................................................. 48

2-2. Troubleshooting Related to Lamps..................................................................... 49

2-2-1. Ready lamp – Flashing; Paper lamp – Lit ...................................................... 49

2-2-2. Ready lamp – Flashing; Film Roll lamp – Lit ................................................. 50

2-2-3 Ready lamp – Flashing .................................................................................... 51

2-2-4. All lamps are flashing ...................................................................................... 53

2-2-5. Ready lamp – Lit; Paper lamp – Flashing; Film Roll lamp – Flashing......... 55

2-2-6. None of the lamps light.................................................................................... 56

2-3. Troubleshooting Related to Paper ...................................................................... 59

2-3-1. Paper jams related to skew (angle), paper bending...................................... 59

2-3-2. Paper jams occur frequently ........................................................................... 60

2-3-3. Paper does not feed from the Paper Tray ...................................................... 62

2-4. Troubleshooting for Print Quality Related Problems ........................................ 64

2-4-1. Areas don't print or print is light..................................................................... 64

2-4-2. Print is coarse and intensity is low. (Or nothing prints).............................. 65

2-4-3. Off-register is large .......................................................................................... 66

Page 40

– 43 –

TROUBLESHOOTING

1. Troubleshooting Guide

The following tables are provided to give you a quick reference to symptoms of printer failures which you can use to

determine the various causes before actually beginning your troubleshooting. Always refer to these tables before

troubleshooting. If you cannot fix the problem, proceed to "2. Troubleshooting Chart" for detailed procedures.

Symptom Possible Cause Handling

Ready lamp – Power cable is not Check that the power cable

Extinguished properly connected. is properly connected.

Power is not turned ON. Turn ON the power switch

located on the back of the printer.

Ready lamp – Flashing There is no paper or paper Put paper in the paper tray.

Paper lamp – Lit has jammed. Refer to the item dealing paper

jams.

Ready lamp – Flashing The Film Roll is empty. Replace the Film Roll.

Film Roll lamp – Lit

Ready lamp – Flashing The top cover may be open. Firmly close the top cover.

Ready lamp – Lit The thermal head may be Allow the printer to cool.

Paper lamp – Flashing too hot.

Film Roll lamp –

Flashing The thermal head may be Allow the printer to warm up.

too cold.

All lamps – Flashing A mechanical or electrical Turn OFF the power to the printer

error has occurred. once and turn it back ON again.

If the same error occurs there is a

problem.

Nothing prints Power cable is not Check that the power cable

properly connected. is properly connected.

The printer Ready button Press the Ready button.

has not been pressed.

(continued on next page)

1-1. General Information

Page 41

– 44 –

TROUBLESHOOTING

Symptom Possible Cause Handling

Neither automatic Paper feed rollers are Clean the inside of the printer.

nor manual feed excessively dirty.

occur.

Paper is either too thick or Use only the paper recommended.

too thin.

The top cover may be open. Firmly close the top cover.

Paper jams occur Platen rollers or pinch Clean the inside of the printer.

frequently rollers are dirty.

Paper is either too thick or Use only the paper recommended.

too thin.

The top cover may be open. Firmly close the top cover.

The film roll setting may Set the same film roll type in the

be incorrect. Printer driver Options dialog box

that is installed in the printer.

You are trying to print on Replace the film roll with the

SA4 size paper with an A4 SA4 size film roll.

size film roll.

Two sheets of Paper is sticking together Properly fan the paper before

paper are fed at the because of static electricity. placing it in the paper tray base.

same time.

(Continued from previous page)

Paper Jams Occur

Note: Always first remove any jammed paper from the inside of the printer. (Refer to page 46 of the Users

Manual.)

(continued on next page)

Page 42

– 45 –

TROUBLESHOOTING

Symptom Possible Cause Handling

Lines appear Thermal head is dirty. Clean the inside of the printer.

in the printout.

Overall print is Paper surface is too rough. Use only the paper recommended.

faint.

Media back and front are Check the proper direction of the

incorrectly being inserted. media.

Print media selection is Set the correct media type in the

incorrect Printer Driver.

Print intensity setting is low. Increase print intensity using the

Printer Driver.

Overall print is Print intensity is too high. Lower print intensity using the

dark Printer Driver.

Print media setting is Properly set it in the Printer Driver.

incorrect.

Patterns are printed Print intensity setting is low. Increase print intensity using the

where intensity is Printer Driver.

high.

Print speed is fast. Properly set the print speed using

Printer Driver.

Color offset is The platen rollers and pinch Clean the inside of the printer.

large. rollers are dirty.

Image data is only The image size and the Make the image size and the print

printed part of the way. print media size are media size the same.

different.

(Continued from previous page)

Print Quality is Poor

Page 43

– 46 –

TROUBLESHOOTING

1-2. Troubleshooting using the Control Panel

* Error Lamp Indicators

READY PAPER FILM ROLL Contents of Error

Flashing Lit Extinguished Error concerning print media.

Flashing Extinguished Lit Error concerning the film roll

Lit Flashing Flashing Indicates that the thermal head has exceeded

the determined temperature range.

Note 1:

Printing will not start until the thermal head

temperature has dropped to below 45°C.

This is to protect the mechanism when the

temperature exceeds 50°C.

Note 2:

Printing will not start below 10°C.

Printing is possible when the thermal head

temperature has risen above 12°C.

Flashing Flashing Flashing Head UP/DOWN error, RAM error or some

other internal operating error.

Paper

Film Roll

Ready

Fig. 5-1 Control Panel

: Orange

: Green

Page 44

– 47 –

TROUBLESHOOTING

Type No. Error Message What to Do

1 Out of paper. Please load the Add more paper and press the "Retry" button

printer with paper. after checking that the printer is in the

"Online" mode.

2 Can't connect to the printer. After checking the following items, click the

Check the power supply, the Retry button.

printer cable, or the "Online" • Is the power turned ON?

state. • Is the cable securely connected?

When using • Is the printer in the "Online" mode?

"Fast Print to

Port" 3 A printer error has occurred. It is possible that the film roll is empty, paper

May be out of Film Roll, paper is out or there was a temperature error with

jam, an abnormal head temper- the Thermal Head. Retry to print after

ture, etc. refering to the section dealing with failures.

4 A printer error has occurred. It is possible paper became jammed after

Can't resume the print job. printing. Remove the jammed paper.

The remaining image cannot be printed, so

send the print command again.

1-3. Error Messages Displayed with Windows

• After removing the causes of the errors for Nos. 1 through 3, printing will start automatically when you click

on the "Retry" button.

• If you are not using "Fast Print to Port," Windows Print Manager will display the error messages.

Page 45

– 48 –

TROUBLESHOOTING

2. Troubleshooting Charts

Refer to "1-1 General Information" first whenever you encounter printer failure. If you cannot solve the problem

using those tables, use the following charts to identify and fix the problem.

2-1. General Information

Refer to "1-1. General Information" Page 43

○○○○○○○○○○○○○○○○

No

Yes

Troubleshooting

related to lamps

Troubleshooting

related to paper

Paper jams related to paper skew (angle),

paper bending. Page 59

Paper jams occur frequently. Page 60

Paper does not feed from the Paper Tray. Page 62

Areas don't print or print is light. Page 64

Printing is coarse and intensity is low

(or nothing prints) Page 65

Off-register is large. Page 66

Did you remove the

cause of the error

in "1-1. General

Information"?

Ready lamp – Flashing; Paper lamp – Lit Page 49

Ready lamp – Flashing; Film Roll lamp – Lit Page 50

Ready lamp – Flashing Page 51

All lamps are flashing. Page 53

Ready lamp – Lit; Paper lamp – Flashing Page 55

Film Roll Lamp – Flashing

None of the lamps light Page 56

Troubleshooting for

print quality related

problems

Page 46

– 49 –

TROUBLESHOOTING

2-2. Troubleshooting Related to Lamps

2-2-1. Ready lamp – Flashing; Paper lamp – Lit

Yes

Output a self test print

Is paper being fed?

Diagnosis How to Handle Ref. Page

Control PC Board

Replace the Control

Page 24

failure PC Board

Is the EOP sensor

connector connected?

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

The EOP sensor is

Properly connect it.

–

disconnected.

Is the Film Roll UP

sensor connected?

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

The Film Roll UP sensor

Properly connect it.

–

is disconnected.

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

The Film Roll DOWN

Properly connect it.

–

sensor is disconnected.

Diagnosis How to Handle Ref. Page

EOP Sensor failure

Replace the A4/SA4

Page 31

Paper Plate Unit.

Film Roll UP sensor Replace the Roller Page 34

failure Base Unit.

Film Roll DOWN sensor Replace the Base. Page 29

failure

Engine PC Board failure Replace the Engine Page 23

PC Board.

No

Yes

Yes

○○○○

No

No

No

Yes

Is the Film Roll

DOWN sensor

connector connected?

Page 47

– 50 –

TROUBLESHOOTING

2-2-2. Ready lamp – Flashing; Film Roll lamp – Lit

Turn OFF the printer and

separate the Film Roll

mark from the Film Roll

DOWN sensor and

perform a self test print

○○○○○○○○○○○

No

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

Paper related failure See the Trouble- Page 59

shooting chart

concerning paper.

Is the Film Roll UP

sensor connected?

○○ ○○○○○○○○○

No

Diagnosis How to Handle Ref. Page

The Film Roll UP sensor

Properly connect it –

is disconnected.

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

The Film Roll DOWN

Properly connect it –

sensor is disconnected.

Yes

No

Yes

Yes

Diagnosis How to Handle Ref. Page

The film roll bobbins Install the Film Page 28

and the bobbin gears Roll Motor.

are not meshing.

Film Roll Motor failure Replace the Film Roll Page 28

Motor

Is the Film Roll being

taken up in the reel?

After the Film Roll

motor stops, does the

Ready lamp flash?

Is the Film Roll

DOWN sensor

connected?

Diagnosis How to Handle Ref. Page

Film Roll UP sensor Replace the Roller Page 34

failure Base Unit.

Film Roll DOWN Replace the Base Page 29

sensor failure Unit.

Engine PC Board failure

Replace the Engine Page 23

PC Board.

Page 48

– 51 –

TROUBLESHOOTING

2-2-3 Ready lamp – Flashing

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

Foreign objects exit

Remove the objects.

–

Roller Base Unit Replace the Roller Page 34

damaged Base Unit.

Base is damaged Replace the Base. Page 29

Can you open the

Top Cover while the

power is ON?

Will the Top

Cover Close?

○○ ○○○○○○○○○

Diagnosis How to Handle Ref. Page

The Sensor is

Properly connect it.

–

disconnected.

Is the Cover Open

Sensor damaged?

Diagnosis How to Handle Ref. Page

Cover Open Sensor is Replace the Paper Page 19

damaged. Motor.

Is the Cover Open

Sensor Connected?

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

Cover Open Sensor is

Properly connect it.

–

disconnected.

No

Yes

○○○○○

No

Is the Cover Open

Sensor attached to the

Paper Motor?

Yes

A

Page 49

– 52 –

TROUBLESHOOTING

○○○○○○○○○○○

No

Output a self test print

Can a self test

be printed?

Diagnosis How to Handle Ref. Page

Engine PC Board Replace the Engine Page 23

Failure PC Board.

Cover Open Sensor Replace the Paper Page 19

Failure Motor.

A

Diagnosis How to Handle Ref. Page

Control PC Board

Replace the Control

Page 24

failure PC Board.

Yes

Page 50

– 53 –

TROUBLESHOOTING

2-2-4. All lamps are flashing

Turn OFF the power,

open the Top Cover

of the printer and turn

the power ON again.

Yes

Are all the

lamps flashing?

○○○

No

Diagnosis How to Handle Ref. Page

Engine PC Board failure Replace the Engine Page 23

PC Board.

Centronics I/F PC

Replace the Centron-

Page 21

Board failure ics I/F PC Board

Is the Head U/D

Motor rotating?

Yes

Is the Head U/D

Motor connected?

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

Head U/D Motor failure

Replace the Head U/D

Page 32

Motor.

Engine PC Board failure Replace the Engine Page 23

PC Board.

No

Hold down the Cover

Open Sensor lever.

(Turn the sensor ON)

A

Diagnosis How to Handle Ref. Page

It is disconnected.

Properly connect it.

–

○○ ○○○

Page 51

– 54 –

TROUBLESHOOTING

A

○○○○○○○○○○○

No

Yes

○○○○○○○○○○○

No

Yes

Does the Paper Plate

Unit raise and lower?

Diagnosis How to Handle Ref. Page

The gear is not catching. Re-attach the Head Page 32

U/D Motor.

Diagnosis How to Handle Ref. Page

The connector is

Properly connect it.

–

disconnected.

Is the Cam

sensor connected?

Diagnosis How to Handle Ref. Page

Cam Sensor failure Replace the Roller Page 34

Base Unit.

Engine PC Board failure Replace the Engine Page 23

PC Board.

Page 52

– 55 –

TROUBLESHOOTING

2-2-5. Ready lamp – Lit; Paper lamp – Flashing; Film Roll lamp – Flashing

○○○○○○○○○○○

No

No

Yes

Yes

Diagnosis How to Handle Ref. Page

It is disconnected.

Properly connect it.

–

Diagnosis How to Handle Ref. Page

It is disconnected.

Properly connect it.

–

Is Harness Head

J12 connector

disconnected?

Is Harness Head

Power disconnected?

Diagnosis How to Handle Ref. Page

Thermal Head failure

Replace the Thermal

Page 17

Head.

Engine PC Board failure

Replace the Engine

Page 23

PC Board.

○○ ○○○○○○○○○

Page 53

– 56 –

TROUBLESHOOTING

A

2-2-6. None of the lamps light

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

The power cable is Replace the power Page 25

defective cable.

Is electricity

flowing through the

power cable ?

Is the power supply

output connector

connected?

○○ ○○○○○○○○○

Diagnosis How to Handle Ref. Page

It is disconnected.

Properly connect it.

–

Yes

No

○○○

○○○○○○○○○○○

Yes

B

Remove the Harness

Head and measure

the voltage

No

Diagnosis How to Handle Ref. Page

Thermal Head failure

Replace the Thermal

Page 17

Head.

Yes

Are the Thermal

Head 24V and GND

shorting?

No

Is there any

power output?

Page 54

– 57 –

TROUBLESHOOTING

A

Yes

Are the Thermal

Head 5V and the

GND shorting?

Diagnosis How to Handle Ref. Page

Thermal Head failure

Replace the Thermal

Page 17

Head.

No

Yes

○○○○○○○

No

Does the initial opera-

tion occur when the

power is turned ON?

Diagnosis How to Handle Ref. Page

Control PC Board

Replace the Control

Page 24

failure PC Board.

○○○○○○○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

Engine PC Board failure

Replace the Engine

Page 23

PC Board

Centronics I/F failure

Replace the Centron-

Page 21

ics I/F PC Board.

○○○○○○○

Page 55

– 58 –

TROUBLESHOOTING

B

Turn OFF the power.

Remove the Harness

Head and and Harness

Engine J30 and turn the

power ON again.

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

Centronics I/F failure

Replace the Centronics

Page 21

I/F PC Board.

Engine PC Board Replace the Engine Page 23

failure PC Board

Control PC Board

Replace the Control

Page 24

failure PC Board

Is there any power

being supplied?

Diagnosis How to Handle Ref. Page

Power supply failure Replace the power Page 25

supply.

○○○○○○○○

Page 56

– 59 –

TROUBLESHOOTING

Yes

Present

○○○○○○○○○○○

○○ ○○○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

Wrong paper is being Use the correct –

used. size.

○○○○○○○○○○○○○

○○○○○○○○○○○○○

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

Paper Plate Unit failure Replace the Paper Page 31

Plate Unit.

Diagnosis How to Handle Ref. Page

Feeder Roller failure Replace the Feeder Page 34

Roller.

How do the paper

guides appear?

Is the paper plate unit

cork piece present?

Does the plate

move smoothly?

Are the paper tray

size and the print

media size the same?

Do the paper guides

in the paper tray move

smoothly?

Yes

No

Deformed

Normal

Has it fallen?

No

Yes

2-3. Troubleshooting Related to Paper

2-3-1. Paper jams related to skew (angle), paper bending.

No

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Page 57

– 60 –

TROUBLESHOOTING

2-3-2. Paper jams occur frequently

Yes

Are there excessive

wrinkles or bends in

the paper?

No

Diagnosis How to Handle Ref. Page

Failure related to skew.

Refer to the paper skew

Page 59

troubleshooting chart.

Yes

Does paper jam

because of the skew

(angle) of the paper?

Is the paper feed path

or the vicinity dirty?

Yes

Diagnosis How to Handle Ref. Page

Improper cleaning.

Remove dirt and any

–

pieces of paper.

(Be careful not to

damage the rollers.)

No

○○○○○○○○○○○

No

Diagnosis How to Handle Ref. Page

The sensor is

Properly connect it.

–

disconnected.

No

Is the paper edge

sensor attached?

A

Yes

○○○○○○○ ○○○○○○ ○○ ○○○○○○

Diagnosis How to Handle Ref. Page

Wrong paper being used

Change the paper type

–

Page 58

– 61 –

TROUBLESHOOTING

○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

The connector is

Properly connect it.

–

disconnected.

Is the paper start

sensor attached?

○○○○○○○○○○○

No

Diagnosis How to Handle Ref. Page

The sensor is

Properly connect it.

–

disconnected.

○○ ○○○○○○○○○

No

Diagnosis How to Handle Ref. Page

The sensor is

Properly connect it.

–

disconnected.

Yes

Yes

Is the paper

edge connector

properly connected?

A

No

Is the paper start

sensor properly

connected?

Yes

Diagnosis How to Handle Ref. Page

Paper edge sensor Replace the Roller Page 34

failure Base Unit.

Paper start sensor failure

Engine PC Board

Replace the Engine

Page 23

failure PC Board

Page 59

– 62 –

TROUBLESHOOTING

Diagnosis How to Handle Ref. Page

The Head U/D Motor

Properly connect it.

–

is disconnected.

Head U/D Motor failure Replace the Head Page 32

U/D Motor.

Engine PC Board

Replace the Engine

Page 23

failure PC Board.

2-3-3. Paper does not feed from the Paper Tray

No

Turn ON the power to the printer

Yes

Does the Paper

Plate Unit work?

○○ ○○○○○○○○○

No

Does the plate of the

paper plate unit stop

when lowered?

○○○○○○○○○○○

How do the paper

feed rollers move?

Not catching

Do not move at all

A

Diagnosis How to Handle Ref. Page

Paper Plate Unit failure Replace the Paper Page 31

Plate Unit.

Cam Sensor failure Replace the Roller Page 34

Base Unit.

Roller Base Unit failure

Head U/D Motor failure Replace the Head Page 32

U/D Motor.

Engine PC Board

Replace the Engine

Page 23

failure PC Board.

Diagnosis How to Handle Ref. Page

Roller Base Unit failure Replace the Roller Page 34

Base Unit.

The Paper Feed Rollers Clean the Paper U/M

are dirty. Feed Rollers.

Yes

○○○○○○○○○○○

Page 60

– 63 –

TROUBLESHOOTING

A

○○○○○○○○○○○

No

Diagnosis How to Handle Ref. Page

The Paper Motor is

Properly connect it.

–

disconnected.

Paper Motor failure Replace the Paper Page 19

Motor.

Engine PC Board failure

Replace the Engine

Page 23

PC Board.

Does the Paper

Motor work?

Yes

Diagnosis How to Handle Ref. Page

The Paper Motor and

Re-attach the Paper

Page 19

the Roller Base Unit are Motor.

separated.

Roller Base Unit failure

Replace the Roller

Page 34

Base Unit.

Page 61

– 64 –

TROUBLESHOOTING

2-4. Troubleshooting for Print Quality Related Problems

2-4-1. Areas don't print or print is light

Yes

Diagnosis How to Handle Ref. Page

Film roll defective

Replace the film roll.

U/M

Are there wrinkles

or inconsistencies in

the film roll?

○○ ○○○

Yes

Are some vertical dots

not printing over a

regular frequency?

Are there vertical lines

appearing in the print?

Yes

Diagnosis How to Handle Ref. Page

The Thermal Head is

Properly connect it.

–

disconnected.

Thermal Head failure

Replace the Thermal

Page 17

Head.

Yes

Are dots not being

printed in a certain pattern,

or are there abnormal

prints outside

of the printing range?

○○○○○○○

Diagnosis How to Handle Ref. Page

Engine PC Board failure

Replace the Engine

Page 23

PC Board

Centronics I/F PC Replace the Centron- Page 21

Board failure ics I/F PC Board.

No

No

No

No

Diagnosis How to Handle Ref. Page

Thermal Head is dirty

Clean the Thermal

U/M

Head.

○○○○○○○○○○○○○○○○○

Diagnosis How to Handle Ref. Page

Damage or warping to Replace the Roller Page 34

the Platen Roller Base Unit.

○○○○○○○

○○○○○○

Page 62

– 65 –

TROUBLESHOOTING

2-4-2. Print is coarse and intensity is low. (Or nothing prints)

○○○○○○○○○○○

No

Yes

Diagnosis How to Handle Ref. Page

Film Roll is defective.

Replace the Film Roll.

U/M

Decrease the voltage for Check and adjust the Page 11

the Thermal Head (24V) voltage (24V) for the

Thermal Head.

○○○○○○○

Diagnosis How to Handle Ref. Page

The Platen Roller is Replace the Roller Page 34

damaged or warped. Base Unit.

Thermal Head defective Replace the Thermal Page 17

Head.

Is printing possible?

Is the overall

print faint?

Diagnosis How to Handle Ref. Page

The Thermal Head.

Properly connect it.

–

is disconnected.

Yes

No

○○○○○○○○○○○○○○○○○

Page 63

– 66 –

TROUBLESHOOTING

No

Yes

2-4-3. Off-register is large

The Platen Roller and

Pinch Roller are dirty.

No

Diagnosis How to Handle Ref. Page

Roller Base Unit failure Replace the Roller Page 34

Base Unit.

Is there excessive

warp with the Platen

Roller?

○○○○○○○

Yes

Yes

No

Does the Paper Motor

power swing and make

strange sounds?

Diagnosis How to Handle Ref. Page

Spring pressure defect Perform Off-register Page 13

with the Pinch Rollers adjustment.

Diagnosis How to Handle Ref. Page

Paper Motor failure Replace the Paper Page 19

Motor.

Engine PC Board Replace the Engine Page 23

failure PC Board.

Diagnosis How to Handle Ref. Page

Improper cleaning Properly clean the U/M

Platen Rollers and

Pinch Rollers using

Ethanol.

○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○

○○○○○○○○○○

Page 64

– 67 –

6

1. Printer Assembly....................................................................................................68

1-1. Disassembly Drawing........................................................................................... 68

1-2. Parts List ............................................................................................................... 70

CHAPTER 6

PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

When there are differences in the specifications of the fuse, destinations,etc.,the differences are described in words

or indicated by two letter.

US.....U.S.A EC.....EC(with Germany) UK.....United Kingdom HK.....Hong Kong

AS.....Australia

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

Page 65

– 68 –

A

26

14

8

7

9

10

18

26

29

19

20

26

23

26

12

262626

22

13

21

26

15

11

26

17

26

16

1. Printer Assembly

1-1. Disassembly Drawing

2

[ 1 / 2 ]

Page 66

– 69 –

A

4

5

1

3

6

26

24

26

28

27

25

26

35

33

34

30

31

32

36

[ 2 / 2 ]

Page 67

– 70 –

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1 80985687 ROLLER BASE UNIT TM300 1 S

2 80985716 TAPPING SCREW M3X12 TM300 2

3 80985673 TOP COVER TM300 1

4 80985674 COVER SHAFT UNIT TM300 1

5 80985676 PAPER PLATE UNIT LTR TM300 1 FOR US S

80985675 PAPER PLATE UNIT A4 TM300 1 EXCEPT FOR US S

6 80985677 HEAD MOTOR ASSY TM300 1

7 80985678 THERMAL HEAD UNIT TM300 1 S

8 80985679 INK MOTOR ASSY TM300 1 S

9 80985680 PAPER FEED MOTOR ASSY TM300 1

10 80985681 POWER SUPPLY UNIT 100V TM300 1 FOR US S

80985682 POWER SUPPLY UNIT 220V TM300 1 EXCEPT FOR US S

11 80985683 BASE ASSY TM300 1

12 80985684 MAIN LOGIC BOARD UNIT TM300 1

13 80985685 INTERFACE BOARD UNIT TM300 1 S

14 80985686 CONTROL PANEL BOARD UNIT TM300 1 S

15 80985701 PAPER MOTOR SPRING TM300 1

16 80985702 HEAD SPRING A TM300 1

17 80985703 HEAD SPRING B TM300 2

18 80985704 GROUND PLATE TM300 1

19 80985705 PLATE COVER TM300 1

20 80985706 IF COVER TM300 1

21 80985707 GROUND PLATE E TM300 1

22 80985708 CABLE UNIT TM300 1

23 80985709 BOTTOM PLATE ASSY TM300 1

24 80985710 HEAD SPRING L TM300 1

25 80985711 HEAD SPRING R TM300 1

26 80985712 TAPPING SCREW M3X10 TM300 31

27 80985713 TAPPING SCREW M3X20 TM300 6

28 80985714 SCREW M3X8 TM300 4

29 80985715 SCREW M3X8 WS/WF TM300 5

30 80985631 PAPER TRAY BASE LTR TM300 1 FOR US

80985632 PAPER TRAY BASE A4 TM300 1 EXCEPT FOR US

31 80985633 PAPER TRAY COVER LTR TM300 1 FOR US

80985634 PAPER TRAY COVER A4 TM300 1 EXCEPT FOR US

32 80985635 FILM ROLL BOBBIN SET TM300 1

33 80985636 POWER CORD US TM300 1 FOR US

80985637 POWER CORD EC TM300 1 FOR EC

80985638 POWER CORD UK TM300 1 FOR UK,HK

80985639 POWER CORD AS TM300 1 FOR AS

34 89598010 FILM ROLL UPC TL1-11C3H 1 FOR US :OPTION

89598030 FILM ROLL UPC TL1-11C4H 1 FOR US :OPTION

89598050 FILM ROLL UPC TL1-14C3H 1 FOR US :OPTION

89598070 FILM ROLL UPC TL1-14C4H 1 FOR US :OPTION

89598090 FILM ROLL UPC TL1-CBH 1 FOR US :OPTION

89598020 FILM ROLL JAN TL1-11C3H 1 EXCEPT FOR US:OPTION

89598040 FILM ROLL JAN TL1-11C4H 1 EXCEPT FOR US:OPTION

89598060 FILM ROLL JAN TL1-14C3H 1 EXCEPT FOR US:OPTION

89598080 FILM ROLL JAN TL1-14C4H 1 EXCEPT FOR US:OPTION

89598100 FILM ROLL JAN TL1-CBH 1 EXCEPT FOR US:OPTION

35 89598110 COATED PAPER UPC A-PWC 1 FOR US :OPTION

89598130 COATED PAPER UPC SA-PWC 1 FOR US :OPTION

89598150 TRANSPARENCY FILM UPC A-TFC 1 FOR US :OPTION

89598170 TRANSPARENCY FILM UPC SA-TFC 1 FOR US :OPTION

89598190 HQ PRINTING PAPER UPC A-PW 1 FOR US :OPTION

89598210 HQ PRINTING PAPER UPC SA-PW 1 FOR US :OPTION

1-2. Parts List

Printer Assembly

Page 68

– 71 –

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

35 89598120 COATED PAPER JAN A4-PWC 1 EXCEPT FOR US:OPTION

89598140 COATED PAPER JAN SA4-PWC 1 EXCEPT FOR US:OPTION

89598160 TRANSPARENCY FILM JAN A4-TFC 1 EXCEPT FOR US:OPTION

89598180 TRANSPARENCY FILM JAN SA4-TFC 1 EXCEPT FOR US:OPTION

89598200 HQ PRINTING PAPER JAN A4-PW 1 EXCEPT FOR US:OPTION

89598220 HQ PRINTING PAPER JAN SA4-PW 1 EXCEPT FOR US:OPTION

36 80088020 SILENT SALESMAN TM300 US 1 FOR US

Printer Assembly

Page 69

Page 70

Printed in Japan, 80824750-A

TM300

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA INC.

70-D Ethel Road West.

Piscataway, NJ 08854, U.S.A

Tel: 908-572-5550

Telefax: 908-572-5693

HEAD QUARTERS

STAR MICRONICS CO., LTD. JAPAN

536 Nanatsushinya, Shimizu,

Shizuoka, 424, Japan

Tel: 0543-47-0113

Telefax: 0543-48-5013

STAR MICRONICS PTY. LTD.

Unit A/107-115 Asquith Street,

Silverwater, NSW 2141

Australia

Tel: 02-748-4300

Telefax: 02-748-3527

STAR MICRONICS ASIA LTD.

18/F., Tower II, Enterprise Square

9 Sheung Yuet Road, Kowloon Bay

Hong Kong

Tel: 2796-2727

Telefax: 2799-9344

STAR MICRONICS (N.Z.) LTD.

64 Lunn Ave. Mount Wellington

P.O. Box 6255, Wellesley St.,

Auckland, New Zealand.

Tel: 570-1450

Telefax: 570-1448

STAR MICRONICS DEUTSCHLAND

GMBH

Westerbachstraße 59 P.O.Box 940330

D-60489 Frankfurt/Main 90

F.R.of Germany

Tel: 069-789990

Telefax: 069-781006

Telex: 417 5825 STAR D

STAR MICRONICS U.K.LTD.

Star House, Peregrine Business

Park, Gomm Road, High Wycombe

Bucks, HP13 7DL U.K.

Tel: 0494-471111

Telefax: 0494-473333

Distributed by

Loading...

Loading...