Page 1

OWNERS GUIDE TO INSTALLATION

AND OPERATION

Fully Automatic

Water Softeners

SINGLE TANK

CABINET MODELS

TWO TANK MODELS

SAFETY INFORMATION

• Read the instructions carefully and learn the specic

details regarding installation and use. Failure to follow

them could cause serious bodily injury and/or property

damage.

• Make certain the electrical outlet is grounded by

having it checked by an electrician or by using a UL

Listed Circuit analyzer. Units are furnished with 3-prong

grounded plugs to protect you against the possibility of

electrical shock.

Do not under any circumstances

remove the ground prong and

never splice or cut the electrical cord.

• The outlet must be within reach of the power cord. Do

not use an extension cord. Extension cords that are too

long or too light do not deliver sufcient voltage to the

unit and could present a safety hazard if the insulation

INSTALL WATER CONDITIONER IN AN AREA PROTECTED FROM FLOODING, RAIN, DIRECT SUNLIGHT, DUST,

SNOW AND FREEZING. THE WARRANTY DOES NOT COVER DAMAGE INCURRED AS A RESULT OF EXPOSURE TO

WEATHER.

were to become damaged. The receptacle should be

located four (4) feet above the basement oor to guard

against the possibility of immersion.

Disconnect power at the main

electrical box before installing or

servicing the unit. Do not plug in unit or change

fuses while standing on wet or damp surfaces and

do not touch any other metal surfaces while plugging in product or changing fuses. Do it with one (1)

hand while keeping the other hand free.

• Check to be sure your power source is capable of

handling the voltage requirements of the unit. Plug into

a dedicated grounded receptacle which contains a fuse

or circuit breaker of 20 amps or less.

• All water treatment installations must conform to local

plumbing, electrical and sanitation codes. These codes

are established for your protection.

95 North Oak Street • Kendallville, IN 46755 • 800-545-2206

FW1741 A

Page 2

IMPORTANT NOTICE

Pay Special Attention to the Following Points

• Installation must be made within

a protected area covered from the

elements and freezing. In areas

where it is common practice to bury

the unit in the ground, the unit must

be protected from direct sunlight,

rain, dust, ooding, snow and

freezing. Failure to do so will void

the warranty.

• Check plumbing inlet and outlet

to ensure the proper ow of water

through the unit. Match plumbing

inlet and outlet with arrows located

on the sides of the valve head and

on the by-pass valve (especially if

replacing an existing unit).

• Make sure the unit is plugged into

a 115 volt grounded outlet which

contains a fuse or circuit breaker of

20 amps or less.

• Do not run 1/2” I.D. semi-rigid drain

tube over 20 running feet. If over 20

ft., increase drain line tubing size to

3/4” I.D. for the entire length of tube.

• Initially ll salt brine tank only 3/4 full

with salt. (Do not pack full.)

• If any red rust stains are apparent,

mix Super Iron Out® with the salt. As

an alternative, there are types of salt

available that contain iron control

agents.

• After installing the unit, manually

regenerate unit, following the control

valve instruction manual.

• Make sure control head is correctly

set for your specic water needs.

• If more than one unit is being

installed, the regeneration/back wash

times should be staggered.

REMEMBER, YOUR PURCHASE IS AN INVESTMENT AND

NEEDS TO BE MAINTAINED PROPERLY.

If any parts are missing, damaged, unit does not seem to be

working properly, or if you have any questions call

1-800-545-2206 or 1-800-345-9422

2

Page 3

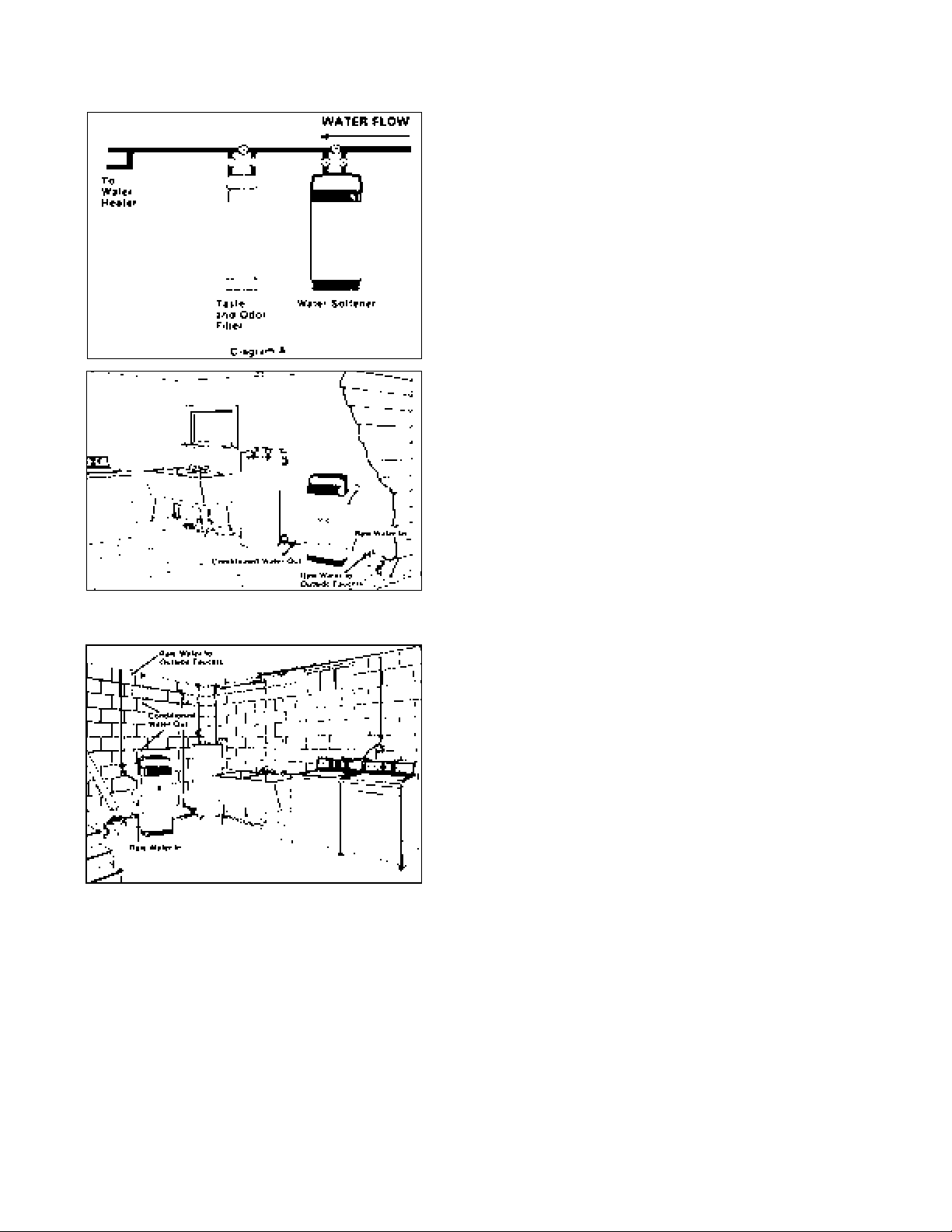

TYPICAL INSTALLATIONS AND EQUIPMENT LOCATION

LOCATE WATER CONDITIONING EQUIPMENT

CORRECTLY:

1. Select the location of your water softener with care.

Various conditions which contribute to proper location

are as follows:

2. Locate as close as possible to water supply source.

3. Locate as close as possible to a oor or laundry tub drain.

4. Locate unit in correct relationship to other water

conditioning equipment, if required. (See Diagram A.)

5. Select location where oor is level. If oor is rough and/

or uneven, you can level by placing cabinet or tanks on

3/4” plywood, and shim to level as needed.

6. Locate the softener in the supply line BEFORE the water

heater. Temperatures above 100°F (38°C) will damage the

softener and void the factory warranty.

Install water conditioner in an area protected from

flooding, rain, direct sunlight, dust, snow and freezing. The warranty does not cover damage incurred as a

result of exposure to the weather.

7. Allow sufcient space around the installation for easy

servicing.

8. Provide a non-switched 110/120V, 60Hz power source for

the control valve.

Typical rst oor installation for utility room or

breezeway, where oor drain exists.

Typical basement installation uses overhead piping

with oor or wash tub drain outlet.

3

Page 4

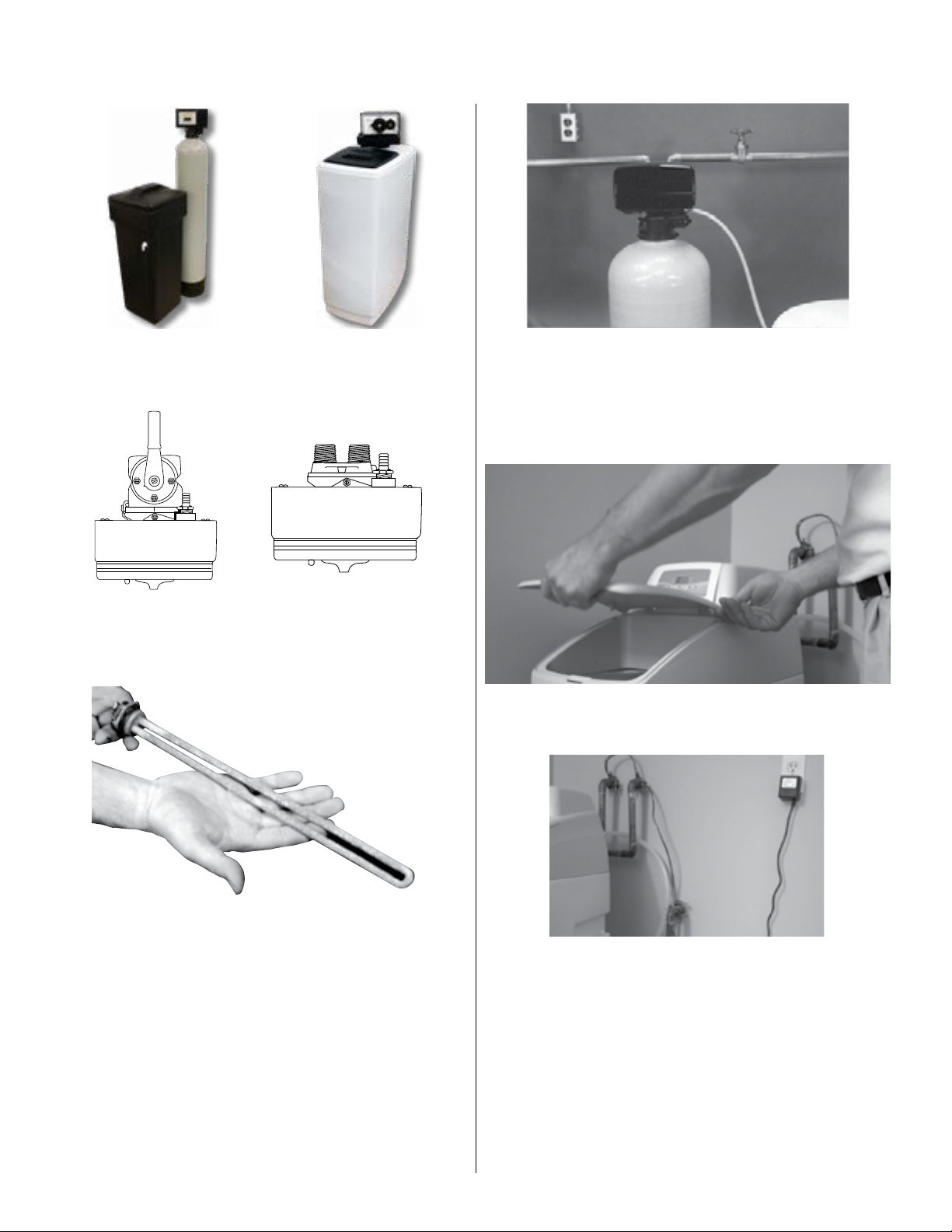

INSTALLATION INSTRUCTIONS

1. Water softeners are available in several styles.

Installation is essentially the same for all of them.

Outlet

By-Pass

Valve

Inlet

Drain

Connection

IL0635

Outlet

Inlet

Drain

Connection

IL0596

2. Units with a by-pass valve (left) use a ¾” female

threaded inlet/outlet, units with a yoke or manifold

(right) use a ¾” male threaded inlet/outlet

4. Install the unit in the water line ahead of the water

heater, close to a drain, and a 115 volt grounded

outlet on a at surface.

NOTE: Make sure electric outlet is grounded and

cannot be turned o by a wall switch or pullchain.

5. Remove the salt compartment cover from single

tank units or the brine tank lid from two tank units.

3. The above water heater element shows the eect

hard water buildup has on water heaters. Scale

buildup from hard water is dramatically increased

when water is heated.

6. Position softener near main water supply line, drain

and electrical outlet. Position so main water supply

shut-o valve is between softener and main water

source.

NOTE: Install unit in an area protected from the

elements and freezing.

4

Page 5

7. Close main water supply shut-o valve.

Outlet

By-Pass Valve

Inlet

Drain Connection

IL0635

11. Above diagram shows unit installed with a by-

pass valve. The unit can be removed easily without

disrupting the plumbing. A 3-valve by-pass system

(Figure 13) is not needed.

8. Open nearest faucet to relieve pressure and drain

plumbing lines.

9. On a new installation not already plumbed for

a water softener, cut out section of main water

supply line downstream from the supply shut o, at

position softener is to be installed.

Outlet

Inlet

Drain Connection

IL0596

12. Above diagram shows unit with a 3/4” manifold.

This installation requires a 3-valve by-pass system

as shown in Figure 13.

10. Check inlet and outlet for correct water ow,

matching arrows on valve head and on by-pass

valve (especially if replacing an existing unit).

CAUTION: Install in directions of arrows.

13. Above diagram shows a 3-valve by-pass system.

Many new houses are plumbed water softener

ready in this manner. A by-pass valve as shown in

Figure 11 can be used with this system.

5

Page 6

INSTALLATION INSTRUCTIONS

14. Before installing 3/4” ttings to the inlet and outlet

of the by-pass valve or manifold, wrap the threads

3 times around with Teon tape. Install 3/4”

ttings. CAUTION: Do not over tighten.

Control

Valve

Inlet

Outlet

Plastic Pipe

Solvent

Bond

Fittings

CONNECTING TO PLASTIC PIPE

17. Turn ttings clockwise with a wrench to tighten. Do

not over tighten.

Control

Valve

Galvanized Pipe

or Nipple

15. Soldering is no longer required to plumb with

copper pipe. Instead, use 3/4” compression ttings.

Connect plumbing as required for the specic

application (see Figures 17, 18 & 19).

CAUTION: IF COPPER PIPING WITH SWEAT

FITTINGS IS USED, DO NOT SWEAT DIRECTLY

INTO THE IN/OUT MANIFOLD OF SOFTENER

VALVE OR BY-PASS VALVE. HEAT WILL DAMAGE

PLASTIC PARTS.

Control

Valve

Sweat

Fittings

Inlet

Outlet

Copper Pipe

Compression

Fittings

IL0704

Connecting to Copper Pipe

16. Turn ttings clockwise with a wrench to tighten. Do

not over tighten.

Inlet

Outlet

CONNECTING TO GALVANIZED PIPE

18. Turn ttings clockwise with a wrench to tighten. Do

not over tighten.

19. Typical nished installation using rigid copper pipe.

Make sure by-pass valve (if being used) is in the

service position to ensure household service of

treated water.

6

Page 7

INSTALLATION INSTRUCTIONS

Brass

Compression

Nut

Brass

Insert

20. Press 1/2” I.D. semi-rigid or non-collapsible plastic

tubing (not included) onto drain line hose barb

until snug and secure with a hose clamp (not

included).

NOTE: Do not run 1/2” drain line over 20’. If over 20’,

increase tube size to 3/4”.

21. Typical drain line to stand pipe with proper 4” air

gap.

NOTE: An air gap is required by most local plumbing

codes to prevent waste water back ow. Check and

follow your local codes.

Poly

Tubing

Plastic

Ferrule

IL0707

23. For 2 tank softener installations only, make sure

you have the plastic ferrule in the right direction for

an air tight seal.

24. Visually check brine tubing for cracks or kinks.

Check ttings for proper assembly and tightness as

diagrammed.

If you are installing a single tank unit, proceed to step

28.

22. Loosen compression nut located on right side of

control valve by turning counter clockwise. Insert

one end of 3/8” O.D. tube (included).

NOTE: This step has already been done on single tank

design units.

25. Turn compression nut clockwise with wrench to

tighten.

CAUTION: Do not over tighten.

NOTE: This step is not required on single tank units.

7

Page 8

INSTALLATION INSTRUCTIONS

26. Insert other end of 3/8”plastic tube, from control

valve, through hole on brine tank. Loosen

compression nut, turning counter clockwise, and

insert tubing.

NOTE: This step is not required on single tank units.

29. Plug cord from control valve into 115V grounded

electrical outlet. Make certain that outlet is supplied

with power at all times. Make sure area is dry

before plugging the unit in.

30. Open main water supply shut-o valve.

CHECK FOR LEAKS! Close previously opened

faucet (step 8).

27. On 2 tank units only, turn compression nut

clockwise with wrench to tighten.

CAUTION: Do not over tighten.

NOTE: This step is not required on single tank units.

28. Install 1/2” I.D. semi-rigid or non-collapsible tubing

(not included) to the overow hose barb located on

the side of the softener cabinet or brine tank and

run to a suitable drain. Do not connect to drain line

o of softener.

Outlet

Service

Position

Inlet

Bypass Valve

IL0635

31. Make sure the bypass valve is in the service

position as shown above. Rotate handle 90

degrees to go into the bypass position, and close

o the valve when needed.

32. On a 3-valve by-pass system, open the inlet and

outlet valves and close the by-pass valve (see

diagram above).

8

Page 9

INSTALLATION INSTRUCTIONS

33. Draw a 5 gallon bucket of water to be used in the

brine tank.

TO PROGRAM THE CONTROL

VALVE, SEE SEPARATELY

ENCLOSED INSTRUCTION

ENTITLED “SETTING THE CONTROL

VALVE.”

34. Pour the 5 gallon bucket of water into the

brine tank. See Figure 42 for location of brine

compartment on single tank models.

35. Measure 1-1/2 oz of chlorine bleach and pour

solution directly into the brine tank or salt

compartment on single tank units.

36. On all tank units, pour salt into compartment. Fill

about 3/4 full initially. Do not pack full. This is also

where iron control agents will be put if you have

rust stains. Replace lids on the salt compartment.

9

Page 10

MAINTENANCE

1. SALT REFILL - During each regeneration of

the water softener, a specic amount of salt is

consumed, thus requiring periodic replenishment.

The frequency of the replenishment depends on the

regeneration schedule. Always replenish salt before

the supply is exhausted to ensure a continuous

supply of softened water.

We suggest using pellet type salt or grade A rock salt

that contains no dirt or sediment. Fill tank about 3/4

full. Do not pack full. Do not use block salt. Potassium

chloride, a salt substitute, can be used.

2. PREVENTING IRON FOULING OF MINERAL

BED - If iron is present in the water supply, the

softener will eventually become iron fouled,

resulting in reduced softening capacity and rust

stained xtures. Mixing one or two ounces of Super

Iron Out® or similar iron cleaner with every 80 lbs. of

salt added to the brine compartment will minimize

these problems. As an alternative, there are types of

salt available on the market that contain iron control

agents.

3. BRINE COMPARTMENT CLEAN OUT - To prevent

service problems, the salt compartment should be

emptied and accumulate. This clean out should be

done when the salt level is low or exhausted.

To eliminate the need of removing the brine tank

(two tank models) or the entire unit (single tank

models), use a wet/dry vacuum cleaner to empty the

old brine water. Once emptied, clean dirt from the

salt compartment. Add 5 gallons of water and new

salt.

4. PERIODICALLY CHECK TIME OF DAY SETTING

- Power outages will cause time of day timer setting

to become incorrect. To reset, refer to “Setting the

Control Valve.”

5. CHANGE OF OPERATING CONDITIONS - Should

your family size, your water usage habits or your

water quality change, the regeneration program

setting may have to be adjusted. Do not lower salt

setting.

PREVENTING WATER CONDITIONERS OR FILTERS

FROM FREEZING WHILE IN STORAGE

NOTE: The warranty does not apply to damage due

to freezing, nor is the manufacturer responsible for

or assume any liability for breakage, missing parts or

consequential damage that results from placing the

unit into storage.

1. Plan Ahead! Placing the unit into storage should be

done when the salt level in the brine tank is low but

NOT completely exhausted.

2. Immediately before storage and before the

salt is completely exhausted, manually start

the regeneration process and allow the unit to

automatically go through all of the regeneration

cycles.

3. Place the unit into the by-pass position,

depressurize and disconnect the plumbing from the

control valve.

4. Remove the control valve from the mineral tank by

turning counterclockwise.

5. Shake as much water out of the valve as possible

and store in an open, dry area. Place any loose

ttings in a plastic bag and tape to the valve.

6. Syphon water from the mineral tank, inserting a

hose into and down the distributor tube. This tube

is in the middle of the mineral tank and can be seen

once the valve is removed.

7. Using a wet/dry vacuum cleaner, empty the

brine tank/salt compartment of brine water. Then

remove as much of the remaining salt as possible.

CAUTION: Salt will become encrusted if allowed to

remain in the brine tank.

8. Using two (2) people, place mineral tank or cabinet

on its side on the oor, using caution as the cabinet

or mineral tank will break if dropped or not handled

carefully.

CAUTION: Water from the mineral tank will cause

damage to carpeting, vegetation, furniture, etc. The

manufacturer of the equipment is not responsible, and

assumes no liability for such damage.

9. DO NOT stand the unit upright until it is to be

placed back into service. To do so will allow

remaining moisture to settle to the bottom of

the mineral tank, expand when freezing, thereby

splitting the tank.

10. To place the unit back into service, refer to

installation and control valve instructions.

10

Page 11

WATER SOFTENER TROUBLE SHOOTING

JUST INSTALLED UNIT AND WATER IS NOT SOFT

WHAT TO CHECK HOW TO CORRECT

Has unit been properly installed Re-read instructions to see that all steps were followed

By-pass in plumbing On a 3-way by-pass valve system, open valves on piping

coming into and out of softener. The valve in between

MUST be closed and in good condition. Most units include

a by-pass valve which is connected to the control valve.

Make certain that it is in the service position.

Is unit piped in backwards Check arrows where pipe threads into valve head and make

sure water is owing consistent with the direction arrows

are pointing.

Hot water tank hardness Allow sucient time for hardness that has built up in your

water heater and pipes to run through system. Repeated

ushing of the water heater tank can also be done.

Is there resin in tank Softeners ship with resin already in the tank. Make sure the

resin has not been emptied or dumped. Put a trouble light

behind resin tank and you should be able to see the resin

thru the mineral tank. The tank should be approx. 2/3 full.

Valve head is not working correctly and causing water ow

not to go through softener

Softener has been undersized and does not eectively

remove the amount of hardness in your water

Water ow rate going through the softener is not allowing

time for the unit to soften

*To depressurize the unit, refer to valve instructions for your particular unit.

Shut o water supply, de-pressurize the unit*, unscrew the

valve head from unit and exchange it.

Draw a sample of untreated water before it goes through

the softener and a sample of treated water after the

softener. Have the samples analyzed to see if any hardness

is being removed.

Open an outside faucet and ll a measured bucket up with

water for 1 minute. The amount of gallons in the bucket tells

you how many gallons per minute are being run through

the softener. Call 1-800-545-2206 to see what the GPM

limit is on the specic unit you have purchased. Add a ow

control accessory to your unit if needed.

WATER TASTES SALTY OR BRINE TANK FILLS WITH WATER

WHAT TO CHECK HOW TO CORRECT

Is backwash water owing freely down to drain with an air

gap and no back siphoning

Brine salt tube and connections not allowing salt solution

into mineral tank to regenerate

Injector or injector screen plugged Put softener in by-pass position and de-pressurize the unit

Put valve into “Backwash” position and follow water ow

down to drain. If over 20 ft., use 3/4” (or larger) drain

tubing. Drain line should be no more than 8 ft. lift.

Visually check tubing for cracks or kinks. Check ttings for

proper assembly and tightness as diagrammed.

Brass

Compression

Nut

Brass

Insert

Poly

Tubing

by putting into “Backwash” position. There will be 2 screws

on neck of valve where the salt rinse line goes into softener.

Remove the 2 screws and clean screen and remove any

chunks of salt, etc.

Plastic

Ferrule

IL0707

11

Page 12

WATER WAS SOFT BUT NOW FEELS HARD

WHAT TO CHECK HOW TO CORRECT

No salt in brine tank Add salt to brine tank and maintain salt level above water level. Manually

initiate the regeneration cycle and allow softener to totally go through all

regeneration cycles.

Electrical service to unit has been

interrupted

Has softener valve head been

programmed to regenerate after

installation?

Has the by-pass been used and not

connected back into service?

Salt is bridging in tank Salt in bottom of tank has hardened and is not allowing water/salt mixture

Salt tube going from salt tank to mineral

tank is plugged or insucient water

owing into brine tank

Brine salt line and connections not

allowing salt solution into mineral tank to

regenerate

Make certain that the power cord is plugged into a 115V grounded outlet that

cannot be turned o accidentally by a wall switch or pull chain. Check for blown

fuses. In case of electrical power outages, reset the time of day. Some valves

utilize a battery - see valve instructions for battery replacement.

See valve programming instructions. Was water properly tested and diagnosed

for correct setting? Have additional people moved in or water usage increased?

Make sure the handle of the bypass valve is in the service position. On a 3-way

bypass position, open the inlet and outlet valves and close the bypass valve.

to get to the bottom of salt and consequently over to mineral tank. Do not ll

salt tank completely (3/4 full). Use a stick or broom handle and poke into salt,

making sure it is broken up.

Put unit into “Brine Rinse” position, make sure salt water ows uninterrupted

from salt tank to mineral tank. Clean or replace brine valve. Clean and unplug

necessary line so water ows uninterrupted.

Visually check tubing for cracks or kinks. Check ttings for proper assembly and

tightness as diagrammed

Brass

Compression

Nut

Brass

Insert

Poly

Tubing

Plastic

Ferrule

IL0707

Injector or injector screen is plugged Put softener in “By-Pass” position and de-pressurize by putting in “Backwash”

position. There are 2 screws on valve neck where salt line tube enters softener.

Remove screws, clean screen and remove chunks of salt, etc.

Line pressure is too low Line pressure must be at least 20 PSI at all times.

Is backwash water owing freely down

Put valve into “Backwash” position and follow water ow down to drain.

to drain with an air gap and no back

siphoning?

Too much iron or tannins have fouled the

bed

A water softener is only eective for up to limited amounts of iron and

yellowish colored tannins. Draw water before it goes into and after it ows

through softener. Have both samples tested to see if iron is being removed or if

mineral bed is already coated and fouled.

Salt level setting on valve head is set too

Verify salt setting and adjust as necessary (consult factory.)

low

Valve head or timer is not cycling Shut o water supply, de-pressurize tank*, unplug unit and replace valve head

motor.

Has softening mineral been exposed to

freezing?

Freezing weather causes the resin to mush and become ineective. Replace

resin, properly insulate and shield unit from direct elements and freezing

temperatures.

Leak in distributor tube Check for cracks in distributor tube. Check “O” ring and tube inlet in bottom of

valve. Replace if necessary.

*To depressurize unit or backwash, refer to the valve instructions for your particular unit.

12

Loading...

Loading...