Page 1

NOTICE TO INSTALLER: Instructions must remain with installation.

Manufacturers of . . .

Quality Products since 1866

95 N. Oak St. Kendallville, IN 46755

1-800-345-9422

FW0131

0202

Supersedes

0701

CRAWL SPACE® PUMPING SYSTEM

S1108

PREINSTALLATION CHECKLIST

Through research and development, design, testing and manufacturing, we have been able to bring products to the market that solve

problems that plague consumers, industry, and the environment. This commitment to our customers has enabled them to enjoy returns

of our joint efforts.

1. Inspect your unit. Occasionally, products are damaged during shipment. If the unit is damaged, contact your dealer before using.

2. Carefully read the literature provided to familiarize yourself with specific details regarding installation and use. These materials

should be retained for future reference.

SEE BELOW FOR LIST OF WARNINGS

1. To reduce the risk of electrical shock, a properly grounded

receptacle of grounding type must be installed and protected

by a ground fault circuit interrupter (GFCI) and in accordance

with national electrical code and local codes.

2. Make certain that the receptacle is within the reach of the

pumps power supply cord. DO NOT USE AN EXTENSION

CORD. Extension cords that are too long or too light do not

deliver sufficient voltage to the pump motor. But more important, they could present a safety hazard if the insulation were

to become damaged or the connection end were to fall into the

sump.

3. Testing for Ground. As a safety measure, each electrical outlet

should be checked for ground using an Underwriters Laboratory Listed circuit analyzer which will indicate if the power,

neutral and ground wires are correctly connected to your outlet.

If they are not, call a qualified electrician.

4. For electrical safety, it is recommended that a GFCI be installed.

5. FOR YOUR PROTECTION, ALWAYS DISCONNECT PUMP FROM

ITS POWER SOURCE BEFORE HANDLING. Single phase

pumps are supplied with a 3-prong grounded plug to help

protect you against the possibility of electrical shock. DO NOT,

UNDER ANY CIRCUMSTANCES, REMOVE THE GROUND PIN.

To reduce the risk of electrical shock, a properly grounded

receptacle of grounding type must be installed and protected

by a ground fault circuit interrupter (GFCI) in accordance with

national electrical code and local codes.

SEE BELOW FOR LIST OF CAUTIONS

1. Check to be sure your power source is adequate for handling

the voltage requirements of the motor, as indicated on the

pump or basin plate.

2. Make sure the pump electrical supply circuit is equipped with

fuses or circuit breakers of proper capacity. A separate branch

circuit is recommended, sized according to the National Electrical Code for the current shown on the pump name plate.

3. Pump should be checked frequently for debris and/or build up

which may interfere with the float on or off position. Repair

and service should be performed by an Authorized Service

Station only.

4. A CHECK VALVE MAY BE REQUIRED TO REDUCE UNNECESSARY CYCLING OF PUMP.

5. Dewatering pumps are not designed or intended for handling

raw sewage.

6. Maximum operating temperature for Crawl Space Drain Pumps

must not exceed 130° F (54° C).

Product information presented here reflects conditions

at time of publication. Consult factory regarding

discrepancies or inconsistencies.

6. Installation and checking of electrical circuits and hardware

should only be performed by a qualified licensed electrician.

© Copyright 2002. All rights reserved.

1

Page 2

Ten Helpful Hints For Easy Installation

1. Read all instructions before beginning installation.

2. Be sure the installation does not exceed a maximum vertical lift of 19 feet.

3. Be sure the basin is level within 1/8 across the diameter.

4. Do not over torque extension tank attachment bolts.

5. Use backfill gravel that is larger than the slots in the basin.

Dos And Don'ts For Installing A Unit

1. DO read all installation material included with the pump.

2. DO inspect unit for any visible damage caused by shipping. Contact dealer

if unit appears to be damaged.

3. DO clean all debris from the pump reservoir.

4. DO always disconnect pump from power source before handling. DO

always connect to a separately protected and properly grounded ground

fault protected circuit. DO NOT ever cut, splice or damage power cord. DO

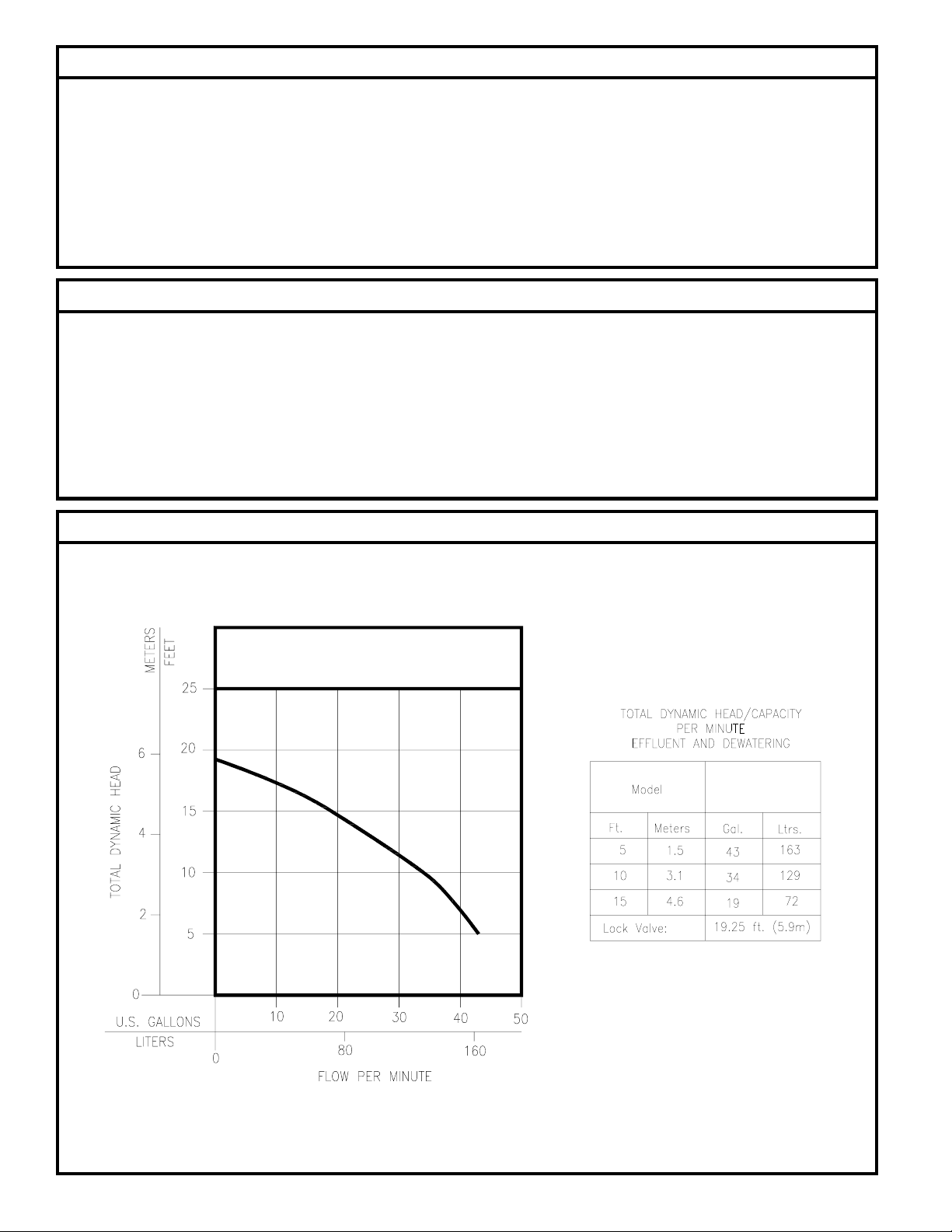

Performance Characteristics

6. Test operation of pump per STEP 5.

7. Do not over tighten bushing, check valve, or hose clamp.

8. Plug pump into a properly grounded, constant voltage source.

9. Do not plug into a device that runs intermittently.

10. Obtain model number and date code prior to calling factory.

NOT carry or lift pump by its power cord. DO NOT use an extension cord

with this Crawl Space Pumping System.

5. DO NOT use a discharge pipe smaller than the diameter of the hose kit.

6. DO test pump immediately after installation to be sure that the system is

working properly.

7. DO review all applicable local and national codes and verify that the

installation conforms to each of them.

Crawl Space Pumping System

HEAD CAPACITY CURVE

CRAWL

SPACE

009897

© Copyright 2002. All rights reserved.

2

Page 3

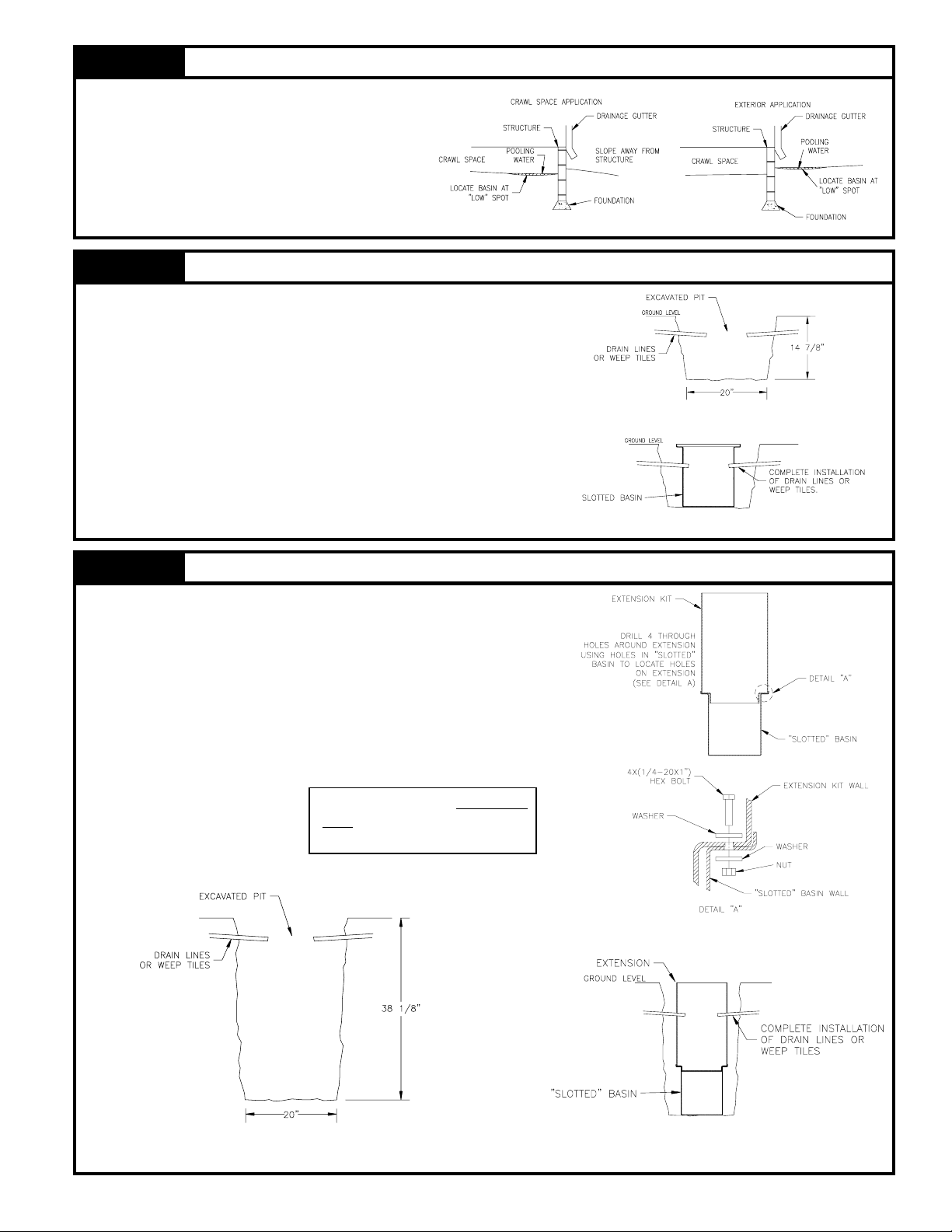

STEP 1 Site Selection for Drain Basin

Note: If freezing of the discharge line is possible, refer to Step 6.

1.1) Select a location that is a low spot or an area that naturally

collects water. Refer to Figure 1.1. Grade crawl space so

water will drain toward pit. Place plastic sheeting on

ground.

Note: If weep tiles or drain lines are to be used, then select a basin

location that will provide the most efficient drainage.

Figure 1.1

STEP 2 Installation of Basin (Typical Crawl Space Application)

Note: Proceed to STEP 2A if installing Slotted basin with extension kit.

2.1) Excavate the site to the dimension shown in Figure 2.1.

Note: If weep tiles or drain lines are to be used, rough-in plumbing should be completed at

this time.

2.2) Lower basin into pit (Refer to Figure 2.2). Complete installation of weep or drain lines.

Figure 2.1

SK1798

Figure 2.2

STEP 2A Installation of Slotted Basin with Optional Extension Kit

2A.1) Excavate the site to the dimensions shown in Figure 2A.1.

Note: If weep tiles or drain lines are to be used, rough-in plumbing should be completed

at this time.

2A.2) Attach the extension to the basin with the four bolts provided in the extension kit.

Refer to Figure 2A.2.

2A.3) Lower basin into pit and complete the installation of weep tiles or drain lines. Refer

to Figure 2A.3.

Note: If concrete is to be poured around the top of the extension, then make the pit depth

34½ to provide for access.

Extension Kit is an Accessory

Item and must be purchased

separately.

Figure 2A.2

SK1800

SK1802

Figure 2A.1

SK1801

© Copyright 2002. All rights reserved.

3

SK1803

Figure 2A.3

Page 4

STEP 3

Installation of Pump and Cover

3.1) Attach the flexible discharge hose to pump and lower into pit.

3.2) Attach lid and complete discharge line connections.

Note: Do not modify the Slotted basin lid. However, if extension kit is used, then it will

be necessary to drill ½ dia. inlet drain holes in the extension kit lid. Refer to Figure 3.2.

Note: After modification, attach the lid to the extension with 4 self-threading sheet metal

screws (included).

DO NOT USE LID SUPPLIED WITH SLOTTED BASIN IF USING

EXTENSION KIT.

Extension Kit is an

Accessory Item and must

be purchased separately.

Figure 3.1 Figure 3.2

STEP 4

4.1) Backfill pit as shown in Figure 4.1 & 4.2.

Backfill Pit

Extension Kit is an

Accessory Item and must

be purchased separately.

SK1799

Figure 4.1

SK1807

Figure 4.2

© Copyright 2002. All rights reserved.

4

Page 5

STEP 5

5.1) Plug in pump.

5.2) Pour water through lid until pump comes on.

5.3) Check all discharge line connections for leaks or obstructions.

5.4) If the pump begins to short cycle as described in part C of the troubleshooting guide, then it will be necessary to install a check valve in the discharge line.

This will prevent water from draining from the discharge line back into the pit. Refer to Figure 5.1. If a check valve is installed, the discharge pipe must be protected

from freezing. Refer to Step 6 for freezing protection.

5.5) If after completing the above procedures the system is not operating properly, refer to the Trouble Shooting Guide.

Testing of System

SK1805

Figure 5.1

STEP 6

Note: If there is the possibility of the discharge line freezing, then install the discharge line as recommended in Figure 6.1.

Freezing Protection

SK1822

Figure 6.1

© Copyright 2002. All rights reserved.

5

Extension Kit is an

Accessory Item and must

be purchased separately.

Page 6

Replacement Parts List

REF.

NO.

DESCRIPTION NOTES

QTY

Present

1 Pump 1 014729

2 Slotted Basin 1 012172

3 Lid 1 012173

4 Hose Kit 1 014732

6/98

to

SK1858

SK1824

SK1823

© Copyright 2002. All rights reserved.

6

Page 7

Trouble Shooting Guide

Condition Possible Cause Remedy

A. PUMP WILL NOT START OR RUN.

B. PUMP TRIPS OVERLOAD OR

BLOWS FUSE.

C. PUMP STARTS AND STOPS TOO

OFTEN.

Blown fuse.

Low voltage.

Thermal overload open.

Impeller bound.

Motor or wiring shorted.

Switch defective.

Damaged float.

Float assembly bound.

Incorrect voltage.

Impeller bound.

Motor shorted.

Short cycling (No check valve in discharge line to prevent water from draining back into pit).

Have a qualified electrician check circuit.

Contact an Authorized Service Station.

Check for debris around float.

Have qualified electrician check circuit.

Contact an Authorized Service Station.

Refer to STEP 5 for installation of check valve.

Defective float.

E. PUMP WILL NOT SHUT OFF.

F. PUMP OPERATES BUT DELIVERS

LITTLE OR NO WATER.

Before servicing a pump, always shut off the main

power breaker and then unplug the pump - making sure you are

not standing in water and are wearing insulated, protective-sole

shoes. Under flooded conditions, contact your local electric

company or a qualified licensed electrician for disconnecting

electrical service prior to pump removal.

Debris under float.

Switch defective.

Switch out of adjustment.

Weep hole plugged (Air-locked).

Obstruction in discharge line.

Discharge head exceeds capacity.

Low voltage.

Discharge line frozen.

Contact an Authorized Service Station.

Remove debris as necessary.

Contact an Authorized Service Station.

Clear weep hole as necessary.

Clear lines as necessary.

Refer to pump performance chart on page 2,

or contact factory.

Have qualified electrician check circuit.

Clear and protect from freezing (See STEP 6).

If the above checklist does not solve the problem, consult our

Technical Service Department. Do not attempt to service or

otherwise disassemble pump.

© Copyright 2002. All rights reserved.

7

Page 8

Manufacturers of . . .

Quality Products since 1866

95 N. Oak St. Kendallville, IN 46755

1-800-345-9422

© Copyright 2002. All rights reserved.

8

Loading...

Loading...