Page 1

GAS

CHARBROILER

MODEL

OCB30, OCB30T, OCB30TH

OCB60, OCB60T, OCB60TH

& ACCESSORIES

Installation and

Operation

Instructions

2M-Z9210 Rev. B 8/26/11

OCB30TH

1

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business

8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 684-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

TABLE OF CONTENTS

SPECIFICATIONS . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 1

GENERAL SAFTEY & WARNING INFORMATION . .. .. .. .. .. .. .. .. .. .. .. .. .. 2-3

GENERAL INSTALLATION DATA

Leg Caster Installation .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 4

Connecting Gas Supply . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5

Leveling the Unit .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5

Checking for Gas Leaks - LP.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5

Burner Adjustments . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5

DAILY OPERATION

Locating the grill . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 6

Lighting Instructions . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 6

Shutting Down Instructions .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 7

Cooking Grates & Radiants Cleaning & Inspecting . .. .. .. .. .. .. .. .. .. .. .. .. 7

Burner Removal & Cleaning .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 7

Cleaning . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 8

Spiders Webs & Nest.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 8

Storage Daily & Long Term.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 8

ACCESSORIES

Hood & Wind Guard Installation .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 9

Removable Tank Caddy . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 9

Installing LP Tank Cart Mounting Brackets .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 9

LP Tanks .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 10

Installing LP Tank to Caddy . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 10

Mounting Caddy TO Charbroiler .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .11

Connecting Gas Supply Line . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .11

Side Shelf Installation . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .11

Steamer & Griddle Plate .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .11

Cleaning .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .11

Seasoning the Griddle Plate .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..11-12

20# LP Tank Bracket Installation .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 12

Natural Gas Conversion .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 12

Checking for Leaks - NAT .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 12

WARRANTY . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 13

OCB30 & OCB60 EXPLODED VIEW . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 14

OCB30 & OCB60 PARTS LIST.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 15

OCB MANIFOLD EXPLODED VIEW .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 16

OCB MANIFOLD PARTS LIST .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 17

OCB ACCESSORIES.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 18

OCB ACCESSORIES PARTS LIST . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 19

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read

the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY: Do not store or use

gasoline or other ammable vapors or liquids

in the vicinity of this or any other appliance.

3

WARNING: This appliance shall be installed

in accordance with current regulations and

used only in well-ventilated space. Refer to

instructions before installing and using this

appliance.

In addition, there should be posted, in a

prominent location, detailed instructions to

be followed in the event the operator smells

gas. Obtain the instructions from the local

gas supplier.

Page 4

SPECIFICATIONS

Units are factory installed for LP gas and may be eld convertible to natural gas.

OCB30

Type: Radiant Style Manual Control

4 Controls for cooking burner; 70,000 BTUH Propane

1 Control for lighter tube

Cooking Surface 720 sq in (4645 sq. cm)

Approximate weight: Installed - 151 Lb (68.5 kg), Shipping - 200 Lb, (90.7 kg)

Dimensions: 32.5" - Width, 32.5" - Depth, 36" - Height

(82.5 cm - Width, 82.5 cm - Depth, 91.5 cm - Height)

OCB30T

Type: Radiant Style Manual Control

4 Controls for cooking burner; 70,000 BTUH Propane

1 Control for lighter tube

Tank Caddy 1-40lb. L.P. Cylinder and Tank Caddy

Cooking Surface 720 sq in (4645 sq. cm)

Approximate weight: Installed - 222 Lb (100.7 kg), Shipping - 279 Lb, (126.6 kg)

Dimensions: 32.5" - Width, 32.5" - Depth, 36" - Height

(82.5 cm - Width, 82.5 cm - Depth, 91.5 cm - Height)

OCB30TH

Type: Radiant Style Manual Control w/Hood

4 Controls for cooking burner; 70,000 BTUH Propane

1 Control for lighter tube

Tank Caddy 40lb. L.P. Cylinder and Tank Caddy

Cooking Surface 720 sq in (4645 sq. cm)

Approximate weight: Installed - 254 Lb (115.2 kg), Shipping - 321 Lb, (145.6 kg)

Dimensions: 32.5" - Width, 32.5" - Depth, 49" - Height

(82.5 cm - Width, 82.5 cm - Depth, 124.5 cm - Height)

OCB60

Type: Radiant Style Manual Control

8 Controls for cooking burner; 140,000 BTUH Propane

2 Control for lighter tube (1 for each cooking section)

Cooking Surface 1440 sq in (9290 sq. cm)

Approximate weight: Installed - 324 Lb (147 kg), Shipping - 398 Lb, (180.5 kg)

Dimensions: 65" - Width, 32.5" - Depth, 36" - Height

(165.1 cm - Width, 82.5 cm - Depth, 91.5 cm - Height)

OCB60T

Type: Radiant Style Manual Control

8 Controls for cooking burner; 140,000 BTUH Propane

2 Control for lighter tube (1 for each cooking section)

Tank Caddy 2-40lb. L.P. Cylinder and Tank Caddy

Cooking Surface 1440 sq in (9290 sq. cm)

Approximate weight: Installed - 437 Lb (198.2 kg), Shipping - 546 Lb, (247.7 kg)

Dimensions: 65" - Width, 32.5" - Depth, 36" - Height

(165.1 cm - Width, 82.5 cm - Depth, 91.5 cm - Height)

OCB60TH

Type: Radiant Style Manual Control w/Hood

8 Controls for cooking burner; 140,000 BTUH Propane

2 Control for lighter tube (1 for each cooking section)

Tank Caddy 2-40lb. L.P. Cylinder and Tank Caddy

Cooking Surface 1440 sq in (9290 sq. cm)

Approximate weight: Installed - 469 Lb (212.7 kg), Shipping - 588 Lb, (266.7 kg)

Dimensions: 65" - Width, 32.5" - Depth, 49" - Height

(165.1 cm - Width, 82.5 cm - Depth, 124.5 cm - Height)

1

Page 5

GENERAL SAFETY INFORMATION

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor

for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels

associated with the unit prior to putting it into operation. Make sure all people associated

with its use understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed.

This unit has been tested and carefully packaged to insure delivery of your unit in perfect

condition. If equipment is received in damaged condition, either apparent or concealed, a

claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is

unpacked, a request for inspection of concealed damage must be made with carrier within

15 days. Be certain to retain all contents plus external and internal packaging materials for

inspection. The carrier will make an inspection and will supply necessary claim forms.

The Star-Max™ series gas charbroiler is equipped for the type of gas indicated on the nameplate

mounted on the front panel. All units are shipped from the factory for use with LP. The unit can

easily be converted for use with Natural Gas, consult your dealer for more information.

-IMPORTANT-

OPERATE IN NON-COMBUSTIBLE OUTDOOR LOCATIONS ONLY!

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE

"ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY RULES AND

REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT

CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR CAN/CGA-B149.2

PROPANE INSTALLATION CODE AND LOCAL CODES WHERE APPLICABLE.

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing the

equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any

other appliance. Keep the appliance area clear and free from combustibles.

WARNING

This appliance shall be installed in accordance with current regulations and used only in

well-ventilated space. Refer to instructions before installing and using this appliance.

In addition, there should be posted, in a prominent location, detailed instructions to be followed

in the event the operator smells gas. Obtain the instructions from the local gas supplier.

2

Page 6

GENERAL SAFETY INFORMATION (continued)

CAUTION - IMPORTANT SAFETY INFORMATION

• Always be sure gas is turned “off” at the burners and at the LP supply gas source when

unit is not in use.

• This unit shall be operated outdoors in a non-combustible location. Maintain 3 ft.

spacing around the unit for operation and servicing. DO NOT use on a recreational

vehicle or boat.

• Unit may be operated outdoors with “0” clearance to non-combustible materials in a noncombustible location. Do not operate under low hanging tree limbs or combustible roofs.

• Always provide adequate space around the unit for combustion air and ventilation air to

the unit. Do not operate the unit in a garage or other conned space.

• Unit can be very hot during operation and shall not be located in high trafc areas or

walk ways.

• Always lock the caster brakes on the wheels to prevent movement. Do not try to move

the unit during operation.

• Always inspect the exible gas hose(s) prior to use. Do not operate unit if there are

signs of abrasion or hose cracking.

WARNING: If damaged, replace hose/regulator prior to operating grill.

• Always use an approved horizontal LP tank secured in the supplied tank caddy. Be sure

the supply hose/regulator are securely attached to the tank valve. The fuel cylinder with

the tank caddy must be constructed and marked in accordance with the specications

for LP (propane) cylinder of the U.S. Department of Transportation or CAN/CSA B339.

The tank shall be a 40 lb. horizontal type, 12” in diameter and 29” in length with a safety

shut off valve and a type 1 QCC1 service outlet connection. It must be so designed to

provide ow-controlled vapor only in the horizontal position when mounted in the caddy.

Do not use a vertical tank in this caddy. Always turn tank supply valve on slowly when

operating grill.

• Unit may be stored indoors provided the LP (propane) cylinders are disconnected and

removed from the unit. Do not store cylinders in an area of high heat such as a

conned space in direct sunlight. Excessive pressure could develop inside of tanks.

Tanks shall be stored outdoors in a well-ventilated space and away from children. Tanks

shall always be secured in place during storage and when transported. Reference

NFPA58 storage and handling of LP gases or CAN/CGA B149.2. Propane gas

installation code.

• Propane gas is highly ammable and heavier than air. Always operate unit in a

well-ventilated space. Do not operate unit on LP at temperatures below 50°F (10°C) and

do not operate grill or locate unit in high wind locations.

• Periodically inspect burners and gas orices for blockage often caused by spiders build

ing webs in conned spaces. Do not operate grill if burner ashes back or is not

operating with an even burner ame. Allow unit to cool, inspect and clean suspect

burner and gas orice.

• Always inspect the front located pans and remove any grease and ash build up from

cooking operation. Do not restrict the ow of air into the bottom or front of the grill.

• This unit is shipped set up for LP propane gas operation. The unit can be converted

to Natural gas operation by changing out the burner and lighter tube orices. A natural

gas regulator should also be supplied (set for 5” water column pressure) or a regulated

gas supply provided to the unit manifold inlet. Do not expose the regulator to pressures

greater than 1/2 PSIG.

-

3

Page 7

GENERAL INSTALLATION DATA

IL1077

Leg Socket

Caster Assembly

Pin Locking

Remove prior to setting

on back side

IL1080

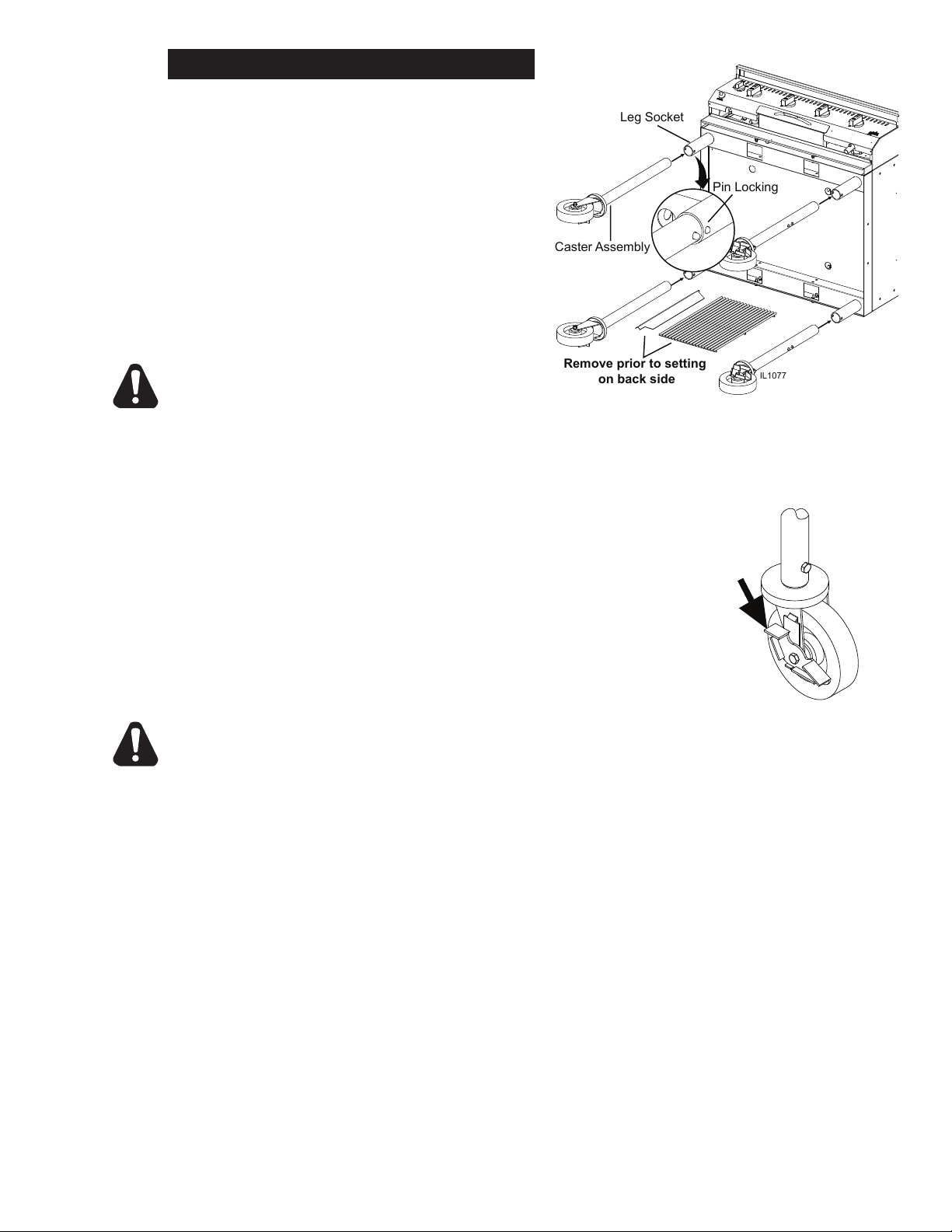

LEG CASTER INSTALLATION

Remove all packing material from the unit.

Remove the cooking grates & radiants from the

unit and with the help of a second person set unit

on its back as shown in Fig. 1. Remove leg/caster

assembly from carton and attach in place on grill

leg sockets. Caster assemblies will slide into

the leg sockets and locks into position by the pin

lock snapping in place inside the socket hole.

After all 4 legs locks securely in position and with

the help of a second person, stand unit upright

and re-install the radiants & cooking grates.

CAUTION

THE GRILL MUST BE PLACED ON A

LEVEL SURFACE AND THE CASTERS

MUST BE LOCKED WHILE OPERATING

Fig. 1 (Above) Attaching leg casters to charbroiler

Fig. 2, (Left) Lock Wheel Casters when using grill

& before mounting tank caddy

THE GRILL TO PREVENT MOVEMENT.

ACCESSORIES INSTALLATION

Information regarding the installation of LP

Tanks and other accessories that are available

with this unit, See General Accessories

Installation Section starting on page 12.

CAUTION

Always use the tanks supplied with the tank caddy or a certied 40 lb. horizontal tank DOT

marked LP propane cylinders with mounting brackets. Never over ll tanks and always

use supported and secured in the horizontal position in the tank caddy. Once lled, the LP

(propane) tank caddy can be easily wheeled using the front handle provided on the cart.

Position the tank caddy in place under the grill (with previously installed hanger brackets)

with the tank valve end located to the front of the grill. Be sure grill caster wheels are locked

in place using wheel brakes provided so grill does not move. (See Figure 2).

4

Page 8

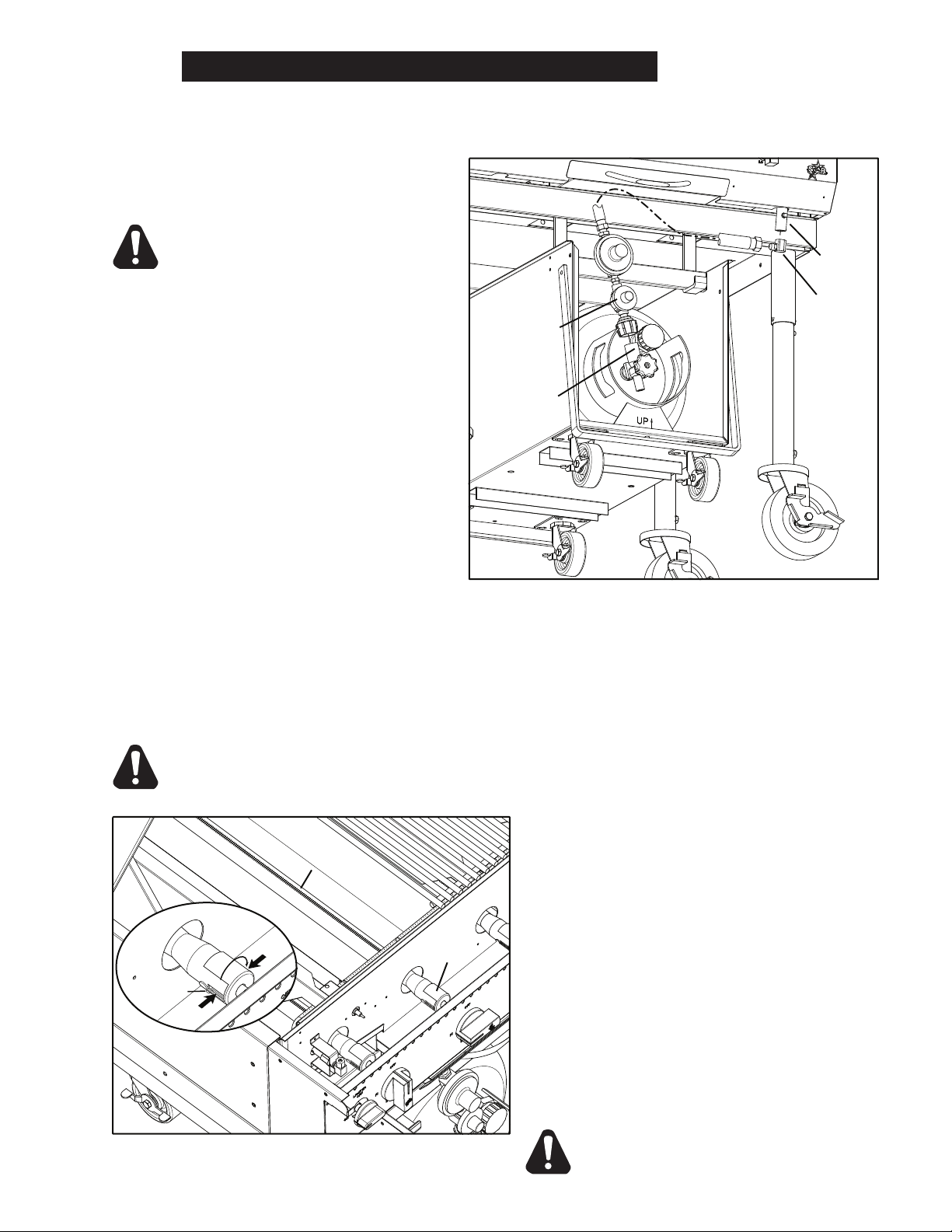

IL1091

Regulator Assy

Tank Outlet

Connector

Grill Inlet

90° Elbow

OCB30 only

Burner

Air Shutter

IL1092

Adj. Screw

air flow

air flow

GENERAL INSTALLATION DATA (continued)

CONNECTING GAS SUPPLY LINE

The grill regulator/hose assembly can then be attached to the 40 lb. tank outlet connector.

Remove the dust guard from the tank outlet connector and carefully screw the type 1

connector in place being careful not

to kink or damage the gas supply

line hose. Screw the connector to

the tank outlet connector hand tight,

DO NOT OVERTIGHTEN (Fig. 1).

Attach the other end to the Grill Inlet

using a wrench

On the 60 model, the left side hose

will mount to the left tank and the right

side hose to the right tank.

LEVELING THE UNIT

Before operating the unit, make sure

it is located on level ground. Units

performance can vary if it is on unlevel

surface

CHECKING FOR GAS LEAKS

Be sure all LP (propane) tanks are

OFF and all burners are in the “OFF”

position, pointing upward in the 12

o'clock position. Using a bubbly

water soap solution (or leak detection

solution), carefully brush all gas connections and slowly open the LP tank valve. Observe all

connections for bubbling to determine a gas leak. If a leak is found, immediately close the tank

valve and re-tighten the leaking gas connection, or call your local gas supplier or an authorized

dealer for service. DO NOT OPERATE GRILL WITH ANY GAS LEAK. If the gas connections

are leak free, the unit is now ready for operation.

Fig. 1, Connecting the Regulator Assembly from the LP Tank to the

Unit.

CAUTION

Matches, candle ame or other sources of ignition shall not be used for this

purpose.

Fig. 2, Adjusting the Burner Air Shutter to obtail proper ame.

5

BURNER ADJUSTMENT

This units Air Shutters were factory set and

should not need adjusting. If an adjustment is

needed follow these steps:

1. Light unit with cooking grills & radiants

removed, and set on High.

Note: it should look similar to Fig. 2.

2. If necessary, turn unit off, remove bullnose

to expose the Air Shutters, slowly decrease

openings of air shutters on burners to give

a soft blue ame having luminous tips, then

slowly increase openings to a point where

the yellow tips disappear and a hard blue

ame is obtained. Turn unit off and allow to

cool, when making these adjustments.

CAUTION

CHARBROILERS ARE HOT!

Page 9

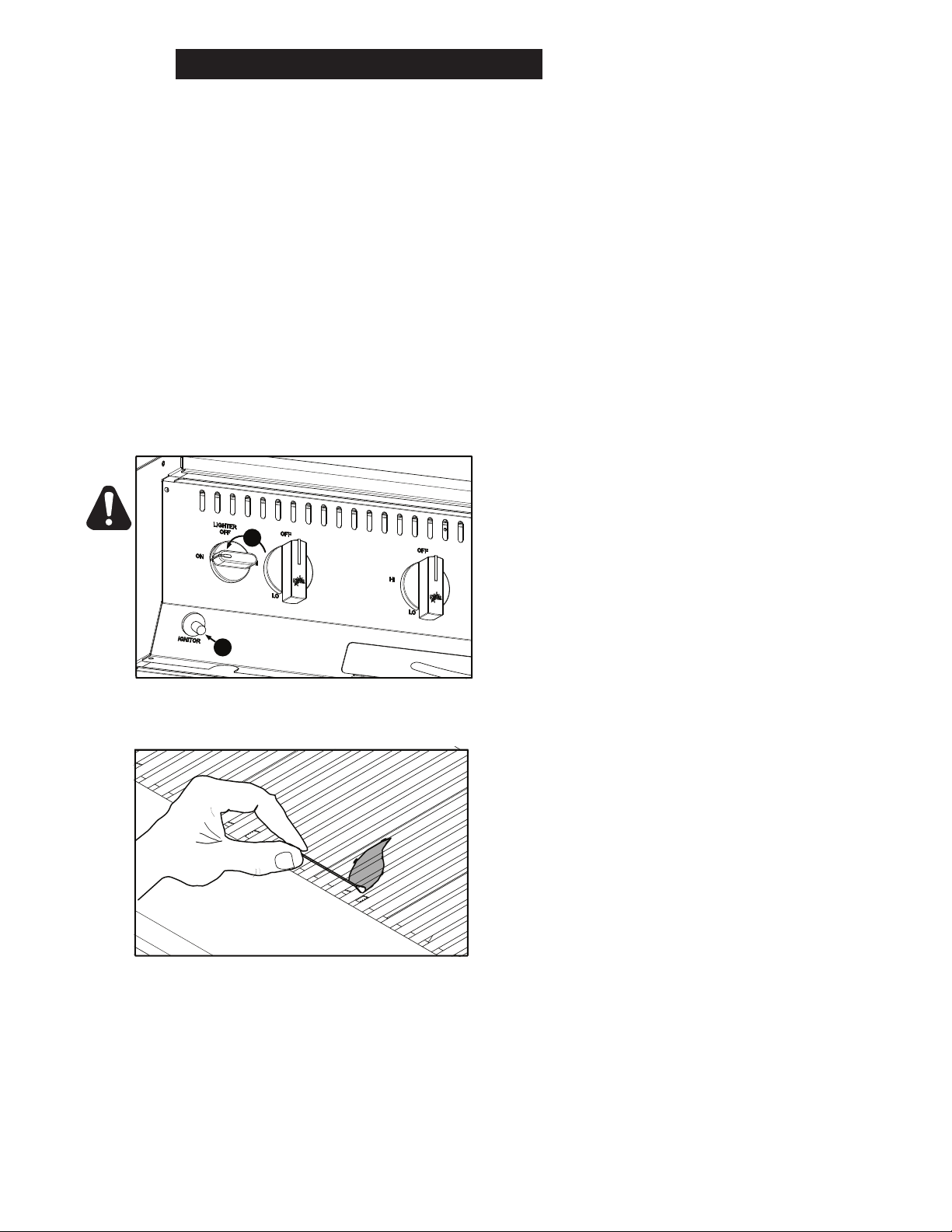

DAILY OPERATION

2

1

IL1085

IL1114

LOCATING THE GRILL

When selecting a suitable location for your grill, take into account concerns such as wind exposure

and areas of high trafc. Do not locate the grill close to a home or any kind of combustible

construction. Do not locate overhead shading umbrellas or other combustible items near or

above the grill. Grill exhaust can be very hot and under extreme conditions can emit ames.

Maintain an open area around the grill and enclosure at all times, keeping the area free from

combustible materials, gasoline, and other ammable vapors and liquids. Be sure your grill is

located on a level surface.

LIGHTING INSTRUCTIONS

NOTE: It’s necessary to open the tank valves slowly to avoid an excess ow surge in the tank

connector safety tting which would cause the gas ow to the manifold to be reduced. This is

a safety feature designed to limit the ow of gas under an excessive ow condition and would

cause the burners to operate with a reduced ame. If this occurs, verify tanks are not empty

or running out of gas. Shut down the grill and “slowly” open the tank gas control valve. Follow

the lighting instructions outlines in steps 1 to 5.

NOTE: The rst time lighting of the appliance may take

longer because of the need to purge the air out of

the gas line and manifold.

Fig. 1, Turn on Gas Supply and press the

igniter button to ignite the igniter tube.

Fig. 2, Use the lighter rod with a lit match to

ignite the igniter tube if the igniter button fails.

1. Be sure LP tank valves are turned “OFF” and are

secured in place. Be sure all knobs are turned

clockwise to “OFF”. If the unit has a hood, be sure

to open it.

2. Slowly open the LP tank gas valve counter clockwise

to allow gas ow to the side of the grill to be lit.

3. Turn the red knob counter clockwise to the “ON”

position and press in the igniter button on the side

to be lit. It may take several tries on the igniter

button to get the small igniter tube lit (Fig 1).

4. If the igniter button does not light the burner after

several tries, turn red knob to OFF position and

use the lighter rod supplied with the unit to hold a

match to light the igniter tube. Push and turn the

red knob counter clockwise to the “ON” position

and using a lit match attached to the lighter rod,

insert this down through the grates to light the 3/8”D

igniter tube. (Fig 2)

5. Verify that the entire length of the lighter tube is lit

and operating. If the lighter tube does not light,

turn off the gas supply, wait 5 minutes and attempt

to re-light the unit. Once the lighter tube is lit, the

burner knobs (black) can be pushed and turned

counter clockwise to the: “HI” position and the

burners should light.

6

Page 10

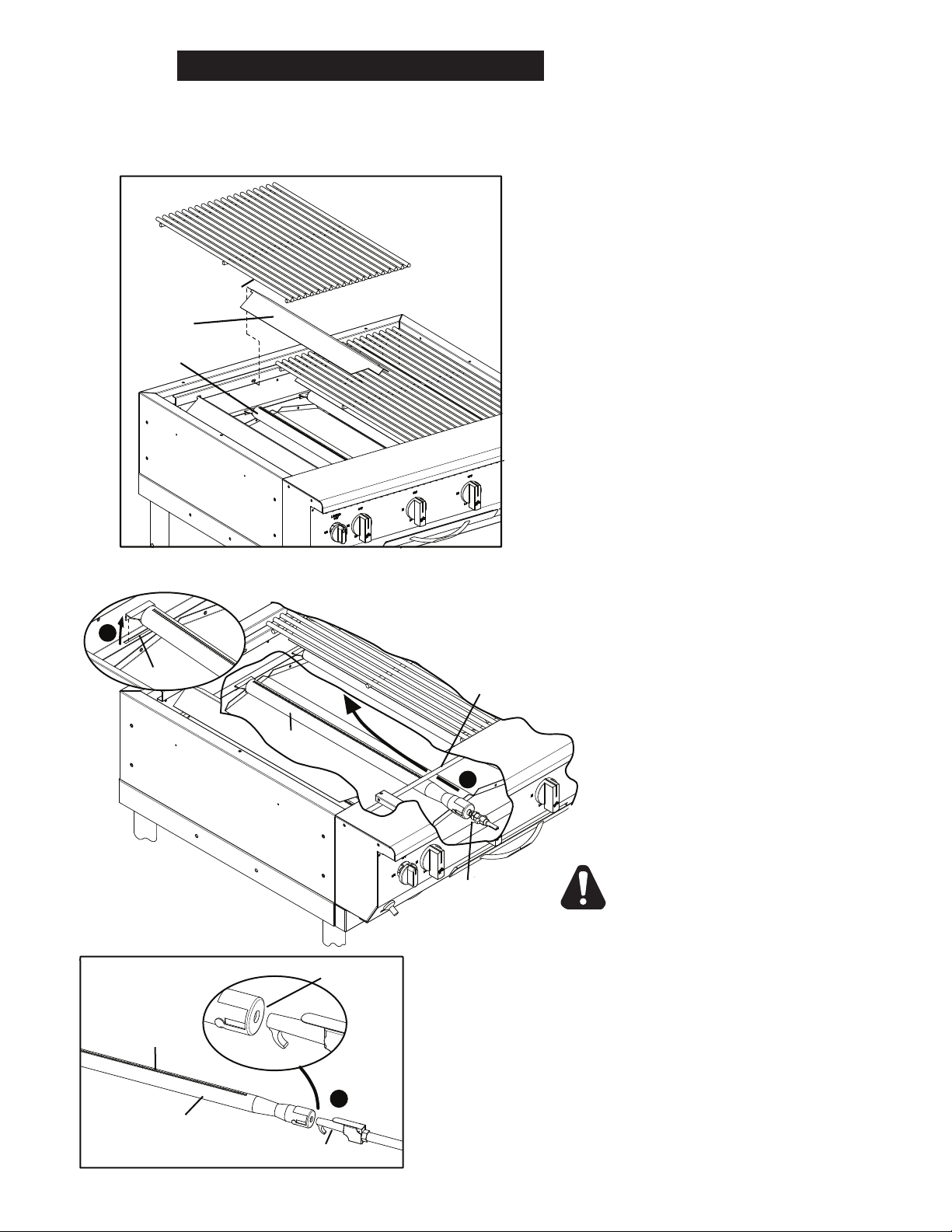

Burner

Radiants

Cooking Grates

IL1082

Burner

IL1084

Burner Slots

Compressed Air

3

Burner Inlet

IL1083

2

Ignitor Tube

Burner

Orifice

1

Rear Slot

DAILY OPERATION (continued)

SHUTTING DOWN INSTRUCTIONS

To shut down the unit, turn all knobs clockwise to the “OFF” position. Turn LP (propane) gas

cylinder control knob clockwise to the “OFF” position. If the unit is not to be used for a while,

disconnect LP (propane) gas supply lines from tank (s) for added safety.

COOKING GRATES & RADIANTS

CLEANING AND INSPECTION

The cooking grates, stainless steel radiants

and the burner can be removed, inspected,

and cleaned as necessary. This is generally

recommended at least once every month of

normal use. The formed hook at the end of

the match lighter rod can be used to lift the

grates up from the grill. Using both hands, lift

up the grate and remove. The grate can be

cleaned with a wire brush and soap solution.

The radiants can be lifted out and inspected

(see illustration). When re-installing the radiants

insert tab into rear slot and place front down

on the alignment stud.

BURNER REMOVAL & CLEANING

Cooking Grates &Radiants can be easily removed for

CAUTION

When re-installing the burner, be sure the burner inlet end

aligns onto the orice as shown in the gure above. The

orice must t straight into the burner inlet hole as shown

and the burner locked in place at the rear with the tab in

the bracket slot. Burner must also sit just below the lighter

tube. Re-install the radiant and grill grates in place above

the burner. Also, at least once a day empty and clean out

the front removable grease pan.

Step 1: The burners can be lifted out by

lifting the end out of the rear slot,

Step 2: Turning to the side while pulling

toward the rear of the grill to remove from

the front orice.

Step 3: Inspect the burner slots, Inlets

& Orice and note their condition. They

can be cleaned using a compressed air

to blow out any debris. If burner slots

are deteriorating or falling apart, replace

burner.

-IMPORTANT-

DO NOT USE COMPRESSED AIR ON

BURNER ORIFICES OR GAS SUPPLY

CONNECTIONS.

Periodically inspect the fuel supply hoses and be sure the

hose is not kinked or wearing in spots. Inspect for cracks or

dried out sections of hose. If there are any cracks or worn

areas, do not operate grill and replace hose immediately.

7

Page 11

DAILY OPERATION (continued)

CLEANING

Clean regularly. Remove cooking grates section to sink for washing use mild detergent and

warm water. Brush out carbonize particles from cooking chamber. Remove and wash grease

pan with mild detergent. Wipe exterior surfaces with detergent and a cloth. A non-abrasive

cleaner can be used on caked areas.

See Accessories Section for any specic instructions on cleaning accessories.

SPIDER WEBS & NEST

Visually inspect the burners & ignitor tube once per year and be sure to visually inspect the inside

inlet venturi & orces for spiders or nests. A spider web in the venturi opening can cause the

following problems:

1. The inability of gas to ow properly into the venturi, resulting in a yellow ame,

no ame, or ashback.

2. The grill does not get up to full temperature. This can also be caused by the

sudden opening of the gas cylinder valve resulting in the actuation of the excess

ow device in the hose/regulator assembly. Turn OFF the gas cylinder valve and

turn the control knob OFF. Wait 15 seconds and slowly turn the LP cylinder valve

ON. Relight the same burner and see if the problem persists. If so, remove the

burner and inspect it for inlet venturi restriction. If there is no restriction, replace

the burner and repeat the lighting steps again by slowly turning on the cylinder

gas valve and lighting the burner. If the burner is still not burning correctly, call

the Star Parts Help Desk at 1-800-807-9054.

STORAGE

DAILY STORAGE

Turn off and disconnect the gas supply when nished using the unit. Once cooled, protect it

with the stainless steal grill grate cover that was provided with the unit or the Hood or Vinyl

Cover Accessory.

LONG TERM STORAGE

Use the following checklist to prepare your unit for long-term storage.

1. Disconnect the gas supply and remove any LP Tank or Tank Caddies that may be on

the unit.

2. Cover any supply hose connectors with caps or plastic bags and secure the ends with

rubber bands or tape, to prevent contamination from occurring.

3. Store LP cylinders outdoors out of reach of children, away from any sources of

heat and ignitors.

4. Clean the inside of your unit.

5. Clean the cooking grids & burners (refer to BURNER REMOVAL & CLEANING) and

lightly oil using cooking oil, and store indoors.

6. Cover the unit, regardless of being stored inside or outside.

8

Page 12

GENERAL ACCESSORY INSTALLATION

IL1100

SHORT BRACKET

LONG BRACKET

IL1086

INITIAL INSPECTION

Remove all packing material from your units accessory and all shipping containers should be checked

for freight damage both visible and concealed. This unit has been tested and carefully packaged to

insure delivery of your unit in perfect condition. If equipment is received in damaged condition, either

apparent or concealed, a claim must be made with the delivering carrier. Read and understand all the

instructions, warnings & labels associated with the unit prior to putting it into operation. Make sure all

individuals associated with its use understand the units operation & safety before they use the unit.

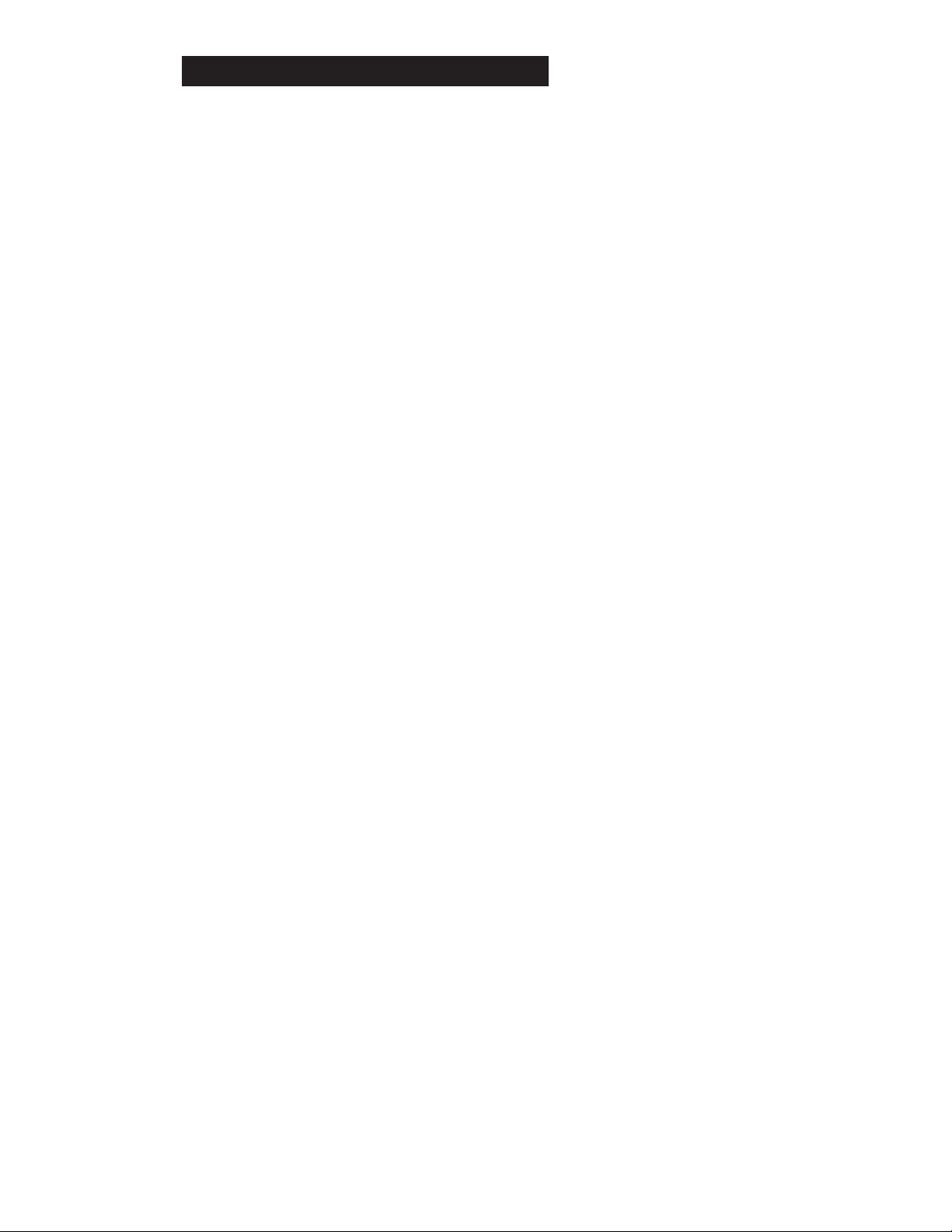

HOOD & WIND GUARD

INSTALLATION

Both the Hood and Wind Guard both install

similarly. Remove the 4 mounting screws

from the top of your grill and set them aside

(2 on the rear and one on each side. Set

the hood and/or wind guard in place and

secure with the mounting screws previously

removed.

REMOVABLE TANK CADDY

These two accessories come complete

and ready to use, once lled (by a qualied

propane gas distributor certied in this

procedure).

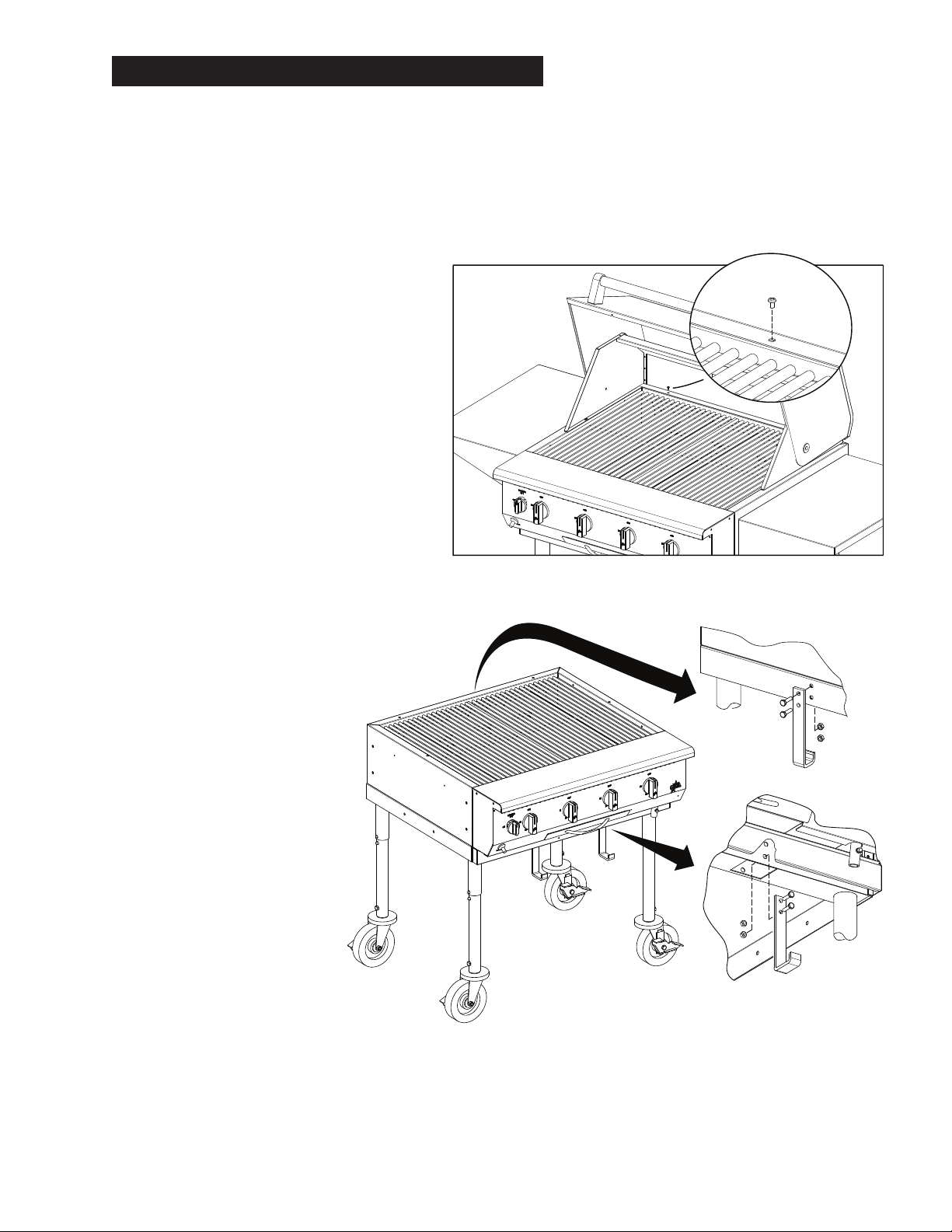

INSTALLING LP TANK CART

MOUNTING BRACKETS

The tank hardware package will

have 4 cart mounting brackets

that attaches directly to the grill

frame. The 2 “longer” spaced

brackets will attach to the front

of the grill frame in the mounting

holes provided. The 2 shorter

spaced brackets will attach to

the rear of the frame assembly.

See the illustration showing

bracket attachment. Once

the brackets are secured in

place, the tank caddy is ready

for mounting on the grill frame

brackets.

Hardware for the LP Tank Caddy Mounting Brackets is

supplied with the tank caddy accessory.

9

Page 13

Fill Valve

IL1087

Tank to Caddy

Mounting Bracket

Gas Valve

THUMBSCREW

IL1088

TANK CADDY

LP TANK

REAR SLOT

REAR TANK BRACKET

FRONT TANK BRACKET

GENERAL ACCESSORY INSTALLATION (continued)

LP TANKS

New LP (propane) tanks are supplied

empty in the tank cart and must be

purged of air and lled with propane

per NPGA (National Propane Gas

Association) recommendations prior

to initial use.

INSTALLING LP TANK CADDY

Open and remove the tank cart and hardware package from the carton. The 2-tank caddy (60) will

require 2 hose assemblies attached to the unit. One tank for each the left and right sides.

During use, tanks must be

mounted in the tank caddy and

secured in a horizontal position.

To remove tank from caddy,

remove the ¼-20 thumbscrew

securing the front tank bracket in

place. Tank can be slid out of the

front of the caddy. To reload the

tank into the caddy, slide the tank

back with the brackets located

down until the rear bracket slides

into the rear slot provided in the

tank cart and then position the front

tank bracket in place and secure

tightly using the thumbscrew

previously removed.

Fig. 1, LP Tank installation to Tank Caddy.

CAUTION

Always use the tanks supplied with the tank caddy or a certied 40 lb. horizontal tank DOT marked

LP propane cylinders with mounting brackets. Never over ll tanks and always use supported

and secured in the horizontal position in the tank caddy. Once lled, the LP (propane) tank caddy

can be easily wheeled using the front handle provided on the cart. Position the tank caddy in

place under the grill (with previously installed hanger brackets) with the tank valve end located to

the front of the grill. Be sure grill caster wheels are locked in place using wheel brakes provided

so grill does not move. (See Figure 2).

10

Page 14

IL1089

FRONT

SUPPORT

BRACKET

FRONT

HANGING

BRACKET

IL1080

IL1101

GENERAL ACCESSORY INSTALLATION (continued)

MOUNTING CADDY TO CHARBROILER

Using the cart handles, lift up the front of the tank cart and place the front hanging bracket

on the front support brackets (Fig 3). Move to the back of the grill and using the rear

cart handle, lift up the cart and slide it back into position on the rear hanging brackets.

Hanging brackets will then support the cart rails of the caddy in place on the grill.

Fig. 2, (Above) Lock Wheel

Casters when using grill &

before mounting tank caddy

Fig. 3 (Left) Mounting Tank

Caddy to Front & Rear Mounting Brackets.

CONNECTING GAS SUPPLY LINE

Refer to General Installation Information section for procedures regarding connecting gas

supply and checking for leaks, as well as other important information.

SIDE SHELF INSTALLATION

The side shelf may be installed to either side of

the grill. Remove two of the screws either left

or right, and back off the other two, but do not

remove. Slide the side shelf between the screw

head and grill. Install the two screws previously

removed and tighten all 4 to secure the shelf in

place.

STEAMER & GRIDDLE PLATE

Fig. 4, (Above) Typical Side Shelf Installation.

The steamer and griddle plate can be easily installed by removing one grate section on the

grill and setting the steamer support or griddle in place on the front and rear grate supports.

Never leave water sitting in the steamer, empty any water when nished cooking and clean.

CLEANING

All sections of the steamer can be cleaned using mild detergent and warm water.

SEASONING THE GRIDDLE COOKING SURFACES

FIRST TIME SEASONING

Light Burners under the griddle plate, set the burner setting halfway between low & high.

Depending on the environmental conditions it may take 20 minutes for the plate to reach the

necessary temperature in order to properly season.

1. Bring the grill to necessary temperature and leave it on while doing the next three steps.

2. Brush the cooking surfaces with a release agent. If using an aerosol agent,

rst apply into a cup and then brush onto cooking surface.

3. Let sit for 20 minutes, and then wipe clean using a warm damp cloth.

11

Page 15

20# TANK BRACKET

IL1102

GENERAL ACCESSORY INSTALLATION (continued)

DAILY SEASONING

The griddle plate should not require much

seasoning while in use. In most cases, brush a

light coating of the baking release agent in the

morning and occasionally throughout the day

will be enough to prevent any sticking. It is not

necessary to coat before grilling each item.

20# LP TANK BRACKET

As shown here the 20# LP Tank Bracket can be

easily installed on the side of the unit. Using the

hardware that was provided with the bracket. It

is recommended to place this on the same side

as the manifold connection. On OCB60 models,

there are separate gas connections for the left &

right sides, and this bracket can be mounted on

each end.

NATURAL GAS - CONVERSION KIT

This charbroiler is equipped with xed orice hoods and is shipped from the factory for use with

propane gas. To convert to natural gas, install the burner orice hoods, provided with accessory.

Use the 5” water column natural gas regulator supplied with accessory. A natural gas supply

line can then be attached to the inlet side of the regulator. Supply pressure must be between

5” and 12” water column. Be sure the installation is made by a qualied service technician

knowledgeable in all local codes and the National Fuel Gas Code ANSI Z223.1/NFPA 54.

1. Remove grates, radiants, burners & bullnose.

2. Remove the burner & ignitor tube orice hoods and install the orice hoods supplied.

3. Replace the bullnose, burners, radiants, and grates.

4. Install the Pressure Regulator to the manifold inlet, being sure that the arrow is pointed

in correct location. Attach the conversion label, supplied with the unit, close to the

nameplate.

CHECKING FOR GAS LEAKS - NAT

Check entire piping system for leaks. Soap and water solution or other material acceptable for

the purpose, shall be used in locating gas leakage.

CAUTION

Matches, candle ame or other sources of ignition shall not be used for locating

gas leaks.

12

Page 16

2M-4497-2 10/2010

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of

the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to

the customer.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

13

Page 17

20

21

22

23

24

21

thru

24

Are sold with Accessories:

30” & 60” Removable Tank Caddies

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

16

17

18

25

26

27

19

STAR MANUFACTURING INTERNATIONAL, INC.

CERTAIN INSTANCES MAY NOT BE AVAILABLE

ILLUSTRATIVE PURPOSES ONLY AND IN

SOME ITEMS ARE INCLUDED FOR

MODEL: OCB

SK2163 REV. -

2/13/06

No reproduction or disclosure of its

to Star Manufacturing International, Inc.

This drawing contains information confidential

contents is permitted.

14

Page 18

PARTS LIST August 16, 2011, Rev. A

MODEL

Fig No Part No QTY Desc Model

1 2B-Z9213

2 H5-Z9237

3 H5-Z9240

4 H5-Z9256

6 H5-OCG0008 1 WRAPPER ASSY OCB30

7 H5-OCG0005 1 BOTTOM FRAME ASSY. OCB30

8 H5-OCG0007 1 FRONT GRATE SUPPORT ASSY OCB30

9 H5-Z9242

10 H5-Z9241

11 H5-Z9236 1 ORFICE BRACKET OCB30

12 H5-OCG0003 1 BULLNOSE ASSY, OCB30

13

14

15 H5-Z9245

16 H5-Z9235

17 H5-Z9234

18 2R-Z6726

19 2C-Z6744

20 2V-Z9214 1 SET CASTER LEG (SET OF 4)

21 2C-Z5555 8 BOLT, 1/4-20 X .75” HEX S.S. included in Caddy Accessory

22 2A-Z9255 2 CADDY HANGING BRKT LONG-FRONT included in Caddy Accessory

23 2C-T1009 8 NUT, 1/4-20 HEX STL NP included in Caddy Accessory

24 2A-Z9254 2 CADDY HANGING BRKT SHORT-REAR included in Caddy Accessory

25 2R-Z6726 1 HANDLE, GRILL GRATE COVER

26 H5-Z9275

27 2J-Z9289

H5-Z9238

H5-Z9239 OCB60

H5-Z9278

H5-Z9279 OCB60

2

4 OCB60

4

8 OCB60

1

2 OCB60

1

2 OCB60

2

4 OCB60

1

2 OCB60

1 FRONT PANEL

1 LOWER FRONT APPEARANCE BRKT.

2

4 OCB60

1

2 OCB60

1

2 OCB60

1

2 OCB60

2

4 OCB60

1

2 OCB60

1

2 OCB60

OUTDOOR CHARBROILER GRILL, OCB30 & OCB60

GRILL GRATE

RADIANT

REAR BURNER SUPPORT BRACKET

PAN SHIELD

SUPPORT BRACKET, IGNITOR TUBE

IGNITOR - BOX

PAN SUPPORT BRKT

PAN - GREASE

PAN - FACEPLATE

HANDLE, PAN

SCREW, 8-32 X 5/16 RHP SS

GRILL GRATE COVER

HOSE-REGULATOR ASSY

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

15

Page 19

1

2

3

4

5

6

7

8

9

11

10

12

13

14

15

STAR MANUFACTURING INTERNATIONAL, INC.

CERTAIN INSTANCES MAY NOT BE AVAILABLE

ILLUSTRATIVE PURPOSES ONLY AND IN

SOME ITEMS ARE INCLUDED FOR

MODEL: OCB-MANIFOLD

SK2161 REV. A

6/8/06

No reproduction or disclosure of its

to Star Manufacturing International, Inc.

This drawing contains information confidential

contents is permitted.

16

Page 20

PARTS LIST August 16, 2011, Rev. A

MODEL

Fig No Part No QTY Desc Model

1 2F-Z9200

2 2J-Z5671

3 2V-Z6939

4 2K-Z9221 1 MANIFOLD OCB30

6 2R-Z4997

7 2R-Z9212

8 2J-Z7195

9 2K-Z6942

10 2J-Z9208

11 2K-Z6941

12

13 2J-Z6908

14 2K-Z6943

OUTDOOR CHARBROILER GRILL MANIFOLD, OCB30 & OCB60

4

8 OCB60

4

8 OCB60

5

10 OCB60

4

8 OCB60

1

2 OCB60

1

2 OCB60

1

2 OCB60

1

2 OCB60

1

2 OCB60

2F-Z9201

2F-Z9202 IGNITOR TUBE, 3/8” LT OCB60

1

1

2 OCB60

1

2 OCB60

BURNER 1 1/4” Dia.

ORIFICE # 56

VALVE HI-LO

KNOB

KNOB, IGNITOR TUBE RED

SWITCH, IGNITOR

FITTING 3/8-27 MALE X 1/4

ORFICE, IGNITOR

FITTING 3/8-27 FEMALE X 1/4

IGNITOR TUBE, 3/8” RT OCB30

IGNITOR - STRAIGHT

GAS LINE 1/4”DIA X 8”L

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

OCB30

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

17

Page 21

OCB-WG30

OCB-H30

OCB-S15

OCB-G15

OCB-SHELF

OCB-TB20

OCB-TC60

OCB-CKNAT

STAR MANUFACTURING INTERNATIONAL, INC.

CERTAIN INSTANCES MAY NOT BE AVAILABLE

ILLUSTRATIVE PURPOSES ONLY AND IN

SOME ITEMS ARE INCLUDED FOR

MODEL: OCB-ACCESSORIES

SK2167 Rev. A

6/07/06

No reproduction or disclosure of its

to Star Manufacturing International, Inc.

This drawing contains information confidential

contents is permitted.

18

Page 22

PARTS LIST August 16, 2011, Rev. A

MODEL

ACCESSORIES FOR OUTDOOR CHARBROILER GRILL

Number

Key

Number

OCB-CKNAT NATURAL GAS CONVERION KIT

2J-Z9207 2 PRESSURE REGULATOR RV47

2J-Z9209 2 ORFICE IGNITOR TUBE # 59

2J-Z9288 8 ORFICE #49

2M-Z7528 1 LABEL “CONVERTED TO NAT”

OCB-G15 GRIDDLE PLATE

H5-OCG0012 1 GRIDDLE PLATE ASSY. 15” W

OCB-H30 HOOD

2C-Z6932 2 ACORN NUT 3/8”

2C-Z6933 4 HEX BOLT, 1/4-20X1”

2C-Z9244 2 PIVOT BOLT, HOOD

2I-Z6924 2 HANDLE INSULATOR

2P-Z6922 2 HANDLE END CAP

2R-Z6988 1 HANDLE

2T-Z9247 1 TEMPERATURE GAUGE

H5-OCG0009 1 HOOD ASSY

H5-Z9251 1 BACK, HOOD SUPPORT

H5-Z9252 1 RIGHT SIDE HOOD SUPPORT

H5-Z9253 1 LEFT SIDE, HOOD SUPPORT

OCB-S15 STEAMER

2D-Z9282 1 WATER PAN FULL SIZE 4”

2D-Z9283 1 PERFORATED PAN F.S. 2 1/2”

2D-Z9284 1 PAN COVER FULL SIZE, NO HANDLE

H5-Z9281 1 STEAMER BODY 15” W

OCB-SHELF SIDE SHELF

H5-Z9273 1 SIDE SHELF

OCB-TB20 20# TANK BRACKET

2C-T1009 2 NUT 1/4-20 HEX STL NP

2C-Z6927 2 1/4-20X1/2”L PH PAN HD

H5-Z9292 1 TANK BRACKET, 20# LP

OCB-TC30 TANK CADDY 30"

2A-Z9254 2 CADDY HANGING BRKT. SHORT

2A-Z9255 2 CADDY HANGING BRKT. LONG

2A-Z9265 2 HANDLE CADDY

2C-Z0280 1 THUMB SCREW

2P-Z6770 2 CASTER RIGID 3 1/2”

2P-Z6771 2 CASTER SWIVEL 3 1/2”

2V-Z9259 1 40# HORIZONTAL LP TANK

H5-OCG0010 1 TANK CADDY BODY ASSY

H5-Z9266 2 CADDY SUPPORT BRKT

H5-Z9269 1 REAR TANK HOLD DOWN BRKT

OCB-TC60 TANK CADDY 60"

2A-Z9254 2 CADDY HANGING BRKT. SHORT

2A-Z9255 2 CADDY HANGING BRKT. LONG

2A-Z9258 2 HANDLE CADDY

2C-Z0280 2 THUMB SCREW

2P-Z6770 2 CASTER RIGID 3 1/2”

2P-Z6771 2 CASTER SWIVEL 3 1/2”

2V-Z9259 2 40# HORIZONTAL LP TANK

H5-OCG0011 1 TANK CADDY BODY ASSY

H5-Z9260 2 CADDY SUPPORT BRKT

H5-Z9263 1 REAR TANK HOLD DOWN BRKT

OCB-WG30 WIND GUARD

H5-Z9276 1 WIND GUARD

Part

Number

Per

Unit

Description and Model Designation

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

19

PAGE

OF

1

1

Page 23

Page 24

Page 25

Page 26

12

20 livres crochet

du réservoir

IL1136

d’inammation pour effectuer un essai d’étanchéité

N’utilisez pas les allumettes, la amme d’une bougie, ou d’autres sources

MISE EN GARDE

acceptable pour cet essai, peut être utiliser pour effectuer un essai d’étanchéité.

Vérier le circuit de tuyauteries entier pour les fuites. Une solution savonneuse or d’autre matériel

Pour effectuer un essai d’étanchéité – gaz naturel

plaque-marque.

vers la zone correcte. Afchez l’étiquette à conversion, fourni avec l’appareil, près de la

4. Installez le régulateur de pression à l’entrée du collecteur, soyez sûr que la èche vise

3. Remplacez le bouchon de conduite, les brûleurs, les radiants et les grilles.

2. Enlevez le brûleur et l’accessoire GPL et montez l’accessoire fourni.

1. Enlevez tous les grilles, les radiants, les brûleurs et le bouchon de conduite.

combustibles ANSI Z223.1/NFPA 54.

est effectuée par un technicien qui connaît tous les codes locaux et le Code national des gaz

d’alimentation doit être entre 5 po et 12 po de colonne d’eau. Assurez-vous que l’installation

l’accessoire. Une conduite du gaz naturel peut être attachée à l’entrée du régulateur. La pression

avec les accessoires. Utilisez le 5 po de colonne d’eau régulateur du gaz naturel fourni avec

avec du gaz propane. Pour convertir au gaz naturel, montez les accessoires du brûleur, fourni

Ce charbroiler est équipé avec un accessoire GPL et il est transporté de l’usine pour l’utilisation

GAZ NATUREL – JEU DE CONVERSION

chaque côté.

et à gauche, et ce crochet peut être monté sur

raccords de gaz différents pour les côtés à droit

connecteur. Sur les modèles OCB60 il y a les

de le placer sur le même côté du raccord du

fourni avec le crochet. Il est recommandé

le côté de l’appareil. Utilisez le jeu de pièces

GPL 20# (9.1kg) peut être facilement monté sur

Comme le démontre ici le crochet du réservoir

GPL

20# (9.1 kg) CROCHET DU RÉSERVOIR

pas nécessaire de napper avant chaque grillage.

pendant la journée de temps en temps. Il n’est

une couche douce d’un antiadhésif au matin et

Généralement, pour prévenir le collage, brossez

d’assaisonnement pendant l’utilisation.

Le gril ne doit pas requérir beaucoup

ASSAISONNEMENT JOURNALIER

INSTALLATION GENERALE DES ACCESSOIRES (SUITE)

Page 27

IL1135

Crochet

avant

Support

d’accrochage

avant

IL1080

IL1101

tablette latérale

11

Fig. 4(Au-dessus) Installation typique de la

3. Laissez pour vingt minutes, ensuite essuyez avec un chiffon chaud et humide.

agent d’aérosol, mettez dans une tasse et puis brossez sur la surface de cuisson.

2. Brossez les surfaces de cuisson avec un agent antiadhésif. Si vous utilisez un

étapes suivantes.

1. Chauffez la grille à la température nécessaire et laissez pendant que vous faites les

température nécessaire an d’assaisonner correctement.

Selon les conditions d’ambiance, il peut prendre vingt minutes pour le gril d’atteindre la

Allumez les brûleurs sous le gril, réglez le réglage du brûleur entre bas et haut (low et high).

ASSAISONNEMENT INITIAL

ASSAISONNEMENT LES SURFACES DE CUISSON DU GRIL

chaude.

Toutes les sections du four à vapeur peuvent être nettoyées avec un détergent doux et de l’eau

NETTOYAGE

vapeur, videz l’eau lorsque vous nissez de cuire et nettoyez.

gril en place sur les supports de grille arrière et avant. Ne laissez jamais d’eau dans le four à

Enlevez une section de la grille sur le barbecue et en mettant le support du four à vapeur ou le

Le four à vapeur et le gril peut être facilement montés.

FOUR À VAPEUR ET GRIL

serrez toutes les 4 vis pour xer le panneau en place.

de la vis et le barbecue. Vissez les 2 vis déjà enlevées et

démontez pas. Glissez le panneau latéral entre la tête

droit, et dévissez un peu les autres 2 vis, mais ne les

barbecue. Démontez deux des vis soit à gauche soit à

Le panneau latéral peut être monté de chaque côté du

INSTALLATION DU PANNEAU LATÉRAL

d’alimentation de gaz et les essais d’étanchéité et d’autres renseignements importants.

Voir la section d’Information Générale d’Installation pour les procédures concernant le branchement

BRANCHER LA CONDUITE DE GAZ

avant et arrière

iot aux supports d’accrochage

Fig. 3 (A gauche) Monter le char-

chariot

barbecue et avant de monter le

roulettes pendant l’utilisation du

Fig 2. (Au-dessus) Verrouillez les

Les supports d’accrochage supporteront les tringles du chariot en place sur le barbecue.

poignée arrière, levez le chariot et glissez-le en position sur les support d’accrochage arrières.

avant sur les crochets de support avant (Fig. 3) Bougez à l’arrière du barbecue et en utilisant la

En utilisant les poignées du chariot, soulevez l’avant du chariot et placez le support d’accrochage

MONTER LE CHARIOT AU CHARBROILER

INSTALLATION GÉNÉRALE (LA SUITE)

Page 28

10

Soupape

d’alimentation

IL1133

Crochet pour

monter le

réservoir au chariot

Soupape

à gaz

Vis à serrage

à main

IL1134

Chariot

Réservoir GPL

Ouverture arrière

Crochet du réservoir arrière

Crochet du réservoir avant

les roulettes et pour prévenir tout mouvement. (Voir la gure 2)

située vers l’avant du barbecue. Assurez-vous d’utiliser les freins de roue fournis pour verrouiller

barbecue (avec les supports d’accrochage déjà installés)avec le bout de la soupape de réservoir

(propane) avec la poignée fournie avec le chariot. Placez le chariot de réservoir au-dessous le

dans le chariot. Une fois remplie, vous pouvez facilement pousser le chariot de réservoir GPL

Ne remplissez jamais excessivement les réservoirs et utilisez toujours en position horizontale

spécications des bouteilles de gaz GPL du département des Transports des États-Unis (DOT)..

certié de 40 lbs (18.1 kg). La bouteille de gaz GPL utilisée doit être identiée conformément aux

Utilisez toujours les réservoirs fournis avec le chariot de réservoir ou un réservoir horizontal

AVERTISSEMENT

avez déjà devisée.

la vis à serrage à main que vous

Fig 1. Installation du réservoir GPL au chariot

place et xez étroitement avec

le crochet du réservoir avant en

dans le chariot, puis positionnez

dedans l’ouverture arrière fournie

que les crochets arrières glissent

crochets situés en bas jusqu’à ce

le réservoir en arrière avec les

le réservoir dans le chariot, glissez

le devant du chariot. Pour remettre

réservoir peut être glissé dehors

le crochet du réservoir avant. Le

¼-20 vis à serrage à main qui xe

réservoir du chariot, devissez la

horizontale. Pour démonter le

chariot et fixés en position

doivent être montés dans le

Pendant l’utilisation les réservoirs

pour le côté gauche.

requerra 2 ensembles de tuyau attachés à l’appareil. Un réservoir pour le côté droit et un réservoir

Ouvrez et enlevez le chariot de réservoir et le jeu de pièces de la caisse. Le chariot à 2 réservoirs

INSTALLATION DU CHARIOT DE RÉSERVOIR GPL

l’utilisation.

propane) les recommandations avant

(Association Nationale du gaz

NPGA

le réservoir avec du propane suite

vider le réservoir d’air et remplissez

chariot de réservoir et vous devez

(propane) sont fournis vides dans le

Les nouveaux réservoirs GPL

RESERVOIRS GPL

INSTALLATION GENERALE DES ACCESSOIRES (SUITE)

Page 29

9

IL1100

crochet court

crochet long

IL1132

fourni avec l’accessoire du chariot.

Le jeu de pièces pour les Crochets du Chariot du Réservoir GPL est

supports de l’encadrement.

est prêt pour monter sur les

en place, le chariot du réservoir

fois que les supports sont xés

l’attachement du support. Une

Voir l’illustration qui démontre

l’ensemble de l’encadrement.

plus courts xeront à l’arrière de

fournis. Les 2 supports qui sont

dans les trous de montage

l’encadrement du barbecue

longs fixeront à l’avant de

Les 2 supports qui sont plus

encadrement du barbecue.

qui fix ent directem ent au

aura 4 supports de montage

Le jeu de pièces du réservoir

LP

DU CHARIOT DU RÉSERVOIR

SUPPORTS DE MONTAGE

I N S T A L L AT I O N D E S

certié du gaz propane).

à utiliser une fois rempli, (par un distributeur

Ces 2 accessoires viennent complets et prêts

DÉMONTABLE

CHARIOT DU RÉSERVOIR

que vous avez enlevées.

et/ou la garde en place et xez avec les vis

il y a une sur chaque côté. Mettez le couvercle

dessus du barbecue (2 se trouve à l’arrière et

pareillement. Enlevez les 4 vis de montage du

Vous installez le couvercle et la garde

DE LA GARDE-VENT

INSTALLATION DU COUVERCLE ET

utilisent l’appareil.

les personnes qui utilisent l’appareil comprennent l’utilisation et la sécurité de l’appareil avant qu’ils

avertissements et les étiquettes associés à l’appareil avant d’utiliser l’appareil. Assurez-vous que toutes

devez réclamer une demande avec le transporteur. Lisez et comprenez tous les renseignements, les

d’un appareil à l’état neuf. Si vous recevez l’appareil endommagé – apparent ou non apparent, vous

dommage de transport soit apparent ou non apparent. L’appareil a été essayé pour assurer une livraison

Enlevez tout matériel d’emballage des accessoires et assurez-vous de vérier les caisses pour le

VERIFICATION INITIALE

INSTALLATION GENERALE DES ACCESSOIRES

Page 30

8

6. Couvrez l’appareil bien que vous le reposiez à l’intérieur ou à l’extérieur.

BRÛLEURS) et lubriez avec de l’huile de cuisson et reposez à l’intérieur.

5. Nettoyez les grilles de cuisson et les brûleurs (voir ENLEVER ET NETTOYER LES

4. Nettoyez l’intérieur de l’appareil.

loin des sources d’inammation ou de chaleur.

3. Entreposez les bouteilles de propane à l’extérieur hors de la portée des enfants,

prévenir la contamination.

plastique et xer les bouts avec des rubans élastiques ou des rubans adhésifs pour

2. Couvrez des raccords des tuyaux d’alimentation avec les couvercles ou les sacs en

réservoir qui sont sur l’appareil.

1. Débranchez l’alimentation en gaz et enlevez tout réservoir GPL ou chariot de

terme.

Utilisez la liste de vérication suivante pour préparer l’appareil pour l’entreposage à long

ENTREPOSAGE A LONG TERME

l’appareil et protégez-le avec la couverture fournie avec l’appareil.

Fermez et coupez l’alimentation en gaz lorsque vous nissez d’utiliser l’appareil. Laissez refroidir

ENTREPOSAGE JOURNALIER

ENTREPOSAGE

pas correctement, appelez Star Parts Help Desk à 1-800-807-9054.

lentement le robinet de la bouteille de gaz et en allumant le brûleur. Si le brûleur ne brûle

n’y a aucune obstruction, remontez le brûleur et reprenez les étapes d’allumage en ouvrant

problème persiste. Si oui, démontez le brûleur et vériez si le tube de venturi est obstrué. Sil

lentement le robinet de la bouteille de gaz GPL. Rallumez le même brûleur et vériez si le

le bouton de commande sur la position OFF (arrêt). Attendez 15 secondes et OUVREZ

bit dans l’ensemble tuyau/régulateur. FERMEZ le robinet de la bouteille de gaz et tournez

une ouverture soudaine de robinet de la bouteille de gaz, ce qui enclenche le limiteur de

2.Le barbecue n’atteint pas sa température maximale. Cela peut également être causé par

jaune, une absence de amme ou un retour de amme.

1. L’obstruction de la circulation de gaz dans le tube de venturi, ce qui produit une amme

à l’intérieur du tube de venturi peut caser les problèmes suivants :

présence d’araignées ou de nids à l’intérieur du tube de venturi et les orices. Une toile d’araignée

Vériez visuellement les brûleurs et l’allumeur une fois par an en vous assurant de vérier la

Les Toiles d’Araignées et les Nids

Les Toiles d’Araignées et les Nids

nettoyage.

Voir la section d’accessoires pour les instructions spéciques pour les accessoires de

Un nettoyeur non abrasif peut être utilise sur les sections très sales.

le plateau d’eau avec un détergent doux. Essuyez les parois avec du détergent et un chiffon.

doux et de l’eau chaude. Brossez les particules de la chambre de cuisson. Enlevez et nettoyez

Nettoyez régulièrement. Enlevez la section des grilles de cuisson et nettoyez avec un détergent

NETTOYAGE

UTILISATION JOURNALIERE (SUITE)

Page 31

Brûleur

Radiants

Grilles de cuisson

IL1129

brûleur

IL1131

Ouvertures

du brûleur

Air comprimé

3

Entrée du brûleur

IL1130

2

Tube de l’allumeur

Brûleur

Orifice

1

Ouverture arrière

MISE EN GARDE

RACCORDS DES CONDUITES DE GAZ

LES ORFICES DES BRÛLEURS OU LES

N’UTILISEZ PAS D’AIR COMPRIME SUR

-IMPORTANT-

brûleur.

du brûleur sont dégénérés, remplacez le

pour soufer aucun résidu. Si les orices

les nettoyer en utilisant l’air comprimé

remarquez leur condition. Vous pouvez

brûleurs, les entrées et les orices et

Étape 3 : Vériez les ouvertures des

7

le barbecue et remplacez le tuyau immédiatement.

trouvez des ssures ou des sections desséchées, n’utilisez pas

pour les ssures ou les sections desséchées du tuyau. Si vous

assurez-vous que le tuyau n’est pas tortillé ou usé. Vériez

Vériez régulièrement les tuyaux de l’alimentation du gaz et

nettoyez le plateau de graisse au moins une fois par jour.

et les grilles en place au-dessus le brûleur. D’ailleurs, videz et

doit rester juste au-dessous le tube éclair. Remontez le radiant

à l’arrière avec l’onglet dans l’ouverture du crochet. Le brûleur

brûleur comme montré et le brûleur doit être verrouillé en place

dans la gure au-dessus. L’orice doit entré dans l’entrée du

de l’entrée du brûleur aligne sur l’orice comme le démontre

Lorsque vous remontez le brûleur, assurez-vous que l’extrémité

enlever de l’orice avant.

tirez vers l’arrière du barbecue pour

Étape 2: Balancez pendant que vous

Les grilles de cuisson et les radiants peuvent être facilement enlever pour le nettoyage.

levant l’extrémité hors de l’ouverture arrière.

Étape 1: Les brûleurs peuvent être soulevés en

ENLEVER ET NETTOYER LES BRÛLEURS

et mettez l’avant sur le goujon d’alignement.

remontez les radiants, insérez dans l’ouverture arrière

radiants et les vérier (voir l’illustration). Lorsque vous

solution d’eau savonneuse. Vous pouvez soulever les

Nettoyez la grille avec une brosse métallique et une

les deux mains, soulevez la grille et déplacez-le.

utilisé pour soulever les grilles du barbecue. En utilisant

Le crochet à l’extrémité du tige d’allumage peut être

moins une fois chaque mois pour l’utilisation normale.

le cas échéant. En général, cela est recommandé au

et le brûleur peuvent être enlevés, vériés et nettoyés

Les grilles de cuisson, les radiants d’acier inoxydable

NETTOYAGE ET VERIFICATION

LES GRILLES DE CUISSON ET LES RADIANTS

pour la sécurité.

l’appareil pour quelque temps, débranchez les conduites de gaz GPL (propane) du réservoir

contraire aux aiguilles d’une montre à la position OFF. Si vous prévoyez de ne pas utiliser

Pour fermer l’appareil tournez tous les boutons des brûleurs et le bouton rouge dans le sens

FERMER L’APPAREIL

UTILISATION JOURNALIERE (SUITE)

Page 32

6

2

1

IL1085

IL1114

(Fig. 2)

pour allumer le tube d’allumeur de 3/8 po D.

attachée à la baguette, l’insérez entre les grilles

(marche) et en utilisant la amme d’une allumette

aux aiguilles d’une montre à la position « ON »

et tournez le bouton rouge dans le sens contraire

allumette pour allumer le tube d’allumeur. Enfoncez

d’allumage fournie avec l’appareil pour tenir une

position « OFF » (arrêt) et utilisez la baguette

plusieurs essais, tournez le bouton rouge à la

4. 4. Si l’allumeur n’allume pas le brûleur après

d’allumeur (Figure 1).

l’allumeur plusieurs fois pour allumer le petit tube

voulez allumer. Il peut être nécessaire d’enfoncer

(marche) et enfoncez l’allumeur sur le côté vous

aux aiguilles d’une montre à la position « ON »

3. Tournez le bouton rouge dans le sens contraire

vous voulez allumer.

laisser la circulation de gaz au côté du barbecue

le sens contraire aux aiguilles d’une montre pour

2. Ouvrez lentement le robinet du réservoir GPL dans

les brûleurs devraient allumer.

et tournés dans le sens contraire aux aiguilles d’une montre à la position « HI » (feu vif) et

l’appareil. Lorsque le tube éclair est allumé, les boutons de brûleur (noir) peuvent être enfoncés

n’allume pas, coupez l’alimentation en gaz, attendez 5 minutes et essayez d’allumer encore

5. Vériez que la longueur entière du tube éclair est allumé et qu’il fonctionne. Si le tube éclair

pas.

allumer le tube si le bouton de l’allumeur ne marche

Fig.2 Utilisez la baguette avec une allumette pour

de l’allumeur.

appuyez sur le bouton de l’allumeur pour allumer le tube

Fig. 1 Tournez le bouton à la position ON (marche) et

l’ouvrir.

Si l’appareil a un couvercle, assurez-vous de

robinets du réservoir GPL (en position «OFF»).

1. Assurez-vous de fermer et xer en place les

dehors la conduite de gaz et le collecteur.

prendre plus de temps parce qu’il faut vider l’air

Remarque : Le premier allumage de l’appareil peut

étapes d’allumage 1 à 5 au-dessus.

le barbecue et « lentement » ouvrez la soupape de commande de réservoir de gaz. Suivez les

amme réduite. Si cela arrive, vériez que les réservoirs ne sont pas vides ou hors gaz. Fermez

une condition d’une circulation excessive et causerait les brûleurs de fonctionner avec une

de réduire. C’est une caractéristique de sécurité conçu pour limiter la circulation de gaz sous

excessif du gaz dans le raccord du réservoir qui peut causer la circulation de gaz au collecteur

Remarque : Il est nécessaire d’ouvrir les robinets du réservoir lentement pour prévenir un débit

ALLUMAGE DU BARBECUE

barbecue repose sur une surface plate.

inammables, d’essence ou d’autres vapeurs ou liquides inammables. Assurez-vous que le

zone ouverte autour du barbecue et de son enceinte, et gardez l’espace exempt de matériaux

et elle peut émettre des ammes dans des conditions extrêmes. Maintenez en tout temps une

inammable à proximité ou au-dessus du barbecue. La sortie de ventilation peut être très chaude

maison ni de toute autre structure inammable. Ne placez pas de parasols ni tout autre article

comme l’exposition au vent et le niveau de circulation. Ne placez pas le barbecue près d’une

Au moment de choisir l’emplacement qui convient à votre barbecue, tenez compte de facteurs

CHOIX DE L’EMPLACEMENT

UTILISATION JOURNALIERE

Page 33

IL1127

90°

OCB30

Ensemble du

régulateur

Orifice de

sortie

L’entrée du

barbecue

LES CHARBROILERS SONT CHAUDS!DAILY

Brûleur

Obturateur

d’air

IL1128

Vis

Débit d’air

Débit d’air

5

MISE EN GARDE

refroidir, lorsque vous faites ces réglages.

et dure paraît. Fermez l’appareil et laissez

jaunes disparaissent et une amme bleue

lentement les entrées à tel point que les bouts

avec les bouts lumineux, ensuite augmentez

pour donner une amme bleue et douce

entrées des obturateurs d’air sur les brûleurs

obturateurs d’air, diminuez lentement les

le bouchon de conduite pour exposer les

2. Si nécessaire, fermez l’appareil, enlevez

: comme le démontre dans la gure 2.

Allumez l’appareil et réglez sur HIGH. Remarque

1. Enlevez les grilles de cuisson et les radiants.

un réglage est requis, suivez ces étapes:

à l’usine et ne devraient pas exigés une réglage. Si

Les obturateurs d’air de cet appareil ont été réglés

amme correcte.

Fig. 2 : Régler l’obturateur d’air du brûleur pour atteindre une

l’appareil

Réglage du brûleur

Fig 1. Brancher l’ensemble du régulateur du réservoir GPL à

essai.

N’utilisez pas les allumettes, les bougies ou d’autre source of ignition pour cet

MISE EN GARDE

l’utilisation.

PAS LE BARBECUE AVEC AUCUNE FUITE. S’il n’y a pas de fuites, l’appareil est prêt pour

ou appelez votre compagnie de gaz locale ou votre détaillant pour le service. N’UTILISEZ

S’il y a une fuite, fermez immédiatement le robinet de gaz et resserrez le raccord avec la fuite,

Observez tous les raccords pour les bulles pour déterminer s’il y a une fuite.

d’étanchéité) et brossez tous les raccords de gaz. Ouvrez lentement le robinet de réservoir GPL.

d’eau savonneuse (ou une solution d’essai

et tous les brûleurs. Utilisez une solution

OFF) tous les réservoirs GPL (propane)

Assurez-vous de fermer (mettre en position

ESSAI D’ÉTANCHÉITÉ

inégale.

varier si vous le reposez sur une surface

Le fonctionnement de l’appareil peut

vous de le reposer sur une surface plate.

Avant l’utilisation de l’appareil, assurez-

NIVELER L’APPAREIL

de coté droit au réservoir droit.

montera au réservoir gauche et le tuyau

Sur le modèle 60, le tuyau de coté gauche

du barbecue avec une clé.

TROP. (Fig. 1) Fixez l’autre bout à l’entrée

l’orice de sortie à main. NE SERREZ

la conduite de gaz. Serrez le raccord à

pas tortiller ou endommager le tuyau de

de type 1 en place. Assurez-vous de ne

(18.1Kg). Enlevez le garde de poussière de l’orice de sortie et vissez soigneusement le raccord

L’ensemble régulateur/tuyau du barbecue peut être xé à l’orice de sortie du réservoir 40 lbs

BRANCHER LA CONDUITE DE GAZ

INSTALLATION GENERALE (suite)

Page 34

4

IL1126

Douille du pied

Ensemble de

la roulette

Verrouillage

Enlever avant de placer

sur le côté arrière

IL1080

prévenir tout mouvement. (Voir la gure 2).

Assurez-vous d’utiliser les freins de roue fournis pour verrouiller les roulettes et pour

installés)avec le bout de la soupape de réservoir située vers l’avant du barbecue.

Placez le chariot de réservoir au-dessous le barbecue (avec les supports d’accrochage déjà

facilement pousser le chariot de réservoir de GPL avec la poignée fournie sur le chariot.

horizontale dans le chariot de réservoir. Après avoir rempli les réservoirs, vous pouvez

(DOT). Ne remplissez jamais excessivement les réservoirs et utilisez toujours en position

aux spécications des bouteilles de gaz GPL du département des Transports des États-Unis

certié de 40 lbs (18.1 kg). La bouteille de gaz GPL utilisée doit être identiée conformément

Utilisez toujours les réservoirs fournis avec le chariot de réservoir ou un réservoir horizontal

MISE EN GARDE

à la page 12.

section d’Installation d’Accessoires Générales

sont disponibles avec cet appareil, voir la

réservoirs GPL et d’autres accessoires qui

Pour les renseignements de l’installation de

INSTALLATION DES ACCESSOIRES

MOUVEMENT.

L’UTILISATION POUR PREVENIR LE

du réservoir.

l’utilisation du barbecue et avant de monter le chariot

Fig. 2 (A gauche) Verrouiller les roulettes pendant

Fig. 1 (Au-dessus) Fixer les roulettes au charbroiler

ÊTRE VERROUILLÉES PENDANT

ET LES ROULETTES DOIVENT

SUR UNE SURFACE PLATE

LE BARBECUE DOIT ÊTRE PLACÉ

MISE EN GARDE

de cuisson.

personne. Remontez les radiants et les grilles

en position verticale avec l’aide d’une autre

Fixez tous les pieds en place et placez l’appareil

douilles de pied et verrouillera en position.

L’ensemble de pied/roulette glissera dans les

caisse et attachez-le dans les douilles du pied.

1. Enlevez l’ensemble de pied/roulette de la

sur le dos comme le démontre dans la gure

à l’aide d’une autre personne. Placez l’appareil

les grilles de cuisson et les radiants de l’appareil

Enlevez tout l’emballage de l’appareil. Enlevez

INSTALLATION DE ROULETTE

INSTALLATION GENERALE

Page 35

3

PSIG.

en gaz fourni à l’entrée du collecteur. N’exposez pas le régulateur aux pressions plus de ½

du gaz naturel doit être fourni (réglé pour une pression d’eau de 5 po) ou une alimentation

l’utilisation du gaz naturel, change out le brûleur et les orices du tube éclair. Un régulateur

• Cet appareil est réglé pour l’utilisation du gaz propane GPL. Pour convertir l’appareil à

circulation d’air dans le bas ou l’avant du barbecue.

• Vériez toujours les plateaux avant et enlevez aucune graisse et résidu. Ne limitez pas la

amme égale. Laissez refroidir l’appareil, vériez et nettoyez tel brûleur et orice de gaz.

N’utilisez pas la grille s’il y a un retour de amme ou le brûleur ne marche pas avec une

• Vériez régulièrement les brûleurs et les orices de gaz pour les nids des araignées.

(10°C) et n’utilisez pas le barbecue ou placez l’appareil dans un endroit venteux.

dans une zone ouverte. N’utilisez pas l’appareil avec GPL aux températures moins de 50°F

• Le gaz propane est hautement inammable et plus lourd que l’air. Utilisez toujours l’appareil

ou CAN/CGA B149.2 code d’installation du gaz propane.

l’entreposage et le transport. Voyez NFPA58 la manipulation et l’entreposage des gaz GPL

dans une zone ouverte hors de portée des enfants. Fixez toujours les réservoirs pendant