Page 1

Manufacturers of . . .

“Quality Products since 1866”

INSTALLATION IN STRUC TIONS

95 N. Oak St. • Kendallville, IN 46755

1-800-345-9422

DRAINMAKER

FW0107

110 4

Supersedes

0704

MODEL:_______________________

DATE CODE: __________________

DATE INSTALLED: _____________

PREINSTALLATION CHECK LIST

Notice to Installer: Instructions must remain with installation.

1. Inspect your unit. Occasionally, prod ucts are dam aged during ship ment. If the unit is damaged, contact your dealer before using.

Do Not remove the test plug from the pump.

2. Carefully read the literature provided to familiarize yourself with specifi c details regarding installation and use. These materials should

be re tained for future reference.

SEE BELOW FOR LIST OF WARNINGS

1. To reduce the risk of elec tri cal shock, a prop er ly ground ed

receptacle of grounding type must be in stalled and pro tect ed

by a ground fault circuit in ter rupt er (GFCI) and in ac cor dance

with National Electrical Code and lo cal codes.

2. Make certain that the receptacle is with in the reach of the pump’s

pow er supply cord. DO NOT USE AN EX TEN SION CORD.

Extension cords that are too long or too light do not deliver

suf fi cient voltage to the pump motor. But more im por tant, they

could present a safety hazard if the insulation were to become

damaged or the con nec tion end were to fall into the sump.

3. Testing for Ground. As a safety mea sure, each elec tri cal outlet

should be checked for ground using an Un der writ ers Lab o ra to ry

Listed circuit analyzer which will in di cate if the pow er, neutral

and ground wires are correctly con nect ed to your out let. If they

are not, call a qualifi ed elec tri cian.

4. For Added Safety. Pump must be con nect ed to a 3-prong

ground ed outlet in ter rupt er de vice (ground fault cir cuit in ter rupt er).

5. FOR YOUR PROTECTION, ALWAYS DIS CON NECT PUMP

FROM ITS POWER SOURCE BEFORE HAN DLING. Sin gle

phase pumps are supplied with a 3-prong ground ed plug to help

protect you against the pos si bil i ty of elec tri cal shock. DO NOT,

UNDER ANY CIR CUM STANC ES, RE MOVE THE GROUND

PIN. To re duce the risk of electrical shock, a properly grounded

re cep ta cle of ground ing type must be installed and pro tect ed

by a ground fault circuit interrupter (GFCI) in ac cor dance with

national elec tri cal code and local codes.

6. Installation and checking of electrical cir cuits and hard ware

should only be performed by a qualifi ed licensed electrician.

7. Risk of electric shock - These pumps have not been in ves ti gat ed

for use in swimming pool areas.

8. According to the state of California (Prop 65), this product

contains chemicals known to the state of California to cause

cancer and birth defects or other reproductive harm.

1. Check to be sure your power source is adequate for handling

the voltage requirements of the motor, as in di cat ed on the

pump or basin plate.

2. Make sure the pump electrical supply cir cuit is equipped with

fuses or circuit breakers of proper ca pac i ty. A sep a rate branch

circuit is rec om mend ed, sized ac cord ing to the National Elec tri cal Code for the current shown on the pump name plate.

3. All plumbing (discharge and vent lines) must be in stalled to

meet local codes. Unit must be vented. DO NOT USE AN

AU TO MAT IC PLUMBING VENT DEVICE SIM I LAR TO A

"PRO-VENT". Some states require this product to be installed

by a licensed plumb er.

4. Repair and service should be performed by an au tho rized

service station only.

5. CHECK VALVE MUST BE USED TO RE DUCE UN NEC ES SARY CYCLING OF PUMP. Check valve must be pur chased sep a rate ly.

6. Dewatering pumps are not designed or intended for han dling

raw sewage.

7. Maximum operating temperature must not exceed 77°F

(25°C).

8. For health reasons, do not unplug, turn off, or disable pump

and use pump tank system as a way to fi ll up a sink or laundry

tray, etc.

9. Unit is designed for above ground installation only.

NOTE: Pumps with the “UL” mark and pumps with the “US” mark

SEE BELOW FOR LIST OF CAUTIONS

are tested to UL Standard UL778. CSA Certifi ed pumps are

certifi ed to CSA Standard C22.2 No. 108.

Product information presented here re fl ects con di tions at time of publication. Consult factory re gard ing dis crep an cies or in con sis ten cies.

© Copyright 2004. All rights reserved.

1

Page 2

Ten Helpful Hints For Easy Installation

1. Read all instructions before beginning in stal la tion.

2. Be certain that basin is on a fi rm level surface.

3. Do not use an automatic plumbing vent device.

4. Do not over-torque lid attachment screws.

5. Always use a check valve on the discharge line.

6. Test operation of pump per STEP 6.

Do’s And Don't’s For Installing A Unit

1. DO read all installation material included with the

pump.

2. DO inspect unit for any visible damage caused by shipping. Contact dealer if unit appears to be damaged.

3. DO clean all debris from the basin and pump.

4. DO always disconnect pump from power source before

han dling. DO always connect to a separately protected

and prop er ly grounded ground fault protected circuit.

DO NOT ever cut, splice or damage power cord. DO

NOT carry or lift pump by its power cord. DO NOT use

an extension cord.

7. Always provide some means to disconnect basin from

plumb ing for maintenance purposes.

8. Run unit at least once a month to verify proper op er a tion.

9. The model number and date code can be found on

the lid warning label.

10. Plug pump into a properly grounded GFCI receptacle.

5. DO NOT use a discharge pipe smaller than the pump

discharge size.

6. DO test pump immediately after installation to be sure

that the system is working properly.

7. DO review all applicable local and national codes and

verify that the installation conforms to each of them.

8. DO NOT install unit in the ground.

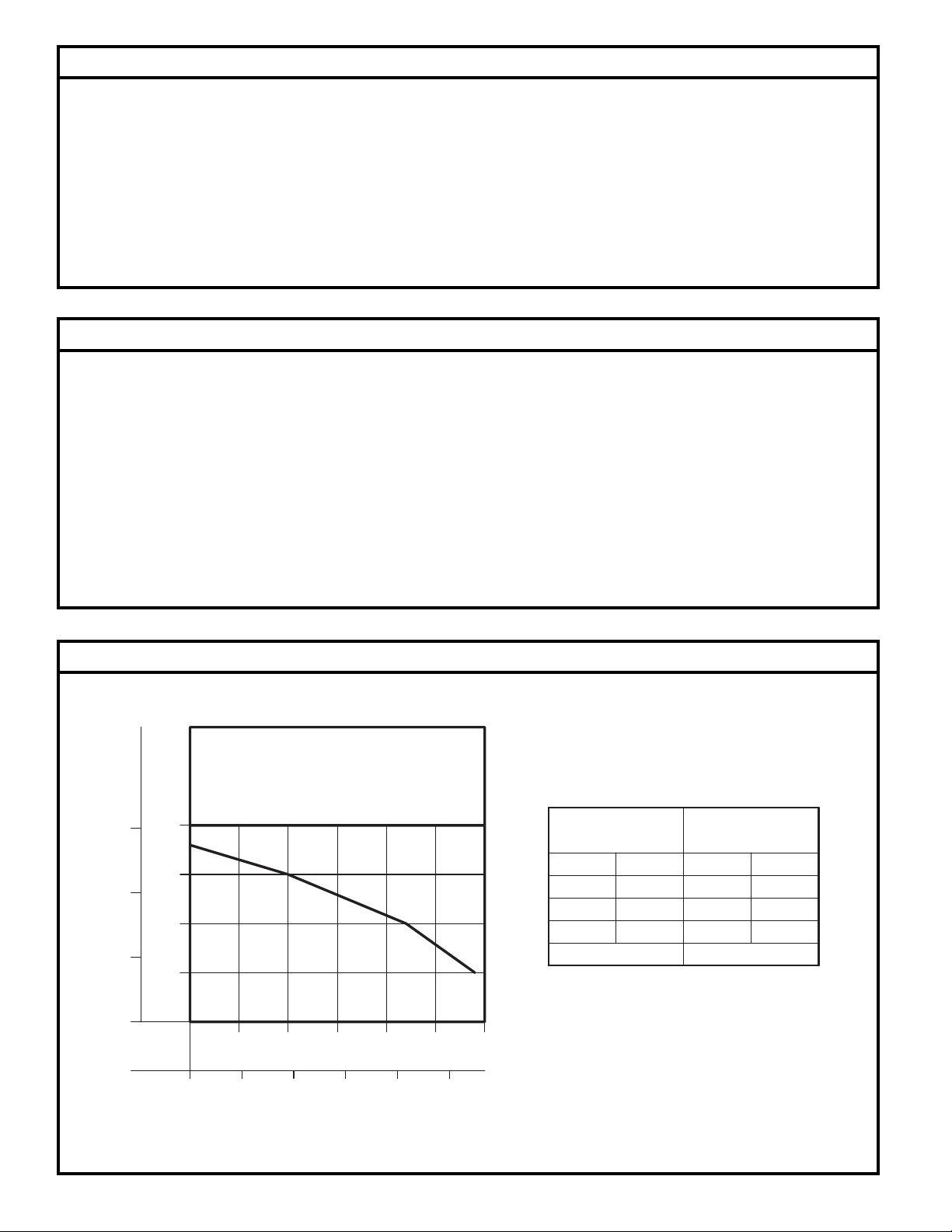

Performance Characteristics for the Pump in the DrainMaker System

TOTAL DYNAMIC HEAD/FLOW

METERS

FEET

20

6

15

4

10

TOTAL DYNAMIC HEAD

2

0

GALLONS

LITERS

PUMP PERFORMANCE CURVE

5

510

0

20 40

DRAINMAKER

15

FLOW PER MINUTE

20

Feet Meters

5

10

15 4.6

Shut-off Head:

25

8060

30

100

PER MINUTE

DEWATERING ONLY

MODEL

1.5

3.0

1048

Gal. Liters

29

22

10 38

18 ft. (5.5m)

110

83

009961BFW

009961AFW

© Copyright 2004. All rights reserved.

2

Page 3

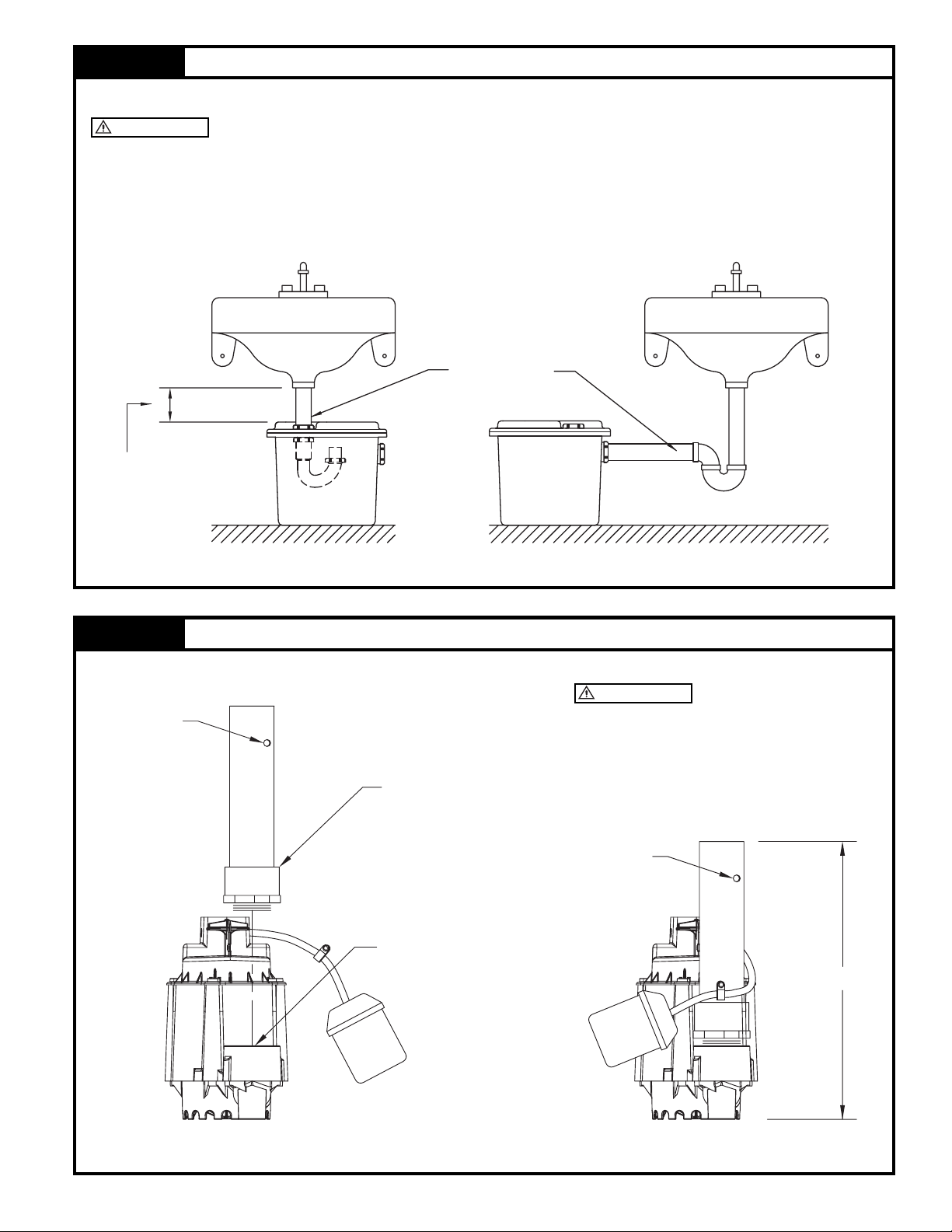

STEP 1 Determine Installation Confi guration

NOTE: The basin is designed to be installed directly under the sink (Internal Trap) or on the side (standard)

IMPORTANT!

Check local and state codes before using the internal trap option.

1.1) Figure 1.1A and 1.1B are typical confi gurations for installation of the drain systems. The actual confi guration

will vary depending on your cabinet and sink confi guration.

NOTE: If installing the internal trap, record the “x” dimension, it will be required in Step 4.

INTERNAL TRAP COMPONENTS SUPPLIED BY OTHERS.

PIPING SHOWN ONLY

FOR CLARITY.

X (4" MIN.)

SEE NOTE

Figure 1.1A

INTERNAL TRAP

STANDARD (EXTERNAL TRAP)

Figure 1.1B

STEP 2 Install the Discharge Pipe onto the Pump

IMPORTANT!

BE SURE THAT WEEP

WEEP HOLE

DISCHARGE PIPE

PUMP DISCHARGE

HOLE IS NOT DIRECTED TOWARD THE

FLOAT!

Water stream will be visible from this

hole during pump run periods.

WEEP HOLE

SK2001

11 3/8"

Figure 2.1

© Copyright 2004. All rights reserved.

3

SK2022

Page 4

STEP 2A Installation of the Float Assembly

2A.1) Install the fl oat as shown in Figure 2A.1 and Figure 2A.2.

WEEP HOLE

DISCHARGE PIPE

IMPORTANT!

FLOAT MUST BE

TETHERED IN THE ORIENTATION SHOWN

IN FIGURE 2A.2.

Water stream will be visible from this hole

during pump run periods.

2 1/4"

DRILL 3/16"

CAP

Figure 2A.1

THRU HOLE

6"

DRILL

Figure 2A.2

STEP 3 Installation of the Foam Gasket

3.1) Install the foam gasket into the “gasket seat” at the top of the basin, refer to Figure 3.1 for details.

OVERLAP DETAIL

FOAM GASKET

CAP

DISCHARGE PIPE

SK2009

GASKET SEAT

Figure 3.1

© Copyright 2004. All rights reserved.

4

APPROXIMATELY 1/4" OVERLAP

GASKET SEAT DETAIL

FOAM GASKET

BASIN

SK2003

Page 5

STEP 4 Internal Trap Installation Only

4.1) Cut the tailpipe to the dimension determined in Figure 4.1.

4.2) Install the sink drain components to the lid as shown in Figure 4.2.

4.3) Orient the lid assembly as shown in Figure 4.3 and secure the trap components.

(HAND TIGHTEN the assembly to the lid at this time. Adjustment will be required in Step 5.)

Note: To insure a proper water seal, the extension must be installed as shown in the “trap detail”.

INTERNAL TRAP COMPONENTS SUPPLIED BY OTHERS.

TRAP DETAIL

TAILPIPE

LENGTH

Figure 4.1

TAIL PIPE

X

4 1/2"

DIMENSION MEASURED

IN STEP 1.

TAIL PIPE

INLET

TRAP

4"

FLANGED TAIL PIPE

(SEE NOTE)

Figure 4.2

TRAP DISCHARGE PARTIALLY

VISIBLE THROUGH THE CORD

SEAL OPENING.

DISCHARGE

CORD SEAL OPENING

VENT

Figure 4.3

SK2004

© Copyright 2004. All rights reserved.

5

Page 6

STEP 5 Final Assembly

NOTE: External plumbing confi guration will vary depending on the location of basin, location of main stack

and available space.

5.1) Place the pump in the basin as shown in Figure 5.1.

NOTE: If installing the internal trap, rotate the tail pipe to the orientation shown in Figure 5.1.

5.2) Install the lid components as shown in Figure 5.2.

NOTE: Pull excess cordage through the opening and install the cordseal as shown in Figure 5.3A.

Ensure o-ring is in the cap before installation.

5.3) Place the basin assembly in its fi nal position and complete plumbing. Secure all connections

(shown in 5.3A or 5.3B).

KEY

Figure 5.1

(PURCHASED SEPARATELY)

CORD SEAL

GFCI

OUTLET

UNION

INLET

SK2005

TRAP INLET

O-RING

CHECK VALVE

CAP

SK2007B

CAP SECTION VIEW

*

CORD SEAL

SEE NOTE

O-RING

CAP

(PURCHASED SEPARATELY)

GFCI

OUTLET

UNION

CAP

CORD SEAL

INLET

2" SLP x NPT

Figure 5.2

1 1/2" SLP x NPT

(APPLY SEALANT TO THREADS)

1/4 - 20 x 1"

S.S. SCREWS

1/4 - 20 STD.

S.S. FLAT WASHERS

DISCHARGE PIPE

1/4 - 20 STD.

S.S. FLAT WASHERS

1/4 - 20

S.S. NUTS

(TORQUE TO 30 IN-LB)

DISCHARGE PIPEDISCHARGE PIPE

SK2007A

*

CHECK VALVE

CAP

INTERNAL TRAP INSTALLATION STANDARD INSTALLATION

Figure 5.3A Figure 5.3B

SK2006

*

CHECK VALVE MUST BE

PURCHASED SEPARATELY

STEP 6 Initial Testing of Drain Basin System

6.1) Plug the cord into a properly grounded GFCI receptacle.

6.2) Fill tank with water.

6.3) Check all plumbing for leaks as the basin fi lls.

6.4) Verify that the pump starts and stops.

6.5.) Check the discharge line for leaks as the pump empties the basin.

6.6.) Repeat steps 6.2 to 6.5 as necessary to insure proper operation.

6.7.) If problems persist refer to the troubleshooting guide located at the back of the manual.

© Copyright 2004. All rights reserved.

6

SK2006

Page 7

Illustrated Parts Breakdown

9

10

11

CHECK VALVE

(PURCHASED

SEPARATELY)

6

8

5

4

15

14

7

12

1

DRAINMAKER

08/00

ITEM DESCRIPTION QUANTITY thru

Current

1 Drain Pump 1 1104RP

2 Md. "WM1048" 1 014725

3 Basin - Tank 1 013017

4 Discharge Tube 1 013732

5 Basin - Lid 1 013018

6 Hard ware Pack 1 013733

7 Basin Seal 1 N/A*

8 Unicheck 1 N/A

9 ¼ - 20X1" lg. RHM Screw S.S. 8 N/A*

10 ¼ - Flat Washer S.S. 16 N/A*

11 ¼ - 20 Hex. Hd. Nut - S.S. 8 N/A*

12 Pipe Cap w/o-ring 1 N/A*

13 O-Ring 1 N/A*

14 Nylon Cable Tie 5/16” 1 N/A*

15 Self Tapping Screw#10x.375 1 N/A*

13

3

2

SK2008

* When ordering this item order the hardware pack item #6.

© Copyright 2004. All rights reserved.

7

Page 8

Service Checklist

ELECTRICAL PRECAUTIONS- Before servicing a pump, always shut off the main power breaker and then unplug the pump - making sure you are not standing in water and wearing insulated protective sole shoes. Under fl ooded conditions, contact your local electric company or a

qualifi ed licensed electrician for disconnecting electrical service prior to pump removal.

Submersible pumps contain oil which becomes pressured and hot under operating conditions — allow 2½ hours after disconnecting before

attempting service.

CONDITION

COMMON CAUSES

A. Pump will not start or run.

B. Motor overheats and trips over load

or blows fuse.

C. Pump starts and stops too often.

D. Pump will not shut off.

E. Pump operates but delivers little

or no wa ter.

F. Drop in head and/or capacity after

a period of use.

G. If tank or fi ttings leak.

If the above checklist does not uncover the problem, consult the factory - Do not attempt to service or otherwise disassemble pump.

Check fuse, low voltage, over load open, open or incorrect wiring, open switch, impeller or seal bound me chan i cal ly,

defective capacitor or relay when used, motor or wiring shorted. Float assembly held down. Switch defective,

dam aged, or out of adjustment.

Incorrect voltage, negative head (discharge open lower than normal) impeller or seal bound mechanically, defective capacitor or relay, motor shorted.

Float switch tether length too short, check valve stuck, or none installed in long distance line, over load open,

switch defective.

Debris under fl oat assembly, fl oat bound by pit sides or other, switch de fec tive, damaged or out of adjustment.

Check strainer housing, discharge pipe, or if check valve is used, the vent hole must be clear. Dis charge head

ex ceeds pump capacity. Low or incorrect voltage. Incorrect motor rotation. Ca pac i tor defective. Incoming water

con tain ing air or causing air to enter pump ing chamber.

Increased pipe friction, clogged line or check valve. Abrasive material and ad verse chem i cals could possibly

deteriorate impeller and pump housing. Check line. Remove base and inspect.

Carefully tighten pipe joints (use pipe dope) and screws. Check gasket location, tighten lid evenly. Do not over

tighten fi ttings or screws.

Manufacturers of . . .

“Quality Products since 1866”

95 N. Oak St. • Kendallville, IN 46755

1-800-345-9422

© Copyright 2004. All rights reserved.

8

Loading...

Loading...