Page 1

NOTICE TO INSTALLER: Instructions must remain with installation.

FW1379 0913

Supersedes 0212

Product information presented

here reects conditions at time

of publication. Consult factory

regarding discrepancies or

inconsistencies.

U

P

C

C

COMPLIES WITH ASME A112.3.4.

®

WATER POWERED EMERGENCY BACKUP

STAR

®

HomeGuard®

OPTIMA

MODEL S1503

SUMP PUMP SYSTEM

PVC CONSTRUCTION

PREINSTALLATION CHECKLIST

visit our web site:

starwatersystems.com

1. Inspect your pump. Occasionally, products are damaged during shipment. If the unit or any of the parts are

damaged, contact your dealer before using.

2. Read all the installation instructions regarding installing and start up. Retain for future reference.

pit peculiarities and is secured so the pump will turn

“on” and “off”. It is recommended that the pit be 18"

SEE BELOW FOR LIST OF WARNINGS

1. For your protection always disconnect the power

supply from its power source before handling the

components of your primary pump.

SEE BELOW FOR LIST OF CAUTIONS

1. This pump is designed for handling clear water. Do not

use in septic tanks to pump efuent or sewage pits to

pump sewage.

2. Repair and service of your backup system should be

performed by an authorized service station.

3. The installation of this backup pump requires the use

of a variable level oat switch for operation. It is the

responsibility of the installing party, to ensure that the

oat switch will not hang up on the pump apparatus or

in diameter or larger to accommodate both a primary

and a backup pump.

4. Check the installation of the primary and backup

pump oats to ensure that both move freely and are

not being encroached upon where the oat cannot

move. Adequate space between the oats must be

maintained.

5. The pump should be manually activated once a month

by lifting the oat rod. Let the pump run for at least 15

seconds to prevent the pump from building up calcium

deposits and debris, which could harm the pump.

Turbulence caused by high velocity

incoming water can negatively affect the on/off action

of the oat mechanism. If this condition exists, the

incoming water must be bafed to avoid excessive

turbulence.

REFER TO WARRANTY ON PAGE 2.

Page 2

Limited Warranty

This product is warranted for one year from the date of purchase or two

years from the date of manufacture, whichever occurs first. Subject to the

conditions hereinafter set forth, the manufacturer will repair or replace to the

original consumer, any portion of the product which proves defective due to

defective materials or workmanship. To obtain warranty service, contact the

dealer from whom the product was purchased. The manufacturer retains

the sole right and option to determine whether to repair or replace defective

equipment, parts or components. Damage due to conditions beyond the

control of the manufacturer is not covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions

resulting from failure to properly install, operate or maintain the unit in

accordance with printed instructions provided; (b) to failures resulting

from abuse, accident or negligence or use of inappropriate chemicals or

additives in the water; (c) to normal maintenance services and the parts

used in connection with such service; (d) to units which are not installed in

accordance with normal applicable local codes, ordinances and good trade

practices; and (e) the unit is used for purposes other than for what it was

designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired

or replaced under this warranty must be returned to the manufacturer

at Kendallville, Indiana or such other place as the manufacturer may

designate, freight prepaid.

Helpful Hints For Easy Installation

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND MAY NOT BE EXTENDED OR MODIFIED

BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE

PERIOD OF THE LIMITED WARRANTY AND THEREAFTER ALL SUCH

IMPLIED WARRANTIES ARE DISCLAIMED AND EXCLUDED. THE

MANUFACTURER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES,

SUCH AS, BUT NOT LIMITED TO DAMAGE TO, OR LOSS OF, OTHER

PROPERTY OR EQUIPMENT, LOSS OF PROFITS, INCONVENIENCE

, OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

TYPE OR NATURE. THE LIABILITY OF THE MANUFACTURER SHALL

NOT EXCEED THE PRICE OF THE PRODUCT UPON WHICH SUCH

LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have other rights

which vary from state to state. Some states do not allow limitations on

duration of implied warranties or exclusion of incidental or consequential

damages, so the above limitations may not apply to you.

WARRANTY VALID IN CANADA AND MEXICO.

1. The system is designed for installation in sumps with

minimum of 18” diameter and 22” deep. For smaller

applications, consult factory.

2. Remove all debris from the pit before installation.

3. Be sure that the pump is clamped securely to the

primary pump discharge pipe and that the two pumps

do not interfere with each other.

4. Install a serviceable check valve in the discharge line.

Do’s And Don’t’s For Installing A Unit

1. DO read all installation materials supplied with the

pump.

2. DO inspect unit for any visible damage caused

by shipping. Contact dealer if unit appears to be

damaged.

3. DO clean all debris from the pit before installation.

4. DO install a union check valve (see STEP 3) in the

discharge line. DO NOT use a discharge pipe smaller

than the recommended pump discharge sizes.

5. DO install a lter or strainer in the water supply line

before the pump to prevent small particles from

clogging the operating valve.

© Copyright 2013 Star Water Systems. All Rights Reserved.

2

5. Install a lter or strainer in the water supply line before

the pump. Size the lter/strainer properly to minimize

pressure drop, while retaining particles at least 0.020"

(0.5 mm) in diameter.

6. Test the unit immediately after installation. Refer to

STEP 5.

7. Check the Float ON/OFF levels per STEP 2 of the

instructions.

8. Obtain model number, date code, and installation

instructions before calling factory.

6. DO test the pump immediately after installation to be

sure that the system is working properly.

7. DO review all applicable local and national codes and

verify that the installation conforms to each of them.

8. DO NOT use the Home Guard

®

Optima in hot water.

DO NOT use the Home Guard® Optima to remove

wastewater, sewage, efuent, or water with debris in it.

9. DO NOT use a garden hose. Garden hose is not

designed to hold municipal pressure indenitely and

could leak or burst causing ooding. The Home Guard®

Optima requires a permanent piping method such as

copper, PEX, or CPVC.

Page 3

Installation

The Home Guard® Optima pump can be installed very easily as a standby to an electric sump pump (see

sketches). However, a check valve is required between the electric pump and the Home Guard® Optima.

Note 1: Per the Uniform Plumbing Code and the Plumbing Codes of some states, installation of this product

requires the use of a RPZ backow protection device. Contact your local plumbing or water authority for more

information regarding the requirements for your specic area.

Note 2: Per the Uniform Plumbing Codes and IAPMO PS119, the discharge of the water-powered sump pump should

not be connected to the discharge of the primary sump pump.

STEP 1: Placement of the Pump in the Pit

Note: If your pit has a cover, it will have to be modied to accommodate the Home Guard® Optima pump.

1.1) Inspect the pit for debris and clean as necessary.

1.2) Place the pump in the pit, making certain that the inlet tting of the pump is at least 6” above the basement oor

or top of the sump pit. Ensure the pump is clamped securely to the primary pump discharge pipe. Mark the

location on the discharge pipe.

This pump is to be used as a backup to your primary pump. Make certain that there is no interference

between the two pumps, especially between the oat systems.

STEP 2: Float Stop Adjustment

2.1) With the Home Guard® Optima pump in the pit, measure the desired oat ON position (this should be a few

inches above the ON level of the existing pump). The pump turns on at a water level of 2” to 3” below the upper

oat stop, depending on the incoming water pressure. Calculate the appropriate oat stop location based on

this distance.

2.2) The OFF level is determined by the buoyancy of the oat as well as the incoming water pressure, roughly 6” to

8” below the ON level. The OFF level must be above the suction screen of the foot valve. Adjusting the lower

oat stop will not change the OFF level of the pump. It is recommended to install the lower stop tight to the

bottom of the oat so that it cannot move on the oat rod.

2.3) Remove the pump from the pit and adjust the oat stops as necessary. Tighten all screws. Be sure to tighten

the lower stop properly so that it will not come off. If the lower stop comes off, the oat will drop off the oat rod,

rendering the pump non-operational and possibly damaging the pump.

2.4) Replace the pump in the pit at the same location on the primary pump discharge pipe as marked earlier (Step

1.2). This will ensure that the ON and OFF levels are consistent with the calculations.

STEP 3: Installation of the Discharge Piping

3.1) Glue the discharge pipe into the pump as shown in the gure below (reference SK2721B).

3.2) Per the Uniform Plumbing Codes and IAPMO PS119, the discharge of the water-powered sump pump should

not be connected to the discharge of the primary sump pump.

3.3) In order for this installation to work properly, a check valve must be installed onto the discharge line. The

following Star Water Systems check valves are recommended: KH34 and KH81. Some local codes require a

union check with ball valve.

STEP 4: Installation of the Source Water Piping

4.1) Shut off the municipal water supply and plumb the tubing/piping into the municipal water supply line. This must

be branched off of a ¾" line and plumbed with ¾" tubing/piping to the Home Guard® Optima . Do not use garden

hose or other exible hose/tubing. Install a shut off valve in the ¾" supply line to the Home Guard® Optima. Use

the appropriate back-ow prevention for your jurisdiction.

© Copyright 2013 Star Water Systems. All Rights Reserved.

3

Page 4

Installation (Continued)

STEP 4: (Continued)

4.2) Do not braze/solder copper ttings within 18” of Home Guard® Optima, as the heat from the torch will damage

the pump body.

4.3) When assembling threaded ttings into the Home Guard® Optima inlet, do not use pipe dope on the inlet threads,

use PTFE (Teon®) sealing tape. Take special care to keep any debris (including pieces of tape) from entering

the inlet tting that might get caught in the operating valve.

4.4) The Home Guard® Optima includes a eld installed Push-to-Connect tting. This tting is designed to be used

with ¾” PEX, CPVC, or copper pipe. The tting must be installed on the ¾" NPT thread of the pump inlet tting.

Caution must be used when installing the tting to not over tighten the inlet tting and crack the body. Using a

backup wrench, hold the inlet tting while tightening the Push-to-Connect tting. If the Push-to-Connect tting

is not used, the same precaution must be used when installing any other tting to the inlet tting.

4.5) Purge the water line prior to connecting to the Home Guard® Optima to ensure that debris does not enter the unit

and clog the operating valve.

4.6) If using the Push-to-Connect tting, cut the tube so that the ends are square. Ensure that there are no burrs or

damage to the cut end. Once the tubing end is cut square and clean, scribe a depth mark on the outside of the

tubing 1” from the end. Insert the tube through the release collar to rest against the grab ring. Push the tube

rmly with a slight twisting action until it reaches the tube stop. The depth mark should be up to the end of the

release collar. The tube liner is not necessary with CPVC or Copper tubing, and may be removed based on

preference or local codes. The tube liner can be easily removed by pulling it out with a needle nosed pliers.

4.7) Once the pump has been installed and the municipal water source connected, open the municipal water source

valve and the supply line valve. Inspect the valve body and all connections looking for leaks. Close the

municipal water valve and x any leaks before operating the pump.

STEP 5: Testing of Pump Operation

5.1) Unplug the primary pump so that it does not start.

5.2) Fill the sump with water until the Home Guard® Optima starts.

5.3) Verify that the pump starts and stops at the desired ON/OFF points.

5.4) Verify that there are no leaks in the discharge line.

5.5) If adjustment is necessary, raise or lower the stops according to STEP 2.

5.6) If the pump is not operating properly after following the above steps, refer to the Troubleshooting guide.

5.7) When nished testing, plug primary pump back into AC receptacle.

WATER PRESSURE:

20 PSI minimum with valve open.

80 PSI maximum with valve open.

100 PSI maximum with valve closed.

EFFICIENCY:

The pumping capacity increases with household water pressure and ow.

At an eight-foot static head and a supply pressure of 20 PSI at water supply inlet with water owing, it takes one (1)

gallon of supply water to remove one gallon from the sump. As the supply pressure increases with the static head

constant, less supply water is required.

© Copyright 2013 Star Water Systems. All Rights Reserved.

4

Page 5

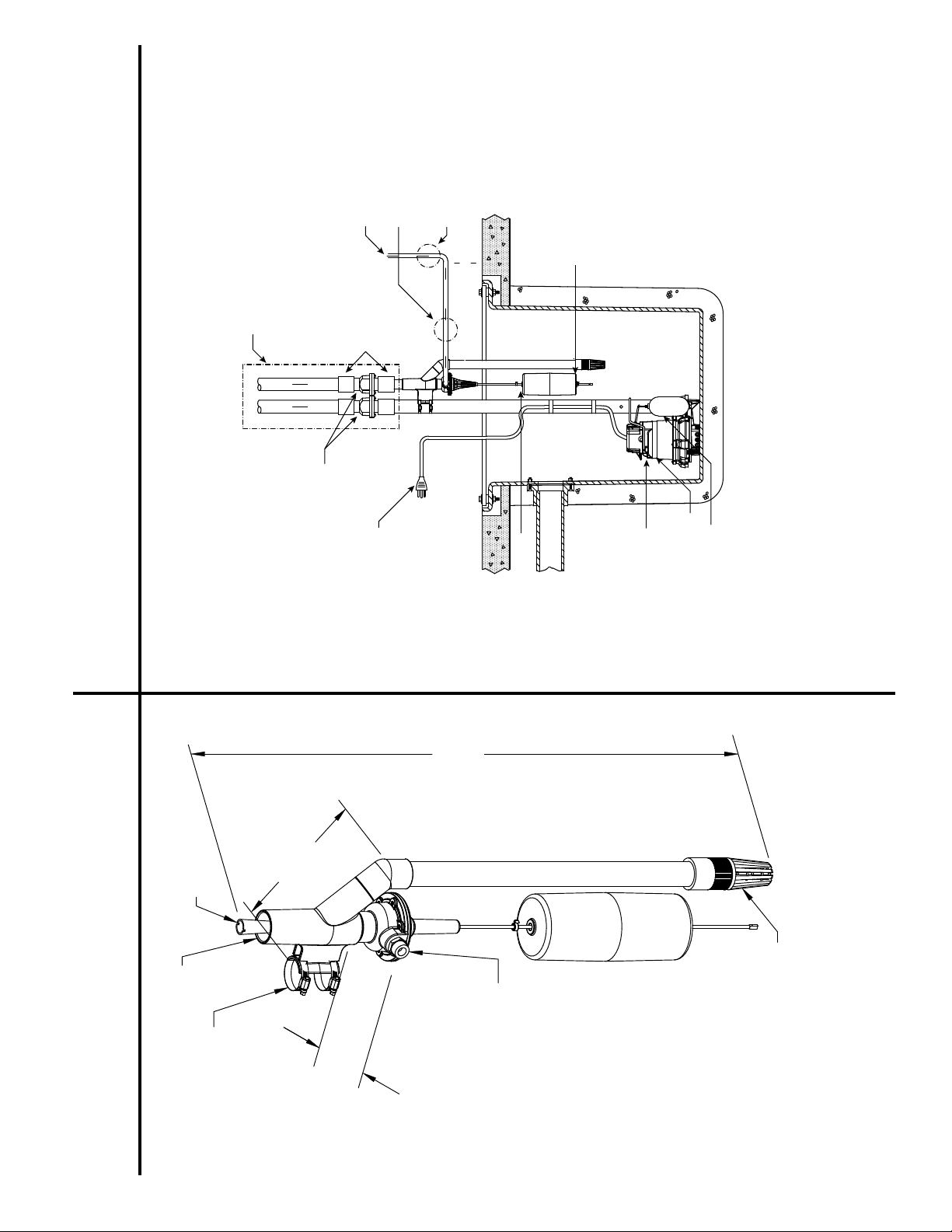

PIP NG ASSEMBLY

(SUPPLIED BY OTHERS)

AND FILTER

SUPPLY LINE

BACK FLOW PREVENTER

INCOMING WATER

COUPLINGS

(SUPPL ED BY OTHERS)

INSTALL DEDICATED SHUT-OFF

SK2721B

SK2721B

VALVE WITHIN 6FT.

OF HOMEGUARD OPT MA

PUMP ON LEVEL

AND ABOVE PRIMARY

ABOVE SUCTION SCREEN

OFF LEVEL MUST BE

6" M N.

and Separate Discharge Pipe

CHECK VALVES

PLUG

3-PRONG

Typical Installation with Submersible Pump

38 3/4

HEIGHT

8 1/8

DISCHARGE

LENGTH

BY TESTING. SEE NSTRUCTIONS.

ON LEVEL TO BE DETERM NED

ON LEVEL

PRIMARY PUMP

FLOAT

ON/OFF

SUBMERSIBLE PUMP

Dimensions

1 1/2

SLIP FIT

HOSE CLAMPS FOR

PUMP DISCHARGE PIPE

ATTACHING TO PRIMARY

© Copyright 2013 Star Water Systems. All Rights Reserved.

5 1/2

WIDTH

SUCTION

3/4 NPT

WATER SUPPLY

5

Page 6

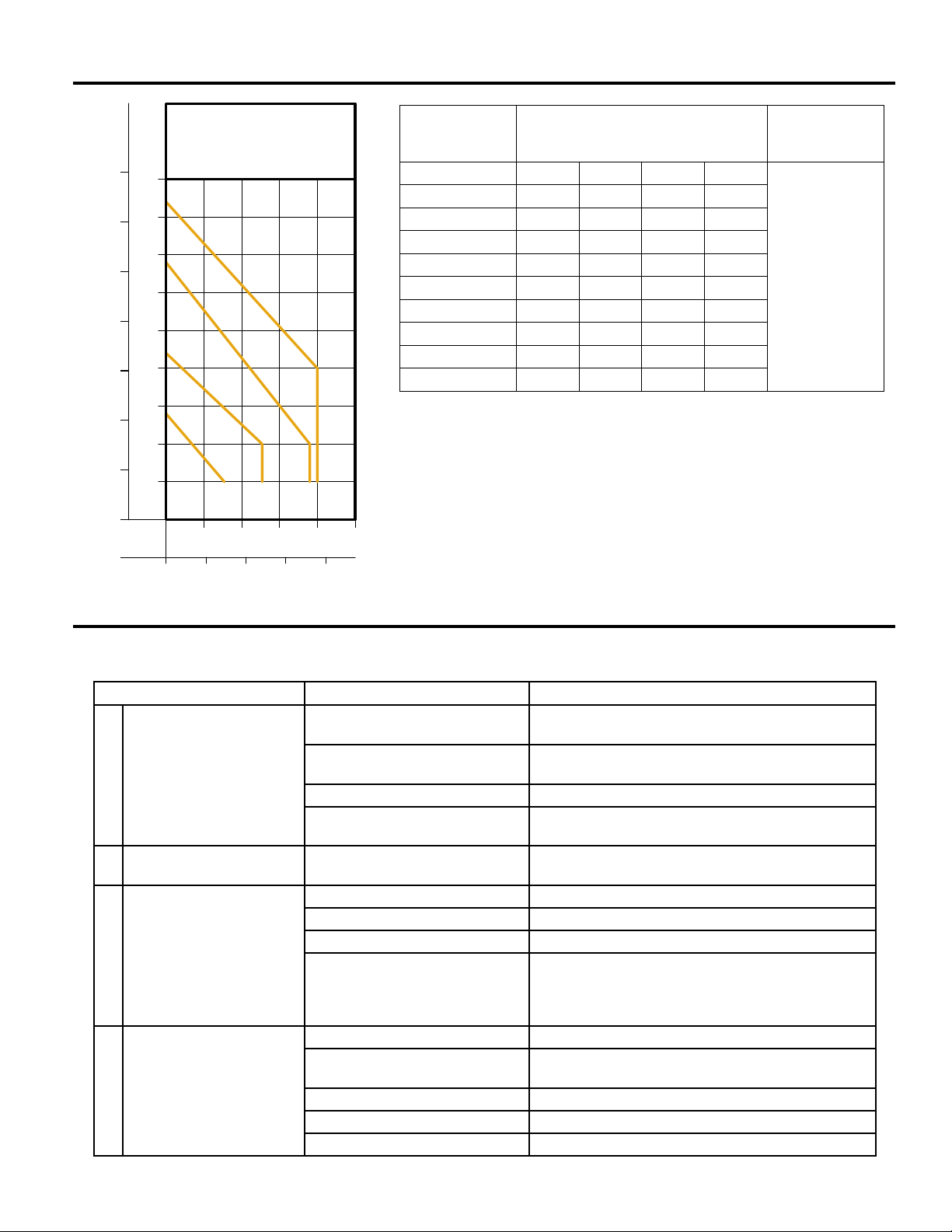

Performance Characteristics

FEET

METERS

14

45

40

12

35

10

30

8

25

TOTAL DYNAMIC HEAD

20

6

15

4

10

2

5

0

GALLONS

LITERS

0

PUMP PERFORMANCE

CURVE

MODEL S1503

80 PSI

60 PSI

40 PSI

20 PSI

5 10

20 40

FLOW PER MINUTE

15

20

8060

IL1080

Total Dynamic Head/Flow per

Minute

Model S1503

Dewatering Only UPC #

Feet 20 PSI 40 PSI 60 PSI 80 PSI

5 7. 7 12.7 19.0 20.0

10 3.4 12.7 19.0 20.0

15 - 7. 4 15.0 20.0

20 - 2.0 11. 1 20.0

25 - - 7. 1 15.3

054757076658

30 - - 3.2 10.9

35 - - - 6.4

40 - - - 1.8

Shut-off Head: 14.0 ft. 22.0 ft. 34.0 ft. 42.0 ft.

Pump capacity varies due to: Inlet Water Pressure, Working Water

Pressure, Discharge Elevation, Number of Pipe Fittings, Inlet and

Outlet Pipe Size, Fluid Viscosity, Degree of Water Clarity, Water

Temperature. The flow rates in the chart are approximate values.

25

NOTE: Some districts may require a reduced pressure principle

backflow preventer per ASSE Standards 1013. Check Local Codes.

Troubleshooting Guide

CONDITION POSSIBLE CAUSE REMEDY

PUMP WILL NOT START

A

OR RUN

PUMP STARTS TOO

B

SOON

PUMP WILL NOT SHUT

C

OFF

PUMP OPERATES BUT

D

DELIVERS LITTLE OR NO

WATER

Inadequate incoming water pressure.

Excessive water pressure. Install regulator and reduce pressure below 100 PSI

Debris around Intake. Clear debris from pit and foot valve strainer.

Float hung up on pit or primary

pump

Float "ON" point is adjusted too

low.

Float is obstructed. Inspect oat operation and correct problem.

Float "OFF" point is too low. Refer to STEP 2.

Foot Valve above water level. Adjust Float - Refer to STEP 2.

Internal valve diaphragm vent

hole is plugged with debris.

Debris around Intake. Clear debris from pit and foot valve strainer.

Inadequate incoming water pres-

sure.

Blockage in discharge pipe. Remove pipe and ush out debris.

Foot Valve above water level. Adjust Float - Refer to STEP 2.

Vertical lift too high. Change discharge piping or contact technical service.

Check incoming water line for closed valve, low water

pressure or clogged lter/strainer.

with valve closed.

Move pumps so that the oats move freely and do not

contact pit, piping or each other.

Refer to STEP 2.

Turn off water supply to pump and back on repeatedly

to dislodge debris. If this process does not remedy

the problem, service pump to clear debris or replace

valve assembly.

Check incoming water line for closed valve or low

water pressure.

© Copyright 2013 Star Water Systems. All Rights Reserved.

6

Page 7

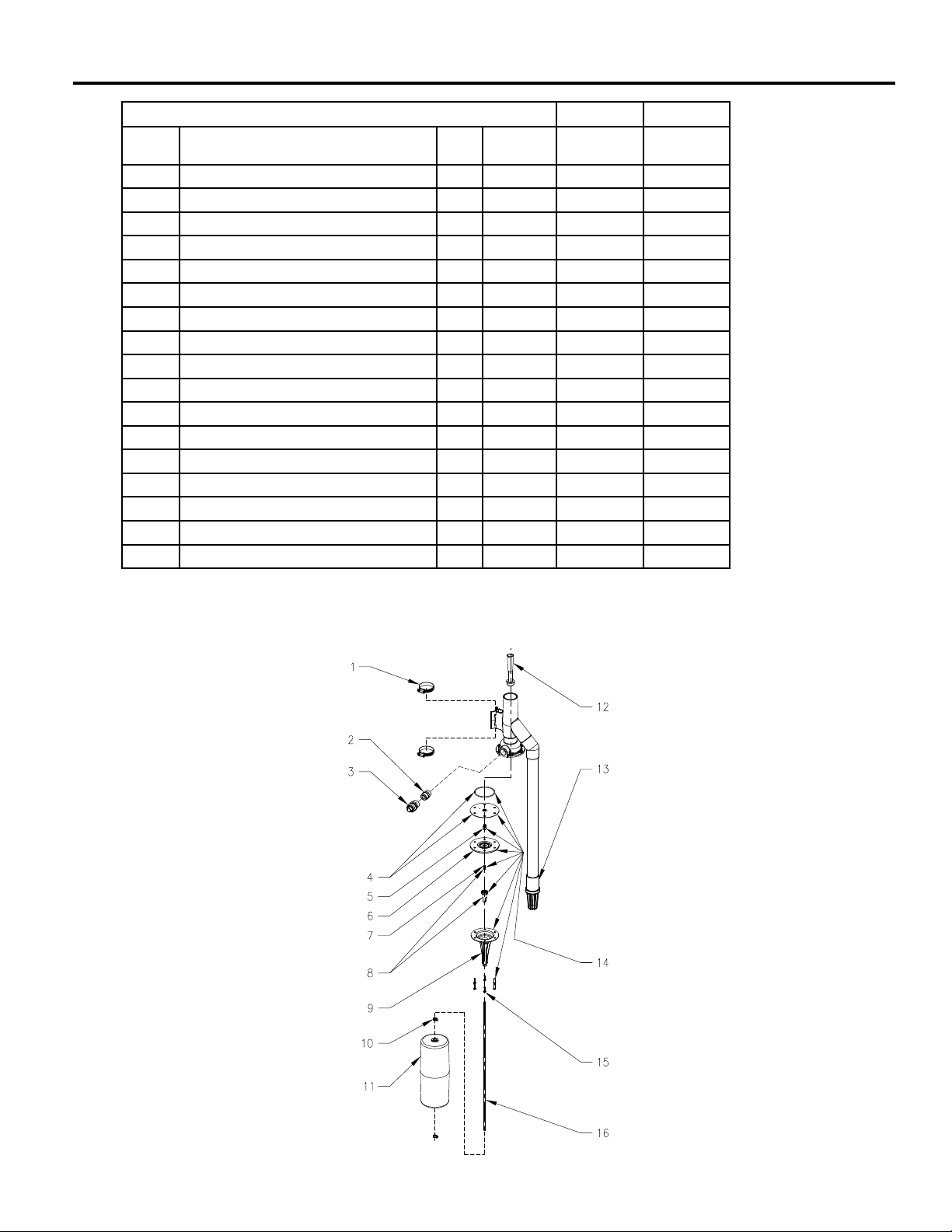

Illustrated Parts Breakdown

HOMEGUARD SERVICE PARTS - MODEL 1503 1503-A 1503-B

ITEM DESCRIPTION QTY NOTES

11/10 thru

05/11

1 Clamps 2 * 001766 001766

2 Backow valve assembly 1 018587 018587

3 Sharkbite tting 1 018584 018584

4 Diaphragm and O-ring 1 * 150553 150553

5 Plunger assembly 1 * 018589 018589

6 Nozzle seat 1 018557 151713

7 Spring 1 * 018564 018564

8 Float rod magnet guide assembly 1 150084 150084

9 Float rod guide 1 150741 150741

10 Float stop assembly 2 * 054085 054085

11 Float 1 018567 018567

12 Venturi 1 4C5532 4C5532

13 Foot valve 1 ** 150260 150260

14 Valve assemby 1 150101 150101

15 Screws 6 * 001885 001855

16 Float rod 1 018583 018583

* Rebuild kit 1 150554 150554

06/11 thru

Current

* Items included in rebuild kit.

** Foot valve will need to be cut off as close to top of valve as possible and new one glued in place.

© Copyright 2013 Star Water Systems. All Rights Reserved.

7

SK2741

Page 8

STAR

95 North Oak St. | Kendallville, IN 46755 | 800-345-9422

®

www.starwatersystems.com

© Copyright 2010 Star Water Systems. All rights reserved.

8

Page 9

AVISO AL INSTALADOR: Las instrucciones deben permanecer en el sitio donde se realice la instalación.

FW1379S 0212

La siguiente información sobre

este producto reeja las condiciones existentes en la fecha de

publicación. Se debe consultar a

la fábrica cualquier discrepancia o

inconsistencia que exista.

STAR

®

Visite nuestro sitio web:

starwatersystems.com

Supersedes

1010

HomeGuard®

OPTIMA

MODELO 1503

SISTEMA DE BOMBA DE SUMIDERO AUXILIAR

DE EMERGENCIA ACCIONADA POR AGUA

FABRICADO EN PVC

LISTA DE VERIFICACIÓN PARA LA PREINSTALACIÓN

1. Inspeccione la bomba. Los productos se dañan ocasionalmente durante el transporte. Si la unidad o cualquiera de sus componentes tiene daños,

comuníquese con su proveedor antes de utilizarla.

2. Lea todas las instrucciones de instalación y arranque. Consérvelas para referencia futura.

VER ABAJO LA LISTA DE ADVERTENCIAS

1. Protéjase; desconecte siempre el suministro de energía de la

fuente de alimentación antes de manipular los componentes de la

bomba primaria.

VER ABAJO LA LISTA DE PRECAUCIONES

1. Esta bomba ha sido diseñada para aguas claras. No la use en

tanques sépticos para bombear euentes o en fosos cloacales para

bombear aguas negras.

2. Todo trabajo de reparación y mantenimiento de su sistema auxiliar

debe ser realizado por un servicio de mantenimiento autorizado.

3. La instalación de esta bomba auxiliar requiere un interruptor de

otador de nivel variable para su funcionamiento. El instalador

debe asegurarse de que la bomba y las peculiaridades del foso

REFIÉRASE A LA GARANTÍA EN LA PÁGINA 2.

© 2013 Star Water Systems. Todos los derechos reservados.

no intereran con el interruptor de otador y de que este esté bien

instalado para que la bomba se encienda y apague. Se recomienda

que el foso tenga un diámetro de 46 cm (18 pulgadas) o más para

que quepan una bomba primaria y una bomba auxiliar.

4. Verique la instalación de los otadores de las bombas primaria y

auxiliar para asegurarse de que ambas se muevan libremente y no

haya obstáculos que intereran con su desplazamiento. Se debe

mantener una distancia apropiada entre los otadores.

5. La varilla de los otadores se debe alzar una vez al mes para activar

la bomba manualmente. Mantenga la bomba encendida durante por

lo menos 15 segundos para prevenir la acumulación de depósitos

de calcio y escombros que podrían dañarla.

La turbulencia causada por el agua que

entra a alta velocidad podría afectar negativamente la acción

de encendido y apagado del mecanismo del otador. Si ocurre

esta condición, se debe amortiguar el agua que entra para evitar

la turbulencia excesiva.

9

Page 10

Garantía limitada

La garantía de este producto expirará después de transcurrido el más

corto de los siguientes lapsos: un año contado a partir de la fecha de

compra o dos años contados a partir de la fecha de fabricación. Sujeto

a las condiciones establecidas a continuación, el fabricante reparará

o reemplazará al consumidor original cualquier porción del producto

identificada como defectuosa debido a materiales o mano de obra

defectuosos. Para obtener servicio en garantía, acuda al establecimiento

donde fue comprado el producto. El fabricante retiene el derecho y

discreción exclusivos para determinar si se debe reparar o reemplazar un

equipo, parte o componente defectuoso. Daños debidos a condiciones que

estén fuera del control del fabricante no están cubiertos por esta garantía.

ESTA GARANTÍA NO CUBRE: (a) defectos o disfunciones resultantes

de una instalación, operación o mantenimiento de la unidad de una forma

diferente a la establecida en las instrucciones impresas proporcionaadas;

(b) fallas producidas por abuso, accidente o negligencia, o por el uso de

productos químicos o aditivos inapropiados en el agua; (c) servicios de

mantenimiento normales así como las partes usadas en conexión con

tales servicios; (d) aquellas unidades que no hayan sido instaladas de

conformidad con los códigos, ordenanzas y buenas prácticas locales

aplicados normalmente en esta industria; y (e) unidades usadas para fines

diferentes a aquéllos para los que fueron diseñadas y fabricadas.

DEVOLUCIÓN DE COMPONENTES GARANTIZADOS: Todo ítem que

deba ser reparado o reemplazado de conformidad con esta garantía

deberá ser devuelto, porte pagado, a la dirección del fabricante en

Kendallville, Indiana, EE. UU. o al lugar que indique el fabricante.

LA GARANTÍA AQUÍ ESPECIFICADA REEMPLAZA TODAS LAS

DEMÁS GARANTÍAS EXPRESAS, Y NO PODRÁ SER EXTENDIDA

NI MODIFICADA POR NADIE. TODA GARANTÍA IMPLÍCITA ESTARÁ

LIMITADA AL PERÍODO DE LA GARANTÍA LIMITADA, MÁS

ALLÁ DEL CUAL DICHAS GARANTÍAS IMPLÍCITAS QUEDARÁN

ANULADAS Y EXCLUIDAS. BAJO NINGUNA CIRCUNSTANCIA

EL FABRICANTE PODRÁ SER RESPONSABILIZADO DE DAÑOS

INCIDENTALES, INDIRECTOS O ESPECIALES TALES COMO,

AUNQUE NO TAXATIVAMENTE, PÉRDIDA DE OTRA PROPIEDAD

O EQUIPO, LUCRO CESANTE, INCOMODIDADES U OTROS

DAÑOS INCIDENTALES O INDIRECTOS DE CUALQUIER TIPO O

NATURALEZA. LA RESPONSABILIDAD DEL FABRICANTE NO

PODRÁ EXCEDER EL PRECIO DEL PRODUCTO SOBRE EL CUAL

ESTÁ BASADA DICHA RESPONSABILIDAD.

Esta garantía le otorga derechos legales específicos, y usted podría tener

también otros derechos que varían de un estado a otro. Algunos estados

no permiten limitaciones en la duración de las garantías implícitas o la

exclusión de daños incidentales o indirectos, en cuyo caso las limitaciones

antes mencionadas podrían no ser aplicables a su caso.

GARANTÍA VÁLIDA EN CANADÁ Y MÉXICO.

Recomendaciones prácticas para facilitar la instalación

1. Retire los escombros que haya en el foso antes de

realizar la instalación.

2. Asegúrese de que la bomba esté rmemente instalada

en la tubería de descarga de la bomba principal y de

que las dos bombas no intereran entre sí.

3. Instale una válvula de retención a la que se le pueda

hacer mantenimiento en la línea de descarga.

4. Instale un ltro o un colador en la línea de suministro

de agua, antes de la bomba. El tamaño del ltro o

colador debe ser apropiado a n de minimizar la caída

Lo que DEBE y NO DEBE hacer para instalar una unidad

1. LEA completamente todo el material sobre la

instalación provisto con la bomba.

2. INSPECCIONE la unidad para determinar si hay algún

daño visible causado durante el envío. Comuníquese

con el proveedor si la bomba está dañada.

3. RETIRE todos los escombros del foso antes de

realizar la instalación.

4. INSTALE una válvula de retención de unión (ver el

PASO 3) en la línea de descarga. NO use una tubería

de descarga de menor tamaño que la descarga

recomendada para la bomba.

5. INSTALE un ltro o colador en la línea de suministro

de agua, antes de la bomba, para evitar que partículas

pequeñas obstruyan el funcionamiento de la válvula.

6. PRUEBE la bomba inmediatamente después de

realizar la instalación para asegurarse de que el

sistema funcione correctamente.

© 2013 Star Water Systems. Todos los derechos reservados.

10

de presión y retener al mismo tiempo las partículas

que tengan un diámetro mínimo de 0,5 mm (0,020

pulgadas).

5. Verique la unidad inmediatamente después de

instalarla. Reérase al PASO 5.

6. Verique los niveles de encendido y apagado del

otador conforme a las instrucciones del PASO 2.

7. Obtenga el número de modelo, el código de fecha y

las instrucciones de instalación antes de llamar a la

fábrica.

7. EXAMINE todos los códigos nacionales y locales

pertinentes y verique que la instalación se realice

conforme a cada uno de ellos.

8. NO use la bomba Home Guard® Optima en agua

caliente. NO use la bomba Home Guard® Optima para

eliminar aguas residuales, aguas negras, euentes o

agua que contenga escombros.

9. NO use una manguera de jardín. Las mangueras de

jardín no están diseñadas para soportar la presión de

los sistemas de suministro de agua públicos y podrían

crear fugas o reventarse, causando inundaciones. La

bomba Home Guard® Optima requiere un sistema de

tuberías permanentes fabricado con componentes de

cobre, PEX o CPVC.

Page 11

Instalación

La bomba Home Guard® Optima se puede instalar muy fácilmente como una bomba de relevo para una bomba eléctrica de

sumidero (ver las ilustraciones). Sin embargo, se debe instalar una válvula de retención entre la bomba eléctrica y la bomba

Home Guard® Optima.

Nota 1: Según el Código Uniforme de Plomería (Uniform Plumbing Code) y los códigos de plomería de algunos estados, la

instalación de este producto requiere el uso de un dispositivo de prevención de contraujo RPZ (Reduced Pressure Zone - Zona

de presión reducida). Comuníquese con su entidad local de reglamentación de aguas públicas para obtener más información

sobre los requisitos en su área especíca.

Nota 2: Según el Código Uniforme de Plomería y la norma IAPMO PS119, la descarga de la bomba de sumidero accionada por

agua no se debe conectar a la descarga de la bomba de sumidero primaria.

PASO 1: Colocación de la bomba en el foso

Nota: Si el foso tiene una tapa, hay que modicarla para acomodar la bomba Home Guard® Optima.

1.1) Inspeccione el pozo para asegurarse de que no tenga escombros y límpielo si es necesario.

1.2) Coloque la bomba en el foso, asegurándose de que la conexión de entrada de la bomba esté por lo menos a 15 cm (6

pulgadas) por encima del piso del sótano o del borde superior del foso. Asegúrese de que la bomba esté rmemente

instalada en la tubería de descarga de la bomba primaria. Marque la posición en la tubería de descarga.

IMPORTANTE Esta bomba se debe utilizar como auxiliar de la bomba primaria. Asegúrese de que no haya interferencias entre

las dos bombas, especialmente entre los sistemas de otadores.

PASO 2: Ajuste de los topes del otador

2.1) Después de colocar la bomba Home Guard® Optima en el foso, mida la posición de encendido deseada (la posición debe

estar algunos centímetros por encima del nivel de encendido de la bomba existente). La bomba se enciende cuando el

nivel de agua cae de 5 a 8 cm (2 a 3 pulgadas) por debajo del tope superior del otador, conforme a la presión del agua de

entrada. Calcule la posición apropiada del tope del otador de acuerdo a esta distancia.

2.2) El nivel de apagado se determina en base a la otación del otador, así como a la presión del agua de entrada,

aproximadamente de 15 a 20 cm (6 a 8 pulgadas) por debajo del nivel de encendido. El nivel de apagado debe estar por

encima de la rejilla de succión de la válvula de aspiración. El nivel de apagado de la bomba no cambia cuando se ajusta el

tope inferior del otador. Se recomienda apretar bien el tope inferior en la parte inferior del otador para que no se deslice

sobre la varilla.

2.3) Saque la bomba del foso y ajuste los topes del otador según sea necesario. Apriete todas las tuercas. Asegúrese de

apretar bien el tope inferior para que no se desprenda. Si el tope inferior se desprende, el otador se caerá de la varilla, la

bomba dejará de funcionar y se podría averiar.

2.4) Vuelva a colocar la bomba en el foso, en la misma posición sobre la tubería de descarga de la bomba primaria, tal como se

marcó previamente (Paso 1.2). Esto asegurará que los niveles de encendido y apagado sean consistentes con los cálculos

realizados.

PASO 3: Instalación de la tubería de descarga

3.1) Fije la tubería de descarga a la bomba con pegamento, tal como muestra la ilustración de abajo (referencia SK2721B).

3.2) Según el Código Uniforme de Plomería y la norma IAPMO PS119, la descarga de la bomba de sumidero accionada por

agua no se debe conectar a la descarga de la bomba de sumidero primaria.

3.3) Se debe instalar una válvula de retención en la línea de descarga para que la instalación funcione correctamente. Se

recomienda utilizar las siguientes válvulas de retención Star Water Systems: KH34 o KH81. Algunos códigos locales

estipulan una válvula de retención de unión con un otador.

PASO 4: Instalación de la tubería de suministro de agua

4.1) Cierre el suministro de aguas públicas y conecte la tubería del sistema a la línea de aguas públicas. Esta línea debe

derivarse de una línea de ¾ de pulgada y conectarse a la bomba Home Guard® Optima mediante una tubería de ¾

de pulgada. No use una manguera de jardín o alguna otra tubería exible. Instale una válvula de cierre en la línea de

suministro de ¾ de pulgada a la bomba Home Guard® Optima. Use el método de prevención de contraujo que se requiera

en su localidad.

© 2013 Star Water Systems. Todos los derechos reservados.

11

Page 12

Instalación (continuación)

PASO 4: (continuación)

4.2) No suelde las conexiones de bronce a menos de 18 pulgadas de la bomba Home Guard® Optima, ya que el calor de la

antorcha dañará la cubierta exterior.

4.3) Cuando instale conexiones roscadas en la entrada de la bomba Home Guard® Optima, no aplique una solución

impermeabilizante en las roscas; use cinta aislante PTFE (Teon®). Tenga especial cuidado de evitar que queden escombros

(incluyendo trozos de cinta aislante) dentro de la conexión de entrada y que puedan obstruir la válvula.

4.4) La bomba Home Guard® Optima incluye una conexión de presión instalada en campo, diseñada para crear uniones con

tubos de cobre, PEX, CPVC de ¾ de pulgada. La conexión se debe instalar en la rosca NPT de ¾ de pulgada, en la

conexión de entrada de la bomba. Durante la instalación se debe tener cuidado de no sobreapretar la conexión en la entrada

de la bomba, ya que se podría romper la cubierta. Sujete la conexión de entrada con una llave auxiliar mientras aprieta

la conexión de presión. Si no utiliza la conexión de presión, debe observar las mismas precauciones que se siguen para

realizar cualquier instalación en la conexión de entrada.

4.5) Purgue la línea de agua antes de conectar la bomba Home Guard® Optima, para evitar la entrada de escombros que

podrían obstruir la válvula.

4.6) Si usa una conexión de presión, corte los extremos del tubo en ángulo recto. Asegúrese de que el extremo cortado no

tenga rebabas ni daños. Después de limpiar el extremo cortado en ángulo recto, dibuje una marca de profundidad en la

pared exterior de la tubería a 2,5 cm (1 pulgada) del extremo. Inserte el tubo a través del collar de desprendimiento hasta

que descanse contra el anillo de sujeción. Empuje rmemente el tubo mientras lo gira ligeramente hasta que se detenga

contra el tope. La marca de profundidad debe observarse en el extremo del collar de desprendimiento. No se requiere un

revestimiento si se utiliza una tubería de CPVC o cobre, y se puede retirar si lo permiten los códigos locales. El revestimiento

de la tubería se puede retirar fácilmente con un alicate de puntas largas.

4.7) Después de instalar la bomba y de conectar el suministro de aguas públicas, abra las llaves de suministro de aguas públicas

y de la línea de suministro de agua. Inspeccione el cuerpo de la válvula y todas las conexiones para asegurarse de que no

haya fugas. Cierre el suministro de aguas públicas y arregle cualquier fuga que haya antes de encender la bomba.

PASO 5: Vericación del funcionamiento de la bomba

5.1) Desenchufe la bomba primaria para que no se encienda.

5.2) Llene el foso de agua hasta que la bomba Home Guard® Optima se encienda.

5.3) Asegúrese de que la bomba se encienda y apague en las posiciones programadas.

5.4) Asegúrese de que no haya fugas en la línea de descarga.

5.5) Si hace falta algún ajuste, suba o baje los topes conforme a las instrucciones del PASO 2.

5.6) Si la bomba no funciona correctamente después de realizar los pasos anteriores, consulte la “Guía de detección y resolución

de problemas”.

5.7) Cuando concluya las pruebas, vuelva a enchufar la bomba primaria a una fuente de corriente alterna.

PRESIÓN DEL AGUA:

20 PSI, presión mínima con la válvula abierta.

80 PSI, presión máxima con la válvula abierta.

100 PSI, presión máxima con la válvula cerrada.

EFICIENCIA:

La capacidad de la bomba aumentará conforme a la presión y el caudal del agua doméstica.

Si se tiene una carga estática de 2,4 metros (8 pies) con una presión de ujo de 20 PSI en la tubería de suministro, se requiere

un caudal de entrada de 3,8 litros (1 galón) para extraer la misma cantidad de agua del foso. A medida que aumente la presión

del suministro de agua, con una carga estática constante, disminuirá la cantidad de agua requerida.

© 2013 Star Water Systems. Todos los derechos reservados.

12

Page 13

CANALISATION

A

D’AMENÉE D’EAU

DISPOSITIF DE

PRÉVENTION DE

RETOUR D’EAU ET

FILTRE (FOURNIS

SK2721B

PAR DES TIERS)

MINI 15,2 CM (6 PO)

TUYAUTERIE (FOURNIE

PAR DES TIERS)

RACCORDS

de descarga separada

CLAPETS DE

NON-RETOUR

FICHE À TROIS

BROCHES

Instalación típica con bomba sumergible y tubería

NIVEAU DE DÉMARRAGE

À DÉTERMINER PAR

UN ESSAI. VOIR LES

DIRECTIVES.

LE NIVEAU D’ARRÊT DOIT SE

TROUVER AU-DESSUS DE LA

CRÉPINE D’ASPIRATION ET DU

POMPE PRIMAIRE

NIVEAU DE DÉMARRAGE DE L

NIVEAU DE

DÉMARRAGE DE LA

FLOTTEUR

MARCHE-ARRÊT

POMPE PRIMAIRE

POMPE SUBMERSIBLE

Dimensiones

CONEXIÓN

DESLIZANTE

DESCARGA

DE 1-1/2

PULGADAS

ABRAZADERAS DE

MANGUERA PARA

CONECTAR LA UNIDAD A

LA TUBERÍA DE DESCARGA

© 2013 Star Water Systems. Todos los derechos reservados.

20,6 CM

(8-1/8 PULG.)

LONGITUD

DE LA BOMBA PR MARIA

14 CM

(5-1/2 PULG.)

ANCHURA

98,4 CM (38-3/4

PULG.) ALTURA

13

SUMINISTRO DE AGUA DE

SUCCIÓN

3/4 DE PULG. NPT

Page 14

Características de rendimiento

14

12

10

8

CARGA DINÁMICA TOTAL

6

4

2

0

PIES

METROS

45

40

35

30

25

20

15

10

5

GALONES

LITROS

REND MIENTO DE LA BOMBA

0

CURVA DE

MODELO S1503

40 PSI

20 PSI

5 10

20 40

CAUDAL POR MINUTO

60 PSI

15

20

CARGA/CAUDAL DINÁMICO TOTAL

POR MINUTO

ACHIQUE SOLAMENTE

S1503

LITROS

GALONES

10,4 m (34,0 pies)

LITROS

GALONES

12,8 m (42,0 pies)

80 PSI

MODELO

PIES

METROS

Altura de interrupción

018586

GALONES

4,3 m (14,0 pies)

LITROS

GALONES

6,7 m (22,0 pies)

La capacidad de la bomba varía debido a: presión de entrada del agua, presión de trabajo

del agua, altura de la descarga, número de conexiones de tubería, tamaño de las tuberías

de entrada y salida, viscosidad del uido, nivel de claridad del agua, temperatura del agua.

Los valores de los caudales en el cuadro son aproximados.

NOTA: Algunas municipalidades podrían requerir un limitador de contraujo principal para

25

reducir la presión, conforme a las normas ASSE 1013. Consulte los códigos locales.

8060

IL1094

LITROS

Guía de detección y resolución de problemas

CONDICIÓN POSIBLE CAUSA SOLUCIÓN

LA BOMBA NO ARRANCA O

NO FUNCIONA

LA BOMBA SE ENCIENDE

DEMASIADO PRONTO

LA BOMBA NO SE APAGA

LA BOMBA FUNCIONA PERO

BOMBEA POCA AGUA O NO

BOMBEA AGUA

Inadecuada presión de entrada del

agua.

Presión de agua excesiva.

Escombros junto a la entrada de

agua.

Flotador atascado en el foso o en la

bomba primaria.

El punto de encendido del otador

está demasiado bajo.

El otador está obstruido. Inspeccione el funcionamiento del otador y corrija el problema.

El punto de apagado del otador está

demasiado bajo.

La válvula de aspiración está encima

del nivel de agua.

El oricio de ventilación de la válvula

de diafragma interna está obstruido

con escombros.

Escombros junto a la entrada de

agua.

Inadecuada presión de entrada del

agua.

La tubería de descarga está ob-

struida.

La válvula de aspiración está encima

del nivel de agua.

La descarga vertical es demasiado

alta.

Revise la línea de entrada de agua para determinar si la válvula está

cerrada, la presión de agua es baja o el ltro/colador está obstruido.

Instale un regulador y reduzca la presión a menos de 100 PSI con la

válvula cerrada.

Limpie los escombros del foso y el colador de la válvula de aspiración.

Mueva las bombas de forma que los otadores se desplacen l bre-

mente sin tocarse entre sí, ni tocar el foso o las tuberías.

Reérase al PASO 2.

Reérase al PASO 2.

Ajuste el otador - Reérase al PASO 2.

Cierre y abra repetidamente el suministro de agua a la bomba para

desprender los escombros. Si este proceso no soluciona el problema, hágale un mantenimiento a la bomba para eliminar los escombros o cambie el ensamblaje de la válvula.

Limpie los escombros del foso y el colador de la válvula de aspiración.

Revise la línea de entrada de agua para determinar si la llave está

cerrada o hay poca presión de agua.

Retire la tubería y elimine los escombros.

Ajuste el otador - Reérase al PASO 2.

Cambie la tubería de descarga o solicite asistencia técnica.

© 2013 Star Water Systems. Todos los derechos reservados.

14

Page 15

Desglose de los componentes en la ilustración

REPUESTOS DE HOMEGUARD - MODELO 1503 1503-A

ÍTEM DESCRIPCIÓN CANT. NOTAS

1 Abrazadera 2 * 001766 001766

2 Conjunto de la válvula de contraujo 1 018587 018587

3 Conector de presión (sharkbite) 1 018584 018584

4 Diafragma y junta tórica 1 * 150553 150553

5 Conjunto del émbolo 1 * 018589 018589

6 Base de la tobera 1 018557 151713

7 Resorte 1 * 018564 018564

8 Conjunto de la guía imantada de la varilla del otador 1 150084 150084

9 Guía de la varilla del otador 1 150741 150741

10 Conjunto del tope del otador 2 * 054085 054085

11 Flotador 1 018567 018567

12 Venturi 1 4C5532 4C5532

13 Válvula de aspiración 1 ** 150260 150260

14 Conjunto de la válvula 1 150101 150101

15 Tornillo 6 * 001885 001855

16 Varilla del otador 1 018583 018583

* Juego de reposición 1 150554 150554

11.10

hasta

05.11

Del

06.11 a la

fecha

* Ítems incluidos en el juego de reposición.

** La válvula de aspiración se debe cortar lo más cerca posible de la parte superior y la válvula nueva se debe

jar con pegamento.

© 2013 Star Water Systems. Todos los derechos reservados.

15

SK2741

Page 16

STAR

95 North Oak St. | Kendallville, IN 46755 | 800-345-9422

®

www.starwatersystems.com

© 2013 Star Water Systems. Todos los derechos reservados.

16

Page 17

AVIS À L’INSTALLATEUR : laisser la notice d’installation avec l’équipement.

L’informa ion sur l’équipement

contenue dans la présente reète

les conditions au moment de la

publication. Prendre contact avec

l’usine en cas de différences ou

d’incohérences.

STAR

®

HomeGuard®

OPTIMA

Modèle S1503

FW1379F 0212

Supersedes

1010

visitez notre site Web:

starwatersystems.com

POMPE D’ASSÈCHEMENT DE SECOURS

À ENTRAÎNEMENT PAR EAU

EN PCV

LISTE DE CONTRÔLE AVANT L’INSTALLATION

1. Inspecter la pompe. Il arrive que des pièces soient endommagées pendant l’expédition. Si la pompe ou l’une de ses pièces est endommagée,

prendre contact avec le distributeur avant de la mise en service.

2. Lire toutes les directives concernant l’installation et le démarrage. Garder la notice pour consultation future.

pompage ou aux parties saillantes de la fosse et est xé de manière

VOIR LA LISTE DES AVERTISSEMENTS CI-DESSOUS

1. Par souci de protection, toujours déconnecter

l’alimentation électrique de sa source avant de manipuler

les composantes de la pompe primaire.

VOIR LA LISTE DES MISES EN GARDE CI-DESSOUS

1. La pompe est conçue pour pomper de l’eau limpide. Ne pas l’utiliser

pour pomper l’efuent d’une fosse septique ni pour pomper les eaux

d’égout.

2. La pompe de secours doit être réparée et entretenue par un centre

de service agréé.

3. La pompe de secours requiert l’installation d’un interrupteur à otteur

détecteur de niveau pour pouvoir fonctionner. L’installateur est tenu

de veiller à ce que l’interrupteur ne s’accroche pas à l’équipement de

à permettre le démarrage et l’arrêt de la pompe. On recommande

que la fosse ait un diamètre d’au moins 45,7 cm (18 po) pour pouvoir

y loger aussi bien la pompe primaire que la pompe de réserve.

4. Vérier le placement des otteurs des pompes primaire et de réserve

pour assurer qu’ils se déplacent librement et ne rencontrent aucune

obstruction qui pourrait empêcher leurs mouvements. Il faut maintenir

sufsamment d’espace entre les otteurs.

5. Activer la pompe manuellement une fois par mois en soulevant la

tige du otteur. Laisser la pompe fonctionner pendant au moins 15

secondes pour l’empêcher d’accumuler des dépôts de calcaire et

des débris qui risquent de l’endommager.

d’au à haute vitesse risque de nuire à l’action marche-arrêt

du mécanisme du otteur. Si c’est le cas, il faut installer des

déecteurs pour éviter une turbulence excessive.

La turbulence causée par l’admission

SE REPORTER À LA GARANTIE À LA PAGE 2

© 2013 Star Water Systems. Tous droits réservés.

17

Page 18

Garantie limitée

Ce produit est garanti pendant la période expirant la première, un

an après la date d'achat ou deux ans après la date de fabrication.

Selon les conditions établies ci-après, le fabricant réparera ou

remplacera pour le client d'origine, toute partie du produit qui s'est

avérée défectueuse à cause d'un défaut de matériau ou de maind'œuvre. Pour obtenir un service sous garantie, communiquer avec

le détaillant qui a vendu le produit. Le fabricant se réserve le droit et

le choix de déterminer s'il remplacera ou réparera l'équipement, les

pièces ou les composants défectueux. Les dommages résultant de

conditions hors du contrôle du fabricant ne sont pas couverts par

cette garantie.

CETTE GARANTIE NE S'APPLIQUE PAS : (a) Aux défauts

ou mauvais fonctionnements résultant d'une installation, d'une

utilisation ou d'un entretien incorrects de l'unité conformément

aux instructions imprimées fournies; (b) Aux pannes résultant

d'un abus, d'un accident ou d'une négligence ou de l'utilisation

d'additifs ou de produits chimiques inappropriés dans l'eau; (c) Aux

services d'entretien normaux et aux pièces utilisées dans le cadre

de cet entretien; (d) Aux unités qui n'ont pas été installées selon la

réglementation locale et les règles de l'art; et (e) L'unité est utilisée

pour des fins autres que celles pour lesquelles elle a été conçue et

fabriquée.

RETOUR DES COMPOSANTS SOUS GARANTIE : Tout article à

être réparé ou remplacé selon les termes de la présente garantie

doit être retourné au fabricant, à Kendalville, Indiana, USA ou à tout

autre endroit désigné par le fabricant, port payé.

LA PRÉSENTE GARANTIE REMPLACE TOUTE AUTRE

GARANTIE EXPRESSE ET NE PEUT PAS ÊTRE PROLONGÉE

OU MODIFIÉE PAR QUICONQUE. TOUTE GARANTIE

IMPLICITE DOIT ÊTRE LIMITÉE À LA PÉRIODE DE LA

GARANTIE LIMITÉE, ET PAR LA SUITE, TOUTE GARANTIE

IMPLICITE SERA REFUSÉE ET EXCLUE. LE FABRICANT NE

DEVRA, EN AUCUNS CAS, ÊTRE TENU RESPONSABLE DE

TOUS DOMMAGES-INTÉRÊTS ACCESSOIRES, INDIRECTS

OU SPÉCIAUX, TELS QUE, MAIS SANS S'Y LIMITER, LES

DOMMAGES OU LA PERTE DE PROPRIÉTÉ OU ÉQUIPEMENT,

PERTES DE REVENUS, INCONVÉNIENTS, OU AUTRES

DOMMAGES-INTÉRÊTS ACCESSOIRES OU INDIRECTS DE

QUELQUE NATURE. LA RESPONSABILITÉ DU FABRICANT

NE DOIT PAS DÉPASSER LE PRIX DU PRODUIT SUR LEQUEL

UNE TELLE RESPONSABILITÉ EST BASÉE.

Cette garantie confère à l'acheteur des droits précis et celui-ci

peut en avoir d'autres selon le lieu. Certains états ou provinces

ne permettent pas de limiter la durée des garanties implicites ou

l'exclusion des dommages-intérêts accessoires ou indirects, auquel

cas les limitations ci-dessus ne s'appliquent pas.

GARANTIE VALIDE AU CANADA ET AU MEXIQUE.

Conseils utiles pour faciliter l’installation

1. Enlever tous les détritus de la fosse avant

l’installation.

2. Vérier que la pompe est solidement xée à la conduite

de refoulement de la pompe primaire et que les deux

pompes ne se gênent pas mutuellement.

3. Monter un clapet de non-retour pouvant être entretenu

dans la conduite de refoulement.

4. Installer un ltre ou une crépine dans le tuyau

d’alimentation d’eau en aval de la pompe. Choisir un

ltre ou une crépine de dimensions correctes, pour

Conseils pour l’installation de la pompe

1. LIRE toute la documentation fournie avec la pompe.

2. INSPECTER la pompe pour détecter les traces visibles

de dommages causés au cours de l’expédition.

Prendre contact avec le fabricant si l’appareil semble

endommagé.

3. ENLEVER tous les détritus de la fosse avant

l’installation.

4. MONTER un clapet de non-retour à raccord union

(voir ÉTAPE 3) dans la conduite de refoulement. NE

PAS utiliser une conduite de refoulement de diamètre

inférieur à celui qui est recommandé.

5. INSTALLER un ltre ou une crépine dans le tuyau

d’alimentation d’eau en amont de la pompe pour

empêcher les petites particules de bloquer la vanne

de commande.

minimiser la chute de pression tout en piégeant les

particules d’un diamètre minimal de 0,5 mm (0,020

po).

5. Essayer l’appareil immédiatement après son

installation. Se reporter à l’ÉTAPE 5.

6. Contrôler les niveaux marche-arrêt du otteur suivant

les directives de l’ÉTAPE 2.

7. Avoir sous la main le numéro de modèle, le code

date et la notice d’installation à portée de main avant

d’appeler l’usine.

6. ESSAYER la pompe immédiatement après l’installation

pour vérier que le système fonctionne correctement.

7. ÉTUDIER tous les codes régionaux et nationaux

applicables et vérier que l’installation est conforme à

chacun d’entre eux.

8. NE PAS utiliser la pompe Home Guard® Optima dans

de l’eau chaude. NE PAS utiliser la pompe Home

Guard® Optima pour éliminer les eaux usées, eaux

d’égout, efuents ou eaux contenant des détritus.

9. NE PAS utiliser un tuyau d’arrosage. Un tuyau de ce

type n’est pas conçu pour supporter indéniment la

pression des eaux municipales et risque d’éclater,

provoquant une inondation. La pompe Home Guard®

Optima nécessite une tuyauterie permanente

fabriquée en cuivre, polyéthylène réticulé PEX ou

chlorure de polyvinyle chloré (PVC-C).

© 2013 Star Water Systems. Tous droits réservés.

18

Page 19

Installation

La pompe Home Guard® Optima peut être installée très facilement pour servir de pompe de secours d’une pompe

de puisard électrique (voir illustrations). Il faut cependant monter un clapet de non-retour entre la pompe électrique

et la pompe Home Guard® Optima.

Remarque 1 : Le code Uniform Plumbing Code (UPC – code régissant la plomberie) et les codes de certains États

régissant la plomberie exigent l’utilisation d’un dispositif RPZ (reduced pressure zone – zone de pression réduite) de

protection contre le retour d’eau. Faire appel à un plombier ou à la société de distribution des eaux pour obtenir plus

d’information concernant les exigences spéciques locales.

Remarque 2 : Les codes UPC et IAPMO PS119 interdisent le raccord du tuyau de refoulement de la pompe de

puisard hydraulique au tuyau de refoulement de la pompe de puisard primaire.

ÉTAPE 1 : Placement de la pompe dans la fosse

Remarque. - Si la fosse est munie d’un couvercle, il faut le modier pour l’adapter à la présence de la pompe Home

Guard® Optima.

1.1) Inspecter la fosse pour détecter la présence de détritus et la nettoyer, le cas échéant.

1.2) Placer la pompe dans la fosse en s’assurant que le raccord d’entrée de la pompe se trouve au moins à 15

cm (6 po) au-dessus du sol du sous-sol ou du rebord supérieur de la fosse du puisard. Vérier que la pompe

est solidement xée au tuyau de refoulement de la pompe primaire. Marquer l’emplacement sur le tuyau de

refoulement.

La pompe doit être utilisée comme pompe de secours de la pompe primaire. Veiller à ce qu’il n’y ait pas

d’interférence entre les deux pompes et surtout entre les dispositifs de otteur.

ÉTAPE 2 : Réglage de la butée du otteur

2.1) Après avoir installé la pompe Home Guard® Optima dans la fosse, mesurer le niveau de démarrage souhaité

du otteur (idéalement, quelques centimètres au-dessus du niveau de démarrage de la pompe existante). La

pompe se met en marche lorsque le niveau d’eau se trouve à environ 5 à 7,5 cm (2 à 3 po) en dessous de la

butée supérieure du otteur, suivant la pression du ux d’eau entrant. Calculer l’emplacement approprié de la

butée du otteur en fonction de cette distance.

2.2) La poussée hydrostatique du otteur et la pression d’eau du ux entrant déterminent le niveau d’arrêt de la

pompe, qui se trouve à environ 15 à 20 cm (6 à 8 po) en dessous du niveau de démarrage. Le niveau d’arrêt doit

se trouver au-dessus de la crépine d’aspiration du clapet de pied. L’ajustement de la butée inférieure ne modie

pas le niveau d’arrêt de la pompe. On recommande de bien serrer la butée inférieure contre le bas du otteur

pour l’empêcher de se déplacer le long de la tige du otteur.

2.3) Enlever la pompe de la fosse et ajuster les butées du otteur selon le besoin. Serrer toutes les vis. Veiller à

correctement serrer la butée inférieure pour qu’elle ne se détache pas. Si la butée inférieure se détache, le

otteur tombera de la tige, mettant la pompe hors service et risquant d’endommager la pompe.

2.4) Réinstaller la pompe dans la fosse au même endroit sur le tuyau de refoulement de la pompe primaire, tel

indiqué précédemment (étape 1.2). Ceci assure que les niveaux de démarrage et d’arrêt correspondent aux

calculs.

ÉTAPE 3 : Installation de la tuyauterie de refoulement

3.1) Coller le tuyau de refoulement dans la pompe, tel indiqué sur l’illustration suivante (no de référence SK2721B).

3.2) Les codes UPC et IAPMO PS119 interdisent le raccord du tuyau de refoulement de la pompe de secours à

entraînement par eau au tuyau de refoulement de la pompe de puisard primaire.

3.3) Il faut monter un clapet de non-retour sur le tuyau de refoulement pour assurer le fonctionnement correct de la

tuyauterie. On recommande les clapets de non-retour Star Water Systems suivants : KH34 et KH81. Certains

codes locaux exigent l’utilisation d’un raccord union à clapet à bille.

© 2013 Star Water Systems. Tous droits réservés.

19

Page 20

Installation (suite)

ÉTAPE 4 : Installation de la tuyauterie à la source d’eau

4.1) Couper l’alimentation d’eau municipale et raccorder la tuyauterie à la canalisation d’amenée d’eau municipale.

Elle doit être branchée sur un tuyau de ¾ po et raccordée à la pompe Home Guard® Optima en utilisant un tube

de ¾ po. Ne pas utiliser un tuyau d’arrosage ou autre tuyau ou tube exible. Monter un robinet d’arrêt dans le

tuyau de ¾ po alimentant la pompe Home Guard® Optima. Utiliser le dispositif de prévention de retour d’eau

approuvé par la juridiction locale.

4.2) Ne pas braser ni souder un raccord en cuivre à moins de 46 cm (18 po) de la pompe Home Guard® Optima, car

la chaleur émanant du chalumeau endommagera le corps de pompe.

4.3) En cas de xation d’un raccord leté à l’orice d’entrée d’eau de la pompe Home Guard® Optima, utiliser du

ruban d’étanchéité PTFE (Teon®) plutôt que de la pâte à joint. Faire très attention d’empêcher des détritus de

tous types (y compris des morceaux de ruban) de pénétrer dans l’orice d’entrée, entraînant le risque de rester

coincés dans la vanne de commande.

4.4) La pompe Home Guard® Optima est munie d’un raccord Push-to-Connect monté sur le terrain. Ce raccord est

conçu pour usage avec un tube de ¾ po en PEX, PVC-C ou cuivre. Il faut le monter sur le let NPT ¾ po du

raccord de l’orice d’entrée de la pompe. Lors de l’installation du raccord, il faut prendre garde de ne pas trop

serrer le raccord de l’orice d’entrée an de ne pas ssurer le corps de pompe. À l’aide d’une clé de dévissage,

maintenir le raccord de l’orice d’entrée pendant le serrage du raccord Push-to-Connect. Si l’on n’utilise pas le

raccord Push-to-Connect, il faut user des mêmes précautions lors du montage d’un quelconque autre raccord

sur le raccord de l’orice d’entrée.

4.5) Purger la canalisation d’eau avant de la raccorder à la pompe Home Guard® Optima, pour empêcher des détritus

éventuels de pénétrer dans la pompe et de boucher la vanne de commande.

4.6) En cas d’utilisation du raccord Push-to-Connect, couper les extrémités du tube perpendiculairement à l’axe du

tube. Vérier que l’extrémité coupée ne présente pas de bavures et n’est pas endommagée. Lorsque l’extrémité

du tube est perpendiculaire à l’axe et propre, placer un repère de profondeur à l’extérieur du tube à 2,5 cm (1

po) de l’extrémité. Glisser le tube au travers du collier de dégagement jusqu’à ce qu’il repose contre l’anneau

de prise. Appuyer fortement sur le tube en le tournant légèrement jusqu’à ce qu’il atteigne la butée de tube. Le

repère de profondeur doit se trouver au niveau de l’extrémité du collier de dégagement. Le revêtement de tube

n’est pas nécessaire en cas d’utilisation de tube en PVC-C ou cuivre et peut être enlevé selon les préférences

ou le code local. Le revêtement se retire facilement en utilisant une pince à bec pointu.

4.7) Après l’installation de la pompe et le raccord à la source d’eau municipale, ouvrir le robinet d’arrivée d’eau

municipale et le robinet de la canalisation d’admission d’eau. Vérier le corps de robinet et tous les raccords pour

détecter une fuite éventuelle. Fermer le robinet d’arrivée d’eau municipale et réparer les fuites éventuelles avant

de mettre la pompe en marche.

ÉTAPE 5 : Mise à l’essai du fonctionnement de la pompe

5.1) Débrancher la pompe primaire pour empêcher son démarrage.

5.2) Remplir le puisard d’eau jusqu’au démarrage de la pompe Home Guard® Optima.

5.3) Contrôler que la pompe démarre et s’arrête aux points ON/OFF souhaités.

5.4) Contrôler que la conduite d’évacuation ne fuit pas.

5.5) Si un réglage s’avère nécessaire, hausser ou baisser les butées du otteur conformément à l’ÉTAPE 2.

5.6) Si la pompe ne fonctionne pas correctement après l’exécution des étapes précédentes, se reporter au Guide de

dépannage.

5.7) Après avoir terminé l’essai, rebrancher la pompe primaire sur la prise c.a.

PRESSION D’EAU

Minimum 20 PSI lorsque la vanne est ouverte

Maximum 80 PSI lorsque la vanne est ouverte

Maximum 100 PSI lorsque la vanne est fermée

RENDEMENT

La capacité de pompage augmente avec la pression d’eau municipale et le débit.

Avec une charge statique de 2,4 m (8 pi) et une pression d’alimentation de 20 PSI à l’orice d’alimentation en eau

et avec l’eau coulant, 1 litre d’eau d’alimentation est requis pour enlever 1 litre d’eau du puisard. Le besoin en

eau d’alimentation diminue avec l’augmentation de la pression d’alimentation lorsque la charge statique demeure

constante.

© 2013 Star Water Systems. Tous droits réservés.

20

Page 21

FILTRO Y LIMIT

ADOR D

FLUJO (SUMINISTRADO

TUBERÍA DE

SUMINISTRO

DE AGUA

SK2721B

POR OTROS)

CONJUNTO DE TUBERÍAS

(SUMINISTRADO POR OTROS)

ACOPLADORES

VÁLVULAS DE

RETENCIÓN

15,2 CM (6 PULGADAS) MÍN.

EL NIVEL DE APAGADO DEBE

ESTAR POR ENCIMA DE LA

REJILLA DE SUCCIÓN Y DEL

NIVEL DE ENCENDIDO DE LA

BOMBA PRIMARIA

et conduite de refoulement distincte

ENCHUFE DE 3

PATILLAS

NIVEL DE ENCENDIDO

Installation typique à dimensions de pompe submersible

EL NIVEL DE ENCENDIDO SE

DETERMINA MEDIANTE

PRUEBAS. VER LAS

INSTRUCCIONES.

BOMBA SUMERGIBLE

DE LA BOMBA PRIMARIA

FLOTADOR DE

ACTIVACIÓN

Dimensions

REFOULEMENT

RACCORD

GLISSANT DE

1 ½ PO

LONGUEUR DE

20,6 CM (8 ½ PO)

LARGEUR DE

BRIDES DE SERRAGE

DE FIXATION AU TUYAU

DE REFOULEMENT DE

LA POMPE PRIMAIRE

14 CM (5 ½ PO)

HAUTEUR DE

98,4 CM (38 ¾ PO)

AL MENTATION

D’EAU NPT 3/4

ASPIRATION

© 2013 Star Water Systems. Tous droits réservés.

21

Page 22

Caractéristiques de rendement

HAUTEUR MANOMÉTRIQUE TOTALE

14

12

10

8

6

4

2

0

PIEDS

MÈTRES

45

40

35

30

25

20

15

10

5

GALLONS

LITRES

COURBE DE RENDEMENT

DE LA POMPE

MODÈLE S1503

60 PSI

40 PSI

20 PSI

15

0

5 10

20 40

DÉBIT PAR MINUTE

80 PSI

20

8060

HAUTEUR MANOMÉTRIQUE/DÉBIT TOTAUX

PAR MINUTE

ASSÈCHEMENT SEULEMENT

MODÈLE

MÈTRES

PIEDS

Hauteur vanne fermée

018586

GALLONS

4,3 m (14 pi)

GALLONS

6,7 cm (22 pi)

S1503

LITRES

GALLONS

10,4 m (34 pi)

LITRES

GALLONSLITRES

12,8 m (42 pi)

LITRES

La capacité de la pompe varie en fonction des facteurs suivants : pression d’eau

à l’orice d’entrée, pression d’eau au fonctionnement, élévation du refoulement,

nombre de raccords de tuyauterie, dimensions de la conduite d’amenée et

d’évacuation d’eau, viscosité du liquide, degré de limpidité de l’eau, température de

l’eau. Les débits indiqués par le graphique sont des valeurs approximatives.

REMARQUE. - Certains districts peuvent exiger un dispositif de prévention de

refoulement à pression réduite, conformément aux normes ASSE 1013. Vérier les

25

codes locaux.

IL1095

Guide de Dépannage

PROBLÈME CAUSE POSSIBLE SOLUTION

Contrôler la conduite d’amenée d’eau pour détecter un robinet fermé,

une pression d’eau insufsante ou une obstruction du ltre ou de la

crépine.

Installer un régulateur et faire baisser la pression à moins de 100 PSI

avec la vanne fermée.

Déplacer les pompes jusqu’à ce que les otteurs bougent l brement

sans entrer en contact avec la fosse, la tuyauterie ou l’un l’autre.

Se reporter à l’ÉTAPE 2.

Se reporter à l’ÉTAPE 2.

Ajuster le otteur. Se reporter à l’ÉTAPE 2.

Fermer et ouvrir plusieurs fois de suite l’alimentation d’eau à la

pompe pour déloger les détritus. Si cette procédure ne résout pas le

problème, entretenir la pompe pour éliminer les détritus ou remplacer

la vanne.

Contrôler la conduite d’amenée d’eau pour détecter un robinet fermé

ou une pression d’eau faible.

Enlever la conduite et purger les détritus.

Ajuster le otteur. Se reporter à l’ÉTAPE 2.

Remplacer la tuyauterie de refoulement ou prendre contact avec le

service technique.

LA POMPE NE DÉMARRE

PAS

OU NE FONCTIONNE PAS

LA POMPE DÉMARRE

PRÉMATURÉMENT

LA POMPE NE S’ARRÊTE

PAS

LA POMPE FONCTIONNE,

MAIS NE PRODUIT QUE

PEU OU PAS D’EAU

La pression d’eau entrante est

insufsante

La pression d’eau est excessive.

Des détritus entourent l’orice d’entrée. Éliminer les détritus des crépines de la fosse et du clapet de pied.

Un otteur reste accroché sur la fosse

ou la pompe primaire.

Le niveau de démarrage du otteur est

réglé trop bas.

Le otteur est bloqué. Contrôler le fonctionnement du otteur et corriger le problème.

Le niveau d’arrêt du otteur est réglé

trop bas.

Le clapet de pied se trouve au-dessus

du niveau de l’eau.

Des détritus bouchent l’évent du

diaphragme de la vanne interne.

Des détritus entourent l’orice d’entrée. Éliminer les détritus des crépines de la fosse et du clapet de pied.

La pression d’eau entrante est

insufsante

La conduite de refoulement est

bloquée.

Le clapet de pied se trouve au-dessus

du niveau de l’eau.

La levée verticale est trop haute.

© 2013 Star Water Systems. Tous droits réservés.

22

Page 23

Vue éclatée

PIÈCES DE RECHANGE HOMEGUARD – MODÈLE 1503 1503-A

ART. DESCRIPTION QTÉ REMARQUES

1 collier de serrage 2 *

2 dispositif de non-retour 1

3 bague en « dents de requin » 1

4 diaphragme et joint torique 1 *

5 piston 1 *

6 siège d’injecteur 1

7 ressort 1 *

8 guide de l’aimant de la tige de otteur 1

9 guide de la tige de otteur 1

10 butée du otteur 2 *

11 otteur 1

12 venturi 1

13 clapet de pied 1 **

14 ensemble de vanne 1

15 vis 6 *

16 tige de otteur 1

* kit de remise à neuf 1

11/10 à

05/11

001766 001766

018587 018587

018584 018584

150553 150553

018589 018589

018557 151713

018564 018564

150084 150084

150741 150741

054085 054085

018567 018567

4C5532 4C5532

150260 150260

150101 150101

001885 001855

018583 018583

150554 150554

du

06/11 au

présent

* Pièces comprises dans le kit de remise à neuf.

** Il faut couper le clapet de pied aussi proche que possible du haut de la valve et en coller un nouveau à la

place.

© 2013 Star Water Systems. Tous droits réservés.

23

SK2741

Page 24

STAR

95 North Oak St. | Kendallville, IN 46755 | 800-742-5044

®

starwatersystems.com

Loading...

Loading...