Page 1

Rolling Tortilla Warmer

Owner’s Manual

Models

RTW14EA and RTW19EA

patent no. 9,516,883

This manual includes material related to installation,

use , cleaning, and care. Exploded view[s], as well

as any available parts list[s] and wiring diagram[s]

pertaining to the unit[s] covered by this manual are also

included.

This manual must be read and understood by all

persons using or installing this appliance. Contact your

Star dealer if you have any questions concerning

installation, use, or maintenance of this equipment.

DO NOT DISCARD THIS MANUAL.

RTW19EA

2M-Z19213 - Rev. G - 08.2018

Page 2

LIMITED EQUIPMENT WARRANTY

Star Manufacturing [as well as its subsidiaries] warranties new products

to be free from defects in material and/or workmanship for a period

of one [1] year from the date of original installation, except as noted

below. Defects that occur as a result of normal use, within the time

period and limitations defined in this warranty, will at Star’s discretion

have the parts replaced or repaired by Star or a Star-authorized service

agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Starauthorized service agency. Star will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Star-authorized service agency must be used.

Star will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agen cy, transportation prepaid .

PORTABLE EQUIPMENT EXAMPLES

• 514LL fryer

• 15MC and 18MCP hot food

merchandisers

• QCS1, QCS2, and RCS2 toasters

• 16PD-A pretzel merchandisers

• condiment dispensers except

HPD- and SPD-series models

• all pop-up toasters

• all pastry display cabinets

• all heat lamps • all accessories

CONTACT

Should you require any assistance regarding the operation or

maintenance of any Star equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone Star/Toasmaster 314.678.6306

Fax 314.781.2714

Email customerservice@star-mfg.com

www.star-mfg.com • www.toastmastercorp.com

• J4R popcorn machine

• 12NCPW and 15NCPW nacho

merchandisers

• nacho cheese warmers except

11WLA-series models

• specialty food warmers except

130R, 11RW, and 11WSA models

• all butter dispensers

• all nacho chip merchandisers

WARRANTY EXCLUSIONS

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been used, cleaned, maintained,

or installed in accordance with the directions published in the

appropriate installation sheet and/or owner's manual as well

as national and local codes, including incorrect gas, electrical,

or water connection. Star is not liable for any unit which has

been mishandled, abused, misapplied, subjected to chlorides, harsh

chemicals, or caustic cleaners, damaged from exposure

to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have

an altered or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls,

air and gas burner/bypass/pilot adjustments, gas or electrical

system checks, voltage and phase conversions, cleaning

of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components, quartz

heating elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and

hotplates, including but not limited to burners, grates, and

radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform

service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily

cleaning routine. such as but not limited to silicone belts, PTFE

non-stick sheets, knobs, control labels, bulbs, fuses, quartz heating

elements, baskets, racks, and grease drawers.

• Components that should be replaced when damaged or worn,

but have been field-repaired instead [eg. field-welded fry pots]

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional

and/or extended warranties.

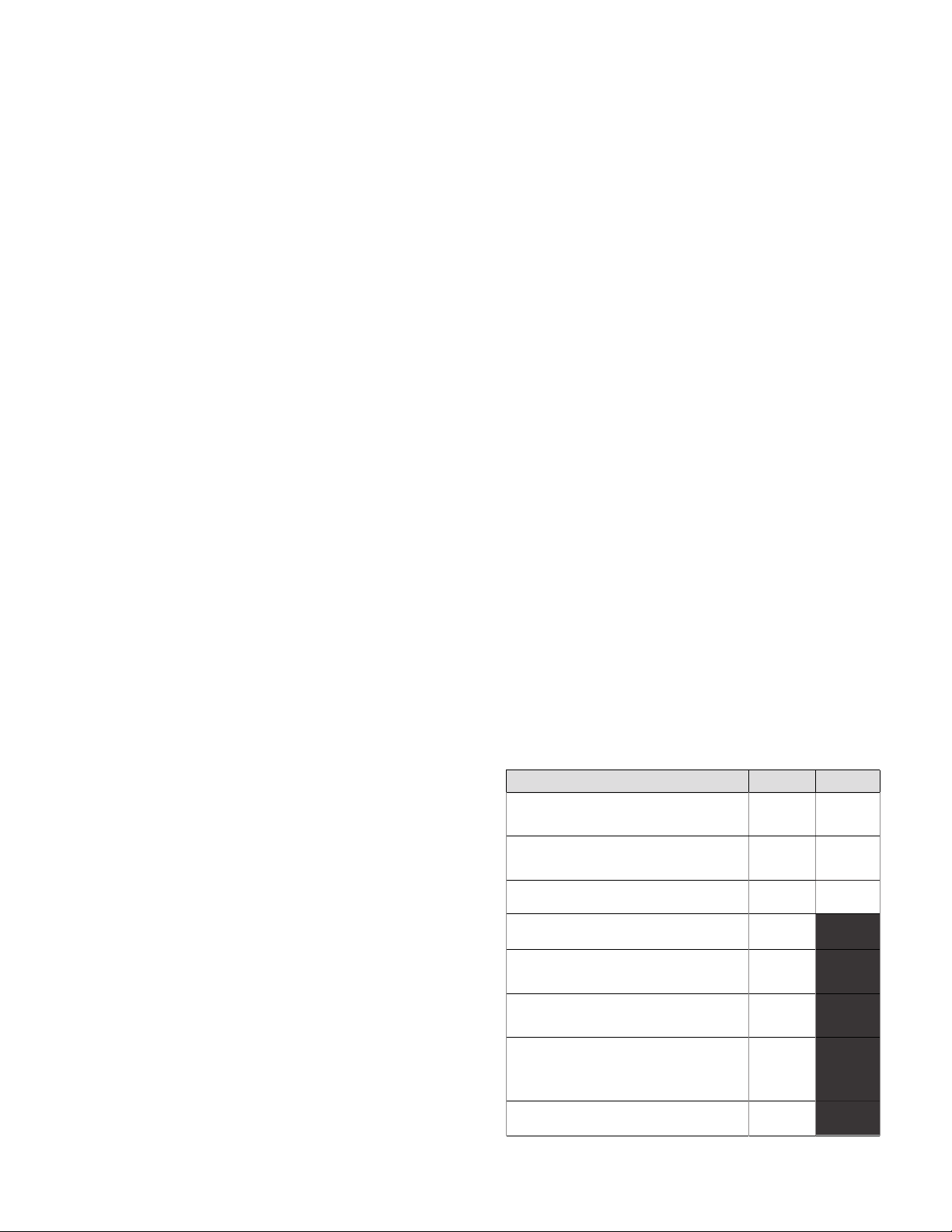

PRODUCTS PARTS LABOR

Star Ultra-Max® griddles,

charbroilers, and hotplates

Star-Max® fryers, griddles,

charbroilers, and hotplates

2 years 2 years

2 years 2 years

Jetstar® popcorn poppers 2 years 2 years

Staltek™ roller grill coatings 5 years

chrome griddle surfaces [against

peeling]

cast iron grates, burners,

and burner shields

5 years

180 days

original Star or Toastmaster parts

sold to repair Star or Toastmaster

90 days

equipment

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z21647 • Rev C • 02.2018

i

Page 3

TABLE OF CONTENTS

Warranty i

General Information and Installation 1–2

Daily Operation 3–4

Cleaning 5

Maintenance 6

Wiring Diagram 7

Exploded Views 8–13

Parts List 14–17

Wall Mount Installation 18–19

Specifications 20

Factory Settings Adjustment 21

ii

Page 4

NOTES

iii

Page 5

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

SAFETY SYMBOLS

These symbols are intended to alert the user to the

presence of important operating and maintenance

instructions in the manual accompanying the appliance.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to ensure delivery of your unit

in perfect condition. However, there are instances in which the unit may be damaged in transit. In the

event you discover any type of damage to your product upon receipt, you must immediately contact

the transportation company who delivered the item to you and initiate your claim with that company.

If this procedure is not followed, it may a ect the warranty status of the unit. Please record the model

number, serial number, voltage, and purchase date in the area below at the time of receipt..

Model Number

Serial Number

Voltage

Purchase Date

NOTICE

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifications

contained in this sheet are subject to change without notice. Star reserves the right to change product

specifications and design without notice. Such revisions do not entitle the buyer to corresponding

changes, improvements, additions or replacements for previously purchased equipment. While Star

International Holdings Inc. exercises good faith e orts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a result

of using the specifications. By using the information provided, the user assumes all risks in connection

with such use.

PLEASE REFER TO THE WARRANTY PAGE FOR SPECIFIC WARRANTY INFORMATION.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please have the

information in the above fields ready when you call to ensure a faster service.

AUTHORIZED SERVICE AGENT LISTING

Reference the listing provided with the unit or for an updated listing go to the website or call customer

service to find an agent.

Business hours: 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone: 314-678-6303

Fax: 314-781-2714

Email: customerservice@star-mfg.com

Website: www.star-mfg.com

1

Page 6

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only, and is intended for use by personnel

trained and experienced in its operation. This is not sold for consumer use in and around the home

nor for use directly by the general public in food service locations.

Before using yo

ur new equipment, read and understand all the instructions and labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use understand

the units operation and safety before they use the unit.

GENERAL INSTALLATION INFORMATION

The unit is shipped fully assembled and ready to plug into a standard outlet specified for its voltage

and amp draw. If improper electrical supply can be determined through troubleshooting, contact

a qualified electrician prior to using the unit. Removal or replacement of the power cord or plug will

void the warranty. Should you require assistance, contact your local authorized service agent for any

service or required maintenance.

Level unit using the adjustable feet under the unit [there is approximately 0.5 (1/2) inch of adjustment].

Allow enough space around the unit for adequate ventilation. It is recommended that you leave a ten

(10) inch gap on the top for cleaning if the unit is to remain stationary. The sides and back of the unit

require no additional clearance.

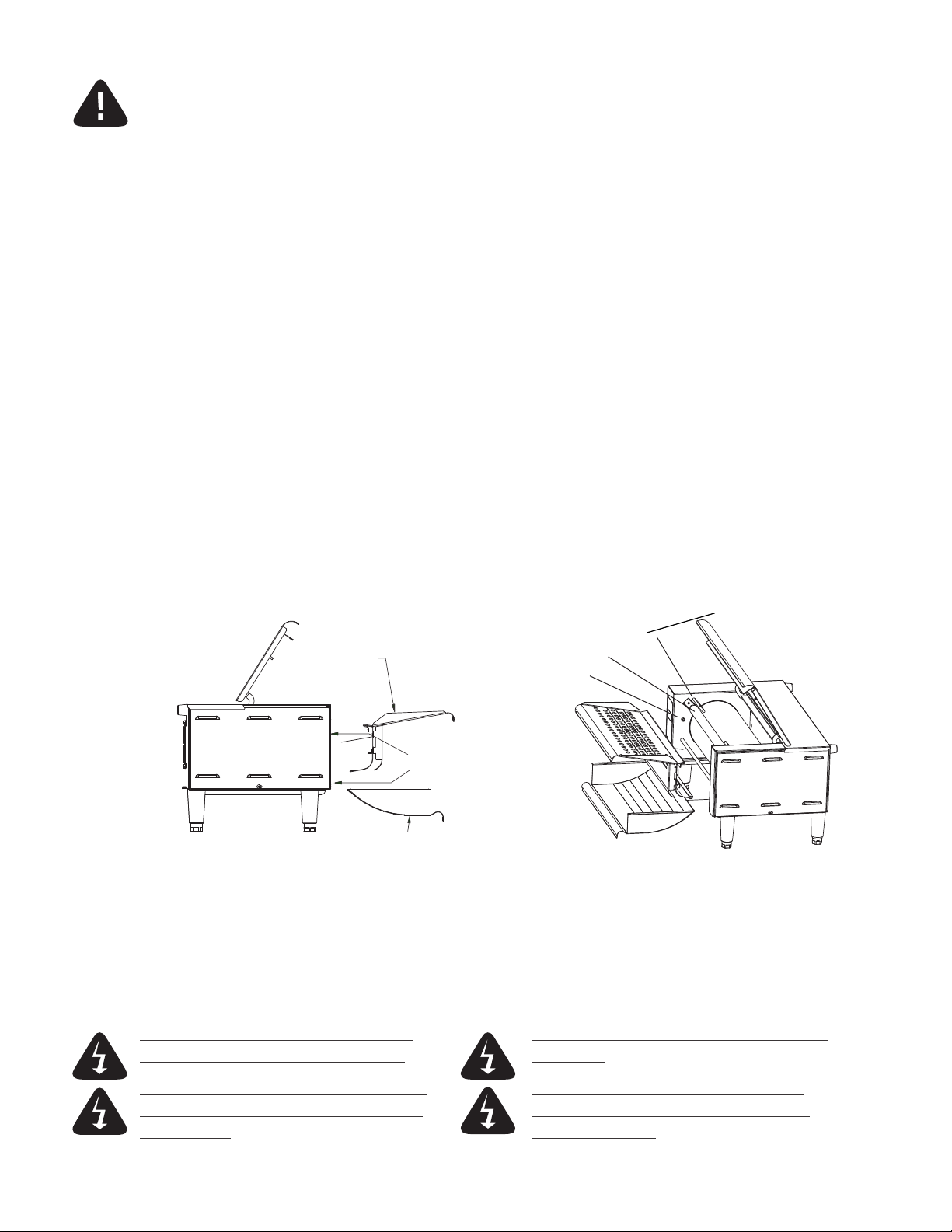

Before using the unit for the first time, make certain to clean it properly. Refer to the "Cleaning Procedure"

document for cleaning instructions. The inlet and outlet trays will also need to be placed on the unit prior to

use. The outlet tray slides on the lip under and in front of the drum area and the inlet tray sits on a rod,

resting against the stop pins.

belt guide

inlet tray

belt roller

stop pin

place here

outlet tray

ELECTRICAL CONNECTION

Before making any electrical connection to this unit, check that the power supply is adequate for the

voltage, amperage, and requirements stated on the rating plate. RTW14EA units will require a NEMA

5-20P receptacle. RTW19EA units will require a NEMA 6-15P receptacle. Make certain to disconnect the

unit from the power source before installing or removing any parts. Be absolutely sure that the ground

connection for the receptacle is properly wired. Do not connect equipment to power without proper

ground connections. Improper grounding may result in personal injury or fatality.

DO NOT CUT OR REMOVE THE PLUG OR DO NOT IMMERSE OR LET THE UNIT STAND

GROUNDING PRONG FROM THE PLUG. IN WATER .

CONNECT UNIT INTO DEDICATED AC LINE DO NOT HOSE DOWN THE UNIT OR THE

ONLY AS SPECIFIED ON THE DATA PLATE TABLE/COUNTER IF THE UNIT IS ON THE

OF THE UNIT. TABLE/COUNTER.

2

Page 7

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

DAILY OPERATION

CERTAIN SURFACES ARE EXTREMELY HOT DURING OPERATION AND

CARE SHOULD BE TAKEN WHILE USING THIS UNIT.

THIS UNIT IS DESIGNED TO WARM DRY, FLEXIBLE PRODUCTS ONLY.

DO NOT ATTEMPT TO RUN WET OR LOOSE MATERIAL THROUGH IT.

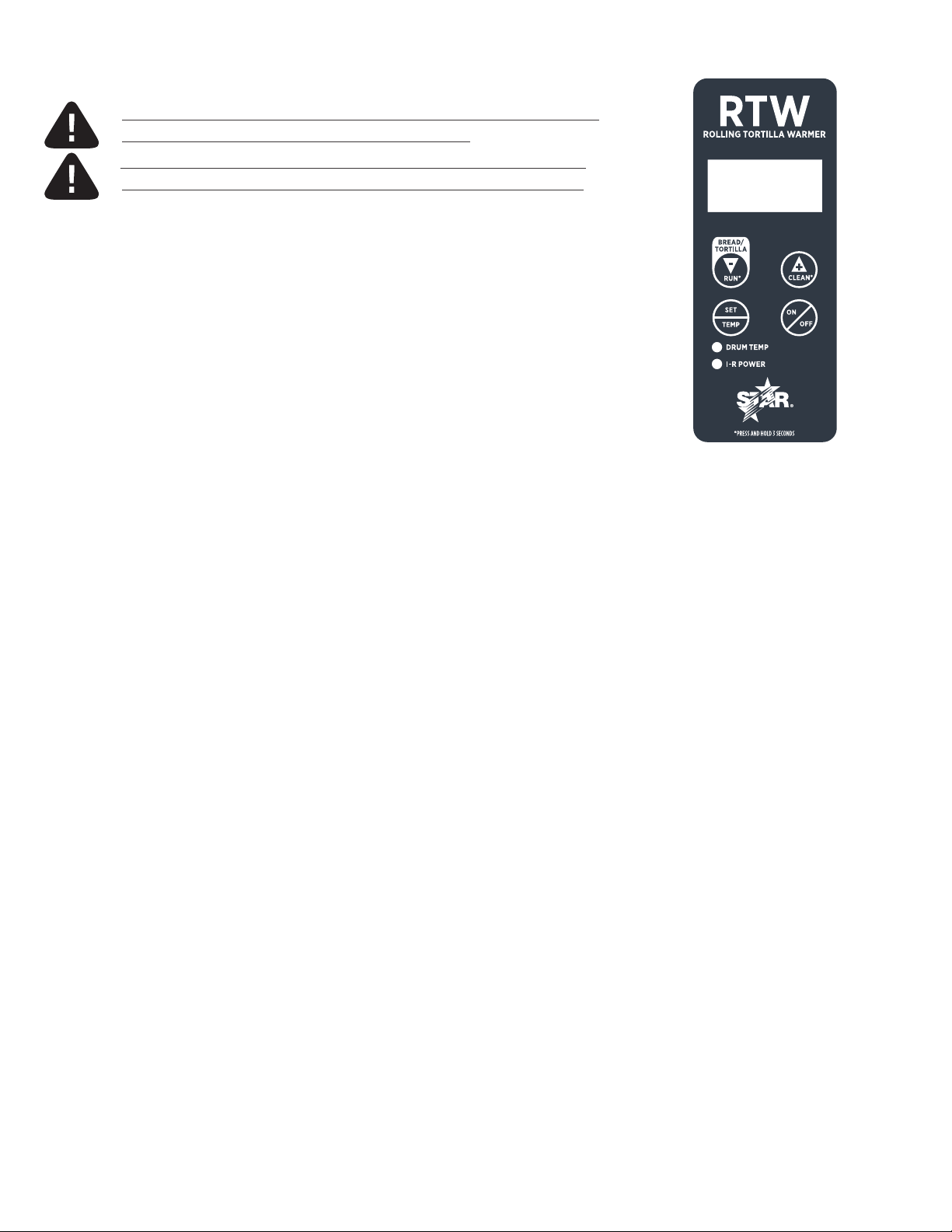

ELECTRONIC CONTROLS

BUTTONS (PRIMARY USES)

• ON/OFF—Turns power on or o to the electrical components of the unit.

• SET/TEMP—Allows adjustment of the roller heating element temperature

up to 480°F (249°C).

• ▲/CLEAN—Accesses “CLEAN” mode and adjusts settings upward in menus.

• ▼/RUN— Accesses “RUN” mode and adjusts settings downward in menus.

FUNCTIONS/MODES

• ON/OFF—All power is turned on, or removed from, the drum motor, heating

elements, and cooling fan. After powering down, the screen will

display “OFF” until the “ON/OFF” button is pressed again. Cooling

fan will be on in all modes other than when the unit is powered down.

• PREH EAT—Drum motor runs at the set “TORT” speed. Heaters bring the drum

temperature up to the set operating temperature.

• TORT—Drum motor runs at the set “TORT” speed. Heaters maintain the drum

temperature at the set operating temperature.

• BREAD—Drum motor runs at the set “BREAD” speed. Heaters maintain the

drum temperature at the set operating temperature. This mode only

lasts for 1–40 seconds before defaulting back to TORT mode.

• COOL— Drum motor runs at the set “TORT” speed. Heaters are off.

• CLEAN— Drum motor does not run. Heaters are off.

1/2 scale RTW

control panel

START-UP

i. When the unit is initially plugged in, the display will read “OFF” for a brief time. No outputs will

receive power at this time.

ii. When “ON/OFF” is pressed, the drive motor, heating elements, and fan motor will be turned on.

The PREHEAT mode will start immediately and will take approximately twenty (20) minutes

to complete. During this time, “PREHT” will appear on the display. Do not attempt to adjust

temperature or speed settings until PREHEAT has completed.

iii. The temperature of the drum can be checked at any time in PREHEAT or TORT modes by pressing

the “SET/TEMP” button. If the temperature has not yet reached 100°F (38°C), the words “LOW”

and “TEMP” will flash on the screen.

iv. There will be a small dot on the lower right of the screen which will remain on whenever the heating

elements are on. When the PREHE AT mode has completed, “TORT” will be displayed on the screen.

3

Page 8

TEMPERATURE ADJUSTMENT

This can be performed in RUN (TORT or BREAD) and CLEAN modes.

i. Press and hold the “SET/TEMP” button for three (3) seconds. The display flashes the drum temperature

setting and the “DRUM TEMP” light on the front label illuminates as well.

ii. Use the ▲ and ▼ buttons to adjust the drum heat to the desired temperature. The display will stop

flashing while ▲ or ▼

adjusted from 210°F–480°F (99°C–249°C). Adjustments of 10°F or 10°C at a time can be made

depending on which the unit is set to read at the time adjusted. The default setting is 480°F (249°C).

iii. Press the “SET/TEMP” button when you are satisfied with your adjustment and move on to a screen

which will allow you to toggle between Fahrenheit and Celsius.

iv. Press the “SET/TEMP” button again to save and exit this mode.

DRUM SPEED ADJUSTMENT

This can be performed in RUN mode (TORT or BREAD).

i. Press and hold the ▲ and ▼ buttons simultaneously for three (3) seconds. The display will sequence

through “TORT”, “SPEED”, and the current “TORT SPEED” speed setting number.

ii. Press the ▲ button to increase the set speed and the ▼ to decrease the set speed. The speed setting can

range from 1–99 and holding the ▲ or ▼ button will make the setting increase or decrease until a limit

is reached.

iii. Press “SET/TEMP” again to save the selected setting. The display will now sequence through “BREAD”,

“SPEED”, and the current “BREAD SPEED” setting number. This is adjusted using the same procedure

as the above “TORT SPEED” in the section above.

iv. Press the “SET/TEMP” again to save the selected setting. The display will now sequence through

“BREAD”, “TIME”, and the current time setting. Bread mode is only activated for a brief time determined

by this setting. Press the ▲ button to increase the set time and the ▼ to decrease the set time anywhere

from 1–40 seconds and holding the ▲ or ▼ button will make the setting increase or decrease until

a limit is reached.

v. Pressing “SET/TEMP” one more time will exit speed adjustment.

are pressed and will indicate the temperature and units. The temperature can be

4

Page 9

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

CLEANING

DO NOT IMMERSE OR LET THE UNIT STAND

IN WATER.

DO NOT HOSE DOWN THE UNIT OR THE

TABLE/COUNTER IF THE UNIT IS ON THE

TABLE/COUNTER.

DO NOT USE CAUSTIC CLEANERS ON ANY

SURFACE OF THE UNIT.

DO NOT USE ANY ABRASIVE CLEANING

UTENSILS ON ANY PART OF THE UNIT.

Preventive maintenance for your unit consists of the following recommended cleaning procedures.

In order to keep your tortilla warmer in top operating condition, these steps should be performed

daily or weekly as indicated.

CLEAN MODE

CLEAN mode is a cool down notification feature alerting the user when the unit reaches a safe handling

temperature. Press the “ON/OFF” button once to activate CLEAN mode. The inlet and outlet trays and

scraper are removable for easy access for cleaning. The recommended cleaner to use is Kay QSR

heavy-duty degreaser.

CLEANING PROCEDURE

i. Press and hold the “ON/OFF” button once to enter COOL DOWN mode. The screen will read “COOL”

until the unit reaches a safe temperature.

ii. Remove the silicone belt with the belt roller and wipe them down with a damp cloth.

iii. Remove the inlet and outlet tray. Wash using warm water and mild detergent.

iv. Wipe the drum using a damp cloth.

v. Reassemble the parts previously removed.

Wipe with damp cloth.

Belt Roller

Clean using warm water

and detergent.

Clean using warm water

and detergent.

RTW14EA

5

Page 10

MAINTENANCE

POWER MUST BE REMOVED FROM THE UNIT

BEFORE ATTEMPTING MAINTENANCE OR SERVICE.

CLEANING THE AIR INTAKE

DISCONNECT UNIT FROM POWER SOURCE

i. Use a vacuum or wipe down with a damp cloth to remove debris.

LUBRICATING THE CHAIN AND SPROCKETS (recommended every 6 months)

DISCONNECT UNIT FROM POWER SOURCE

i. Remove the screw holding the right side panel and remove the panel.

ii. Use an extreme pressure synthetic chain lubricant rated up to at least 400°F (204°C) [Star part number

1L-Z12397] and liberally lubricate the chain and sprockets.

iii. Reinstall the side panel using the previously removed hardware.

§REPLACING THE FAN MOTOR

DISCONNECT UNIT FROM POWER SOURCE

i. Remove the screws holding the rear panel and lower the panel.

ii. Remove the four [4] screws holding the fan motor and fan guard in place.

iii. Unplug the power supply cord from the fan motor and remove the old motor.

iv. Place the replacement motor and existing fan guard in place and secure with previously removed hardware.

v. Reconnect the power supply cord to the fan motor.

vi. Secure the rear panel using the previously removed hardware.

REPLACING THE BELT DRIVE MOTOR

DISCONNECT UNIT FROM POWER SOURCE

i. Remove the screws holding the right side panel and remove the panel.

ii. Remove the drive motor sprocket and chain from drive motor.

iii. Remove the screws holding the rear panel and lower the panel.

iv. Disconnect the tachometer connection on the top of the drive motor.

v. Disconnect the drive motor wire connection from the control board.

vi. Remove the four [4] screws securing the drive motor and remove the drive motor out of the rear of the unit.

vii. Install the new drive motor using the previously removed hardware.

viii. Connect the new drive motor wire connection from the control board.

ix. Reconnect the tachometer to the top of the drive motor.

x. Connect the drive motor sprocket and chain, making sure to line it up with the driven sprocket. The two

sprockets should line up parallel with each other, so the chain does not twist any during operation.

xi. Reinstall the rear and side panels using the previously removed hardware.§

6

Page 11

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

WIRING DIAGRAM

POWER MUST BE REMOVED FROM THE UNIT BEFORE ATTEMPTING REPAIR OR SERVICE.

MAKE CERTAIN TO CHECK ALL CONNECTIONS THOROUGHLY BEFORE RESTORING POWER

TO THE UNIT. THE BELOW INFORMATION IS FROM WIRING DIAGRAM 2M-Z22547.

Please review the following information before proceeding with any electrical diagnosis or repair.

DRUM ELEMENT:

TEMP CONTROL

CF

TSS

7

i. Check for proper voltage jumper connection on power board.

ii. Fan cord, communication cable, IR sensor cable, and tachometer are not numbered.

iii. Hold back-up nut when tightening element terminals to prevent twisting the cold pin.

iv. Make certain that infrared sensor is supported when inserting connector.

Page 12

CENTER DRUM, ROLLERS, AND ELEMENTS

RTW1 pictured

6

5

12

13

14

9

8

10

11

15

22

16

17

18

7

63

20

21

19

8

Page 13

RIGHT SIDE [CHAIN DRIVE]

RTW19EA pictured

30

29

31

32

29

33

28

27

26

28

24

23

25

18

41

52

9

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

Page 14

LEFT SIDE [PANEL]

RTW19EA pictured

36

34

35

37

39

38

17

40

10

Page 15

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

REAR [1]

RTW19EA pictured

35

43

49

44

22

45

36

42

48

60

61

29

46

47

51

50

64

53

54

55

56

22

59

34

18

41

58

50

51

57

11

Page 16

REAR [2]

RTW19EA pictured

51

50

50

12

51

53 39

64

54

Page 17

62

4

LOCTITE

3

1

2

LOCTITE

4

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

CENTER SECTION

RTW14EA pictured

13

Page 18

PARTS LIST

REF NO MODEL PART NUMBER DESCRIPTION QTY PAGE NO

RTW14EA 2D-Z20320 DRUM RTW14 1

RTW19EA 2D-Z22549 DRUM RTW19

2 ALL RTW 2A-Z20247 DRUM INSERT - DRIVE END 1 13

3 ALL RTW 2A-Z20248 DRUM INSERT - ELEMENT END 1 13

4 ALL RTW 2C-Z20246 1/4-20X3/4 LOW EHEAD SOC CAP SCREW 8 13

RTW14EA D6-RTW086 ASSY,TOP,FRONT, RTW-14 8

RTW19EA D6-RTW068 ASSY,TOP,FRONT, RTW-19 8

6 ALL RTW 2I-Z22463 BELT,SILCON,12"W 1 8

RTW14EA D6-RTW090 ASSY,ROLLER,IDLER,RTW-14 8

RTW19EA D6-RTW075 ASSY,ROLLER,IDLER,RTW-19 8

8 ALL RTW 2A-Z22577 BEARING,ROLLER,IDLER 2 8

9 ALL RTW 2C-70381 SCREW 1/4-20X3/4 SL TR MS 2 8

RTW14EA D6-RTW091 ASSY,ELEMENT,120V,1750W 8

10 1

11 ALL RTW 2P-Z21755 BEARING AND ELEMENT MOUNT 1 8

12 ALL RTW D6-Z22466 SUPPO RT,ELEMENT,DRUM 1 8

RTW14EA D6-RTW092 ASSY,ELEMENT,208-240V,1750W 8

RTW19EA D6-RTW074 ASSY,ELEMENT,208-240V,1750W 8

15

17

131

13 ALL RTW 2C-200121 WASHER #10 SPLIT SS 3 8

14 ALL RTW 2C-20301-32 NUT HEX ACORN 10-24 S/S 3 8

RTW14EA D6-Z22649 8

RTW19EA D6-Z22592 8

RTW14EA 2A-Z18673 INFEED SUPPORT ROD RTW14 8

16 1

RTW19EA 2A-Z22560 INFEED SUPPORT ROD RTW19 8

17 ALL RTW 2M-Z18246 LABEL, CONTROL TW ELEC 1 8

18 ALL RTW 2A-Z5942 FOOT, 1/2-13 X 4"L. 4 8

RTW14EA D6-Z22648-1 8

19 CATCH PAN WELDMENT 1

RTW19EA D6-Z22576-1 8

20 ALL RTW D6-Z22489-1 SU PPORT,BE ARING,PEM 2 8

RTW14EA D6-RTW089 ASSY,INFEED,RTW-14 8

21

RTW19EA D6-RTW067 ASSY,INFEED,RTW-19 8

RTW14EA D6-RTW083 ASSY,CHASSIS,RTW-14 8

22 1

RTW19EA D6-RTW065 ASSY,CHASSIS,RTW-19 8

23 ALL RTW D6-Z20933 POWER SUPPLY BRACKET 1 9

24 ALL RTW 2U-Z19838 GEARMOTOR 24V BLDC 15RPM 1 9

GUIDE,BELT 215

1

25 ALL RTW 2P-Z22457 SPROCKET,35BS11 .375ID 1 9

26 ALL RTW 2P-Z18415 CHAIN #35 18.75" 50 LINKS 1 9

14

Page 19

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

REF NO MODEL PART NUMBER DESCRIPTION QTY PAGE NO

27 ALL RTW 2P-Z22458 SPROCKET,35BS18 .500 ID 1 9

28 ALL RTW 2P-Z18423 THRUST WASHER HI-TEMP 4 9

29 ALL RTW 2C-Z6929 10-24 KEPS NUT S.S. 16 9

30 ALL RTW 2C-1810 WASHER 3/16 BURR STL NP

2

9

31 ALL RTW 2P-Z18417 FLANGE BEARING,1/2" 1 9

32 ALL RTW 2C-Z18418 BURR WASHER 3/16 X 3/8 SS 6 9

33 ALL RTW D6-Z22468-1 PLATE,DRUM,END 1 9

34 ALL RTW 2C-6349 SCREW #8X3/8 B THP STL NP 2 10

35 ALL RTW D6-Z22470 PANEL,SIDE 2 10

36 ALL RTW 2K-Y8571 BUSHING SNAP 2 1/8 1 10

37 ALL RTW 2C-31053 NUT 8-32 KEPS MS NICKEL 20 10

38 ALL RTW 2C-200467 CLAMP, NYLON WIRE 5/8 2 10

39 ALL RTW 2C-200067 SCREW 6-32X1/4 THP SS 9 10

40 ALL RTW 2J-Z20026 CONTROLLER, RTWE IR TEMP 1 10

RTW14EA 2E-200375 CORDSET, 14/3 5-15P TERMS

41

RTW14EA 2E-Z13852

ALL RTW

ALL RTW

2E-Z19137 CORDSET, 14/3 6-15P TERMS

2E-GR0411 CORDSET, 14/3 CH2-16P TERMS

CORDSET, 14/3 5-20P TERMS

1 11

42 ALL RTW 2K-Y6764 BUSHING - STRAIN RELIEF 1 11

RTW14EA D6-RTW087 ASSY,DEFLECTOR,AIR RTW14 11

43 1

RTW19EA D6-RTW072 ASSY,DEFLECTOR,AIR RTW19 11

44 ALL RTW 2T-Z22461 THERMOSTAT,HI-LIMIT 1 11

45 ALL RTW 2C-200200 NUT, 6-32 HEX 2 11

46 ALL RTW D6-Z20718 IR SENSOR RETAINER 1 11

47 ALL RTW 2A-Z20443 SENSOR HOLDER 1 11

48 ALL RTW 2E-Z20415 IR TEMP SENSOR 1 11

49 ALL RTW 2C-8833 SCREW 8-18X1/2 HEX STL NP 6 11

50 ALL RTW 2C-Z9632 10-32 X 1/2 SCREW FZA 6 11

51 ALL RTW 2R-200562 GUARD, FAN - WIRE 2 11

52 ALL RTW 2E-Z20780 POWER SUPPLY 24VDC 10W 1 11,12

RTW14EA 2U-200559 MOTOR,FAN 120V 23BTM

53 RTW14EA 1 11,12

2U-200561 MOTOR,FAN208-240V 23BTM

RTW19EA

54

RTW14EA

RTW19EA

D6-Z22634-1 COVER,TOP,REAR,PEM

D6-Z22567-1 1 11.12

COVER,TOP,REAR,PEM

1 11.12

55 ALL RTW 2I-Z0057 FOOT, RUBBER 2 11

56 ALL RTW 2C-3033 SCREW-MACH8-32X3/4 THP SS 2 11

57 ALL RTW 2C-Y6138 RIVET 1/8X.250 POP SS SM 14 11

15

Page 20

REF NO MODEL PART NUMBER DESCRIPTION QTY PAGE NO

58 ALL RTW 2M-Z18710 NAMEPLATE, BLANK RTW 1 11

59 ALL RTW 2P-Z8478 HINGE 2 11

60 ALL RTW 2M-Z7207 STICKER, GROUND SYMBOL 1 11

61 ALL RTW 2C-35736 NUT 8-32 HEX KEPS MS GREEN 1 11

62 1 13

RTW14EA D6-RTW093 ASSY,DRUM,RTW-14

RTW19EA D6-RTW071 ASSY,DRUM,RTW-19

RTW14EA D6-RTW085 ASSY,DRUM,SPROCKET,RTW-14

63 1 8

RTW19EA D6-RTW070 ASSY,DRUM,SPROCKET,RTW-19

64 ALL RTW 2E-Z17513 POWER BOARD 1 11

16

Page 21

WALL MOUNT INSTALLATION

LAG SCREWS MUST BE INSTALLED INTO STUDS FOR SUPPORT OF THE RTW UNIT. FAILURE TO INSTALL

IN STUDS COULD RESULT IN DAMAGE TO UNIT AND/OR HARM TO PERSONS OR PROPERTY. STAR IS NOT

RESPONSIBLE FOR DAMAGE RELATED TO INCORRECT INSTALLATION OR FAULTY CONSTRUCTION.

THESE INSTRUCTIONS REFERENCE INSTALLATION SHEET NUMBER 2M-Z21299.

16.000

O.C.

WOOD STUDS (BEHIND WALL)

STEP 1 - INSTALL LAG SCREWS (ITEM 1) INTO WALL

(SEE NOTE ON PAGE ***)

-!!!!DO NOT TIGHTEN LAG BOT FULLY INTO WALL!!!

-MARK AND LOCATE CENTER OF WALL STUDS

-STANDARD CONSTRUCTION IS 16" ON CENTER (O.C.)

REPRESENTATION WALL

A

REPRESENTATION

DETAIL A

SCALE 1 / 2

Do not fully

tighten lag bolt

into wall.

KEYWAY

DETAIL B

SCALE 1 / 2

4

STEP 2 - HANG RTW WALL MOUNT BRACKET(ITEM 4)

OVER LAG BOLTS-SLIDE DOWN INTO KEYWAY

17

2M-Z19213 Rev G - Owner's Manual for RTW Rolling Tortilla Warmer

Page 22

STEP 3 - FINISH TIGHTENING DOWN LAG BOLTS

AND INSTALL TRUSS SCREWS (ITEM 2)

AS SHOWN.

STEP 4 - PLACE TORTILLA WARMER INTO BRACKET

ALIGN MOUNTING HOLES ON BOTTOM OF UNIT

WITH HOLES IN WALL MOUNT BRACKET.

SCREW IN BUTTON SOCKET SCREW(S) (ITEM 3)

AND TIGHTEN TO SECURE.

1

2

BUTTON SOCKET SCREW

TIGHTEN WITH 5/16" ALLEN

WRENCH

ITEM

18

3

Wall Mount Parts List

P/N

2C-Z21298 HEX LAG SCREW, 2-5/16 X 2" X

1/2" HEX SIZE

2

2C-Z21297 K-LATH SCREW, TRUSS, #8, 1"

3

2C-Z19191 BOLT 1/2-13x1/2 BHSC SS

D6-Z226694

D6-Z22668

BRACKET,WALL MOUNT,RTW19EA

BRACKET,WALL MOUNT,RTW14EA

TITLE

SOCKET SCREW

INSTALLED

4X PLACES

QTY

21

2

4

1

Page 23

Rolling Tortilla Warmer

RTW14EA RTW19EA

E

D

MODEL HE I GHT

[A]

in .

(mm)

B

WIDTH

[B]

in .

(mm)

14.5 in.

370 mm

6.75

172 mm

A

DE P TH

in .

(mm)

CLEARANCES

Please allow at least ten [10] inches

RTW19EA is the model

used in these drawings.

in.

(254 mm) of space to open the top

for cleaning if the unit is to remain

stationary. There should be at least

one [1] inch (25 mm) of clearance on

each side and behind the unit as well.

8.1 in.

(206 mm)

C

5 in.

(76 mm)

LEG HEIG HT VOLTS AMPS WATTS POWER APPROX.

[C] PLUG SHIP

in . WEIGHT

(mm)

1 in.

(25 mm)

0.1 in.

(2.5 mm)

F

.5 in.

(12.7 mm)

5-15P

APPROX.

WEIGHT

INSTALLED

5-20P

RTW14EA

RTW19EA

MODEL CORD DISTANC E FR OM

RTW14EA 12.2 in. 2.1 in 14.1 in. 13 .0 in.

RTW19EA 14.0 in. 2.1 in 18.9 in. 18.0 in.

patent no. 9,516,883

Due to periodic changes in designs, methods, procedures, policies and regulations, the specifications contained in this sheet are subject to change

omissions in information provided or conclusions reached as a result of using the specifications. By using the information provided, the user assumes

all risks in connection with such use.

13

(305) (498) (541 ) ( 1 02)

13

(305) (610 ) (541 ) (102)

CONTROL SI

19.6 21.3

24.0 21.3

DE [D]

(310 mm) (53 mm) (358 m m) (330 mm)

(356 mm) (53 mm) (480 mm) (45 7 mm)

5

5

CORD DISTANCE FR OM

CONTR OL RE A R

120

208-240

208-240 1905-2537

STAR MANUFACTURING INTERNATIONAL INC.

Telephone 888 356 5362

•

Fax 314 781 5445

www.star-mfg.com

14.9

6.3-7.2

9.1-10.5

1,787 69 lb. 50 lb.

1,351-1787

5-15P

(31.4 kg) (22.7 kg)

P

6-15

P

6-15

IN LET TR AY OUTP UT TR AY WIDTH

77 lb. 62 lb.

(35.0 kg) (28.1 kg)

Printed in the U.S.A. • 2M-Z21286 • Rev E • 08.2018

Please refer to the owner’s manual for information

regard

ing installation or use.

[F]WI DTH [E]

r

19

CH2-16P

6-15P

Page 24

FACTORY SETTINGS ADJUSTMENT

i. With the machine OFF hold the “SET/TEMP” and “▲/CLEAN” buttons.

ii. While in this menu, the display alternately flashes a parameter and the current setting for that parameter.

iii. Use the ▲ and ▼ buttons to adjust the current parameter, then press the “SET/TEMP” button to move

to the next parameter. After moving through all parameters, "OFF" will once again appear on the screen.

DISPLAY D E FAULT DE S CRIPTI O N ADJUSTM E N T

READOUT SET TING

MOTOR BDC motor t ype [brushles s DC motor] -

DIR

PPM

RATIO

PREHT

OFFST

COOL

IRDRP

IRRCV

DIGIR

CCW drum rot ation d irec tion -

8250 m otor speed [pulse per minute] 0–1 5 ,000

10 turn down ratio of the drum speed 1–60

2 1–10

0

30 cool down timer setting [measu red in m inutes] 0–60

20 percent age of set po int tempe ratu re 1–99

180 tim er for IRDR P corre c tion 30 –300

YES digit al infra -red setting YES/ N O

time the heat system pau ses during prehe at cycle

[measure d in minutes]

oset adde d to raw d rum temp for disp lay

±2 00°F

(±93°C)

IRHPT

trigger s the IRRCV tim er when tem p erature is b elow this pe rce ntage of set point temper ature

if the I RDRP temper ature is bel ow the trigger point co ntinuously for th e en tire time, it will trigger

a "BAD PRO BE " fault condition

if the tempe ratu re is be low 300°F when tim e limit is reache d , a "BA D PR OBE " fau lt cond ition will be acti ve

STAR MANUFACTURING INTERNATIONAL INC.

Telephone 800 264 7827

18 pre heat mode tim er [measured in mi nute s] 1–30

Printed in the U.S.A. • 2M-Z19213 • Rev • 08.2018

Specifications are subject to change without notice.

•

Fax 314 781 5445

www.star-mfg.com

20

Loading...

Loading...