Page 1

STAR

Q y

S !

®

SW0614

1213

Supersedes

0212

POWERFLUSH OPTIMA

Product information presented

here reflects conditions at time

of publication. Consult factory

regarding discrepancies or

inconsistencies.

Patent No. 7,203,976

Other Patents

Pending

MODEL #

S1201/S1202/S1203

For missing, damaged parts or technical help, Call

1-800-742-5044

before returning product

For replacement pump, order N202RP

or see complete repair parts list on page 22

ATTACH YOUR RECEIPT HERE

Purchase Date

STOP

MODEL NO. ___________________

DATE CODE: __________________

DATE INSTALLED: _____________

P/N 018547

1

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION

Safety Information ....................................2

Package Contents ....................................4

Specications ...........................................4

Preparation ...............................................4

General Pump Uses .................................5

Dimensions ...............................................7

Location ofGrinder/Tank Unit ....................7

Toilet Assembly .........................................8

Water Supply Hookup ...............................9

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the product.

Inspect all materials before installation. If parts are damaged or missing, call 1-800-742-5044 before returning to

your retailer.

Exposed Grinder/Tank Installation .......... 11

Hidden Grinder/Tank Installation ............12

Piping......................................................13

Toilet Installation .....................................15

Adding Other Fixtures.............................18

Typical Installation ..................................19

Troubleshooting ......................................20

Warranty .................................................21

Replacement Parts .................................22

WARNING

ELECTRICAL SHOCK HAZARD.

To help reduce the risk of electrical shock, a properly grounded receptacle or control box of

grounding type must be installed and protected by a ground fault circuit interrupter (GFCI) in

accordance with the National Electrical Code and applicable local codes. Never remove ground

pin from plug.

ELECTRICAL SHOCK HAZARD.

Make certain that the ground fault interrupter protected receptacle is within reach of the pump’s

power supply cord. DO NOT USE AN EXTENSION CORD. Extension cords that are too long

or too light do not deliver sufficient voltage to the pump motor. But more important, they could

present a safety hazard if the insulation were to become damaged or the connection end were to

fall into a damp or wet area.

ELECTRICAL SHOCK HAZARD.

Make sure the pump’s electrical supply circuit is equipped with fuses or circuit breakers of proper

capacity. A separate branch circuit, sized according to the National Electrical Code for the current

shown on the pump name plate is recommended (see Note 3).

ELECTRICAL SHOCK ALERT.

TESTING FOR GROUND. As a safety measure, each electrical outlet should be checked for

ground using an Underwriters Laboratory Listed circuit analyzer which will indicate if the power,

neutral and ground wires are correctly connected to your outlet. If they are not, call a qualified

licensed electrician.

WARNING

ELECTRICAL SHOCK ALERT.

Installation and checking of electrical circuits and hardware should only be performed by a qualified

licensed electrician.

CHEMICAL ALERT.

According to the state of California (Prop 65), this product contains chemicals known to the state of

California to cause cancer and birth defects or other reproductive harm.

CAUTION

PRODUCT DAMAGE MAY RESULT

This unit is not designed to handle any material other than human waste and toilet paper. The following list

includes, but is not limited to, items that should not be used with this system: Feminine sanitary products,

condoms, cotton balls and swabs, baby wipes, paper towels, etc.

PRODUCT DAMAGE MAY RESULT

Check to be sure your power source is adequate to handle the amperage requirements of the motor as indicated

on the pump or unit I.D. tag.

PRODUCT DAMAGE MAY RESULT

All plumbing (discharge and vent lines) must be installed to meet local codes. Unit must be vented. Do not use

an automatic plumbing vent device. Toilet will not flush.

PRODUCT DAMAGE MAY RESULT

Maximum operating temperature for models S1201 / S1202 must not exceed 104°F (40°C). Duty cycle should

not exceed 30 seconds on/30 seconds off.

PRODUCT DAMAGE MAY RESULT

Do not use cleaning products containing bleach in the toilet tank, toilet or attached fixtures as they will degrade

the pump seals.

NOTES:

Repair and service should be performed by an Authorized Service Station only. (Consult Factory.)

Recommended for installations up to 20’ total dynamic head. Consult Factory if installation is above 15’ vertical

height in 1” pipe. Mini-grinder Pump is designed for use in PowerFlush Optima units only. It is not designed for use

in any other application.

Mini-grinder pump is rated for 115V, 60 Hz, 7 Amps, .5 HP.

ELECTRICAL SHOCK ALERT.

FOR YOUR PROTECTION ALWAYS DISCONNECT PUMP FROM ITS POWER SOURCE

BEFORE HANDLING. If pump is wired direct, de-energize the circuit at the control box. Grounded

pumps are supplied with a 3-prong grounded plug to help protect you against the possibility of

electrical shock. DO NOT UNDER ANY CIRCUMSTANCES REMOVE THE GROUND PIN. To

reduce the risk of electrical shock, a properly grounded receptacle of grounding type must be

installed and protected by a ground fault circuit interrupter (GFCI) in accordance with National

Electrical Code and applicable local codes.

2 3

Pumps with the “UL” mark and pumps with the “US” mark are tested to UL Standard UL778. CSA Certified pumps

are certified to CSA Standard C22.2 No. 108. PowerFlush Optima units only. It is not designed for use in any other

application.

Both S1201 and S1202 toilets utilize 1.28 gallons per flush.

All fixtures connecting to the system must be on the same floor level.

Page 3

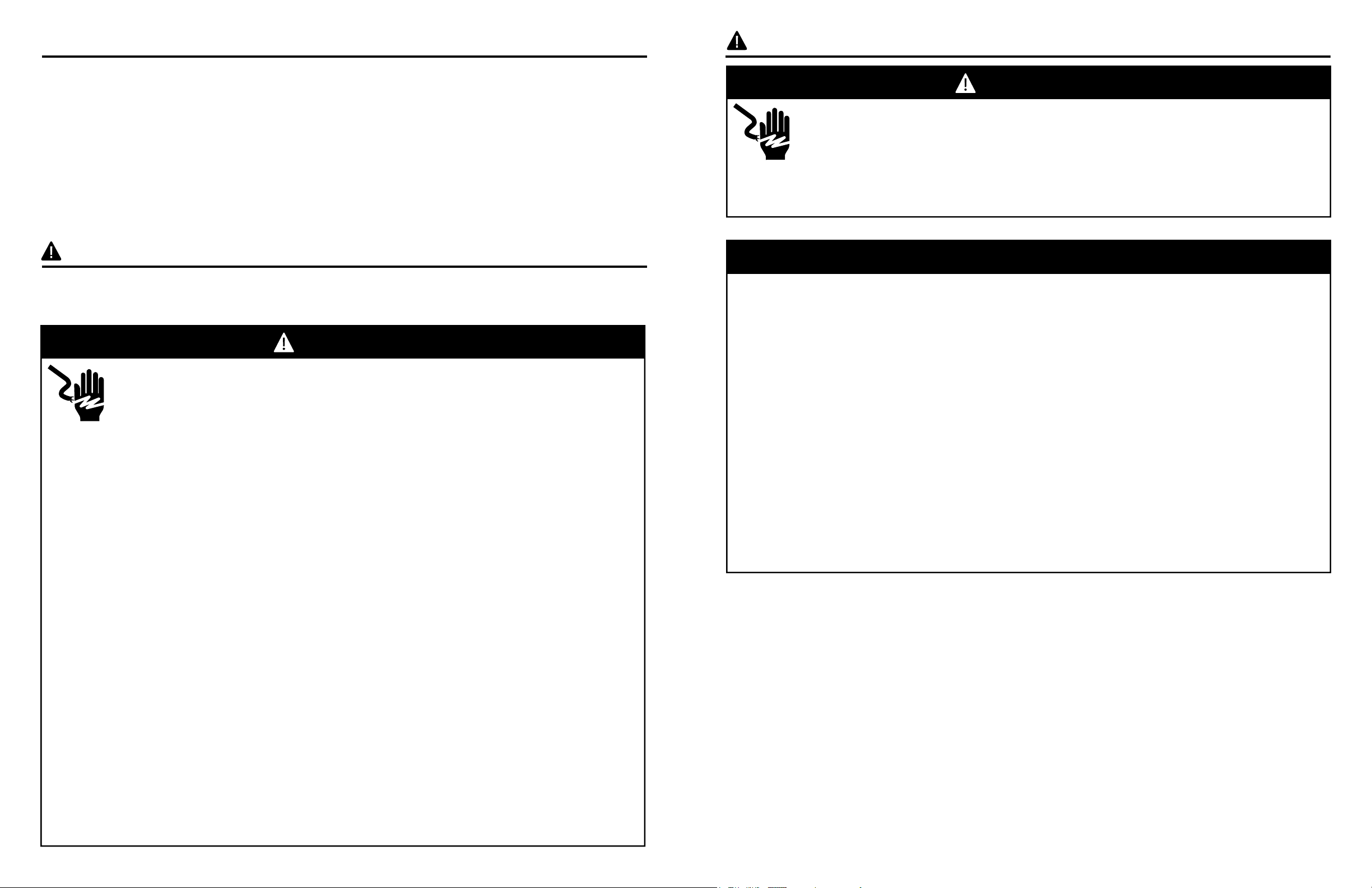

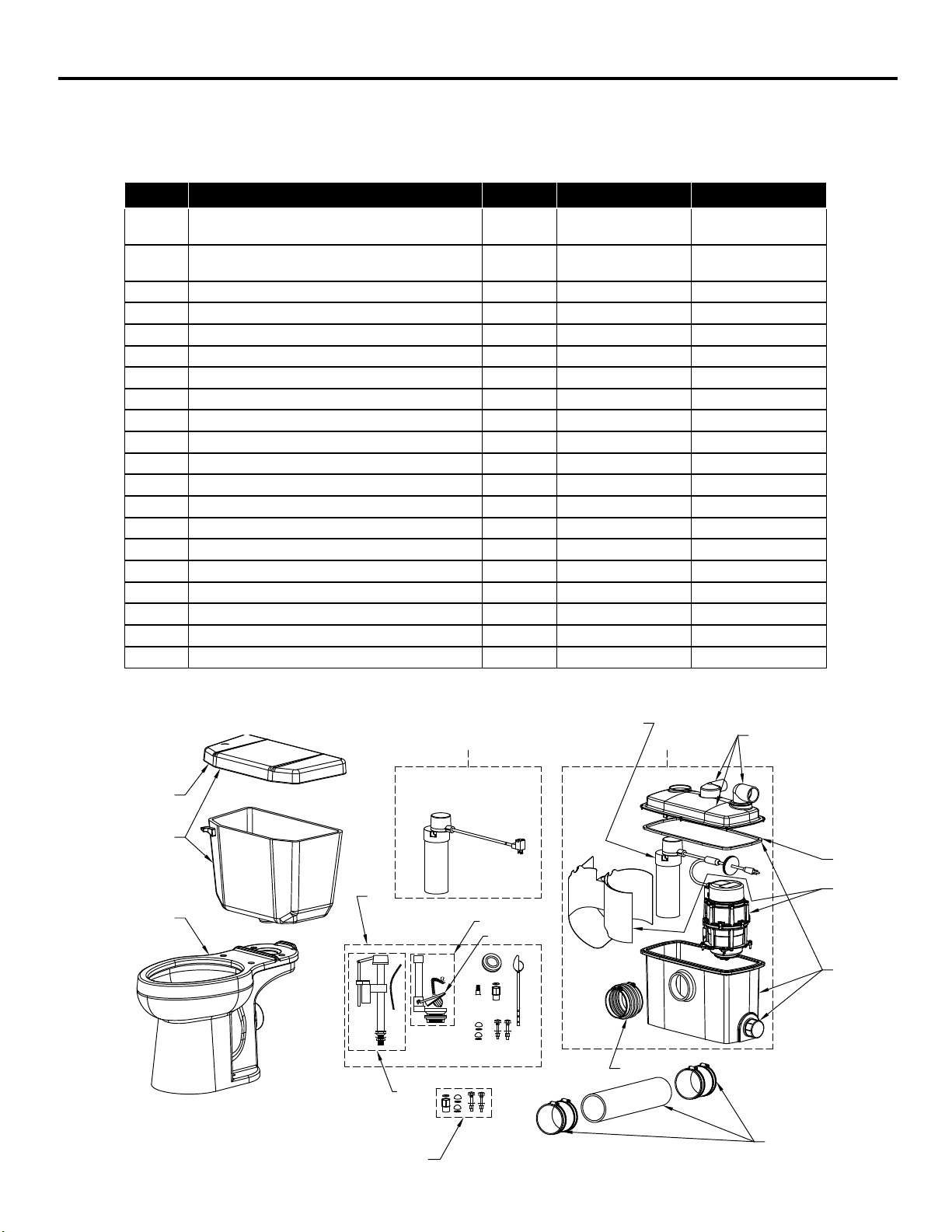

PACKAGE CONTENTS

GENERAL PUMP USES

Part Description Quantity

A Rear ush toilet 1

B Toilet tank, lid & gasket 1

1/2 HP mini-grinder pump unit

C

with discharge ttings 1

D 2 in. x 1 in. 90° discharge tting 1

E 1-1/2 in. vent tting 1

F Check valve 1

G Grinder tank hardware pack 1

H Rubber coupling 1

J Clamps for rubber coupling 2

K Toilet hardware pack 1

L* Installation instructions 1

*Not Shown

NOTE: For installations with pump unit hidden behind a wall,

purchase extension kit 023260.

IL1729

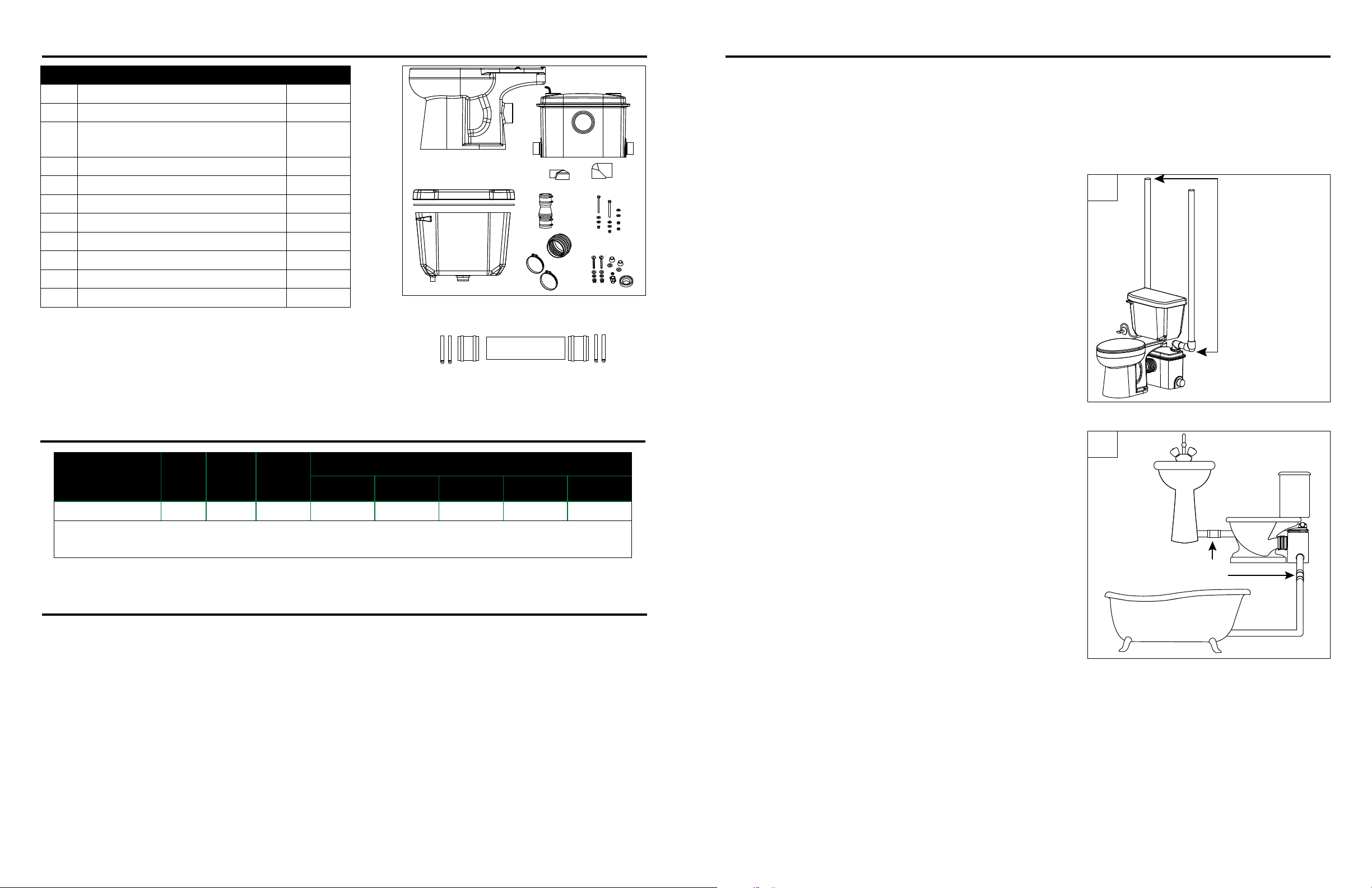

The Powerflush Optima allows you to add a bathroom in a variety of places:

A

Basements

New Homes

C

Cabins

Additions

D

E

1. The patented grinder/tank system is designed to move

waste water and sewage up to existing sewer lines

F

G

recommended for installations up to 20 ft. total dynamic

head.

H

K

J

B

IL1764

Workshops

Garages

Slab Construction

Commercial Buildings

1

Recommended

for up to 20 ft.

total dynamic

head

IL1733

SPECIFICATIONS

Gallons Per Hour Lift Capacity

Model HP Volts Amps

S1201/S1202 1/2 115 7 2700 2400 2100 1620 960

5 ft. 10 ft. 15 ft. 20 ft. 25 ft.

Recommended for installations up to 20 ft. total dynamic head. Consult factory if installation is

above 15 ft. vertical height in 1 in. pipe.

PREPARATION

Before beginning installation of product, make sure all parts are present. Compare parts with package

contents list. If any part is missing or damaged, do not attempt to assemble the product.

Estimated Installation Time: 5 hours for non-hidden installation or additional xtures.

Tools Required for Assembly (not included): tape measure, pipe tape, hacksaw, flathead screwdriver,

2-step PVC glue system (primer and sealer), hydraulic cement or other material

2. Multiple fixtures can drain into Powerflush Optima,

allowing you to include a bath or shower as well as

a vanity sink. Simply plumb these additional items

directly to the grinder/tank unit.

2

Check

Valve

IL1734

Parts Required For Assembly (not included): ,Discharge pipe and fittings per code, vent pipe and

fittings per code, ball valve or gate valve, union, water supply line, closet screw sets designed for

cement, 2 step PVC gluing system.

NOTE: For installations with pump unit hidden behind a wall, purchase extension kit 023260.

4 5

Page 4

GENERAL PUMP USES

This grinder/tank system can be used in the following installations:

3. Exposed Installation (grinder/tank unit is

visible behind toilet).

3

DIMENSIONS

All dimensions are in

inches.

17-1/2 in.

14-3/8 in.

Dim A.

Dim A:

20 in.

S1201 Round Bowl = 29 in.

S1202 Elongated Bowl = 31.5 in.

4. Hidden Installation (grinder/tank unit is hidden behind

wall). For installation behind a wall, extension kit

023260 (sold separately) is required.

4

Grinder/Tank

Unit

Optional Extension Kit 023260

Wall

IL1730

IL1731

LOCATION SELECTION AND LEVELING OF TANK

NOTE: If grinder/tank unit wlll be hidden behind a wall,

be sure to allow access to the pump & switch after

installation.

1. Select a location which is readily accessible to

the existing discharge and vent lines. Installation

behind a wall will require extension kit 023260 (sold

separately).

2. Level grinder/tank unit to within 1/8 in. for length and

width. Use hydraulic cement or similar material for

leveling.

1

Grinder/Tank

Unit

Optional Extension Kit 023260

2

Power cord

Wall

IL1731

CAUTION: Do not use wooden shims to level tank.

CAUTION: Ensure that nails, screws or other sharp

objects do not puncture tank

6 7

Level to within 1/8 in.

Page 5

TOILET ASSEMBLY

TOILET ASSEMBLY

1. Turn the toilet tank upside down and rest on protective

padding. Install the tank to bowl gasket over the bottom

threads of the flush valve, making sure that the tank

gasket covers the flush valve nut and the tapered side is

toward the bowl.

CAUTION: Do not use pipe dope on any plastic or rubber

parts.

CAUTION: Be careful when tightening bolts or nuts

against china to prevent cracking the china.

2. Lift the toilet tank right side up and position the tank on the

bowl by centering the gasket and aligning holes on the

bowl. Install tank to bowl bolts and rubber washers with

narrow side down, through the tank and bowl.

1

Toilet Tank

Tank to Bowl

Gasket

Flush Valve

Threads

Flush Valve Nut

2

Tank to Bowl Bolts

Rubber Washer

Toilet Tank

IL1735

Item Description

1 Toilet tank cover

2 Toilet tank

3 Toilet tank to toilet bowl gasket bolts

4 Rubber toilet tank to toilet bowl gasket

5 Water supply connection

6 Water supply line rubber seal

7 Water supply line adapter

8 Water supply line (not included)

9 Plastic flat washer

10 Plastic nut

11 Bolt cover

12 Toilet bowl

WATER SUPPLY HOOKUP

1. Make sure the incoming water supply is turned

off.

IL1763

1

Water Supply

Shut-off Valve

3. Push down on the top of the toilet tank one side at a time

while tightening plastic washers and nuts under the bowl.

Alternate tightening nuts to achieve a watertight seal,

while make sure the bowl and tank are level.

CAUTION: Do not overtighten or china may crack.

3

Plastic Washers

Plastic Nuts

Toilet Bowl

IL1736

IL1737

2. Insert the plastic coupling wing nut, plastic washer and

rubber seal over the end of the water supply line (not

included).

2

Plastic Coupling

WIng Nut

Rubber

Seal

Plastic

Washer

Water Supply Line

(Not Included)

8 9

IL1738

Page 6

WATER SUPPLY HOOKUP

IL1741

EXPOSED PUMP UNIT INSTALLATION

3. Connect the water supply line to the ballcock shank

that extends below the toilet tank by tightening the

plastic adapter with rubber washer over the end of the

ballcock shank.

CAUTION: Do not overtighten. Ballcock shank may

split and void the warranty.

EXPOSED PUMP UNIT INSTALLATION

1. Position the grinder/tank unit a minimum of 1/8" from

the wall with the inlet facing forward. Attach the rubber

coupling to the inlet using the worm drive clamp provided.

3

Rubber Washer

Plastic Adapter

1

Wall

1/8 in.

Minimum

Rubber

Coupling

Ballcock

Toilet

Tank

Grinder

Pump Unit

3. Lightly mark the locations of the grinder/tank unit, toilet

and closet screw set locations on the floor.

4. Lightly mark the wall with the height of the grinder/tank

unit and the bottom and sides of the toilet tank to prevent

interference from pipe runs during pipe installation.

Remove the toilet from the grinder/tank unit and set it

aside until piping is installed.

Grinder Pump Unit Location

3

4

Grinder/

tank unit

Toilet Tank Bottom and Sides

Closet

Screw Set

Locations

2. Place the toilet in front of grinder/tank unit; aligning the

discharge of the toilet with the inlet of the grinder/tank unit.

Check to be sure that the rubber coupling will bridge the

gap adequately for final installation. The toilet tank should

be a minimum of 1/2 in. from the wall.

CAUTION: Do not connect rubber coupling to toilet at this

time.

2

Wall

1/2 in. Minimum

Grinder

Unit

Inlet

Toilet Discharge

Inlet

Clamp

IL1740

IL1743

10 11

Page 7

HIDDEN PUMP UNIT INSTALLATION

PIPING

NOTE: Installing the grinder/tank unit behind a wall will

require an extension kit (P/N 023260) sold separately.

1. Place the toilet assembly a minimum of 1/2" from the

wall and mark the closet screw set locations on the floor.

2. Position the grinder/tank unit behind the wall. Measure

the appropriate length of 3½ in. Schedule 40 PVC pipe

provided with the extension kit and cut it to length. Set

toilet aside.

CAUTION: Toilet assembly is top heavy. Take special

precautions to ensure that toilet does not tip over and

break.

Toilet Tank Bottom and Sides

1

Grinder/

tank unit

2

Grinder/tank

unit

IL1743

1. Cut and dry-fit the pipe and fittings as required for

1" diameter discharge pipe (may be reduced to 3/4"

diameter if codes permit). While dry-fitting the discharge

pipe, position and mark the location of the grinder/tank

unit discharge fitting.

2. Cut and dry-fit 1-1/2 in. vent pipe as required to

ensure that the vent pipe does not interfere with other

components. Make the connection to the grinder/tank

unit with the provided street elbow.

CAUTION: Proper venting is required for the toilet to

flush. Do not use a mechanical type vent.

1

2

1 in.

Discharge

Pipe and

Fittings

Discharge

Pipe

Street

Elbow

Grinder/tank unit

discharge fitting

IL1745

Vent Pipe

Sched 40

PVC Pipe

IL1744

3. A 2 in. x 1 in. 90° discharge fitting and a 1-1/2 in.

street elbow vent fitting have been provided for space

constraints in an exposed configuration. However, these

are not required for a hidden (behind a wall) installation.

On a hidden installation, simplify installation and

improve performance by replacing the 90° discharge

fitting with a straight discharge pipe instead. Use a 2 in.

straight coupling and reduce it down to 1 in.

3

2 in.

Coupling

IL1746

1 in.

Discharge

Pipe

IL1747

12 13

Page 8

PIPING

Discharge

TOILET INSTALLATION

4. Temporarily set the toilet in place to check that there

is no piping interference. Remove the toilet and set it

aside.

5. Using a 2 step PVC gluing system, connect the

discharge piping and grinder/tank unit discharge fitting.

CAUTION: When applying glue to discharge fitting,

ensure that none gets into the check valve assembly,

which is built into the cover of the grinder/tank unit. Pay

close attention to the proper alignment of the discharge

fitting previously marked in STEP 1.

4

5

Discharge

Fitting

Pipe

IL1748

2-Step

PVC

Gluing

System

1. Pre-drill holes for closet screw sets at the points marked

earlier and install screws in holes.

2. Place the toilet assembly over the closet screw sets.

Install the anchoring hardware and tighten in an

alternating pattern. Check for level and shim as required.

Be careful when tightening bolts or nuts against china to

avoid cracking the china.

1

Toilet

Location

2

Grinder/tank unit location

Closet

Screw Set

Locations

IL1751

6. Using a 2 step PVC gluing system, connect vent piping

as required for proper venting.

6

Discharge

Pipe

Check

Valve

Assembly

IL1749

Vent

Pipe

IL1750

3. For exposed installation, Install rubber coupling onto the

toilet discharge and grinder/tank unit hub and secure

with the worm clamps provided .

IL1748

3

Grinder/

tank unit

Inlet

Closet Screw Sets

Rubber coupling

Toilet Discharge

Clamps

IL1753

14 15

Page 9

TOILET INSTALLATION

TOILET INSTALLATION

4. For hidden installation, (using optional extension kit

023260) install the rubber couplings to both the grinder/

tank unit and the toilet discharge and secure to extension

pipe with worm clamps provided.

5. Install the water supply line from the existing water

shut-off valve to the toilet water supply connection.

4

Grinder/tank

unit

5

Rubber Washer

Couplings

Clamps

Sched 40

PVC Pipe

IL1754

Ballcock

Toilet

Tank

7. Plug the pump’s power cord into the GFCI outlet.

8. Flush the toilet and watch for proper operation. Listen for

the pump to start. The pump unit requires proper venting

in order for toilet to flush. Check for leaks. Repeat flush

cycles to assure proper operation.

7

8

GFCI

Outlet

Pump

Plug

RESET

TEST

RESET

TEST

IL1756

6. Open the water supply valve and check for leaks.

The toilet tank should fill to the proper level. Adjust if

required.

Plastic Adapter

6

Water Supply

Shut-off Valve

IL1739

9. Install an elongated toilet seat for Model S1202 or round

toilet seat for Model S1201 (sold separately). Set the lid

on the toilet tank.

9

Check

for

leaks

Listen for pump

to start

IL1757

16 17

Elongated

Bowl

Round

Bowl

IL1758

Page 10

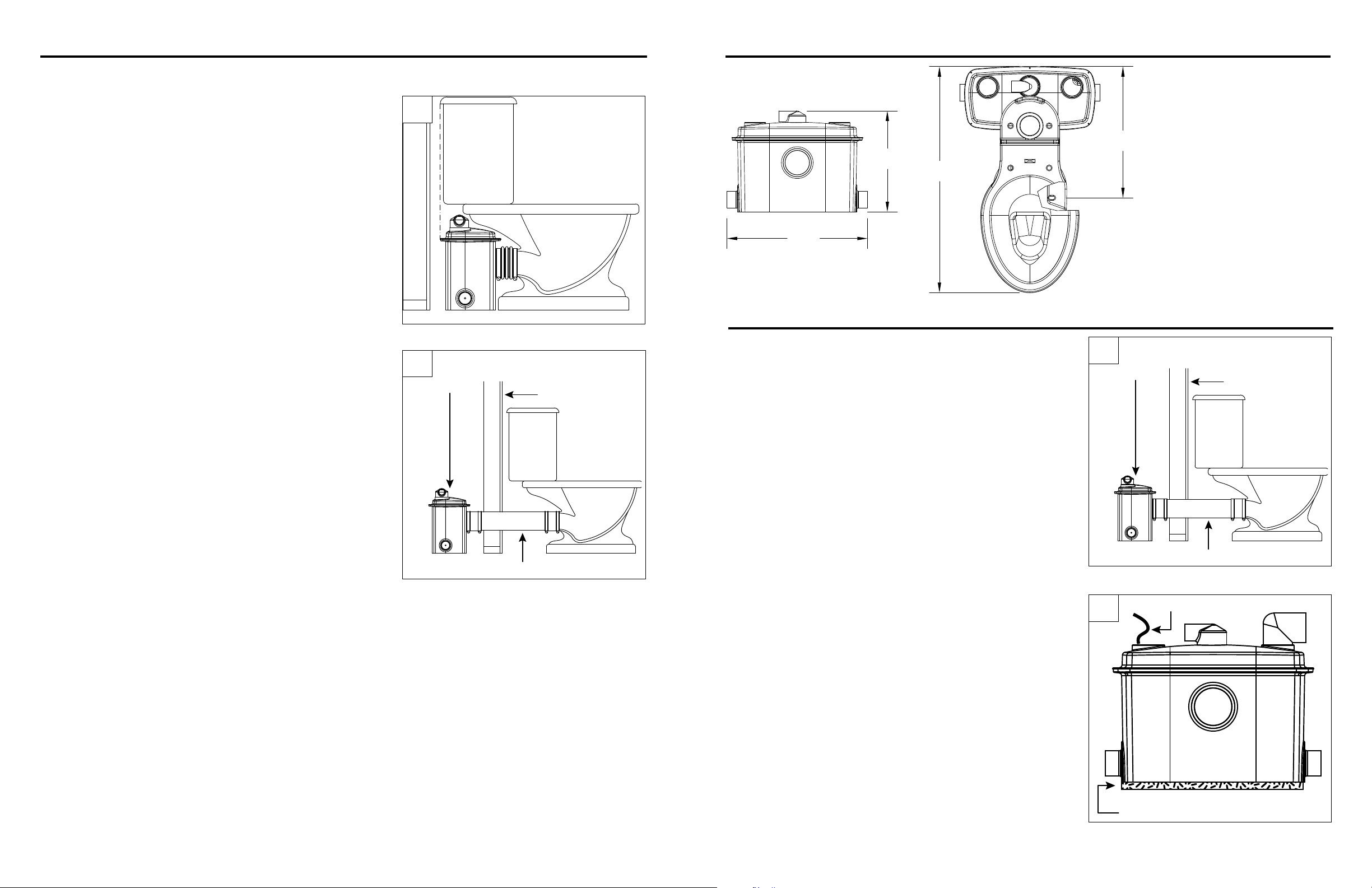

ADDING OTHER BATHROOM FIXTURES

TYPICAL INSTALLATION

1. PowerFlush Optima is designed to accept additional

bathroom fixtures utilizing the two side inlets.

2. Additional fixtures can be attached either to the 2

in. MPT (outside diameter) or the 1½ in. slip (inside

diameter). These side inlets are sealed by the factory

to prevent leaks when inlets are not used. Before use,

these side inlets must be drilled out using a 1¾ in. hole

saw.

1

2

Tub

Grinder

Pump

Unit Side

Inlets

Sink

IL1759

8 Ft. Ceiling

7 Ft. Ceiling

8”

Min

NOTE: All installations must comply with all applicable Electrical and

Plumbing Codes, including, but not limited, to National Electrical Code;

Local; Regional and/or State Plumbing Codes, etc.

Sub Floor

3/4” Thick

Minimum

2 x 8 Floor

Joists

3. When utilizing side inlets, install a check valve on the

incoming line.

Drill Point

IL1760

3

2" MPT

Outside

1-1/2"

Slip Inside

Check

Valve

IL1761

18 19

Page 11

TROUBLESHOOTING

WARRANTY

Condition Possible Cause Remedy

Pump will not start or run. Low voltage, blown fuse,

open circuit.

Impeller bound. Contact the Technical Service

Motor or wiring shorted.

Debris on oat switch. Remove debris

Pump starts too soon. Float “ON” point is adjusted

too low.

Water level excessive

before pump turns on.

Pump will not shut off or

runs too long before water

is pumped.

Pump operates but

delivers little or no water.

Float “ON” point adjusted to

high.

Debris under oat. Remove debris from around oat.

Faulty oat switch. Contact the Technical Service

Float “Off” point adjusted too

low.

Pump is air locked. Make sure vent hole in discharge pipe is

Water level too low. Raise the lower oat stop.

Waste material has

accumulated blocking ow of

material.

Debris around intake. Clean area around intake.

Blockage in discharge pipe. Remove pipe and ush out debris.

Low or incorrect voltage. Have a qualied electrician check house

Damaged Impeller. Contact the Technical Service

Incorrect oat adjustment. Contact the Technical Service

Pump is air locked. Make sure vent hole in discharge pipe is

Vertical lift too high. Change discharge piping or contact the

Have a qualied electrician check fuse and

circuit.

Department.

Raise the oat stops, make sure the oat is

between the two stops.

Lower the upper oat stop.

Department.

Raise the lower oat stop.

clear.

Hold ush handle down on toilet for 15

seconds. If unit will not clear, unplug

and wait 30 minutes. Plug unit back in

and repeat. If unit still will not turn off, it

will need to be opened and the debris

relocated.

wiring.

Department.

Department.

clear.

Technical Service Department.

Manufacturer warrants, to the purchaser and

subsequent owner during the warranty period,

every new product to be free from defects in

material and workmanship under normal use and

service, when properly used and maintained,

for a period of one year from date of purchase

by the end user, or 18 months from date of

original manufacture of the product, whichever

comes rst. Parts that fail within the warranty

period, one year from date of purchase by the

end user, or 18 months from the date of original

manufacture of the product, whichever comes

rst, that inspections determine to be defective

in material or workmanship, will be repaired,

replaced or remanufactured at Manufacturer’s

option, provided however, that by so doing we will

not be obligated to replace an entire assembly,

the entire mechanism or the complete unit. No

allowance will be made for shipping charges,

damages, labor or other charges that may occur

due to product failure, repair or replacement.

This warranty does not apply to and there shall

be no warranty for any material or product

that has been disassembled without prior

approval of Manufacturer, subjected to misuse,

misapplication, neglect, alteration, accident or

act of God; that has not been installed, operated

or maintained in accordance with Manufacturer’s

installation instructions; that has been exposed

to outside substances including but not limited

to the following: sand, gravel, cement, mud,

tar, hydrocarbons, hydrocarbon derivatives (oil,

gasoline, solvents, etc.), or other abrasive or

corrosive substances, wash towels or feminine

sanitary products, etc. in all pumping applications.

The warranty set out in the paragraph above is in

lieu of all other warranties expressed or implied;

and we do not authorize any representative or

other person to assume for us any other liability

in connection with our products.

Contact Manufacturer at, 95 North Oak Street,

Kendallville, IN 46755, Attention: Customer

Service Department to obtain any needed repair

or replacement of part(s) or additional information

pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS

LIABILITY FOR SPECIAL, CONSEQUENTIAL

OR INCIDENTAL DAMAGES OR BREACH

OF EXPRESSED OR IMPLIED WARRANTY;

AND ANY IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE AND OF

MERCHANTABILITY SHALL BE LIMITED

TO THE DURATION OF THE EXPRESSED

WARRANTY.

Some states do not allow limitations on the

duration of an implied warranty, so the above

limitation may not apply to you. Some states do

not allow the exclusion or limitation of incidental

or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specic legal rights and

you may also have other rights which vary from

state to state.

20 21

Page 12

REPLACEMENT PARTS

For replacement parts, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m.,

EST, Monday - Friday.

1202-A

09/09-06/12

1202-B

7/12 thru Current

PREMIUM CUTTER

ITEM DESCRIPTION QTY PART NO. PART NO.

1 PowerFlush Optima Md S1201, S1202 Sewage

removal system w/o toilet

PowerFlush Optima Md S1203 Sewage removal

system w/o toilet (Premium Cutter)

2 Pump with standard cutter and discharge pipe 1 N202RP N/A

Pump with premium cutter and discharge pipe N/A WM202RPPC

3 Tank cover with discharge ttings 1 017373 017373

4 Tank 1 018500 018500

5 Seal 1 017350 017350

6 Float switch assembly / Piggyback oat style 1 018501 N/A

Float switch assembly / Float rod kit N/A 151805

7 Toilet bowl-Model S1201 / Round Bowl 1 023465 023465

Toilet bowl-Model S1202 / Elongated Bowl 023112 023112

8 Toilet Tank with cover (1.6 GPF) 1 023111 023111

9 Toilet tank cover 1 150012 150012

10 Rubber coupling with hose clamps 1 018505 151802

11 Extension kit for behind wall installation 1 023260 023260

12 Tank to Toilet hardware 1 017360 017360

13 Flush valve replacement kit 1 150658 150658

14 Fill valve assembly with tube 1 150823 150823

15 Flush valve assembly 1 150824 150824

16 Flapper with clip and chain 1 150825 150825

1 1202-1000 N/A

N/A 1202-1001

1202-B (Float Rod Kit)

6

1

1202-A

9

(Piggyback Float Style)

3

8

5

6

13

7

15

2

16

4

10

14

11

12

IL1765

22

Loading...

Loading...