Page 1

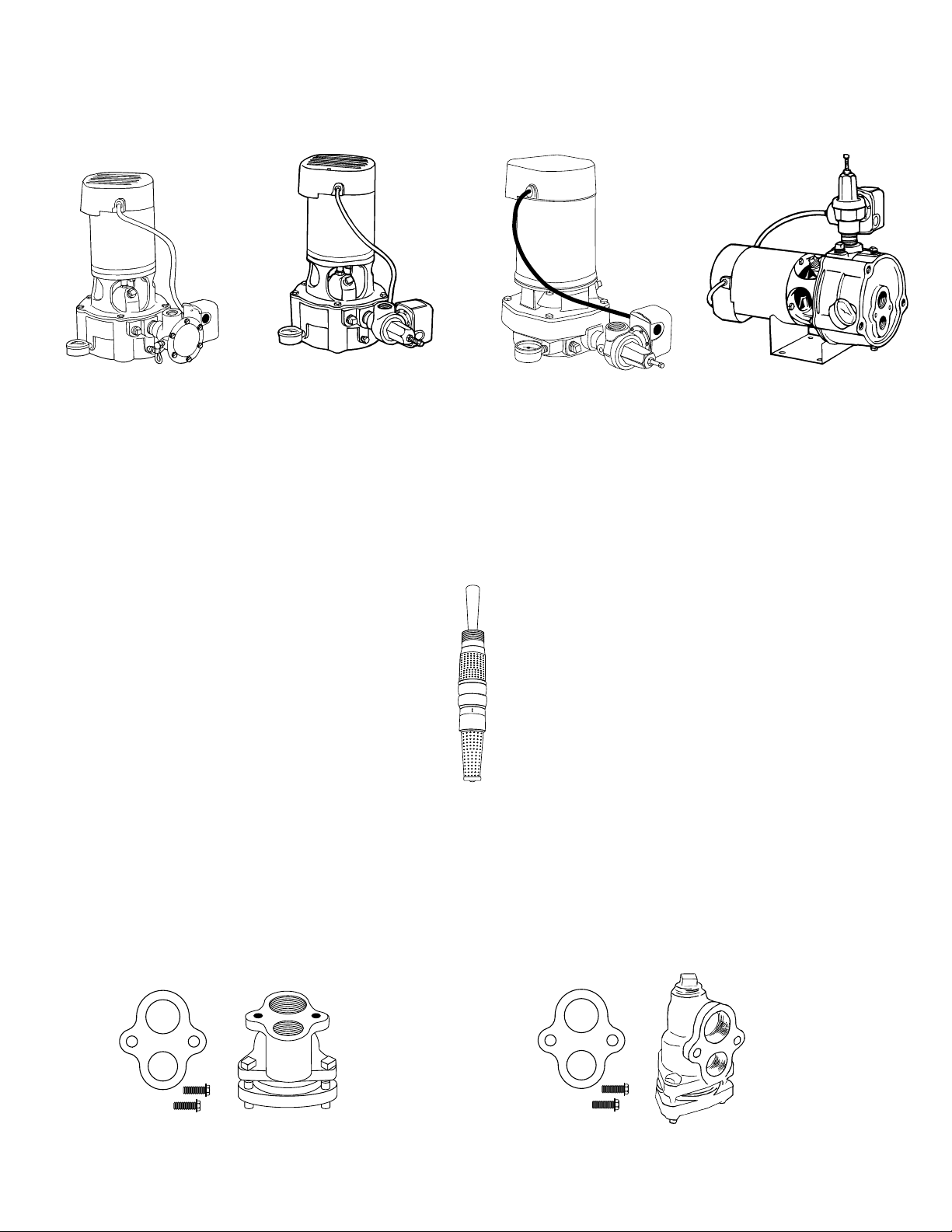

VERTICAL JET PUMPS

IL0316

IL0438

INSTALLATION INSTRUCTIONS & PARTS MANUAL

FW0636

0413

Supersedes

0909

IL0319

“VA” SERIES 1/2 - 1-1/2 HP

FULLY AUTOMATIC

CONTROL VALVE

3/4 - 1-1/2 HP TWO STAGE

“VS” SERIES 1/2 - 1-1/2 HP

SEMI AUTOMATIC

CONTROL VALVE

3/4 - 1-1/2 HP TWO STAGE

“VPH” SERIES - 1 HP

SEMI AUTOMATIC

CONTROL VALVE

1 HP SINGLE STAGE

EJECTORS AND ADAPTERS

L0195

IL0435

“VS” SERIES 1/2 - 1-1/2 HP

HORIZONTAL POSITION

USING OPTIONAL 135276

PUMP BASE

Single pipe ejector,

leather packers

for 2” wells

RIGHT ANGLE WELL ADAPTERSTRAIGHT WELL ADAPTER

L0437

1

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

135258

Page 2

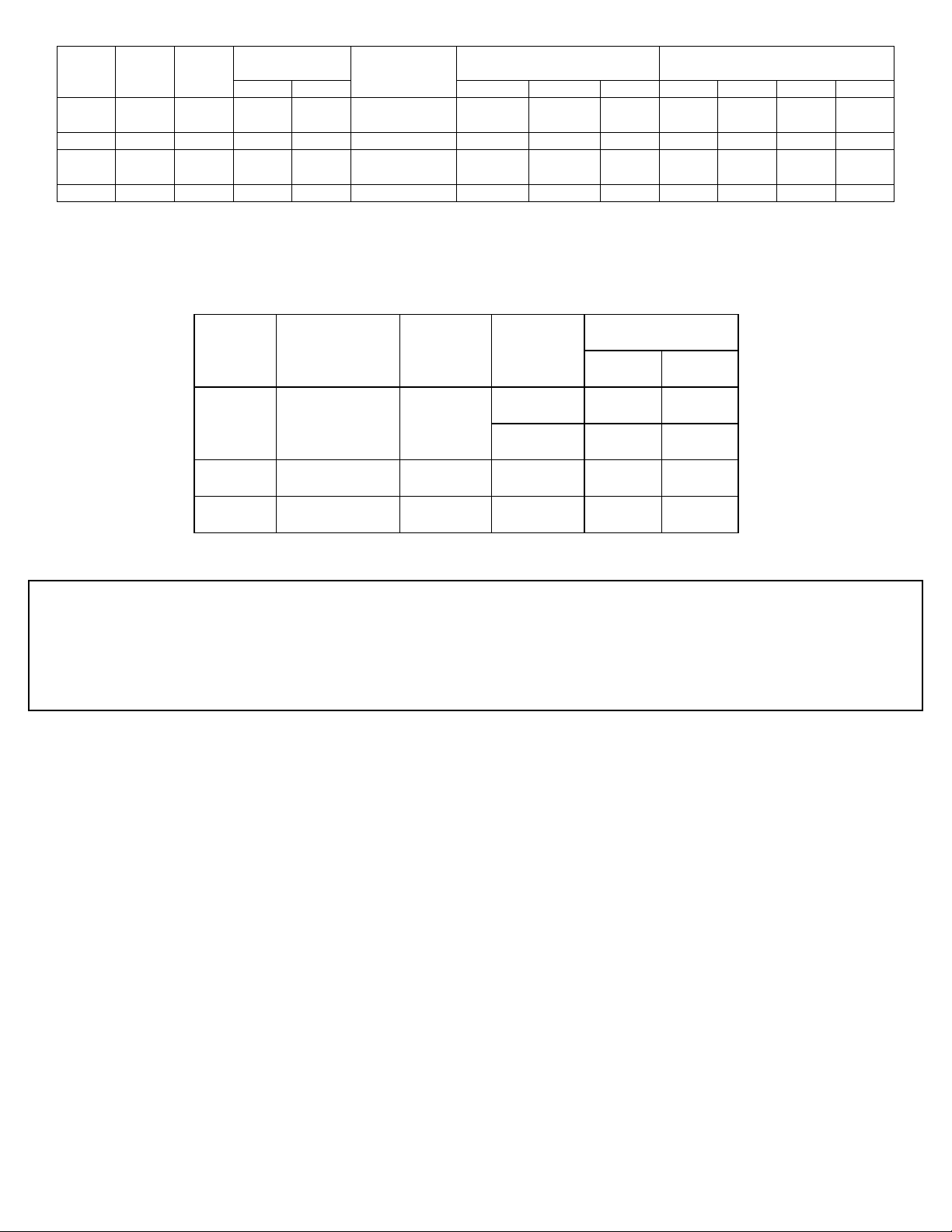

MOTOR SPECIFICATION CHART

PUMP

MODEL

NO.

VS207P

VA207P

VPH10 1 1 18 9 230V 1” 1-1/4” 1” 15-1/2” 6-1/2” 14-1/2” 56 lb.

VS210P

VA210P

VS215P 1-1/2 2 25 12.5 230V 1” 1-1/4” 1” 18-1/8” 9-1/4” 15-1/8” 76 lb.

All motors are single phase 60 Hz., 3450 RPM.

Motor can be changed to either 115V or 230V by following diagram on motor decal.

Pressure switch settings are 30 - 50 PSI for the above models.

HP STG.

3/4 2 18 9 230V 1” 1-1/4” 1” 17” 9-1/4” 15-1/8” 67 lb.

1 2 21 10.5 230V 1” 1-1/4” 1” 17-5/8” 9-1/4” 15-1/8” 72 lb.

NAMEPLATE

MAX AMPS

115V 230V DISCHG. SUCTION PRESS. H W L WT.

MOTOR

CONNECTED

FOR

TAPPING SIZE INCHES DIMENSIONS INCHES

EJECTOR SPECIFICATIONS AND WELL ADAPTER SELECTION CHART

EJECTOR

ORDER

NO.

SP20BL 2” Brass, Leather

SP20CL

SP22CL

*129205 1-1/4” turned coupling required. Order separately.

EJECTOR

DESCRIPTION

2” Cast Iron,

Leather

2” Cast Iron,

Leather

EJECTOR

DROP PIPE

TAPPING

1” F

1-1/4” M

1” F 2” x 1”

1-1/4” M 2” x 1-1/4”

WELL SIZE /

DROP PIPE

2” x 1”

2” x 1-1/4”*

WELL ADAPTER

REQUIRED

PACKAGE

NO.

129719

127025

129720

129723

129719

127025

129720

129723

Rt. Angle

Rt. Angle

Rt. Angle

Rt. Angle

TYPE

Straight

Straight

Straight

Straight

READ THESE INSTRUCTIONS CAREFULLY

Read these installation instructions in detail before installing your pump. Be sure to check the following:

1. Be certain the motor is connected for the correct line voltage being used (check motor nameplate).

2. Be certain the pump is completely primed before starting. Otherwise damage may occur to the seal.

EVERY pump is tested before leaving the factory, and its performance depends largely on the installation.

GENERAL SAFETY INFORMATION

A. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC) and the Occupational

Safety and Health Act (OSHA).

B. Replace or repair damaged or worn cords immediately.

C. Do not kink power cable and never allow the cable

to come in contact with oil, grease, hot surfaces, or

chemicals.

D. Protect the power cable from coming in contact with

sharp objects.

E. Be careful when touching the exterior of an operating

motor--it may be hot enough to be painful or cause injury.

With modern motors, this condition is normal if operated

at rated load and voltage. Modern motors are built to

operate at higher temperatures.

F. Make certain that the power source conforms with the

requirements of your equipment.

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

G. Always disconnect power source before performing any

work on or near the motor or its connected load. If the

power disconnect point is out-of-sight, lock it in the open

position and tag it to prevent unexpected application of

power. Failure to do so could result in fatal electrical

shock.

H. Do not handle the pump with wet hands or when

standing in water, as fatal electrical shock could occur.

Disconnect main power before handling unit for ANY

REASON!

I. Unit must be securely and adequately electrically

grounded. This can be accomplished by wiring the unit

to a grounded metal-clad raceway system or by using a

separate ground wire connected to the bare metal of the

motor frame or other suitable means.

J. WARNING: Risk of electric shock. This pump has not

been investigated for use in swimming pool areas.

K. WARNING: This product contains chemicals known to

the State of California to cause cancer and birth defects

or other reproductive harm.

L. NOTE: Pumps with the “CSA” mark are tested to UL

standard UL778 and certified to CSA standard C22.2

No. 108.

2

Page 3

PRELIMINARY CONSIDERATIONS

I. Location

A. Pump can be located at the well or can be offset some

distance away from the well. For best performance, it

should be located as close to the well as possible.

B. Location can be in the basement, a pit below ground, or

in a pump house above ground.

C. Ventilation and drainage must be provided to prevent

damage from moisture to the motor and pressure switch.

D. The pump and all piping must be protected from freezing.

E. Pump and pipe line must be drained when not in use if

there is any danger of freezing.

II. Well Conditions

A. New wells should be pumped clean of all sand and

foreign matter before installing the pump, or damage may

result to the operating parts.

B. The foot valve should be installed a minimum of five feet

from the bottom of the well to prevent sand, mud or other

foreign matter from entering the system.

C. The well must be capable of furnishing a sufficient

quantity of water to satisfy the demands of the pump and

personal needs. The water level must not draw down

below the maximum rated depth of the pump, or loss of

capacity and prime will result.

D. For weak well installations, see Paragraph A under Deep

Well (Double Pipe System) installations.

E. For sanitary reasons, install a well seal or pitless adapter

as required and in accordance with local and state

codes.

III. Piping

A. Old or badly scaled pipe should not be used, because

dislodged flakes of scale can cause stoppage of the

ejector nozzle and malfunction the entire system.

B. Use only pipe in good condition, free of rust and

scale. Threads should be sharp, cleanly cut and with a

minimum of two threads remaining when connection is

completely drawn up.

C. On galvanized steel pipe installations, the ends should

be reamed to ensure maximum capacity.

D. All joints and connections should be doped (male threads

only) and drawn up tightly.

CAUTION: THE ENTIRE SYSTEM MUST BE AIR

AND WATER TIGHT FOR EFFICIENT OPERATION

IV. Type of Pipe

A. Plastic or galvanized steel pipe may be used in the

installation of jet pumps.

B. Plastic pipe must have a minimum pressure rating of 160

P.S.I.

C. DO NOT USE PLASTIC PIPE IN THE WELL ON

SINGLE PIPE EJECTOR INSTALLATIONS.

V. Well To Pump Piping

A. All offset piping should slope upwards from well to pump.

B. Avoid dips or pockets in offset piping, or air will

accumulate at high points and make priming difficult.

C. Install unions at pump and at well to aid in servicing.

D. Allow enough room around pump and piping installation

for using pipe wrenches, and for service and installation.

E. Do not use piping of sizes smaller than those listed in

Chart 1, or pump will not operate properly.

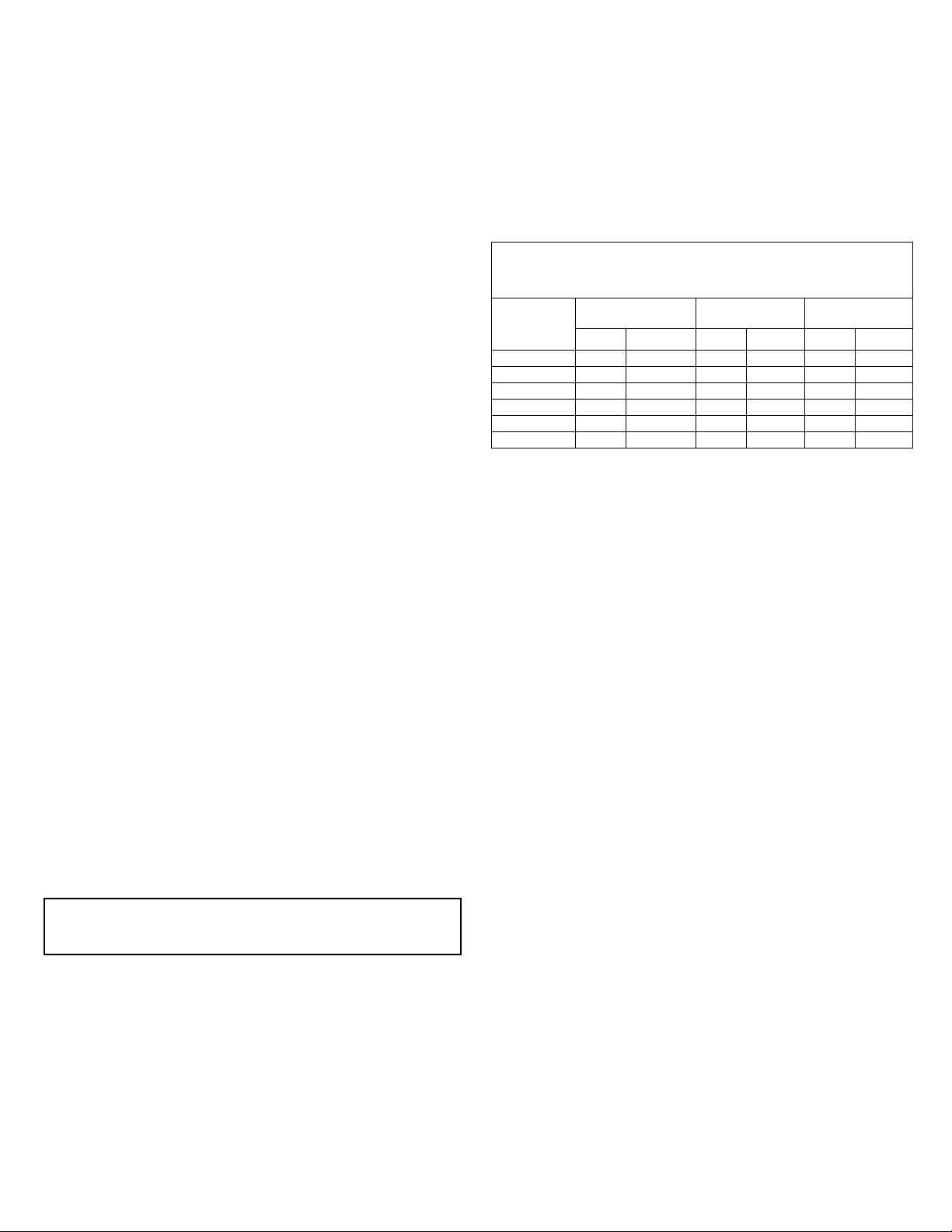

CHART I

PIPE SIZES REQUIRED FOR HORIZONTAL

PIPING BETWEEN PUMP AND WELL

Distance:

Well to

Pump

0’ - 25’ 1-1/4” 1” 1-1/4” 1” 1-1/4” 1”

25’ - 50’ 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4”

50’ - 75’ 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4”

75’ - 100’ 1-1/2” 1-1/4” 1-1/2” 1-1/4” 1-1/2” 1-1/4”

100’ - 125’ 1-1/2” 1-1/2” 1-1/2” 1-1/2” 1-1/2” 1-1/2”

125’ - 150’ 1-1/2” 1-1/2” 1-1/2” 1-1/2” 1-1/2” 1-1/2”

3/4 HP 1 HP 1-1/2 HP

Suc. Press. Suc. Press. Suc. Press.

NOTE - USE PIPE JOINT COMPOUND ON

EXTERNAL THREADS OF ALL CONNECTIONS

INSTALLATION

I. Deep Well (Double Pipe System)

Application - Where the inside diameter of well is 3-1/2

inches or larger. (See illustration C & D).

A. Attach the foot valve to the ejector using a galvanized

steel or plastic nipple. Add sufficient pressure pipe (1”)

and suction pipe (1-1/4”) to submerge ejector 10 to 15’

below pumping water level, making certain foot valve is

at least 5 feet from bottom of well. If pressure pipe and

suction pipe of the same diameter are used, be sure to

identify them clearly so that they will be connected to the

proper tappings of the pump.

If a known weak well exists, replace nipple with 34 feet of

1” tail pipe between the ejector and the foot valve. This

will provide a continuous source of water for the pumping

system.

B. Check pipe and foot valve for leaks by filling pipes with

water. A continuous loss of water indicates a leak in the

piping, foot valve or unions, and must be corrected.

C. If no leaks are found, connect pressure and suction pipes

from well to pump using piping of the same diameter as

the suction pipe (1-1/4”) and pressure pipe (1” ) tappings

of the pump. For long offset distances, refer to Chart I.

for the proper pipe size.

D. Unions in suction and discharge piping near pump and

well will aid in servicing. Leave enough surrounding

room so that wrenches can be used without difficulty.

3

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

Page 4

II. Deep Well (Single Pipe System)

Application - Where the inside diameter of well is 2, 2-1/2 or

3 inches (See Illustration A & B).

A. Attach foot valve directly to bottom of ejector assembly

(tail pipe not used on single pipe installations). Ejector

is to be submerged 10 to 15 feet below pumping water

level, making certain foot valve is at least five feet from

bottom of well.

B. Attach foot valve and packer ejector to suction pipe

(presoak packer leathers for approximately two hours).

Start the assembly down the well. Some force may be

required to push the packer down the casing.

C. As each section is lowered, check for leaks by pouring

water into the suction pipe.

D. Attach well adapter to suction pipe, lower over casing top

and tighten adapter flange.

E. If pump is offset from the well, run suction and pressure

pipes from well to pump, using piping of the same

diameter as the suction tapping (1-1/4”) and pressure

tapping (1” of the pump. For long offset distances, refer

to Chart I for the proper pipe size.

F. Unions in suction and discharge piping near pump and

well will aid in servicing. Leave enough surrounding

room so that wrenches can be used without difficulty.

III. Pressure Tank Hook Up

A. Standard vertical pressure tanks require an air volume

control to ensure the proper air-to-water ratio in

the pressure tank. The air volume control tubing is

connected to the 1/4” tapping on the pump case (see

Illustration E).

B. Air-E-Tainer tanks are equipped with a diaphragm or

bladder that keeps the air and water from mixing. Since

these tanks are factory precharged with air, an air

volume control is not required.

C. On vertical tank installations, galvanized steel or plastic

pipe can be used to connect the pump to the tank. To

assist in servicing, place shut-off valve and union in line

between pump and tank (See Illustration E).

D. DO NOT install a check valve between pump and

pressure tank. This will cause the pressure switch to

malfunction.

IV. Wiring

A. All jet pump motors are suitable for use with 60 cycle

A.C. current only. Pumps with 3/4 thru 1-1/2 HP motors

are connected for 230 volt service.

B. All pumps (3/4 thru 1-1/2 HP) are dual voltage and may

be field connected for either 115 or 230 volt service.

C. Check the motor nameplate diagram if a voltage change

is required. Always use the higher voltage when

possible.

Your pump motor has built-in thermal overload that protects

the motor against burnout from overload of low voltage,

high voltage and other causes. The device is automatic

and resets itself once the temperature has dropped to a

safe point. Frequent tripping of the device indicates trouble

in the motor or power lines, and immediate attention is

needed. The device should never be tampered with, and

unless trouble is located and corrected, motor failure can

eventually be expected.

CHART II-A

RECOMMENDED WIRE AND FUSE SIZES

MAX. FUSE CAPACITY WIRE GAUGE

15A

20A

30A

45A

60A

14

12

10

8

6

CHART II-B

RECOMMENDED WIRE SIZES

Distance From

Motor To Meter

0-50’

115V

230V

50-100’

115V

230V

100-150’

115V

230V

150-200’

115V

230V

200-300’

115V

230V

HP Rating of Single Phase Motors

3/4 1 1-1/2

12 GA

14 GA

12 GA

14 GA

12 GA

14 GA

10 GA

14 GA

8 GA

14 GA

12 GA

14 GA

12 GA

14 GA

10 GA

14 GA

10 GA

12 GA

8 GA

12 GA

12 GA

14 GA

12 GA

14 GA

10 GA

12 GA

12 GA

10 GA

8 GA

6 GA

CAUTION: Never examine, make wiring changes or

touch the motor before disconnecting the main electrical supply switch. The thermal device may have

opened the electrical circuit.

D. Undersize wiring can cause motor failure (low voltage),

frequent cutout of motor overload protector, television

interference and even fire. Make certain the wiring

is adequately sized (Chart II-B), well insulated and

connected to a separate circuit outside the house in case

of fire. For added safety, the pump and motor should be

securely grounded to the well casing or to a separate

ground rod driven eight feet into the ground. Consult

local codes before attempting a wiring installation.

NOTE: Charts II-A and II-B assume copper wire to be

installed.

E. When fusing the pump service entrance box, consult

Chart II-A for proper fuse size. Use only the fuse that is

stipulated for your particular installation. Never use one

larger. Service should never be reinstated to the pump

motor by attempting to circumvent a blown fuse by any

other means.

4

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

Page 5

F. The pressure switch is wired to the motor by connecting

the motor lead to the two inside terminals of the pressure

switch. Connect the power lines to pressure switch

terminals marked L-1 and L-2.

Motor

Load

LoadLoad

Line 1 Line 1

Power

Supply

IL0199

PRIMING & ADJUSTMENT

CAUTION: Before starting motor, the pump body

must be completely filled with water. Running the

pump dry will cause seal damage.

I. Pumps With Fully Automatic Control Valve

A. Remove priming plug from pump. Fill pump body

completely with water until all air has been expelled.

Replace plug.

B. Start pump. If pump is properly primed, pressure will

build quickly and register on the pressure gauge. If

pressure does not build, repeat the priming operation.

ON DEEP WELL INSTALLATIONS, ALL AIR MUST BE

VENTED FROM THE DRIVE AND SUCTION PIPES AS

WELL AS THE PUMP BODY BEFORE THE PUMP WILL

PRIME. IT MAY BE NECESSARY TO FILL THE PUMP

BODY SEVERAL TIMES TO ACHIEVE PRIME.

C. Once prime is achieved, unit will adjust automatically to

the average operating pressure.

II. Pumps With Semi-Automatic Control Valve

A. Remove priming plug from pump. Fill pump body

completely with water until all air has been expelled.

Replace plug.

B. Screw adjusting stem on control valve all the way in, then

start the pump. If the pump is properly primed, pressure

will build quickly and register on the pressure gauge. If

pressure does not build, repeat the priming operation.

C. With the pump operating at high pressure and no

pressure in the tank (two or more faucets open) slowly

unscew the adjusting stem until maximum flow is

obtained. The case pressure at this point will be the

average operating pressure and should agree with the

chart shown below.

D. If the control valve is opened too far, a slight cavitation

noise will be noticeable and still further opening will

cause the pump to lose prime.

AVERAGE OPERATING PRESSURE

MODEL NO.

SETTING

VS, VA207P 3/4 46 PSI

VS, VA210P 1 57 PSI

VS, VA215P 1-1/2 72 PSI

VPH10 1 47 PSI

HP PRESSURE

NOTE: PUMP WILL NOT PRIME IF THERE IS ANY

LEAKAGE IN THE SUCTION PIPING.

III. Pumps Installed In A Horizontal Position

A. “VA” and “VS” pumps can be installed horizontally by

using the optional 135276 pump base.

B. If installed horizontally, prime through the priming port of

the pump body.

C. By following this procedure, the entire pump cavity can

be filled with water and air will be expelled more readily.

MAINTENANCE

A. LUBRICATION

The pumps and motors require no lubrication. The ball

bearings of the motor have been pre-lubricated and

under normal operating conditions should require no

further greasing.

B. FREEZING

Drain the entire system if there is danger of freezing. A

drain plug is provided at the bottom of the pump case for

this purpose.

ROTARY SEAL ASSEMBLY

REPLACEMENT

CAUTION: Make certain that the power supply is

disconnected before attempting to service the unit!

The rotary seal assembly must be handled carefully

to avoid damaging the precision lapped faces of

the sealing components.

A. Disengage pump body from motor and mounting ring.

B. Remove diffuser and unthread impeller from the pump

shaft.

NOTE: To prevent the shaft from rotating when removing

the impeller, use an 11/16” open end wrench on the hex

of the pump shaft.

C. The carbon seal face, friction ring, and stainless steel

shell & spring of the rotary seal will come loose at this

time. Use a screwdriver (or similar instrument) to pry the

ceramic seal and rubber gasket from the recess of the

mounting bracket.

CAUTION: Be careful not to damage the motor

shaft or recess surface.

D. Clean the recess and pump shaft thoroughly.

5

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

Page 6

E. Install the new rotary seal assembly:

1. Insert the ceramic seal and the rubber gasket into the

recess.

NOTE: To help facilitate installation, apply a light

coating of oil to the outside diameter of the rubber

gasket. Make certain that the ceramic seal is kept

clean and free of dirt and/or oil.

2. Slip the remaining parts of the rotary seal assembly

onto the motor shaft.

NOTE: Apply a light coating of oil to the inside diameter of

the rubber drive ring.

F. Replace the impeller and diffuser removed in Step B.

G. Reassemble the pump body to the motor and mounting

bracket.

MOTOR REPLACEMENT

CAUTION: Before attempting to replace the motor,

make certain that the power supply is disconnected

and the systems pressure is relieved.

A. The motor can be removed without disturbing the seal

assembly or hydraulic components of the pump. Make

certain that the service factor of the replacement motor

corresponds with the motor being replaced.

B. Remove four bolts that hold the motor to the motor

mounting ring.

C. Break the motor shaft free from the pump shaft by using

an 11/16” wrench on the pump shaft and a 9/16” wrench

on the flats of the motor shaft. Unthread motor shaft

while holding the pump shaft.

D. Reassemble the new motor.

TROUBLESHOOTING CHART

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

PUMP WON’T

START OR RUN

PUMP STARTS

AND STOPS

TOO OFTEN

PUMP WON’T

SHUT OFF

PUMP

OPERATES,

BUT DELIVERS

LITTLE OR NO

WATER

1. Blown fuse

2. Low line voltage

3. Loose, broken or incorrect wiring

4. Defective motor

5. Defective pressure switch

6. Impeller or seal

7. Bad capacitor

1. Leak in pressure tank

2. Defective air volume control

3. Faulty pressure switch

4. Leak on discharge side of system

5. Leak on suction side of system

6. Leak in foot valve

1. Wrong pressure switch setting, or

setting “drift”

2. Defective pressure switch

3. Loss of prime

4. Low well level

5. Fouled ejector

1. Low line voltage

2. System incompletely primed

3. Air lock in suction line

4. Undersized piping

5. Leak in air volume control or tubing

6. Leak on suction side of system

7. Low well capacity

8. Plugged ejector

9. Defective or plugged foot valve and/

or strainer

10. Worn or defective pump parts or

plugged impeller

1. If blown, replace with fuse of proper size. Use time delay fuses.

2. If voltage under recommended minimum, check size of wiring from main switch

on property. If OK, contact power company.

3. Rewire any incorrect circuits. Tighten connections, replace defective wires.

4. Replace

5. Adjust switch settings. Clean contacts with emery cloth, if dirty.

6. If impeller won’t turn, remove housing and locate source of binding.

7. Replace.

1. Repair leaks or replace tank.

2. Clean or replace defective control.

3. Adjust switch settings. Clean contacts with emery cloth, if dirty.

4. Repair leaks as necessary.

5. Make sure above ground connections are tight. Then repeat test. If necessary,

pull piping and repair leak.

6. Repair or replace.

1. Adjust switch to proper setting.

2. Replace switch if defective.

3. Reprime if necessary.

4. If undersized, replace pump or ejector.

5. Clean.

1. If voltage under recommended minimum, check size of wiring from main switch

on property. If OK, contact power company

2. Reprime if necessary.

3. Rearrange pipingi to eliminate air lock.

4. Replace undersized piping or install pump with higher capacity.

5. Tighten all fittings and replace control if necessary.

6 Make sure above ground connections are tight. Then repeat test. If necessary,

pull piping and repair leak.

7. Close down the valve on the discharge side of pump to limit the flow of water, in

keeping with well capacity.

8. Clean and reinstall if dirty.

9. Clean, repair, or replace as needed.

10. Replace worn parts or entire pump. Clean parts if required.

6

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

Page 7

DEEP WELL JET PUMP REPAIR PARTS

“VA”, “VS” & “VPH” SERIES

(For Pricing Refer To Repair Parts Price List)

FORM NO. FW0035

0413

SUPERSEDES 1009

PAGE 3-1A REPAIR PARTS

“VA”

1

13

10

IL0319

14

11

10

IL0316

14

12

“VPH”

1

13

10

14

12

“VS”

1

2

13

3

4

5

6

7

8

5

7

9

10

IL0426

HORSEPOWER

STAGE 1 2 2 2 1

ITEM DESCRIPTION

MODEL NO.

PART NO. QTY.

1‡Motor, Nema J (Thd)

Motor Cover w/screws

Screws Cover

023212

021302

Motor Lead Wire

2

Shaft

3

Mounting Ring

Hex Hd. Cap Screws 3/8 x 3/4”

4

Seal, Rotary w/Spring

5

Impeller †

6

Spacer, Shaft

‡

Spacer, Suction

7

Diffuser †

8‡Intermediate Stage

Bearing, Intermediate Stage

9

Ring, Square Cut

‡

Rubber, Diffuser

10

Pump Body

11

Control Valve “VA”

12

Control Valve “VS” & “VPH”

13

Pressure Switch

14

Pressure Gauge

‡

Plug, Priming 1/2” NPT

‡

(*) Standard hardware item

(†) For quantity required — See number of stages

(‡) Not shown

NOTE: For horizontal installations, use optional pump base 135276A

Plug, Drain 1/4” NPT

135235

*

131100

135245

135243

135246

135247

135240

132428

135237

020346

023294

*

*

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

1/2 3/4 1 1-1/2 1

VA105P VA207P VA210P VA215P

VS105P VS207P VS210P VS215P

98H105

1

2

136135A

135238

1

9

1

135248

—

1

135242

—

—

1

—

1

C981D

132446

1

1

2

1

98H107

1

2

136135A

135239

1

9

1

127960

1

—

135241

1

1

1

—

1

C981G

133383

1

1

2

1

98H110

1

2

136135A

135239

1

9

1

132613

1

—

135241

1

1

1

—

1

C981G

133383

1

1

2

1

98H115

1

2

136136A

135239

1

9

1

135248

1

—

135242

1

1

1

—

1

C981G

133383

1

1

2

1

7

VPH10

98J110

1

2

136135A

N/R

136873

8

1

134138

—

—

132425

—

—

132429

1

134312

—

132446

1

1

2

1

Page 8

Priming

Port

Priming

Port

Priming

Port

Pump

Gasket

Straight

Adapter

Suction

Pipe

Well

Casing

Single Pipe

Ejector

Foot Valve

Illustration (A)

Single Pipe Over the Well

Installation

Right Angle

Well Adapter

IL1707

Pump

Gasket

Suction

Pipe

Well

Casing

Single Pipe

Ejector

Foot Valve

Illustration (B)

Single Pipe Oset

Installation

Pressure

Pipe

IL1708

Pump

Gasket

Suction

Pipe

Illustration (C)

Double Pipe Over the Well

Installation

Well Seal

Pressure

Pipe

Double Pipe

Ejector

Tail Pipe

Foot Valve

IL1709

Suction

Pipe

Well Seal

Priming

Port

Pump

Gasket

Well Casing

Double Pipe

Ejector

Tail Pipe

Foot Valve

Illustration (D)

Double Pipe Oset

Installation

Pressure

Pipe

IL1710

Fuse

Disconnect

Box

House

Water

Supply

Line

Illustration (E)

Pressure Tank

Installation

Pressure Tank

Air

Volume

Control

IL1711

8

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

Loading...

Loading...