STAR SJ-144, SJ-144MC Service manual

Laser-Quality Printer

SJ-144

SJ-144MC

TECHNICAL MANUAL

[THIRD EDITION]

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

© Copyright 1996 Star Micronics Co.,Ltd.

INTRODUCTION

This manual is an introduction to Laser Quality printers as shown below.

It is intended for use as a reference for periodic inspections and maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

PC MAC

On the following pages,

SJ-144 IBM PC compatible

SJ-144MC Macintosh

• This manual is divided into the following chapters:

Chapter 1 General Specifications

Chapter 2 Theory of Operation

Chapter 3 Adjustments

Chapter 4 Parts Replacement

Chapter 5 Maintenance and Lubrication

Chapter 6 Troubleshooting

Chapter 7 Parts List

refers to the SJ-144 and refers to the SJ-144MC.

Model Hardware required

1

2

3

4

5

• First edition : Jun. 1993

Second edition : Jun. 1994

Third edition : Apr. 1996

6

7

GENERAL SPECIFICATIONS

– 2 –

CHAPTER 1

GENERAL SPECIFICATIONS

1. General Specifications..........................................................................................3

2. External Appearance and Composition ..............................................................7

3. Control Panel.............................................................................................................8

3-1. Switch Combination Functions ............................................................................. 8

3-2. EDS Mode Settings ............................................................................................... 11

4. Parallel Interface..................................................................................................12

4-1. General Specifications ......................................................................................... 12

4-2. Connector Signals ................................................................................................ 12

5. Serial interface.....................................................................................................13

1

GENERAL SPECIFICATIONS

– 2 –

1. General Specifications

GENERAL SPECIFICATIONS

Printing system Plain paper, Heat fusion process

Print speed At 7.5 lines per inch At 6 lines per inch

MACPC

MACPC

Pica (10 CPI) 306 cps 255 cps

Elite (12 CPI) 367 cps 306 cps

Semi-condensed (15 CPI) 459 cps 382 cps

Condensed pica (17 CPI) 520 cps 433 cps

Condensed elite (20 CPI) 612 cps 510 cps

Note:50% speed reduction in Color, OHP, and Label modes.

Print speeds have been estimated for each font because the SJ-

144MC printer does not have bitmapped fonts.

Paper feed speed 380 ms (line feed at 144/360 inch)

Printing direction Uni-directional logic seeking (left to right)

Number of columns

MACPC

MACPC

MACPC

Pica (10 CPI) 80

Elite (12 CPI) 96

Semi-condensed (15 CPI) 120

Condensed pica (17 CPI) 137

Condensed elite (20 CPI) 160

Proportional Variable

Printing head 144 elements

Resolution 360 × 360 dots per inch

Fonts and typefaces

MACPC

MACPC

PC

Font styles

Scalable TrueType fonts American Text, Broadway, Brush 445, Caslon Openface, Cloister

Black, Commercial Script, Cooper Black, DAVIDA, Dom Casual,

Engravers’Roman, Exotic 350 Demi Bold, Freeform 721, Freehand

521, Handel Gothic, Hobo, Humanist 521 Extra Bold, Impress,

Kaufmann, OCR, Old Dreadful No. 7, Onyx, Orbit-B, Parisian, Park

Avenue, Playbill, P.T.Barnum, Raleigh Demi Bold, Schadow Black

Condensed, Seagull Heavy, shotgun, Tango, University Roman, VAG

Rounded, Vineta, Windsor

Note:TrueType typefaces are supplied on diskette for use with Win-

dows 3.1 applications.

Bulit-in bitmapped fonts Roman, Roman Bold, Roman Italic, Roman Italic Bold, H-Gothic, H-

Gothic Bold, H-Gothic Italic. H-Gothic Italic Bold

Character matrix

Pica (10 CPI) 48 × 36 at 360 dots per inch

Elite (12 CPI) 48 × 30 at 360 dots per inch

Semi-condensed (15 CPI) 48 × 24 at 360 dots per inch

Condensed pica (17 CPI) 48 × 21 at 360 dots per inch

Condensed elite (20 CPI) 48 × 18 at 360 dots per inch

Proportional 48 × n at 360 dots per inch

Bit image dot-matrix

8-bit 60, 80, 90, 120, 240 dots per inch

24-bit 60, 80, 90, 180, 360 dots per inch

48-bit 60, 80, 90, 180, 360 dots per inch

144-bit 60, 80, 90, 180, 360 dots per inch

Character sets

ASCII 96

International 16 sets

IBM special 111

IBM block graphics 50

IBM code page 6 sets

Download 128

– 3 –

GENERAL SPECIFICATIONS

Fonts and typefaces

MAC

Font styles

Scalable TrueType fonts American Text, Broadway, Brush 445, Caslon Openface, Cloister

Black, Commercial Script, Cooper Black, DAVIDA, Dom Casual,

Engravers’Roman, Exotic 350 Demi Bold, Freeform 721, Freehand

521, Handel Gothic, Hobo, Humanist 521 Extra Bold, Impress,

Kaufmann, OCR, Old Dreadful No. 7, Onyx, Orbit-B, Parisian, Park

Avenue, Playbill, P.T.Barnum, Raleigh Demi Bold, Schadow Black

Condensed, Seagull Heavy, shotgun, Tango, University Roman, VAG

Rounded, Vineta, Windsor

Note:TrueType typefaces are supplied on diskette for use with Macin-

tosh applications.

Raster graphics 360 dots per inch

Paper feed Single bin paper tray with 30 sheet capacity

MACPC

MACPC

Friction roller feed from the front of the printer

Friction roller feed from the rear of the printer

Paper specifications

MACPC

Width 3.94" ~ 9.53" (100.0 ~ 242.0 mm)

Length 3.94" ~ 14.0" (100.0 ~ 356 mm)

Thickness Paper tray: 0.00236" ~ 0.00394" (0.06 ~ 0.10 mm)

Rear path: 0.00236" ~ 0.00906" (0.06 ~ 0.23 mm)

Surface Xerography-quality or smoother (Such as Hammermill LaserPrinter),

Laser-quality, overhead projection (OHP) film, post cards and label

sheet.

Emulations

PC

Standard mode Epson LQ-860, NEC 24-wire Graphic Commands

IBM mode IBM Proprinter X24E

Emulation CDM conforms to Apple QuickDraw running system 6 or later.

Interface Centronics Paralle 36 PIN

Interface RS-422A Serial 8 PIN 57.6 Kbps

Maximum buffer size

MAC

PC

MAC

PC

Whithout Download 35 KB + 3 line buffer (176 KB)

With Download 16 KB + 3 line buffer (176 KB)

Maximum buffer size 35 KB + 2 line buffer (102 KB)

Environment

MAC

MACPC

Temperature Stand-by: +5 to +35˚C (41 to 95˚F)

Operating: +5 to +35˚C (41 to 95˚F)

+10 to +30˚C (50 to 86˚F) for Color, OHP, Label

Storage: –25 to +60˚C (–13 to +140˚F)

Humidity: Stand-by: 30 to 90 % RH (No condensation)

Operating: 30 to 70 % RH (No condensation)

Storage: 30 to 90 % RH (No condensation)

Reliability

MACPC

Mean-time between failure (MTBF) 10,000 hours

Maximum recommended duty cycle 2,000 pages/2,000 power-on hours per year

Printer life 10,000 pages or 5 years

Print head life 50 million pulses per element

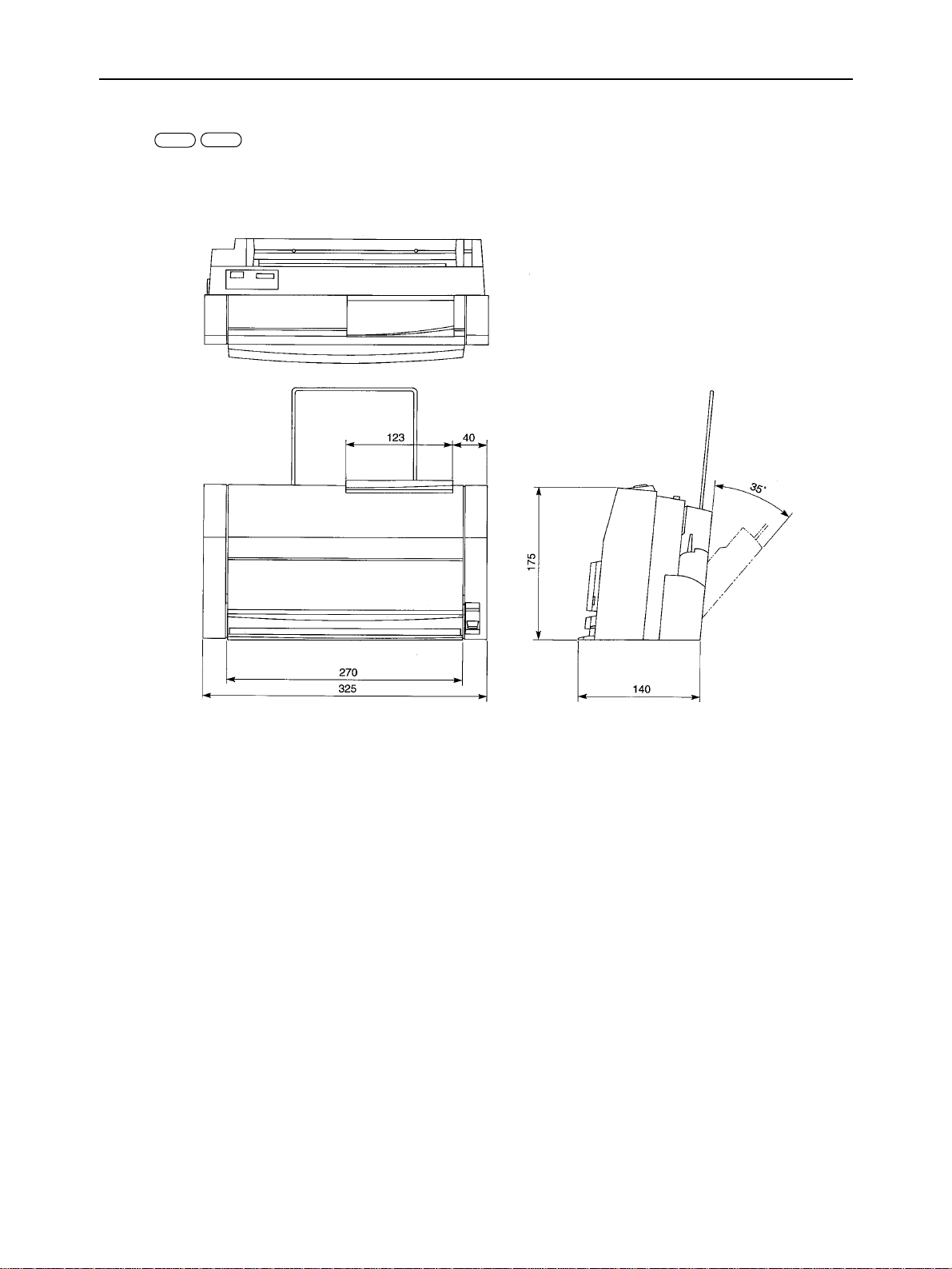

Dimensions and Weight

MACPC

Width 325 mm (12.8")

Depth 140 mm (5.5")

Height 175 mm (6.9")

Weight 2.5 kg (5.5 lbs)

AC adapter power supply 100 ~ 120 VAC, 220 ~ 240 VAC, 50/60Hz

MACPC

(varies according to the country of purchase)

– 4 –

GENERAL SPECIFICATIONS

Options

PC

MAC

Ink ribbon cartridge for plain paper

T144BK (Sold in 3 pack) Type: Monochrome ribbon (one time use)

Life: 345,000 characters (12CPI, 6 LPI)

180 pages/cartridge (1500 characters per page)

Length: 340 m

Width: 12.7 mm

T144CL (Sold in 3 pack) Type: Color ribbon (one time use)

Life: 8.0 pages per cartridge (8.0" × 9.6" Full graphics per page.)

Length: 193 cycles, 210 m

Width: 12.7 mm

Ink ribbon cartridge for overhead

projection (OHP) film

T144BKO Type: Monochrome ribbon (one time use)

Life: 200,000 characters (10CPI, 6LPI)

100 pages/cartridge (1500 characters per page)

Length: 200 m

Width: 12.7 mm

T144CLO Type: Color ribbon (one time use)

Life: 10.5 pages per cartridge (8.0" × 9.6" Full graphics per page.)

Length: 257 cycles, 270 m

Width: 12.7 mm

Ink ribbon cartridge for strip labels Type: Single color printing on single color background

125 labels per cartridge (1.8 inches per label)

Maximum label length: 7.2" (printable)

Strip label height: 0.5"

Background Color Printing Color

T01SL Transparent Black

T02SL White Black

T03SL Red Black

T04SL Blue Black

T05SL Green Black

T06SL Yellow Black

T07SL Gold Black

T08SL Silver Black

T31SL Transparent Red

T32SL White Red

T41SL Transparent Blue

T42SL White Blue

– 5 –

GENERAL SPECIFICATIONS

MACPC

Fig. 1-1 External Dimensions

– 6 –

GENERAL SPECIFICATIONS

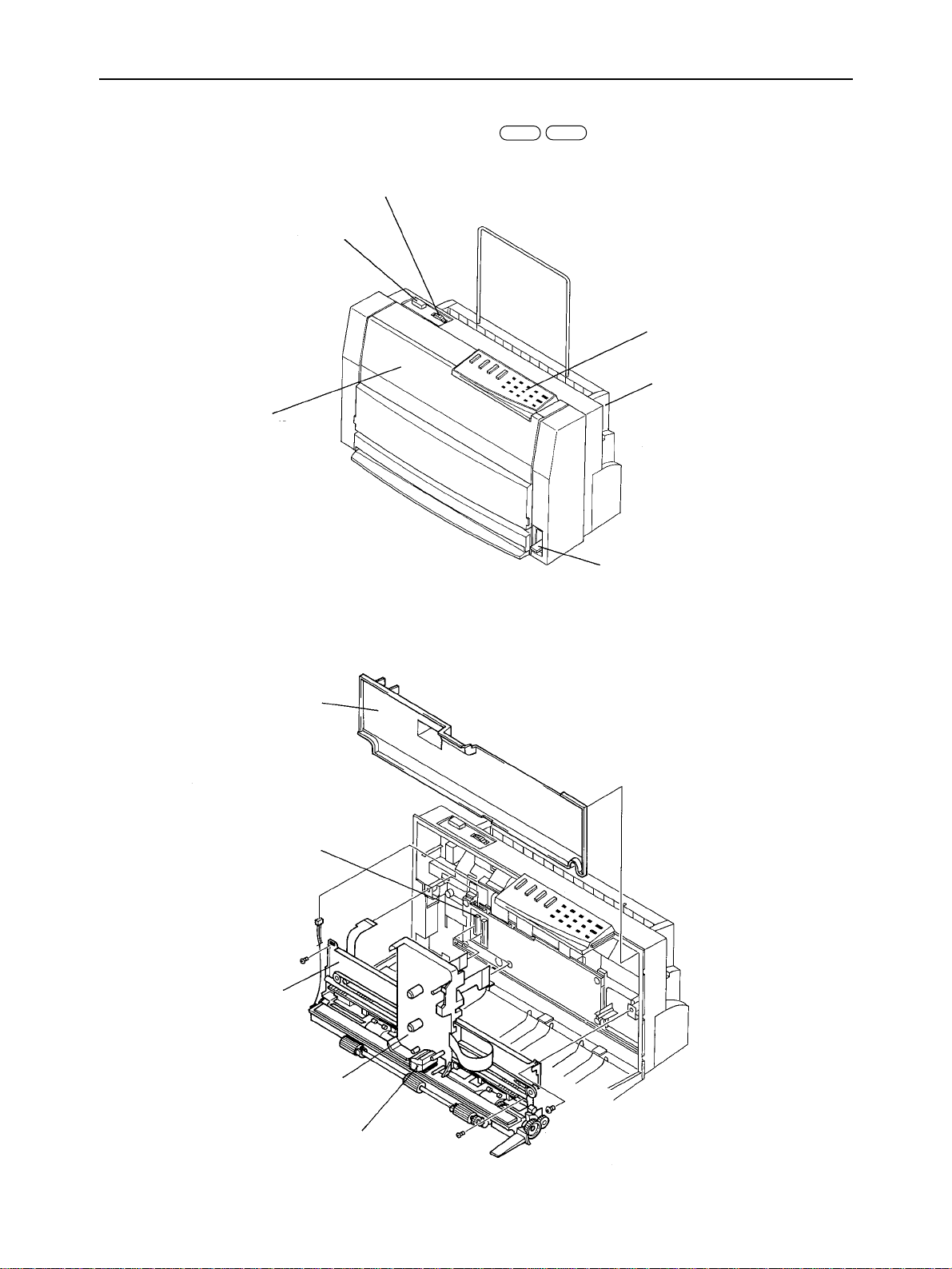

2. External Appearance and Composition

Print density Dial

Power Switch

Front Cover

MACPC

Control Panel

ASF Ass’y

Release Lever

Board Cover

Main Logic Board

Printer Mechanism

Fig. 1-2 Front View of the Printer

Carriage

Print Head

Fig. 1-3 Diagram of Internal Composition

– 7 –

GENERAL SPECIFICATIONS

3. Control Panel

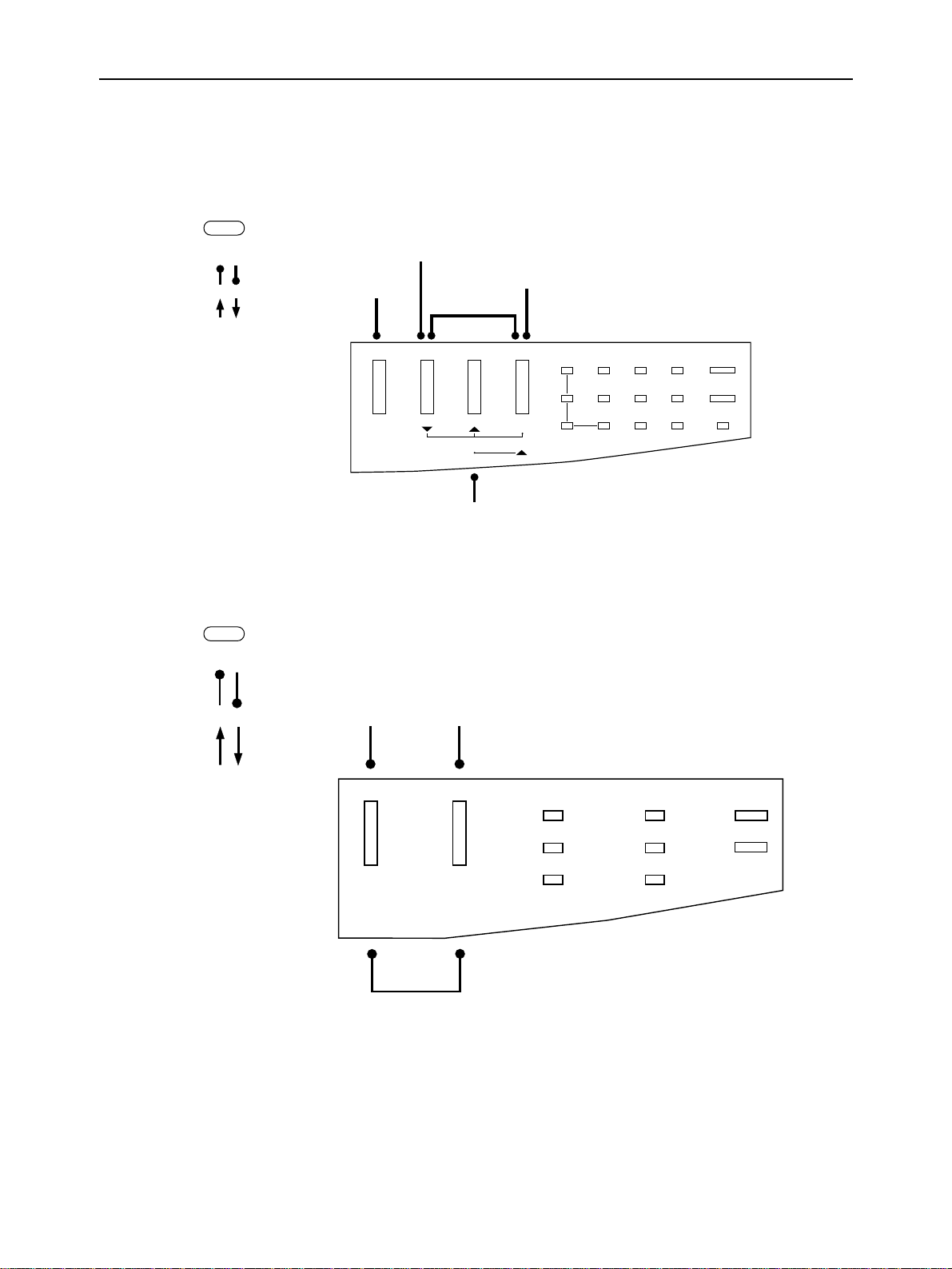

3-1. Switch Combination Functions

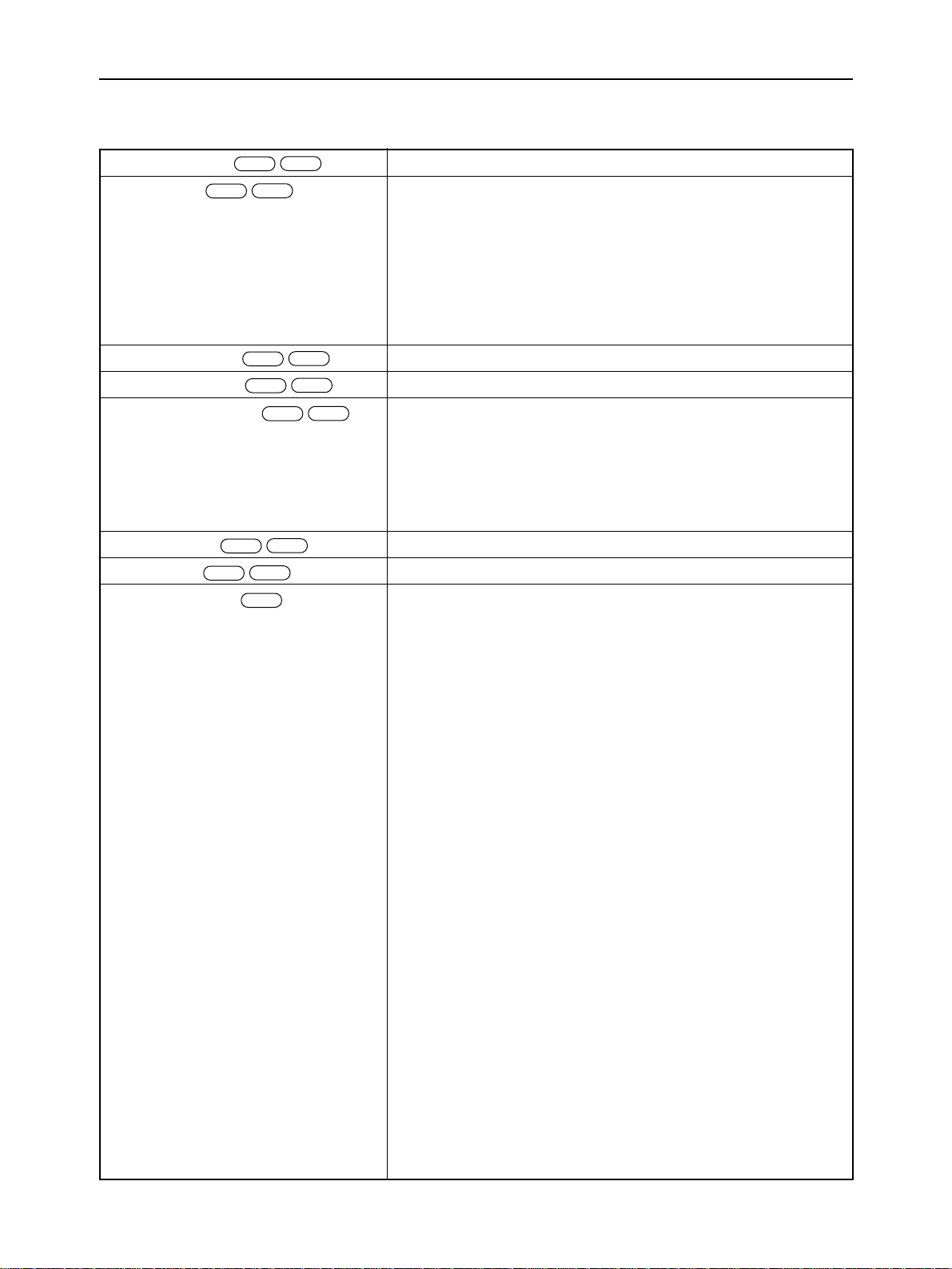

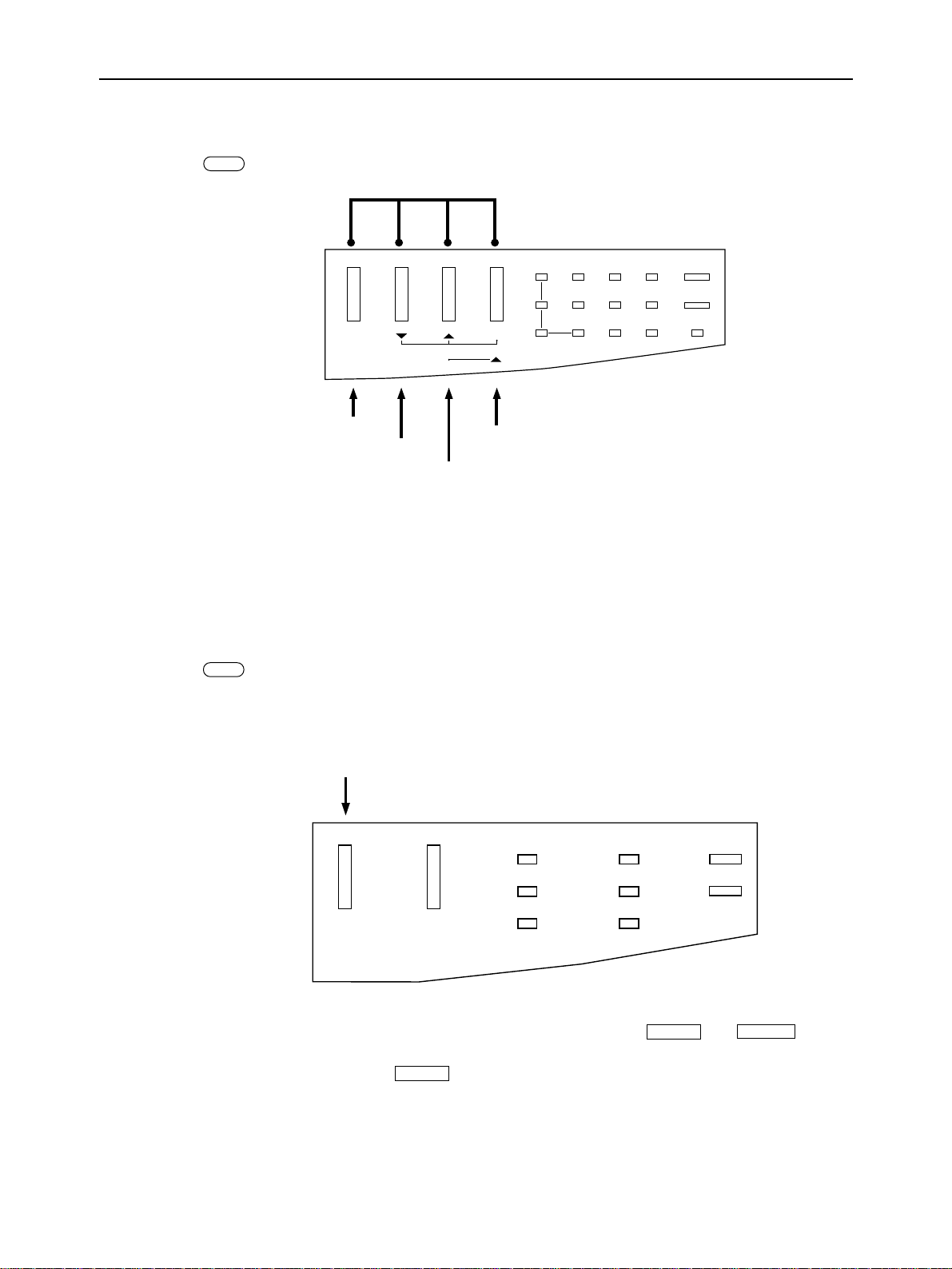

1) At power on

PC

Hold

Push

EDS mode

Hexadecimal dump

Short test (Color test)

LF adjustment

MAC

Hold

Push

Zoom Paper Ready

ALT Macro 2-Page Clear

Micro Freed

FF

Zoom AEC Color Paper Power

80%

CDM OHP Ribbon Ready

67%

2-Page Label Macro Data

50%

Long test

Fig. 1-4 Switch combination functions at power-on

Self-test1 Self-test1

COLOR

PAPER READY

OHP

PAPER

POWER

READY

RIBBON

LABEL

Adjustment mode

Fig. 1-5 Switch combination functions at power-on

– 8 –

DATA

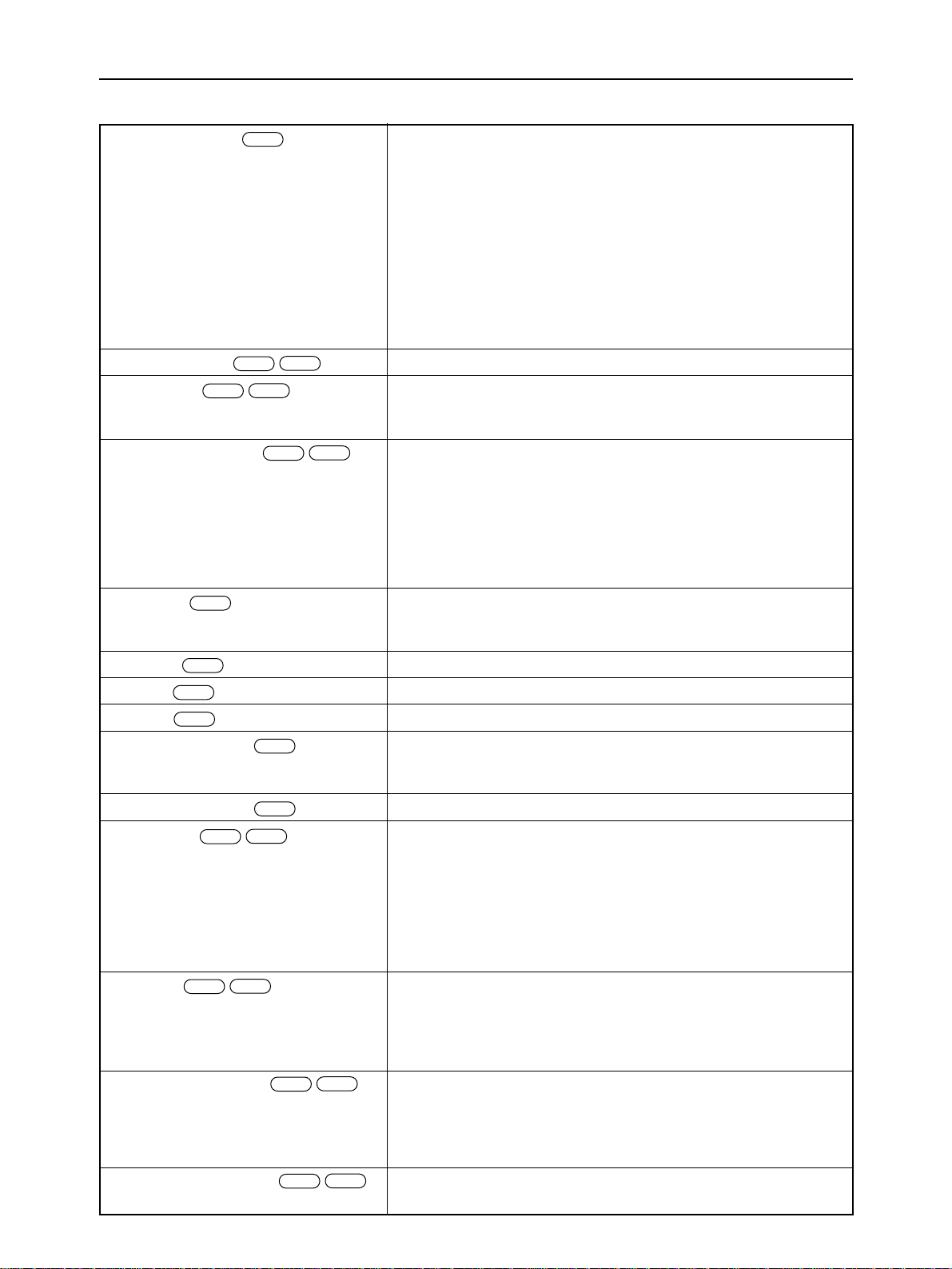

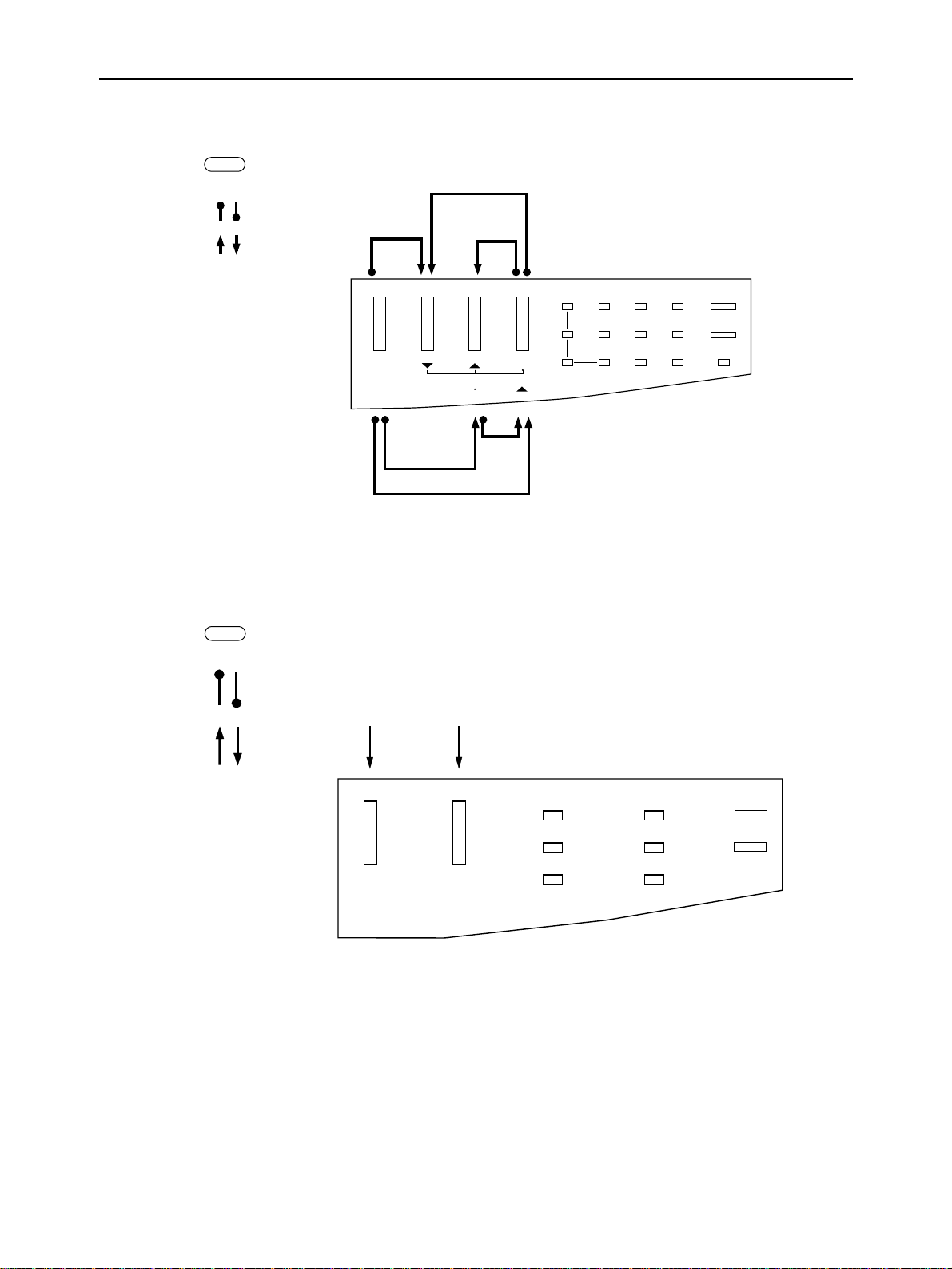

2) At off line

GENERAL SPECIFICATIONS

PC

Reverse micro-feed

MAC

Hold

Push

Saving macro

definition

ALT Macro 2-Page Clear

Forward

micro-feed

Zoom Paper Ready

Micro Freed

FF

Zoom AEC Color Paper Power

80%

CDM OHP Ribbon Ready

67%

2-Page Label Macro Data

50%

Paper

eject

2-Page mode

Cleaning the buffer/All reset

Fig. 1-6 Switch combination functions at off-line

Hold

Push

Sets printer on-linePaper feed/Feed

COLOR

PAPER READY

OHP

LABEL

Fig. 1-7 Switch combination functions at off-line

PAPER

POWER

READY

RIBBON

DATA

– 9 –

GENERAL SPECIFICATIONS

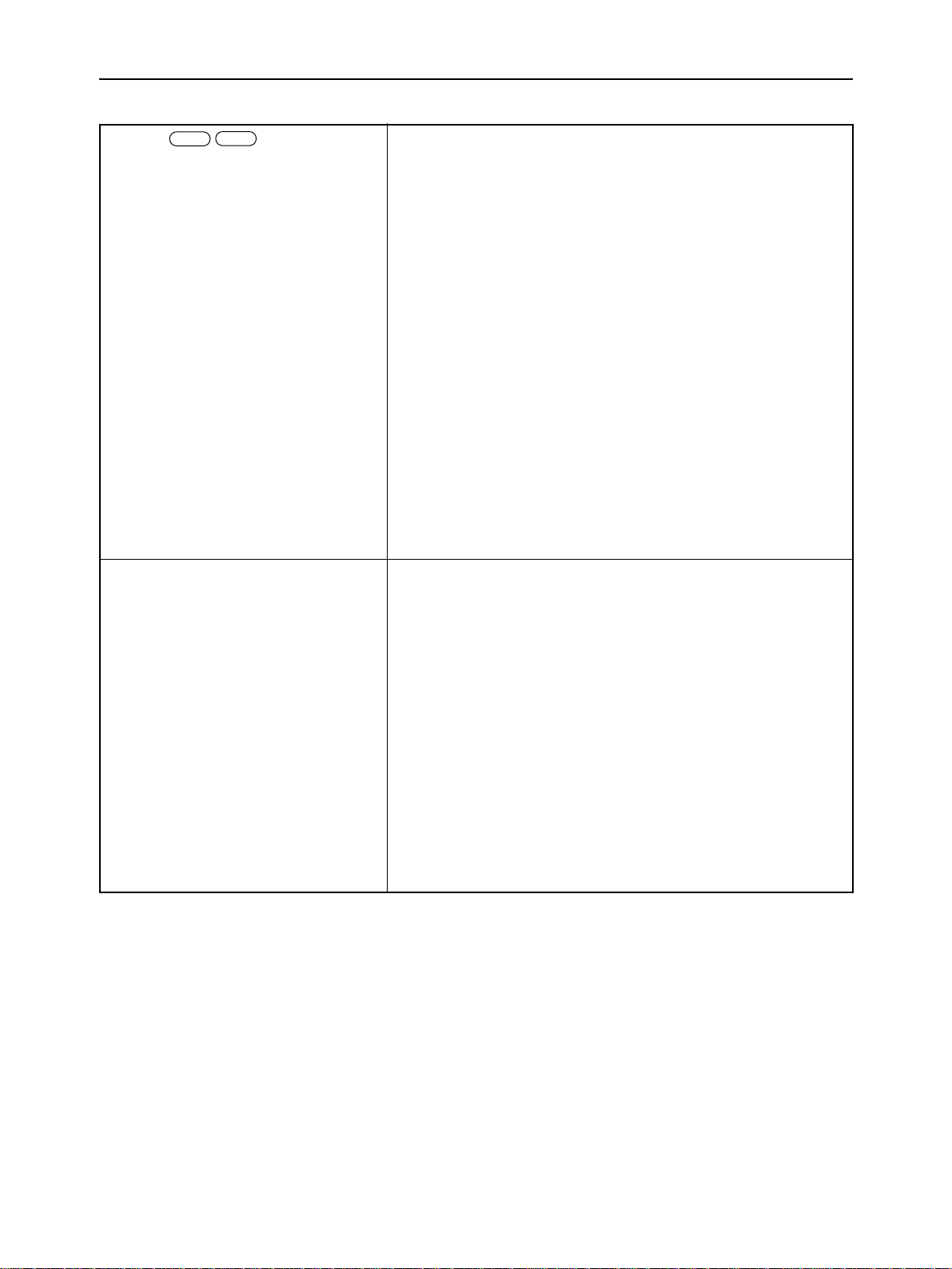

3) At power on (adjustment mode)

PC

Adjustment mode

Zoom Paper Ready

ALT Macro 2-Page Clear

LF adjustment

AN rotation printing

EE-PROM data dump

Micro Freed

FF

EE-PROM data reset

Zoom AEC Color Paper Power

80%

CDM OHP Ribbon Ready

67%

2-Page Label Macro Data

50%

[1]Turn the power on (press the power switch) while holding down the four buttons. The printer enters

adjustment mode.

[2]When in adjustment mode, pressing any one of the four function buttons will activate the appropriate function.

Refer to chapter 3 for further information.

Fig. 1-8 Adjustment mode

MAC

When a plain paper or OHP ribbon (monochrome or color) is installed, the printer

prints the factory-default pattern.

COLOR

PAPER READY

OHP

LABEL

[1]Turn the power on (by pressing the power switch) while holding down the

The printer enters adjustment mode.

In adjustment mode, pressing the

PAPER

button activates the function mentioned above.

Fig. 1-9 Adjustment mode

PAPER

RIBBON

DATA

PAPER

POWER

READY

and

READY

buttons.

– 10 –

GENERAL SPECIFICATIONS

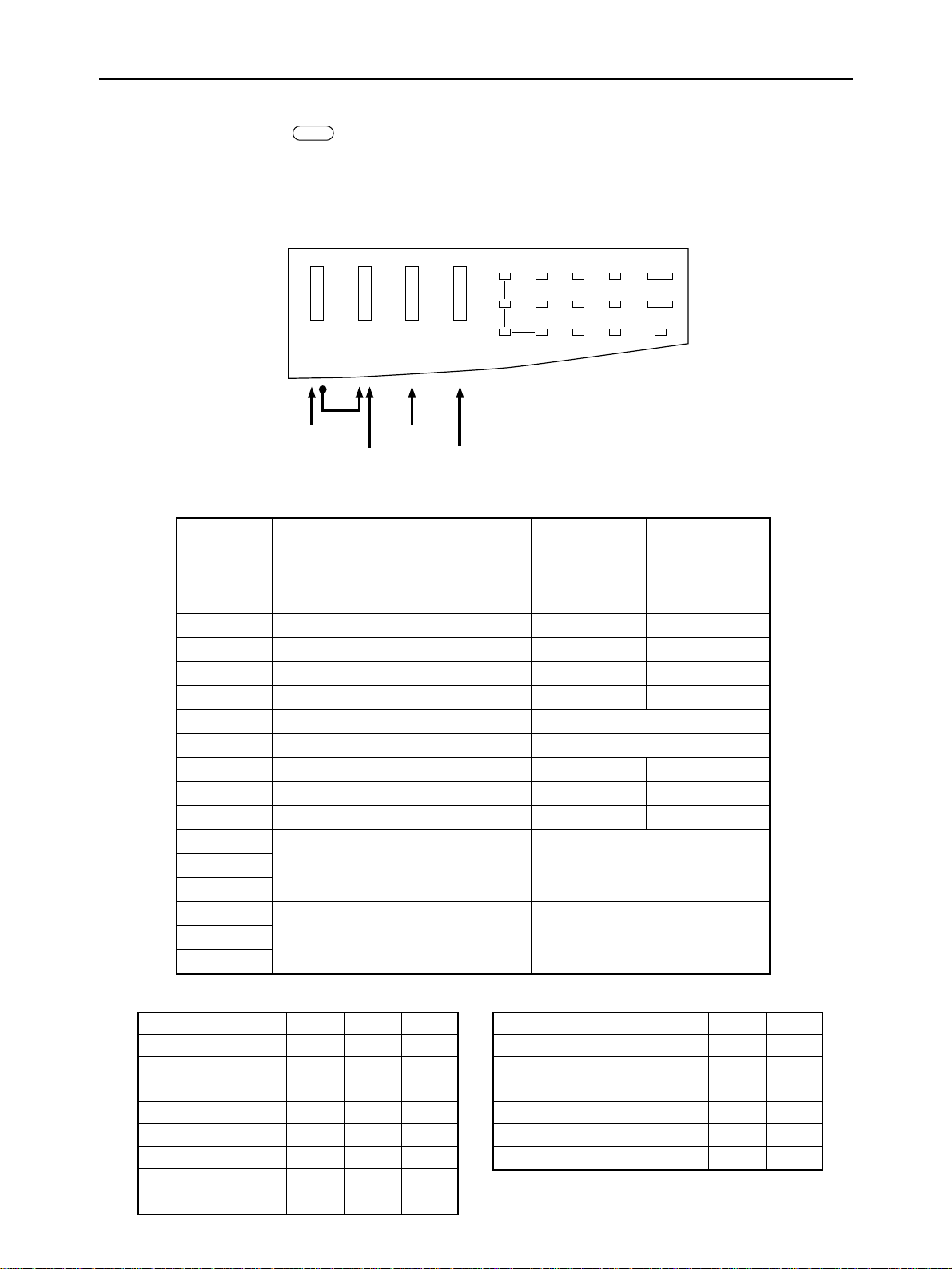

3-2. EDS Mode Settings

PC

The EDS (Electronic DIP Switch) mode in the printer has 12 functions that you can set as the power-on default.

Turn the printer ON while holding down the ALT button. One of the Zoom lamps will blink to indicate that you have

entered the EDS mode.

In EDS mode, the buttons on the control panel are used as shown below in Fig. 1-7.

Zoom Paper Ready

ALT Macro 2-Page Clear

Exit

Select Bank

Select Switch

Print

Change Setting

Zoom 1 4

A

B

C

25

3 6 On/Off

Fig. 1-10 Button and indicator functions in the EDS mode

Bank Switch Function ON OFF

A-1 Emulation Standard/Epson IBM

A-2 Auto Emulation Change (AEC) mode Enabled Disabled

A-3 RAM usage Input buffer Download buffer

A-4 Ribbon save mode Enabled Disabled

A-5 Time out paper eject Enabled Disabled

A-6 Page length Letter/11" A4/11.7"

B-1 Auto LF with CR Disabled Enabled

B-2 (Not used)

B-3 (Not used)

B-4 Font selection Roman H-Gothic

B-5 Epson character table Graphics Italics

B-6 IBM character table IBM #2 IBM #1

C-1

C-2 International character set (See table below)

C-3

C-4

C-5 IBM Code Page (See table below)

C-6

Country C-1 C-2 C-3

U.S.A. ON ON ON

France OFF ON ON

Germany ON OFF ON

England OFF OFF ON

Denmark I ON ON OFF

Sweden OFF ON OFF

Italy ON OFF OFF

Spain I OFF OFF OFF

IBM Code Page C-4 C-5 C-6

#437 U.S.A. ON ON ON

#850 Multi-lingual OFF ON ON

#860 Portuguese ON OFF ON

#861 Icelandic OFF OFF ON

#863 Canadian French ON ON OFF

#865 Nordic OFF ON OFF

– 11 –

GENERAL SPECIFICATIONS

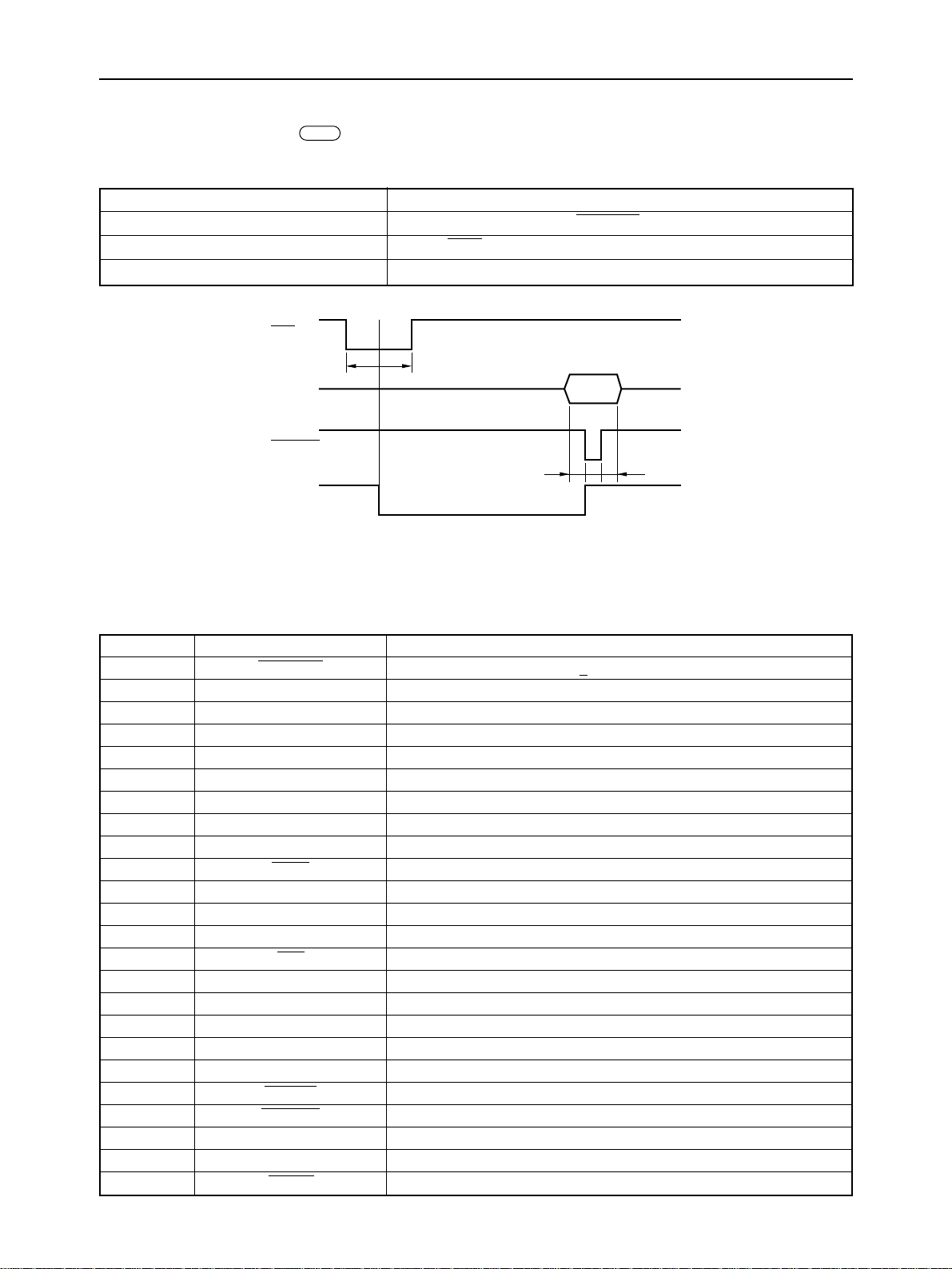

4. Parallel Interface

PC

4-1. General Specifications

Item Specifications

Synchronization System Via externally supplied STROBE pulse

I/F Protocol By ACK and BUSY signals

Logic Level Compatible with TTL level

ACK

5µs5µs

Data

STROBE

BUSY

T: More than 0.5µs

Fig. 1-11 Timing Charts of Parallel Interface

T

TT

4-2. Connector Signals

Pin No Signal Name Function Description

1 STROBE Goes from high to low (for≥ 0.5µs) when active.

2 DATA0 High when active.

3 DATA1 High when active.

4 DATA2 High when active.

5 DATA3 High when active.

6 DATA4 High when active.

7 DATA5 High when active.

8 DATA6 High when active.

9 DATA7 High when active.

10 ACK 10µs low pulse acknowledges receipt of data.

11 BUSY Low when printer ready to receive data.

12 PAPER OUT High when paper out.

13 SELECT High when printer is on-line.

14 AF0 Unused.

15 NC Unused.

16 SIGNAL GND Signal ground.

17 CHASSIS GND Chassis ground.

18 +5V +5V DC output from printer (Max. 40 mA)

19 ~ 30 GND Twisted pair ground return.

31 RESET When this input signal is low, printer is reset.

32 ERROR Outputs low when printer cannot continue, due to an error.

33 SIGNAL GND Signal ground.

34 ~ 35 NC Unused.

36 SELIN Unused.

– 12 –

GENERAL SPECIFICATIONS

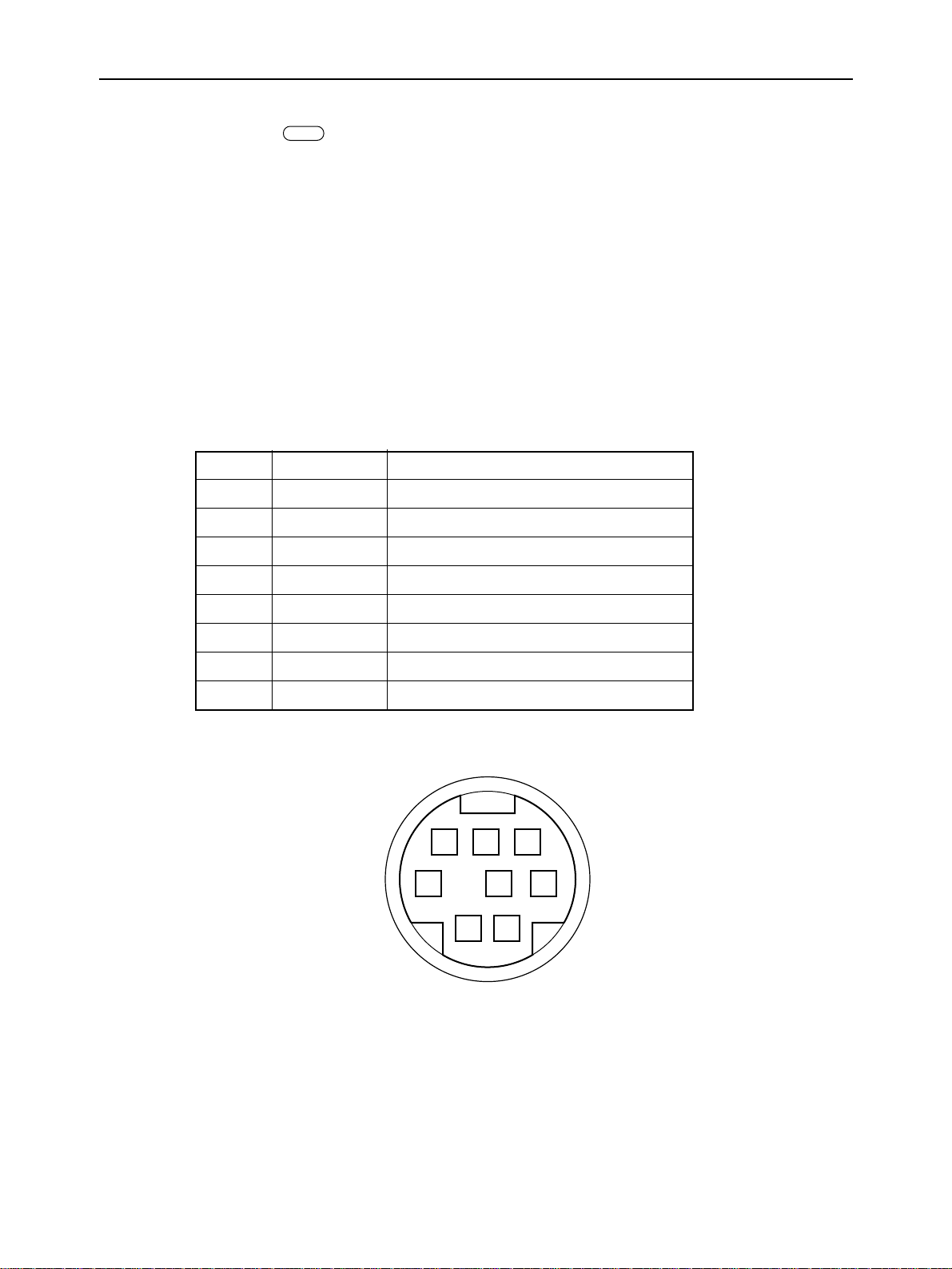

5. Serial interface

Transmission method

Standard : RS-422 Serial

•

• Transmission system : all dual

• Transmission speed : 57,600 bps

• Deviation : +0.23%

Data format

Data length : 8 bits

•

• Start bit : 1 bit

• Stop bit : 1 bit

• Parity bit : none

Connector

Mini Din serial port connector or equivalent

•

Pin Signal name Description

1 OPEN

2 OPEN

3 TxD – Data transmitted from the printer (negative)

4 GND Ground potential for all data

MAC

5 RxD – Data transmitted to the printer (negative)

6 TxD + Data transmitted from the printer (positive)

7 OPEN

8 RxD + Data transmitted to the printer (positive)

678

543

12

Fig. 1-12 Connector pin specifications

– 13 –

GENERAL SPECIFICATIONS

– 2 –

CHAPTER 2

THEORY OF OPERATION

This chapter explains the principles of the electric circuits and the mechanisms.

1. Block Diagram .....................................................................................................17

2. Main logic Board .................................................................................................19

2-1. Parallel Interface....................................................................................................... 19

2-2. Serial interface input/output circuit .................................................................... 20

2-3. General Flow Chart ............................................................................................... 21

2-3-1. Editing ............................................................................................................... 22

2-3-2. Print Head Drive Circuit................................................................................... 22

2-3-3. Motor Driving Circuit........................................................................................ 23

3. Power Supply Circuit ..........................................................................................24

2

4. Mechanism...........................................................................................................25

4-1. Printing Mechanism.............................................................................................. 25

4-1-1. Identification of Ribbon/Label Cartridge........................................................ 26

4-1-2. Feature for Pressing Head and Reeling Ink Ribbon...................................... 27

4-1-3. Ribbon Detector ............................................................................................... 30

4-2. Print Head Carrying Mechanism ......................................................................... 30

4-3. Paper Feed Mechanism........................................................................................ 31

4-3-1. Routes of Paper Sheet Passage ..................................................................... 31

4-3-2. Paper Support and Release............................................................................. 32

4-3-3. Paper End Detector.......................................................................................... 32

4-3-4. Auto Loading Detector..................................................................................... 33

THEORY OF OPERATION

– 16 –

THEORY OF OPERATION

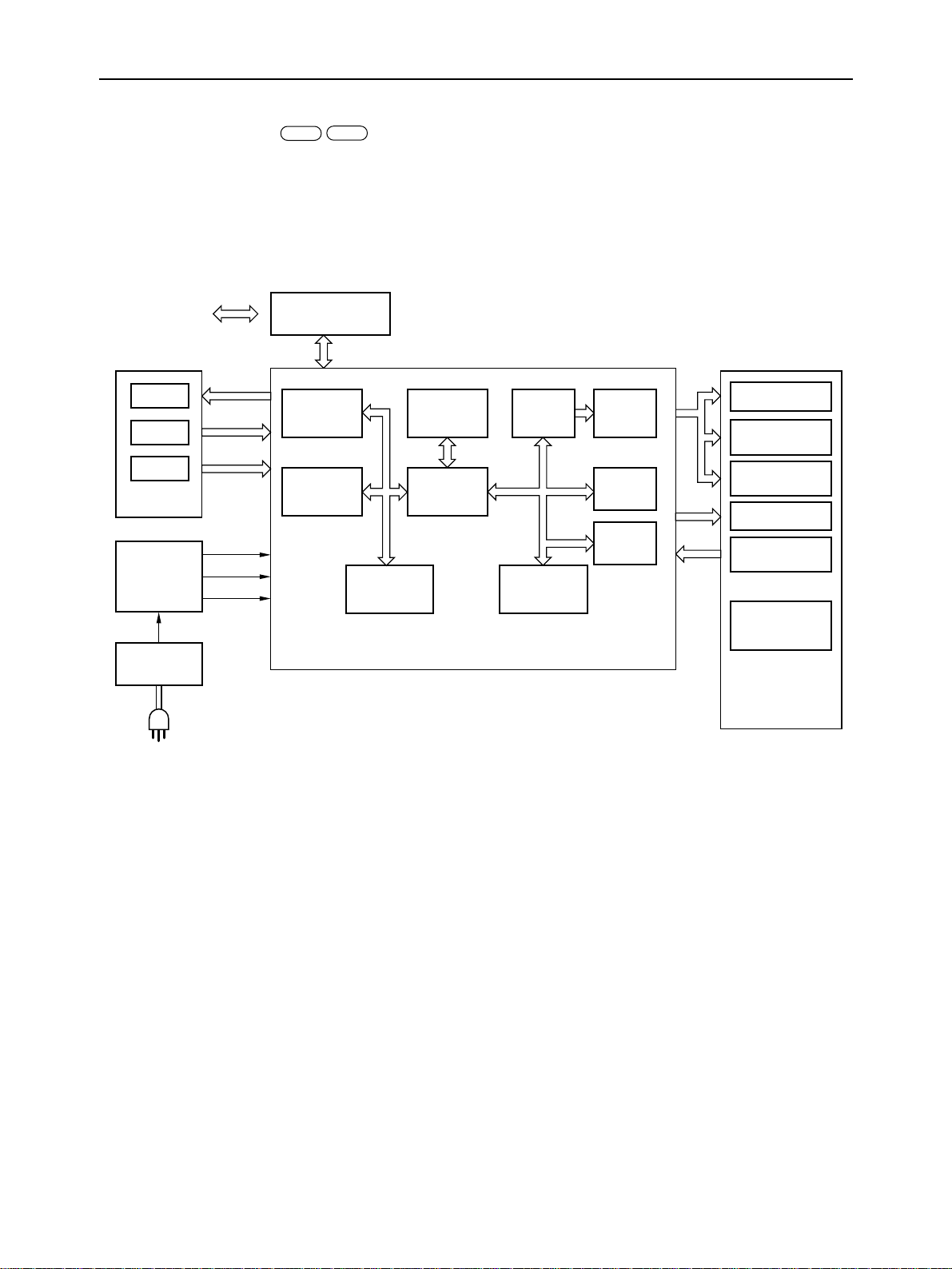

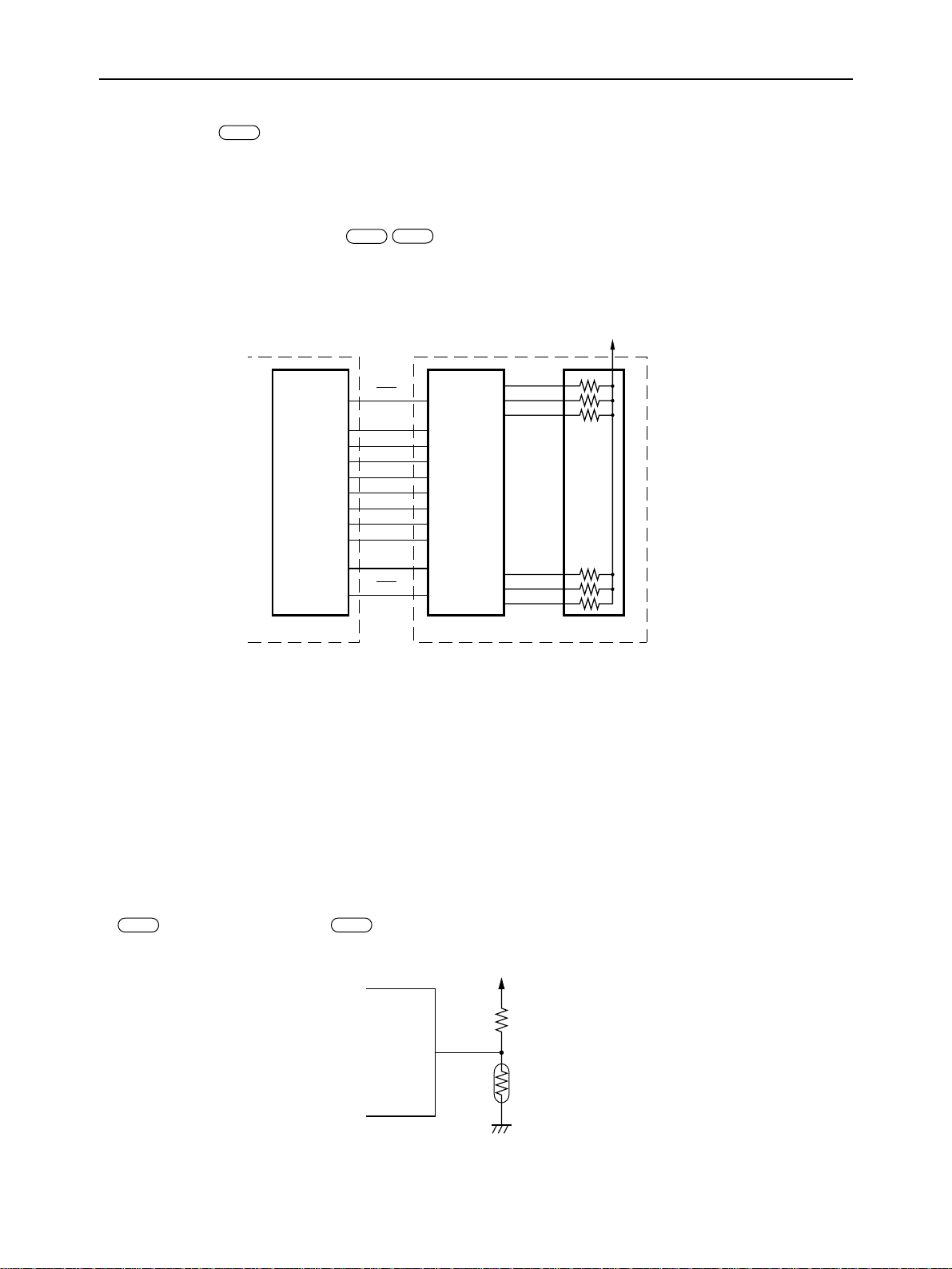

1. Block Diagram

MACPC

The block diagram of this printer is shown in Fig. 2-1.

Data

(From computer)

Lamp

Switch

Detector

Control

Panel Board

DC/DC

Converter

24VDC

AC Adapter

I/F Connector

Unit

Parallel

Interface

Masked

ROM(IC7)

28~40VDC

24VDC

5VDC

(Interface PC : Parallel MAC : Serial)

(Masked ROM IC3 and IC7 PC : 78k II, V25 MAC : 78k II MC, V25MC)

RAM

(IC24,25)

(IC6)

CPU

(IC5)

Main Logic Board

LSI

LSI

(IC2)

CPU

(IC1)

Motor

Driver

ETCC

(IC4)

Masked

ROM(IC3)

Carriage Motor

Paper Feed

Motor

Ribbon Feed

Moter

Print Head

Detectors

Automatic

Sheet Feeder

Fig. 2-1 Block Diagram

Printer

Machanism

– 17 –

THEORY OF OPERATION

(1) Main Logic Board

This board receives the data from the computer and stores it in the RAM in the order of arrival. The CPU on this

board reads the data from the RAM, and edits it according to the program stored in the masked ROM.

When the editing is completed, various drive signals from the CPU are sent to the printer mechanism to perform

printing.

<Explanation>

1. CPU uPD78213 (IC 1)

Carries out most of printer mechanism control, and emulations control.

2. CPU uPD70325 (IC 5)

Controls the character font and parallel interface.

3. LSI ETCC (IC 4)

Controls the thermal compensation for the print head.

4. LSI uPD91316 (IC 2)

Carries out motor control and part of printer mechanism control.

5. LSI uPD65640 (IC 6)

Controls the RAMs (IC24 and IC25).

(2) Control Panel Board

This board is provided with LEDs which display the operating condition of the printer and control switches which

are used to set each mode.

(3) Printer Mechanism

The printer mechanism consists of a print head, carriage motor, paper feed motor, ribbon feed motor, detectors, and

automatic sheet feeder.

(4) AC Adapter

Converts AC voltage into 24 VDC.

(5) DC/DC Converter

Converts 24 VDC into 28 to 40 VDC, and 5 VDC for the logic circuit.

– 18 –

THEORY OF OPERATION

2. Main logic Board

2-1. Parallel Interface

Communications between the computer and this printer are facilitated via parallel interface. The circuit of this interface

is shown in Fig. 2-2.

CN6

PC

DATA 0

DATA 7

STROBE

BUSY

ACK

IC18

LS373

D1

D8

Q1

Q8

EN

D0

D7

STB

BSY

ACK

IC6

CPU

MD0

MD8

WE

IC24

RAM

IO1

IO4

WE

IC25

RAM

IO1

IO4

WE

Fig. 2-2 Data Input Circuit with Parallel Interface

The following is an explanation of this handshake.

(1) When the BUSY signal is LOW (Ready), the computer outputs 8-bit data 0 through 7 to the connector CN6. The

computer carries the STROBE pulse signal to the printer. This signal is normally held HIGH by the computer. When

the computer has data ready for the printer, it sets this signal to LOW for at least 0.5 µs.

(2) The CPU turns the BSY signal LOW at the fall of the STROBE signal. IC18 latches data at the rise of the STROBE

signal.

(3) When the BSY signal goes LOW, the BUSY signal through connector CN6 turns HIGH, and the computer is

informed that the printer cannot receive data.

(4) The CPU reads in data from IC 18 for storage in the RAM. When the reading-in is completed, the CPU turns the

BSY and ACK signals HIGH.

(3) When both the BSY and ACK signals output from the CPU turn HIGH, both the BUSY and ACK signals output

through connector CN6 go LOW, and the computer is informed that the printer can receive data and sends the

following data to the printer.

ACK

Data

STROBE

BUSY

5µs5µs

TT

T: More than 0.5µs

Fig. 2-3 Timing chart of Parallel Interface

– 19 –

T

THEORY OF OPERATION

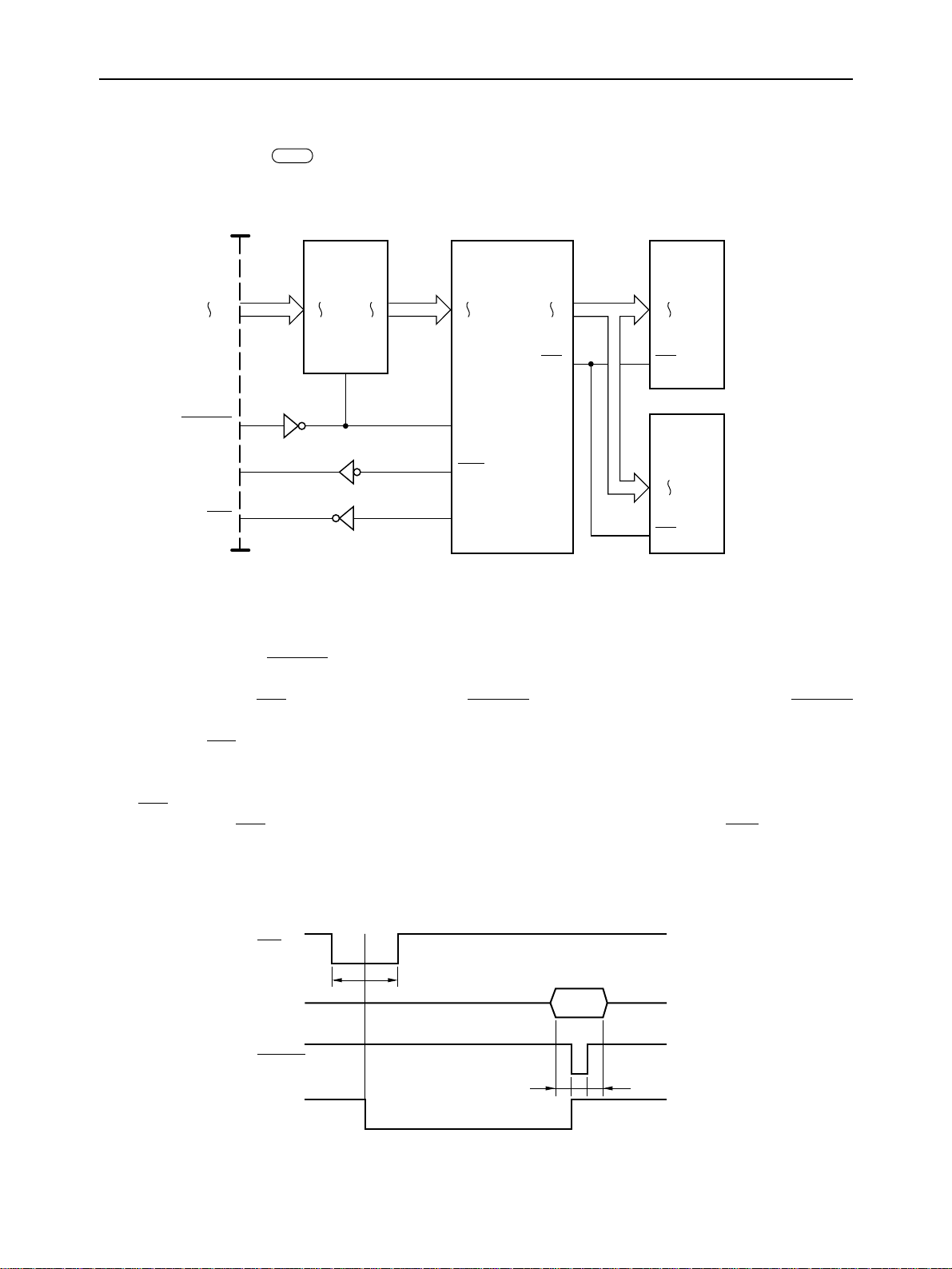

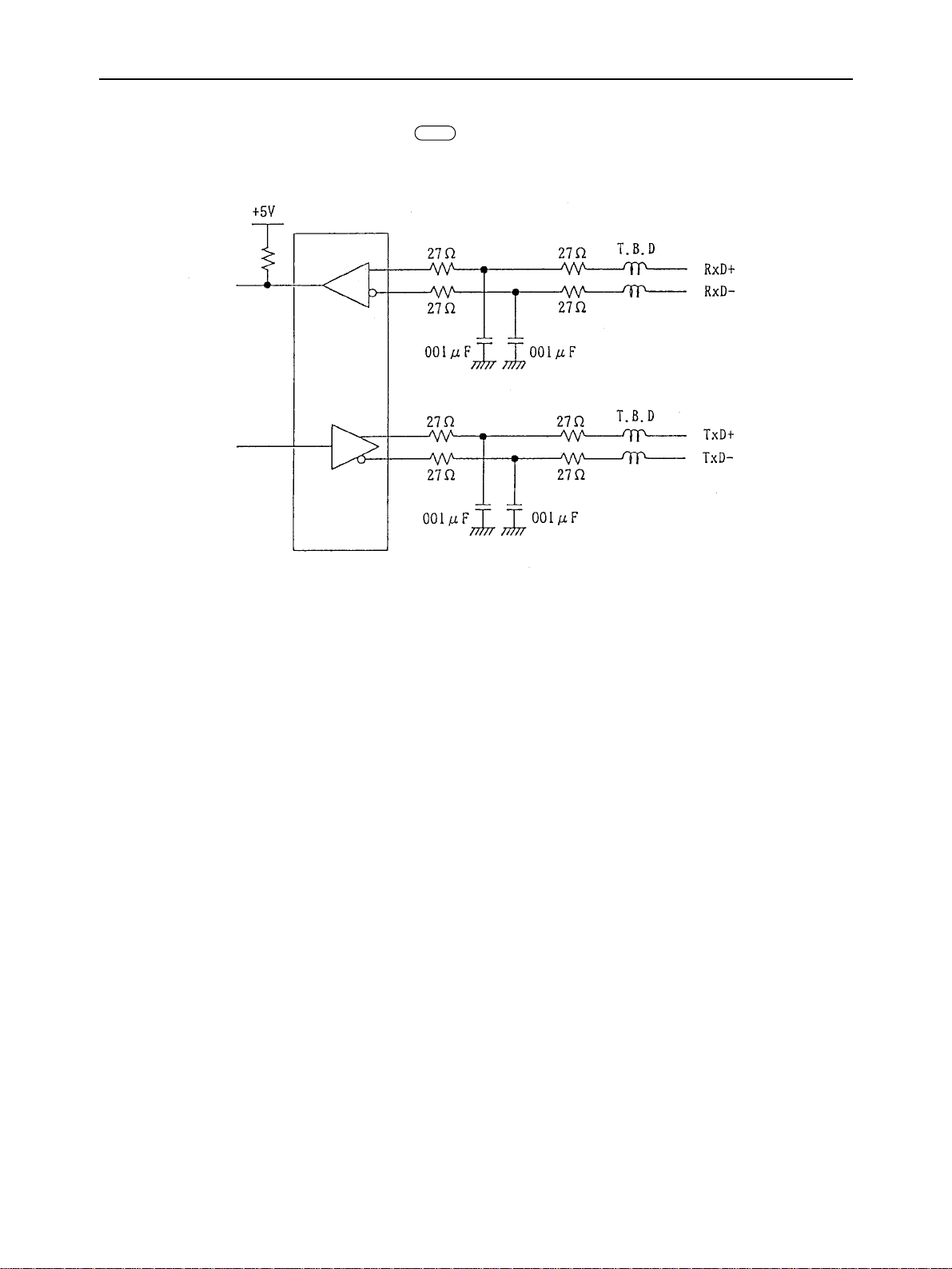

2-2. Serial interface input/output circuit

To CPU port

From CPU port

IC26

MAC

Fig. 2-4 Input/output circuit

IC26 is an RS-422 driver/receiver equipped with an internal transformer which can generate from the +5V power supply

the ±2~5V necessary for RS-422 output. Thus it can convert between RS-422C and TTL signals. Data transmitted by the

host computer is input to the CPU from RXD via IC26. The serial data input to the CPU is converted to parallel data in

the CPU, then output to the main logic board. Conversely, parallel data is converted to serial data in the CPU and output

on TXD via IC26.

– 20 –

THEORY OF OPERATION

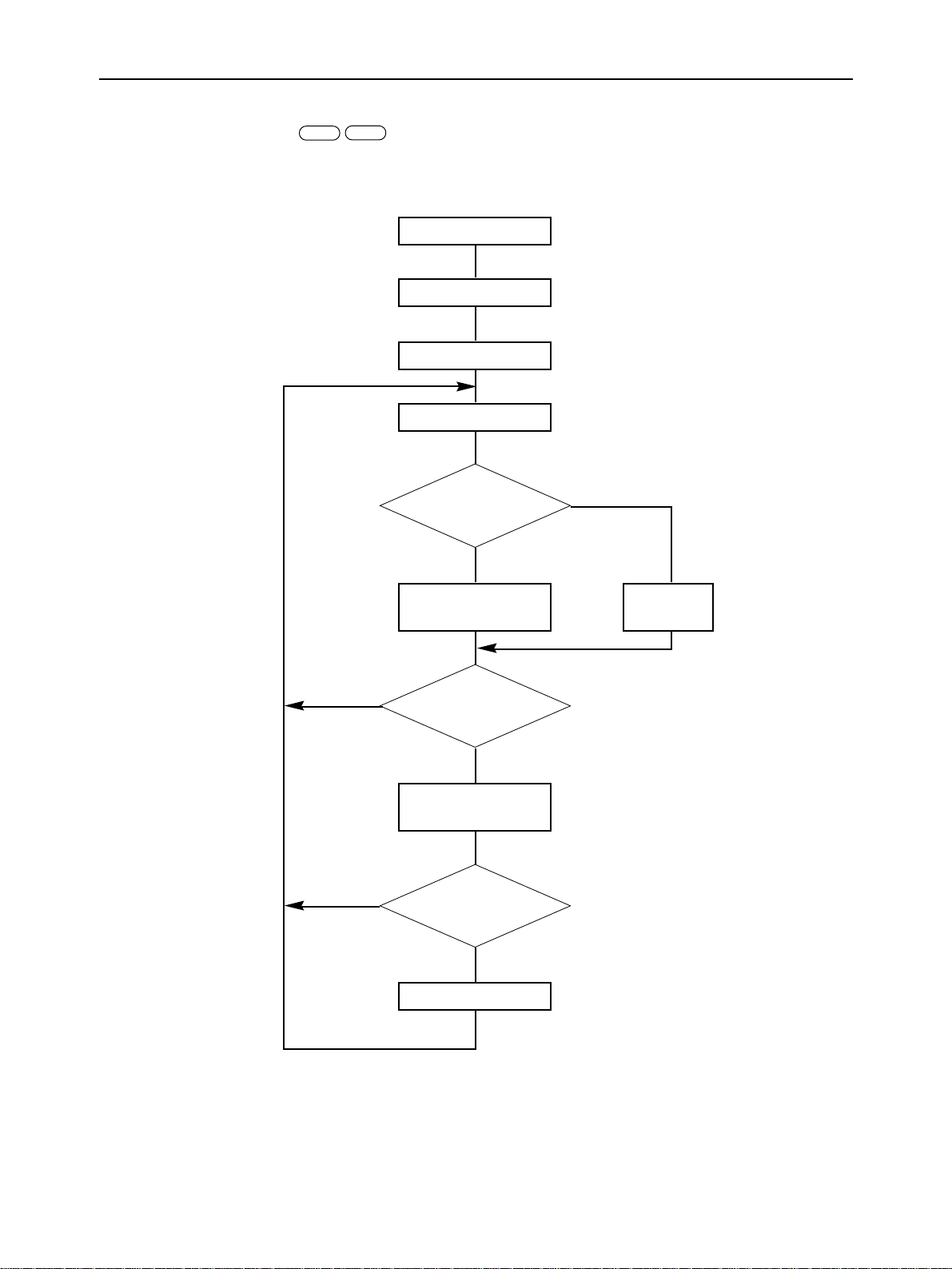

2-3. General Flow Chart

PC

MAC

A general flow chart of editing and printing operations are presented in Fig. 2-5.

POWER ON

Initialization

Ready State

Read Data

Control Code?

NO

YES

NO

NO

Control Code

Processing

Print?

YES

Data Processing

or Printing

Return?

YES

Return Action

Data

Storage

(Line buffer detemination)

(Print out of data)

Fig. 2-5 General Flow Chart of Editing and Printing

– 21 –

THEORY OF OPERATION

2-3-1. Editing

PC

Data stored in the RAM is read out sequentially by the CPU and then edited according to a function code that has been

specified in advance.

This editing takes places until the line buffer becomes full.

MAC

2-3-2. Print Head Drive Circuit

PC

The print head contains 144 heating resistor elements. Data is printed by switching ON and OFF each of the elements.

The print head also incorporates a driver with a data latch function.

IC4 (ETCC) functions as a thermal head controller. It sends 18 bytes of data in units of 8 bits (8 bits × 18 bytes = 144

bits) to the head driver as one row of data in sync with the HCLK signal.

HD1

HD2

HD3

HD142

HD143

HD144

IC4

ETCC

HEN

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HCLK

HLT

Driver

Vhd (28~40V)

Main Logic Board Print Head

Fig. 2-6 Print Head Drive Circuit

• Printing density depends on the heat accumulated on the print head, the ambient temperature, the ink ribbon type and

the dispersion of the thermal print head resistance. IC4 controls the printing energy by changing the heat energizing

period in accordance with data such as the heat accumulated on the print head, ambient temperature and the ink ribbon

type, to provide the optimum print density. To provide against the dispersion of the thermal print head resistance, DC/

DC converter controls print head voltage Vhd. This control process is explained in “Power Supply Circuit” in item

3.

The heat accumulated on the print head is determined by reading past data of energizing a specific heating resistor

element (whether the element is energized over the last 1-4 dots) and past data records of the adjacent elements (whether

the elements are energized over the last 1-3 dots).

• Ambient temperature is measured by the ambient temperature detection circuit in the control panel unit for the

????? and the carriage unit for the ??????. The circuit reads the voltage divided by the 10 kΩ resistor and the thermistor

MACPC

at analogue input port PT2 of the CPU, and the CPU calculates the temperature on the basis of the read voltage.

+5V

R148

PT2

IC5

CPU

Thermistor

Fig.2-7 Ambient temperature detection circuit

• Ink ribbon types are identified depending on whether each of the three cassette switches is turned ON or OFF, to detect

the type of the ribbon cartridge or the label cartridge set on the carriage unit.

– 22 –

THEORY OF OPERATION

MAC

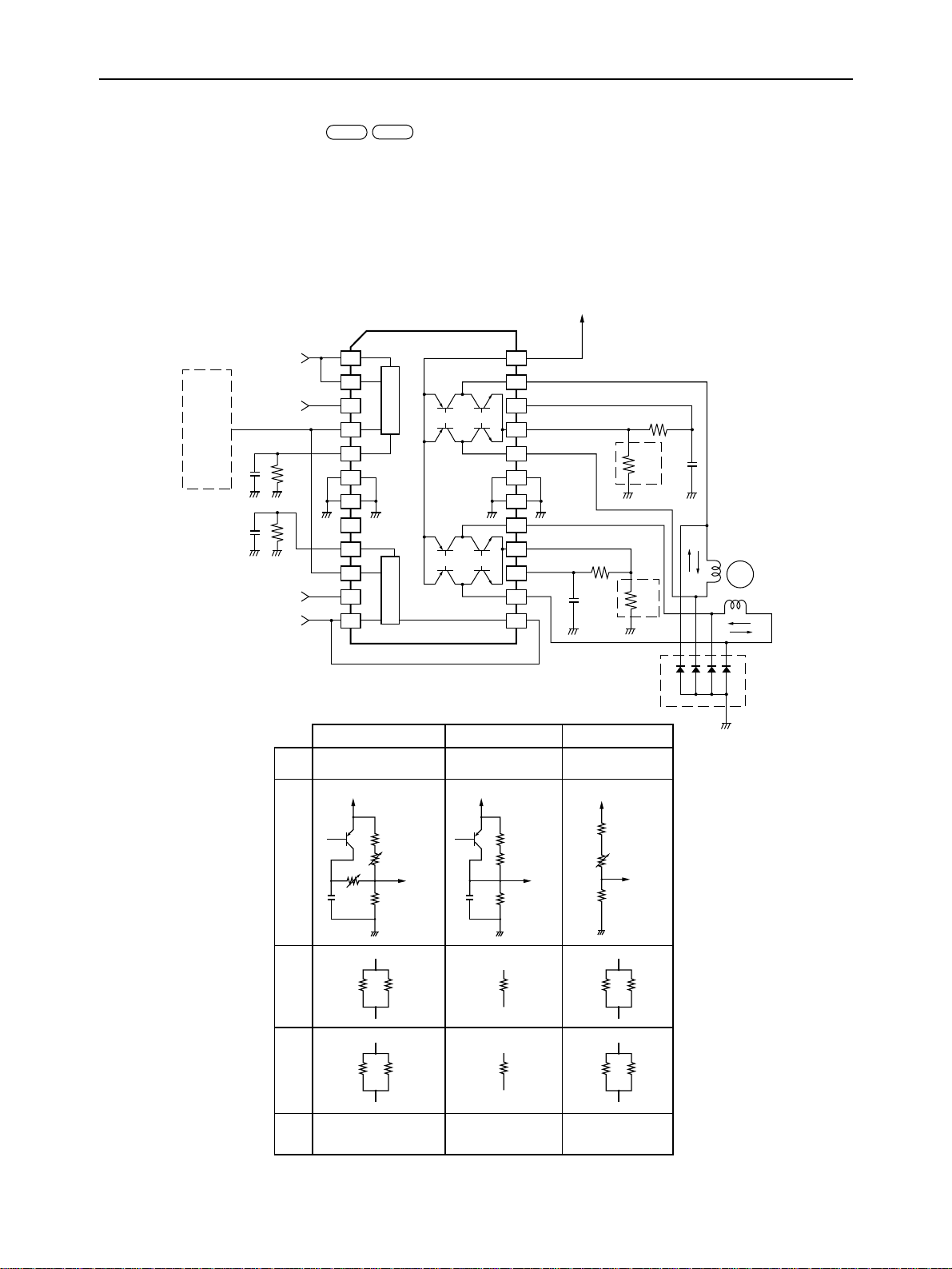

2-3-3. Motor Driving Circuit

The carriage motor, the paper feed motor and the ribbon feed motor are implemented as bipolar-type pulse ones. Any

of their drive circuits is based on chopper-type constant current control.

The three motor drive circuits have the same configuration, and employ driver ICs (UDN2916) as their main parts. The

three circuits are different in reference voltage VREF, current detection resistance RS and use of diodes. The diodes are

used to prevent the motor and driver IC (UDN2916) from generating heat.

Current IO through the motor is calculated by the following equation:

IO =K × VREF/RS

where, K: constant

PC

+24V

UDN 2916

Control 3

Control 1

V

REF

Control 0

Control 2

1

2

3

4

5

6

7

8

5V V

9

10

11

12

CC

PWM 2PWM 1

24

23

2

22

21

20

S

R

19

18

17

1

16

15

14

R

13

ø3

ø2

S

M

ø1

ø0

Diode

Carriage Motor Paper Feed Motor Ribbon Feed Motor

IC IC11 IC10 IC12

+5V

+5V

+5V

TR5 TR11

REF

V

R

S1

R

S2

Diode

R226

VR3

VR4

R228

Mounted Not mounted Mounted

Fig. 2-8 Motor Driving Circuit

R217

REF

V

R222R265 R213 R261R267

R224R266 R215

R219

REF

V

– 23 –

R256

VR5

R258

REF

V

R263R268

THEORY OF OPERATION

MAC

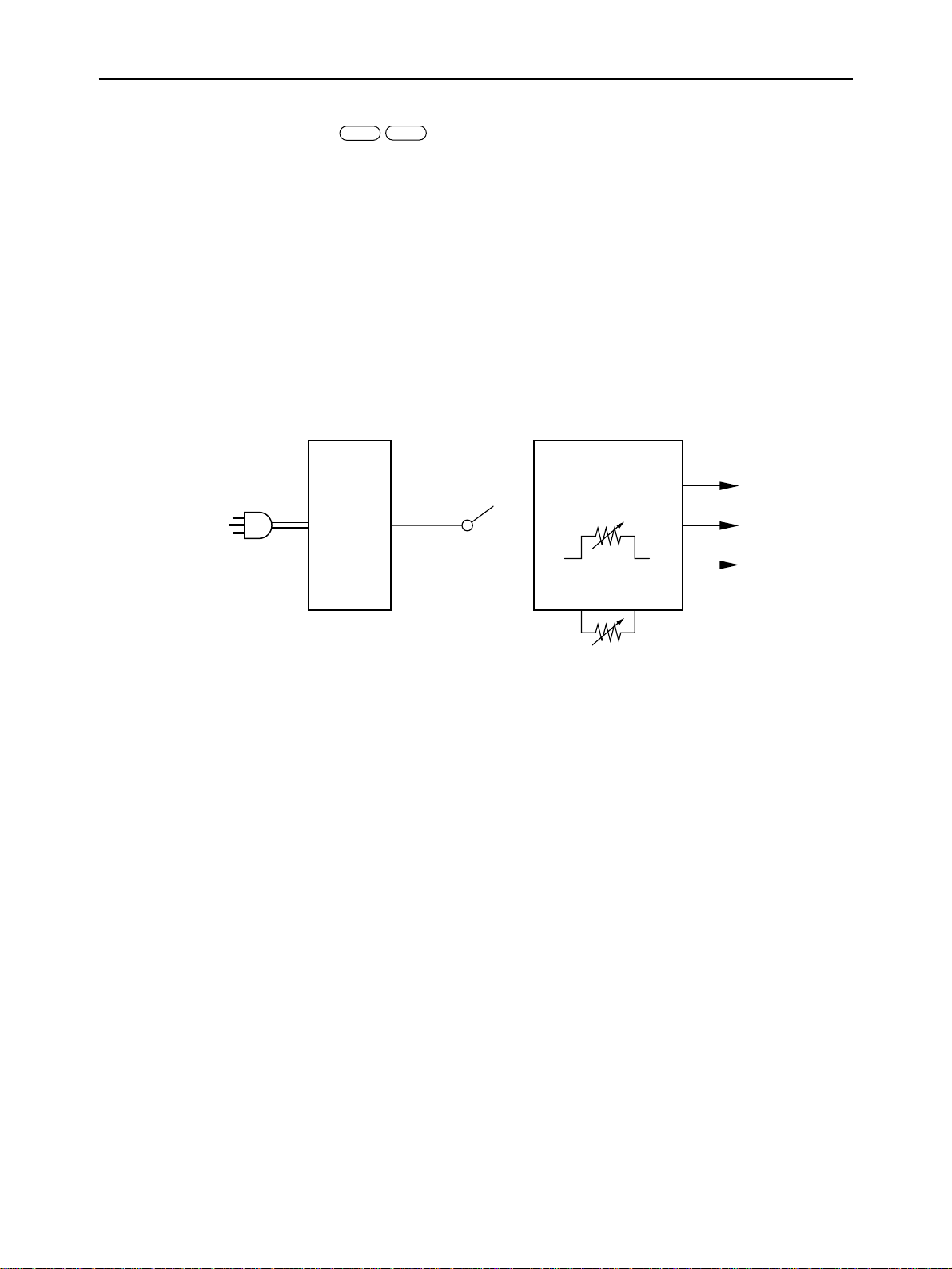

3. Power Supply Circuit

Commercial AC voltage is converted into 24 VDC by an AC adaptor. The voltage of 24 VDC is converted into three types

of DC voltage by the DC/DC converter unit. These three types of DC voltage are 5 volts for the control circuit, and 24

volts for motor, and 28 to 40 voltages for the print head.

The voltage applied for the print head is variable from 28 to 40 VDC using potentiometers for printing density adjustment

VR1 and for the head rank VR2.

Potentiometer VR1 can be controlled by turning the printing density dial by the user. Potentiometer VR2 functions to

compensate for the dispersion of the thermal print head resistance in accordance with the resistance of the thermal print

head.

For adjusting the potentiometers, see Item 1 in Chapter 3.

PC

100~120VAC

220~240VAC

AC

Adapter

24VDC

Power Switch

Fig. 2-9 Power Supply Circuit

DC/DC

Converter

VR2

VR1

5VDC

24VDC

28~40VDC

– 24 –

THEORY OF OPERATION

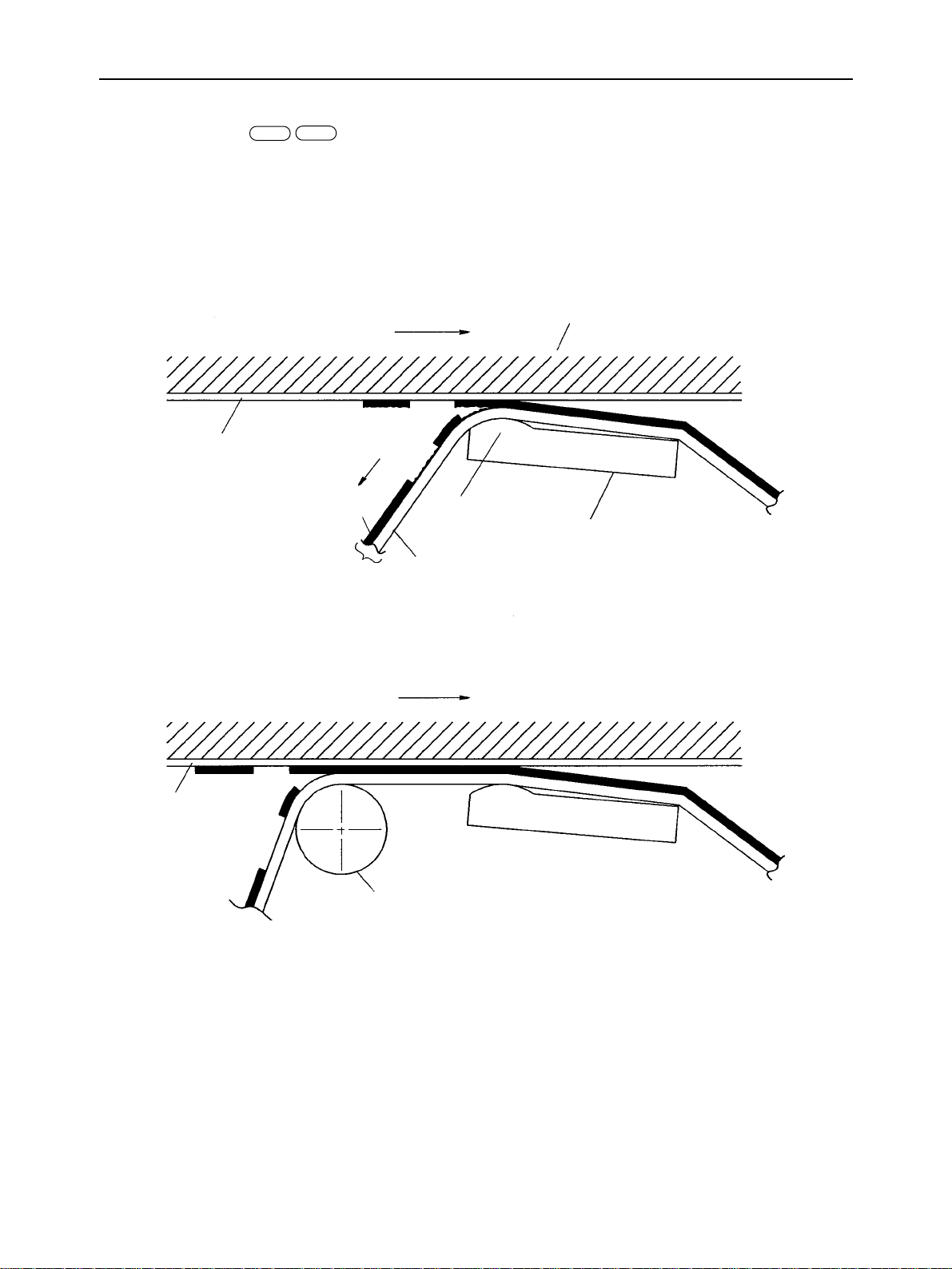

4. Mechanism

MACPC

4-1. Printing Mechanism

The printing mechanism is composed of a print head, an ink ribbon and a platen incorporated in a carriage unit. The print

head is of a thermal type, comprising a ceramic board provided with 144 heating elements. Applying current to and heating

the thermal head melts ink on the ink ribbon (film ribbon) for transcription onto a paper sheet. An ink ribbon for an OHP

is such that the roller comes by the side of the thermal head to delay the timing at which the ink ribbon is pulled off a OHP

film.

Printing for Plain Paper, Label

Platen

Printing Direction

Paper or Label

Ribbon Reel

Ink

Ink Ribbon

Heating Element

Thermal Head

Base Film

Printing OHP Film

OHP Film

Printing Direction

Roller

Fig. 2-10 Principle of thermal transcription strategy

– 25 –

THEORY OF OPERATION

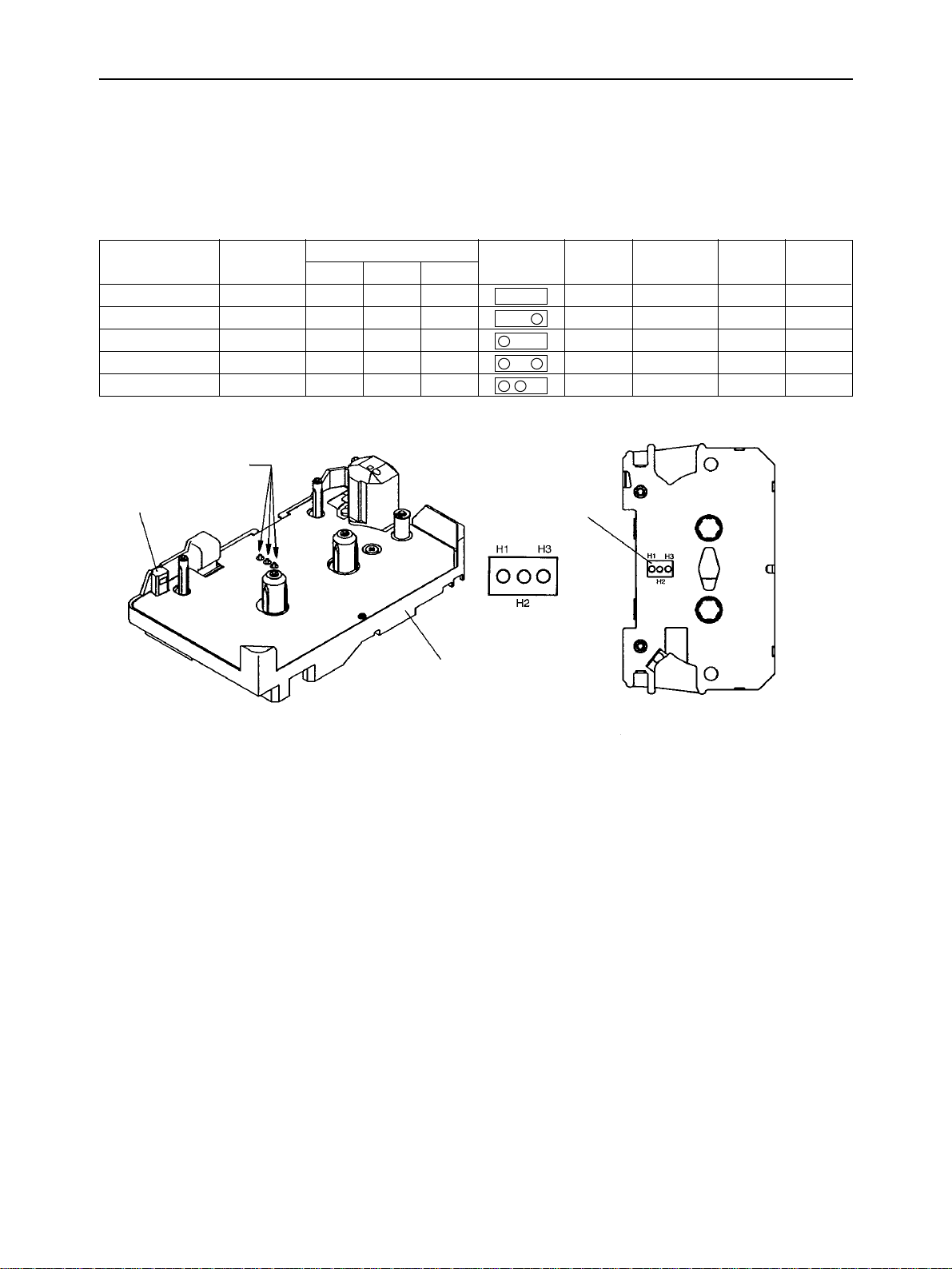

4-1-1. Identification of Ribbon/Label Cartridge

The ribbon cartridge and the label cartridge are holed for type identification. The carriage unit is provided with three

cassette switches (three pins) for sensing this hole. The pins play a role as a switch to identify the type. Depending on

the type, a number of factors are varied which include the carriage speed, the period of energizing the print head, pressing

force and the timing at which the ink ribbon is pulled off the paper sheet.

Ribbon/Label Type

OHP Monochrome

OHP Color

Color

Monochrome

Label

Cassettl Switch

Ribbon Detector

Print Media

OHP Film

OHP Film

Paper

Paper

Itself

Holes

H1 H2 H3

Closed Closed Closed

Closed Closed Opened

Opened Closed Closed

Opened Closed Opened

Opened Opened Closed

Carriage Unit

View

Hole for cartridge

Identification

Carriage

Head energiz-

Speed

Low

Low

High

High

Low

ing period

Long

Long

Long

Short

Longest

Bottom View of Ribbon/

Label Cartridge

Pressing

force

High

High

Low

Low

High

Pulling

timing

Slow

Slow

Fast

Fast

Fast

Fig. 2-11 Identification of ribbon/label cartridge

– 26 –

Loading...

Loading...