Page 1

®

2.0

7” Tabletop

Two-Sided Grill

Electronic Controls

TWO SIDED GRILLS INSTALLATION INSTRUCTIONS

MODEL

These symbols are intended to alert the

user to the presence of important operating

and maintenance instructions in the manual

accompanying the appliance.

Go to:

www.star-mfg.com/scripts/manuals.aspx

to obtain this units installation & operations manual

along with other documents.

NOTICE

Using any part other than genuine Star factory supplied parts

relieves the manufacturer of all liability.

Star reserves the right to change specications and product

design without notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or replacements

for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies

and regulations, the specications contained in this sheet are subject

to change without notice. While Star Manufacturing exercises

good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided

or conclusions reached as a result of using the specications.

By using the information provided, the user assumes all risks in

connection with such use.

CAUTION

This equipment is designed and sold for commercial use only by

personnel trained and experienced in its operation and is not sold

for consumer use in and around the home nor for use directly by

the general public in food service locations.

Before using your new equipment, read and understand all the

instructions & labels associated with the unit prior to putting it into

operation. Make sure all people associated with its use understand

the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both

visible and concealed. This unit has been tested and carefully

packaged to insure delivery of your unit in perfect condition.

If equipment is received in damaged condition, either apparent or

concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until

after equipment is unpacked, a request for inspection of concealed

damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials

for inspection. The carrier will make an inspection and will supply

necessary claim forms.

GENERAL SAFETY INFORMATION

GENERAL INSTALLATION INFORMATION

The unit time and temperature are preset by the factory to the

customer requirements. If adjustments are required, refer to the

time or temperature programming sections in this manual.

INSTALLATION

1. Plug unit into dedicated receptacle,

see nameplate for voltage requirements.

2. DO NOT plug into incorrect voltage line.

Doing so will damage the unit and void the warranty.

3. Each unit has been properly wired and inspected at the factory

for operation on the voltage specied on the nameplate.

4. DO NOT operate without burn guards (Certian units only).

DO NOT CONNECT TO ANY OTHER

WARNING

TYPE OF CURRENT OR THE MACHINE

WILL BE SERIOUSLY DAMAGED.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local

service company for service or required maintenance.

Go to www.star-mfg.com to nd a service agent near you.

Replacement cord sets must be purchased from Star Manufacturing

International, Inc. or our authorized agents.

Should you need any assistance regarding the operation or

maintenance of any Star equipment; write, phone, fax or e-mail

our service department. In all correspondence mention the

model number and the serial number of your unit, along with the

voltage.

Business Hours: 8 am to 4:30 p.m. Central Standard Time

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail: Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A.

2M-Z20466, Rev. - 5/26/15

Page 2

ALL UNITS

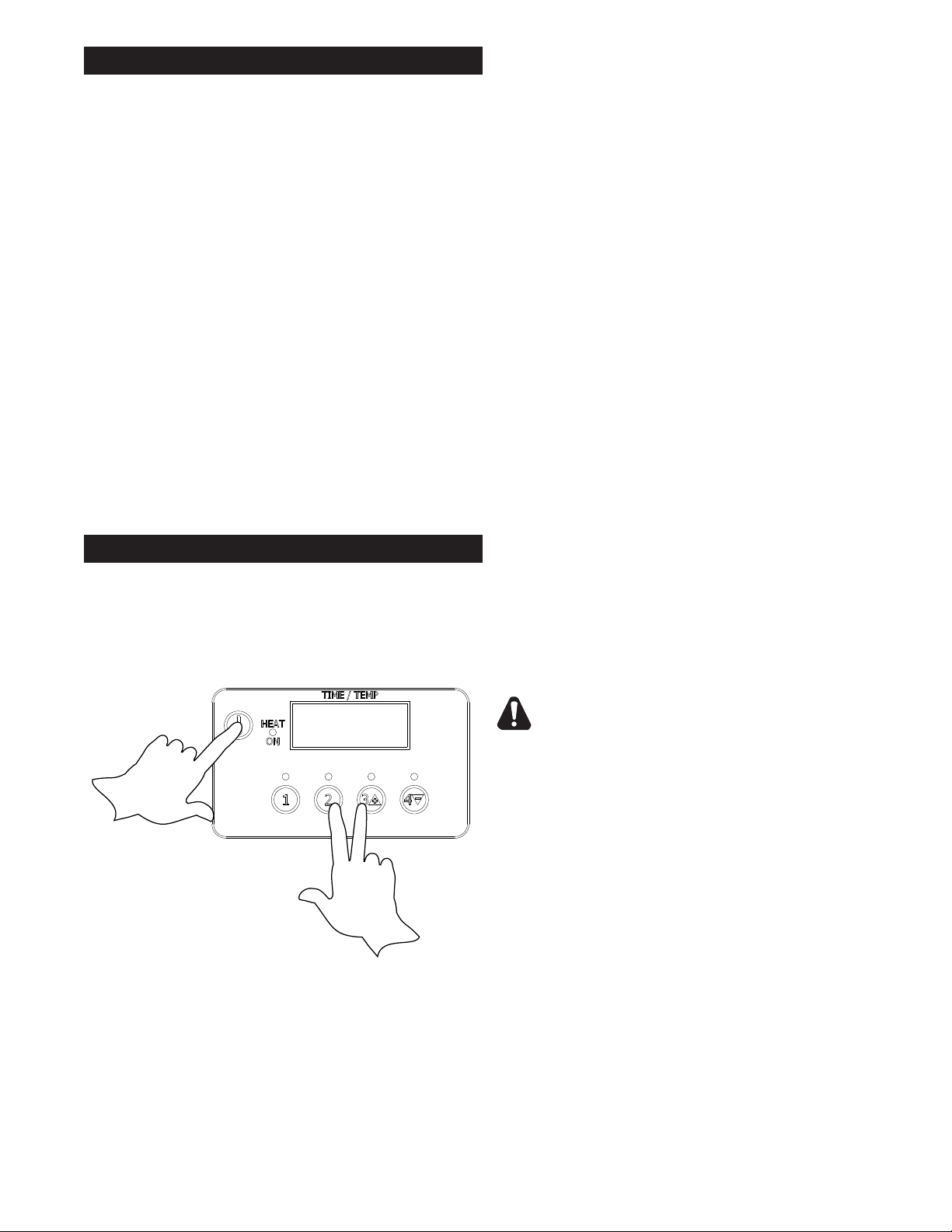

ELECTRONIC TEMP CONTROL OPERATION

Initial Start Up

Level unit using the adjustable feet under the unit (approximately

1/2" adjustment).

Before using the unit for the rst time, clean and heat for

approximately 45 minutes. The grill may emit a small amount of

smoke as the cooking surfaces reach 300-350°F. Do not be alarmed,

as the smoke is caused by oils associated with the manufacturing

process and will stop when the grill reaches 400°F. Best to do this

in a well ventilated area.

Seasoning The Cooking Surfaces

First Time Seasoning

Follow your company/corporate guidelines for seasoning cooking

surfaces or:

1. Bring the grill to 275°F by placing the unit in “CLN” mode

by pressing the “TEMP” button and button’s 2 & 3 for 3

seconds.

2. Wait for unit to reach 275°F (press the “TEMP” button to

display units current temperature.

3. Brush the cooking surfaces with a SALT-FREE release

agent. If using an aerosol agent, rst apply into a cup and

then brush onto cooking surface.

4. Let sit for 20 minutes, and then wipe clean using a warm

damp cloth.

5. To Exit “CLN” mode, turn unit “OFF” then “ON” or press any

of the four (4) program buttons.

Daily Seasoning

The grill should not require much seasoning while in use. In most

cases, brush a light coating of a SALT-FREE baking release agent

in the morning and occasionally throughout the day will be enough

to prevent any sticking. It is not necessary to spray before grilling

each item.

Time & Temp Display

Temp Button

1:30

Heat On

Indicator

LED

Operating Instructions

1. Turn the unit on by placing the switch in the ON position.

The HEAT ON indicator, Time & Temp Display & the LED

indicator will ash until it reaches operating temperature.

Initial startup heating time is approximately 30 minutes.

When the unit reaches operating temperature, the heat

indicator LED will turn off and the program LED and the

Time & Temp Display will stop ashing.

2. Place product on the cooking surface of the unit and close

the lid.

3. Press the PROGRAM button to start the timer, the LED light

above the button will “FLASH” and the displayed time will

count down to “0” at which time the unit will display “done”

and beep. To turn off the beeper, press the PROGRAM

button again.

4. To CANCEL a program during the cooking process, press

and hold the PROGRAM button for 5 seconds.

5. Raise the lid and remove the food product. Using a spatula,

scrape residue into the grease catcher tray.

NOTE: Metal utensils may be used; however, using nonmetal

utensils will prolong the life of the cooking surface.

6. Turn the unit off when it is not in use.

Using Multiple Timers:

1. Place product on the cooking surface and close the lid.

2. Press the (1st) PROGRAM button to start the timer, the

LED light above the button will “FLASH” and the displayed

time will begin counting down.

3. Place second product on the cooking surface and close the

lid.

4. Press the (2nd) PROGRAM button to start the second timer,

the 1st LED will change from ashing to solid, and the 2nd

LED will be ashing. The time countdown will be for the

program with the ashing LED indicator.

5. Pressing the (1st) PROGRAM button will change that LED

indicator back to ashing and the countdown display will

represent this program button. The LED indicator for the

(2nd) program will change from ashing to solid.

6. When the (1st) program is completed, “done” will be displayed

and an alarm will sound. The display will change to the

remaining time on the (2nd) program and that programs

LED indicator will change to ashing.

7. When the (2nd) program is completed, “done” and an

alarm will sound. The countdown time for the last program

selected will be displayed and that programs LED indicator

will remain solid.

Temperature:

You can view the unit’s actual temperature by pressing the temp

button.

Program Buttons

IL3001

Page 3

TO PROGRAM TIME AND TEMPERATURE:

1. Press and hold TEMP (actual temperature displays).

2. While holding TEMP, press and hold any program button on

the left for one second. The LED above the program number

will light and the display will read "_ _ _ _." Enter the fourdigit security code sequence: 4, 3, 2, 1. The security code

will not show on the display. Once the correct sequence has

been entered, the preset time will be displayed and the LED

for that program will begin to ash.

3. Set the desired time with the "3” increase or “4" decrease

buttons.

4. Press the TEMP button to save the time.

5. The bottom and top temperature settings can now be

programmed.

6. The bottom temperature setting for the selected switch will

now be displayed.

7. Change the bottom temperature setting using "3” increase or

“4" decrease. Press the “TEMP” buttom when the desired

setting is displayed.

8. The top temperature setting for the selected switch will now

be displayed.

9. Change the top temperature setting using "3” increase or

“4" decrease. Press the “TEMP” buttom when the desired

setting is displayed.

10. Press any other program button within 15 seconds to continue

programming without re-entering the security code.

ALL UNITS

Cleaning

Begin the cleaning procedure by following your corporate guidelines,

or follow the steps below.

1. Enter the cleaning cycle by pressing and holding the “TEMP”

button and buttons 2 & 3 for 3 seconds.

2. “CLN” will be displayed

7. Using a mixture of 1/2 tablespoon dish detergent & 1/2 cup

warm water.

8. Pour 1/4 cup of above cleaning solution onto the bottom

cooking surface.

9. Immediately spread cleaning solution around the surface

with cleaning pad. Use moderate pressure to scrape away

burnt-on food.

10. Apply cleaning solution to cleaning pad.

11. Use moderate pressure to scrape away burnt-on food on

top cooking surfaces.

12. Drain cleaning solution to grease trap.

13. Wipe off remaining cleaning solution with thick damp cloth

until clean.

14. Empty and clean grease catcher cup as required using

detergent and water after removing cup from unit.

15. Reseasoning the grill cooking surfaces by following the

Daily Seasoning procedures.

16. To Exit “CLN” mode, turn unit “OFF” then “ON” or press any

of the four (4) program buttons.

NOTE: It is best not to let food cook onto the grill, as food build-up

on the grill will increase sticking and smoking. In addition, carbon

may build up on the grill surface and reduce the cooking efciency.

Carbon Buildup: A black matter that forms on or near the cooking

surface. Generally this is a combination of: releasing agents, oils,

food particles etc. ,that have cooked to the surface. After a period

of time without cleaning, this will reduce performance and material

may start aking off. When that happens, follow the "Carbon

Cleaning" procedures.

Carbon Cleaning

When carbon build up occurs, use a carbon removal agent (safe

for aluminum surfaces) according to the instructions provided with

the cleaner. When this process is complete, you must re-season

the grill according to your company/corporate guidelines, or the

seasoning instructions in this manual.

CLN

IL3007

3. The cooking surfaces will go to 275°F (135°C), pressing

the TEMP button display the current temperature.

4. When the unit has reached 275°F (135°C), raise the

top platen and remove the non-stick protective sheets.

NOTE: COOKING SURFACES ARE HOT AND CAUTION

MUST BE TAKEN.

5. Scrape cooking surfaces with a spatula to remove any loose

food debris

6. If using a carbon cleaning agent (safe for aluminum or cast

iron) follow those instructions.

CAUTION

DO NOT IMMERSE OR LET THE UNIT STAND IN

WATER.

DO NOT HOSE DOWN THE UNIT OR THE TABLE/

COUNTER IF THE UNIT IS ON THE TABLE/COUNTER.

KEEP AWAY FROM RUNNING WATER.

DO NOT USE SHARP OBJECTS TO REMOVE

CARBON BUILD-UP.

DO NOT USE ICE ON THE COOKING SURFACE!

BEFORE CLEANING MAKE SURE POWER IS TURNED

OFF, UNIT IS UNPLUGGED AND IS NOT TOO HOT.

Apply only cleaners which are safe for aluminum

and iron surfaces.

DO NOT SPLASH FRONT CONTROL PANEL!

DO NOT SPLASH FLEX CONDUIT CONNECTING TOP

AND BOTTOM OF THE UNIT.

Page 4

22

3

23

4

9

8

5

6

7

19

20

21

10

11

24

14

18

13

12

5

5

15

16

3

1

17

2

1

40

36

37

38

39

28

36

34

35

37

26

27

45

44

35

34

25

29

30

29

31

32

33

41

42

43

42

33

40

46

Model: PST7E-CH Platten Assy

47

29

48

49

29

SK2911 Rev. - 6/30/15

Page 5

Model: PST7E-CH Platen Assemblies

Fig. No Part Number Qty Description Application

1 2C-Z18300 2 SCR,SHLDR,SS,3/8 DIA.X1.0

2 2B-Z19515 1 ARM,RIGHT,7 IN.

3 2C-Z18751 4 SCR,SHLDR,SS,3/8 DIA.X.50

4 D9-GR0650 1 LINK AY., LEFT

5 2C-Z18752 4 LOCKNUT, ACORN,1/4-20,SS

6 2C-37498 4 BOLT HEX 3/8-16 X 1 SS

7 2V-Z18468 1 PLATE, LIFTING, LEFT SIDE

8 D9-Z20580 1 PTFE BRACKET, FRONT CLIP

9 D9-GR0746 1 WELD ASY, TOP HOUSING, 7”

10 2C-Z3780 2 RETAINER, CONDUIT

11 2C-Z3917 2 RIVET, POP, .188 (AD66BS)

12 2E-Z2898 1 CONDUIT ASSY. - PTFE

13 2A-Z3827 1 PLATE,STAMPING - CONDUIT

14 2E-Z3768 1 LOCKNUT, CONDUIT, 1/2 IN.

15 2V-Z18311 1 PLATE,LIFTING,RIGHT SIDE

16 D9-GR0651 1 LINK AY., RIGHT

17 2B-Z19514 1 ARM,LEFT.7 IN.

18 D9-Z20575 1 PTFE BRACKET, REAR

19 2R-Z20574 2 MAGNET

20 D9-Z20579 1 INTERNAL BRACKET

21 2C-Z6929 2 NUT, 10/24 KEPS SS

22 2V-Z19512 1 HANDLE,7 IN.

23 2C-Z18749 4 SCREW,SS,10-32X625 PH FHD

24 2C-2853 1 SCREW #8X5/8 A THP STL NP

25 B9-04-WB-0046 1 CLAMP WIRE SUPPORT

26 2C-Y1451 2 RIVET 1/8 x .337 MORISON

27 D9-Z13012 1 WIRE MOUNT

28 D9-Z2133 1 INSULATION FIBERGLAS TOP

29 2C-Z2893 16 NUT 10-24 HEX STL ZP

30 D9-Z13013 2 BRACKET, INSULATION HOLD

31 D9-Z13011 1 PLATE-TOP ELEMENT RET.

32

33 2C-08-07-0285 8 SCREW 10-24X3/4X3/8 TYPE

34 2C-1512 3 SCREW 10-24X3/8 RHP STL

35 2C-1827 3 WASHER #10 EXT STL NP

36 2C-8833 2 SCREW 8-18X1/2 HEX STL NP

37 2C-Z3350 1 HALF CLAMP .188 D STL ZP

38 2E-Z3278 1 RTD PROBE - 60” LONG WIRE

39 D9-Z3903 1 BRACKET, PROBE MOUNT

40 D9-GR0722 2 LOWER BRACKET ASSY

41 PS-GR0356 1 KIT, 2F-Z3237 TOP CASTING, SMOOTH

42 2C-Z5883 8 10-24 X 1/2 FZA SCREW

43 2F-Z17103 1 CASTING,BTTM,SMOOTH,AL,7

44 D9-Z19534 1 BRACKET,PROBE,BOTTOM,7

45 2E-Z1470 1 SNSR-RTD,2K OHM,24”LDS

46

47 D9-Z12012 1 PLATE, BOTTOM ELEMENT

48 D9-Z19424 1 INSULATION,7,BOTTOM

49 D9-Z12885 2 INSULATION HOLD DOWN,

PS-Z9325

PS-Z9326 ELEMENT HEATING TOP 500W 230V, 240V, UK

2N-Z17082

2N-Z19546 ELEMENT,925W,240V, 7 BTTM 230V, 240V, UK

ELEMENT HEATING TOP 500W 120V

1

ELEMENT,925W,120V,7 BTTM 120V

1

Page 6

1

2

3

4

2

5

6

7

8

9

6

29

28

27

30

26

31

33

25

23

32

2

18

2

34

20

21

22

35

19

18

14

15

16

5

10

10

10

10

17

24

Model: PST7E Base Assembly

SK2845 Rev. - 1/26/15

Page 7

Model: PST7E, PGT7E Base

Fig. No Part Number Qty Description Application

1

2 2C-Z2594 19 NUT 6-32 HEX W STL NP

3 D9-GR0680 1 WELD AY.,RELAY & TFMR MT.

4 2E-Z3335 2 RELAY DBL POLE-SNGL THROW

5 2C-Z18302 2 SCR,SHLDR,1/4 DIA.X1.5

6 2A-Z18301 2 COLLAR AND STOP

7 D9-Z19543 1 SPRING COVER, 7”

8 D9-GR0704 1 ASSY.,HINGE,7,Z18289 SPRG

9 2C-41180 12 BOLT HEX 1/4-20X1 1/4

10 2C-20301-20 6 NUT LOCK STOVER 1/4-20

11 2K-Y2968 1 BUSHING - HEYCO 7W-2 120V, 240V

12 2C-Y6138 6 RIVET 1/8X.250 POP SS SM

13 D9-Z19225 1 CORD PLATE 120V, 240V

14 2C-Z3447 1 NUT 8-32 HEX W/EXTERNAL

15 2E-Z2894 1 TERMINAL BLOCK (304)

16 D9-Z19226 1 PAN,TERMINAL BLOCK

17 2R-Z18201 4 FOOT 1.69X1 SIL 1/4 20

18 2C-6349 10 SCREW #8X3/8 B THP STL NP

19 D9-Z19505 1 ANGLE,CTRL,7

20 2C-8477 2 CLIP .125 PO STL PHOS

21 2M-Z18452 1 LABEL, PRO-MAX

22 2M-Z15305 1 STAR LOGO, SMALL

23 D9-GR0696 1 WLD & RIVET AY.,7 GRS HSG

24 D9-GR0690 1 GREASE CUP AY.,7

25 2E-Z3808 1 SWITCH(EATON)-30A@120V,

26 Z1-70-07-0343 1 SWITCH GUARD

27 2M-Z18461 1 LABEL, POWER, ON AND OFF

28 2I-05-07-0013 1 BOOT SWITCH

29 2M-Z19409 1 OVERLAY,Z11593 EL CONTROL

30 2J-Z11593 1 CONTROL BOARD, SINGLE SG

31 2K-Z1971 4 SPACER .257X.75X.25 NYLON

32 2K-08-07-0004 4 SPACER ROUND NYLON

33 D9-Z19533 1 INSULATION,ELEC. CTRL.,7”

34 D9-Z19242 1 HEAT SHIELD,CTRL,7

35 2K-Z19330 1 BUSHING HEYCO #2883

NI 2E-Z2935 1 CORD SJTO 14/3 NEMA 5-15P 120V

NI 2E-Y9251 1 CORD SET CONT EUR 16AMP 230V

NI 2E-Z9192 1 CORDSET(DETACHABLE) - UK UK

NI 2E-Y9253 1 INLET IEC 320 16 AMP 230V, UK

NI 2M-Z19532 1 OVERLAY,BEZEL,GRS. CUP,7

2E-05-07-0351

2E-05-07-0350 TRANSFORMER 230V/10V 6VA 230V, 240V, UK

1

TRANSFORMER 115/10V 6VA 120V

Page 8

1

2

3

5

6

1

4

4

IL2986, Rev. B 6/29/15

D9-GR0720; 7” SG NON-STICK SHEET KIT

Fig No Part No Qty Description

1 2C-Z5883 not included SCREW, 10-24 X 1/2 SELF-DRILLING

2 D9-Z20145 not included REAR BRACKET

3 D9-Z20580 not included

4 D9-GR0722 not included LOWER BRACKET ASSY

5 2H-Z20036 6 UPPER NON-STICK SHEET

6 2H-Z20035 6 LOWER NON-STICK SHEET

PTFE BRACKET, FRONT CLIP

STAR MANUFACTURING GROUP

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303 (314) 781-2777

www.star-mfg.com

Loading...

Loading...