Page 1

NOTICE TO INSTALLER: Instructions must remain with installation.

Manufacturers of . . .

“Quality Products since 1866”

95 N. Oak St. • Kendallville, IN 46755

1-800-345-9422

MODEL S1585

BATTERY BACKUP PEDESTAL SUMP PUMP

PREINSTALLATION CHECKLIST

FW0264

1008

Supersedes

0305

1. Inspect your pump. Occasionally, products are dam aged during shipment. If the unit or any of the parts are dam aged, contact your dealer

before us ing.

2. Read all the installation instructions regarding in stall ing and start up. Retain for future ref er ence.

SEE BELOW FOR LIST OF WARNINGS

1. Testing for Ground. As a safe ty mea sure each elec tri cal outlet

should be checked for ground using an Underwriters Laboratory

list ed cir cuit ana lyzer, which will indicate if the power, neu tral and

ground wires are correctly con nected to your out let. If they are

not, call a qualifi ed licensed electrician.

2. For your pro tec tion always dis con nect the pow er supply from its

power source before handling the com po nents of your DC back up

pump or the pri ma ry pump.

3. Installation and checking of elec tri cal cir cuits and hard ware should

be per formed by a qualifi ed, li censed electrician.

SEE BELOW FOR LIST OF CAUTIONS

4. All elec tri cal and safety codes must be fol lowed in ad di tion to the

National Electrical Code and all applicable local codes.

5. It is the owner’s responsibility to check the bat tery

and bat tery connection at least once a month. Bat-

ter ies con tain acid and cau tion must be taken when

han dling.

6. Risk of electric shock - These pumps have not been investigated

for use in swimming pool areas.

7. According to the state of California (Prop 65), this product contains

chemicals known to the state of California to cause cancer and

birth defects or other reproductive harm.

1. Make sure there is a properly ground ed 115V re cep tacle avail-

able. Do not use primary pump cir cuit. The location must be within

6' of the control box and battery. The power supply for your DC

control system plugs directly into the 115V outlet. DO NOT USE

AN EX TEN SION CORD.

2. Make sure the 115V electrical supply circuit is equipped

with fuses or circuit breakers of prop er capacity.

3. DC emergency pumps are de signed for han dling clear water. Do

not use in septic tanks to pump ef fl u ent or sew age pits to pump

sewage.

95 N. Oak St. • Kendallville, IN 46755 • 1-800-345-9422

© Copyright 2008. All rights reserved.

4. Repair and service of your DC backup sys tem should be per formed

by an authorized service station.

5. The installation of DC automatic back up pumps re quires the use

of a variable level fl oat switch for operation. It is the responsibility

of the installing party, to ensure that the teth ered fl oat switch will

not hang up on the pump ap pa ra tus or pit pe cu li ari ties and is

secured so the pump will turn “on” and “off”. It is recommended

that the pit be 18" in diameter or larger to ac com mo date both a

pri ma ry and a DC backup pump.

1

Page 2

Ten Helpful Hints For Easy Installation

1. Remove all debris from pit before installation.

2. Use a deep cycle battery only. Refer to battery de scrip tions on page 6.

3. Be sure the pump is on a fi rm, level surface.

4. Install a serviceable check valve in the discharge

line.

5. Test the unit immediately after installation. Refer to

STEP 6.

Do’s And Don't’s For Installing A Unit

1. DO read all installation material with the pump and

charger.

2. DO inspect unit for any visible damage caused by shipping. Contact dealer if unit appears to be damaged.

3. DO clean all debris from the pit.

4. DO always disconnect pump from power source before

han dling. DO always connect to a separately protected

and prop er ly grounded ground fault protected circuit.

DO NOT ever cut, splice or damage power cord. DO

6. The battery & charger should be placed on a shelf.

7. Check fl oat On/Off levels per STEP 2 of instructions.

8. Apply grease to the Positive and Negative terminals

of the battery to prevent corrosion.

9. Check the battery water level once a month and add

distilled water as necessary.

10. Obtain model number, date code and in stal la tion in struc tions be fore calling factory.

NOT carry or lift pump by its power cord. DO NOT

use an extension cord with the Aquanot®. DO NOT

lengthen battery/pump leads.

5. DO install union check valve (see step 3) in the dis charge line. DO NOT use a dis charge pipe smaller

than the rec om mend ed pump discharge sizes.

6. DO test pump immediately after installation to be sure

that the system is working properly.

7. DO review all applicable local and national codes and

verify that the installation conforms to each of them.

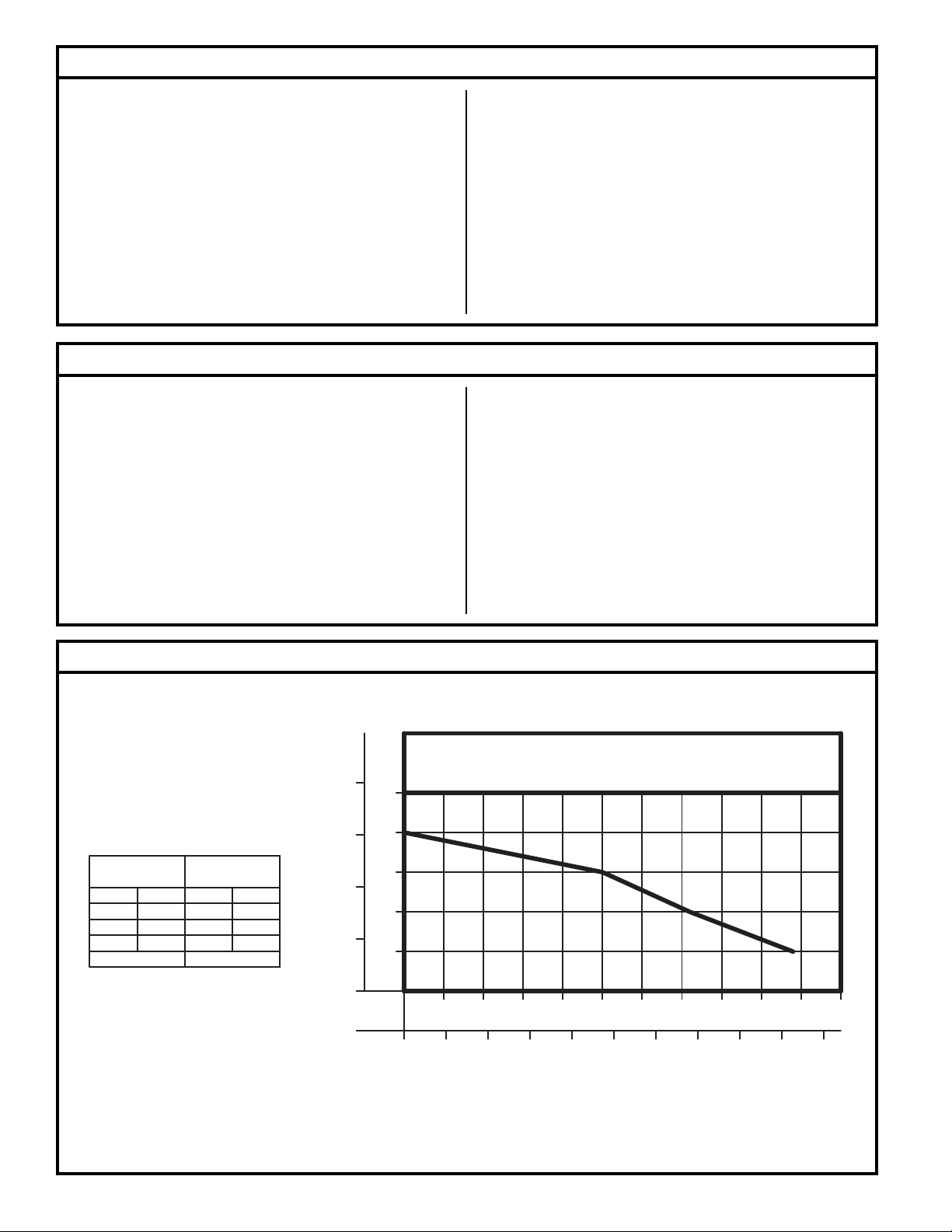

Performance Characteristics

METERS

FEET

8

TOTAL DYNAMIC HEAD/FLOW

PER MINUTE

EFFLUENT AND DEWATERING

MODEL

Feet

Meters

5

10

15

Shut-off Head:

1.5

3.0

S1585

Gal.

49

36

254.6

20 ft.(6.1m)

Liters

186

136

95

25

20

6

15

4

TOTAL DYNAMIC HEAD

10

2

5

0

GALLONS

LITERS

5

020

Note: Aquanot® II (Model S1585) data was de vel oped with the charger supplying DC power to the pump.

PUMP PERFORMANCE CURVE

MODEL S1585

2010 15 25

40 60 80 100

FLOW PER MINUTE

30

120 140 160 180

4035 45 50

55

200

011922FW

© Copyright 2008. All rights reserved.

2

Page 3

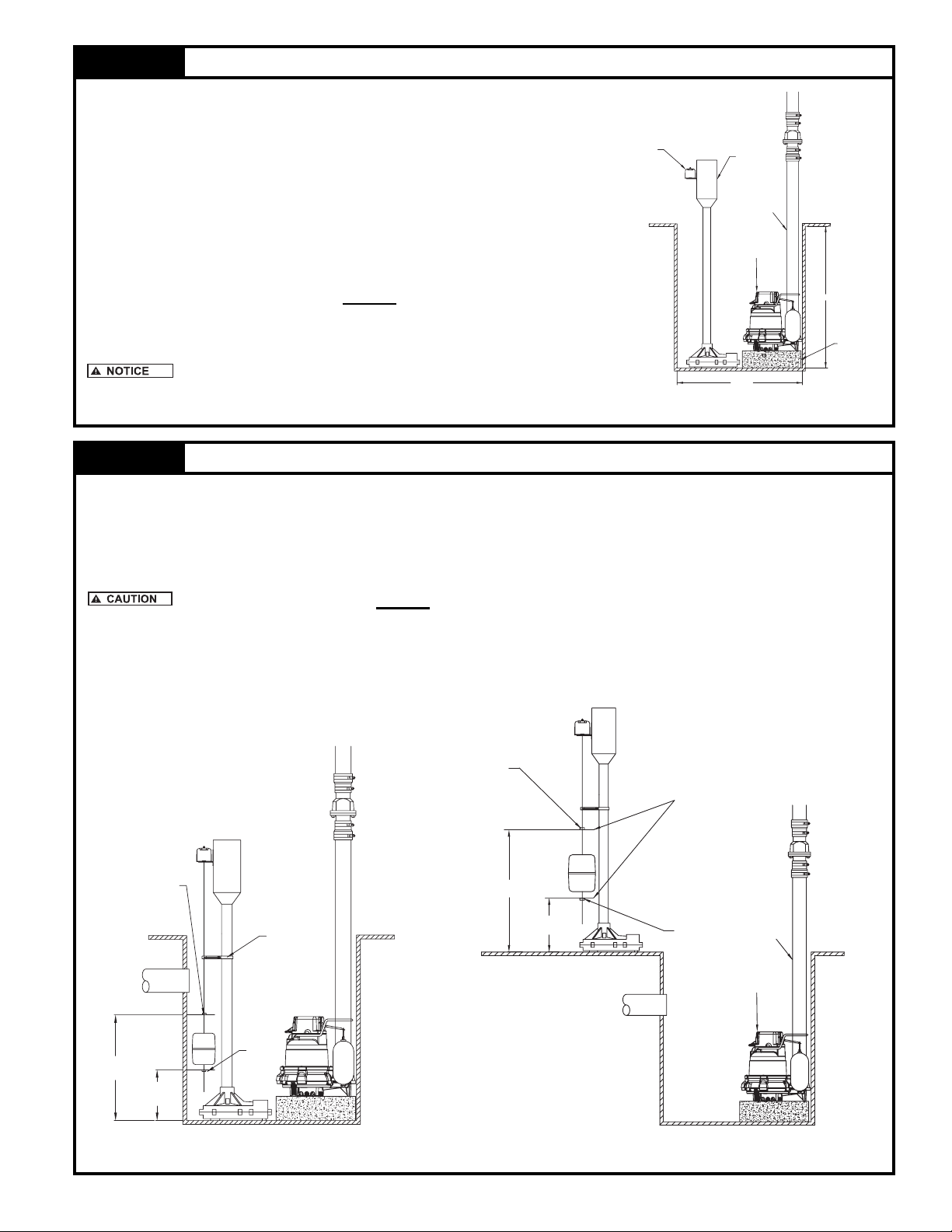

STEP 1 Placement of the Pump in the Pit

Note: If your pit has a cover, then it will have to be modifi ed to accept the

Aquanot®.

1.1) Inspect the pit for debris and clean as nec es sary

ON/OFF SWITCH

PUMP MOTOR

1.2) Place the pump in the pit making certain that it is on a stable level

surface. Refer to Figure 1.1.

MAIN DISCHARGE

LINE

IMPORTANT: If this pump is to be used as a backup to your primary pump,

then make certain that there is no interference between the two pumps.

The motor is not watertight. It should NEVER be below fl oor level.

If necessary, bricks or similar materials, can be placed under the Aquanot®.

This product is meant to be used as a battery backup pump to

your primary pump only. Consult factory for advice before installing this unit

as a primary pump.

PRIMARY PUMP

18 MIN.

Figure 1.1

22 MIN.

BRICK OR SIMILAR

MATERIAL

SK1775

STEP 2 Float Stop Adjustment

2.1) With the pump in the pit, measure the desired fl oat stop on/off positions as shown in Fig. 2.1. These two dimen-

sions will de ter mine the on/off levels of the pump. The spacing between the upper and lower stops will de ter mine

the amount of water removed from the pit.

Note: It may be necessary to raise the fl oat rod guide to adjust the stops to the dimensions determined in Step 2.1.

The fl oat rod guide should NEVER be between the upper and lower stop.

2.2) Remove the pump from the pit and adjust the fl oat stops as necessary. Tighten all screws.

Note: If a brick, or similar material has been used to raise the pump in the pit, it will be necessary to account for the

thickness of the brick.

UPPER

STOP

"ADJUST" ON/OFF POSITIONS

"ON"

HEIGHT

UPPER

STOP

"OFF"

HEIGHT

FLOAT ROD

GUIDE

LOWER

STOP

"ON"

HEIGHT

"OFF"

HEIGHT

LOWER

STOP

MAIN DISCHARGE

LINE

PRIMARY PUMP

SK1776 SK1777

Figure 2.2Figure 2.1

© Copyright 2008. All rights reserved.

3

Page 4

STEP 3 Installation of the Discharge Piping

3.1) Assemble the discharge pipe into the pump as shown in

CHECK VALVE

Figure 3.1.

IMPORTANT: In order for this installation to work properly, a check

valve must be installed onto the discharge line.

( Recommend the following Star check valve, #KH34.

Some local codes require union check with ball valve.

STEP 4 Electrical Connections

4.1) Complete electrical connections as shown in Fig ure 4.1.

4.2) Proceed to STEP 6.

Do not place battery or charger directly on ground. If the

battery or charger must be placed directly on the ground, then place

a piece of wood between the units and the ground. Do not put the

charger on top of the battery.

BATTERY

RED LEAD

TO POSITIVE(+)

BLACK LEAD

TO NEGATIVE(-)

ALARM

MAIN

DISCHARGE

LINE

PRIMARY PUMP

Figure 3.1

POSITIVE(+)

BATTERY TERMINAL

RED LEAD

TO POSITIVE(+)

OR

NEGATIVE(-)

BATTERY TERMINAL

BLACK LEAD

TO NEGATIVE (-)

CHARGER

MOTOR

CHECK VALVE

MAIN

DISCHARGE

LINE

PRIMARY PUMP

SK1778

OUTLET

SWITCH

CUT AWAY OF SUMP PIT

Figure 4.1

STEP 5 Testing of Pump Operation

6.1) Unplug the primary pump so that it does not start.

6.2) Fill pit with water until the Aquanot® starts.

6.3) Verify that the pump starts and stops at the desired on/off points.

6.4) Verify that there are no leaks in the discharge line.

6.5) If adjustment is necessary, raise or lower the appropriate stop(s) according to STEP 2.

IMPORTANT: Spacing between upper and lower stops determine amount of water removed from pit.

6.6) If the pump is not operating properly after following the above steps, refer to the Troubleshooting guide on page 8.

6.7) When fi nished testing plug primary pump back into AC receptacle.

SK1783

© Copyright 2008. All rights reserved.

4

Page 5

Operation of the Aquanot® Charger

The charger automatically monitors and charges your battery. In the event of a power outage the pump will be powered by the

battery. Once line power is restored, the charger will recharge the battery. If there is a failure of the primary pump, the charger will

supply power to the pump through the battery if line power is present; otherwise, the battery will take over until the problem has

been corrected.

The lights on the front panel of the charger indicate the state of system:

The red light: Indicates that AC line power is present.

The green light: Indicates that the battery is charged to 12V DC*.

During periods of extended power outage the charge on the battery may drop below 12V DC which would cause the green

light to go out. This is normal. The green light will be illuminated once the charger restores the voltage level to 12V DC.

The yellow light: Indicates that the battery is charged above 8V DC.

If the yellow light is not illuminated, it indicates that the charge on the battery is below 8V DC. If the line power is out, the pump

may have depleted the battery due to normal operation. If there has been no power outage and the primary pump is working

properly, it may indicate that the battery is defective or that the controller is defective. Refer to the Troubleshooting guide on

page 8 for further instructions.

If the Green and Yellow lights fl ash intermittently, refer to Section G in the Trouble Shooting Guide on page 8.

*Voltage is only one indicator of the state of the battery, and does not refl ect the true condition of the battery. Use a hydrometer to

more accurately determine the condition of the battery.

Operation of the Audible Alarm

All Aquanot® pump systems are equipped with an alarm which sounds when the pump is activated. The alarm will automatically

silence when the pumping cycle is completed.

Activation of the audible alarm indicates that the primary pump has failed or line power to the primary pump is not present. When-

ever the alarm is activated the primary pump and outlet should be inspected.

The On/Off switch, located on the side of the alarm enclosure, allows the audible alarm to be turned off, however, this practice is

not recommended. Verify that the alarm switch is in the “on” position, by manually turning the pump “on”.

The Aquanot® Battery

There are millions of batteries manufactured each year, so it is impossible to guarantee consistent quality. A defective battery will

never become fully charged and may damage the circuits of the charger. It is for this reason that Star offers its own MaintenanceFree AGM Battery, which will power the pump for over 3½ hours without AC power. This time is based on continuous pumping at 10’

of static head. Actual times will vary depending on static head, volume of water entering the pit, and the condition of the battery.

When purchasing a battery for the Aquanot® II unit, follow these recommendations:

• Use a B.C.I. size 27 deep-cycle battery, 175 minute reserve capacity, or larger.

• Do NOT use a “maintenance-free” battery unless it is Gel-fi lled or AGM.

• Replace your battery every 3 years.

• Do not let corrosion build up on the battery terminals.

• Do not place your battery on a concrete fl oor where it will discharge faster.

• To check specifi c gravity, follow the instructions on a hydrometer (not applicable for Gel or AGM batteries).

PROTECT YOUR WARRANTY:

• Water level in batteries must be checked once a month (not applicable for Gel or AGM batteries).

NOTE: The purchase of an Aquanot® battery from Star Water Systems will extend the limited warranty to three years from date of

installation. The three year limited warranty is valid only when a complete system is purchased and used as a backup to a primary

dewatering system. A complete system includes the Aquanot® II Model S1585 and Aquanot® battery.

© Copyright 2008. All rights reserved.

5

Page 6

Illustrated Parts Breakdown

20-MODEL S1585 COMPLETE PUMP

REF.

NO.

1 Motor Brushes 2 013878

2 Pump Alarm 1 012485 012485

3 Pump Switch 1 017205 017205

4 Float Kit & Cable 1 012709 012709

5 Lead Wires 1 012401 012401

6 Terminal Spade 1 004442 004442

7 Terminal Ring 1 011939 011939

8 Pump Motor 1 013873 013873

9 Column 1 011942 011942

10 Adapter, Drive 1 011940 011940

11 Shaft 1 011944 011944

12 Head w/Brass Bearing 1 012137 012137

13 Washer, Thrust 1 002140 002140

14 Impeller 1 011945 011945

15 Base Plate 1 012138 012138

16 Screws 8 012118 012118

17 Guide, Float Rod 1 003903 003903

18 Battery Charger 1 015409 015409

19 N/A N/A

20 Pump S1585 1 015407 015407

21 Float 1 012707 012707

22 Stop, Float 2 054085 054085

23 Rod, Float 1 012706 012706

24 Screws 1 003925 003925

*Advise motor Leeson or CIM.

DESCRIPTION QTY

MODEL: S1585-A S1585-B

03/02

to

12/04

1/05

to

Current

*Consult

Factory

21

1

8

9

2

10

3

11

4

17

24

5

12

13

7

6

14

15

16

TERMINAL

DETAIL

22

23

18

SK1786FW

Carbon Monoxide Detectors

Whether you have an Aquanot® Battery Backup Sump Pump System, or a competitive brand, all batteries give off gaseous by-

products when charging. Some of these by-products can produce a rotten egg odor. Also, some of these by-products can cause

a CO detector to falsely activate. In order to help prevent false activation, we recommend moving the battery as far apart from the

CO detector as possible or, if necessary, vent the battery to the exterior. We provide the previous statements only as guidelines

to help prevent false activation of the CO detector. In no way are they meant to supersede the instructions that accompany the

detector nor do they supersede advice from the CO detector manufacturer.

If the audible alarm associated with your CO detector is activated, we recommend the following actions:

1) Take immediate action for personal safety as recommended in the CO detector literature.

2) Contact the appropriate agency to determine if the CO is being produced by your furnace, water heater, or any other device

which uses natural gas.

3) If you are certain that no CO is being produced, then a charging battery may be producing gaseous by-products which are

causing the CO detector to activate. Contact the manufacturer of the CO detector, and ask for recommendations as to what

can be done to prevent the alarm activation.

© Copyright 2008. All rights reserved.

6

Page 7

REPLACEMENT PARTS LIST FOR:

AQUANOT® S1585 CHARGER

CHARGER

REF.

NO.

1 Fuse, In-line/Resetable/10 amp 1 012285

2 Cover, “S1585” Charger 1 011963

3 Screw, #10-32 X .375 Pan HD/Phillips/Self Tap/Zinc 6 011984

4 Transformer, “Aquanot®” 1 011967

5 Nut, Hex 10-32 HH Zinc 3 012129

6 Overload, 40 amp/12v/#54-240/“Aquanot®” 1 011968

7 Rectifi er, Asm “Aquanot®” 1 N/A

8 Base, Charger “Aquanot®”/Model S1585 1 012360

9 Nut, Kep 1/4-28 HH Zinc 3 N/A

10 Fastener,Rivet,Alum-#64 1-3/16 X .125 X .25 4 011966

11 Wire Asm-f-s(1)Wire 6"Lg/10ga 1 012288

12 Diode, IN1183A B1197 2 N/A

13 Circuit Board, “Aquanot®” 1 016787

14 Cord & Term “S1585” Charger 1 012297

15 Wire Asm-F-S(1)Wire 66” Lg/Red 1 012342

16 Wire Asm-F-R(1)Wire 66” Lg/Black 1 012341

17 Screw,#10-32 X.50 Pan HD/Phillips/Zinc 1 011929

18 Clamp,Strain Relief-cord #1200 1 011974

19 Clamp,Strain Relief-lead Wire-#1504 1 011975

20 Screw, #6-32X .438 RH PH TP 1 STZI 2 004644

21 Charger, 25A Model S1585 1 015409

22 Wire, Asm, 6” Long/Black, Crimped & Soldered 1 012449

DESCRIPTION QTY

Current

A

03/02

to

2

3

4

5

6

7

(OPTIONAL)

8

9

10

11

22

12 (OPTIONAL)

13

20

9

18

19

17

1

14

15 RED

16 BLACK

TO ORDER REPLACEMENT PARTS:

PLEASE FURNISH THE FOLLOWING INFORMATION:

• Part Number of Unit.

• Revision Letter.

• Part Number and De scrip tion of part.

© Copyright 2008. All rights reserved.

7

21

SK1841

Page 8

Troubleshooting Guide

CONDITION POSSIBLE CAUSE REMEDY

Low voltage, blown fuse open circuit. Have a qualifi ed electrician check fuse and cir cuit.

Impeller bound.

A PUMP WILL NOT START OR RUN.

B PUMP STARTS TOO SOON. Float “ON” point is adjusted too low. Refer to STEP 2.

C PUMP WILL NOT SHUT OFF.

PUMP OPERATES BUT DELIVERS

D

LIT TLE OR NO WATER.

RED LIGHT ON CHARGER (MODEL

E

585) IS OUT.

F RED LIGHT FLASHING (MODEL 585). The charger fan may be defective. Have a qualifi ed electrician inspect the charger.

GREEN & YELLOW LIGHTS FLASH

G

INTERMITTENTLY

RED, GREEN & YELLOW LIGHTS

H

FLASH IN SEQUENCE (MODEL 585).

CONSTANTLY ADDING DISTILLED

I

WATER TO BATTERY.

J ROTTEN EGG SMELL IN BASEMENT. Charger is overcharging battery.

Blown pump fuse.

Defective Switch

Motor or wiring shorted.

Float is obstructed. Inspect fl oat operation and correct problem.

Float “Off” point adjusted too low. Adjust “Off” point. Refer to STEP 2.

Faulty fl oat switch. Contact factory.

Debris around intake. Clean area around intake.

Blockage in discharge pipe. Remove pipe and fl ush out debris.

Low voltage.

Blown fuse, open circuit. Have a qualifi ed electrician check circuit.

Incorrect fl oat adjustment Refer to STEP 2 for proper installation.

Pump is air locked. Drill ¼” hole in discharge pipe below waterline.

Vertical lift too high. Change discharge piping or contact tech. service.

Base plate is “loose” or corroded. Remove pump from pit and tighten as necessary.

Pump runs in reverse.

Damaged Impeller. Contact factory.

Resettable fuse tripped. Reset fuse located on charger housing.

Power outage.

Defective controller or light burned

out.

Positive & Negative battery leads

are re versed.

Battery has a “Dead Short”.

Loose battery connections. Tighten red and black battery leads.

Corroded battery terminals.

Lights fl ash for approximately for 4

seconds.

Defective battery.

Defective controller. Contact factory.

Replace fuse.

Contact factory.

Check condition of battery. Replace as nec es sary

or recharge.

Make certain that the red(+) lead and black(-) leads

go to the appropriate battery terminals.

Normal condition Red light will be illuminated once

line power is restored.

Contact factory.

Check water lever of battery, refi ll as nec es sary

(Do not overfi ll).

Defective battery. Replace as necessary.

Make certain that the positive (red) & negative (black)

leads go to the proper battery ter mi nals.

Replace battery. Battery has aged beyond its ability

to chemically store electricity.

Clean terminal as necessary. Apply grease to

ter mi nals to prevent future corrosion prob lems.

Normal condition. The lights indicate that the sys

is properly installed.

Have battery inspected. The charger will over charge

a battery with a defective cell.

Have battery inspected. The charger will over charge

a battery with a defective cell.

tem

Before servicing a pump, always shut off the main

pow er breaker and then unplug the pump - making sure you are

not stand ing in water and are wearing in su lat ed pro tec tive sole

shoes. Un der fl ooded con di tions, con tact your local elec tric company or

© Copyright 2008. All rights reserved.

a qualifi ed licensed electrician for dis con nect ing electrical service prior

to pump re mov al. If the following checklist does not solve the prob lem,

con sult our Technical Service De part ment 1-(800) 345-9422 - Do not

at tempt to service or oth er wise dis as sem ble pump.

8

Loading...

Loading...