Page 1

INSTALLATION INSTRUCTIONS

Supersedes

Fully Automatic Water Filters

SW0015

0310

0201

INSTALLATION INFORMATION

Model No. ______________________________________

Unit Date Code __________________________________

Date Installed ____________________________________

WATER ANALYSIS RECORD

Hardness _____ GPG Sulfur _____ PPM

Iron _____ PPM pH _____

Manganese _____ PPM Tannins _____ PPM

Turbidity _____ FTU

Other:

Other Water Treatment Equipment Installed:

Installed By:

AUTOMATIC MODELS

07AF-10

134841

95 North Oak Street • Kendallville, IN 46755

For Service Call:

1

Page 2

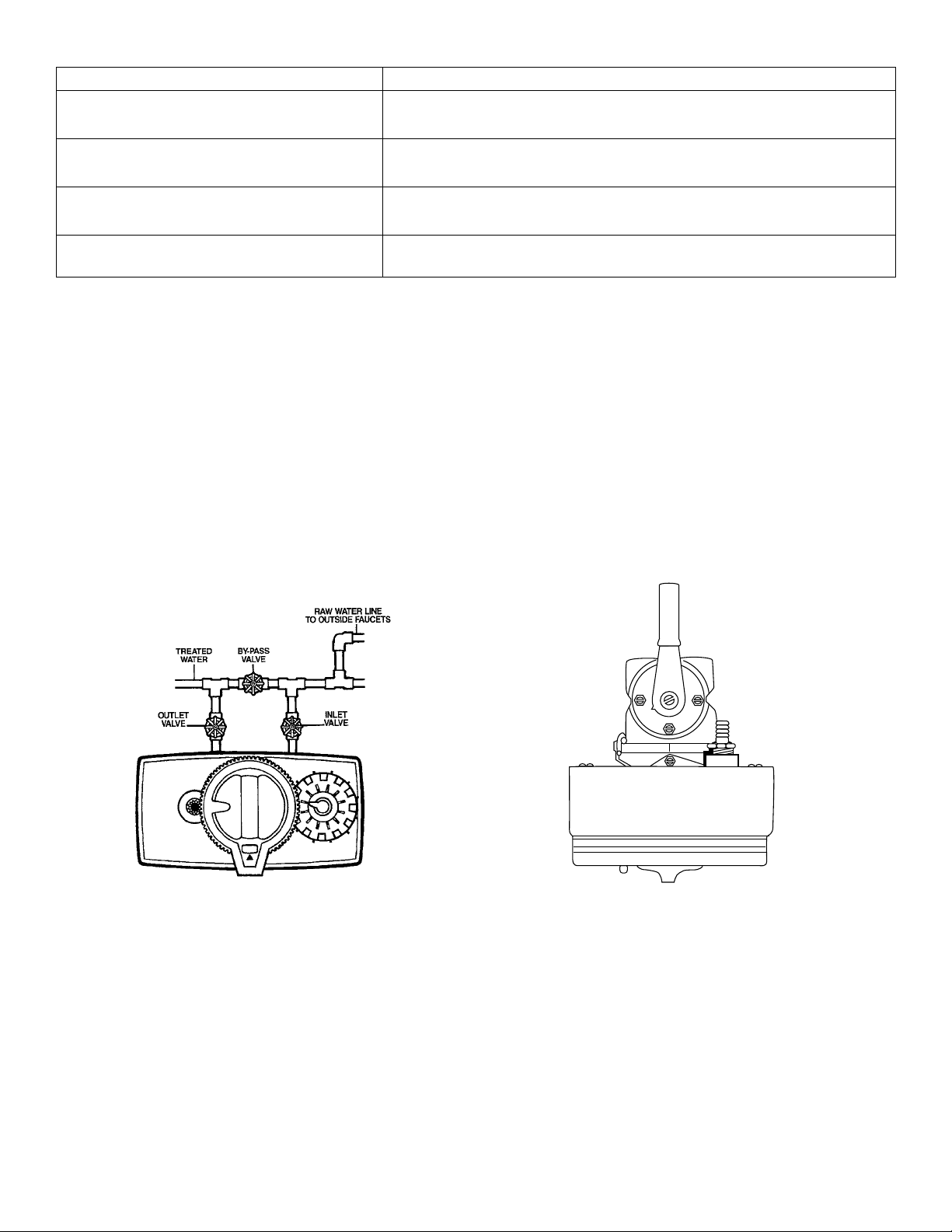

WATER FILTER SPECIFICATIONS (Figure 1)

IL0635

APPLICATION FILTER BED

Neutralizing Acid Water, 6.0 to 7.0 pH 1 cu. ft. Neutralizing Mineral and 20 lbs.* “D” Gravel (Underbed)

Taste and Odor Removal, Wide Application 1 cu. ft. Activated Carbon and 20 lbs.* “D” Gravel (Underbed)

Remove up to 10 PPM Iron 1 cu. ft. Birm and 20 lbs.* “D” Gravel (Underbed)

Remove fine suspended matter and turbidity

1 cu. ft. Filter-Ag and 20 lbs.* “D” Gravel (Underbed)

up to 125 PPM

*Gravel installed in mineral tank at factory

INSTALLATION ILLUSTRATIONS (Figure 2)

Outlet Inlet

By-Pass

Valve

Drain

Connection

3-VALVE BY-PASS SYSTEM INCLUDED BY-PASS VALVE

2

Page 3

FILTER INSTRUCTIONS

These instructions cover fully automatic filters. Read

thoroughly before proceeding with the installation. Check to

be sure water is available in sufficient volume and pressure

to adequately backwash the equipment at the specified rate.

When higher service flow rates are required or water for

backwash is limited, two units should be installed in parallel.

Such an installation doubles the service flow rate without

increasing the backwash requirement. Naturally, they should

be set to backwash at different times - at least two hours

apart.

Filter Operation - During “Service” the water flows down

through the mineral bed and out to service lines. Collected

turbidity and sediment must be regularly removed from a

filter by reversing the flow of water through the filter and

running to drain. Called “backwashing”, and lasting 15

minutes, this process expands the mineral bed, freeing the

turbidity - which is then washed out to drain.

Normally, the units should be set to backwash twice every

12 days. Where conditions are extreme a more frequent

backwash schedule will be required to assure the

maintenance of a clean filter bed.

A 46 minute setting period follows the backwashing where

no flow to drain will be observed. Then a down flow rinse to

drain follows to purge untreated water from bottom of filter

bed and to settle the bed before returning to service.

During backwashing and rinsing, untreated water is

by-passed to the service lines so that uninterrupted water

service is maintained.

1. UNPACKING

Check packing list located on outside of tank carton against

cartons received. The large carton contains the filter tank,

main control valve and underbed gravel. Filter mineral is

available and is packaged separately.

2. LOCATION

For complete customer satisfaction, all water in the home

should be filtered with the exception of the outside faucets.

Select a location near the water service inlet and near a

floor drain. Be certain that all sides of the filter are easily

accessible for service and maintenance. On a private water

system, locate filter as shown in Diagram A. An uninterrupted

115 volt circuit must be nearby for automatic units.

3. MINERAL

The tank must be loaded with mineral after the tank has

been placed at the desired location. Remove the valve by

unscrewing from the mineral tank. Leave distributor tube in

the tank while filling. Cover top of distributor tube to prevent

mineral from entering tube while filling. Place funnel in hole.

Pour several gallons of water in the tank then pour in the

filter mineral.

The required quantity of each type of filter mineral is shown

under specifications, Figure 1. When filled, the tank should

be approximately two thirds full. As a check, measure

distance from top of filling port to the mineral bed surface.

This distance should be approximately 18 inches.

Fill tank with water by using a garden hose or several

buckets of fresh water. This will permit the filtering material

to become soaked while preparing the installation and will

prevent the control valve from being plugged with floating

mineral on initial backwash. Remove funnel and the plastic

plug from the distributor tube. Replace the valve, while

being careful to position the distributor tube into the

distributor pilot tube in the adapter.

3

Page 4

4. WATER SUPPLY CONNECTIONS

Figure 2 shows typical installations. Inlet and outlet

connections are 3/4 inch pipe size and are marked with

raised arrows on the sides of the plastic valve. Turn off main

water supply and connect the pipes, valves and fittings.

CAUTION: IF COPPER PIPING WITH

SWEAT FITTINGS IS USED, DO NOT

SWEAT DIRECTLY INTO THE IN/OUT

MANIFOLD OF FILTER VALVE OR

BY-PASS VALVE. HEAT WILL DAMAGE

RUBBER AND PLASTIC PARTS.

5. DRAIN LINE CONNECTIONS

Install 1/2” I.D. plastic pipe or tubing from the hose barb

located on right side of main control valve to an open

drain. Do not connect the drain line directly to a sewer as

this would violate sanitary codes. A 4 inch gap between

the end of the drain line and a sewer is recommended.

Keep drain line as short as possible. An overhead drain

line can be used if necessary, but should discharge below

the main control valve if possible.

CAUTION: NEVER CONNECT DRAIN LINE

INTO A DRAIN, SEWER LINE OR TRAP.

ALWAYS ALLOW AN AIR GAP BETWEEN

THE DRAIN LINE AND THE WASTE WATER

TO PREVENT THE POSSIBILITY OF

SEWAGE BEING BACK SIPHONED.

6. ELECTRICAL CONNECTIONS

AUTOMATIC CONTROL VALVE

7. SETTING THE TIME CONTROL

Time of Day - Depress the red button, disengaging the large

gear. Turn the large gear until the actual time of day appears

at the Time of Day arrow. Note “AM” and “PM” selections on

the large gear and set the time accordingly. Release the red

button, making sure the gear is engaged.

Backwash Frequency - Set the days you want regeneration

to occur by sliding tabs on the skipper wheel outward to

expose fingers. By sliding one tab, the filter will backwash

every 12 days. Slide tabs 1 and 7 to backwash every 6

days.

Other Settings - The starting time of backwash is preset for

2:00 A.M. on each day for which skipper wheel tab is slid

out. All other settings such as Backwash, Rinse, and Fast

Rinse have been preset.

8. CONTROL VALVE POSITIONS

AUTOMATIC FILTER - The automatic control valve must

be started in service position! The words “In Service” are

imprinted in the manual regeneration knob dial. Rotating the

manual knob CLOCKWISE will place the unit in the various

positions printed on the dial.

The positions printed on the dial and cycle times are as

follows:

Automatic filters are equipped with a 6 ft., 115 volt,

grounded power cord. When the plug is inserted into a

properly grounded receptacle, it will guard the user against

electrical shock if the unit insulation should fail for any

reason.

Do not plug into an outlet controlled by a wall switch or a

pull chain that could be inadvertently turned off.

DIAL READING

1. In Service

2. Regeneration

3. Rinse

4. Backwash

5. Pause

6. Rapid Rinse

7. Settle Rinse

4

CYCLE TIME

5 Min. Rinse

12 Min. Backwash

46 Min.Settling period

12 Min. Backwash

5 Min. Rinse

Page 5

9. STARTING THE UNIT

Place the control valve in the SERVICE POSITION and

follow these steps:

(a) Place the by-pass valve (valves) to SERVICE position

and allow water to flow into the mineral tank. On a

3-valve system (Figure 2) open the inlet and outlet

valves and close the by-pass valve.

(b) When the water stops flowing, open a treated water tap

until all air is released from the lines, then close the

tap.

(c) Manually index knob to the BACK WASH POSITION.

(Clockwise rotation.)

(d) Plug in the electrical cord. Set the days of backwash

desired. Set the time of day as also noted in Section 7.

On all units except carbon filters, allow the unit to

backwash 15 minutes or until the water becomes clear

at drain. This will wash out the fine material from the

mineral. Check water at drain to be certain large

quantities of mineral are not being lost. If so, return

valve to IN SERVICE position and allow mineral to soak

longer before being backwashed.

NOTE: WHEN INSTALLING A CARBON FILTER, IT IS

BEST TO ALLOW AT LEAST 3 HOURS OR

PREFERABLY OVERNIGHT FOR CARBON TO SOAK

BEFORE ATTEMPTING TO BACKWASH. TO SPEED

WETTING, OPEN THE FAUCET OF THE TREATED

SUPPLY AND ALLOW TO RUN 5 MINUTES OR

LONGER OR UNTIL WATER IS CLEAR. IF

CONSIDERABLE CARBON IS STILL BEING LOST

WHEN BACKWASHING, LEAVE IT SOAK FOR A DAY

OR TWO LONGER.

(e) Position to RAPID RINSE. The automatic valve will

automatically return to IN SERVICE after approximately

17 minutes.

13. FINAL CHECKOUT

(a) Be certain by-pass valve is closed and inlet and outlet

valves are fully open.

(b) Check electrical supply to be certain cord is connected

to an uninterrupted 115 volt outlet.

(c) Be certain warranty card is filled out and mailed in.

14. ADDITIONAL INFORMATION

(a) Carbon filter mineral must be replaced periodically to

ensure filter effectiveness. Maximum carbon life is three

years.

(b) Calcite filter mineral dissolves slowly. Therefore, it will be

necessary to add calcite to the unit from time to time.

10. BACKWASH

Units will now Backwash on a frequency as established in

Step 7 “Setting the Time Control.”

11. EXTRA BACKWASH

Valve can be manually regenerated by turning the control

knob to the Backwash position. The unit will automatically

continue through the regeneration cycle and return to the

SERVICE position when regeneration is complete.

12. TO SKIP BACKWASH

For vacations or extended periods of absence, the timer

cord plug can be pulled out of receptacle. Upon return, plug

in timer, reset the time of day (Section 7-A) and backwashing

will resume as normal.

5

Loading...

Loading...