Page 1

STAR

®

FW1591

0113

Supersedes NEW

BATHROOM ADD-ON SYSTEM

Patent No. 5,038,418

MODEL #

Español p. 20

S1101

For missing, damaged parts or technical help, Call

1-800-742-5044

For replacement pump, order 1102RP

or see complete repair parts list on page 17

ATTACH YOUR RECEIPT HERE

Purchase Date

STOP

before returning product

P/N 152521

1

Page 2

TABLE OF CONTENTS

Safety Information ............................................................................................................................2

Package Contents ............................................................................................................................4

Preparation .......................................................................................................................................5

General Pump Uses .........................................................................................................................5

Dimensions .......................................................................................................................................6

Pump System Location.....................................................................................................................6

Bolt Location .....................................................................................................................................7

Testing Operation .............................................................................................................................8

Connect to Plumbing ........................................................................................................................9

Installation of Toilet - Exposed Installation ...................................................................................... 11

Installation of Toilet - Hidden Installation ........................................................................................ 11

Additional Fixtures ..........................................................................................................................13

Replacement Parts .........................................................................................................................17

Troubleshooting ..............................................................................................................................18

Spotting Template ........................................................................................................................... 19

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the

product.

Inspect all materials before installation. If parts are damaged or missing, call 1-800-742-5044 before

returning to your retailer.

DANGER

ELECTRICAL SHOCK HAZARD.

Always disconnect power source before performing any work on or near the motor or its

connected load. If the power disconnect point is out-of-sight, lock it in the open position and tag it

to prevent unexpected application of power. Failure to do so could result in fatal electrical shock.

ELECTRICAL SHOCK HAZARD.

Do not handle the pump with wet hands or when standing in water as fatal electrical shock could

occur. Disconnect main power before handling unit for ANY REASON!

RISK OF ELECTRIC SHOCK.

These pumps have not been investigated for use in swimming pool areas.

2

Page 3

SAFETY INFORMATION

WARNING

ELECTRICAL SHOCK ALERT.

To reduce the risk of electric shock, install only a circuit protected by a ground-fault circuit-interrupter

(GFCI). Make certain that the ground fault receptacle is within the reach of the pump’s power supply

cord. DO NOT USE AN EXTENSION CORD.

ELECTRICAL SHOCK ALERT.

Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

ELECTRICAL SHOCK ALERT.

Do not kink power cable and never allow the cable to come in contact with oil, grease, hot surfaces,

chemicals or sharp objects. Replace damaged or worn wiring cord immediately.

ELECTRICAL SHOCK ALERT.

As a safety measure, each electrical outlet should be checked for ground using an Underwriters

Laboratory Listed circuit analyzer which will indicate if the power, neutral and ground wires are

correctly connected to your outlet. If they are not, contact a licensed electrician.

ELECTRICAL SHOCK ALERT.

These pumps are supplied with a 3-prong grounded plug to help protect you against the possibility

of electrical shock. DO NOT UNDER ANY CIRCUMSTANCES REMOVE THE GROUND PIN.

ELECTRICAL SHOCK ALERT.

Make sure the pump electrical supply circuit is equipped with fuses or circuit breakers of proper

capacity. A separate branch circuit is recommended, sized according to the National Electrical

Code for the current shown on the pump nameplate.

CHEMICAL ALERT.

This product contains chemicals known to the state of California to cause cancer and birth defects

or other reproductive harm.

CAUTION

PRODUCT DAMAGE MAY RESULT

Make certain the power source conforms to the requirements of your equipment.

PRODUCT DAMAGE MAY RESULT

Maximum continuous operating water temperature for standard model pumps must not exceed 130°F (54°C).

PRODUCT DAMAGE MAY RESULT

Do not use an automatic plumbing vent device such as a “Pro-Vent.” Some states require this product to be

installed by a licensed plumber.

• NOTE: Pumps with the “UL” mark and pumps with the “US” mark are tested to UL Standard

UL778. CSA certied pumps are certied to CSA Standard C22.2 No. 108. (CUS.)

• Do not use wax seal that includes a ange that extends into the tank. If a oor is installed over the

tank, use the oor ange extender seal kit included with the system.

• For installation below the original oor line, call 1-800-742-5044.

3

Page 4

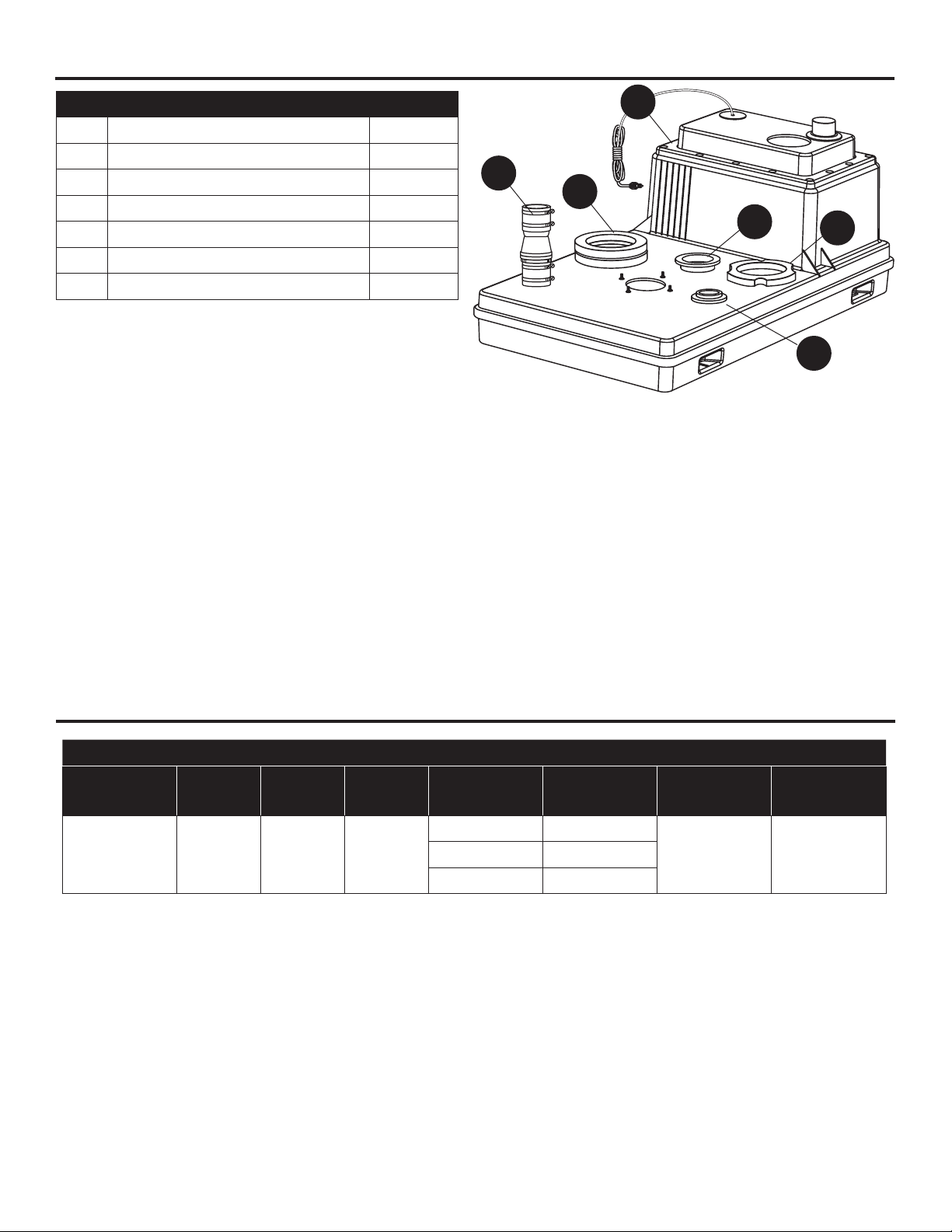

PACKAGE CONTENTS

Part Description Quantity

A Pre-assembled Pump System 1

B 2 in. Pipe Seal for 3 in. hole 2

C 2” Check Valve 1

D 3 in. Pipe Seal for 4 in. hole 1

E Wax Ring 2

F Locator Ring 1

* Hardware Pack 1

*Not Shown

C

E

A

D

F

B

SPECIFICATIONS

PERFORMANCE

Model

Number

S1101 .4 1 115

NOTE: Be sure installation has a minimum of 5 ft. vertical head. Recommended for maximum of

13 ft. vertical head.

HP Phase Volts Ft. of Head Flow (GPM)

5 73

15 19

Shut Off

Head (Ft.)

17.5 2 in.10 39

Discharge

Size

4

Page 5

PREPARATION

Before beginning installation of product, make sure all parts are present. Compare parts with package

contents list. If any part is missing or damaged, do not attempt to assemble the product.

Estimated Installation Time: 5 hours for non-hidden installation or additional xtures.

Tools Required for Assembly (not included): tape measure, pipe tape, hacksaw, flathead screwdriver,

2-step PVC glue system (primer and sealer), hydraulic cement or other material

Parts Required For Assembly (not included): 2 in. Rubber coupling or union, 2 in. and 3 in. PVC pipe

and fittings as required to complete installation, shut-off valve as required by codes.

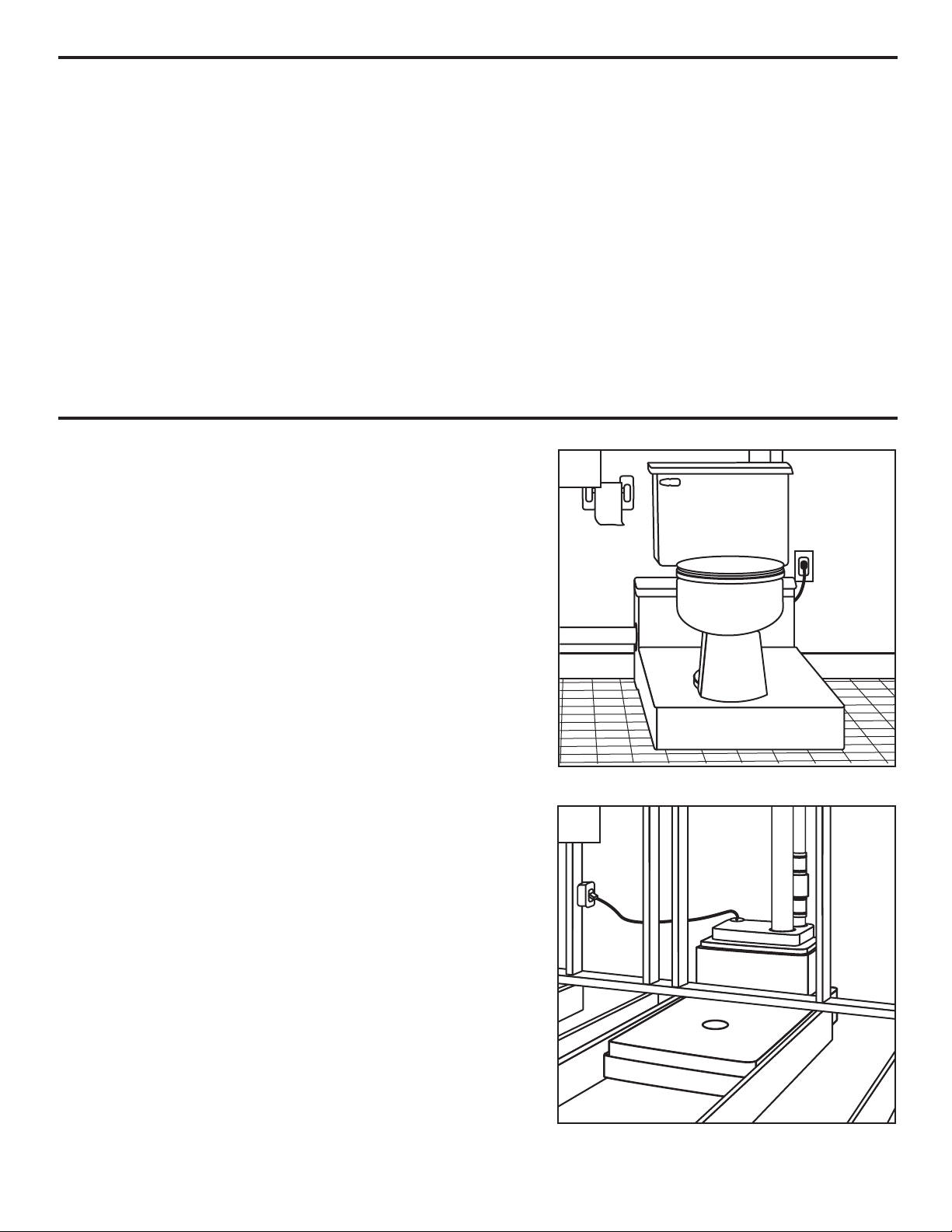

GENERAL PUMP USES

This pump system can be used in the following installations:

1. Exposed Installation (no subflooring is used).

2. Hidden Installation (subflooring is installed over unit).

1

2

5

Page 6

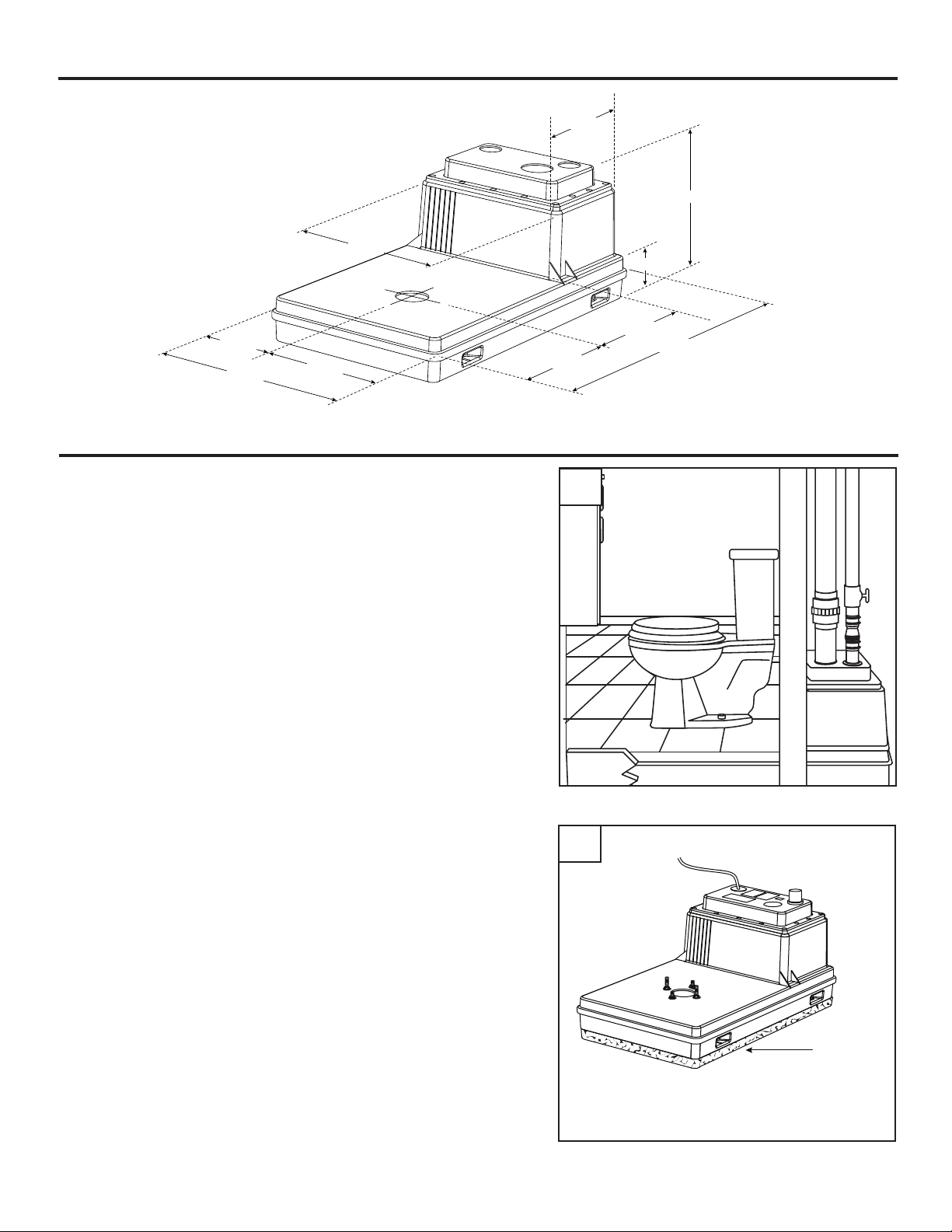

DIMENSIONS

All dimensions are in

inches.

20-1/2

12-1/4

24-1/2

12-1/4

LOCATION SELECTION AND LEVELING OF TANK

NOTE: If a built in installation is to be used, locate pump

chamber in an area that will allow access to the pump &

switch.

13-1/2

17

5-1/2

14-1/8

42-3/16

13-1/4

IL1653

1

1. Select a location which is readily accessible to the

existing discharge and vent lines.

2. Level tank to within 1/8 in. for length and width. Use

hydraulic cement or similar material for leveling.

CAUTION: Do not use wooden shims to level tank.

CAUTION: Ensure that nails, screws or other sharp

objects do not puncture tank

2

Level to

within

1/8 in.

6

Page 7

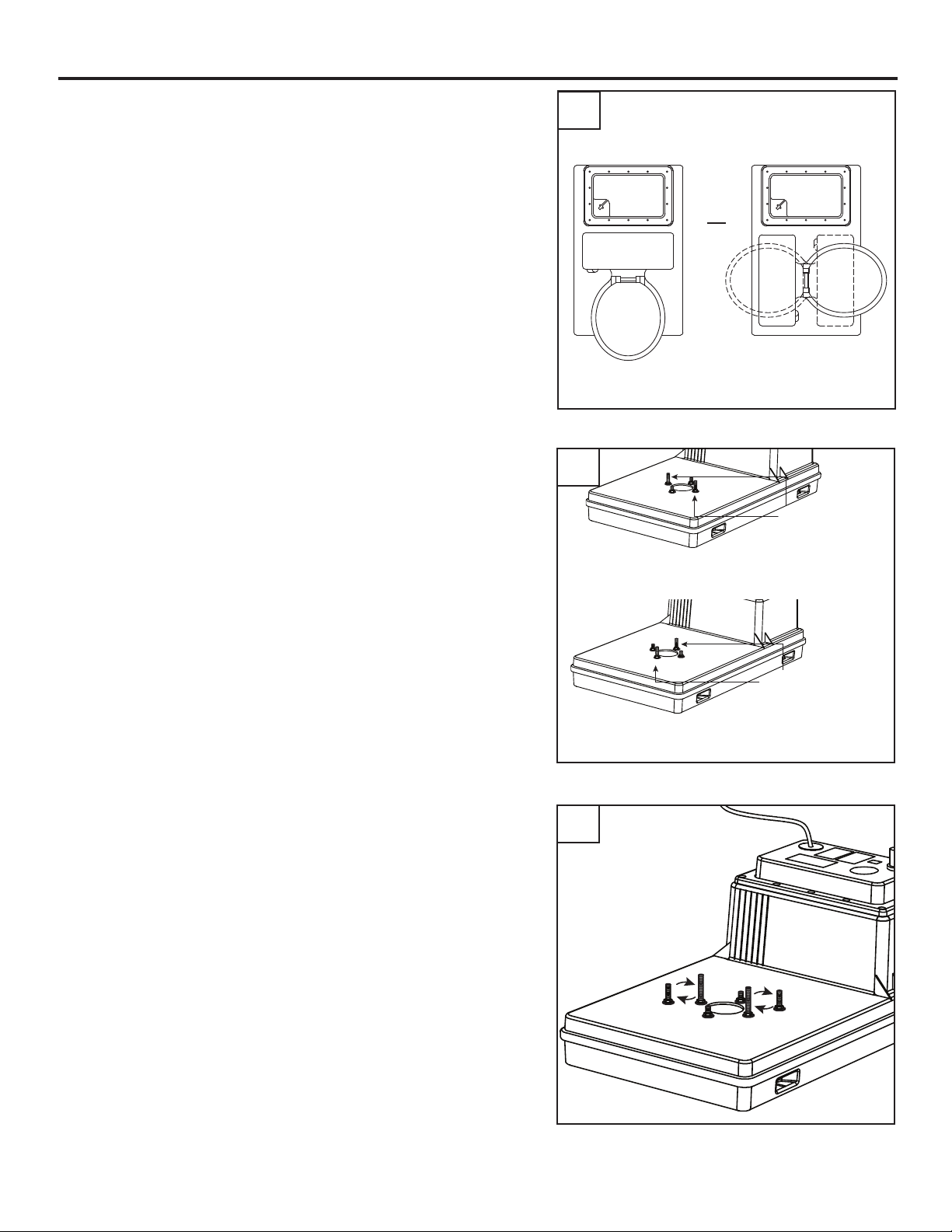

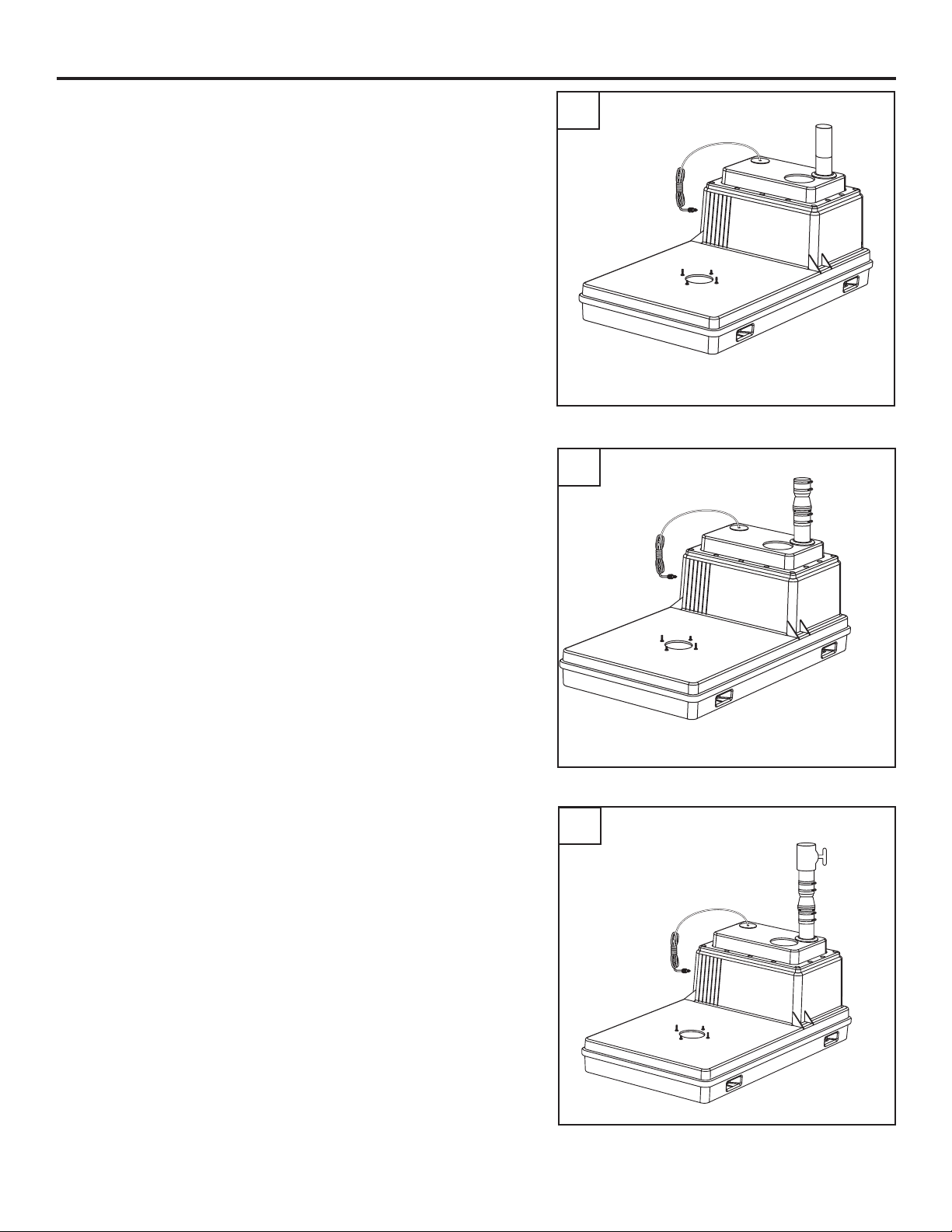

TOILET BOLT LOCATION

1. Determine how you will be placing the toilet on the

pump system. This determines the location of the long

bolts in step 2.

Note: Pump system ships preassembled in the forward

installation position.

If a side installation is desired, take note of the

2.

position of the 2 in. bolts and remove the all four bolts

located around toilet inlet hole in tank.

Rotate the location of each bolt 90 degrees around the

pre-drilled toilet installation hole and reinstall. Torque

screws to 25-30 in-lbs. DO NOT over-torque screws.

1

Side PositionForward Position

OR

2

2 in. bolt

location

for toilet in

foward mount

position

3. If subooring is installed, remove the 2 in. bolts located

around the toilet inlet hole in tank and replace with 3 in.

bolts from hardware pack.

2 in. bolt

location for

toilet in side

mount

position

3

7

Page 8

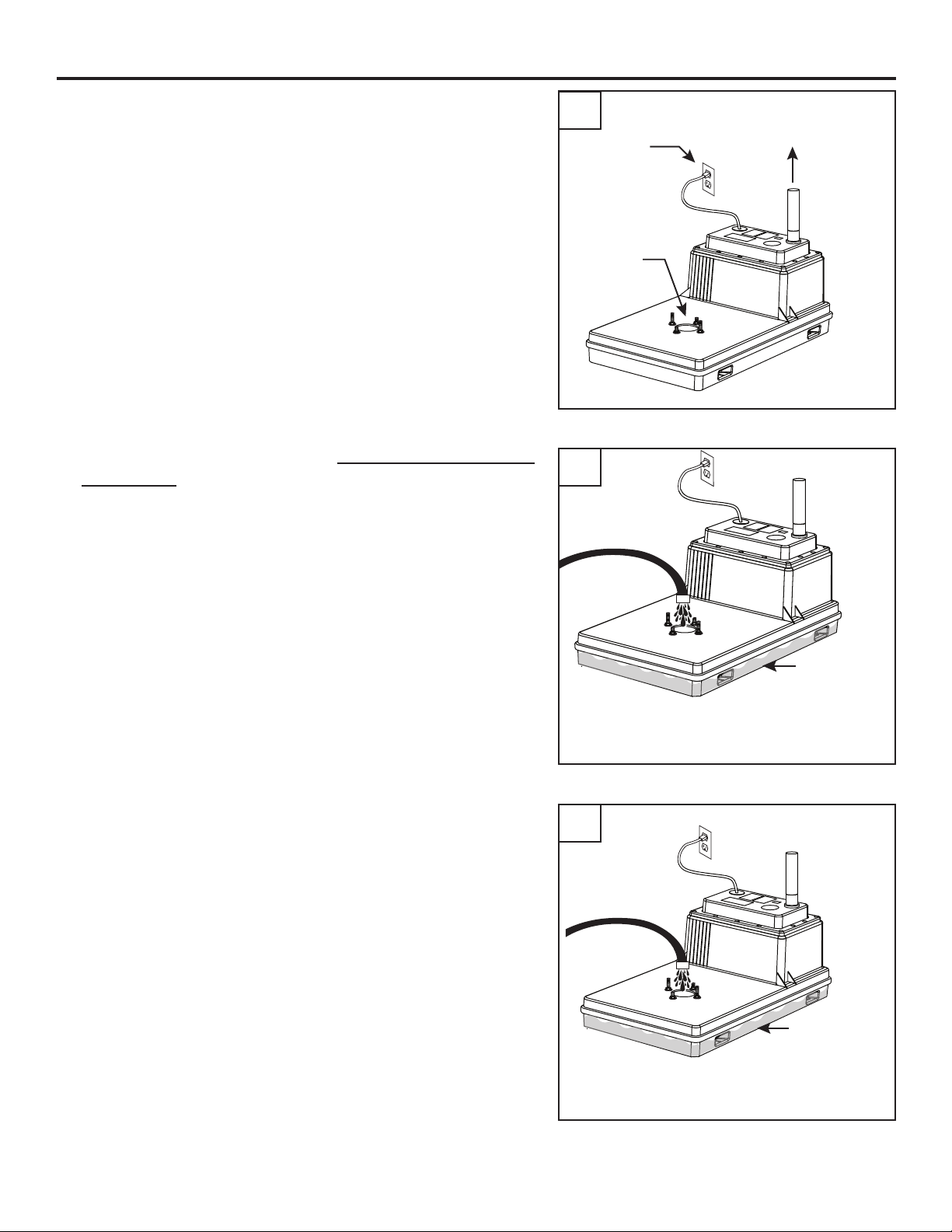

TESTING OPERATION

1. NOTE: Float switch on/off level has been preset

but should be checked by viewing through the toilet

inlet.

Temporarily connect the pump discharge pipe to the

house drain pipe and plug in pump

2. Fill the tank with 4 in. of water. Be sure the pump does

not turn on.

1

2

GFCI

Outlet

Toilet

Inlet

Temporary

Connection

To house

Drain

3. Add an additional 1/2 in. of water to the tank. The pump

should turn “ON” when the water level reaches 4-1/2

in. If “ON” level is correct, unplug pump, disconnect

temporary discharge piping and proceed to next section.

If “ON” level is incorrect, refer to Troubleshooting on

page 18.

4 in.

Water

3

4-1/2 in.

Water

8

Page 9

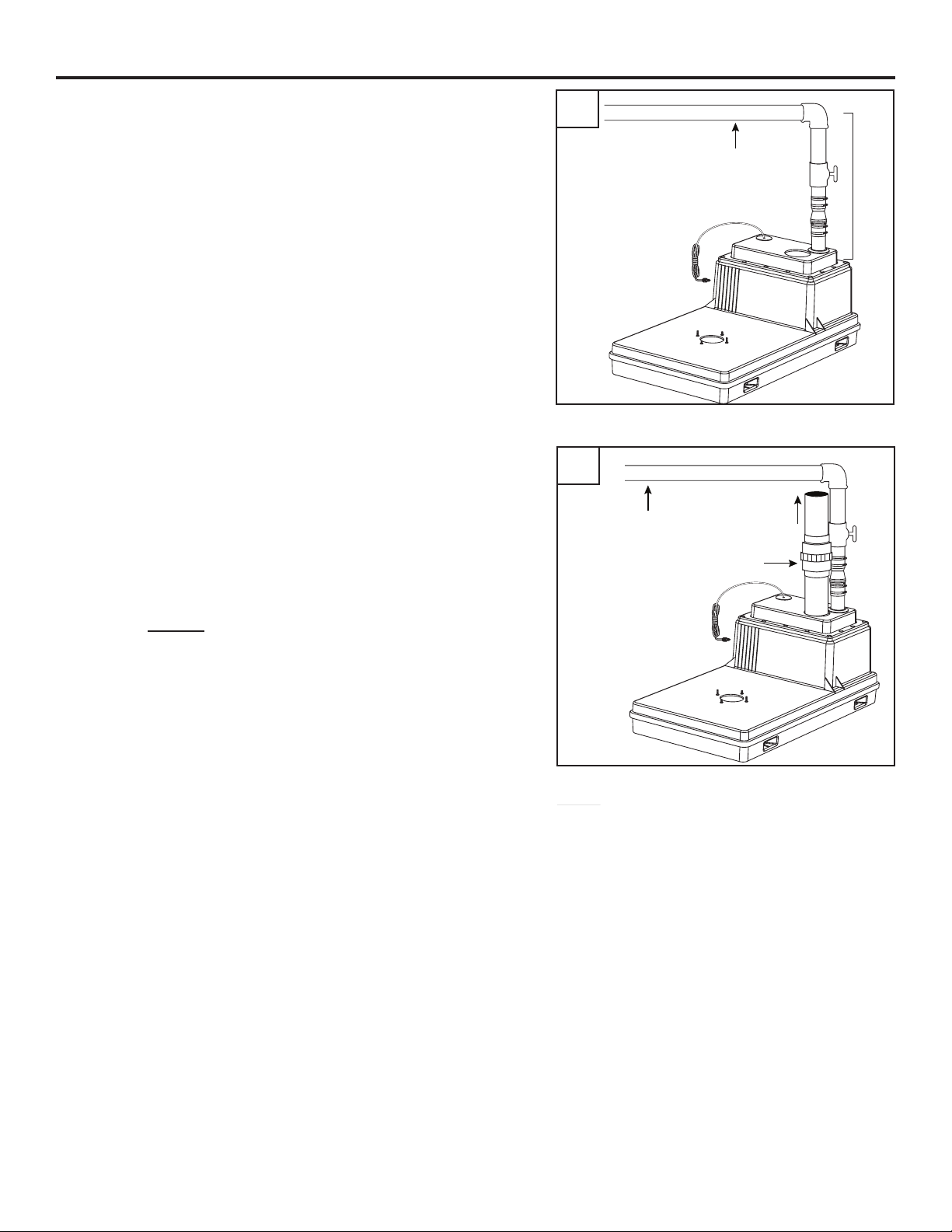

CONNECT TO PLUMBING

1. Install rigid 2 in. discharge pipe (not included) according

to local, regional and state codes. Use a 2-step PVC

glue system (not included) to join pipe and any ttings

needed.

CAUTION: Do not use a discharge pipe smaller than the

discharge pipe pre-installed in the system.

2. Install 2 in. check valve (included) in discharge pipe to

prevent back-ow.

CAUTION: Make sure the ow arrows on the check valve

are pointed up.

1

2

Discharge

Pipe

Check

Valve

3. Install 2 in. shut off valve (not included) above the

check valve in discharge pipe.

9

3

Shut

Off

Valve

Page 10

CONNECT TO PLUMBING

4. Connect discharge pipe into main waste line to sewer or

septic tank.

NOTE: Be sure discharge pipe has a minimum of 5 ft.

vertical head and a maximum of 13 ft. vertical head.

5. Connect rigid 3 in. vent pipe (not included) per local,

regional and state codes. Include a union in the line for

easy maintenance.

4

5

Main

waste line

Main

waste line

To Roof

Vent

5 Ft.

Min.

13 Ft.

Max.

NOTE: Check with local code authority if a reduction in

vent pipe size is desired.

CAUTION: Do Not use mechanical vent of any kind.

Union

10

Page 11

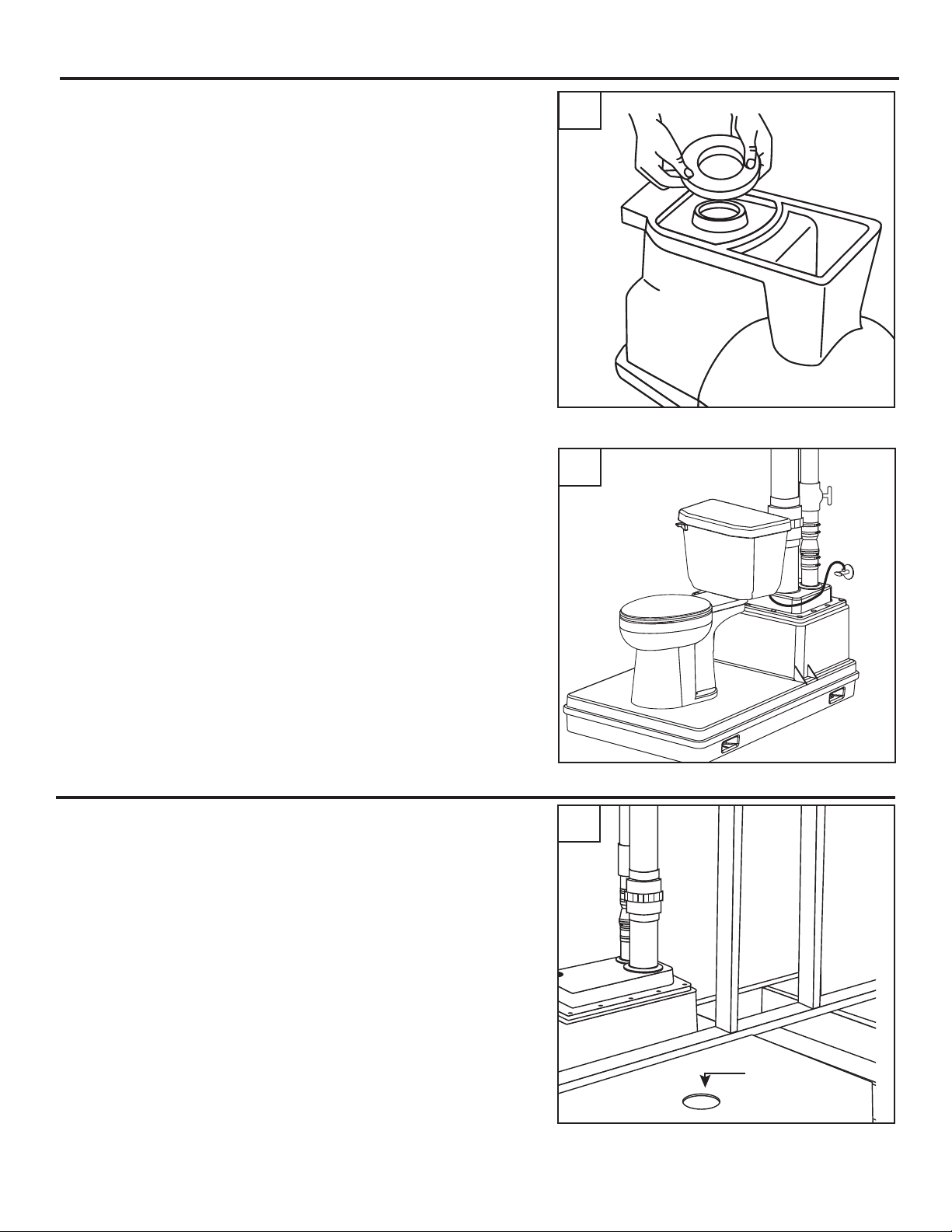

INSTALLATION OF TOILET - EXPOSED INSTALLATION

Exposed Installation (no subflooring is used)

1. Install 1 wax toilet bowl ring (included) and toilet as

described on the toilet ring carton.

2. Connect water line to toilet. Fill tank and test pump

system.

1

2

Water

Supply

INSTALLATION OF TOILET - HIDDEN INSTALLATION

1. Cut a 6-1/2 in. diameter hole in the suboor, centered

on the toilet tank opening in pump system.

NOTE: When using subooring, the 2 in. bolts pre-

installed in the tank must be replaced by the 3 in.

bolts included in the hardware kit.

11

1

6-1/2 in.

diameter hole

Page 12

INSTALLATION OF TOILET - HIDDEN INSTALLATION

2. Firmly press wax toilet bowl ring inside the 3 in. bolts

against the top surface of the pump system.

3. Place plastic locator ring (included) on tank system and

rmly press into place until wax has completely lled

the ring. This can be checked by looking through the

four air holes on the locator ring.

2

3 in. Bolts

1st Wax Ring

3

4. Place the second wax ring (included) over the toilet

and install toilet. Lock in place using the 3 in. pan

head bolts, washer and nuts from the hardware kit.

4

3 in. Pan

Head Bolt

Toilet

Locator Ring

1st Wax

Ring

Plastic

Locator Ring

1st Wax Ring

2nd Wax

Ring

Sub Floor

Tank

Cast Iron Toilet

Stabilizer Plate

(pre-installed)

12

Page 13

INSTALLATION OF TOILET - HIDDEN INSTALLATION

5. Connect water line to toilet, fill tank and test pump

system.

INSTALLATION OF ADDITIONAL FIXTURES

1. A 3 in. hole must be drilled into pump system in order to

add additional xtures. The hole can only be drilled in

the areas shown.

CAUTION: Do not drill in cross-hatched areas noted.

5

Water

Supply

7 in. Min.

1

1-1/2 in. Min.

5 in. Min.

NOTE: Use only with additional xtures normally found

in a typical bathroom. Not recommended for washing

machines, dishwashers or other equipment.

2. Attach the spotting template from page 19 to the

desired location on pump system and center the punch

hole as shown on the template.

NOTE: Pump system is preassembled with pump

inside tank. Use caution when drilling into tank. Be sure

to remove any drilled plastic material from tank when

drilling is complete.

Do not drill in

Cross-hatched areas

of tank

2

7 in. Min.

2 in. Min.

6 in. Min.

Center line point

for 3 in. hole saw.

3 in. Dia.

Cut Template

Along This Line.

13

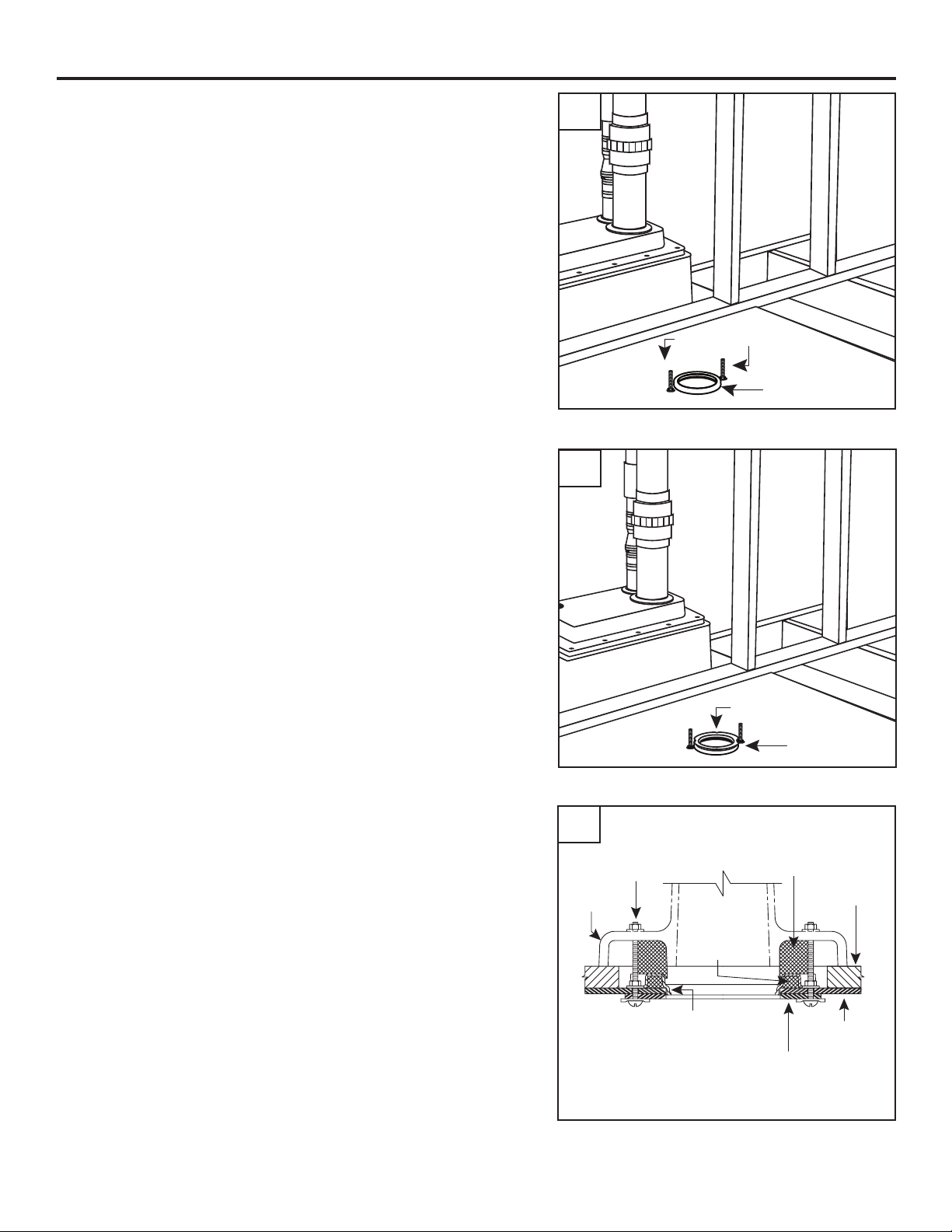

Page 14

INSTALLATION OF ADDITIONAL FIXTURES

3. Insert 2 in. pipe seal (included) into the 3 in. hole drilled

in Step 2. Lubricate the inside diameter of the seal with

soapy water to make it easier to insert pipe.

NOTE: Pipe installed in this 2” seal must be supported

vertically.

4. Insert approximately 3/4 in. of pipe through seal into

the tank.

NOTE: The bottom of the 3 in. hole drilled in Step 2

must be a minimum of 5 or 6 in. above the base of the

tank, depending on where the hole is drilled.

See Figures 5, 6, 7 and 8 for typical installations.

3

Do not drill in

Cross-hatched areas

of tank

4

1-1/2 in. Min.

5 in. Min.

Do not drill in

Cross-hatched areas

of tank

7 in. Min.

7 in. Min.

3 in. hole

2 in.

Pipe Seal

2 in. Min.

6 in. Min.

14

Page 15

INSTALLATION OF ADDITIONAL FIXTURES

5

Typical installation with raised tub, lavatory, vent & discharge

CAUTION: Do not drive any nails in area of tank.

Vent

Vent

4 in.

Min.

NOTE: 1) All vents and discharge piping must be installed according to local codes.

2) Wall board removed for clarity to show piping.

Vent

Gate

Valve

Discharge

GFCI

Union

by Others

Back

Flow

Device

SK1615

Alternate installation with special oor mounted raised bottom tub, lavatory, vent & discharge

6

8 Ft. Ceiling

7 Ft. Ceiling

Subfloor

3/4 in. Thick

Minimum

2x6

Floor

Joists

CAUTION: Do not drive any nails in area of tank.

GFCI

Vent

3 in.

Min.

NOTE: 1) All vents and discharge piping must be installed according to local codes.

2) Wall board removed for clarity to show piping.

3) To install a shower in place of a tub, raise the shower stall to provide a gravity drain

to the system tank and connect as shown in the diagram above.

Vent

Union

by

Others

Discharge

Shut-off Valve

by Others

Back

Flow

Device

Vent

SK1616

15

Page 16

INSTALLATION OF ADDITIONAL FIXTURES

Alternate installation with raised tub, lavatory, vent & discharge

7

8 Ft. Ceiling

7 Ft. Ceiling

Vent

Subfloor

3/4 in. Thick

Minimum

2 x 4

studs

2x6

Floor

Joists

NOTE: 1) All vents and discharge piping must be installed according to local codes.

2) Wall board removed for clarity to show piping.

GFCI

CAUTION: Do not drive any nails in area of tank.

4 in.

Min.

Vent

GFCI

Vent

Union

by

Others

Discharge

Shut-off Valve

by Others

Back

Flow

Device

SK1617

Alternate installation with special oor mounted raised bottom tub, lavatory, vent & discharge

8

8 Ft. Ceiling

7 Ft. Ceiling

Subfloor

3/4 in. Thick

Minimum

2x6

Floor

Joists

CAUTION: Do not drive any nails in area of tank.

Vent

3 in.

Min.

Discharge

Union

by

Others

Vent

Shut-off Valve

by Others

GFCI

Back

Flow

Device

Vent

NOTE: 1) All vents and discharge piping must be installed according to local codes.

2) Wall board removed for clarity to show piping.

16

SK1618

Page 17

REPLACEMENT PARTS

For replacement parts, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m.,

EST, Monday - Friday.

PART DESCRIPTION PART #

A Replacement pump and switch 1101RP

B 2 in. Tank Seal KH85

C 2 in. Check Valve 006817

A

C

B

17

Page 18

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Pump will not

start or run.

Pump starts too

soon.

Water level

exceeds 4-1/2

in. before pump

turns on.

Pump will not

shut off.

Pump operates

but delivers little

or no water.

Pump runs

too long

before water is

pumped.

Low voltage, blown fuse open circuit. Have a qualied electrician check fuse

and circuit.

Impeller bound. Contact an Authorized Service Station.

Motor or wiring shorted. Contact an Authorized Service Station.

Faulty or stuck oat switch Remove lid and check oat

Float “ON” point is adjusted too low. Raise the top oat stop. Make sure the

oat is between the two stops. Refer to

Testing Pump/Tank Section.

Float “ON” point adjusted to high. Lower the top oat stop. Make sure the

oat is between the two stops.

Debris under oat. Remove debris from around oat.

Faulty oat switch. Contact an Authorized Service Station.

Float “Off” point adjusted too low. Raise the bottom oat stop. Make sure

the oat is between the two stops. Refer

to Testing Section.

Debris around intake. Clean area around intake.

Blockage in discharge pipe. Remove pipe and ush out debris.

Low or incorrect voltage. Have a qualied electrician check house

wiring.

Damaged Impeller. Contact an Authorized Service Station.

Incorrect oat adjustment Make sure the oat is between the two

stops. Refer to Testing Section.

Pump is air locked. Make sure vent hole on discharge pipe

is clear.

Vertical lift too high. Change discharge piping or contact

tech. service.

Pump is air locked. Make sure vent hole on discharge pipe

is clear.

Water level too low. Clear debris from around bafe. Make

sure the oat is between the two stops.

Refer to Testing Section.

18

Page 19

SPOTTING TEMPLATE

Hole must be round. Use 3" hole saw.

Hole sizes greater than 3.040" can create leaks.

Center line point

for 3 in. hole saw.

3 in. Dia.

Cut Template

Along This Line.

SK1279

19

Page 20

STAR

®

FW1591

0113

Supersedes NEW

SISTEMA COMPLEMENTARIO

PARA EL BAÑO

¡

ALTO!

MODELO #

Patente No. 5,038,418

S1101

En caso de piezas faltantes o dañadas, o asistencia técnica, llame al

1-800-742-5044

antes de devolver el producto

Para obtener la bomba de repuesto, pida la 1102RP o consulte la Lista completa

de piezas de reparación en la página S17.

ADJUNTE SU RECIBO AQUÍ

Fecha de compra

S1

Page 21

ÍNDICE

Información de seguridad .............................................................................................................. S2

Contenido del paquete .................................................................................................................. S4

Preparación ................................................................................................................................... S5

Usos generales de la bomba ......................................................................................................... S5

Dimensiones .................................................................................................................................. S6

Ubicación del sistema de bomba................................................................................................... S6

Ubicación de los pernos ................................................................................................................ S7

Operación de prueba ..................................................................................................................... S8

Conectar a la plomería .................................................................................................................. S9

Instalación del inodoro: instalación expuesta ...............................................................................S11

Instalación del inodoro: instalación oculta ....................................................................................S11

Ensambles adicionales ................................................................................................................ S13

ezas de repuesto ......................................................................................................................... S17

Solución de problemas ................................................................................................................ S18

Plantilla de ubicación ................................................................................................................... S19

INFORMACIÓN DE SEGURIDAD

Lea y comprenda completamente este manual antes de intentar ensamblar, usar o instalar el

producto.

Revise todos los materiales antes de su instalación. Si faltan piezas o estas están dañadas, llame al

1-800-742-5044 antes de volver a la tienda.

PELIGRO DE DESCARGA ELÉCTRICA.

Siempre desconecte la fuente de alimentación antes de llevar a cabo cualquier trabajo en el motor o cerca

de este, o en su carga conectada. Si el punto de desconexión de la alimentación está fuera de la vista,

asegúrelo en la posición abierta y etiquételo para evitar una aplicación de alimentación inesperada. El

incumplimiento de dicho paso podría provocar una descarga eléctrica fatal.

PELIGRO DE DESCARGA ELÉCTRICA.

No manipule la bomba con las manos húmedas ni cuando esté parado en el agua, ya que podría ocurrir

una descarga eléctrica fatal. SIN IMPORTAR EL MOTIVO, desconecte la alimentación principal antes de

manipular la unidad.

RIESGO DE DESCARGA ELÉCTRICA.

No se ha verificado el uso de estas bombas en piscinas.

Page 22

INFORMACIÓN DE SEGURIDAD

ALERTA DE DESCARGA ELÉCTRICA.

Para reducir el riesgo de descargas eléctricas, instale solo a un tomacorriente protegido por un interruptor

de circuito de falla de puesta a tierra (GFCI, por sus siglas en inglés). Asegúrese de que el receptáculo de

falla de puesta a tierra esté al alcance del cable de suministro de electricidad de la bomba. NO UTILICE UNA

EXTENSIÓN ELÉCTRICA.

ALERTA DE DESCARGA ELÉCTRICA.

Siga todos los códigos locales eléctricos y de seguridad, además del Código nacional de electricidad (NEC, por sus siglas

en inglés) y la ley de la Administración de Salud y Seguridad Ocupacional (OSHA, por sus siglas en inglés).

ALERTA DE DESCARGA ELÉCTRICA.

No pliegue el cable de alimentación ni permita que entre en contacto con aceite, grasa, superficies calientes, sustancias

químicas u objetos afilados. Reemplace inmediatamente los cables dañados o desgastados.

ALERTA DE DESCARGA ELÉCTRICA.

Como medida de seguridad, se debe examinar cada tomacorriente para comprobar que cuenta con puesta a tierra con un

analizador de circuitos con calificación de Underwriters Laboratory que indicará si los conductores de alimentación, neutro

y de puesta a tierra están correctamente conectados en el tomacorriente. Si no lo están, póngase en contacto con un

electricista calificado.

ALERTA DE DESCARGA ELÉCTRICA.

Estas bombas se suministran con un enchufe de 3 clavijas con puesta a tierra para ayudar a protegerlo contra la

posibilidad de descargas eléctricas. NO RETIRE LA CLAVIJA DE PUESTA A TIERRA BAJO NINGUNA CIRCUNSTANCIA.

ALERTA DE DESCARGA ELÉCTRICA.

Asegúrese de que el circuito de suministro eléctrico de la bomba esté equipado con fusibles o interruptores de circuito de

la capacidad adecuada. Se recomienda un circuito de derivación aparte, de tamaño acorde al Código eléctrico nacional

para la corriente que se muestra en la placa de datos de la bomba.

ALERTA DE PRODUCTO QUÍMICO.

Este producto contiene sustancias químicas reconocidas por el estado de California como causantes de cáncer y defectos

congénitos u otros daños en el aparato reproductivo.

PUEDE PROVOCAR DAÑO AL PRODUCTO

Asegúrese de que la fuente de alimentación cumpla los requisitos de su equipo.

PUEDE PROVOCAR DAÑO AL PRODUCTO

La temperatura máxima del agua de funcionamiento continuo para bombas de modelo estándar no debe exceder los

54 °C (130 °F).

PUEDE PROVOCAR DAÑO AL PRODUCTO

No utilice dispositivos automáticos de ventilación de plomería como “Pro-Vent”. Algunos estados exigen que estos

productos sean instalados por un plomero certificado.

• NOTA: Las bombas con la marca “UL” y con la marca “US” se prueban para cumplir los estándares de UL

UL778. Las bombas con certi cación CSA cumplen con el estándar CSA C22.2 No. 108. (CUS.)

• No use un sello de cera que incluya una brida que se extiende por el tanque. Si se instala un piso sobre el

tanque, use el kit para sello extensor de brida del piso incluido con el sistema.

• Para la instalación por debajo de la línea del piso original, llame al 1-800-742-5044.

S3

Page 23

CONTENIDO DEL PAQUETE

Pieza Descripción Cantidad

A Preensamblada 1

Sello de tubería de 2 pulg

B

C Válvula de control de 2 pulg 1

D

E Anillo de cera 2

F Anillo de ubicación 1

* Kit de aditamentos 1

*No se muestra

para un agujero de 3 pulg 2

Sello de tubería de 3 pulg

para un agujero de 4 pulg 1

C

E

A

D

F

B

ESPECIFICACIONES

RENDIMIENTO

Número de

Modelo

S1101 .4 1 115

NOTA: Asegúrese de que la instalación tenga un cabezal vertical de un mínimo de 5 pies. El

máximo recomendado para un cabezal vertical es de 13 pies.

HP Fase Voltios

Pies de

cabezal

5 73

15 19

Flujo (GPM)

Cabezal de

cierre (pies)

17.5 2 pulg10 39

Tamaño de

descarga

Page 24

PREPARACIÓN

Antes de comenzar a instalar el producto, asegúrese de tener todas las piezas. Compárelas con la

lista del contenido del paquete. No intente ensamblar el producto si falta alguna pieza o si estas están

dañadas.

Tiempo estimado de instalación: 5 horas para una instalación no oculta o ensambles adicionales.

Herramientas necesarias para el ensamblaje (no se incluyen): Cinta métrica, cinta para tuberías,

sierra de mano, destornillador de cabeza plana, sistema de pegamento PVC de 2 pasos (cebado y

sellado), cemento hidráulico u otro material

Piezas necesarias para el ensamblaje (no se incluyen): Unión o acoplamiento de goma de 2 pulg,

se requieren conectores y tubos de PVC de 2 pulg y 3 pulg para completar la instalación, válvula de

cierre según lo requieran los códigos.

USOS GENERALES DE LA BOMBA

Este sistema de bomba puede utilizarse en las siguientes instalaciones:

1. Instalación expuesta (no se utiliza subsuelo).

2. Instalación oculta (se instala un subsuelo sobre la

unidad).

1

2

S5

Page 25

DIMENSIONES

Todas las dimensiones

están expresadas en pulg.

20-1/2

12-1/4

24-1/2

12-1/4

UBICACIÓN DEL SISTEMA DE BOMBA

NOTA: Si se utilizará una instalación empotrada, ubique

la cámara de la bomba en un área que permita el

acceso a la bomba y el interruptor.

13-1/2

17

5-1/2

14-1/8

42-3/16

13-1/4

IL1653

1

1. Seleccione una ubicación de acceso fácil para las

tuberías de descarga y ventilación existentes.

2. Nivele el tanque hasta 1/8 de pulg de largo y ancho.

Para nivelar, use cemento hidráulico o un material

similar.

PRECAUCIÓN: No use calzas de madera para nivelar

el tanque.

PRECAUCIÓN: Asegúrese de que clavos, tornillos u

otros objetos losos no perforen el tanque.

2

Nivele

hasta 1/8

de pulg.

Page 26

UBICACIÓN DE LOS PERNOS

1. Determine como colocará el inodoro en el sistema

de bomba. Esto determina la ubicación de los pernos

largos en el paso 2.

Nota: El sistema de bomba se envía preensamblado

con la posición de instalación hacia delante.

2. Si se desea una instalación lateral, tome nota de la

posición de los pernos de 2 pulg y retire los cuatro

pernos alrededor del agujero de entrada del inodoro

en el tanque.

Gire la ubicación de cada perno en 90 grados

alrededor del agujero de instalación del inodoro

pretaladrado y vuelva a instalarlo. Torque los tornillos

hasta 2,88 a 3,46 kgf-m. NO torque demasiado los

tornillos.

1

Posición lateralPosición hacia delante

O

2

Ubicación del

perno de 2 pulg

para el inodoro

en posición de

montaje

hacia delante

Ubicación del

perno de 2

pulg para el

inodoro en

posición de

montaje lateral

3. Si se instala un subsuelo, retire los pernos de 2 pulg

que se encuentran alrededor del agujero de entrada

del inodoro en el tanque y reemplácelos con los

pernos de 3 pulg del kit de aditamentos.

S7

3

Page 27

OPERACIÓN DE PRUEBA

1. NOTA: El nivel de encendido y apagado del

interruptor del otador ha sido preajustado, sin

embargo, debe veri carse revisando la entrada del

inodoro.

Conecte temporalmente la tubería de descarga de la

bomba a la tubería de desagüe doméstica y enchufe

la bomba

2. Llene el tanque con 4 pulg de agua. Asegúrese de que

la bomba no se encienda.

1

Tomacorrientes

con interruptor

de circuito de

falla de

puesta a tierra

Entrada

del inodoro

2

Conexión

temporal al

desagüe

doméstico

3. Agregue 1,27 cm adicional de agua al tanque. La

bomba debe encenderse (“ON”) cuando el nivel de

agua alcance 4-1/2 pulg. Si el nivel de encendido

es el correcto, desenchufe la bomba, desconecte

temporalmente la tubería de desagüe y continúe con la

siguiente sección.

Si el nivel de encendido no es el correcto, consulte

Solución de problemas en la página S18.

10,16 cm

de agua

3

11.43 cm

de agua

Page 28

Válvula

CONECTAR A LA PLOMERÍA

1. Instale la tubería de descarga rígida de 2 pulg (no se

incluye) de acuerdo con los códigos locales, regionales

y estatales. Use un sistema de adhesivo PVC de 2

pasos (no se incluye) para unir la tubería y cualquier

conector necesario.

PRECAUCIÓN: No utilice una tubería de desagüe

más pequeña que la tubería de desagüe preinstalada

en el sistema.

2. Instale una válvula de control de 2 pulg (se incluye) en

la tubería de desagüe para evitar el re ujo.

PRECAUCIÓN: Asegúrese de que las echas de ujo

en la válvula de control apunten hacia arriba.

1

2

Tubería de

descarga

Válvula

de control

3. Instale una válvula de cierre de 2 pulg (no se incluye)

sobre la válvula de control en la tubería de desagüe.

S9

3

de

cierre

Page 29

13 pies

CONECTAR A LA PLOMERÍA

4. Conecte la tubería de desagüe en la tubería de desagüe

principal que va hacia el desagüe o el tanque séptico.

NOTA: Asegúrese de que la tubería de desagüe tenga

un cabezal vertical de mínimo 5 pies y máximo 13 pies.

5. Conecte la tubería de ventilación rígida de 3 pulg

(no se incluye) de acuerdo con los códigos locales,

regionales y estatales. Incluya una unión en la línea

para facilitar el mantenimiento.

NOTA: Veri que con la autoridad de código local si

desea reducir el tamaño de la tubería de ventilación.

PRECAUCIÓN: No utilice ventilación mecánica de

ningún tipo.

4

5

Tubería de

desagüe

principal

Tubería de

desagüe

principal

A la

ventilación

de techo

Unión

5 pies

mín.

máx.

Page 30

Suministro

INSTALACIÓN DEL INODORO: INSTALACIÓN EXPUESTA

Instalación expuesta (no se utiliza subsuelo)

1. Instale 1 anillo de cera para taza de inodoro (se incluye)

y el inodoro como se describe en la caja del anillo para

inodoro.

2. Conecte la tubería de agua al inodoro. Llene el tanque y

pruebe el sistema de bomba.

1

2

de agua

INSTALACIÓN DEL INODORO: INSTALACIÓN OCULTA

1. Corte un agujero de 6-1/2 pulg en el subsuelo,

centrado en la abertura del tanque del inodoro en el

sistema de bomba.

NOTA: Cuando utilice un subsuelo, los pernos de 2

pulg preinstalados en el tanque deben reemplazarse

con los pernos de 3 pulg incluidos en el kit de

aditamentos.

S11

1

Agujero de

6-1/2 pulg

de diámetro

Page 31

Primer anillo

de cera

de cera

INSTALACIÓN DEL INODORO: INSTALACIÓN OCULTA

2. Presione rmemente el anillo para taza de inodoro

dentro de los pernos de 3 pulg contra la super cie

superior del sistema de bomba.

3. Coloque el anillo de ubicación de plástico (se incluye)

en el sistema de tanque y presione rmemente en el

lugar hasta que la cera llene por completo el anillo.

Esto puede veri carse a través de los cuatro agujeros

de aire en el anillo de ubicación.

2

Pernos de 3 pulg

Primer anillo

3

4. Coloque el segundo anillo de cera (se incluye) sobre

el inodoro e instale el inodoro. Asegúrelo en su lugar

con los pernos de cabeza plana de 3 pulg, arandelas

y tuercas del kit de aditamentos.

4

Perno de cabeza

plana de 3 pulg

Inodoro

Anillo de ubicación

de plástico

Anillo de

ubicación

Segundo

anillo de cera

Subsuelo

Primer anillo

de cera

Tanque

Placa estabilizadora

de inodoro de hierro

forjado (preinstalada)

Page 32

Mínimo de

INSTALACIÓN DEL INODORO: INSTALACIÓN OCULTA

5. Conecte la tubería de agua al inodoro, llene el tanque y

pruebe el sistema de bomba.

ENSAMBLES ADICIONALES

1. Debe taladrarse un agujero de 3 pulg en el sistema

de bomba para agregar ensambles adicionales. El

agujero solo puede taladrarse en las áreas que se

muestran.

PRECAUCIÓN: No taladre en las áreas marcadas con

líneas diagonales.

NOTA: Use solo ensambles adicionales que se

encuentran normalmente en un baño típico. No

se recomienda para lavadoras, lavaplatos u otros

equipos.

5

1

Mínimo de

3,81 cm

Mínimo

de

12,7 cm

No taladre en las áreas del

tanque marcadas con

líneas diagonales

Mínimo de 17,78 cm

Mínimo de 17,78 cm

Suministro

de agua

2 pulg

Mínimo

de

15,24 cm

2. Adjunte la plantilla de ubicación de la página 19 a la

ubicación deseada en el sistema de bomba y centre el

agujero perforado como se muestra en la plantilla.

NOTA: El sistema de bomba está preensamblado con

el tanque de la bomba dentro. Tenga cuidado cuando

taladre la parte interna del tanque. Una vez nalizada

la perforación, retire cualquier material de plástico

taladrado del tanque.

S13

2

Punto central para la

sierra de perforación

de 3 pulg

3 pulg de

diámetro

Corte la plantilla

por esta línea.

Page 33

Mínimo de

ENSAMBLES ADICIONALES

3. Inserte un sello de la tubería de 2 pulg (se incluye) en

el agujero de 3 pulg taladrado en el Paso 2. Lubrique

el diámetro interno del sello con agua y jabón para

facilitar la inserción de la tubería.

NOTA: La tubería instalada en este sello de 2 pulg

debe tener un soporte vertical.

4. Inserte aproximadamente 3/4 de pulg de la tubería a

través del sello al tanque.

NOTA: La parte inferior del agujero de 3 pulg

taladrado en el Paso 2 debe tener un mínimo de

12,7 cm o 15,24 cm por sobre la base del tanque,

dependiendo del lugar donde se taladre el agujero.

Consulte las instalaciones típicas en las Figuras 5, 6,

7 y 8.

3

No taladre en las áreas

del tanque marcadas

con líneas diagonales

4

Mínimo de

3,81 cm

Mínimo

de

12,7 cm

No taladre en las áreas del

tanque marcadas con

líneas diagonales

Mínimo de 17,78 cm

Mínimo de 17,78 cm

Agujero de

3 pulg

Sello de la

tubería de

2 pulg

2 pulg

Mínimo

de

15,24 cm

Page 34

ENSAMBLES ADICIONALES

5

Instalación típica con bañera, lavamanos, ventilación y desagüe elevados

PRECAUCIÓN: No atornille clavos en el área del tanque.

Ventilación

Ventilación

Ventilación

Válvula

de compuerta

Mínimo

de

10,16 cm

NOTA: 1) Todas las tuberías de ventilación y desagüe deben instalarse acuerdo con los

códigos locales, regionales y estatales.

2) Se retiró la tabla para pared para claridad al mostrar la tubería.

Descarga

GFCI

Unión

de otros

Dispositivo

de reflujo

SK1615

Instalación alternativa con piso especial montado para elevar bañera, lavamanos, ventilación

6

y desagüe inferiores

Techo de 2,44 m

Techo de 2,13 m

Grosor mínimo

del subsuelo

de

19,05 mm

2 x 6

viguetas

de piso

PRECAUCIÓN: No atornille clavos en el área del tanque.

Ventilación

Mínimo

de

7,62 cm

NOTA: 1) Todas las tuberías de ventilación y desagüe deben instalarse acuerdo con los

códigos locales, regionales y estatales.

2) Se retiró la tabla para pared para claridad al mostrar la tubería.

3) Para instalar una ducha en lugar de una bañera, levante el compartimiento para

ducha para proporcionar un desagüe de gravedad al tanque del sistema

GFCI

Ventilación

Unión

de

otros

Descarga

Válvula de

cierre de

otros

Disposit vo

de reflujo

Ventilación

SK1616

S15

Page 35

ENSAMBLES ADICIONALES

Instalación alternativa con bañera, lavamanos, ventilación y desagüe elevados

7

Techo de 2,44 m

Techo de 2,13 m

GFCI

PRECAUCIÓN: No atornille clavos en el área del tanque.

Ventilación

Grosor mínimo

del subsuelo de

19,05 mm

Montantes

de 2 x 4

2 x 6

viguetas

de piso

NOTA: 1) Todas las tuberías de ventilación y desagüe deben instalarse acuerdo con los

códigos locales, regionales y estatales.

2) Se retiró la tabla para pared para claridad al mostrar la tubería

Instalación alternativa con piso especial montado para elevar bañera, lavamanos, ventilación

8

Mínimo

10,16 cm

Ventilación

GFCI

Ventilación

Unión

de

otros

Descarga

Válvula de

cierre de

otros

Dispositivo

de reflujo

y desagüe inferiores

Techo de 2,44 m

Techo de 2,13 m

SK1617

Grosor mínimo

del subsuelo

de

19,05 mm

2 x 6

viguetas

de piso

PRECAUCIÓN: No atornille clavos en el área del tanque.

Descarga

Ventilación

NOTA: 1) Todas las tuberías de ventilación y desagüe deben instalarse acuerdo con los

códigos locales, regionales y estatales.

2) Se retiró la tabla para pared para claridad al mostrar la tubería.

Mínimo

de

7,62 cm

Ventilación

Unión

de

otros

Válvula de

cierre de otros

GFCI

Dispositivo

de reflujo

Ventilación

SK1618

Page 36

PIEZAS DE REPUESTO

Para obtener piezas de repuesto, llame a nuestro Departamento de Servicio al Cliente

al 1-800-742-5044, de lunes a viernes de 7:30 a.m. a 5:00 p.m., hora estándar del Este.

PIEZA DESCRIPCIÓN PIEZA #

A Bomba e interruptor de reemplazo 1101RP

B Sello de tanque de 2 pulg KH85

C Válvula de control de 2 pulg 006817

A

C

B

S17

Page 37

SOLUCIÓN DE PROBLEMAS

Problema Causa posible Acción correctiva

La bomba no

enciende ni

funciona.

La bomba

se enciende

demasiado

pronto.

El nivel del

agua excede

11,43 cm antes

de encender la

bomba.

La bomba no se

cierra.

La bomba

funciona pero

sale muy poca o

nada de agua.

La bomba trabaja

mucho antes de

bombear el agua.

Voltaje bajo, fusible fundido, circuito

abierto.

El impulsor se salta. Póngase en contacto con una estación de

Se produjo cortocircuito en el motor o

cableado.

El interruptor de otador está defectuoso o

atascado

El punto de encendido (“ON”) del otador

está ajustado en una posición demasiado

baja.

El punto de encendido (“ON”) del otador

está ajustado en una posición demasiado

alta.

Hay desechos bajo el otador. Retire todos los desechos alrededor del

El interruptor del otador está defectuoso. Póngase en contacto con una estación de

El punto de apagado (“Off”) del otador

está ajustado en una posición demasiado

baja.

Hay desechos alrededor de la entrada. Limpie el área alrededor de la entrada.

Hay un bloqueo en la tubería de descarga. Retire la tubería y enjuague los desechos.

El voltaje es incorrecto o bajo. Pídale a un electricista cali cado que revise

El impulsor está dañado. Póngase en contacto con una estación de

El ajuste del otador es incorrecto Asegúrese de que el otador quede entre

La bomba está bloqueada con aire. Asegúrese de que el agujero de ventilación

La elevación vertical es demasiado alta. Cambie la tubería de desagüe o póngase

La bomba está bloqueada con aire. Asegúrese de que el agujero de ventilación

El nivel de agua es demasiado bajo. Limpie los desechos alrededor del de ector.

Pídale a un electricista cali cado que revise

el fusible y el circuito.

servicio autorizada.

Póngase en contacto con una estación de

servicio autorizada.

Retire la tapa y revise el otador

Levante el tope superior del otador.

Asegúrese de que el otador quede entre

los dos topes. Consulte la sección Prueba

de la bomba/el tanque.

Baje el tope superior del otador. Asegúrese

de que el otador quede entre los dos

topes.

otador.

servicio autorizada.

Levante el tope inferior del otador.

Asegúrese de que el otador quede entre

los dos topes. Consulte la sección Prueba.

el cableado doméstico.

servicio autorizada.

los dos topes. Consulte la sección Prueba.

en la tubería de desagüe esté despejado.

en contacto con el servicio técnico.

en la tubería de desagüe esté despejado.

Asegúrese de que el otador quede entre

los dos topes. Consulte la sección Prueba.

Page 38

PLANTILLA DE UBICACIÓN

El agujero debe ser redondo. Use una

perforación del agujero de 3 pulg.

Los agujeros de más de 3,040 pulg pueden

provocar ltraciones.

Punto central para la

sierra de perforación

de 3 pulg

3 pulg de

diámetro

Corte la plantilla

por esta línea.

SK1279

S19

Loading...

Loading...