Page 1

Starjet SJ-48

TECHNICAL MANUAL

[ SECOND EDITION ]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

© Copyright 1996 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

This manual is an introduction to ink jet printer SJ-48.

It is intended for use as a reference for maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

• This manual is divided into the following sections:

Chapter 1 General Specifications

Chapter 2 Theory of Operation

Chapter 3 Adjustments

Chapter 4 Parts Replacement

Chapter 5 Precautions and Maintenance

Chapter 6 Troubleshooting

Chapter 7 Parts List

• First edition : Oct.1991

Second edition: Oct.1992

1

2

3

4

5

6

7

Page 4

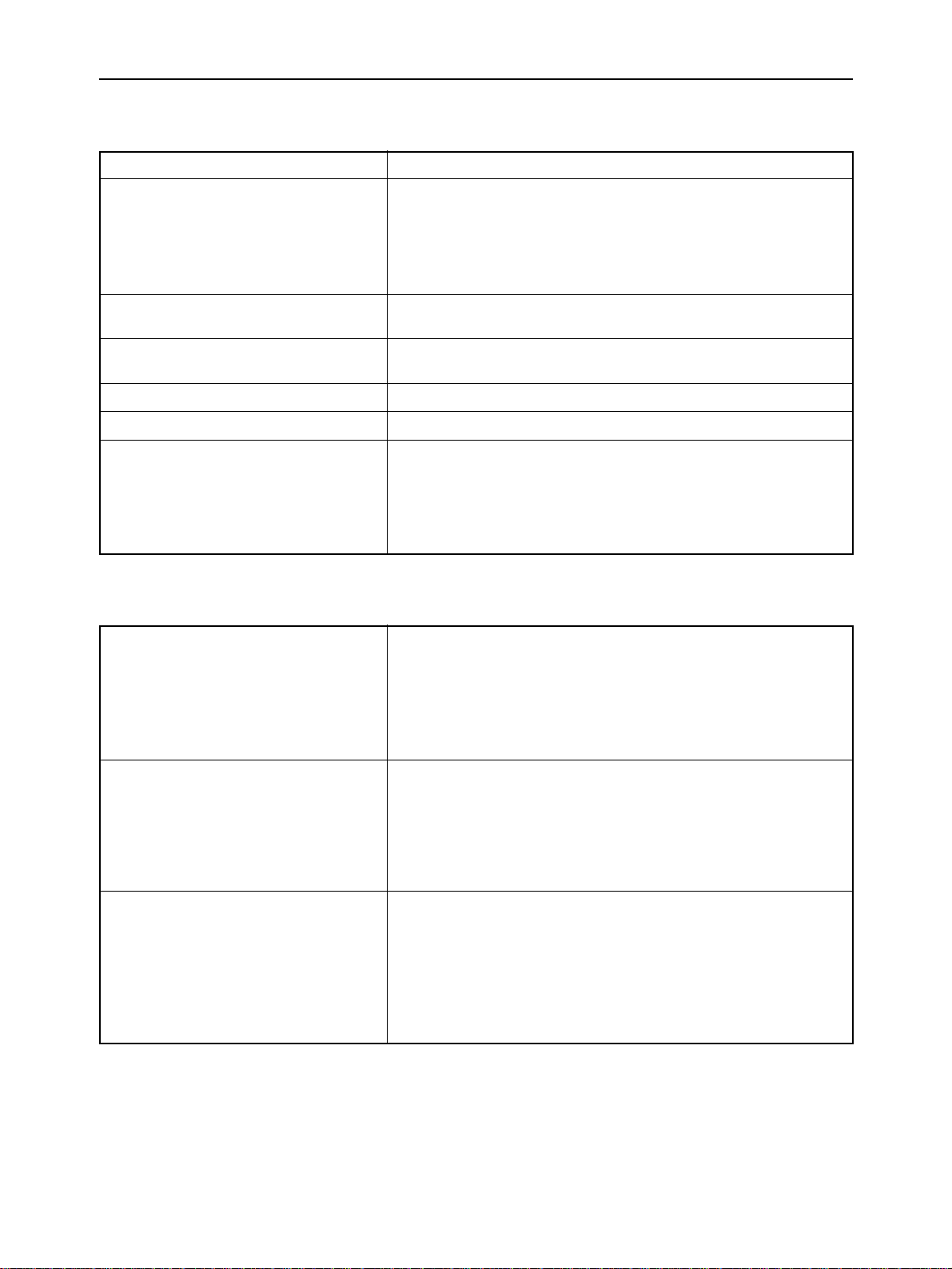

GENERAL SPECIFICATIONS

– 2 –

Page 5

CHAPTER 1

GENERAL SPECIFICATIONS

1. General Specifications..........................................................................................3

2. External Appearance and Composition ..............................................................6

3. DIP Switch Settings...............................................................................................7

4. Parallel Interface....................................................................................................8

4-1. General Specifications ........................................................................................... 8

4-2. Connector Signals .................................................................................................. 8

1

Page 6

GENERAL SPECIFICATIONS

– 2 –

Page 7

GENERAL SPECIFICATIONS

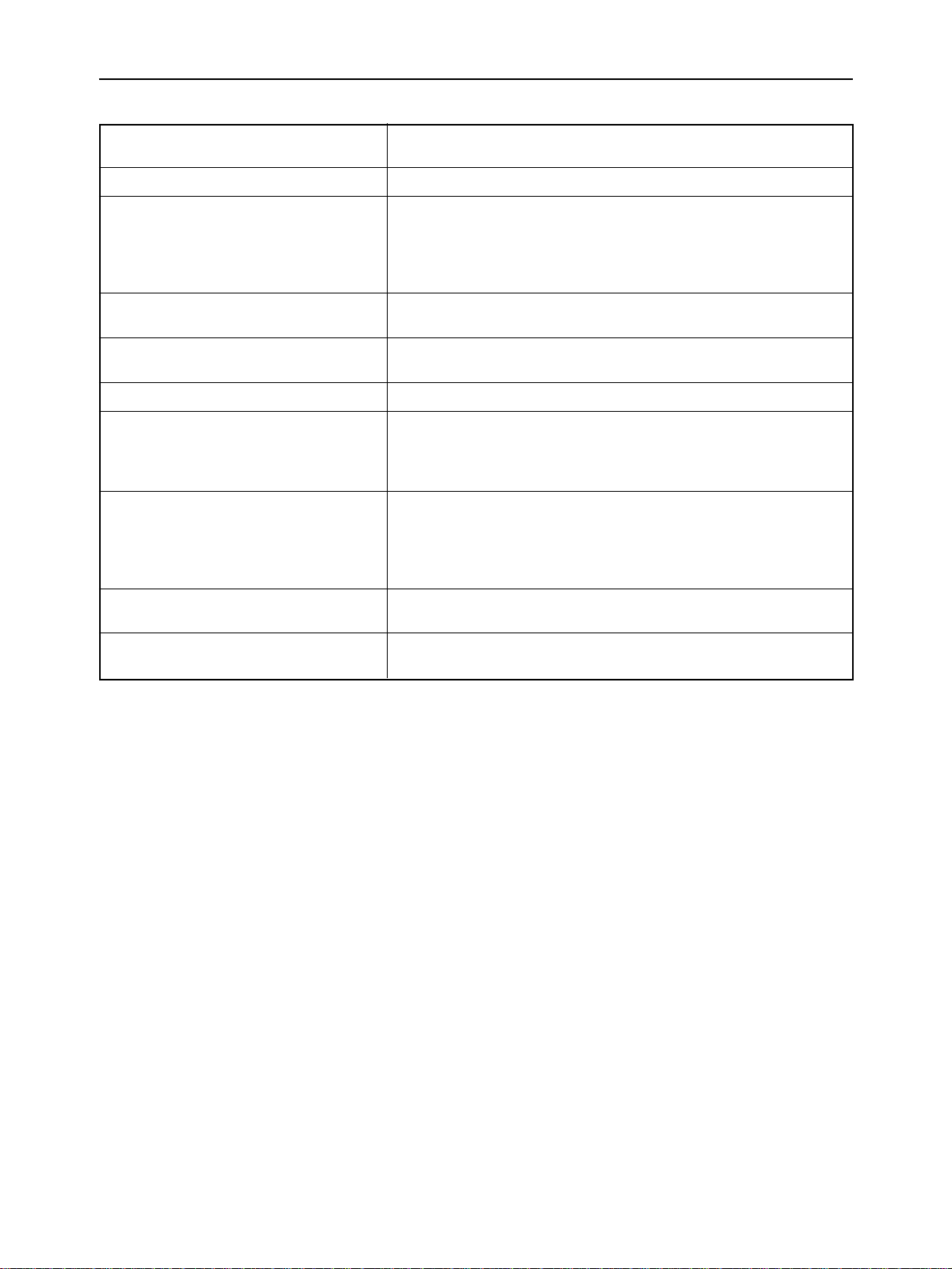

1. General Specifications

Printing system Serial Ink Jet Dot-matrix

Printing speed High Quality mode Economy mode

Pica 83 cps 83 cps

Elite 100 cps 100 cps

Semi-condensed 124 cps 124 cps

Condensed pica 142 cps 142 cps

Condensed elite 166 cps 166 cps

Print direction Bi-directional, logic-seeking

Uni-directional, logic-seeking (selectable)

Print head 48 nozzles

Life: 700,000 characters

Line spacing 1/6, 1/8, n/60, n/72, n/180, n/216, n/360

Font styles Roman and H-Gothic

Characters ASCII 96

International 16 sets(*)

IBM special 111

IBM block graphic 50

IBM code page 6 sets (**)

Download 128

* USA, France, Germany, England, Denmark I, Sweden, Italy, Spain I, Japan, Norway, Denmark II, Spain II,

Latin America, Korea, Irish, Legal

** #437 (U.S.A.), #850 (Multi-Lingual), #860 (Portuguese), #861 (Icelandic), #863 (Canadian French), #865 (Nordic)

Number of columns CPI Normal type

Pica 10 80

Elite 12 96

Semi-condensed 15 120

Condensed pica 17 137

Condensed elite 20 160

Proportional Variable

Character matrix High Quality Economy

Pica 48 × 36 24 × 36

Elite 48 × 30 24 × 30

Semi-condensed 32 × 24 16 × 24

Condensed pica 48 × 21 24 × 21

Condensed elite 48 × 18 24 × 18

Proportional 48 × n 24 × n

Bit image dot-matrix. DPI 8-bit 24-bit 48-bit

Normal-density 60 8 × 480 24 × 480 48 × 480

CRT graphics mode I 80 8 × 640 (Not supplied) (Not supplied)

CRT graphics mode II 90 8 × 720 24 × 720 48 × 720

Double-density 120 8 × 960 24 × 960 48 × 960

Triple-density 180(Not supplied) 24 × 1440 48 × 1440

Quadruple-density 240 8 × 1920 (Not supplied) Not supplied)

Hex-density 360(Not supplied) 24 × 2880 48 × 2880

– 3 –

Page 8

GENERAL SPECIFICATIONS

Paper feed Friction roller feed

Friction flat feed

Paper feed speed 5/6 inches/second max

Paper specifications

Width 7.2" ~ 8.5" (182 ~ 216 mm)

Length 7.2" ~ 14" (182 ~ 356 mm)

Weight 52 ~ 105 g/m

Envelope Commercial 10 only

Maximum buffer size Without Download 28 kB

With Download 4 kB

Emulations Standard mode: Epson LQ-860, NEC 24-wire Graphics command

IBM mode: IBM Proprinter X24E

Interface Centronics parallel

Ink Cartridge

Type Single cartridge ink supply (SC-10)

Ink Color Black only

Ink amount 28 g (0.9 oz)

Dimensions and Weight

Width 310 mm (12.2")

Depth 216.5 mm (8.5")

Height 47.5 mm (1.9")

Weight 1.8 kg (4.0 lb)

AC adapter power supply 120 VAC, 220 VAC, 240 VAC, 50/60 Hz

(varies according to the country of purchase)

Options Battery pack (BP-10)

Automatic Sheet Feeder (SF-10CA)

2

– 4 –

Page 9

GENERAL SPECIFICATIONS

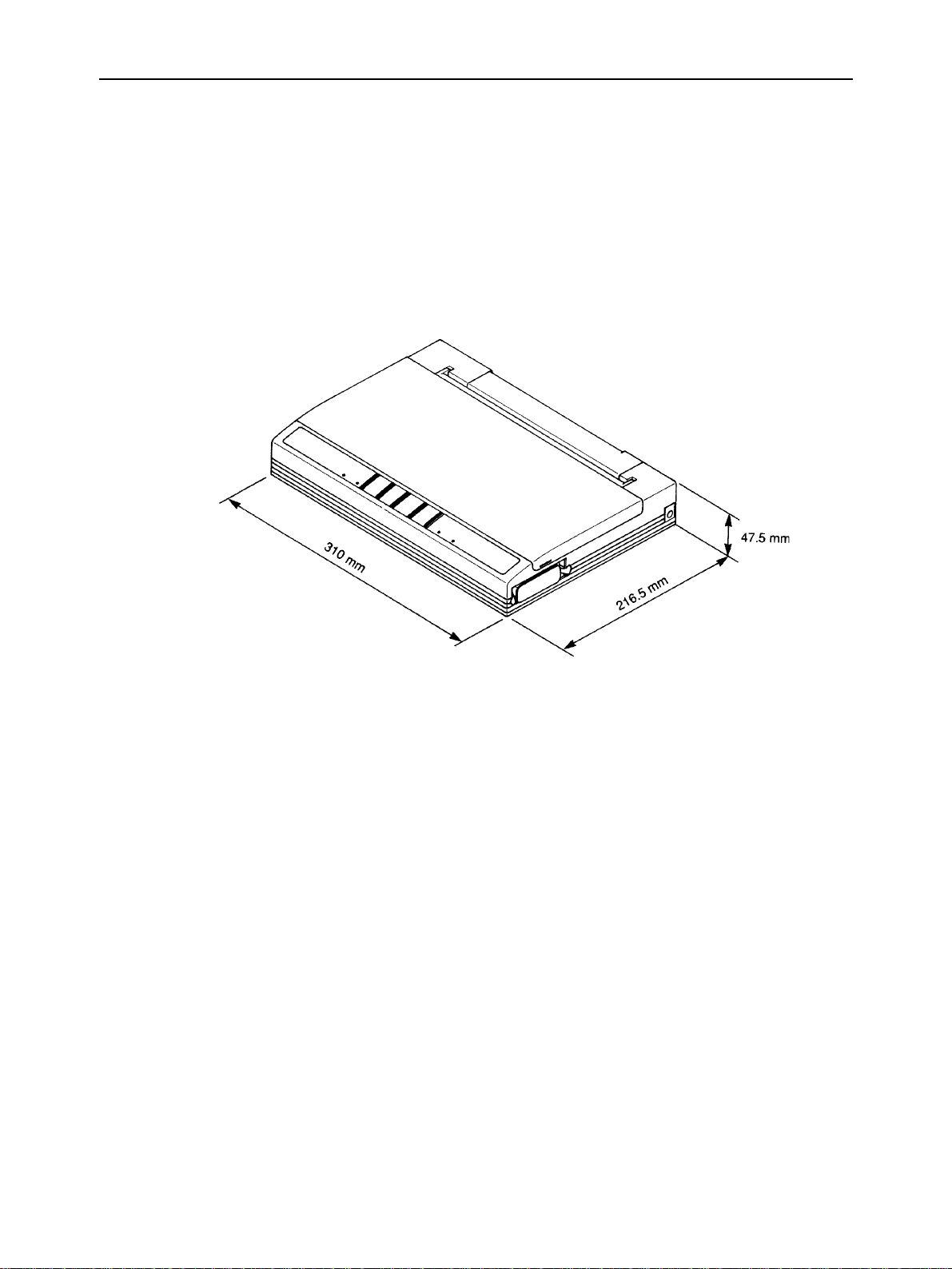

Fig. 1-1 External Dimensions

– 5 –

Page 10

GENERAL SPECIFICATIONS

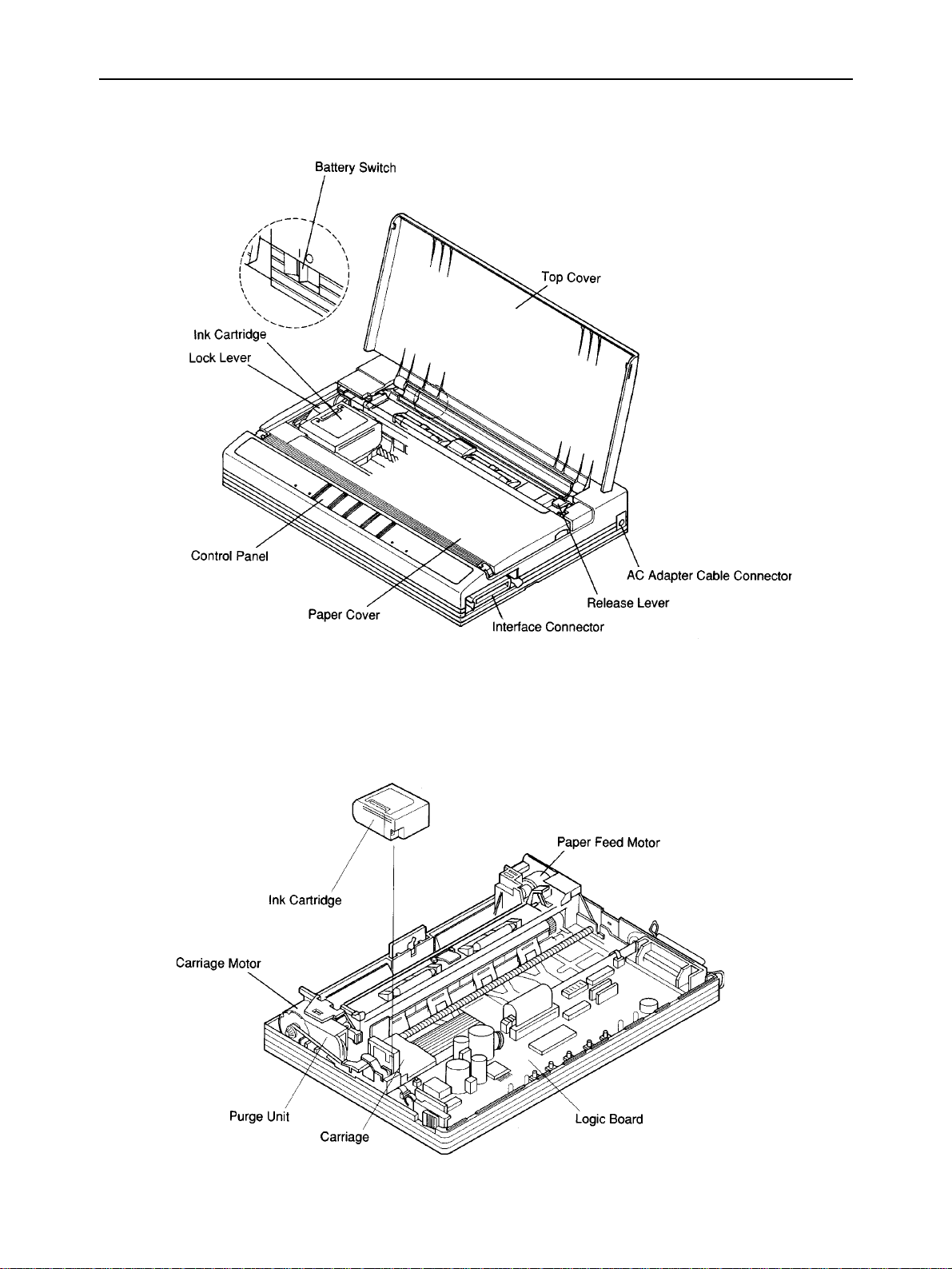

2. External Appearance and Composition

Fig. 1-2 Front View of the Printer

Fig. 1-3 Diagram of Internal Composition

– 6 –

Page 11

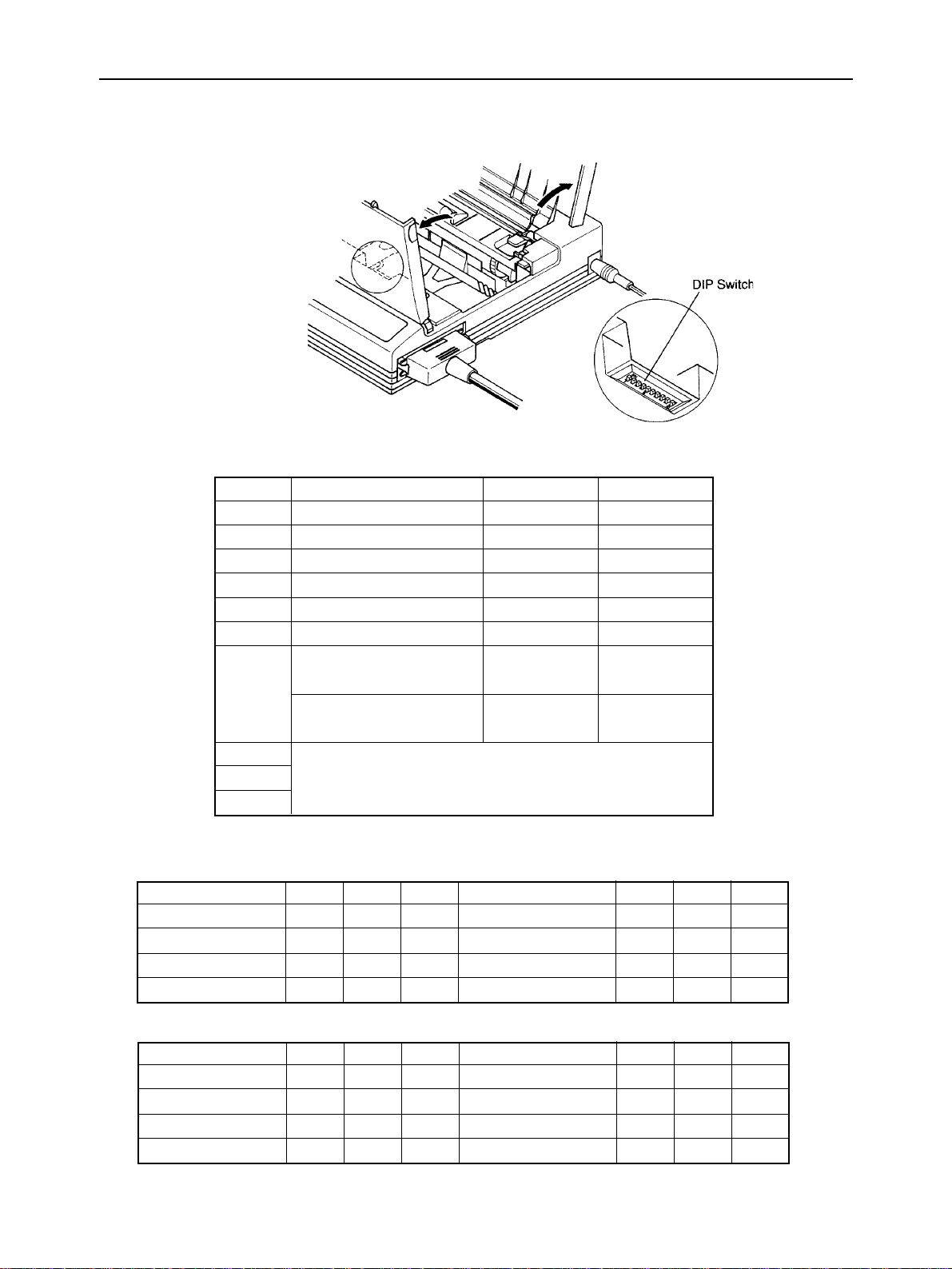

3. DIP Switch Settings

Switch Function ON OFF

1 Emulation Standard IBM

2 RAM usage Buffer Download

3 Auto LF with CR Disabled Enabled

4 Automatic Sheet Feeder Inactive Active

5 Font style Roman H-Gothic

6 Print mode Normal size Quarter size

7

8 International Character Set (See table below)

9or

10 IBM Code Page (See table below)

Character set

(Standard mode)

Character set

Fig. 1-4 DIP Switch Settings

Graphics Italics

(IBM) mode

Set #2 Set #1

GENERAL SPECIFICATIONS

All switches are set ON when the printer leaves the factory.

International Character Set (In the standard italics character set)

Country 8 9 10 Country 8 9 10

U.S.A. ON ON ON Denmark I ON O N OFF

France OFF ON ON Sweden OFF ON OFF

Germany ON OFF ON Italy ON OFF OFF

England OFF OFF ON Spain I OFF OFF OFF

IBM Code Page (Except in the standard italics character set)

Code Page 8 9 10 Code Page 8 9 10

#437 U.S.A. ON ON ON #863 Canadian French ON ON OFF

#850 Multi-Lingual OFF ON ON #865 Nordic OFF ON OFF

#860 Portuguese ON OFF ON (Reserved) ON OFF OFF

#861 Icelandic OFF OFF ON (Reserved) OFF OFF OFF

– 7 –

Page 12

GENERAL SPECIFICATIONS

4. Parallel Interface

4-1. General Specifications

Item Specifications

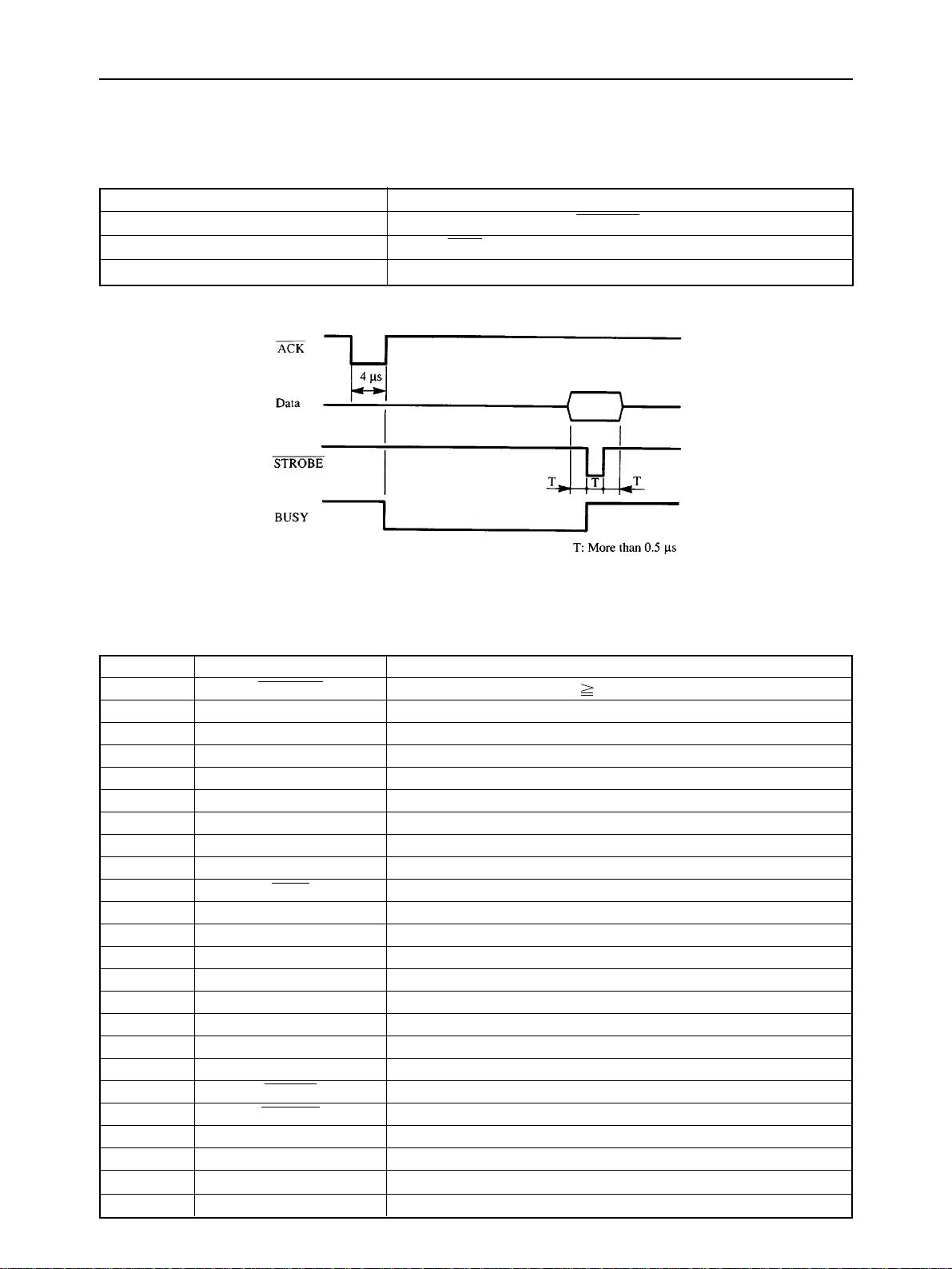

Synchronization System Via externally supplied STROBE pulse

I/F Protocol By ACK and BUSY signals

Logic Level Compatible with TTL level

Fig. 1-5 Timing Charts of Parallel Interface

4-2. Connector Signals

Pin No Signal Name Function Description

1 STROBE Goes from high to low (for 0.5µs) when active.

2 DATA1 High when active.

3 DATA2 High when active.

4 DATA3 High when active.

5 DATA4 High when active.

6 DATA5 High when active.

7 DATA6 High when active.

8 DATA7 High when active.

9 DATA8 High when active.

10 ACK 4µs low pulse acknowledges receipt of data.

11 BUSY Low when printer ready to receive data.

12 PAPER END High when paper out.

13 SELECT High when printer is on-line.

14,15 NC Unused.

16 SIGNAL GND Signal ground.

17 CHASSIS GND Chassis ground.

18 NC Unused.

19 ~ 30 GND Twisted pair ground return.

31 RESET When this input signal is low, printer is reset.

32 ERROR Outputs low when printer cannot continue, due to an error.

33 EXT GND External ground.

34 NC Unused.

35 +5V +5V DC output from printer.

36 NC Unused.

– 8 –

Page 13

CHAPTER 2

THEORY OF OPERATION

1. Block Diagram .....................................................................................................11

2. Mechanism...........................................................................................................12

2-1. Overview................................................................................................................ 12

2-2. Ink Cartridge.......................................................................................................... 13

2-2-1. Ink Jet Mechanism ......................................................................................... 13

2-2-2. Ink Cartridge Structure .................................................................................. 13

2-2-3. Ink Jet Head Unit Structure ........................................................................... 14

2-3. Purge Unit.............................................................................................................. 17

2-3-1. Purge Unit Functions..................................................................................... 17

2-3-2. Purge Unit Structure ...................................................................................... 17

2-4. Carriage Section ................................................................................................... 19

2-4-1. Carriage Section Functions .......................................................................... 19

2-4-2. Carriage Section Structure............................................................................ 19

2-5. Paper Feed Section .............................................................................................. 22

2

2-5-1. 3-way Paper Feed Section ............................................................................. 22

2-5-2. Paper End Detection Section ........................................................................ 22

3. Logic Board .........................................................................................................24

3-1. Logic Board Functions......................................................................................... 24

3-2. Control Section Block Diagram........................................................................... 26

3-3. Control Section Components .............................................................................. 27

3-4. Power Supply Section Block Diagram................................................................ 28

3-5. Power Supply Section Components ................................................................... 29

4. Auto Sheet Feeder...............................................................................................31

4-1. Gear Train.............................................................................................................. 31

4-2. Spring Clutch ........................................................................................................ 31

Page 14

THEORY OF OPERATION

– 10 –

Page 15

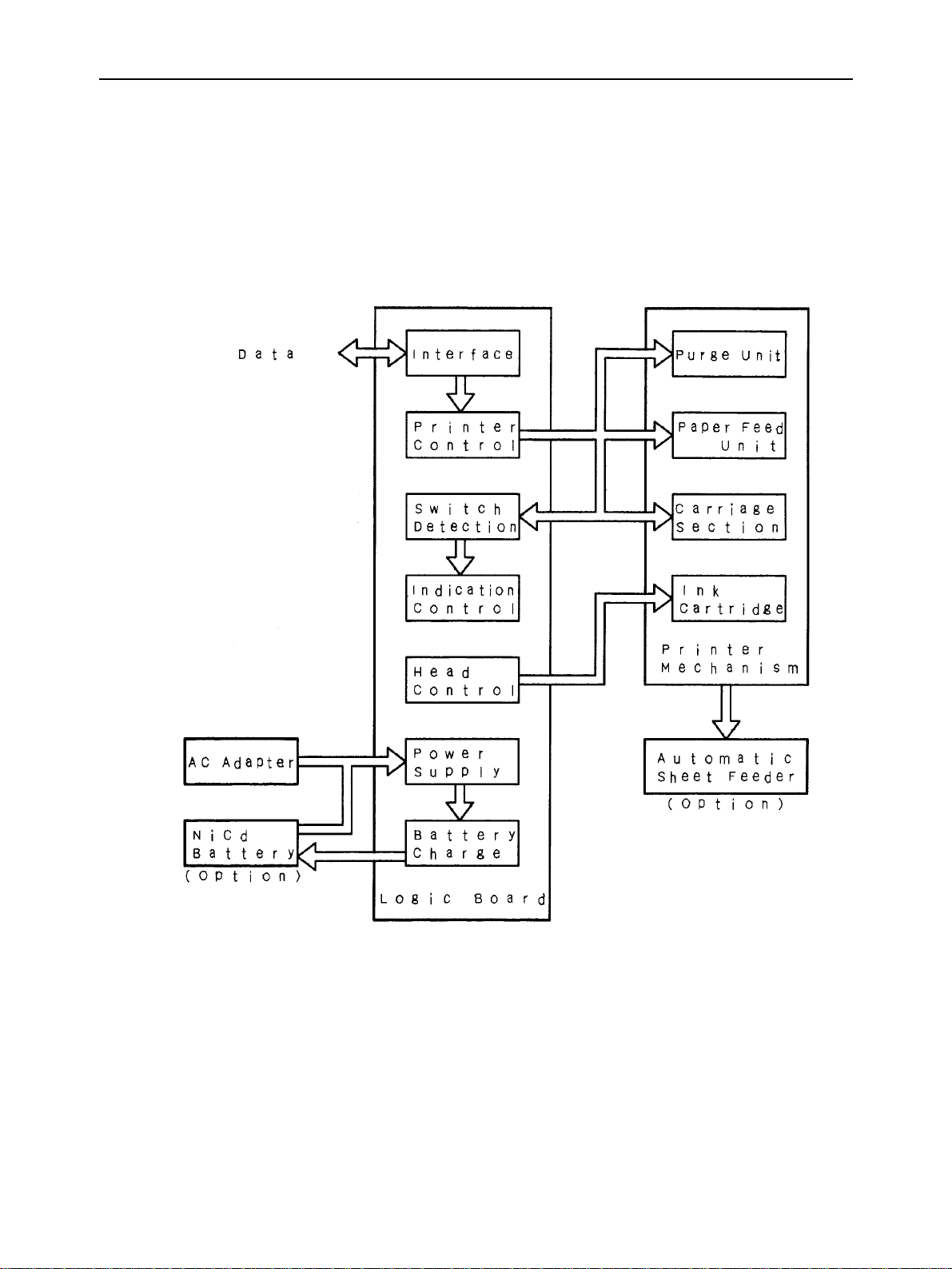

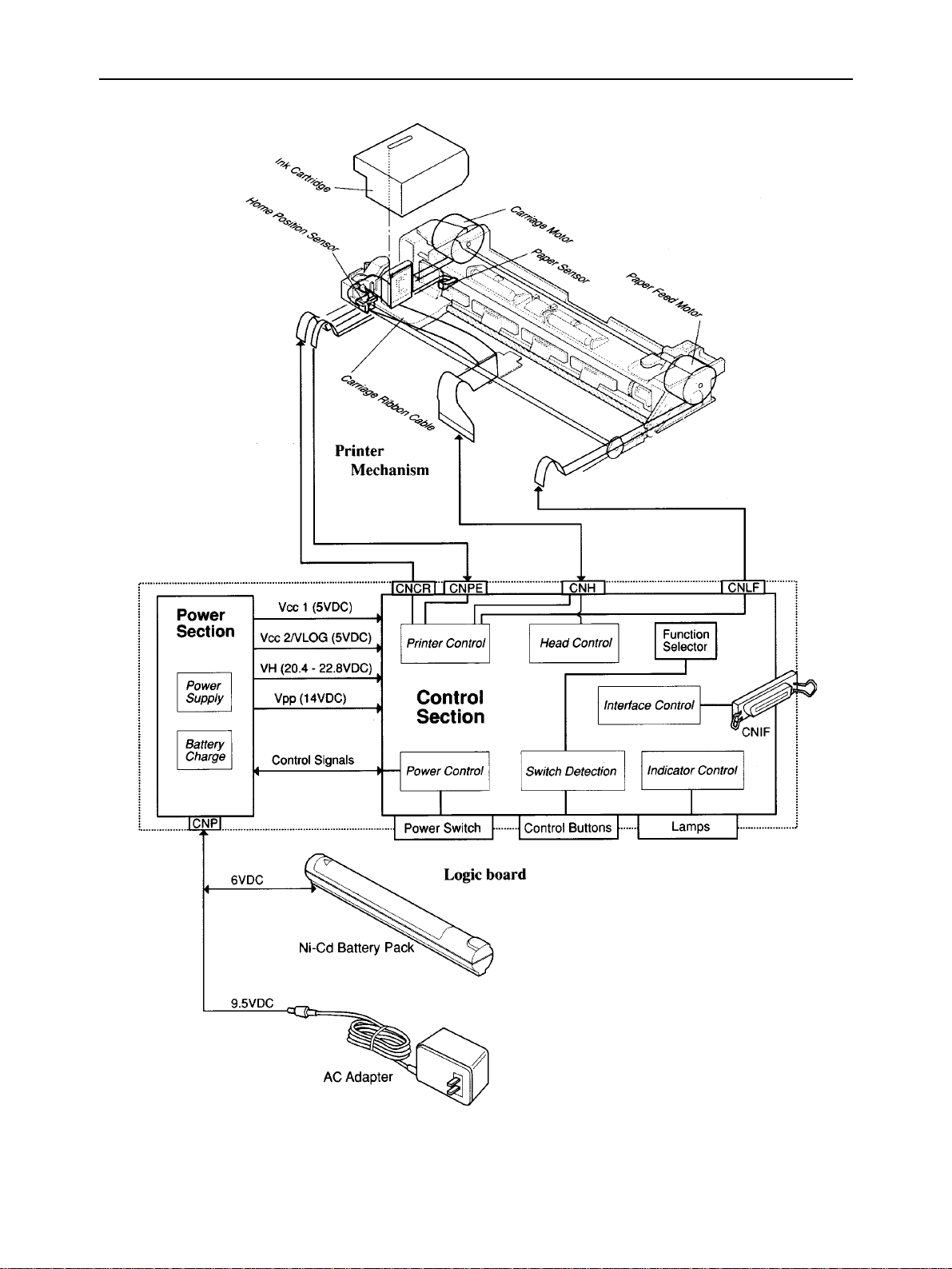

1. Block Diagram

The block diagram of this printer is shown in Figure 2-1.

THEORY OF OPERATION

Fig. 2-1 Block Diagram

– 11 –

Page 16

THEORY OF OPERATION

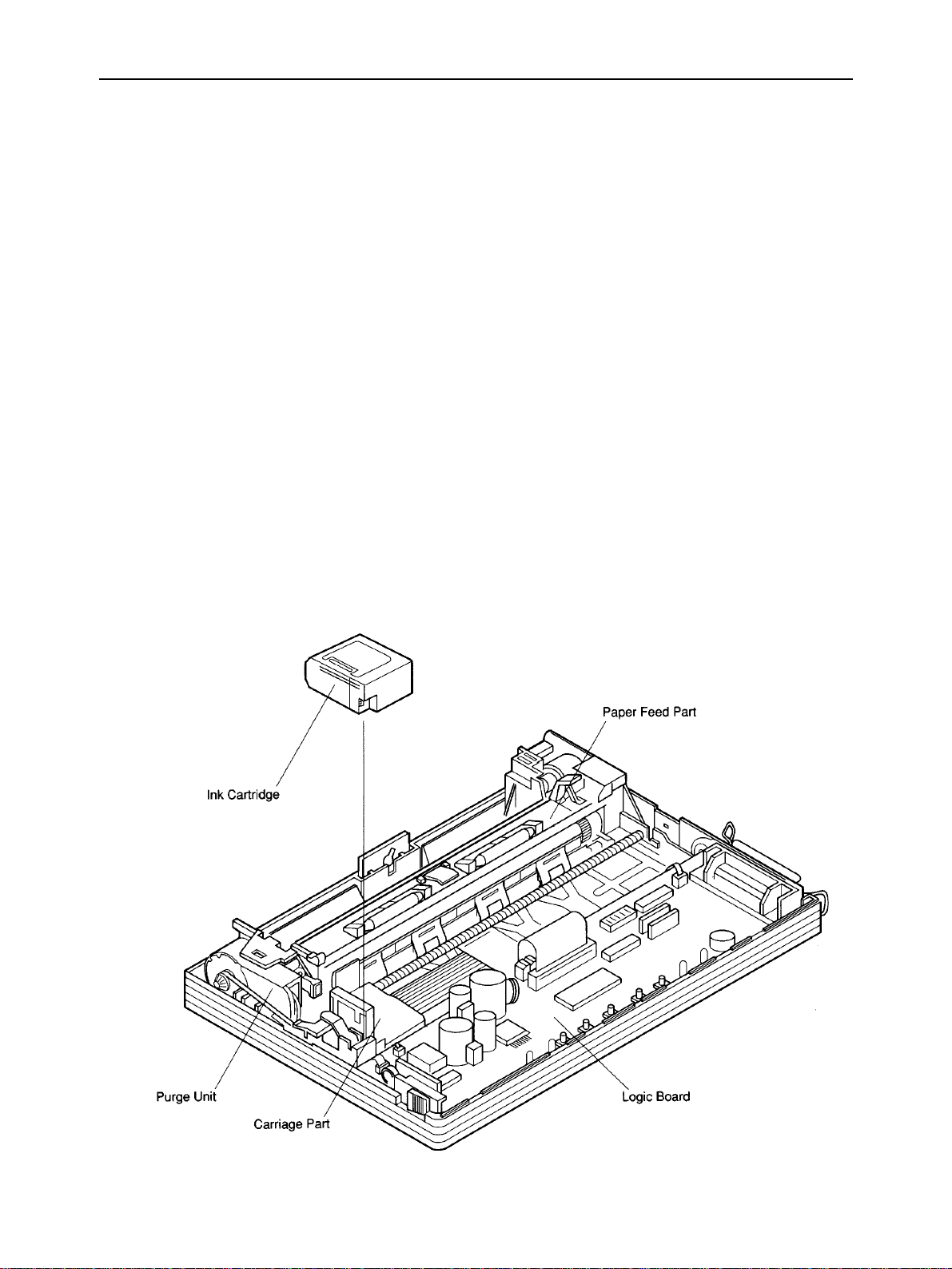

2. Mechanisms

2-1. Overview

This section explains the outline of the printer mechanism. The following sections explain each details.

a) Ink cartridge

The ink cartridge contains the 64-nozzle ink jet head with resolution of 360 DPI and ink tank.

b) Purge unit

The purge unit, drive by the carriage motor, maintains the ink jet nozzles of the ink cartridge to keep the best

printing quality.

c) Carriage part

The carriage, driven by the carriage motor, moves horizontally to the print paper with logical seeking. The carriage

motor drives either the purge unit or the carriage.

Printing signals are transmitted from the logic board to the ink cartridge on the carriage through the ribbon cable.

d) Paper feed part

The paper feed parts, driven by the paper feed motor, rotates the feed roller and moves the print paper vertically.

When the printer is placed horizontally, paper can be fed from the top of the printer. When the printer is placed

vertically, paper can be inserted from the bottom slot of the printer for flat feeding and can be fed from the optional

auto sheet feeder. Since the printer has no paper feed knob for manual feeding, paper is always fed using control

buttons.

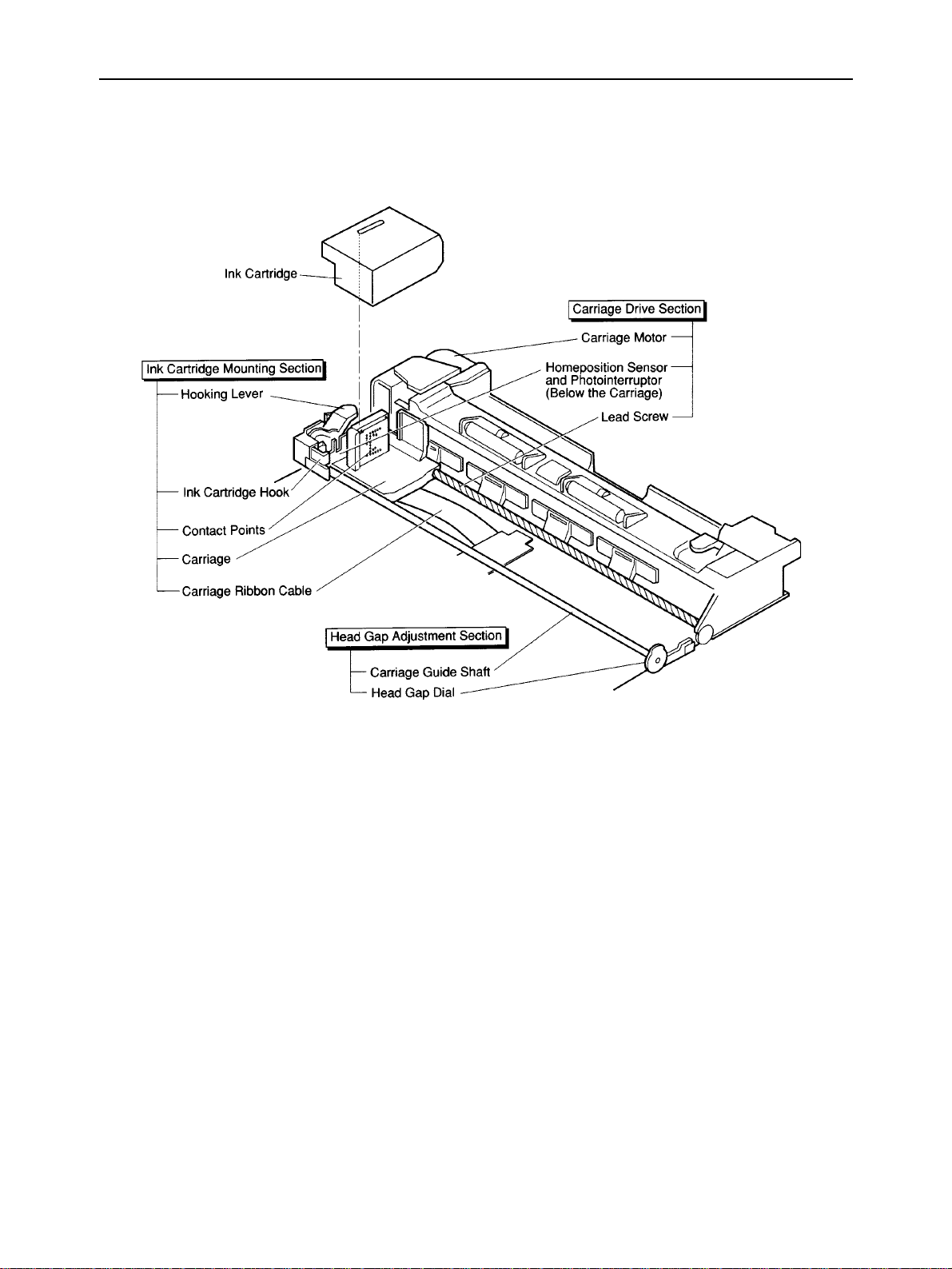

Fig. 2-2 Internal View

– 12 –

Page 17

THEORY OF OPERATION

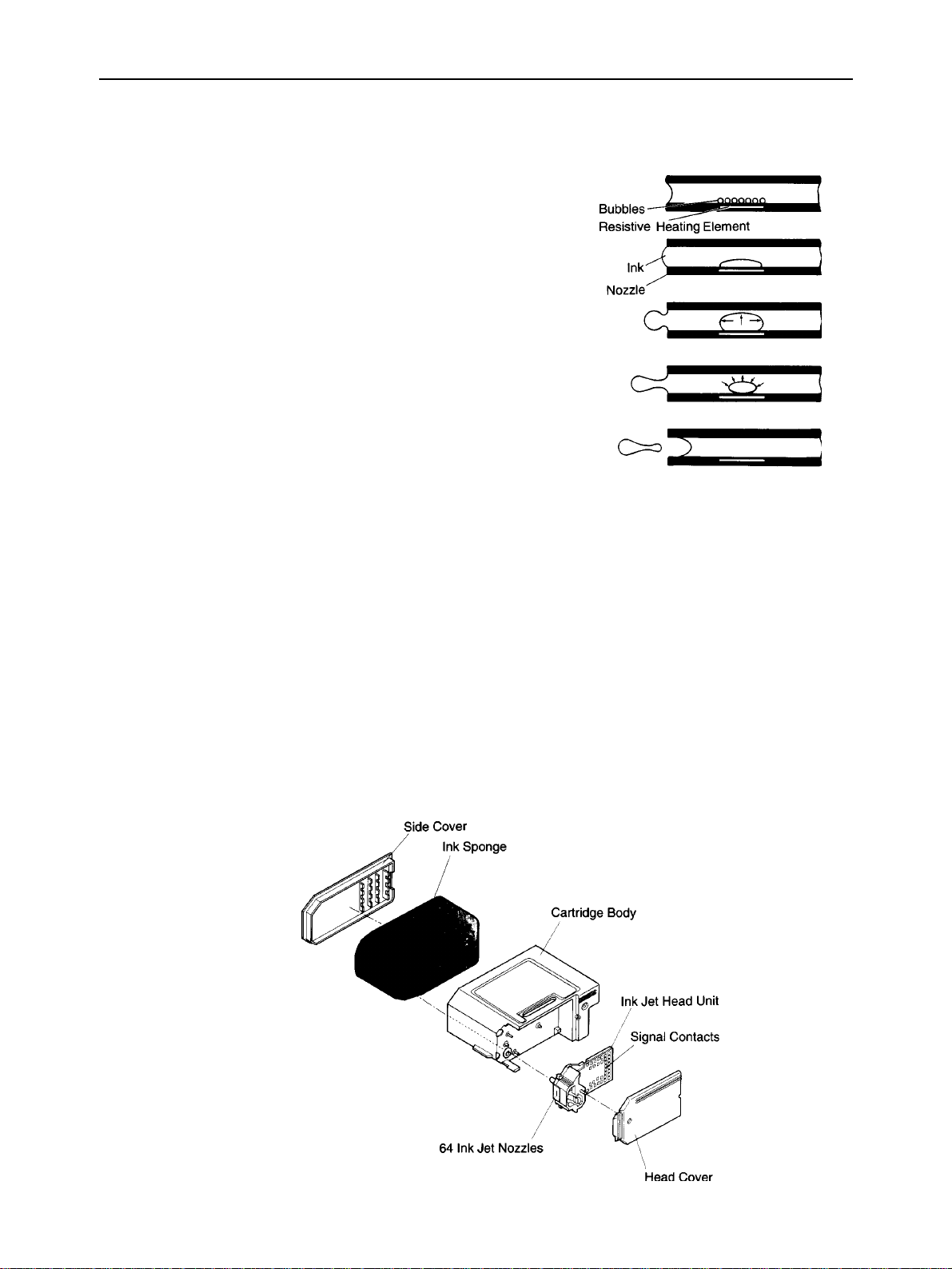

2-2. Ink Cartridge

2-2-1. Ink Jet Printing Mechanism

The ink jet printing system prints characters and graphics by firing ink

drops at the paper from thin nozzles. Heating the ink in these nozzles

produces bubbles that quickly expand and eject the ink. The heat is

generated by applying electrical pulses to the heating elements built into

each nozzle. Each pulse serves a two-fold purpose.

(1) The electrical pulse first generates heat that vaporizes the ink almost

instantly.

The resulting bubble generates a pressure wave that ejects an ink drop

from the nozzle.

(2) A vacuum is then produced as the bubble contracts after the pulse

ends.

This draws fresh ink into the nozzle.

2-2-2. Ink Cartridge Structure

a) Side cover

This plastic cover has been adhered to the cartridge body to prevent leakage of ink from the ink sponge.

b) Ink sponge

The ink sponge contains about 20 grams of black ink for printing about 450 pages of regular office paper (ordinary

paper).

c) Cartridge body

The plastic cartridge body holds the ink sponge and ink jet head unit.

d) Ink jet head unit

The ink jet head unit loads ink to the 64 ink jet nozzles from the tip of the joint pipe that contacts with the ink sponge.

Printing signals are transmitted from the signal contacts.

e) Head cover

The plastic head cover protects the ink jet head unit.

Fig. 2-3 Exploded View of Ink Cartridge

– 13 –

Page 18

THEORY OF OPERATION

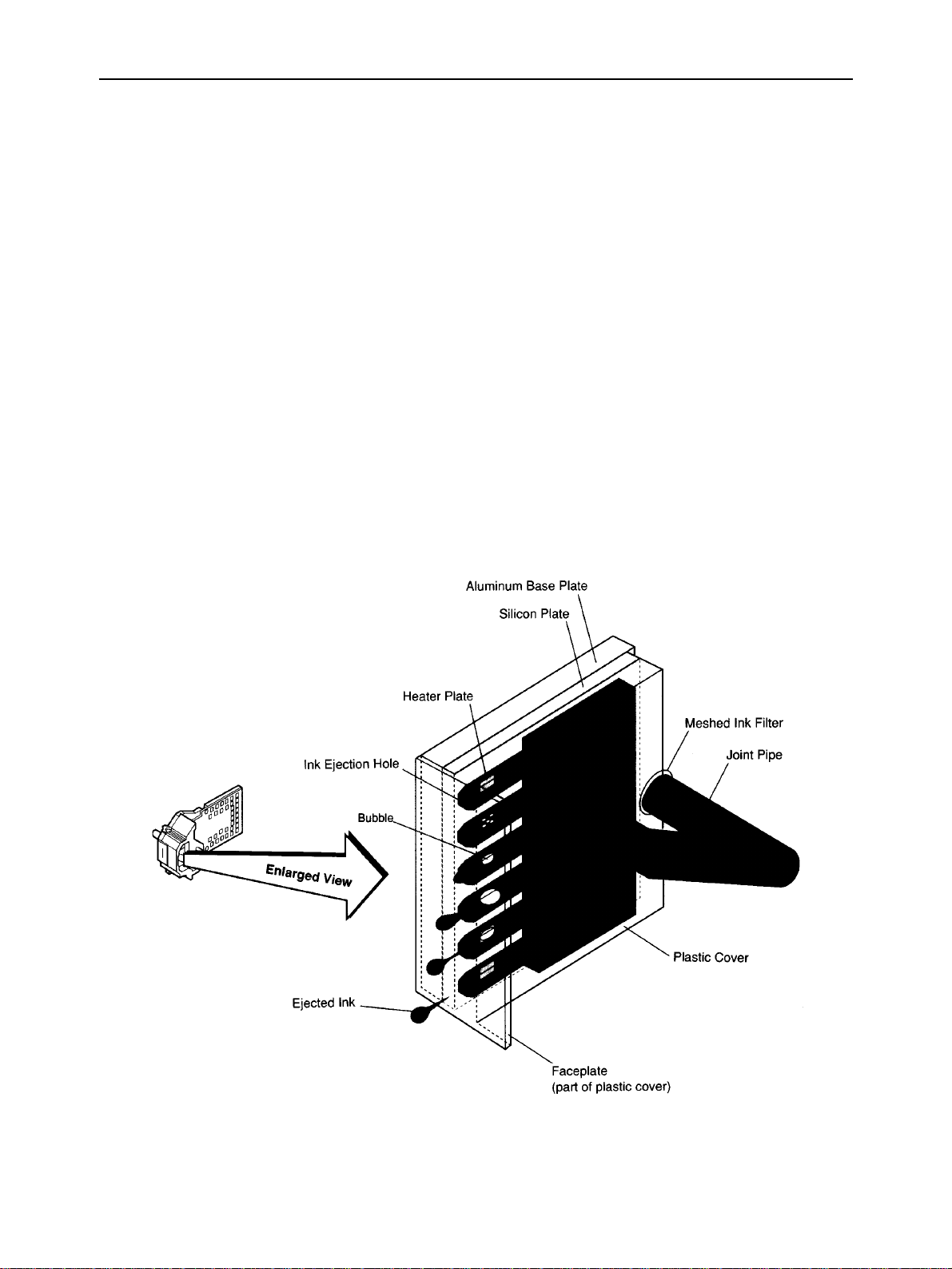

2-2-3. Ink Jet Head Unit Structure

a) Ink jet nozzles

The ink in the ink sponge pass through the meshed ink filter to remove dust, and is flowed to the ink jet nozzles

through the joint pipe. When the head drive current flows through the heater plate of a nozzle, the ink boils and

bubbles are produced, forming into one large bubble. The head drive current is cut off before a drop of ink is ejected

from the nozzle, but bubbling is grown because of the remaining heat on the heater, and the drop of ink is ejected

from the nozzle at about 12 m/s. After ejected the drop of ink, the nozzle is refilled with ink.

The ink jet head is formed on the silicon plate based on semiconductor technology.

The heater and its electrical wiring are formed on the plate.

A plastic cover with face plate and 64 nozzles is bonded to the plate.

Fig. 2-4 Ink Jet Nozzles

– 14 –

Page 19

THEORY OF OPERATION

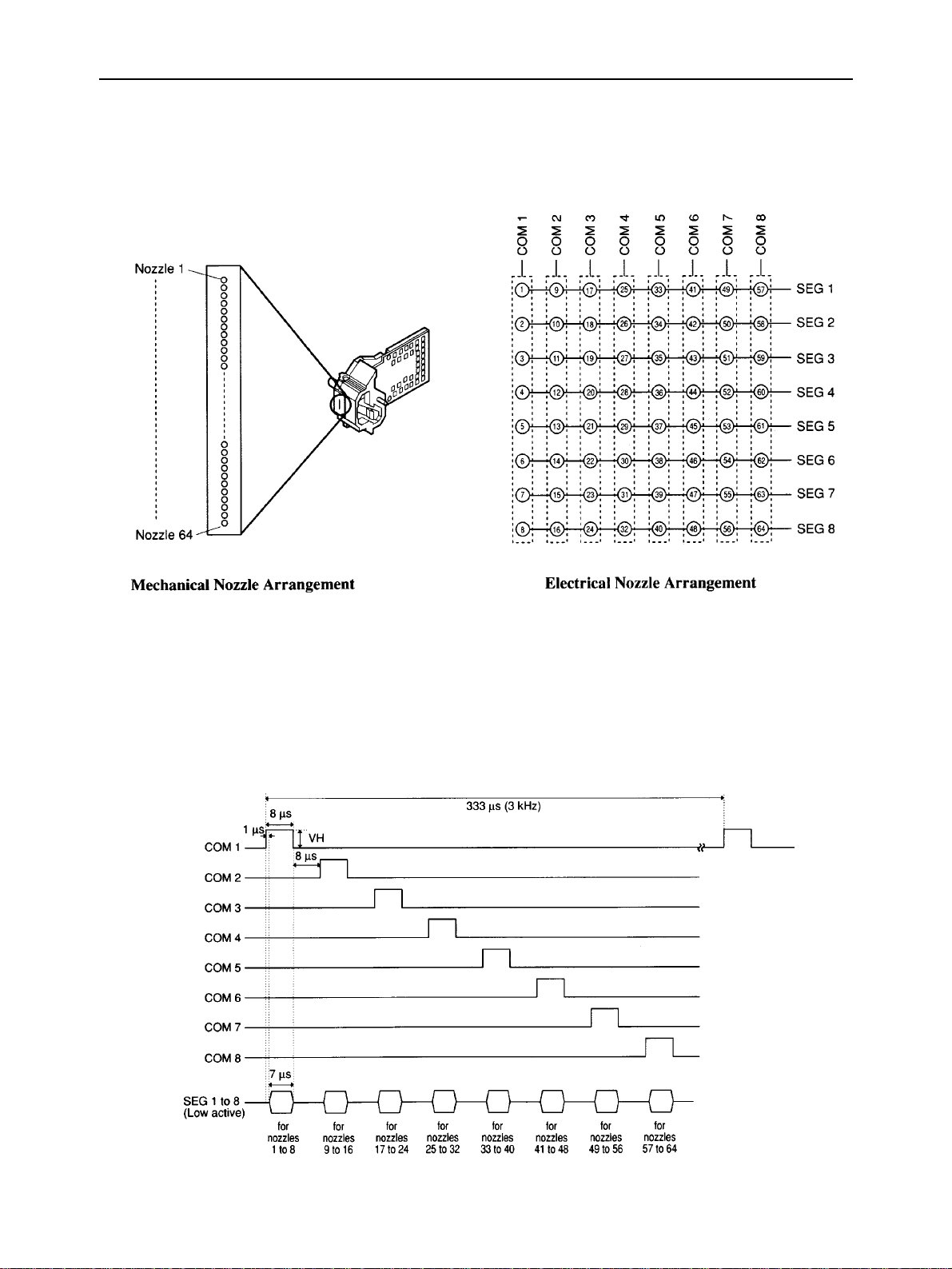

b) Nozzle arrangement

The 64 ink jet nozzles are arranged in a line at intervals of 1/360 inch. The upper 60 nozzles are used for actual

printing. The 64 heater plates are controlled by the matrix structure of the 8 COM signal circuits and 8 SEG signal

circuits.

Fig. 2-5 Nozzle Arrangement

c) Printing signals

The COM signal connects circuits COM1 to COM8 to the head drive power supply (VH) in order so that the 64

nozzles are ready to print in units of 8 nozzles.

The SEG signal connects the SEG circuit (SEG1 to SEG8) nozzles to be used for printing to the ground while the

COM signal is connected to the head drive power supply, and applies the heater voltage to the heater plate.

Fig. 2-6 Printing Signals

– 15 –

Page 20

THEORY OF OPERATION

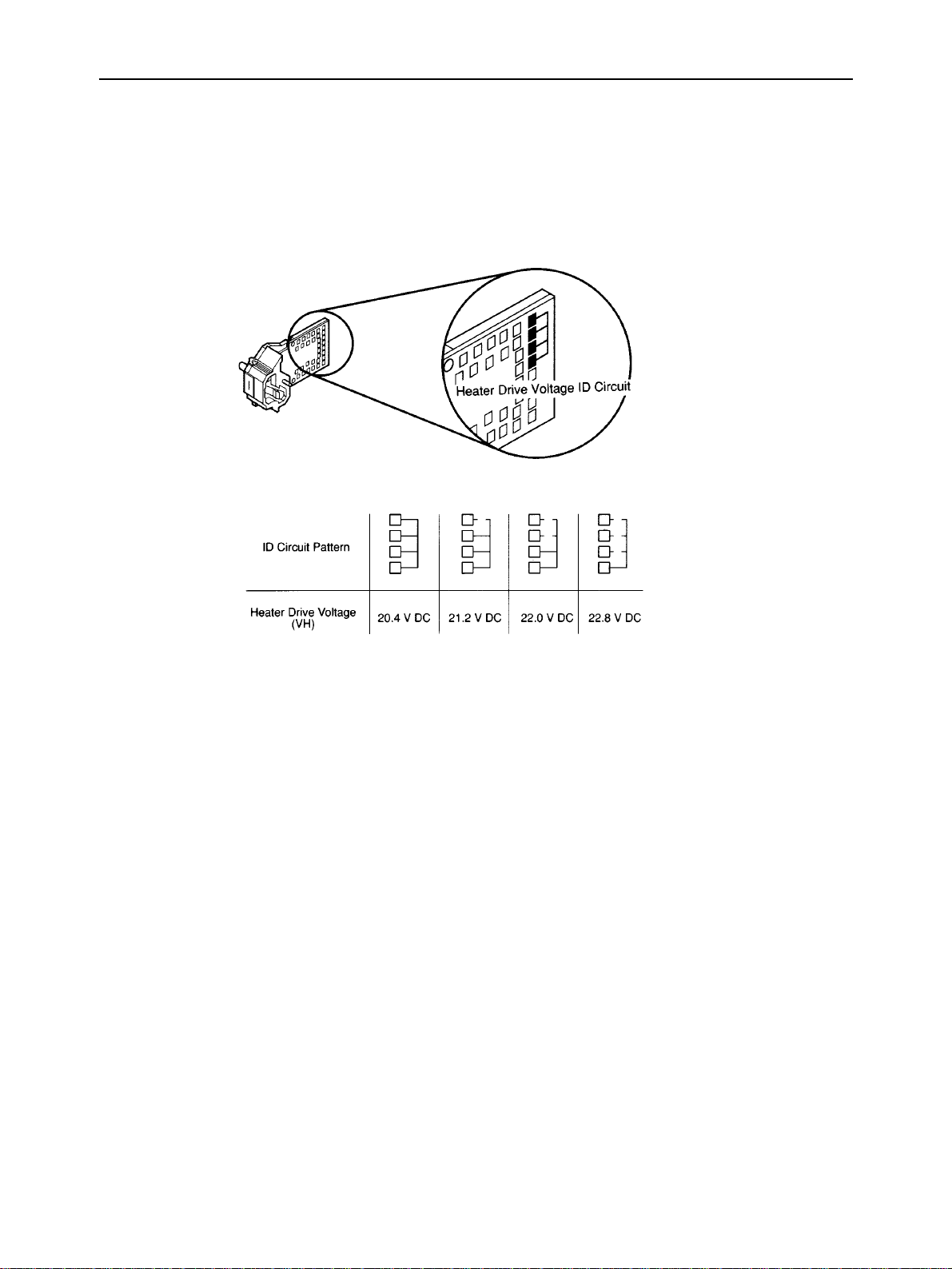

d) Heater voltage

One of four heater voltage levels that determine the ink jet speed is selected to correct any manufacturing variations

in the ink jet head units. The heater voltage ID is indicated by the PCB pattern of the contact points of the ink jet

head unit, and is used to switch the heater voltage output of the printer heater drive voltage supply circuit.

Fig. 2-7 Heater Drive Voltage ID

– 16 –

Page 21

THEORY OF OPERATION

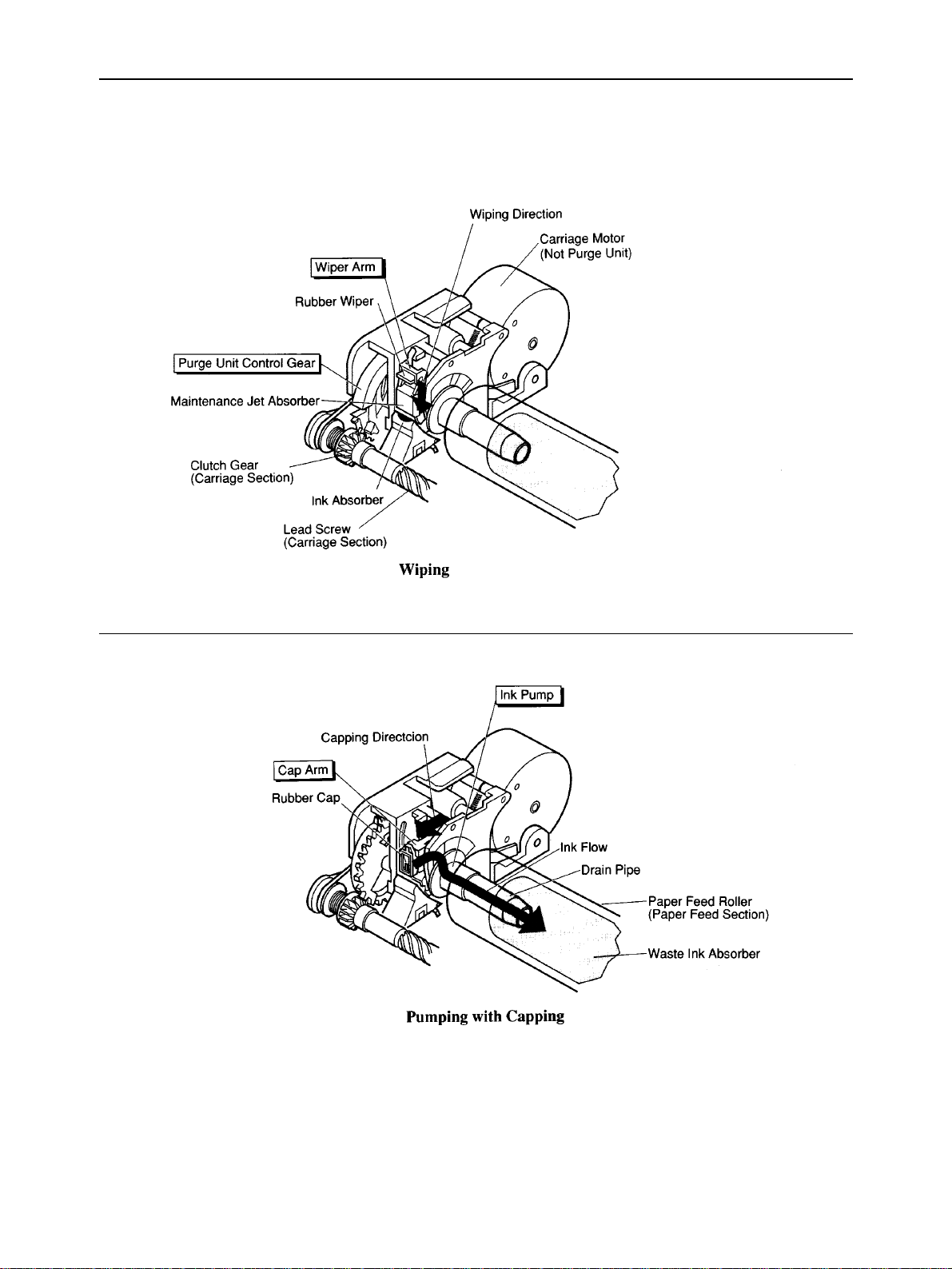

2-3. Purge Unit

2-3-1. Purge Unit Functions

a) Capping function

When printing does not take place for more than five seconds or when the printer goes offline, the capping function

pushes the rubber cap of the purge unit against the face plate (nozzle part) of the ink cartridge to prevent the ink from

drying up or leaking.

b) Cleaning function

To maintain high quality printing with the ink cartridge, the cleaning function is performed for about 12 seconds

when the “Head cleaning buttons” are pressed until the beeper sounds at the state of the power being on or the printer

being online. For cleaning, a wiping operation takes place to wipe off paper fiber and ink remaining on the face plate

of the ink cartridge, and a pumping operation takes place to suck about 0.1cc of ink from the capped ink cartridge

and fill the nozzles with fresh ink.

2-3-2. Purge Unit Structure

a) Purge unit control gear

The purge unit control gear is driven by the clutch gear of the lead screw, which is driven by the carriage motor.

This gear functions as a cam that drives the purge unit rubber wiper, cap, and pump, and controls the overall

movement of the purge unit operations.

b) Wiper arm unit

The wiper arm has a rubber wiper and a maintenance jet absorber. The rubber wiper wipes off the face plate of the

ink cartridge from top to bottom every 60 seconds during cleaning, before starting printing, and during printing.

The maintenance jet absorber absorbs the ejected ink from the nozzles as a test to stabilize the nozzles when the

power is switched on, before starting printing and every 12 seconds while printing. The stains on the rubber wiper

and the ink in the maintenance jet absorber are mopped up by the ink absorber when the wiper arm goes down.

c) Cap unit

The cap arm with its rubber cap advances and caps the ink cartridge when the wiper arm goes down. The rubber

cap connects to the ink pump and sucks ink from the ink cartridge during cleaning.

d) Pump unit

The pipe-shaped pump unit sucks ink through the rubber cap and runs it to the waste ink absorber in the paper feed

roller.

– 17 –

Page 22

THEORY OF OPERATION

Fig. 2-8 Purge Unit

– 18 –

Page 23

THEORY OF OPERATION

2-4. Carriage Section

2-4-1. Carriage Section Functions

a) Ink cartridge mounting function

The carriage fixes the ink cartridge mechanically and connects the electrical circuits to the logic board.

b) Carriage drive function

The carriage is moved horizontally over the print paper by the carriage motor.

c) Head gap adjustment function

The gap between the head and print paper can be adjusted with the head gap dial to suit the paper thickness.

d) Purge unit drive function

The carriage motor returns the carriage to its home position and drives the purge unit.

2-4-2. Carriage Section Structure

a) Ink cartridge mounting section

The hook that is moved with the hooking lever fixes the ink cartridge on the carriage. When the ink cartridge is fixed

on the carriage, the contact portion of the ribbon cable connects with the contact portion of the ink jet head unit to

transfer printing signals from the logic board.

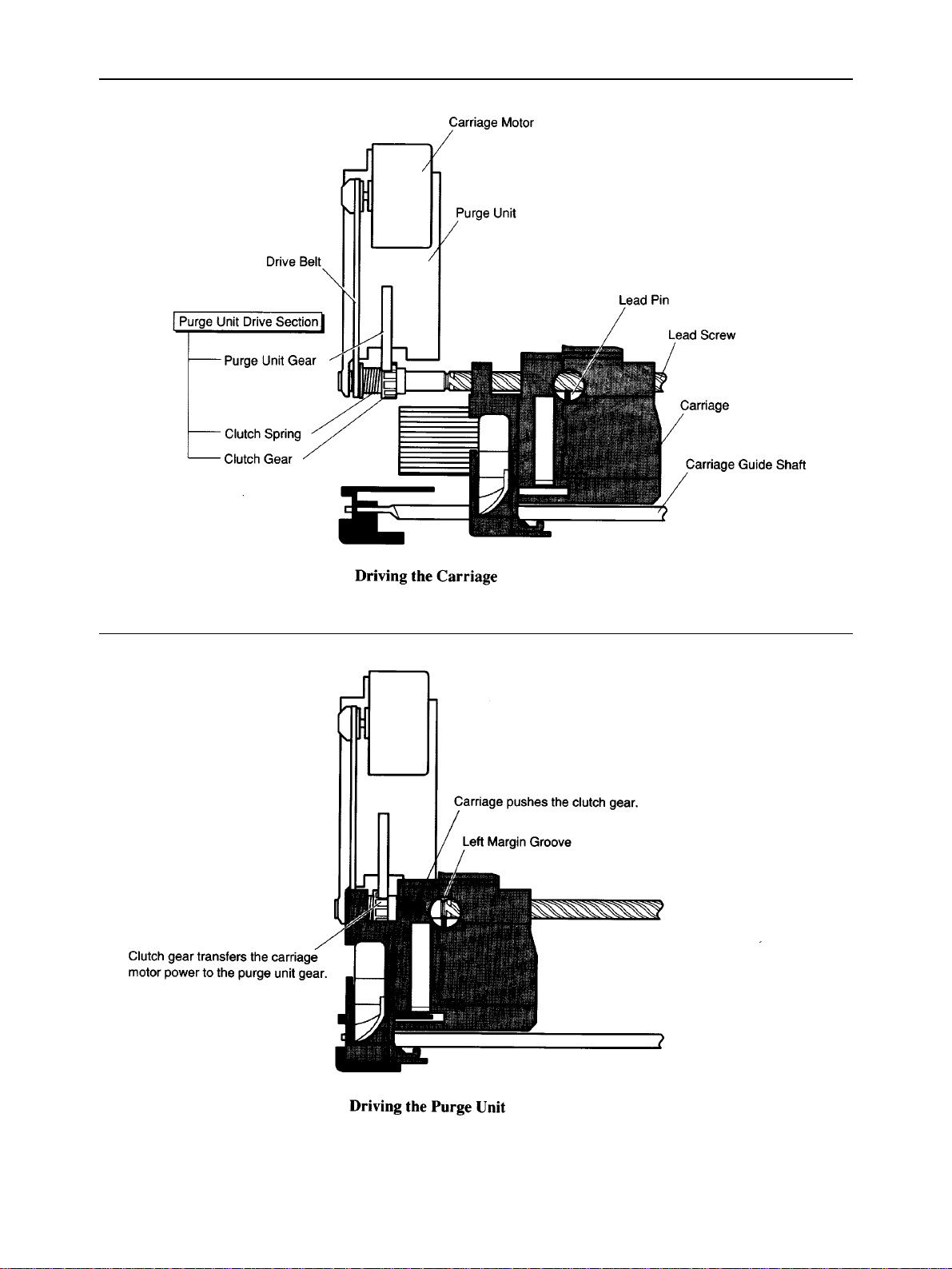

b) Carriage drive section

The DC stepping carriage motor rotates the lead screw via the drive belt. The carriage moves horizontally over the

print paper driven by lead pin, which engages in the groove of the lead screw. For the carriage position, the

photocoupler home position sensor under the carriage detects the photointerrupter (part of the guide shaft holder)

at the left of the carriage guide shaft, and logical seeking takes place using a stepping pulse transmitted to the

carriage motor.

c) Head gap adjustment function

The eccentric carriage guide shaft can be adjusted with the head gap dial on the bottom of the printer to match the

head gap to the print paper thickness. The head gap is about 0.04 inch (1 mm) when the dial is turned fully in the

direction of the cut sheet mark and about 0.075 inch (1.9 mm) when turned fully in the direction of the envelope

mark. When the optional auto sheet feeder is used, set the dial to the middle point between the cut sheet mark and

envelope mark where the dial clicks.

d) Purge unit drive section

When the lead pin enters the left margin groove, the carriage pushes the clutch gear of the lead screw to the purge

unit, and transmits the carriage motor power to the purge unit control gear.

– 19 –

Page 24

THEORY OF OPERATION

Fig. 2-9 Carriage

– 20 –

Page 25

THEORY OF OPERATION

Fig. 2-10 Purge Unit Drive Section

– 21 –

Page 26

THEORY OF OPERATION

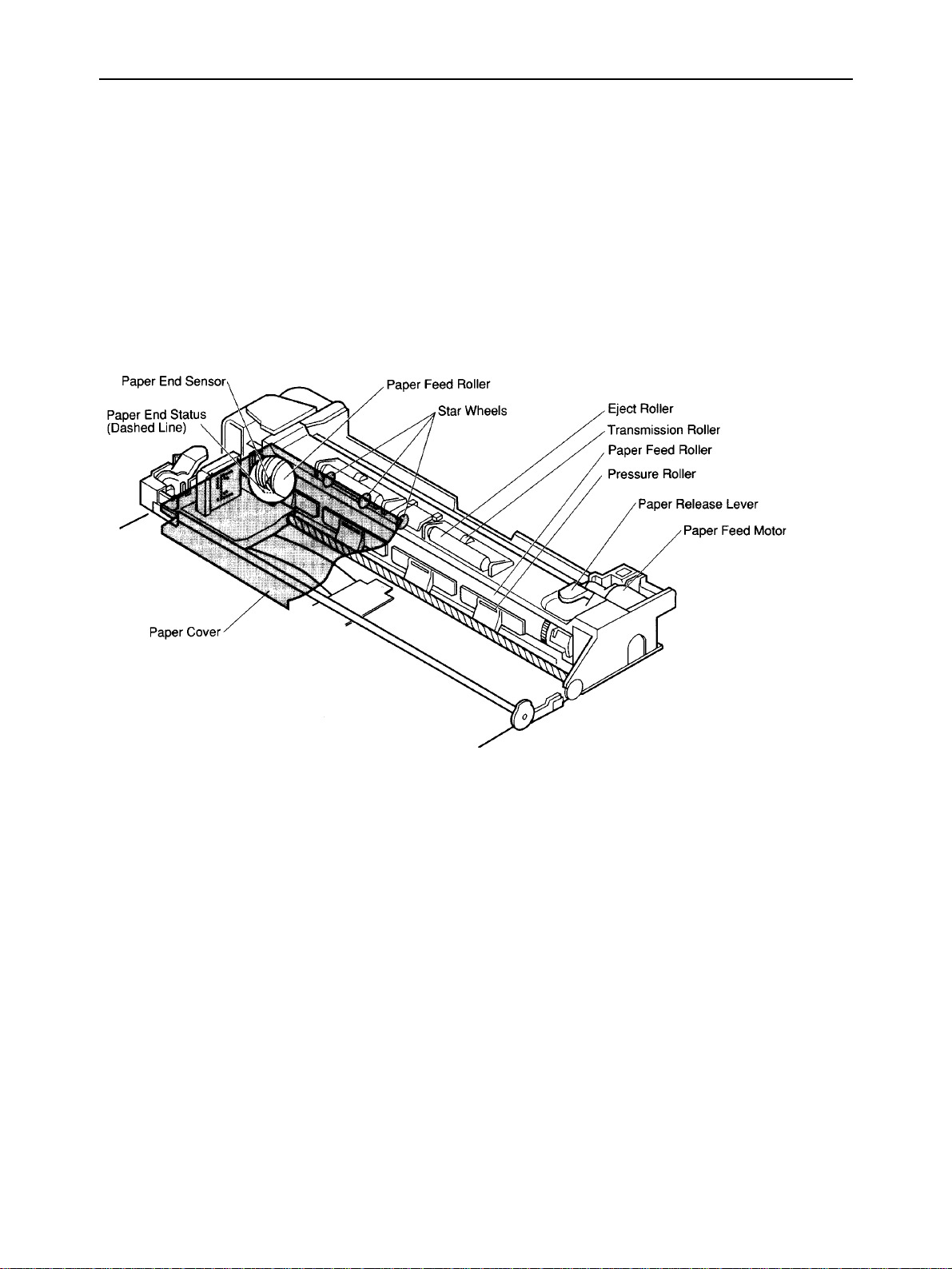

2-5. Paper Feed Section

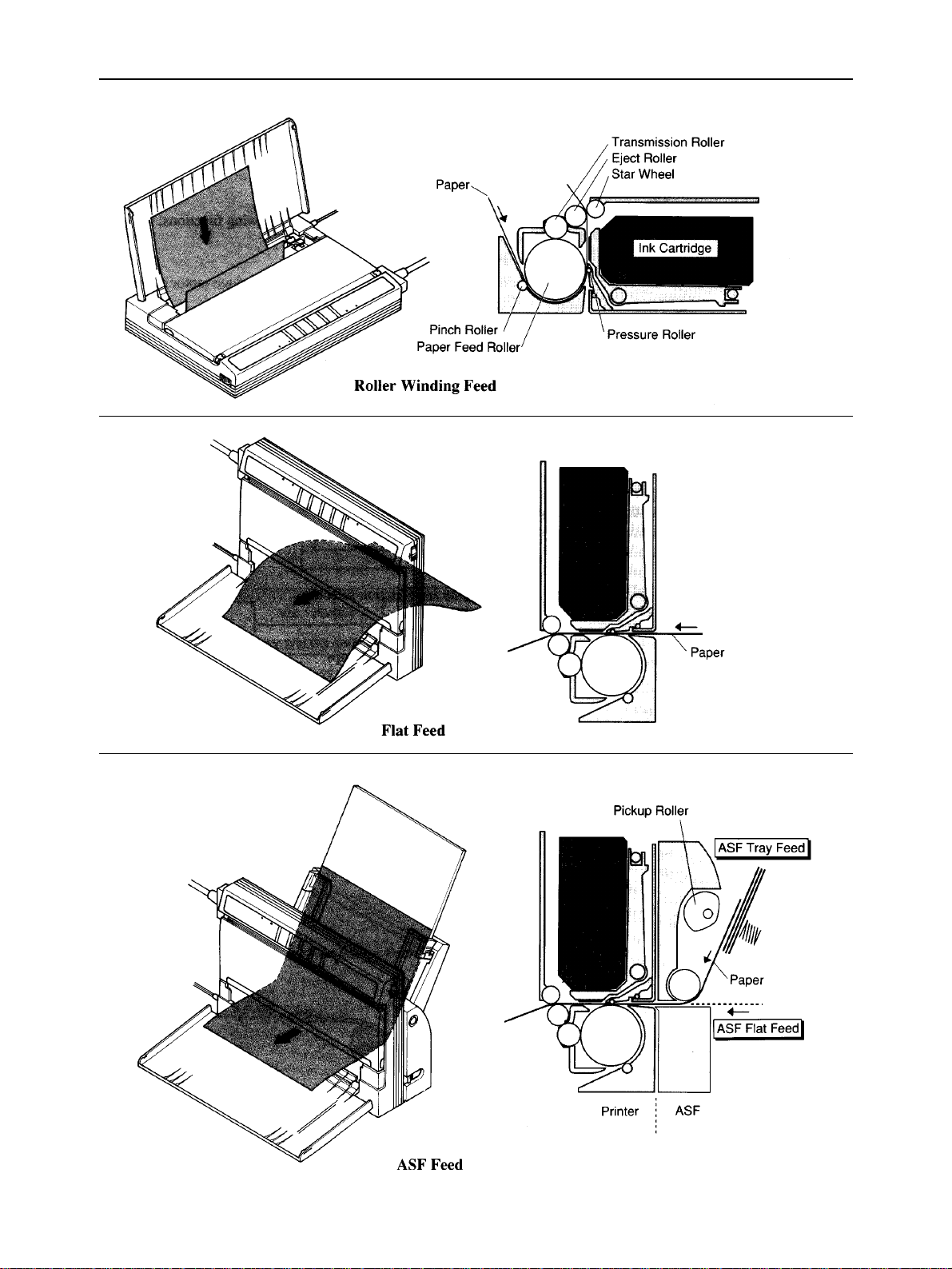

2-5-1. 3-way Paper Feed Section

The 3-way paper feed section is driven by the DC stepping paper feed motor. In roller-wind feeding, print paper is inserted

from the top rear of the printer, and fed around the paper feed roller. In flat feeding, print paper is inserted from the paper

slot in the bottom part of the printer, and fed by the paper feed roller and pressure roller. In ASF feeding, when the optional

auto sheet feeder is fitted to the printer, automatic paper feed and manual flat feed can be done.

2-5-2. Paper End Detection Section

The leaf switch paper end sensor at the lower left of the feed roller detects print paper.

Fig. 2-11 Paper Feed Section

– 22 –

Page 27

THEORY OF OPERATION

Fig. 2-12 3-way Paper Feed

– 23 –

Page 28

THEORY OF OPERATION

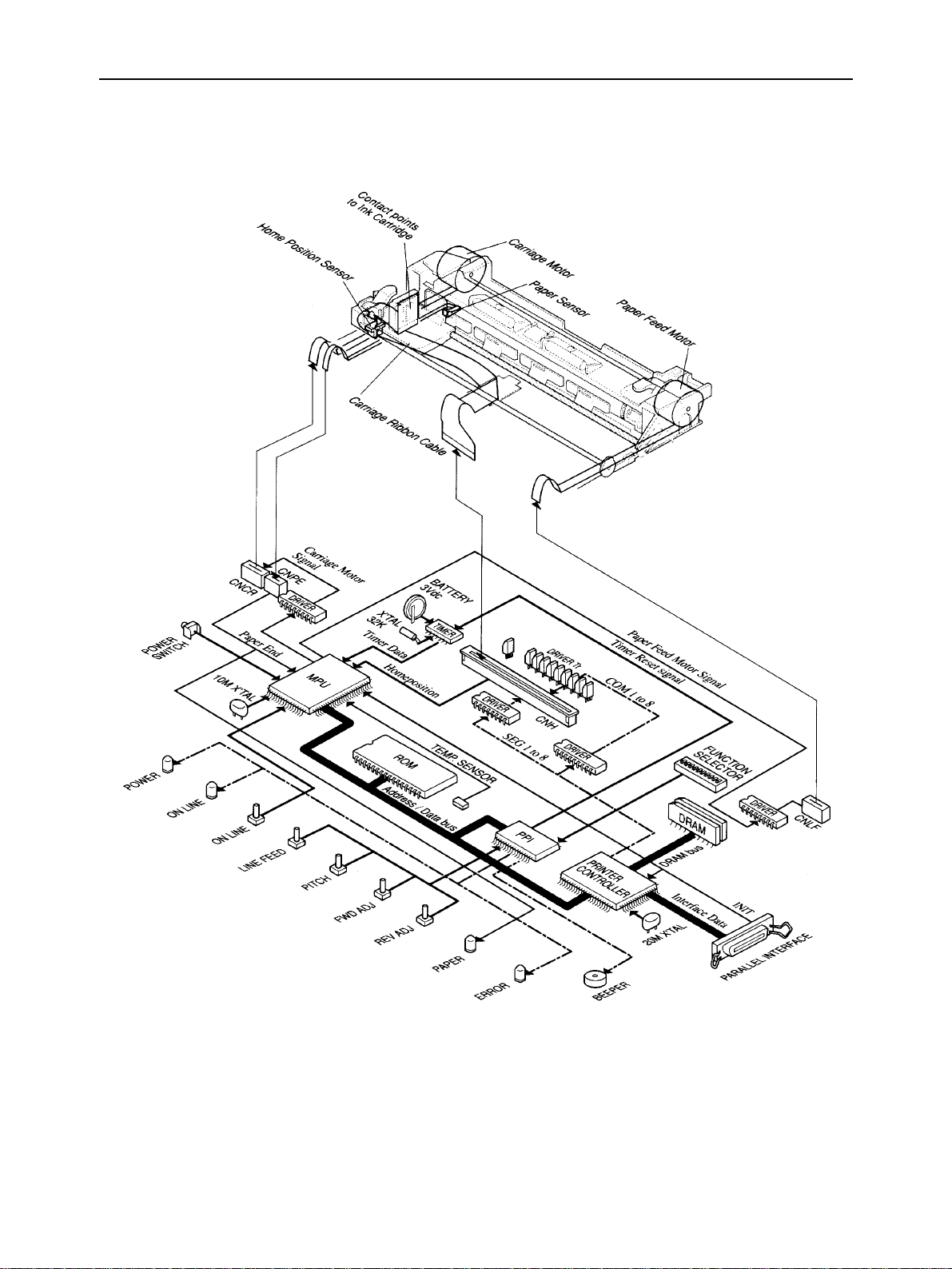

3. Logic Board

The logic board converts data from the interface to printing signals or printer operational signals

3-1. Logic Board Functions

The logic board, consisting of a control section and a power supply section, provides the following functions;

a) Printer control

The control section logically controls printer operations with the paper feed motor and carriage motor according

to the printer state monitored with a paper sensor and a home position sensor.

b) Interface control

The control section converts data from the computer via a parallel interface to print data and printer control

commands.

c) Head control

The control section converts print data to print signals for the ink cartridge and controls printing.

d) Power control

The control section controls the power supply circuit according to signals from the control buttons, power switch

and outputs from the power supply circuit.

e) Switch detection

The control section detects the states of the control buttons and function selectors.

f) Indicator control

The control section displays the printer operating states with indicator lamps.

g) Power supply

The power supply section makes various DC voltages for the printer from the Ni-Cd battery pack and AC adapter.

h) Battery charger

When the power is switched on with an AC adapter connected to the printer and the

until the beeper sounds, the Ni-Cd battery pack is charged by power supply section.

ON LINE

button is held down

– 24 –

Page 29

THEORY OF OPERATION

Fig. 2-13 Block Diagram of Logic Board

– 25 –

Page 30

THEORY OF OPERATION

3-2. Control Section Block Diagram

Fig. 2-14 Control Section Block Diagram

– 26 –

Page 31

THEORY OF OPERATION

3-3. Control Section Components

a) MPU (Microprocessor)

The MPU (TMP90C840AF) contains an 8-bit CPU, an 8-Kbyte ROM, a 256-Kbyte RAM, a 20-bit address bus port,

an 8-bit data bus port, a 2-channel stepping motor controller, a serial interface, an interrupt controller, and input

ports.

b) Printer controller

The printer controller (TC24SC090AF) contains the interface controller, DRAM controller, print head controller,

and address decoder. The independent 20 MHz clock input to the printer controller time the interface and DRAM

bus. The bus timing with the CPU is determined by 2.5 MHz CLK0 input from the CPU.

c) PPI

The PPI (82C55AFP) is controlled by the CPU bus.

• Input port

The input port detects the input states of the

and the settings of the function selectors.

• Output port

The output port switches the POWER, ONLINE, and ERROR lamps on and off, controls the buzzer, and resets the

timer after cleaning.

LINE FEED PITCH FWD ADJ REV ADJ

, and,,

buttons

d) DRAM

The DRAM is used as a receive buffer/font download area, single-line print buffer, and work area.

– 27 –

Page 32

THEORY OF OPERATION

3-4. Power Supply Section Block Diagram

Fig. 2-15 Power Section Block Diagram

– 28 –

Page 33

THEORY OF OPERATION

3-5. Power Supply Section Components

a) Input power sources

Power is supplied to the power supply section from two input power sources: a 9.5 VDC outputs AC adapter and

a 6 VDC outputs Ni-Cd battery pack.

When the DC plug of AC adapter is inserted into the DC jack, the power supply is automatically switched from the

Ni-Cd battery to the AC adapter.

The DC input passes through a 4.0 A fuse and a noise filter, and its voltage is checked by the MPU A/D converter

to determine whether it is from the 9.5 VDC AC adapter or the 6 VDC Ni-Cd battery pack. This determination makes

the low-battery detection function and auto power-off function be enabled when the Ni-Cd battery pack is being

used. When the Ni-Cd battery pack is being charged, the determination confirms DC input supplied from the AC

adapter and makes the auto charge-off function be enabled.

b) Vcc1 output

The +5 VDC Vcc1 produced by the regulator IC is supplied for the MPU, MPU power-on reset IC, and power switch

pull-up voltage even when the power is off. This is because the power switch on/off signal must be read even while

the power is off.

c) Vcc2/VLOG output

The +5 VDC Vcc2 and VLOG produced by the zener diode via the 0.3 A fuse is supplied as a power for the logic

for other than the MPU, and the power-on reset circuit for the printer controller and PPI. When the power is switched

on, the MPU reset signal outputs Vcc2 when the printer controller is reset to activate the printer controller in a stable

condition. When the power is switched off, the MPU stops the Vcc2 output.

d) Vpp output

The +14 VDC Vpp produced by the DC/DC converter is supplied for the carriage motor driver, paper feed motor

driver, buzzer, and Vcc2 control circuit. To stabilize the output voltage, the Vpp-ref voltage produced from the Vpp

output is fed back to the DC/DC converter control IC.

e) VH output

The VH produced by the DC/DC converter is supplied for the print signal SEG driver IC, COM driver transistors,

and the ink cartridge warm-up heater driver transistor.

One of +20.4 V, +21.2 V +22.0 V, and +22.8 V is selected as the VH output voltage by feeding back the VH-ref

voltage based on the ink cartridge head rank pattern to the DC/DC converter control IC.

– 29 –

Page 34

THEORY OF OPERATION

f) Battery charge output

When the power is switched on with an AC adapter connected and the online button is held down until the beeper

sounds, the power lamp flashes and the MPU connects the Vpp output to the battery charge circuit to begin charging

the Ni-Cd battery pack.

The MPU A/D converter checks the battery voltage being charged every 2 minutes.

If it is less than 6 V, the Ni-Cd battery pack is considered overdischarge or defective and the power and error lamps

flash alternately.

When about 10 hours elapse after charging begins, the auto charge-off function automatically stops the charging

and switches the printer off.

– 30 –

Page 35

THEORY OF OPERATION

4. Auto Sheet Feeder

This section explains the outline of the internal components of the auto sheet feeder.

4-1. Gear Train

The gear train, driven by the printer feed roller, rotates the pickup roller and feed roller.

4-2. Spring Clutch

The spring clutch controls the power from the gear train to the pickup roller by rotating the printer feed roller forward or

backward. The position of this clutch is initialized when the printer power is switched on.

When paper is loaded to the printer, the feed roller rotates slightly backward to engage the clutch, then the pickup roller

feeds the topmost sheet of paper in the paper bin into the printer. When the paper end sensor detects paper loading, the

printer stops the paper to the print starting position on the first line with a top margin of about 0.12 inch (3 mm). When

the pickup roller is completely detached from the sheet, the clutch is disengaged and the pickup roller stops.

Fig. 2-16 ASF Internal View

– 31 –

Page 36

THEORY OF OPERATION

– 32 –

Page 37

CHAPTER 3

ADJUSTMENTS

This section describes the head gap adjustment required for reassembling.

Please check this explanation when making maintenance inspections or when replacing parts to correct

malfunctions.

1. Adjustment Point.................................................................................................35

2. When Adjustment is Necessary.........................................................................35

2-1. When Adjustment is Absolutely Necessary....................................................... 35

2-2. When Adjustment may be Necessary................................................................. 35

2-3. Tools Required for Adjustment ........................................................................... 36

3. Adjustment Method.............................................................................................36

3-1. Preparations for Adjustment ............................................................................... 36

3

3-2. Adjustment ............................................................................................................ 37

Page 38

ADJUSTMENTS

– 34 –

Page 39

ADJUSTMENTS

1. Adjustment Point

The only printer adjustment is that of the head gap to keep the distance between the ink cartridge and printing paper

constant.

Adjust the head gap so that the distance between the ink cartridge nozzle and printing paper is about 0.04 inch (1 mm)

by rotating the adjustment dials (white) on the right and left sides of the printer mechanism.

The left adjustment dials is under the purge unit and part of it. The right adjustment dial is fitted into the paper feed base.

The head gap adjustment dials can be turned when the printer mechanism is removed from the lower case.

Fig. 3-1 Adjustment Dials

2. When Adjustment is Necessary

The head gap must be adjusted when the default adjustment dial position is changed.

2-1. When Adjustment is Absolutely Necessary

• When the purge unit is replaced.

2-2. When Adjustment may be Necessary

• When the adjustment dial position is changed when the carriage is removed.

• When the lead screw is removed and the adjustment dial position is changed.

If it is unnecessary to change the adjustment dials in servicing: mark the original positions of the dials on the chassis with

a felt-tipped pen. (Refer to item 5 of chapter 4 for the marking method.)

– 35 –

Page 40

ADJUSTMENTS

2-3. Tools Required for Adjustment

UseTool

Phillips screwdriver For the purge unit fastening screws

Gap gauges (0.5 mm) For head gap measurements (Three gauges are necessary.)

Ink cartridge Same as normal ink cartridge (Do not use user’s ink cartridge since the gauge may

strike against its nozzle.)

3. Adjustment Method

3-1. Preparation for Adjustment

1) Remove the printer mechanism from the lower case. (Refer to item 5 of chapter 4 for the disassembly procedure.)

2) Place and lock the ink cartridge on the carriage and turn the black head gap dial on the right side of the carriage guide

shaft clockwise until it stops.

3) Turn the white adjustment dial (R) on the right side of the lead screw counterclockwise until it stops.

4) Loosen the purge unit fastening screw, then turn the white adjustment dial (L) under the purge unit so that the mark

faces the carriage motor side.

Fig. 3-2 Preparations for Adjustment

– 36 –

Page 41

ADJUSTMENTS

3-2. Adjustment

1) Set the release lever upright, insert two gap gauges into the places shown in the following figure from under the

printer mechanism, then push the release lever back to its original position.

Caution: Take care not damage the paper feed roller when inserting the gauges.

2) Turn the carriage drive belt counterclockwise and move the carriage so that the ink cartridge nozzles are facing the

gap gauges placed on the left side.

Fig. 3-3 Head Gap Adjustment (1)

– 37 –

Page 42

ADJUSTMENTS

3) Insert the third gap gauge between the set gap gauge and nozzle.

4) Turn the white adjustment dial (L) under the purge unit until there is no clearance between the two gauges and the

ink carriage nozzle.

5) Push the ink cartridge to the right and move it so that if faces the gap gauges on the right side.

6) Turn the white adjustment dial (R) on the right side of the lead screw until there is no clearance between the two

gauges and the ink carriage nozzle.

7) When the head gap is adjusted at one place, the adjusted head gap at the other place changes. Therefore, adjust the

right and left head gaps several times.

8) When the adjustment is complete, remove the gap gauges, then retighten the purge unit fastening screw.

Fig. 3-4 Head Gap Adjustment (2)

– 38 –

Page 43

CHAPTER 4

PARTS REPLACEMENT

This chapter explains disassembly and reassembly of the printer. Note the following precautions during

disassembly and reassembly.

1. Disconnect the printer from the wall outlet before servicing it.

2. Assembly is the reverse of disassembly unless otherwise specified.

3. Lubrication information is not provided in this chapter. Refer to item 3 in Chapter 5.

1. Battery Cover.......................................................................................................41

2. Paper Cover .........................................................................................................41

3. Upper Cover.........................................................................................................42

4. Logic Board .........................................................................................................42

5. Printer Mechanism ..............................................................................................43

6. Power Switch ...................................................................................................... 43

7. Purge Unit ............................................................................................................44

8. Carriage Ribbon Cable Holder ...........................................................................44

9. Lead Pin Holder ...................................................................................................45

10. Lead Screw ..........................................................................................................45

11. Carriage Ribbon Cable........................................................................................46

12. Carriage Guide Shaft...........................................................................................46

13. Transmission Roller............................................................................................47

14. Paper Feed Roller................................................................................................47

15. Paper Feed Motor................................................................................................48

4

16. Pinch Roller .........................................................................................................48

17. Pressure Plate Holder .........................................................................................49

18. ASF Instruction Panel .........................................................................................49

19. ASF Covers..........................................................................................................50

20. ASF Locking Levers............................................................................................50

21. ASF Paper Guide Table.......................................................................................51

22. ASF Paper Lifting Plate.......................................................................................51

23. ASF Guide Plates ................................................................................................52

24. ASF Paper Guides ...............................................................................................52

25. ASF Feed Roller...................................................................................................53

26. ASF Pick-up Roller Shaft ....................................................................................53

Page 44

PARTS REPLACEMENT

– 40 –

Page 45

PARTS REPLACEMENT

1. Battery Cover

(1) Remove

• Printer stand [1]

Rotate the printer stand [1]135 degrees and pull it.

• Battery cover [2]

2. Paper Cover

(1) Remove

• Top cover [1]

• Paper cover [2]

– 41 –

Page 46

PARTS REPLACEMENT

3. Upper Cover

(1) Remove

• Battery cover according to the procedure de-

scribed in item 1.

• Paper cover according to the procedure

described in item 2.

• Screw [1]

• Upper cover [2]

Press a minus driver into joints [3] of upper

cover [2] and lower cover [4] for separation.

4. Logic Board

(1) Remove

• Upper cover according to the procedure

described in item 3.

• Two screws [1]

• Screw [2]

• Five connectors [3]

• Logic board [4]

– 42 –

Page 47

PARTS REPLACEMENT

5. Printer Mechanism

(1) Remove

• Logic board according to the procedure

described in item 4.

• Two screws [1]

• Printer mechanism [2]

Mark the dial positions [3] for the head gap

adjustment.

• Paper end sensor [4]

6. Power Switch

(1) Remove

• Logic board according to the procedure

described in item 4.

• Power switch unit [1].

Press a minus driver into joints [2] of power

switch unit and lower cover for separation.

• Power switch [3]

• Switch holder [4]

– 43 –

Page 48

PARTS REPLACEMENT

7. Purge Unit

(1) Remove the printer mechanism according to the

procedure described in item 5.

(2) Move the carriage unit [1]

(3) Remove

• Carriage drive belt [2]

Press the carriage motor in the direction of the

arrow for separation.

• Screw [3]

• Carriage shaft stopper [4]

• Purge unit [5]

Release the three joints [6] for separation

• Carriage motor [7]

• Belt tension spring [8]

(4) Adjust

• Head gap

Refer to Chapter 3.

8. Carriage Ribbon Cable Holder

(1) Remove

• Printer mechanism according to the procedure

described in item 5.

• Carriage ribbon cable holder [1]

– 44 –

Page 49

PARTS REPLACEMENT

9. Lead Pin Holder

(1) Remove

• Purge unit according to the procedure described

in item 7.

• Lead screw [1] from the printer mechanism.

• Lock cover [2]

Release the hook [3] for separation

• Locking lever [4]

• Ink cartridge lock [5]

• Spring [6]

• Carriage cover [7]

Release the two hooks [8] for separation

• Lead pin holder [9]

Caution in assembly:

Use new Lock cover [2], if this parts is removed.

10. Lead Screw

(1) Remove

• Lead pin holder according to the procedure described in item 9.

• Lead pin [1]

• Lead screw [2]

Caution in assembly:

Insert the lead pin [1] in the groove [3].

– 45 –

Page 50

PARTS REPLACEMENT

11. Carriage Ribbon Cable

(1) Remove

• Lock cover and carriage cover according to the

procedure described in item 9.

• Ribbon Cable lower holder [1]

• Ribbon Cable upper holder [2]

• Contact pad [3]

• Carriage ribbon cable [4]

Release the hook [5] for separation

Caution in assembly:

Bend the ribbon at the four marks [6]

12. Carriage Guide Shaft

(1) Remove

• Lead screw from the printer mechanism accord-

ing to the procedure described in item 9.

• Carriage guide shaft [1]

• Guide shaft holder [2]

(2) Adjust

• Head gap

Refer to Chapter 3.

– 46 –

Page 51

PARTS REPLACEMENT

13. Transmission Roller

(1) Remove

• Carriage guide shaft according to the procedure

described in item 12.

• Four pressure plates [1]

• Four pressure rollers [2]

• Platen plate [3]

Caution: The hook [4] of the platen plate [3] is

very weak.

• Paper separator [5]

• Two ejectrollers [6]

• Two roller shafts [7]

• Two transmission rollers [8]

14. Paper Feed Roller

(1) Remove

• Platen plate according to the procedure described

in item 13.

• Feed roller stabilizer [1]

Press a minus driver into joints of feed roller

stabilizer [1] and base for separation.

• Lead screw holder [2]

• Adjust dial [3]

• Release rod [4]

• Paper feed roller [5]

• Release crank [6]

• Feed roller holder [7]

– 47 –

Page 52

PARTS REPLACEMENT

15. Paper Feed Motor

(1) Remove

• Paper feed roller according to the procedure de-

scribed in item 14.

• Paper feed motor [1]

Press a minus driver into joints of paper feed

motor [1] and paper feed base [2] for separation

• Slowdown gear [3]

• Release lever [4]

Caution in assembly:

Align these gears [5] when reassembling.

16. Pinch Roller

(1) Remove

• Paper feed motor according to the procedure

described in item 15.

• Two pinch roller leaf springs [1]

• Pinch roller release shaft [2]

• Two pinch roller holders [3]

• Two pinch rollers [4]

– 48 –

Page 53

PARTS REPLACEMENT

17. Pressure Plate Holder

(1) Remove

• Pinch roller according to the procedure described

in item 16.

• Paper feed base [1]

• Ink absorber A [2]

• Ink absorber B [3]

• Pressure plate release shaft [4]

• Two pressure plate left springs [5]

• Four pressure plate holders [6]

• Chassis [7]

Caution in assembly:

Use new one, if the paper feed base [1] is removed.

18. ASF Instruction Panel

(1) Remove the ASF assembly from the printer.

(2) Remove

• Paper support [1]

• Instruction panel [2]

– 49 –

Page 54

PARTS REPLACEMENT

19. ASF Covers

(1) Remove

• Instruction panel according to the procedure de-

scribed in item 18.

• Right cover [1]

Press a minus driver into three joints [2] for

separation.

• Release button [3]

• Left cover [4]

Press a minus driver into three joints [5] for

separation.

• Transfer gear [6]

20. ASF Locking Levers

(1) Remove

• Covers according to the procedure described in

item 19.

• Two springs [1]

• Right locking lever [2]

• Left locking lever [3]

– 50 –

Page 55

PARTS REPLACEMENT

21. ASF Paper Guide Table

(1) Remove

• Covers according to the procedure described in

item 19.

• Two shaft pins [1]

• Paper guide table [2]

• Paper tray unit [3]

• Sheet feeder base unit [4]

22. ASF Paper Lifting Plate

(1) Remove

• Paper tray unit [1] according to the procedure

described in item 21.

• Wedge pin [2]

• Paper lifting plate [3]

• Spring [4]

– 51 –

Page 56

PARTS REPLACEMENT

23. ASF Guide Plates

(1) Remove

• Paper lifting plate according to the procedure

described in item 22.

• Left guide looking lever [1]

• Right guide looking lever [2]

• Two guide locking shafts [3]

• Two rubber rings [4]

• Two washers [5]

• Left guide plate [6]

• Right guide plate [7]

24. ASF Paper Guides

(1) Remove

• Guide plates according to the procedure

described in item 23.

• Two paper stoppers [1]

• Four slide guides [2]

• Right paper guide [3]

• Left paper guide [4]

• Paper tray [5]

– 52 –

Page 57

PARTS REPLACEMENT

25. ASF Feed Roller

(1) Remove

• Sheet feeder base unit according to the procedure

described in item 21.

• Gear holder [1]

Release the three joints [2] of gear holder [1] and

sheet feeder base unit for separation.

• Idol gear [3]

• Slowdown gear [4]

• Feed roller [5]

• Two rubber rings [6]

26. ASF Pick-up Roller Shaft

(1) Remove

• Feed roller according to the procedure described

in item 25.

• Arm pressure spring [1]

• Positioning arm [2]

• Pick-up roller shaft [3]

• Two pick-up rubbers [4]

• Control cam [5]

• Clutch spring [6]

• Pick-up gear [7]

– 53 –

Page 58

GENERAL SPECIFICATIONS

– 2 –

Page 59

CHAPTER 5

PRECAUTIONS AND MAINTENANCE

1. Precautions..........................................................................................................57

1-1. High-Temperature Components.......................................................................... 57

1-2. Disposing of Ni-Cd Battery .................................................................................. 57

1-3 Handling the power Supply ................................................................................. 57

1-4 Damage by Electrostatic discharge .................................................................... 58

1-5 Nozzle Protection.................................................................................................. 58

2. Maintenance.........................................................................................................59

2-1. Cleaning................................................................................................................. 59

2-2. Checks................................................................................................................... 59

3. Lubrication...........................................................................................................60

3-1. Lubricant ............................................................................................................... 60

3-2. Lubricating Method .............................................................................................. 60

3-3. Lubricated Area .................................................................................................... 60

4. List of Tools .........................................................................................................60

4-1. General Tool.......................................................................................................... 60

4-2. Special Tool........................................................................................................... 60

5

Page 60

– 56 –

Page 61

PRECAUTIONS AND MAINTENANCE

1. Precautions

1-1. High-Temperature Components

The printer logic board contains components that get hot when the Ni-Cd battery pack is being charged.

DANGER: The temperature of the resistor (R9) rises to about 212°F (100°C) during charging of the Ni-Cd battery pack.

The temperature of the regulator IC (Q14) and transistor (Q13) that produce the logic circuit Vcc rises to

about 140°F (60°C) when the printer is on.

Fig. 5-1 High Temperature Components

1-2. Disposing of Ni-Cd Battery

When you dispose of the optional Ni-Cd battery pack, follow local laws and regulations.

DANGER: To prevent explosion, do not throw the Ni-Cd battery in a fire or even near one.

1-3. Handling the power Supply

a) AC adapter

Do not use any AC adapter except the one supplied with the printer. Do not use the printer AC adapter for any other

equipment.

b) Ni-Cd battery pack

The optional Ni-Cd battery pack for portable power supply has a built-in temperature-sensitive circuit breaker that

cuts the battery circuit internally, when the battery temperature rises over 158°F (70°C) because the terminals have

been shorted together. However, to avoid damaging the battery by sudden discharge, do not short its terminals

together.

Caution : Do not disassemble the Ni-Cd battery.

– 57 –

Page 62

PRECAUTIONS AND MAINTENANCE

1-4. Damage by Electrostatic discharge

The electrostatic charge on your body, produced by the rubbing of your clothes, can damage electronic components

or change their electrical characteristics. To prevent such damage, do not touch the carriage contact between the

ink cartridge and the logic board.

Fig. 5-2 Contact Points

1-5. Nozzle Protection

To prevent the nozzles clogging, do not touch the nozzles or wipe them with tissue paper, etc. Do not leave the

cartridge outside the printer without the head cover and sealing tape.

The ink cartridge cannot be disassembled or washed.

Fig. 5-3 Ink Cartridge

– 58 –

Page 63

PRECAUTIONS AND MAINTENANCE

2. Maintenance

In order to maintain the optimum performance of this printer and to prevent troubles, maintenance must be carried out

according to the following items.

2-1. Cleaning

(1) Removal of dirt

Clean the printer regularly to avoid print problems. If the printer cover becomes dirty with ink mist or paper debris,

wipe it away with a soft, wet cloth.

Caution:1. Turn the printer off when cleaning it.

2. Cleaning the printer body with volatile liquids like thinner or benzine will damage the surface of the body.

3. Never wipe the head of the ink cartridge with a cloth.

4. The ink is not harmful for human body, but contains isopropyl alcohol 67-63-0.

Do not swallow it or splash into your eyes. The ink characteristics is water soluble, but contains dye. Ink

cannot be removed if it gets on your clothes.

5. During cleaning, be careful not to moisten or damage electronic parts, wiring, or mechanical parts.

(2) Removal of dust, pile, etc.

Vacuum cleaning (with an electric cleaner) is preferred. Remove all dust, etc., inside the printer.

2-2. Checks

Checks must be carried out at two levels: “Daily check” which the operator can easily carry out during operation, and

“Periodic check” which an expert should carry out.

(1) Daily check

When the printer is used on a daily basis, check to be sure that the printer is being used properly. Make sure that

the printer is operating under the best conditions.

• Is there any foreign matter inside the printer?

(2) Periodic check

None

– 59 –

Page 64

PRECAUTIONS AND MAINTENANCE

3. Lubrication

3-1. Lubricant

For this printer, FLOIL G-311S (made by Kanto Chemicals Co.,Ltd.) are recommended.

3-2. Lubricating Method

When lubrication is carried out in assembly and disassembly, wash parts well to remove dust and dirt before lubrication.

3-3. Lubricated Area

The only lubricated area is lead screw part.

Fig. 5-4 Lubricated Area

4. List of Tools

4-1. General Tool

Tool Use

Phillips screwdriver For removing screws

Precision standard screwdriver For removing plastic parts

Tweezers For removing Ni-Cd battery terminals

Soldering iron (30 W or less) For replacing electronic components

Double-sided adhesive tape For fastening the flexible motor cable

Felt-tipped pen For marking the head gap dial positions

4-2. Special Tool

Tool Use

Gap gauges (0.5 mm) For head gap adjustments (Three gauges are necessary.)

Grease (FLOIL G-311S) Apply 0.1 to 0.2g of grease to the lead screws

Note:Refer to the Chapter 7 Parts List for the tool numbers of the special tools.

– 60 –

Page 65

CHAPTER 6

TROUBLESHOOTING

TROUBLESHOOTING

1. Errors Displayed By Indicator Lamps ...............................................................63

1-1. Error Display ......................................................................................................... 63

1-2. Error Recovery...................................................................................................... 63

2. Errors Not Displayed By Indicator Lamps ........................................................65

2-1. Error Conditions ................................................................................................... 65

2-2. Error Recovery...................................................................................................... 65

3. Auto Sheet Feeder...............................................................................................67

3-1. Error Recovery...................................................................................................... 67

6

– 61 –

Page 66

TROUBLESHOOTING

– 62 –

Page 67

TROUBLESHOOTING

1. Errors Displayed By Indicator Lamps

1-1. Error Display

The printer has a service function that displays printer errors with four indicator lamps.

Error state POWER ON LINE PAPER ERROR

RAM error Off On * On

Home position error On Off * On

Carriage control error On On * On

Paper out On Off On Flashing

Paper jam On Off Off Flashing

Low battery Flashing Off * On

Ni-Cd battery error Flashing Off * Flashing

* On when paper is empty, off when paper is set.

Note:The Ni-Cd battery error occurs when the battery is being charged. If the Ni-Cd battery pack is overdischarged, a

battery error may occur even with a normal battery. If the Ni-Cd battery pack is charged again but still produces

the error, it is defective.

1-2. Error Recovery

The errors indicated by the indicator lamps are recovered as follows:

Error

RAM error

Home position error

Note:When the logic board and the printer mechanism are repaired, replace the parts in the “Parts replacement” column.

Check/Action

1. Replace the logic board.

1. Remove any foreign objects that obstruct error the

carriage movement.

2. Check that the home position sensor is correctly installed.

3. Check the carriage ribbon cable connection.

4. Check the home position sensor:

MPU port 51 (pin #62) is high when the carriage is in the

home position.

5. Check the carriage motor: about 45 ohms per phase.

6. Replace the logic board.

When the logic board is repaired: check the carriage

motor drive pulse of IC 15. See figure 6-1.

Parts replacement

a. DRAMs (IC8,9)

b. Printer controller

(IC 3)

a. Carriage motor

b. Carriage motor

driver (IC 15)

– 63 –

Page 68

TROUBLESHOOTING

Fig. 6-1 Carriage Motor Drive Pulse (During Printing)

Error

Carriage control error

Paper out error

Paper jam error

Low battery error

Ni-Cd battery error

Check/Action

1. Apply 0.1 to 0.2 g of the grease (FLOIL G-311S) to the

lead screws.

2. Replace the printer mechanism.

1. load the paper.

2. Check the paper end sensor:

MPU port 52 (pin #63) is low while paper is present.

3. Replace the logic board.

1. Remove the jammed paper.

2. Check the paper end sensor:

MPU port 52 (pin #63) is high while paper is not present.

3. Replace the logic board.

1. Charge the Ni-Cd battery pack.

2. Replace the Ni-Cd battery pack.

1. Recharge the Ni-Cd battery pack.

2. Replace the Ni-Cd battery pack.

3. Replace the logic board.

When the logic board is repaired:

a. Check the charging signal:

PPI port PA6 (PIN #38) is high while charging.

b. Check the charging circuit:

The Q21 collector output is about 11.3 VDC (under

no load) while charging.

c. Check the charging circuit:

Check the thermal fuse in R9.

Parts replacement

a. Carriage and lead

screws

b. purge unit

a. Paper end sensor

b. MPU (IC11)

a. Paper end sensor

b. MPU (IC11)

a. IC10

b. Q21

c. R9

– 64 –

Page 69

TROUBLESHOOTING

2. Errors Not Displayed By Indicator Lamps

2-1. Error Conditions

The errors not indicated by indicator lamps include no power, printing errors, and paper feed errors.

2-2. Error Recovery

Error

No power

Check/Action

1. Set the battery switch to on.

2. Check the AC adapter output.

(9.5 VDC or higher)

3. Replace the Ni-Cd battery pack.

4. Replace the logic board.

When the logic board is repaired, Check the power

supply circuit output (Vcc1,Vcc2 and VLOG:5 VDC;

VH:24 VDC; Vpp:14VDC)

a. When all outputs are not present:

1. Check fuse F1

b. If Vcc2 is not output:

1. Check fuse F2

c. If VH is not output:

1. Check that 1.28V is fed back from VH-ref.

2. Check that the Q11 base outputs 10 µs pulses.

3. Check that the IC14 OUT1 outputs 10 µs pulses.

See figure 6-2.

d. If Vpp is not output:

1. Check that 1.28V is fed back from Vpp-ref.

2. Check that the Q12 base outputs 10 µs pulses.

3. Check that the IC14 OUT2 outputs 10 µs pulses.

See figure 6-2.

Parts replacement

a. F1

b. F2

c. R3-7

d. Q11

e. IC14

f. R97,98

g. Q12

h. IC14

Fig. 6-2 DC/DC Converter Timing (Idle State)

– 65 –

Page 70

TROUBLESHOOTING

Error

Printing errors

No paper feed

Check/Action

1. Clean the ink cartridge at least five times.

2. If dots are missing at random,printing is unstable,or

splash occurs after cleaning.

See figure 6-3.

a. Replace the ink cartridge.

b. Clean the ink cartridge at least five times.

If the printing error is not corrected, replace the purge

unit

3. If one of every eight dots is missing after cleaning.

a. Replace the ink cartridge.

b. Clean the ink cartridge at least five times.

If the printing error is not corrected, replace the logic

board.

1. Check the paper feed motor:

about 45 ohms per phase

2. Replace the logic board.

When the logic board is repaired:

a. Check the paper feed motor drive pulse of IC 2. See

figure 6-4.

b. Replace the MPU.

Parts replacement

a. Purge unit

b. IC5,6

c. Q1 to Q8

(See figure 2-5 and

2-6.)

a. Paper feed motor

b. Paper feed motor

driver (IC 2)

c. MPU

Fig. 6-3 Nozzle Test Print Pattern

Fig. 6-4 Paper Feed Pulse (During line feeding by Line Feed Switch)

– 66 –

Page 71

3. Auto Sheet Feeder

3-1. Error Recovery

TROUBLESHOOTING

Error

Feeder does not operate

No paper feed

Several sheets are fed together

Paper fed askew

Check/Action

1. Set the printer in the ASF mode by DIP switch 4.

2. Check that the ASF is correctly fitted to the printer.

3. Disassemble the ASF and check that the clutch spring,

control cam, and positioning arm are correctly operated.

4. Check that the printer functions properly.

1. Set the paper release lever to the friction feed position

(push down).

2. Press the paper bin release button.

3. Check for paper jam.

4. Clean the pick-up roller with alcohol.

1. Arrange the sheets of paper conforming to the ASF

specifications in order; and place them in the paper bin,

taking care not to deform them.

2. Set the paper guide position to fit the paper width.

1. Arrange the sheets of paper conforming to the ASF

specifications in order; and place them in the paper bin,

taking care not to deform them.

2. Set the paper guide position to fit the paper width.

3. Clean the pick-up roller with alcohol.

Parts replacement

a. Clutch spring

b. Control cam

c. Positioning arm

a. Pick-up rubber

ring

a. Pick-up rubber ring

– 67 –

Page 72

GENERAL SPECIFICATIONS

– 2 –

Page 73

CHAPTER 7 PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Part that have been added in the revised edition are indicated with “#”.

Part that have been abolished in the revised edition are indicated with “*”.

#1 : First edition → Second edition *1 : First edition → Second edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

When there are differences in the specifications of the fuse, destination, etc., the differences are described in

words or indicated by two letters.

US ..........U.S.A. EC ..........EC UK ..........United Kingdom

AS ..........Australia HK ..........Hong Kong

The seal number of ROM is described in this column. The “*” mark of seal number is a variable representing

on the software version.

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

Parts marked “N” are not stock items. They are produced on a special-order basis.

(8) REFERENCE NO.

This column shows the reference number.

7

1. Printer Assembly................................................................................................................70

1-1. Disassembly Drawing..............................................................................................................70

1-2. Parts List...................................................................................................................................71

2. Printer Mechanism .............................................................................................................72

2-1. Disassembly Drawing..............................................................................................................72

2-2. Parts List...................................................................................................................................73

3. Carriage Unit...................................................................................................................... 74

4. Special Tools ..................................................................................................................... 75

5. Wiring Scheme of Printer ................................................................................................. 76

6. Logic Board ........................................................................................................................77

6-1. Circuit Diagram ........................................................................................................................77

6-2. Component Layout ..................................................................................................................83

6-3. Parts List...................................................................................................................................85

7. Automatic Sheet Feeder ....................................................................................................89

7-1. Disassembly Drawing..............................................................................................................89

7-2. Parts List...................................................................................................................................92

8. Numerical Index .................................................................................................................93

8-1. Parts Number Index.................................................................................................................93

8-2. Reference Number Index.........................................................................................................95

Page 74

1. Printer Assembly

1-1. Disassembly Drawing

– 70 –

Page 75

1-2. Parts List

Printer Assembly

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

1- 1 QG1-5272-000 PRINTER MECHANISM 1 S 80985203

2 QA2-0968-000 COVER,LOWER 1 80985177

3 *1 QG2-2396-000 BOARD,LOGIC 1 S 80985206

#1 QG2-2396-030 BOARD,LOGIC 1 S 80985206

4 F45-0132-400 INK CARTRIDGE UPC SC-10 1 FOR US S 89599030

F45-0131-500 INK CARTRIDGE JAN SC-10 1 EXCEPT US S 89599040

5 Q70-1592-410 AC ADAPTER: 120V MODEL 1 FOR US 80985030

Q70-1598-410 AC ADAPTER: 220V MODEL 1 FOR EC,HK 80985040

Q70-1591-410 AC ADAPTER: 240V(UK) MODEL 1 FOR UK 80985050

Q70-1804-410 AC ADAPTER: 240V(AS) MODEL 1 FOR AS 80985060

6 QA2-0967-000 COVER,UPPER 1 S 80985176

7 QS1-1586-000 LABEL,KEY PANEL 1 80985214

8 Q70-1790-412 BATTERY PACK UPC BP-10 US 1 FOR US 89599050

Q70-1780-413 BATTERY PACK JAN BP-10 EC 1 EXCEPT US 89599060

9 *1 QA2-0973-000 STAND,PRINTER 1 S 80985180

#1 QA2-0973-020 STAND,PRINTER 1 S 80985180

10 QA2-0972-000 COVER,BATTERY 1 80985179

11 QA2-0971-000 COVER,TOP 1 S 80985178

12 QF1-5102-000 COVER,PAPER 1 S 80985199

13 QA2-0975-000 SWITCH,POWER 1 S 80985182

14 QA2-0312-000 HOLDER,SWITCH 1 80985100

15 QA2-0806-000 FOOT,RUBBER(BLACK) 4 80985173

16 QA2-0503-000 CAP,CONNECTOR 1 80985166

17 QH8-8302-000 SENSOR,PAPER END 1 S 80985209

18 QG2-2315-020 UNIT,DC INLET 1 80985205

19 QA2-0793-000 KEYTOP 1 80985171

20 QA2-0794-000 INDICATOR,ASSY,LED 2 80985172

21 QA2-0974-000 SWITCH,BATTERY 1 80985181

22 QA2-0897-000 LABEL,GROUNDING 1 80985175

23 QS1-1585-000 LABEL,INSTRUCTION 1 80985213

24 QA2-0807-000 FOOT,RUBBER(BLACK) 2 80985174

25 XB4-7300-809 SCREW,TAP,BINDING HEAD:M3X8 3 S 80985341

26 XA9-0533-000 SCREW,B-TIGHT:M3X14 MM 3 S 80985339

— Q70-1770-412 ASF SF-10CA UPC 1 FOR US 89599010

Q70-1770-414 ASF SF-10CA JAN 1 EXCEPT US 89599020

– 71 –

Page 76

2. Printer Mechanism

2-1. Disassembly Drawing

– 72 –

Page 77

2-2. Parts List

Printer Mechanism

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

2- 1 QA2-0327-000 CHASSIS 1 80985105

2 QF1-5032-020 SHAFT,CARRIAGE GUIDE 1 80985194

3 QF1-5036-000 SHAFT,PRESSURE PLATE RELEASE 1 80985195

4 QA2-0322-000 HOLDER,CARRIAGE RIBBON CABLE 1 80985102

5 QA2-0328-000 LEAF SPRING,PRESSURE PLATE 2 80985106

6 QA2-0331-020 HOLDER,GUIDE SHAFT 1 80985109

7 QA2-0333-000 ABSORBER,INK 1 80985110

8 QA2-0329-000 HOLDER,PRESSURE PLATE 4 80985107

9 QA2-0330-000 PLATE,PRESSURE 4 80985108

10 QA2-0415-000 ROLLER,PRESSURE 4 80985135

11 QG1-5270-000 SCREW,LEAD 1 80985202

12 QA2-0362-020 PIN,LEAD 1 80985111

13 QA2-0383-020 SHAFT,PINCH ROLLER RELEASE 1 80985124

14 QA2-0386-000 DIAL,ADJUST 1 80985127

15 QA2-0392-000 HOLDER,LEAD SCREW 1 80985130

16 QA2-0380-000 BASE,PAPER FEED 1 80985122

17 QA2-0505-020 HOLDER,PINCH ROLLER 2 80985167

18 QA2-0506-000 ROLLER,PINCH 2 80985168

19 *1 QG1-5299-000 PURGE UNIT 1 S 80985204

#1 QG1-5299-030 PURGE UNIT 1 S 80985204

20 QF1-5037-000 MOTOR,CARRIAGE 1 S 80985196

21 QA2-0321-000 BELT,CARRIAGE DRIVE 1 80985101

22 QA2-0323-000 SPRING,BELT TENSION 1 80985103

23 QA2-0391-000 ABSORBER,INK 1 80985129

24 QA2-0381-000 LEAF SPRING,PINCH ROLLER 2 80985123

25 QA2-0385-000 HOLDER,FEED ROLLER 1 80985126

26 QA2-0384-000 CRANK,RELEASE 1 80985125

27 *1 QF1-5038-000 ROLLER,PAPER FEED 1 80985197

#1 QF1-5038-060 ROLLER,PAPER FEED 1 80985197

28 QA2-0405-000 SHAFT,ROLLER 2 80985134

29 QG1-5062-000 ROLLER,TRANSMISSION 2 80985200

30 QA2-0388-000 ROD,RELEASE 1 80985128

31 QA2-0659-000 STABILIZER,FEED ROLLER 1 80985170

32 QA2-0400-000 LEVER,RELEASE 1 80985132

33 QA2-0399-000 GEAR,SLOWDOWN 1 80985131

34 QH4-4020-000 MOTOR,PAPER FEED 1 S 80985207

35 QA2-0404-030 PLATE,PLATEN 1 S 80985133

36 QG1-5063-000 ROLLER,EJECT 2 80985201

37 *1 QA2-0420-020 SEPARATOR,PAPER 1 80985136

#1 QA2-0420-030 SEPARATOR,PAPER 1 80985136

38 QA2-0657-000 SLIDER 1 80985169

39 QA2-0325-000 STOPPER,CARRIAGE SHAFT 1 80985104

40 XB1-2260-405 SCREW,PAN HEAD:M2.6X4 MM 1 S 80985340

– 73 –

Page 78

3. Carriage Unit

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

3- 1 QA2-0366-030 BASE,CARRIAGE 1 80985114

2 *1 QA2-0370-020 LOCK,INK CARTRIDGE 1 80985118

#1 QA2-0370-030 LOCK,INK CARTRIDGE 1 80985118

3 QA2-0371-000 SPRING 1 80985119

4 QA2-0372-020 LEVER,LOCKING 1 80985120

5 *1 QA2-0373-020 COVER,LOCK 1 80985121

#1 QA2-0373-030 COVER,LOCK 1 80985121

6 QY6-0021-000 CABLE,CARRIAGE RIBBON 1 HP SENSOR 80985215

7 QA2-0367-000 PAD,CONTACT 1 80985115

8 QA2-0363-020 HOLDER,LEAD PIN 1 80985112

9 QA2-0369-000 HOLDER,RIBBON CABLE(LOWER) 1 80985117

10 QA2-0368-000 HOLDER,RIBBON CABLE(UPPER) 1 80985116

11 QA2-0364-000 COVER,CARRIAGE 1 80985113

– 74 –

Page 79

4. Special Tools

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

4- 1 QY9-0001-000 GAUGE,GAP:0.50 MM 1 S 80985240

2 TKC-0953-000 GREASE,FLOIL G311S 1 S 80985241

– 75 –

Page 80

5. Wiring Scheme of Printer

– 76 –

Page 81

6. Logic Board

6-1. Circuit Diagram

123

A

B

C

4

5

D

E

F

G

– 77 –

Page 82

678

9

10

A

B

C

D

E

F

G

– 78 –

CIRCUIT DIAGRAM (1/3)

Page 83

123

A

B

C

4

5

D

E

F

G

– 79 –

Page 84

6

78

9

10

A

B

C

D

E

F

G

– 80 –

CIRCUIT DIAGRAM (2/3)

Page 85

123

A

B

C

4

5

D

E

F

G

– 81 –

Page 86

6

78

9

105

A

B

C

D

E

F

G

– 82 –

CIRCUIT DIAGRAM (3/3)

Page 87

6-2. Component Layout

– 83 –

Page 88

– 84 –

Page 89

6-3. Parts List

Logic Board

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

6-Q1-9 WA2-5134-000 TRANSISTOR,2SB1497(PNP) 9 80985312

Q10 WA2-5115-000 TRANSISTOR,2SB1188 Q,R(PNP) 1 80985309

Q11 WA2-5110-000 TRANSISTOR,2SC4549 L,K(NPN) 1 80985306

Q12 WA2-5119-000 TRANSISTOR,2SD2243 L,K(NPN) 1 80985311

Q13 WA2-5111-000 TRANSISTOR,2SD2038 E,F(NPN) 1 80985307

Q14 WA4-5223-000 IC,REGURATOR:TA78DLO5S 1 80985321

Q15 WA2-5107-000 TRANSISTOR,COMPOUND:FN1L4M(PNP) 1 80985305

Q16 WA2-0998-000 TRANSISTOR,COMPOUND:FA1L4M(NPN) 1 80985304

Q17 WA2-5114-000 TRANSISTOR,COMPOUND:FA1F4M(NPN) 1 80985308

Q18 WA2-0998-000 TRANSISTOR,COMPOUND:FA1L4M(NPN) 1 80985304

Q19 WA2-5117-000 TRANSISTOR,2SC2412K BR,BS(NPN) 1 80985310

Q20 WA2-5193-000 TRANSISTOR,2SA1036 K,Q,R(NPN) 1 80985313

Q21 WA2-5115-000 TRANSISTOR,2SB1188 Q,R(PNP) 1 80985309

Q22 WA2-5117-000 TRANSISTOR,2SC2412K BR,BS(NPN) 1 80985310

Q23 WA2-5114-000 TRANSISTOR COMPOUND:FA1F4M(NPN) 1 80985308

Q24-25 WA2-0998-000 TRANSISTOR,COMPOUND,FA1L4M(NPN) 2 80985304

IC1 WA3-1227-000 IC,TTL:SN74LS14NS 1 80985314

IC2 WA4-0541-000 IC,ULN2003A,DRIVER 1 80985318

IC3 QH8-8308-000 IC,PRINTER CONTROLLER 1 80985210

IC4 WA3-5423-000 IC,TTL,SN74LSO5NS 1 80985316

IC5 *1 WA2-0416-000 IC,DRIVER:ULN2803A 1 80985303

#1 WA4-5116-000 IC,DRIVER:ULN2803A 1 80985373

IC6 WA4-1120-000 IC,DRIVER:TD62382AP 1 80985320

IC7 *1 QH8-8456-000 IC,EP-ROM UOD27C2001D-20 1 80985211

#1 QH8-8476-000 IC,MASK-ROM:HN62302BPC30 (IC7) 1 NOTE1 80985377

IC8-9 QH9-0001-000 IC,D-RAM:256K 2 80985212

IC10 WA3-4392-000 IC,M5M82C55AFP2 1 80985315

IC11 QH8-8277-000 IC,MPU:TMP90C840AF 1 WITHIN ROM 80985208

IC12 WA3-5423-000 IC,TTL:SN74LSO5NS 1 80985316

IC13 WA4-5224-000 IC,LINEAR:IC-PST575EMT 1 80985322

IC14 WA4-0859-000 IC,DUAL SWITCHING REGURATOR MB3775P 1 80985319

IC15 WA4-0541-000 IC,ULN2003A,DRIVER 1 80985318

IC16 WA3-5489-000 IC,TIMER:S3500A 1 80985317

ZD1 WA1-5143-000 DIODE,ZENER,RD30FB 1 80985300

ZD2-3 WA1-1025-000 DIODE,ZENER,RD7.5MB3 2 80985294

ZD4 WA1-0694-000 DIODE,ZENER,RD5.6MB3 1 80985293

ZD5 WA1-5106-000 DIODE,ZENER,RD4.7MB3 1 80985296

ZD6-7 WA1-5163-000 DIODE,ZENER,HZS7A-2 2 80985301

ZD8 WA1-1047-000 DIODE,ZENER,HZS16-2 1 80985295

D1-2 WA1-5113-000 DIODE,D1NS4 2 80985298

D3 WA1-5110-000 DIODE,MA720 1 80985297

D7 WA1-5110-000 DIODE,MA720 1 80985297

D9 WA1-5170-000 DIODE,RM10Z LF-A4 1 80985302

D11 WA1-5170-000 DIODE,RM10Z LF-A4 1 80985302

D12 WA1-5113-000 DIODE,D1NS4 1 80985298

D13 WA1-5124-000 DIODE,MA28T-A 1 80985299

D16-17 WA1-5113-000 DIODE,D1NS4 2 80985298

R1 VR7-0811-962 RESISTOR,CHIP,METAL:19.6K OHM 1/10W 1 80985262

R2 VR7-0811-242 RESISTOR,CHIP,METAL:12.4K OHM 1/10W 1 80985260

R3 VR7-0811-911 RESISTOR,CHIP,METAL:1.91K OHM 1/10W 1 80985261

R4 VR7-0813-092 RESISTOR,CHIP,METAL:30.9K OHM 1/10W 1 80985263

R5-7 VR7-0811-201 RESISTOR,CHIP,METAL:1.20K OHM 1/10W 3 80985259

NOTE1: The EP-ROM D27C2001D-200NS (REF. No.08222058) can be used as a spare for the IC7.

The latest version of the software is 8456-03A (Ver. 1.2A) (released October 1992).

– 85 –

Page 90

Logic Board

DRWG.NO. REV. PARTS NO. PARTS NAME Q'TY REMARKS RANK REF. NO.

6-R8 VR7-0811-001 RESISTOR,CHIP,METAL:1.00K OHM 1/10W 1 80985258

R9 VR7-1590-330 RESISTOR,FUSE:33 OHM 1.6W 1 80985264

R10-13 VV1-2115-562 RESISTOR,CHIP,METAL:5.6K OHM 1/10W 4 80985285

R14 VV1-2115-102 RESISTOR,CHIP,METAL: 1K OHM 1/10W 1 80985272

R15-23 VV1-2115-562 RESISTOR,CHIP,METAL:5.6K OHM 1/10W 9 80985285

R24 VV1-2115-302 RESISTOR,CHIP,METAL:3.0K OHM 1/10W 1 80985278

R25 VV1-2115-101 RESISTOR,CHIP,METAL: 100 OHM 1/10W 1 80985271

R26 VV1-2115-562 RESISTOR,CHIP,METAL:5.6K OHM 1/10W 1 80985285

R27-28 VV1-2115-101 RESISTOR,CHIP,METAL: 100 OHM 1/10W 2 80985271

R29 VV1-2115-202 RESISTOR,CHIP,METAL:2.0K OHM 1/10W 1 80985276

R30-33 VV1-2115-101 RESISTOR,CHIP,METAL: 100 OHM 1/10W 4 80985271

R34 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 1 80985277

R35 VV1-2115-332 RESISTOR,CHIP,METAL:3.3K OHM 1/10W 1 80985279

R37-40 VV1-2115-562 RESISTOR,CHIP,METAL:5.6K OHM 1/10W 4 80985285

R51 VV1-2115-105 RESISTOR,CHIP,METAL: 1M OHM 1/10W 1 80985274

R52 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 1 80985277

R53 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 1 80985282

R54-55 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 2 80985277

R56 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 1 80985282

R57 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 1 80985277

R58 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 1 80985282

R59 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 1 80985277

R60-61 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 2 80985282

R62-63 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 2 80985277

R64-65 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 2 80985282

R66-67 VV1-2115-301 RESISTOR,CHIP,METAL: 300 OHM 1/10W 2 80985277

R68 VV1-2115-511 RESISTOR,CHIP,METAL: 510 OHM 1/10W 1 80985282