Page 1

SHALLOW WELL JET PUMP

STAR

MODEL SJ05S 1/2 HP

®

starwatersystems.com

Questions, problems, missing parts? Before

returning to your retailer, call our customer service

STOP

department at 1-800-742-5044, 7:30 a.m. - 5 p.m.,

EST, Monday - Friday.

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Español p. 18

Copyright © 2013 Star Water Systems. All rights reserved.

1

FW1626 A

Page 2

Product Specications ......................................................................................................................2

Safety Information ............................................................................................................................2

Package Contents ............................................................................................................................4

Preparation .......................................................................................................................................4

General Pump Information ...............................................................................................................5

Well to Pump Connection .................................................................................................................6

Pump to Tank Connection ................................................................................................................9

Tank to House Connection .............................................................................................................10

Pump Electrical Connections..........................................................................................................11

Pump Priming and Startup .............................................................................................................13

Care and Maintenance ...................................................................................................................15

Warranty .........................................................................................................................................15

Troubleshooting ..............................................................................................................................16

Replacement Parts .........................................................................................................................17

PRODUCT SPECIFICATIONS

Power supply required ...........................................................................115 volts or 230 volts, 60 Hz

(Pump is set by the factory to run on 230 volts)

Maximum water temperature ...........................................................................................77°F (25°C)

Individual branch circuit required ............................................................................15 Amp minimum

Discharge connection .......................................................................................................... 1 in. NPT

Suction connection ........................................................................................................1-1/4 in. NPT

Motor duty..................... Continuous duty with enforced air cooling and thermal overload protection

Pressure switch ........................................................................... Preset at 20 PSI “on” / 40 PSI “off”

Water depth rating ................................................................................................. Maximum of 25 ft.

CAPACITY - U.S. GALLONS PER

MODEL HP VOLTAGE HZ AMP

SJ05S 1/2 115/230 60 7.8/3.6 9.5 6.5 3.5

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the

product.

MINUTE AT DISCHARGE 20 PSI

5 FT. 15 FT. 25 FT.

SAFETY INFORMATIONTABLE OF CONTENTS

DANGER

ELECTRICAL SHOCk HAZARD.

Always disconnect power source before performing any work on or near the motor or its

connected load. If the power disconnect point is out-of-sight, lock it in the open position

and tag it to prevent unexpected application of power. Failure to do so could result in

fatal electrical shock.

ELECTRICAL SHOCk HAZARD.

Do not handle the pump with wet hands or when standing in water as fatal electrical

shock could occur. Disconnect main power before handling unit for ANY REASON!

RISk OF ELECTRIC SHOCk.

These pumps have not been investigated for use in swimming pool areas.

WARNING

ELECTRICAL SHOCk ALERT.

Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and

the Occupational Safety and Health Act (OSHA).

ELECTRICAL SHOCk ALERT.

Replace damaged or worn wiring cord immediately. Never use an extension cord.

ELECTRICAL SHOCk ALERT.

Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces, or chemicals.

ELECTRICAL SHOCk ALERT.

Wire motor to correct supply voltage. See motor nameplate and wiring diagrams and check

voltage of power supply.

ELECTRICAL SHOCk ALERT.

Unit must be securely and adequately electrically grounded. This can be accomplished by

wiring the unit to a ground metal-clad raceway system or by using a separate ground wire

connected to the bare metal of the motor frame or other suitable means.

ELECTRICAL SHOCk ALERT.

Do not disassemble the motor housing. This pump has no repairable internal parts and

disassembling may cause leakage or dangerous electrical wiring issues.

ELECTRICAL SHOCk ALERT.

Make certain the electrical power source is adequate for the requirements of the pump.

ELECTRICAL SHOCk ALERT.

Never use an extension cord with this pump.

CHEMICAL ALERT.

This product contains chemicals known to the state of California to cause cancer and birth

defects or other reproductive harm.

HAZARDOUS PRESSURE ALERT.

Install pressure relief valve in discharge pipe. Release all pressure on system before working

on any component.

ExPLOSION ALERT

Do not use to pump ammable or explosive uids such as gasoline, fuel oil, kerosene, etc.

Do not use in ammable and/or explosive atmospheres.

Copyright © 2013 Star Water Systems. All rights reserved.

2

Copyright © 2013 Star Water Systems. All rights reserved.

3

Page 3

SAFETY INFORMATION

GENERAL PUMP INFORMATION

CAUTION

PRODUCT DAMAGE MAY RESULT

This pump is not to be used for irrigation or water systems.

PRODUCT DAMAGE MAY RESULT

Protect the power cable from coming in contact with sharp objects.

PRODUCT DAMAGE MAY RESULT

Do not run pump dry.

PRODUCT DAMAGE MAY RESULT

Pump and plumbing must be full of water before startup.

PRODUCT DAMAGE MAY RESULT

Do not pump water which contains sand, mud, silt, or debris.

INJURY MAY RESULT

Be careful when touching the exterior of an operating motor. It may be hot enough to be painful or

cause injury.

PACkAGE CONTENTS

Description Quantity

Pump 1

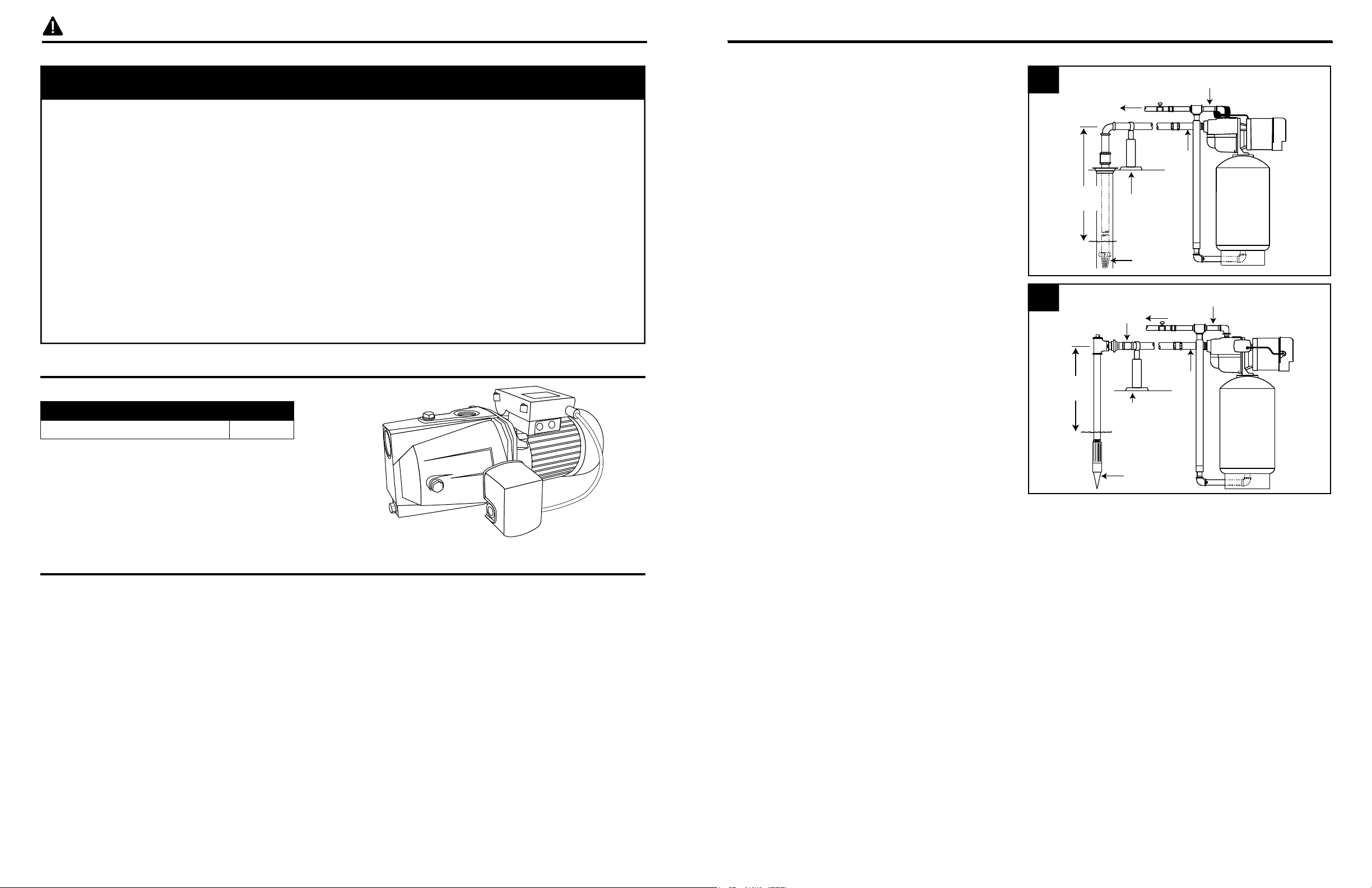

Typical Pump Setup

1. Shallow well jet pumps are designed for use

where the suction lift is 25 ft. or less. They

can be used with drilled or cased wells.

2. Jet pumps can also be used with dug wells,

driven wells or with cisterns or lakes.

1

2

Suction

Lift

25 ft.

Max

Suction

Lift

25 ft.

Max

Discharge

to Home

Pipe

Support

Water Level

Foot Valve

Check

Valve

Discharge

to Home

Pipe

Support

Water Level

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

IL1104

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

PREPARATION

Before beginning installation of product, make sure all parts are present. If any part is missing or

damaged, do not attempt to assemble the product. Compare parts to package contents list.

Estimated Installation Time: 2 hours.

Tools Required for New Installation (not included): pipe wrench, pliers, Phillips screwdriver, pipe clamp,

2-step PVC glue system (primer and sealer), thread tape, tire gauge or compressor

Parts Required for New Installation (not included): well seal, 1-1/4 in. to 1 in. male PVC adapter (2),

1-1/4 in. male PVC adapter, 1 in. male PVC adapter, 1-1/4 in. foot valve, 1-1/4 in. PVC pipe and

couplings, 1 in. PVC pipe and couplings, 1-1/4 in. PVC elbow, 1 in. PVC elbow, 1 in. discharge tee,

galvanized bushing, pressure gauge (optional) or pipe plug, 1-1/4 in. union (optional), 1 in. union

(optional), electrical wire, electrical wire strain relief, 1 in. x 1 in. x 1 in. tee, 3/4 in. x 3/4 in. slip coupling,

1 in. x 1 in. slip adapter, 1 in. x 3/4 in. slip adapter

Drive Point

IL1472

Ventilation - Ventilation and drainage must be provided to prevent damage to the motor from heat

and moisture.

Freezing - Pump and all piping must be protected from freezing. If freezing weather is forecast, drain

pump or remove completely from the system.

Water Supply - The water source must be able to supply enough water to satisfy the capacity of

pump and water needs. See performance chart on page 2.

Suction Lift - Suction lift is the vertical distance from the lowest level of the water to the pump intake.

Pump will move water as long as it is within 25 vertical ft. of the water source.

Horizontal Distance - The horizontal distance is the horizontal measurement between pump suction

and the water source. This distance may affect the ability of pump to operate. If it is more than 100 ft.,

call the manufacturer for assistance: 1-800-742-5044.

Copyright © 2013 Star Water Systems. All rights reserved.

4

Copyright © 2013 Star Water Systems. All rights reserved.

5

Page 4

GENERAL PUMP INFORMATION

WELL TO PUMP CONNECTION (SUCTION PIPE)

Pipe And Fittings

3. Use galvanized steel or NSF PW Schedule

40 PVC pipe and ttings. This material is

designed for water pressure and will seal

3

1 in. NPT

Discharge

1-1/4 in.

Suction

against air and water under pressure. Do

not use DWV ttings, as these are designed

for drains without pressure and will not seal

properly.

CAUTION: The entire system must be

air and water tight for efcient operation and to

maintain prime.

Wire Size:

The wire size is determined by the distance from the power source to the pump motor and the

horsepower rating of the motor. See the wire chart on page 11 for proper wire size.

WELL TO PUMP CONNECTION (SUCTION PIPE)

CAUTION: Dry-t entire assembly to ensure proper t before gluing or taping parts.

2. Using a 2-step PVC system (not included),

attach enough 1-1/4 in. PVC pipe and

couplings (not included) to the adapter to

equal the depth of the well, minus 5 ft.

3. Before sliding the pipe assembly into the

well, rmly clamp the assembly with a pipe

clamp (not included) to prevent the assembly

from sliding down into the well.

2

1-1/4 in. PVC pipe

3

Pipe clamp

25 ft. maximum

Water level

CAUTION: Follow all proper gluing procedures as specied by the glue manufacturer. Always

glue in a vertical direction whenever possible to prevent glue from dripping inside pipe or ttings

CAUTION: Use pipe tape and pipe paste compound on all male threads. Tighten with wrench to

a snug t and add another 1/4 turn to ensure proper seal.

1. Thread 1-1/4 in. male PVC adapter (not

included) into a 1-1/4 in. foot valve (not

included). Hand tighten, then tighten 1/2 turn

with a pipe wrench.

1

1-1/4 in. male

PVC adapter

1-1/4 in. Foot valve

4. Remove the pipe clamp and slide a well seal

(not included) over the PVC pipe and onto

the well casing. The PVC pipe should extend

approximately 12 in. above the top of the well

seal, depending on the height of the pump.

NOTE: Do not let the assembly slide down into the

well. Tighten the well seal until the rubber gaskets

are tight against the well casing and the PVC pipe.

5. Using a 2-step PVC system, attach a 1-1/4 in.

PVC elbow (not included) onto the rigid PVC

pipe extending from the well seal.

4

Well Seal

5

5 ft. minimum

Approx.

12 in.

1-1/4 in. PVC

Elbow

Copyright © 2013 Star Water Systems. All rights reserved.

6

Copyright © 2013 Star Water Systems. All rights reserved.

7

Page 5

WELL TO PUMP CONNECTION (SUCTION PIPE)

PUMP TO TANk CONNECTION (DISCHARGE PIPE)

6. Wrap thread tape (not included) around the

threads of a 1-1/4 in. male PVC adapter (not

included). Thread the adapter into the 1-1/4 in.

opening in the front of pump.

7. An optional 1-1/4 in. union (not included)

is recommended for easy connection and

disconnection.

6

7

1-1/4 in. male

PVC adapter

1-1/4 in. Union

1. Wrap thread tape around threads of a 1 in.

discharge tee (not included). Using a pipe

wrench, thread the 1 in. discharge tee into the

1 in. opening in the top of pump.

2. Install a 1 in. MPT x 1/4 in. FPT galvanized

bushing and (optional) pressure gauge (both

not included), or a pipe plug (not included). Do

not tighten, as you will prime pump later at this

location.

1

2

1 in. Discharge Tee

Pressure Gauge or

Pipe Plug with Bushing

8. Using 2-step PVC system, attach 1-1/4 in.

PVC pipe and couplings as needed to connect

the 1-1/4 in. male PVC adapter to the 1-1/4 in.

PVC elbow attached to the top of the well pipe

in Step 5.

NOTE: Be sure the pipe slopes downward slightly

from pump to the well to prevent air pockets.

8

1-1/4 in. PVC Pipe

Well

3. Wrap thread tape around the threads of a 1 in.

male PVC adapter (not included) and thread

the adapter into the discharge tee.

4. Continue with 1 in. ttings and pipe to

the pressure tank. An optional 1 in. union

(not included) is recommended for easy

connection and disconnection.

3

1 in. male PVC adapter

4

To pressure tank

1 in. union

Copyright © 2013 Star Water Systems. All rights reserved.

8

Copyright © 2013 Star Water Systems. All rights reserved.

9

Page 6

68

TANk TO HOUSE CONNECTION

TANk TO HOUSE CONNECTION

1. Most pressure tanks will have a 1 in. inlet

elbow on the bottom. Connect to this elbow

with a 1 in. MPT x 1 in. slip (glue) adapter and

short piece of pipe.

2. Attach a 1 in. elbow (not included) to the pipe.

1

2

Glue

Glue

Adapter

Pipe

Elbow

5. Attach the pipe from the pump to the tee

installed in Step 4. Then, from the tee,

install 3/4 in. pipe and optional shut off

valve (not included) to connect tee to

house plumbing.

6. IMPORTANT: Air pressure in the tank

must be 2 PSI lower than the “cut-in” of

the pressure switch. Pump has a 20/40

PSI pressure switch, so tank pressure

must be set at 18 PSI. Locate the air

valve/stem on the tank and check

pressure with a tire gauge (not included).

If air needs to be removed, press down on

valve to bleed off air. Use a tire pump or

air compressor to add air if needed.

5

From Pump

6

Air Valve/Stem

Glue

Shut off valve

To House

Plumbing

Tank

Tire gauge

3. Attach a 1 in. pipe (not included) to the elbow

and a 1 in. x 3/4 in. reducer bushing (not

included) to the pipe.

4. Attach a 3/4 in. pipe (not included) to the

reducer bushing. Install an optional 3/4

in. union (not included) and continue with

pipe and 3/4 in. x 3/4 in. x 3/4 in. tee (not

included).

3

4

1 in. x

3/4 in.

Reducer

Bushing

1 in. Pipe

Glue

Tee

Glue

Union

3/4 in. pipe

Reducer

bushing

PUMP ELECTRICAL CONNECTIONS

WARNING:

• Always disconnect pump from electricity before performing any work on the motor.

• Under-sized wiring can cause motor failure and even re. Use proper wire size specied in the

Wire Size Chart.

• Replace damaged or worn wiring cord

immediately.

• Do not kink power cable and never allow the

cable to come in contact with oil, grease, hot

surfaces, or chemicals.

• The pump must be properly grounded using

the proper wire cable with ground.

CAUTION:

• Protect the power cable from coming in

contact with sharp objects.

• All wiring should be performed by a qualied

electrician in accordance with the National

Electric Code and local electric codes.

• Connect the pump to a separate electrical

circuit with a dedicated circuit breaker. Refer

to the Wire Size Chart for proper fuse size.

Distance from

Motor to Meter

0-50 Ft.

50-100 Ft.

100-150 Ft.

150-200 Ft.

200-300 Ft.

Fuse Size (Amps)

(*)

Not economical to run in 115 V, use 230 V

WIRE SIZE CHART

Recommended Copper

Wire and Fuse Sizes

Single Phase Motors

1/2 HP

115 Volt 230 Volt

14

12

10

8

*

15 15

14

14

14

14

12

Copyright © 2013 Star Water Systems. All rights reserved.

10

Copyright © 2013 Star Water Systems. All rights reserved.

11

Page 7

PUMP ELECTRICAL CONNECTIONS

Wire from

Wire from

Ground Screws

Priming plug

Discharge Tee

Vent plug

Vent plug

opening

Priming plug

opening

PUMP ELECTRICAL CONNECTIONS

Wiring the pressure switch

CAUTION: Make certain that the power source

matches the pump requirements. This pump has

a dual voltage motor and can run on either 115 V

or 230 V.

Pump is pre-set at the factory to run on 230 V.

1. To change pump voltage, remove the square

voltage switch cover at the top of pump and

move the voltage switch as shown.

2. To connect the pressure switch, remove the

switch cover and insert an electrical wire

strain relief (not included) into the opening in

the side of the pressure switch.

1

2

Strain

Relief

Pressure

Switch

115 V

Setting

230 V

Setting

Wire from

motor

5. Connect the green ground wire from the

power supply to the remaining green ground

screw in the pressure switch and re-attach

the pressure switch cover.

PUMP PRIMING AND STARTUP

PRIMING

CAUTION: All pumps must be primed

(lling the cavity with water) before they are

rst operated. This may take several gallons

of water, as the suction pipe will be lled in

addition to the cavity of pump.

1. Remove pipe plug or pressure gauge (not

included) at the top of the discharge tee and

the vent plug in front of the discharge tee.

5

1

Wire from

power

supply

Wire

from

motor

or pressure

gauge

Vent plug

Suction

Pipe

3. Thread the electrical wire (not included) from

the power supply through the strain relief and

tighten both screws on the strain relief. Do

not crush wire.

4. Connect the two wires from the power supply

to the two outside terminals on the pressure

switch.

3

4

Wire from

power

supply

Wire from

power

supply

Outside

terminal

motor

motor

Outside

terminal

2. Slowly ll the discharge tee with water until

water overows the vent plug opening.

Replace the vent plug loosely.

NOTE: It will take several minutes to fill pump

and suction pipe completely.

3. Be sure entire suction pipe is filled when

priming. Depending on the length of suction

pipe, many gallons will be needed to fill the

entire system.

2

3

Suction

Pipe

Copyright © 2013 Star Water Systems. All rights reserved.

12

Copyright © 2013 Star Water Systems. All rights reserved.

13

Page 8

PUMP PRIMING AND STARTUP

Water Level

Check for leaks

Suction

pipe

Vent Plug

Pressure

Gauge or

Discharge

Tee Plug

Plug

CARE AND MAINTENANCE

4. Check to be sure water in the cavity of pump

stays constant. If water level goes down, it

could indicate a leak in the foot valve, check

valve or suction pipe.

5. Once pump is lled, wrap the pressure

gauge or discharge tee plug and vent plug

threads with thread tape and thread into

pump. Tighten with wrench.

NOTE: Before turning on breaker, open several

outlets or faucets to allow water ow during

priming.

6. Turn on breaker to start pump.

IMPORTANT: If the pump hums instead

of pumping or turns off repeatedly, shut pump

off immediately. Check voltage. Make sure

your incoming voltage matches the pump

wiring voltage. See PUMP ELECTRICAL

CONNECTIONS.

IMPORTANT: If pump fails to prime within

ve minutes:

Turn power off at the breaker box and check

all pipe connections for leaks. All connections

must be water and air tight in order for pump to

operate.

7. Check suction pipe for any sagging. Support

suction pipe in a straight line to the pump.

NOTE: Look for leaks or a milky color in the

discharged water, which indicates an air leak.

Re-prime if necessary, following steps 1 through

6 above. Reset breaker at the breaker box. All

connections must be water and air tight in order

for pump to operate.

4

5

6

7

Breaker Box

1 in.

Discharge Pipe

To Pressure

Tank

1-1/4 in.

Suction Pipe

Well

Foot Valve

Winterizing

1

Vent Plug

CAUTION: Drain the entire system if

there is danger of freezing.

1. To drain pump, remove the drain plug

located on the front of pump and the vent

plug located on the top of pump.

Drain

WARRANTY

This product is warranted for one year from the date of purchase or two years from the date of manufacture, whichever occurs

first. Subject to the conditions hereinafter set forth, the manufacturer will repair or replace to the original consumer, any portion of

the product which proves defective due to defective materials or workmanship. To obtain warranty service, contact the dealer from

whom the product was purchased. The manufacturer retains the sole right and option to determine whether to repair or replace

defective equipment, parts or components. Damage due to conditions beyond the control of the manufacturer is not covered by this

warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions resulting from failure to properly install, operate

or maintain the unit in accordance with printed instructions provided; (b) to failures resulting from abuse, accident or

negligence or use of inappropriate chemicals or additives in the water; (c) to normal maintenance services and the

parts used in connection with such service; (d) to units which are not installed in accordance with normal applicable

local codes, ordinances and good trade practices; and (e) the unit is used for purposes other than for what it was

designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired or replaced under this warranty must be returned

to the manufacturer at Kendallville, Indiana or such other place as the manufacturer may designate, freight prepaid.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES, AND MAY NOT BE

EXTENDED OR MODIFIED BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE PERIOD

OF THE LIMITED WARRANTY AND THEREAFTER ALL SUCH IMPLIED WARRANTIES ARE DISCLAIMED AND

EXCLUDED. THE MANUFACTURER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES, SUCH AS, BUT NOT LIMITED TO DAMAGE TO, OR LOSS OF,

OTHER PROPERTY OR EQUIPMENT, LOSS OF PROFITS, INCONVENIENCE , OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY TYPE OR NATURE. THE LIABILITY OF THE MANUFACTURER SHALL NOT

EXCEED THE PRICE OF THE PRODUCT UPON WHICH SUCH LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states

do not allow limitations on duration of implied warranties or exclusion of incidental or consequential damages, so the

above limitations may not apply to you.

FOR YOUR WARRANTY PROTECTION, THE WARRANTY REGISTRATION MUST BE COMPLETED AND

RETURNED TO THE WARRANTY INFORMATION CENTER WITHIN TEN DAYS OF INSTALLATION. WARRANTY

VALID IN CANADA AND MEXICO.

Copyright © 2013 Star Water Systems. All rights reserved.

14

Copyright © 2013 Star Water Systems. All rights reserved.

15

Page 9

TROUBLESHOOTING

REPLACEMENT PARTS LIST

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Little or no

discharge

1. Pump is not primed 1. Follow priming instructions (page 13)

2. Suction lift too high or too long 2. Move pump closer to water source.

Lift should be less than 25 ft.

3. Hole or air leak in suction line 3. Repair or replace. Use pipe tape and

pipe sealing compound

4. Foot valve too small 4. Match foot valve to piping or install

one size larger foot valve

5. Foot valve or suction line not

5. Submerge lower in water

submerged deep enough in water

6. Voltage switch incorrect 6. Be sure 115 V or 230 V power supply

matches voltage switch setting on

pump

7. Casing gasket leaking 7. Replace

Pump will not

deliver water

or develop

pressure

1. Pump is not primed 1. Follow priming instructions (page 13)

2. Leak in suction line 2. Repair or replace. Pipe dope all

threads

3. Discharge line is closed and priming

air has nowhere to go

3. Open several outlets or faucets

during priming procedure

4. Foot valve is leaking 4. Replace foot valve

5. Foot valve not submerged below

5. Lower foot valve and reprime

water level

Pump vibrates

and/or makes

excessive

noise

Pump will not

start or run

1. Mounting plate or foundation not rigid

1. Reinforce

enough

2. Foreign material in pump 2. Disassemble pump and clean

3. Impeller damaged 3. Replace

1. Voltage switch incorrect 1. Be sure 115 V or 230 V power supply

matches voltage switch setting on

motor

2. Blown fuse or open circuit breaker 2. Replace fuse or close circuit breaker

3. Loose or broken wiring 3. Tighten connections, replace broken

wiring

4. Stone or foreign object lodged in

impeller

4. Disassemble pump and remove

foreign object

5. Thermal overload has opened circuit 5. Allow unit to cool, restart after reason

for overload has been determined

For replacement parts, call our customer service department at 1-800-742-5044,

7:30 a.m. - 5 p.m., EST, Monday - Friday.

PART DESCRIPTION PART NO.

B O-rings / Nozzle / Venturi Kit 023735

C Diffuser 023707

D Impeller 023709

E Mechanical Seal 023720

F O-Ring 023721

G Pressure Switch 023722

F

E

D

C

B

G

Copyright © 2013 Star Water Systems. All rights reserved.

16

Copyright © 2013 Star Water Systems. All rights reserved.

17

Loading...

Loading...